Abstract

Ground improvement through fiber-reinforced soil has been in practice in the recent past. However, with increasing concern for sustainable development, researchers are encouraged to investigate alternative forms of reinforcement than the mainstream synthetic fibers. Coir fibers have been in practice as an alternative natural fiber for ground improvement. In this study, fibers extracted from a local coconut plantation were used to improve the strength characteristics of a local hill soil. The strength characteristics of the soil-coir fiber composite have been compared with the same soil reinforced with synthetic polypropylene fiber. The study investigates the strength variation and change in ductility of both soil-fiber composite with respect to bare soil. The fiber percentage added to soil was selected at 0.5, 0.75 and 1% of the dry weight of soil. A series of unconfined compressive strength (UCS) tests were conducted to ascertain the strength characteristics of the soil. The reinforcement strength results of the soil-coir fiber composite show the efficacy of using such a natural fiber to improve the soil strength characteristics.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the modern times, when the world is facing an acute problem of land shortage coupled with poor soil property, the need of soil reinforcement has gained traction. Reinforcement of such soils is required to improve the engineering properties, thus increasing the shear strength and ductility (Vidal 1969). In the past, a large range of tensile inclusions ranging from low-modulus polymeric materials to high tensile strength metallic sheets has been used (Hejazi et al. 2012). However, the inherent disadvantages of such planar inclusions are the existence of an inherent plane of weakness. Fiber reinforcement has been popularly used in shallow depth soil reinforcement, due to its inherent advantages (strength isotropy, increased ductility), which is generally not provided by the aforementioned planar reinforcement (Maher and Gray 1990). This soil-fiber composite is conventionally discussed as randomly distributed fiber reinforced soil (RDFS). Among the fibers used in RDFS, they are briefly discussed as natural and synthetic fiber. The common synthetic fibers used are polypropylene fiber, glass fiber and nylon fibers. They are basically by-products of petroleum—thus exhaustive and relatively costly compared to natural fibers (Hejazi et al. 2012). The utility of using natural fibers over synthetic fibers in specific sites is due to its cheap cost, easy availability and its favorability to subsequent vegetation. Such sites, where the mechanical strength provided by this natural reinforcement is required for short-term constructions (1–2 years) such as approach roads, landfill cover system, military roads; this form of reinforcement is ideal and cost effective.

One of the natural fibers used in the current study is coir. Coir is derived from coconut, Cocos Nucifera, and is one of the most popular natural fibers used in soil reinforcement (Faruk et al. 2012). It has remarkable property of adapting to various soil types, and can be found throughout the tropical and subtropical regions of the world. Coir contains high percentage of lignin, which leads to a relative high degradation life of the fiber. According to a study, the service life of coir fiber during its use in field is found to be from 4 to 10 years and thus makes it suitable for soil reinforcement.

The objective of the work was to find out the strength characteristics of coir fiber-reinforced soil. The results based on the stress–strain response from a series of unconfined compressive strength (UCS) test, are compared with polypropylene (PP) fiber-reinforced soil. The tests were carried out for three percentages for both fiber type in the soil viz. 0.5, 1, and 1.5% of the dry soil mass. The effect of compaction state (i.e., the density and water content), on the strength and ductility of soil-fiber composite has been investigated. The density of soil-fiber composite was kept at 0.95 MDD (Maximum Dry Density), MDD and 1.05 MDD; while the moisture content was selected at optimum moisture content (OMC), (OMC −5%) and (OMC +5%). Based on the results obtained from the tests conducted, the effect of compaction on strength characteristics of soil has been discussed. The inclusion of fiber reinforcement and its subsequent effect on the stress strain response has been discussed in detail.

2 Materials and Methods

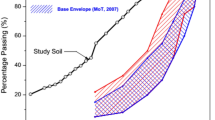

The soil used in the tests was collected from a local construction site. The grain size distribution of the soil sample was done as per the provisions of IS-2720-Part 4-1985. The percentage of silt in the soil was 53.07% whereas the clay percentage was found to be 24.34%. Various other physical properties of the soil are as listed in Table 1.

Coir used as reinforcement in this study is a natural fiber. Mainly derived from plants, natural fibers are referred to as cellulosic and lignocellulose fibers (Methacanon et al. 2010). The three main constituents of natural fibers are cellulose, hemicellulose, lignin, and ash. Cellulose is responsible for the tensile strength of natural fibers. The hemicellulose plays an important role in moisture absorption by fibers. Ash content acts as a measure of the mineral content and other inorganic matter in a biomass and also provides natural capacity of plant for metal adsorption. Due to relatively high amount of lignin and high resistance to biodegradation, coir is the one of the most popular fibers used for reinforcing soil. The general properties of coir fiber are given in Table 2.

2.1 Sample Preparation and Test Procedure

The fibers of length 15 mm and required fiber content were taken and uniformly mixed with dry soil, and subsequently water was added to the mixed soil. The composite was kept in desiccator for 24 h before UCS samples were made in an in-house developed mould at the selected compaction density. The Proctor’s light compaction technique was used for soil sample testing and determination of MDD and the OMC. The UCS test was performed at a constant strain rate of 1.25 mm/min in accordance with IS-2720 part-10-1991, to determine the strength of the reinforced soil. The addition of fibers was restricted to 1%, to avoid formation of low density pockets in the soil-fiber composite.

3 Results and Discussions

Figure 1 shows the stress–strain curves of plain soil and soil reinforced with coir and PP fibers at 0.5% fiber content. It is evident that the peak strength of the soil is higher after fiber inclusion. This was because fiber interface. Failure of the UCS sample occurs when the alied shear stress exceeds the interarticle friction interface. Failure of the UCS sample occurs when the applied shear stress exceeds the interparticle friction inclusion increased the friction at the fiber-soil causing the soil to fail at a particular failure plane. The increase in friction resisted the shear stress and increased the strength of the fiber reinforced soil samples leading to bridging effect of the fibers (Fig. 1a, b). This bridging effect restricts soil particles to roll over in the shear plane. Randomly distributed fiber reinforcement also prevented the formation of a single failure plane thus delaying the failure of the UCS sample.

The drop in post peak strength in unreinforced sample was much higher (83%) than coir (16%) and PP (22%). This is because in the absence of fibers, once the unreinforced sample fails, it loses its resistance against shear stress as the only friction acting is due to rolling of the soil particles against each other. The fibers help in interlocking the surrounding soil and resisting slippage. Hence, even after the soil loses its strength, the fiber-soil composite shows residual strength due to the tenacity of the fibers. The peak strain corresponding to the peak strength of the soil increased from unreinforced, PP-reinforced to coir-reinforced indicating the increase in ductility of the samples. Coir sample had higher peak strength and peak strain as well as a lower drop in post peak strength than PP sample.

The variation of mean UCS with density for coir and polypropylene fiber reinforced soil in comparison to unreinforced soil is presented in Fig. 2. It could be observed that the strength of reinforced soil was much higher than that of unreinforced soil for the corresponding water content. UCS of soil increased with the density of the soil sample. As density increased, the packing of soil articles becomes closer which led to a higher abrasion between the particles. Denser packing also increased matric suction, hence, the strength of the sample. Similar trend could be noted with a variation of moisture content in the soil. The strength of soil decreased with increasing water content and the maximum strength values were that of the samples with OMC-5% water content. At a micro-level, water present in the voids reduced the friction between the soil particles because water cannot resist shear force. So as water content increased, the strength of the soil decreased.

From Fig. 2 it can be observed that there is no specific trend followed by the varying fiber content of the soil. However, optimum fiber contents at which the reinforcement was at its highest efficiency for coir and PP fibers were found to be 1 and 0.75% respectively.

While both fibers showed improvement of strength over unreinforced soil samples, coir-reinforced samples exhibited relatively higher values of strength than that of polypropylene-reinforced samples. Due to the rougher surface of the natural fiber, coir fibers offered more shear resistance than the polypropylene fibers and enhanced the strength of the soil sample. Coir also has lesser specific gravity than PP. Therefore, the number of discrete coir fibers in unit volume of the sample was higher than the number of PP fibers. This led to higher friction and cohesion in the coir-reinforced samples. With higher UCS, ductility and tensile strength, coir fibers indicated better reinforcement than PP fibers, reaching its maximum efficiency at OMC-5% water content.

4 Conclusions

In this study, UCS tests were done on unreinforced, coir-reinforced, and PP-reinforced samples with varying moisture contents, densities, and fiber contents. It was observed that fiber inclusion increased not only the peak strength of the samples but also its ductility. It was also noted that water content of 5% dry of optimum moisture content showed the maximum strength. Moreover, soil samples reinforced with coir fibers were equally efficient (if not more) in resisting shear stress and showed higher strength characteristics than conventional polypropylene-reinforced soil samples. Thus, this study concludes that coir as natural fiber reinforcement could be successfully employed in field where short-term and effective fiber reinforcement is desired.

References

Faruk, O., Bledzki, A. K., Fink, H. P., & Sain, M. (2012). Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science, 37(11), 1552–1596.

Hejazi, S. M., Sheikhzadeh, M., Abtahi, S. M., & Zadhoush, A. (2012). A simple review of soil reinforcement by using natural and synthetic fibers. Construction and Building Materials, 30, 100–116.

Maher, M. H., & Gray, D. H. (1990). Static response of sands reinforced with randomly distributed fibers. Journal of Geotechnical Engineering, 116(11), 1661–1677.

Methacanon, P., Weerawatsophon, U., Sumransin, N., Prahsarn, C., & Bergado, D. T. (2010). Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohydrate Polymers, 82(4), 1090–1096.

Vidal, H. (1969). The principle of reinforced earth. Highway Research Record, 282.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Pachauri, S., Indu Priya, M., Garg, A. (2019). Comparative Analysis of Strength Characteristics of Soil Reinforced with Coir and Polypropylene Fibers. In: Thyagaraj, T. (eds) Ground Improvement Techniques and Geosynthetics. Lecture Notes in Civil Engineering , vol 14. Springer, Singapore. https://doi.org/10.1007/978-981-13-0559-7_40

Download citation

DOI: https://doi.org/10.1007/978-981-13-0559-7_40

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0558-0

Online ISBN: 978-981-13-0559-7

eBook Packages: EngineeringEngineering (R0)