Abstract

For improving soil properties, use of natural fiber is advantageous because they are cheap, locally available, biodegradable and eco-friendly. Therefore, in the present investigation, coir fiber has been chosen as the reinforcement material and randomly included in to the soil at different percentages of fiber content, i.e., 0, 0.5, 1 and 1.5% by weight of raw soil. The soil used for this research is highly compressible soil. Length of fiber is considered as 20 mm for this study. The objective of this investigation is focused on the durability of soil reinforced with coir fiber. The compaction, unconfined compressive strength (UCC) and California bearing ratio (CBR) tests are conducted for each percentage of natural fiber mixed with soil. For finding the durability of coir-reinforced soil, the specimens for UCC test is prepared with optimum fiber content (OFC) by using concentrated hydrochloric acid (HCL) solution as pore fluid. The fibers with and without bitumen emulsion coating are used in the study. Thus, prepared samples are cured for 7 and 30 days. Based on the results obtained, it is observed that the inclusion of coir fiber improves the strength of the soil, and bitumen emulsion-treated coir fiber has more durability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Soil is considered by the civil engineer as a complex material. Apart from the testing and classification of various types of soil, in order to determine the stability and physical properties, the knowledge of problems related to foundation design and construction, pavement design, design of embankments and excavation and design of earth dams is necessary. Problems faced before or after construction mainly due to type of soil. Soil stabilization is of major concern in the construction activities due to rapid growth of urbanization and industrialization. The term soil improvement is used for the techniques which improve the index properties and other engineering characteristic of weak (or problematic) soils. Stabilization can increase the shear strength of a soil and/or control the shrink-swell properties of a soil, thus improving the load bearing capacity.

The different types of method used for soil stabilization are like soil stabilization with cement, soil stabilization with lime, soil stabilization using bitumen, chemical stabilization and a new emerging technology of stabilization by geo-textiles and geo-synthetic fibers. Soil reinforcement is an effective and reliable technique for improving strength and stability of the soil.

One of the soil stabilization methods considered as soil stabilization using natural fibers like coir fiber. Coir or coconut fiber belongs to the group of hard structural fibers. It is an important commercial product obtained from the husk of coconut. The coir fiber is elastic enough to twist without breaking, and it holds a curl as though permanently waved. Shorter mattress fibers are separated from the long bristle fibers which are in turn a waste in the coir fiber industry. So this coir fiber waste can be used in stabilization of soil, and thus, it can be effectively disposed of.

Durability is one of the major properties to consider in soil stabilization with natural fibers. In order to increase the life of natural fibers, fibers have been successfully treated with bitumen, copper-based chemicals, phenol and some other patented chemical compounds.

2 Materials

2.1 Soil

Natural soil is collected from Perumbakkam village near Cheran Nagar, Changalpattu district, Tamil Nadu state. Then, the soil was sieved through 4.75 mm sieve to remove the gravel fraction. Soil was oven dried for 24 h before execution of geo-technical tests. By conducting laboratory tests, the following index properties of the soil were evaluated (Table 1).

2.2 Stabilizer

Stabilizers used for this research are raw coconut coir fibers for the soil, and the fiber collected from the industry and after cutting into 20 mm length is shown in Fig. 1.

The properties of the coir fiber used in the present study are shown in Table 2.

2.3 Bitumen

For increasing the life of fiber, the bitumen emulsion is used, which has water content 46%, and brownish-black color. The bitumen emulsion used for this study is collected from industry.

2.4 Concentrated HCL

For finding the durability of coir-reinforced soil, the specimens for UCC test are prepared with optimum fiber content (OFC) by using concentrated hydrochloric acid (HCL) solution as pore fluid. The HCL solution is prepared by mixing the 5 ml of HCL acid with 600 ml of tap water.

3 Test Results and Discussion

The interpretations of tests result from the laboratory tests have been discussed in following sections with graphical results.

3.1 Compaction Test

The standard Proctor compaction test has been conducted for various samples; the variation of optimum moisture content (OMC) and maximum dry density (MDD) with fiber content is shown in Figs. 2 and 3, respectively.

It is observed that addition of 0.5% coir to the soil increased the OMC and decreased the MDD. Because fibers have tendency to absorb moisture, and this can be attributed to the increase in OMC. And using of materials has weight less than the weight of soil particles at the same volume which leads to decrease MDD, but further increase the fiber content leads to replace the soil particles, and it leads to reduce the soil moisture absorption, so OMC for soil mixture (soil + fiber) decreases. Further increase of fiber content fills up the interlocking spaces within the soil matrix and held the particles together.

3.2 California Bearing Ratio Test

The CBR test has been conducted for various samples. The test results are shown in Fig. 4. It is noticed that the addition of coir fiber increased the CBR value. Addition of 1.5% of coir fiber increased the CBR value by nearly 50%.

3.3 Unconfined Compression Test

The unconfined compression test has been conducted on various samples of size 3.6 cm diameter and 7.5 cm length. The coir-stabilized soil specimens are prepared at their respective MDD and OMC using water as the pore fluid. The unconfined compressive strength of the soil is increased by the addition of coir fiber. The variation of unconfined compressive strength with the fiber content is shown in Fig. 5. With the addition of 1% fiber, the unconfined compressive strength of the soil is increased by about 17%. The unconfined compressive strength remained nearly the same for further increase in fiber content. Hence, 1% fiber content is taken as optimum fiber content that is the minimum fiber content required to achieve the maximum strength gain.

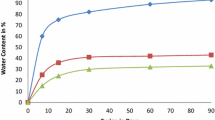

For finding the durability of coir reinforced soil, the specimens for UCC test are prepared at MDD and OMC with optimum fiber content (OFC), which is 1% in the present study, by using concentrated hydrochloric acid (HCL) solution as pore fluid. The fiber is coated with bitumen. The prepared samples are cured for 7 and 30 days. The unconfined compressive strength of natural soil, soil stabilized with untreated fiber and soil treated with fiber coated with bitumen, is shown in Fig. 6.

From Fig. 6, it is inferred that the inclusion of coir fibers in to the soil as reinforcement shows higher unconfined compressive strength and bitumen-treated coir fiber has more durability compared to untreated coir fiber.

4 Conclusions

Based on the laboratory investigations, it can be concluded that the compaction characteristics of soil is influenced by the addition of coir fiber. The CBR value increases with increase of coir fiber content in soil. The unconfined compressive strength of soil is increased with coir fiber addition, and even 0.5% of fiber content is able to increase the strength by about 17%.

As far as the durability of coir fiber stabilized soil is concerned, it is witnessed that the bitumen-coated fiber is more durable than uncoated fiber in the acidic environment.

References

Abhijith, R.P.: Effect of natural coir fibres on CBR strength of soil subgrade. Int. J. Sci. Res. Publ. 5, 1–4 (2015)

Goyal, A., Parkash, V., Kumar, V.: Soil stabilization of clayey soil using jute fibre and gypsum. IJIRSET 5, 15513–15519 (2016)

Chakraborty, A., Sil, A.: Experimental study of unreinforced and reinforced soil retaining wall using shake table facility. J. Civ. Eng. Environ. Technol. 2(12), 13–21 (2015)

Bairagi, H.: Effect of jute fibers on lime treated black cotton soil. Int. J. Eng. Sci. Res. Technol. 705–707 (2014)

Singh, H.P.: Strength and stiffness of soil reinforced with jute geo-textile sheets. Int. J. Curr. Eng. Technol. 3, 1143–1146 (2013)

Kulhar, K.S., Raisinghani, M.: Shear strength performance of sandy soil reinforced with jute fiber. J. Basic Appl. Eng. Res. 4, 624–629 (2017)

Upadhyay, P., Singh, Y.: Soil stabilization using natural fiber coir. IRJET 4, 1808–1812 (2017)

Lakshmi, S.M., Sasikala, S., Padmavathi, V., Priya, S., Saranya, V.: Utilization of coconut coir fibre for improving sub-grade strength characteristics of clayey sand. IRJET 5, 2873–2878 (2018)

Soundara, B., Senthil Kumar, K.P.: Effect of fibers on properties of clay. Int. J. Eng. Appl. Sci. (IJEAS) 2, 123–128 (2015)

Chakrabarti, S.K., Saha, S.G., Paul, P., Dewan, A.R., Das, K., Chowdhury, P.K., Gon, D.P., Ray, P.: Specially treated woven jute geo-textiles for river bank protection. Indian J. Fibre Textile Res. 41, 207–211 (2016)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Teja, M.D., Muttharam, M. (2022). Durability Study on Coir Fiber-Reinforced Soil. In: Satyanarayana Reddy, C.N.V., Muthukkumaran, K., Satyam, N., Vaidya, R. (eds) Ground Characterization and Foundations. Lecture Notes in Civil Engineering, vol 167. Springer, Singapore. https://doi.org/10.1007/978-981-16-3383-6_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-3383-6_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3382-9

Online ISBN: 978-981-16-3383-6

eBook Packages: EngineeringEngineering (R0)