Abstract

Migration of natural reservoir fines is one of the main causes of formation damage in oil and gas fields. Yet, fines migration can be employed for enhancing reservoir sweep and water production control. Permeability decline due to fine particles’ detachment from reservoir rocks, mobilisation, migration and straining has been widely reported in the petroleum industry since the 1960s and is being researched worldwide. The topic of colloidal-suspension flows with particle detachment is also of wide interest in environmental, chemical and civil engineering. The current work begins with a detailed introduction on laboratory and mathematical modelling of fines migration, along with new mathematical models and experimental results. Each of the next three sections explores a particular cause of fines mobilisation, migration and straining. Section 2 covers high flow velocity that causes particle detachment accompanied by consequent permeability decline. Section 3 covers low-salinity water injection, where the decreased electrostatic attraction leads to particle mobilisation. Section 4 covers the effect of high temperature on production rate and low-salinity water injection in geothermal reservoirs. We attribute the long permeability stabilisation period during coreflooding with fines migration, to slow fines rolling and sliding and to diffusive delay in particle mobilisation. We derive the analytical models for both phenomena. Laboratory fines-migration coreflood tests are carried out, with the measurement of breakthrough fines concentration and pressure drop across the whole core and the core’s section. Treatment of the experimental data and analysis of the tuned coefficients show that the slow-particle model contains fewer coefficients and exhibits more typical strained concentration dependencies of the tuned parameters than does the delay-release model.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Fines migration with consequent permeability reduction has been widely recognised to cause formation damage in numerous petroleum, environmental and water resource processes (Noubactep 2008; Noubactep et al. 2012; Faber et al. 2016). Fines migration takes place during oil and gas production in conventional and unconventional reservoirs, significantly reducing well productivity (Sarkar and Sharma 1990; Byrne and Waggoner 2009; Byrne et al. 2014; Civan 2014). Natural and induced fines migration has occurred in the waterflooding of oilfields. It also causes drilling and completion fluids to invade the formation (Watson et al. 2008; Fleming et al. 2007, 2010). Despite significant progress in the above-mentioned technologies, clogging of production and injection wells remains a major operational issue.

The distinguishing features of natural reservoir fines migration are mobilisation of the attached particles, their capture by straining in the rock, permeability reduction and consequent decline in well productivity and injectivity (Fig. 1). Several laboratory studies observed permeability decline during coreflooding with piecewise-constant increase in velocity in (Ochi and Vernoux 1998). Similar effects occur during piecewise-constant change in water salinity or pH during coreflooding (Lever and Dawe 1984). Numerous authors attribute the permeability reduction during velocity increase, salinity decrease and pH increase, to mobilisation of the attached fine particles and their migration into pore spaces until size exclusion in thin pore throats (Muecke 1979; Sarkar and Sharma 1990). Figure 1 shows a schematic for attached and size-excluded fine particles in the porous space, along with definitions of the concentrations of attached, suspended and strained particles. Detachment of fines from the grain surfaces yields an insignificant increase in permeability, whereas the straining in thin pore throats and consequent plugging of conducting paths causes significant permeability decline. The main sources of movable fine particles in natural reservoirs are kaolinite, chlorite and illite clays; quartz and silica particles can be mobilised in low-consolidated sandstones (Khilar and Fogler 1998). Usually, the kaolinite booklets of thin slices cover the grain surfaces (Fig. 2). Detachment of a thin, large slice from the booklet can result in plugging of a large pore.

Figure 3a, e show typical decreasing permeability curves during velocity increase.

Normalised permeability, flow rate, critical fine radius and drift delay factor against time, during coreflood with piecewise increasing velocity during test I (first column) and test II (second column): a, e experimentally determined permeability decline with time; b, f increasing velocity during the test; c, g decrease of the mobilised fines radius as velocity increases as calculated from torque balance; and d, h drift delay factor from the model adjustment

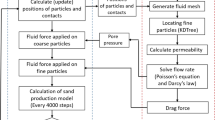

The laboratory-based mathematical modelling supports planning and design of the above-mentioned processes. Classical filtration theory applied to particle detachment includes a mass balance equation for suspended, attached and strained particles:

where c, σa and σs are the concentrations of suspended, attached and strained particles, respectively, and U is flow velocity of the carrier fluid, which coincides with particle speed.

The kinetics of simultaneous particle attachment and detachment is given by the relaxation equation (Bradford and Bettahar 2005; Tufenkji 2007; Bradford et al. 2012, 2013; Zheng et al. 2014; Bai et al. 2015b)

where λa is the filtration coefficient for attachment and kdet is the detachment coefficient.

The irreversible fines straining rate in thin pore throats is expressed by the linear kinetics equation where the straining rate is proportional to the advective flux of suspended particles (Herzig et al. 1970; Yuan and Shapiro 2011a, b; You et al. 2013; Sacramento et al. 2015):

Modified Darcy’s law accounts for permeability damage due to both attachment and straining (Pang and Sharma 1997; Krauss and Mays 2014):

Figure 1 illustrates the common assumption that the coating of grain by attached particles causes significantly lower permeability damage than does straining: \( \beta_{\text{s}} \gg \beta_{\text{a}} \), i.e. the combination of particle detachment and straining is the primary cause of the decline in permeability. Therefore, the term \( \beta_{\text{a}} \sigma_{\text{a}} \) in Eq. (4) that accounts for permeability increase due to detachment is negligible.

Civan (2010, 2014) presented numerous generalisations of the governing Eqs. (1)–(4), to account for non-Newtonian behaviour of suspension fluxes, non-equilibrium for deep-bed filtration of high-concentration suspensions and colloids, and particle bridging at thin pore throats.

Quasi-linear system of partial differential Eqs. (1)–(3) exhibits the delayed reaction to an abrupt injection rate alteration, whereas laboratory tests show an instant permeability and breakthrough concentration response (Ochi and Vernoux 1998; Bedrikovetsky et al. 2012a, b). This discrepancy between the modelling and laboratory data, and the corresponding shortcoming in the theory, has been addressed in the modified model for particle detachment, by introducing the maximum attached concentration as a velocity function σa = σcr(U) (Bedrikovetsky et al. 2011a, b). If the attached concentration exceeds this maximum value, particle detachment occurs and the detached particles follow the classical filtration Eq. (3); otherwise, the maximum attached concentration holds. The dependency σa = σcr(U) is called the maximum retention function. The following set of equations captures the above attachment–detachment scenario:

The maximum retention function decreases as the flow velocity increases. Therefore, the velocity increase causes instant release of the excess attached fine particles.

The maximum retention function σcr(U) is an empirically based (material) function of the model and can be determined only by the inverse-problem approach applied to fines-migration tests (Figs. 4 and 5). However, it can be calculated theoretically for a simplified geometry of porous space, using the conditions of mechanical equilibrium of particles attached to the rock surface.

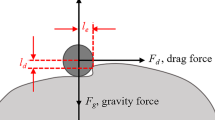

Freitas and Sharma (2001), Bergendahl and Grasso (2003), and Bradford et al. (2013) discussed the torque balance of attaching and detaching forces exerting on a particle situated at the rock or internal cake surface (Fig. 6):

Scenarios involving particle detachment in monolayer on the grain surface and forces exerting on the particles. Torque and force balance on a fine particle attached to the pore wall: a the lever arm is equal to the contact area radius, deformation due to attracting electrostatic force. b The lever arm is determined by the asperity size. c Velocity distribution in Hele–Shaw flow in a pore

Here, Fd, Fe, Fl and Fg represent drag, electrostatic, lift and gravitational forces, respectively; ld and ln are the lever arms for drag and normal forces, respectively. Substitution of the expressions for drag, electrostatic, lift and gravitational forces into the torque balance equation (6) yields an expression of the maximum retention function (Bedrikovetsky et al. 2011a). The maximum retention function (5) for the case of poly-layer attachment of single-radius particles in rock having mono-sized cylindrical capillaries is a quadratic polynomial with flow velocity as the variable. The maximum retention function for a monolayer of polydispersed particles is expressed via size distribution for fine particles (You et al. 2015, 2016).

Expression (5) substitutes the equation for simultaneous attachment and detachment (2) in the mathematical model for colloidal-suspension transport (1)–(3). The modified model consists of three Eqs. (1), (3) and (5) for three unknown concentrations c, σa and σs. Equation (4) for pressure is separated from system (1), (3) and (5). Let us discuss the case of low straining concentration, where size exclusion does not affect the probability of particle capture. In this case, the filtration coefficient λs is constant, whereas it should be a σs-function in the general case. We also discuss the case of injection with timely decreasing rate, where the attached concentration is equal to the maximum retained concentration [second line in Eq. (5)]. The one-dimensional flow problem with attachment and detachment allows for exact solution, yielding suspended, attached and strained concentrations and pressure drop across the core. The laboratory- and theoretically determined maximum retention functions are in high agreement, which validates the maximum retention function as a mathematical model for particle detachment (Zeinijahromi et al. 2012a, b; Nguyen et al. 2013).

In the case of large stained concentration, λs = λs(σs). Suspended concentration can be expressed from Eq. (4) as a time derivative of a σs-dependent potential. Its substitution into Eq. (1) and integration in t reduces the system to one non-linear first-order partial differential equation, which is solved analytically using the method of characteristics (Alvarez et al. 2006, 2007).

Usually, fines-migration tests are performed under piecewise-constant decreasing velocity (Ochi and Vervoux 1998; Bedrikovetsky et al. 2011a; Oliveira et al. 2014, 2016). The amount of released particles during abrupt velocity alteration forms the initial suspended concentration for system (1), (3) and (4) with unknowns c, σs and p. Thus, the basic governing equations for deep-bed filtration and fines migration are the same (Herzig et al. 1970). The initial suspended concentration for deep-bed filtration in clean beds is zero, whereas for fines migration the initial suspended concentration is defined by the velocity alteration. Inlet boundary condition for deep-bed filtration is equal to concentration of the injected suspension, whereas it equals zero for fines migration. Therefore, the methods of exact integration of direct problems and regularisation of inverse problems, developed by Alvarez et al. (2006, 2007) for deep-bed filtration, can be applied for fines migration also.

The axisymmetric analogue of Eqs. (1), (3)–(5) describes the near-well flows, allowing estimating the well inflow performance accounting for fines migration. Zeinijahromi et al. (2012a, b) derive an analytical model for intermediate times with steady-state suspension concentration. Bedrikovetsky et al. (2012b) present an analytical steady-state model for late times, when all fines are either produced or strained. Marques et al. (2014) derive the analytical transient model for the overall well inflow period.

However, the exact solution of system (1), (3), (4) and (5) shows stabilisation of the pressure drop after injection of one pore volume (Bedrikovetsky et al. 2011a, b), whereas numerous laboratory studies have exhibited periods of stabilisation within 30–500 PVI (here PVI stands for pore volume injected) (Ochi and Vernoux 1998; Oliveira et al. 2014). Figure 3a shows the permeability stabilisation within 70–3000 PVI, for various injection velocities (Ochi and Vernoux 1998). The stabilisation times for flow exhibited in Fig. 3e vary from 300 to 1200 PVI. Therefore, the modified model for colloidal-suspension transport in porous media (1), (3) and (5) approximates well the stabilised permeability but fails to predict the long stabilisation period.

Several works have observed slow surface motion of the mobilised particles and simultaneous fast particle transport in the bulk of the aqueous suspension. Li et al. (2006) attributed the slow surface motion to particles in the secondary energy minimum. Yuan and Shapiro (2011a) and Bradford et al. (2012) introduced slow particle velocity into the classical suspension flow model, resulting in a two-speed model that matched their laboratory data on breakthrough concentration. Navier–Stokes-based simulation of colloids’ behaviour at the pore scale, performed by Sefrioui et al. (2013), also exhibited particle transport speeds significantly lower than the water velocity. However, classical filtration theory along with the modified particle detachment model assumes that particle transport is at carrier fluid velocity (Tufenkji 2007; Civan 2014).

Oliveira et al. (2014) attributed long stabilisation periods to slow drift of fine particles near the rock surface in the porous space. However, a mathematical model that depicts slow-particle migration and accurately reflects the stabilisation periods is unavailable in the literature.

Application of nanoparticles (NPs) can significantly decrease migration of the reservoir fines and the consequent permeability impairment (Habibi et al. 2012). Under certain salinity and pH, NPs attract both fines and grain. Low size of NPs causes high mobility and diffusion, spreading them over the grain surfaces. NPs ‘glue’ the fines and significantly increase the electrostatic fine-grain attraction (Ahmadi et al. 2013; Sourani et al. 2014a, b). The basic system of equations includes two mass balance equations for NPs and salt. Yuan et al. (2016) solved the system by the method of characteristics (Qiao et al. 2016). Combination of low-salinity and NP waterfloods in oilfields adds the above-mentioned mass balance and deep-bed filtration equations to Buckley–Leverett equation for two-phase flow in porous media (Bedrikovetsky 1993; Arab and Pourafshary 2013; Assef et al. 2014; Huang and Clark 2015; Dang et al. 2016).

Mahani et al. (2015a, b) observed delay between salinity alteration and corresponding surface change. This delay was attributed to saline water diffusion from the contact area between the deformed particle and rock surface. The Nernst–Planck diffusion in the thin slot between two plates subject to molecular-force action is significantly slower than the Brownian diffusion, so the Nernst–Planck diffusion can bring significant delay. The diffusive delay in particle mobilisation due to water salinity decrease can serve as another explanation for the long stabilisation period. Yet, a mathematical model that accounts for delay in particle mobilisation due to salinity alteration also seems absent from the literature.

In the current work, the long times for permeability stabilisation are attributed to slow surface motion of mobilised fine particles. The governing system (1), (3) and (5) is modified further by replacing the water flow velocity U by the particle velocity Us < U (Fig. 1). We also introduce a maximum retention function with delay, which corresponds to the Nernst–Planck diffusion from the grain–particle contact area into the bulk of the fluid. We derive the maximum retention function for a monolayer of size-distributed fines, which accounts for its non-convex form. We found that during continuous velocity/pH/temperature increase or salinity decrease, the largest particles were released first. The obtained system with slow fines migration and delayed maximum retention function allows for exact solution for cases of piecewise-constant velocity/pH/temperature increase or salinity decrease. High agreement between the laboratory and modelling data validates the proposed model for slow surface motion of released fine particles in porous media.

The structure of the text is as follows. Section 2 presents the laboratory study of fines migration due to high velocities and presents the mathematical model for slow-particle migration that explains the long stabilisation periods. The derived analytical model provides explicit formulae for concentration profiles, histories and the pressure drop. Section 3 presents the laboratory study of fines migration due to low salinities, and it derives the mathematical model that accounts for slow-particle migration and for delayed fines mobilisation. Here, we also derive the analytical model. Section 4 presents the analytical model for fines mobilisation at high temperature. The recalculation method for varying salinity, temperature, pH, or velocity is developed. Section 5 presents fines migration in gas and coal-bed-methane reservoirs. Section 6 presents the conclusions.

2 Fine Particles Mobilisation, Migration and Straining Under High Velocities

This section presents the modelling and laboratory study of fine particles that migrate after having been detached by drag and lift forces at increased velocities. Section 2.1 presents a brief physical description of fines detachment in porous media and introduces the maximum retention function for a monolayer of size-distributed particles. A qualitative analysis of the laboratory results on long-term stabilisation gives rise to a slow-particle modification of the mathematical model for fines migration in porous media. Section 2.2 presents those basic equations accounting for slow-particle transport. Section 2.3 derives the analytical model for one-dimensional flow under piecewise increasing flow velocity with consequent fines release and permeability impairment. Section 2.4 describes the laboratory coreflood tests with fines mobilisation and examines how closely the analytical model matches the experimental data. Section 2.5 discusses the model’s validity, following the results of the laboratory and analytical modelling.

2.1 Physics of Fines Detachment, Transport and Straining in Porous Media

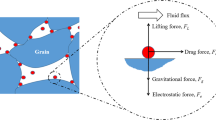

In this section, we discuss the physics of fines detachment/mobilisation on a micro-scale. In the presence of low ionic strength or high flow velocity, reservoir fines are detached from the rock surface, mobilise and flow through the porous media as shown in Fig. 1. Four forces act on a fine particle attached to the surface of the grain: drag, lift, electrostatic and gravity (Fig. 6). For calculation of drag, we use the expression proposed by Bergendahl and Grasso (2003) and Bradford et al. (2013); lift is calculated using the formula of Akhatov et al. (2008); and the electrostatic forces are calculated using DLVO (Derjaguin–Landau–Verwey–Overbeek) theory (Khilar and Fogler 1998; Israelachvili 2011; Elimelech et al. 2013).

Elastic particles located on the grain surface undergo deformation due to gravitational, lift and electrostatic forces acting normal to the grain surface. The right side of Eq. (6) contains the resultant of these forces (normal force). We assume that at the mobilisation instant, a particle rotates around the rotation-touching point in the boundary of the particle–grain contact area (Fig. 6a). Also assumed is that the lever arm is equal to the radius of the contact area of particle deformation, which is subject to the normal force (Freitas and Sharma 2001; Schechter 1992; Bradford et al. 2013). The contact area radius is equal to the lever arm ln and is calculated using Hertz’s theory of mutual grain–particle deformation:

Here, K is the composite Young modulus that depends on Poisson’s ratio ν and Young’s elasticity modulus E of the particle and of the surface. Indices 1 and 2 refer to the particle and solid matrix surfaces, respectively.

Figure 6b depicts the scenario in which a particle revolves around the contacting roughness (asperity) on the surface of a grain. The elastic properties of rock and particle determine the value of ln in the first scenario (Fig. 6a). In the second scenario (Fig. 6b), the value of ln is determined by the surface roughness.

Two coreflood tests (I and II) at piecewise-constant increasing fluid velocity on Berea sandstone cores were carried out by Ochi and Vernoux (1998) and resulted in mobilisation of kaolinite particles (Fig. 3). We used the following electrostatic constants and parameters for quartz and kaolinite in order to calculate Fe in Eq. (6): surface potentials ψ01 and ψ02 (−55, −50 mv) for test I and (−70, −80 mv) for test II (Ochi and Vernoux 1998); the Hamaker constant 2.6 × 10−20 J (Welzen et al. 1981); atomic collision diameter 0.4 × 10−9 m (Das et al. 1994); and salinity 0.1 mol/L for test I and 0.01 mol/L for test II. The Hamaker constant was calculated using dielectric constant for water D = 78.0 and permittivity of free space (vacuum) ε0 = 8.854 × 10−12 C−2 J−1 m−1 (Israelachvili 2011; Khilar and Fogler 1998). Electron charge was e = 1.6 × 10−19 C, Boltzmann’s constant was kB = 1.3806504 × 10−23 J/K and temperature was T = 25 °C. Young’s modulus for kaolinite was 6.2 GPa and for quartz was 12 GPa (Prasad et al. 2002), and Poisson’s ratios were 0.281 and 0.241 (Gercek 2007) and were used to evaluate the lever arm ratio according to Eq. (7). The above parameters were used to construct graphs for electrostatic potential and force versus separation particle–grain distance (Fig. 7a, b).

The total potential of interaction V determines electrostatic force Fe. Zero values for Fe correspond to energy extremes Vmax and Vmin, and the minimum value of electrostatic force is obtained from the inflection point of the total potential of interaction curve. The first test of Ochi and Vernoux (Fig. 3a–d) was favourable for attachment of kaolinite particles to the grain surface, which resulted in the absence of the secondary minimum on the total potential of interaction curve. For the second test (Fig. 3e–h), the values of the primary and secondary energy minima equalled 550 and 19 kT, respectively. The energy barrier was 87 kT, exceeding the values of the secondary minimum and allowing a particle to jump from secondary minimum to primary minimum (Elimelech et al. 2013). Therefore, the second test was unfavourable for kaolinite particle attachment to the grain surface.

Under the condition of mechanical equilibrium given by the torque balance Eq. (6), fluid flow velocity affects lift and drag forces, whereas particle size determines the magnitudes of all forces in the equation. Therefore, the critical radius of the particle mobilised by fluid flow with velocity U can be determined as follows: \( r_{\text{scr}} = r_{\text{scr}} \left( U \right) \). This is an implicit function from Eq. (6), i.e. Equation (6) is a transcendent equation for implicit dependency rscr = rscr(U). The stationary iterative numerical procedure can be used to solve Eq. (6) (Varga 2009). The graph of the function rscr = rscr(U) obtained using the above parameters shows that the size of each mobilised particle rscr(U) decreases monotonically as fluid velocity increases. Therefore, those particles that remained immobilised on the grain surface at fluid velocity U have sizes r < rscr(U). The magnitude of Fe increases as the Hamaker constant increases (see Fig. 8), resulting in the right-shift of the rscr(U)-curve.

Assume that the attached particles form a monolayer on the rock surface. The initial concentration distribution of attached particle sizes is denoted as Σa(rs). Particles are mobilised by descending size, as mentioned above. Thus, the critical retention concentration in Eq. (5) includes all particles with radii smaller than rscr(U):

Now assume that the attached particles are size-distributed according to the breakage algorithm (i.e. log-normal distribution for attached particle sizes Σa(rs) holds (Jensen 2000). The forms of the maximum retention function as calculated by Eq. (8) for different size distributions of the attached particles, using the above values for electrostatic and elastic constants, are shown in Fig. 9.

Maximum retention function for the attached fines forming a monolayer on the pore surface: a for log-normal particle-size distributions with varying mean particle size. b For log-normal particle-size distributions with varying variance coefficient. c Determining the maximum retention function from the number of particles released at each abrupt velocity alteration

Bedrikovetsky et al. (2011a, b) found that σcr(U) for mono-sized particles that form the poly-layer coating on the surface of cylindrical pores is a quadratic polynomial. The corresponding curves σcr(U) are convex. The model for the poly-layer coating can be modified by the introduction of size distributions for spherical particles and cylindrical pores; the resulting maximum retention curves can contain the concave parts (Fig. 9).

Figure 9 indicates that the maximum retention function for monolayer fines is not convex. The calculated σcr(U)-curves for three particle-size distributions characterised by equal variance coefficients support the above observation that the larger the particle, the higher the drag on the particle and the fewer the remaining particles (Fig. 9a). Similar calculations for log-normal distributions with the same average particle size and different variance coefficients result in the σcr(U)-curves shown in Fig. 9b. The higher fraction of mobilised large particles corresponds to larger coefficient of variation Cv. For the low-velocity range, σcr(U)-curves having high standard deviation lie lower; whereas with the increase in fluid velocity, σcr(U)-curves shift to higher σcr-values. Equation (8) shows that the σcr(U)-curve has a step shape for mono-sized particles (Cv → 0), meaning that the maximum retention function is a step function. The wider the attached particle-size distribution, the wider the transitional spread of the σcr(U)-curves. The phenomenological model for fines detachment in porous media (1), (3)–(5) assumes the existence of a maximum retention function whose form is unconstrained.

Now consider particle-free water being injected with increasing piecewise-constant velocity into a core. The movable attached fines concentration is σa0. There is no particle mobilisation at low fluid velocities (see Fig. 9c), because the attaching torque from Eq. (6) exceeds the detaching torque for all size particles: points (U < U0, σa0) are located below the maximum retention curve. Concentration of attached particles remains constant along the horizontal arrow from the point U = 0 to critical velocity U = U0. Value U0 corresponds to the minimum velocity that results in mobilisation of particles and the consequent first fine appearance in the core effluent.

The initial concentration of attached fines σa0 determines the critical velocity U0 (Miranda and Underdown 1993; Hassani et al. 2014) as follows:

Movement along the σcr(U)-curve corresponds to velocity increase above the critical value U > U0. An instant rate change from U1 to U2 is accompanied by instant particle mobilisation with concentration ∆σa1 = σcr(U1) − σcr(U2) and increase in suspended concentration by [σcr(U1) − σcr(U2)]/ϕ. The mobilised particle moves along the rock surface with velocity Us < U until it is strained by a pore throat smaller than the particle size. This results in rock permeability decline due to plugging of the pores. The increased strained particle concentration yields the permeability decline according to Eq. (4). The stabilised damaged permeability values at various fluid velocities, due to increasing strained particle concentration for tests I and II, is presented in Fig. 10a, b.

Let us introduce the non-dimensional pressure drop across the core, normalised by the initial pressure drop. This is denoted as the impedance J:

where 〈k〉(T) is the average core permeability and T is dimensionless time (pore volume injected). The permeability decline curves in Fig. 3a, e are recalculated to yield the impedance growth curves in Fig. 11a, b, respectively.

The increase in pressure drop across the core from Δpn−1 to Δp n , or permeability decline from kn−1 to k n , is caused by increasing fluid velocity U n , n = 1, 2, 3…, which leads to particle mobilisation.

Permeability decline during the increase in fluid velocity is shown in Fig. 3. According to the data from tests I (Fig. 3a) and II (Fig. 3b), rock permeabilities stabilise after injection of many pore volumes. Classical filtration theory implies that for a mobilised particle to appear at the end of the core, it must traverse the overall core length. Each fine particle is transported by the carrier fluid; it is strained in the core or must arrive at the outlet after injection of at most one pore volume. According to Fig. 3a, e, permeability stabilisation times are significantly higher than 1 PVI. This can be explained by slow-particle drift along the rock surface: the mobilised particles move along the rock with velocity Us that is significantly lower than the carrier fluid velocity U.

The next section introduces the basic governing equations for the transport of suspended colloids in porous media. The basic system includes the maximum retention function σcr which models particle detachment and its slow drift along the porous medium with low velocity Us < U.

2.2 Governing System for Suspension-Colloidal Transport and Detachment in Porous Media

The following assumptions are introduced for the development of the mathematical model for detachment/mobilisation of particles and transport of suspended colloids in porous media (Yuan and Shapiro 2011a; Yuan et al. 2012, 2013):

-

the mobilised fine particles cannot reattach to the rock surface;

-

the mobilised particles do not diffuse in long micro-homogeneous cores;

-

the carrier fluid is incompressible;

-

small concentrations of suspension in flowing fluid do not change the density or viscosity of the carrier fluid, which equal those of injected water;

-

there exists a phenomenological maximum retention function for particles attached to the rock surface;

-

volume balance of the incompressible carrier fluid is not affected by the presence of small concentrations of suspended, attached or strained particles; and

-

the mobilised particles move with velocity Us which is smaller than fluid velocity U.

Mobilised particles move along the surface of grains with velocity Us < U, meaning that the drifted particle concentration is significantly higher than the suspended concentration of fine particles carried by water stream (see Fig. 1). The drift speed Us is a phenomenological constant of the model.

The slow-fines-drift assumption Us < U determines the difference between the above formulated assumptions and those for modified model (1), (3)–(5). Thus, the system of governing equations includes a mass balance equation for suspended, attached and strained fines, where the suspended particles are transported by water flux with reduced velocity Us:

The straining rate is assumed to be proportional to particle advection flux, cUs (Herzig et al. 1970; Xu 2016):

If the maximum retention concentration is greater than attached concentration, the particle attachment rate of Eq. (5) is also assumed to be proportional to the particle advection flux cUs:

Otherwise, the attached particle concentration is expressed by the maximum retention function given by Eq. (8).

Four Eqs. (4), (11), (12) and (13) with four unknowns c, σa, σs and p constitute a closed system and a mathematical model for fine-particle migration in porous media.

Now we introduce the following dimensionless parameters:

Here, the particle drift velocities Usn and delay factors α n , n = 1, 2, 3… correspond to flow velocities U n ; T is the accumulated non-dimensional volume of injected water. For the case of piecewise-constant flow velocity U(t), the dimensionless accumulated injected volume T(t) is piecewise linear.

Substitution of dimensionless parameters (14) into governing Eqs. (4), (11)–(13) yields the following dimensionless system, which consists of the particle balance:

particle straining kinetics (Xu 2016),

particle attachment–detachment kinetics,

and the modified Darcy’s law that accounts for permeability damage due to fines retention

In the next section, we solve non-dimensional governing system (15)–(18) for the conditions of laboratory tests with piecewise-constant increasing velocity.

2.3 Analytical Model for One-Dimensional Suspension-Colloidal Flow with Fines Mobilisation and Straining

During coreflood when velocity U1 is higher than critical velocity U0, i.e. σa0 > σcr(U1), the excess of the attached concentration is instantly released into the colloidal suspension. Particle straining in the proposed model is irreversible; therefore, it is assumed that initial porosity and permeability already account for the strained particle initial concentration. Coreflood with constant fluid velocity results in constant attached concentration Sa given by the maximum retention function. Thus, the initial conditions are

The inlet boundary condition corresponds to injection of water without particles:

Substituting the expression for straining rate (16) into mass balance Eq. (15) and accounting for steady-state distribution of attached particles Sa yields the linear first-order hyperbolic equation

The next section uses the method of characteristics to solve Eq. (21).

2.3.1 Exact Analytical Solution for Injection at Constant Rate

The characteristic velocity in Eq. (21) is equal to α1. The solution C(X, T) is presented in Table 1, and integration of Eq. (16) over T determines the strained concentration profile Ss(X, T).

As illustrated in Fig. 12a, the concentration front of the injected particle-free fluid moves along the path X = α1T. Behind the concentration front, suspended particle concentration is zero and the ‘last’ mobilised particle arrives at the core outlet at T = 1/α1. The mobilised particles are assumed to be uniformly distributed: they move with the same velocity and have the same probability of capture by pore throats. Therefore, the profile of suspended particle concentration is uniform during fluid flow, and concentration of suspension at X > α1T is independent of X (as indicated by the second line in Table 1). This leads to the conclusion that the concentration of particles strained in thin pores is independent of X ahead of the concentration front. Particle straining occurs for non-zero concentration of suspended particles. Therefore, the strained particles accumulate at a reservoir point X until the arrival of the concentration front, after which the concentration of suspended particles remains unchanged. Therefore, the concentration of strained particles behind the concentration front is steady-state.

Schematic for the analytical solution of 1-D fines migration under piecewise increasing velocity at times before and after the breakthrough (moments T a and T b , respectively): a trajectory of fronts and characteristic lines in (X, T) plane. b Suspended concentration profiles in three moments T = 0, T a , and T b . c Strained concentration profiles at three instants

The profiles of suspended particle concentration at T = 0, T a (before the arrival of the concentration front at the outlet of the core) and T b (after the arrival of the concentration front) are shown in Fig. 12b. We denote ∆Sa1 as the initial concentration of the released suspended particles. The profile of the concentration of suspended particles equals zero behind the concentration front and is constantly ahead of the front. After the front’s arrival, the breakthrough concentration of suspended particles equals zero because all mobilised particles either are strained in thin pore throats or emerge at the rock effluent.

Three profiles of concentration of strained particles, for times 0, T a and T b , are shown in Fig. 12c. No strained particles are present in the rock before particle mobilisation. The concentration of strained particles continues to grow until the front’s arrival, after which it remains constant. The duration of particle straining during the flow becomes longer with X. Therefore, the profiles of strained particle concentration grow as X increases. The probability of particle capture ahead of the front remains constant. Thus, the particle advective flux is uniform, and the strained profile is uniform.

Figure 13 shows the history of particle breakthrough concentration. The later the arrival, the higher the particle capture probability. According to Herzig et al. (1970), the coefficient of filtration λs equals the probability of particle straining per unit length of the particle trajectory. Therefore, the number of particles captured by thin pore throats increases with time, and breakthrough concentration C(1, T) decreases with time. All mobilised fine particles either are strained or exit the core at time Tst,1, i.e. concentration of suspended particles becomes zero and the rock permeability stabilises at time Tst,1.

The impedance can be calculated directly from Eq. (10). Impedance for the time interval having the constant fluid velocity from Eq. (18) equals

Substituting the solution for the concentration of the retained particles (rows 4 and 5 in Table 1) into Eq. (23) and integrating over X results in the following explicit formula for impedance increase with time:

Substituting the expression for stabilisation time (22) into Eq. (24) yields the stabilised value of the impedance

Monotonic increase of dimensionless pressure drop from one to the maximum stabilised value is achieved at time equal to 1/α1, which coincides with the arrival of the ‘last’ mobilised particle at the core outlet.

2.3.2 Analytical Solution for Multiple Injections

The solution of problem (15)–(18) where fluid velocity has changed from Un−1 to U n is similar to that of the first stage under U1. The only difference is that the concentration of strained particles for T > T n equals the total of the concentration of strained particles before the fluid velocity alteration at time T = T n − 0 and the concentration of particles that have been strained during time T > T n . We discuss the case where the change in fluid velocity occurs after permeability stabilisation.

When the fluid velocity changes from Un−1 to U n at instant T = T n , the attached particles are immediately mobilised. The mobilised particle concentration is ΔSan = Scr(Un−1) − Scr(U n ). The strained concentration at T = T n equals that before velocity alteration at T = T n − 0:

Substituting the strained concentration (see Table 1) into Darcy’s law (18) and integrating for pressure gradient over X along the core yields the impedance for T > T n :

Substituting stabilised time T = T n + 1/α n into Eq. (27) gives the stabilised impedance after the n-th injection with velocity U n .

The analytical model-based formulae for impedance (rows 12 and 13 in Table 1) will be validated against the laboratory tests in the next section.

2.4 Using the Laboratory Results to Adjust the Analytical Model

In order to replicate water injection in a well, Ochi and Vernoux (1998) performed two laboratory corefloods using Berea cores at conditions similar to bottom-hole pressures and temperatures and at various fluid velocities. Permeability and flow velocity for test I are shown in Fig. 3a, b, respectively, and for test II in Fig. 3e, f, respectively. Initial and boundary conditions (19) and (20) correspond to injection of particle-free water with piecewise-constant increasing velocity. Pressure drop along the core was measured. Both tests used Berea sandstone cores prepared from the same block, so that the rock properties for both cores would be similar. As fluid velocity increased, kaolinite particles detached from the grain surface. The mobilised fines migrated and were strained by the rock. Pressure drop predicted by the analytical model proposed in Sect. 2.3 was compared to the actual pressure drop across the cores during the tests. Minimisation of the difference between the modelled and measured pressure drop was used to adjust the phenomenological constants of the model: α, Δσ, λL and β.

2.4.1 Tuning the Rheological Model Parameters from Laboratory Coreflooding Data

Formation damage and filtration coefficients were assumed to remain constant for the duration of the experiment. Therefore, these parameters would be independent of fluid velocity and concentration of the retained particles. The drift delay factor was assumed to vary, i.e. the alteration of rock surface during detachment/mobilisation of particles affects drift velocity.

For stabilised permeability, according to Eq. (4), the permeability values k n fulfil the following relationship:

Pressure drops along the core, which define the permeabilities k i , were measured during coreflood tests with varying fluid velocities U i . The least-squares method was used to tune the above experimental pressure drop data and obtained filtration coefficient λs, the products βsΔσcr(U n ), n = 1, 2…, and the drift delay factors α n for different fluid velocities U n . The optimisation problem (Coleman and Li 1996) was solved using the reflective trust region algorithm in Matlab (Mathworks 2016).

The average core permeabilities (Fig. 3a,e) were used to calculate the impedances in Fig. 11. For Berea sandstone, we assumed typical porosity of 0.2 and typical concentration of kaolinite particles of 0.06 (Khilar and Fogler 1998). The attached volumetric concentration is equal to σa0 = 0.06 × 0.8 = 0.048, which is equivalent to σcr for U0 < U1 (see Eq. (9)). We calculated the formation damage coefficient for the condition of total removal of all attached particles at the maximum fluid velocity, during the last fluid injection:

Substituting formation damage coefficient (29) into the products βsΔσ an results in the values of released concentrations Δσan. The maximum retention concentrations at different fluid velocities can be calculated as follows:

2.4.2 Results

Table 2 and Fig. 11 show results for history matching of impedance for the two coreflood tests by Ochi and Vernoux (1998). Tuning the model parameters resulted in monotonically decreasing dependency of the drift delay factor α = α(S) for corefloods in cores I and II (Fig. 3d, h, respectively). The higher the strained concentration, the higher the rock tortuosity, which decelerates particle drift. Also, the higher the strained concentration, the smaller the mobilised particles, which drifted at lower velocity.

The experimental data closely matched the model (R2 values of 0.99 and 0.98 for cores I and II, respectively). Fixing the drift delay factor for the overall period of fluid injection and then comparing the impedance data resulted in significantly lower R2 values during adjustment of the proposed model. Using Eq. (30) to tune the model for two cores yielded the maximum retention function shown in Fig. 14. The increase in fluid velocity resulted in the increase in drag and lift forces, which detached the kaolinite particles from the surface of the rock grains and reduced the concentration of kaolinite particles remaining immobilised on the rock grain surface. If a monolayer of poly-sized kaolinite particles is attached to the surface of rock grains, mechanical equilibrium model (6) and (8) indicates that the obtained σcr-curves would not be convex.

The proposed model can be used to calculate the size distribution of attached fine particles Σa(rs) from the maximum retention function σcr(U): the minimum mobilised size rscr(U) is determined from Eq. (6), and size distribution function Σa(rs) is calculated from Eq. (8) by regularised numerical differentiation (Coleman and Li 1996).

Because the fluid velocity was changing stepwise during coreflood tests (seven velocities for test I, and four velocities for test II), the calculated kaolinite particle distributions are given in the form of a histogram (Fig. 15). As follows from Fig. 3c, g, the minimum radius of detached particles decreases as fluid velocity increases. This observation agrees with the shape of the velocity dependency of the critical radius exhibited in Fig. 8.

Figure 16a, b compare the various forces acting on a particle at the critical instant of its mobilisation. According to Fig. 15, the ranges of particle radii cover the ranges of size distributions for particles attached to the surface of rock grains. The drag force was two orders of magnitude smaller than the electrostatic force. The drag force was significantly larger than the gravitational or lift force. Because lever arm ratio l significantly exceeded one, the small drag torque exceeded the torque developed by electrostatic force.

The maximum retention function can be parameterised by the critical particle radius σcr(U) = σcr(rscr(U)). Considering the value σcr(rscr) as an accumulation function of retained concentration for all particles with radius smaller than rscr yields the corresponding histogram (Fig. 15), representing the concentration distribution of initial reservoir fines for various radii. Thus, the maximum retention function, σcr, for various sized particles attached to the grain surface can be explained: if particles attached to the grain surface cannot be mobilised by fluid flowing with velocity U, then their radii are smaller than rscr(U) and their concentration is expressed as σcr(U). Increasing fluid velocity U results in the decrease of minimum radius of particles detached by flow with velocity U.

The calculated values of filtration and formation damage coefficients (Table 2) fall within the common ranges of these coefficients reported by Pang and Sharma (1997). The orders of magnitude of drift delay factor, which vary between 10−3 and 10−4 in the present work, are the same as those reported by Oliveira et al. (2014).

2.5 Summary and Discussion

According to mathematical model (1), (3) and (5), which accounts for the maximum retention function for detachment and migration of particles at velocity equal to carrier fluid velocity, rock permeability should stabilise after 1 PVI. However, the experimental data showed that the permeability stabilisation periods are significantly greater than 1 PVI. Such behaviour can be explained only if a mobilised particle moves significantly slower than the flowing fluid. This behaviour could be described by a two-speed particle-transport model (Yuan and Shapiro 2011a, b; Bradford et al. 2012).

The model contains six constants of mass exchange between particles moving slow and fast, detachment coefficient and filtration coefficient for fast particles, corresponding coefficients for slow particles and velocity of slow particles. The model tuning for the experimental breakthrough curves is not unique. Complete characterisation of the two-speed model would require complex experiments in which pressure drops along a core and along the particle breakthrough curve are measured and the retained particle concentrations are calculated. Yet, most coreflood studies have reported data for pressure drop along the core only. For this reason, the present study considers a rapid exchange between populations of particles migrating with fast and slow velocities along each rock pore, yielding a unique particle drift velocity. Also, this exchange is assumed to occur significantly faster than the capture of particles by the rock after a free run in numerous pores, resulting in equal concentrations of particles moving with fast and slow velocities. The above assumptions translate to a single-velocity model (You et al. 2015, 2016).

Proposed model (15)–(18) is applied to the data treatment of laboratory tests. The modelling results show that the migrating particles move significantly slower than the carrier fluid. Hence, there is a delay in the permeability stabilisation due to fines migration. The delay time is 500–1250 PVI, which corresponds to the drift delay factor α n varying within 0.0008–0.002.

Migrating particles can be divided into two groups according to the velocity. One group of particles travel with the same velocity as the carrier fluid; while the other group drifts along the grain surfaces with significantly lower velocity (slow particles). The percentage of slow particles depends on particle-size distribution, velocity of the carrier fluid and electrostatic forces between the particles and grains (both magnitude of the electrical forces and whether they are repulsive or attractive). The slow particles can slide or roll on the grain surfaces, or temporarily move away from grain surface to the bulk of the fluid, before colliding with grain surface asperities again (Li et al. 2006; Yuan and Shapiro 2011b; Sefrioui et al. 2013).

The largest size of particles that can stay attached to the grain surface at each velocity can be calculated using torque balance Eq. (6), i.e. there exists a critical particle radius for each velocity such that all particles with larger radii will be mobilised by the carrier fluid: rscr = rscr(U) (see Fig. 6).

The maximum retention function, σcr(U), can be defined for a monolayer of attached particles as the concentration of attached particles with r < rscr. The minimum size of mobilised particles as a function of fluid velocity follows from torque balance given by Eq. (6). It allows calculation of σcr using size distribution of the particles that can be mobilised at each fluid velocity. The function σcr depends on particle-rock electrostatic constants, Young’s moduli, Poisson’s ratio and size distribution of the attached particles.

Maximum retention is a monotonically decreasing function of mean particle size (Fig. 9a). The higher the variance coefficient of particle-size distribution, the lower the σcr at low fluid velocities, and the higher the σcr at high velocities (Fig. 9b).

The σcr curve for a monolayer of multi-sized particles has a convex shape at low fluid velocities and a concave shape at high velocities (Fig. 9c). However, for a multilayer attachment of mono-sized particles, that curve has a convex shape for all velocities.

For 1-D (one-dimensional) suspension flow with piecewise increase of the fluid velocity, the exact analytical solution can be obtained. The process includes particle migration and subsequent capture (straining) at the pore throats. Changing the fluid velocity creates a particle concentration front that starts moving from the core inlet. The concentration front coincides with the trajectory of the drifting particles and separates the particle-free region (behind the front) from particle-migration region (ahead of the front). The concentration profiles of the suspended and strained particles are uniform ahead of the front.

The drift delay factor α n is a function of the particle size and the geometry of the porous media, which undergoes a continuous change during straining of migrating particles at the pore throats. Small particles move along the grain surface more slowly than do large particles. Hence, the drift delay factor is smaller for small particles than for large particles. Because larger particles are detached at lower fluid velocities, the size of the released particles decreases during the coreflood test with piecewise increase of fluid velocity. This explains the decrease in drift delay factor during the experiment (Fig. 3d, h). Hence, the introduction of a phenomenological function of the form α n = α n (rs,σs) can further improve the proposed model for colloidal-suspension transport in porous media with instant particle release and slow drift (Eqs. 15–18).

The proposed mathematical model has been found to yield pressure data that closely approximate those from coreflood tests with piecewise increase of velocity. To completely validate the model for where velocity of the migrating particles differs significantly from that of the carrier fluid, parameters such as particle retention profiles, breakthrough concentration of particles and size distribution of produced particles should also be measured. Then, these measured data would be compared against the analytical solutions presented in Table 1. Such a test with measurement of all required parameters is not available in the literature.

3 Fines Detachment and Migration at Low Salinity

Salinity alteration affects the electrostatic forces between fines and the rock surface, thereby influencing fines detachment. Decreasing salinity of the flowing brine increases the repulsive component of the electrical forces (double-layer electrical force). This weakens the total attraction between the attached fines and rock surface, which may cause fines to be mobilised by the viscous forces from flowing brine (Eq. 6). The detached fine particles migrate with the carrier fluid and plug pore throats smaller than they are, leading to a significant permeability reduction.

Section 3.1 describes the methodology and experimental setup for coreflood tests with piecewise salinity decrease. Section 3.2 presents the experimental results. Section 3.3 derives a mathematical model for fines detachment and migration in porous media, accounting for slow fines migration and delayed fines release during salinity alteration. Section 3.4 compares the experimental data and the mathematical model’s prediction.

3.1 Laboratory Study

This section presents the experimental setup, properties of the core and fluids, and the experimental methodology.

3.1.1 Experimental Setup

A special experimental setup was developed to conduct colloidal-suspension flow tests in natural reservoir rocks. The core permeability and produced fines concentration were measured. In addition, an extra pressure measurement was taken at the midpoint of the core, which complements the routine core inlet and outlet pressure measurements. The schematic drawing and the photograph of the apparatus are shown in Figs. 17 and 18, respectively. The system consisted of a Hassler type core holder, a high-pressure liquid chromatography pump (HPLC) and a dome back-pressure regulator to maintain a constant pressure at the core outlet. Three Yokogawa pressure transmitters were used to record the pressure data at the core inlet, outlet and the intermediate point, and a fraction collector was used to collect samples of the produced fluid. The overall volumetric concentration of solid particles at the effluent was measured using a PAMAS SVSS particle counter with a particle-size range of 1–200 µm. Prior to the tests, the concentration of solid particles in the solution was measured and used as the background particle concentration in the calculations.

Schematic of laboratory setup for fines migration in porous media: (1) core plug. (2) Viton sleeve. (3) Core holder. (4) Pressure generator. (5, 9, 14, 15, 16) Manual valves. (6, 10, 11, 17) Pressure transmitters. (7) Suspension. (8) HPLC pump. (12) Back-pressure regulator. (13) Differential pressure transmitter. (18) Data acquisition module. (19) Signal converter. (20) Computer. (21) Beakers. (22) PAMAS particle computer/sizer

3.1.2 Materials

A sandstone core plug was used to perform a coreflood test with piecewise salinity decrease. The core was taken from the Birkhead Formation (Eromanga Basin, Australia) and had a permeability of 34.64 mD. A water-cooled diamond saw was used to fashion several core plugs, each having a diameter of 37.82 mm and a length of 49.21 mm. These were subsequently dried for 24 h.

The XRD test showed that the core sample contains a considerable amount of movable clay, including 9.2 w/w% of kaolinite and 18.6 w/w% of illite (see Table 3 for the full mineral composition).

The ionic composition of the formation fluid (FF) is listed in Table 4a (supplied by Amdel Laboratories, Adelaide, Australia). The ionic composition was expressed as salt concentration in order to prepare an artificial formation fluid (AFF) with similar ionic strength (0.23 mol/L) to the formation water (Table 4b). The AFF was prepared by dissolving the calculated salt concentrations in deionized ultrapure water (Millipore Corporation, USA; later in the text it is called the DI water). NaCl was then added to the AFF, in order to increase the ionic strength of the solution to 0.6 mol/L, equivalent to the ionic strength of the completion fluid. The composition of high-salinity AFF is listed in Table 4b (AFF (NaCL)). In order to decrease salinity of the injected fluid during the experiment, the AFF was diluted using DI water to obtain the desired ionic strength for each injection step (maintaining the salinity 0.6, 0.4, 0.2, 0.1, 0.05, 0.025, 0.01, 0.005, 0.001 mol/L).

3.2 Methodology

Prior to the experiment, the air was displaced from the core by saturating the core sample with 0.6 M AFF under a high vacuum. Then, the core plug was installed inside the core holder, and the overburden pressure was gradually increased to 1000 psi and maintained during the experiment. Afterwards, the 0.6 M AFF was injected into the core sample with a constant volumetric flow rate of 1.0 mL/min (superficial velocity: 1.483 × 10−5 m/s). The pressure drop was recorded at three points: inlet, outlet and the intermediate point. The intermediate pressure point was placed 25.10 mm from the core inlet.

Fluid injection continued until permeability stabilisation was achieved with uncertainty of 3.2% or less (Badalyan et al. 2012). The test then proceeded by stepwise decreasing the ionic strength of injected brine in nine consecutive steps: 0.4, 0.2, 0.1, 0.05, 0.025, 0.01, 0.005, 0.001 mol/L and DI water. Permeability stabilisation was achieved at each step. The produced fluid was sampled using an automatic fraction collector. The sampling size was 0.17 PV at the beginning and then increased to 0.86 PV after 2 PVI.

The overall solid particle concentration in the produced samples was measured using a PAMAS particle counter, which uses laser scattering in a flow-through cell to measure the number and size distribution of the solid particles (from 0.5 to 5.0 µm) in the suspension, assuming spherical particles. Multiplying the size distribution function by the sphere volume and integrating with respect to radius yields the overall volumetric particle concentration. The electrolytic conductivity of the produced samples was also measured, to calculate breakthrough ionic strength.

3.3 Experimental Results

The initial core permeability and porosity were 34.64 mD and 0.13, respectively. This allowed calculation of mean pore radius (rp = 6.62 µm, \( r_{\text{p}}^{2} = k/(4.48\phi^{2} ) \)) (Katz and Thompson 1986). The analysis of effluent samples shows that the mean size of produced particles was 1.47 µm. The so-called 1/7–1/3 rule of filtration was introduced by Van Oort et al. (1993). They suggested that particles larger than 1/3 of the pore size cannot enter the porous media and form an external filter cake, but that particles smaller than 1/7 of the pore size can travel through porous media without being captured. Particles between 1/3 and 1/7 of the pore size can enter the porous media; however, they can be retained at the pore throats, which impairs permeability. In the current experiment, the particle-to-pore size ratio (jamming ratio) was 0.22 (between 1/3 and 1/7), implying that particles can be captured at pore throats after being released by reduction of fluid salinity. This explains the observed impedance growth (Fig. 19a) during reduction of injection fluid salinity (ionic strength).

If all mobilised particles were released instantly and moved at the same velocity as the carrier fluid, permeability would be expected to stabilise in 1 PVI after each salinity alteration. However, the measured pressure data show that permeability stabilisation takes much longer (Fig. 19a). This delay in permeability stabilisation could be attributed to delay in particle detachment after salinity alteration or to the slow migration of released particles drifting along the rock surface (Yuan and Shapiro 2011a; You et al. 2015).

Figure 20 shows the cumulative produced particles and effluent ionic strength. The salinity and produced particle fronts coincide after each salinity alteration. The salinity alteration is accompanied by fine particle production and permeability reduction. This confirms that the fines mobilisation during salinity alteration is the mechanism for the permeability impairment. Similar to permeability behaviour, the fines were produced for a much longer period than 1 PVI.

3.4 Analytical Model for Slow Fines Migration and Delayed Particle Release

The impedance (reciprocal of permeability) growth curve presented in Fig. 19a indicates that after each salinity alteration, permeability stabilisation was achieved in tens to hundreds of PVI rather than the expected 1 PVI. As mentioned previously, one possible mechanism for the slow permeability stabilisation is the delay in particle detachment after salinity alternation. This phenomenon can be explained by electrokinetic ion-transport theory (Nernst–Planck model). It describes the diffusion of ions between the bulk fluid and the particle–grain area (Mahani et al. 2015a, b, 2016), which is not considered in slow-migration model (15)–(18). In this section, the slow-migration model is modified to account for both slow fines migration and delayed particle release.

Introducing a delay τ into the maximum retention function results in an expression for delayed fines detachment: σa(x, t + τ) = σcr(γ(x,t)), where γ(x, t) is the fluid salinity at time t. Retaining the first two terms of Taylor’s expansion for a small value of τ results in

The equation for maximum retention function (13) can now be replaced by kinetic Eq. (31). The system of three Eqs. (11), (12) and (31) describes suspension transport in porous media and accounts for delayed release of the reservoir fines during salinity reduction. This system can be solved for the unknown values c, σa and σs.

Replacing σa0 with released particles concentration Δσcr in dimensionless group (14) yields a dimensionless system of equations for suspension transport in porous media that accounts for delayed release of reservoir fines:

where the delay factor ε is defined as \( \varepsilon = {{U\tau } \mathord{\left/ {\vphantom {{U\tau } {\phi L}}} \right. \kern-0pt} {\phi L}} \).

Because it takes significantly longer than 1 PVI for the mobilised particles to reach the core outlet (1/α ≫ 1), i.e. α ≪ 1, the initial and boundary conditions for injection of particle-free fluid with salinity γ1 are

where γ0 and γ1 are initial and injected salinities, respectively. The initial concentration of attached particles is σa0 = σcr(γ0) for γ0 > γ1.

The solution to linear ordinary differential Eq. (33) with initial condition (35) is

It yields the following equation for the detaching rate:

Substituting the equations for straining rate (34) and detaching rate (37) into overall particle balance equation (32) results in the following equation for suspended concentration:

Introduction of the following constants:

simplifies Eq. (38) as

Ahead of the front of the mobilised fines (T ≤ X/α), the characteristic form of the linear hyperbolic Eq. (40) is

If αΛ ≠ b, the solution to the linear ordinary differential Eq. (42) is

If αΛ = b, the solution to (42) is

Similar to fines migration due to abrupt velocity increase (row 3 in Table 1), the initial uniform profile of the suspended particles moves with an equal capture probability for all the suspended particles. Thus, the profile of the suspended particles remains uniform, and the suspended concentration is time-dependent only.

Behind the front of mobilised fines (T > X/α), the characteristic form of Eq. (38) with a zero boundary condition is

If αΛ ≠ b, the solution to the linear ordinary differential Eq. (46) is

Substituting the constant η along the characteristic line

into solution (48) yields the following expression for the suspended concentration behind the front:

If αΛ = b, the solution to Eq. (46) is

Substituting the constant η along the characteristic line (48) into solution (50) yields the following expression for the suspended concentration behind the front:

Formulae for strained concentration Ss are obtained by substituting suspended concentration from Eqs. (43), (44), (49) and (51) into the equation for straining rate (34) and then integrating with respect to T. This solution is listed in Table 5 for αΛ ≠ b and in Table 6 for αΛ = b. The profiles of suspended and strained concentrations are shown in Fig. 21.

3.5 Treatment of Experimental Data

The result of the coreflood test with piecewise salinity decrease (presented in Sect. 3.1) is modelled in this section. The three models that have been presented in previous sections are applied to the experimental data treatment: the slow-particle migration model (Table 1), the delayed-particle-release model (Tables 5 and 6 with α = 1), and the general model that accounts for both effects (Tables 5 and 6). The pressure drop along the core (whole core) and between inlet and midpoint (half-core), and the accumulated produced fines are matched separately by all three models. The reflective trust region algorithm (Coleman and Li 1996) is applied for optimisation using Matlab (Mathworks 2016).

Figure 19 presents the treatment of impedance and cumulative produced fines data using the slow-particle migration model. The coefficient of determination R2 is 0.9902. The model tuning parameters are formation damage coefficient β, filtration coefficient λ, released concentration Δσ, delay factor ε, and drift delay factor α. The pore space geometry and values of the tuning parameters change during coreflood, as a result of pore throat plugging by mobilised fines. Hence, the tuning parameters vary with change in injected fluid salinity, which causes fines mobilisation and permeability impairment. Table 7 and Fig. 22 show the values of the tuning parameters at each salinity.

The drift delay factor α decreases as salinity decreases (Fig. 22a). This can be attributed to the decreasing size of released particles during the salinity decrease. Smaller particles are subject to lower drag force and therefore move at lower velocity. Also, the rock tortuosity increases due to straining, so that the fines move at lower velocity. Regarding formation damage coefficient β, there are two competing factors during the salinity decrease. The first is permeability, which inversely affects the formation damage coefficient. The other is particle size, with which the formation damage coefficient varies. The retained-concentration dependency for the formation damage coefficient, shown in Fig. 22b, is attributed to particle size’s dominating the permeability effect. The filtration coefficient for straining, λ, increases with rock tortuosity increase during salinity reduction (Fig. 22c). Yet, it should decrease due to decrease in released particle size. Figure 22d presents the salinity dependency of the maximum retention function, which exhibits a typical form (Bedrikovetsky et al. 2012a, b; Zeinijahromi et al. 2012a, b).

The results of comparison with the delayed-particle-release model are presented in Fig. 23a for impedance, and in Fig. 23b for accumulated particle concentration. Table 8 shows the tuning parameter values. The values of tuned parameters β, λ, ε and Δσ versus the salinity injected are also presented in Fig. 24a–d, respectively. The coefficient of determination is equal to R2 = 0.9874 and is slightly lower than that for the slow-particle model.

Figure 24a shows that formation damage coefficient β increases as salinity declines, which contradicts the above conclusion for the slow-particle model. We attribute this to the dominant role of permeability decline on the formation damage coefficient: the lower the permeability, the higher the formation damage. Yet, this explanation contradicts the observation made above for the slow-particle model, where the formation damage coefficient decreases with the deposit increase.

The filtration coefficient λ decreases during salinity reduction (Fig. 24b), which also contradicts the above observation for the slow-particle model. We attribute this to the blocking filtration function, where λ is proportional to the vacancy concentration: the filtration function approaches zero as the number of pores smaller than particles approaches zero. Also, the released particle size decreases during salinity decrease, so the probability of particle straining declines, which is another explanation why the filtration coefficient declines during the injection.

The delay factor ε decreases with increase in strained concentration (Fig. 24c), which we attribute to more confined porous space and smaller diffusive path. Also, the interstitial velocity increases during straining, resulting in higher effective (Taylor’s) diffusion in each pore and yielding the delay decline.

The maximum retention function (Fig. 24d) is unlike the usual release of fine particles at very low salinity, which is close to freshwater. The effect of fines release decrease during salinity decrease might be explained by low concentration of small particles on the rock surface. This hypothesis could be tested by measuring particle-size distributions in the breakthrough fluid.

Mahani (2015a, b) measured the delay period, which is 10–20 times longer than that expected by diffusion alone and is explained by slow electrokinetic Nernst–Planck ion-diffusion in the field of electrostatic DLVO forces. The delay time t τ varies from 10,800 to 363,600 s, which corresponds to dimensionless time (ε = Ut τ /ϕL) varying from 15.49 to 521.62 PVI for conditions of the test presented in Sect. 3.1 (ϕ = 0.13, U = 1.48 × 10−5 m/s). These values have the same order of magnitude as those obtained by tuning the parameter ε from laboratory tests and are presented in Tables 8 and 9.

Figure 25a presents the results of impedance matching by the general model that accounts for both phenomena of slow-particle migration and delayed particle release. Figure 25b presents the results for accumulated particle concentration. Table 9 shows the tuning parameter values. The coefficient of determination is equal to R2 = 0.9899. The modelling data are in close agreement with the laboratory results, with deviation observed only for freshwater injection. The strained concentration dependencies for α, β, λ and Δσ (Fig. 26a–c, e, respectively) follow the same tendencies as those exhibited by the slow-particle model. The delay factor ε (Fig. 26d) has the same form as that for the delay-detachment model. Thus, the tendencies for tuned values as obtained by the general model agree with the results of both particular models.

3.6 Summary and Discussion

The laboratory study of fines migration due to decreasing brine salinity provided three measurement histories during each injection step with constant salinity: impedance across the half-core, impedance across the whole core and the outlet concentration of fine particles. Each pressure curve and each concentration curve has at least two degrees of freedom. Thus, the three measured curves have six degrees of freedom for constant-salinity periods.

The slow-particle migration model has four independent coefficients; therefore, a six-dimensional dataset was compared to the model with four tuned coefficients, and the latter was found to be highly accurate. We explained the strained saturation dependencies of the tuned parameters by the well-known dependencies for formation damage parameters of particle and pore sizes. Under the conditions where the degree of freedom for the experimental data are higher than the number of tuned constants, close agreement between the experimental data and the model allows concluding the validity of the slow-particle migration model. The delay-release model has five independent coefficients. This is higher than that for the slow-particle migration model, but still lower than the six degrees of freedom of the laboratory dataset. The agreement coefficient is also very high between the laboratory data and the model-predicted data. The obtained delay periods have the same order of magnitude as do those observed in laboratory tests by Mahani et al. (2015a, b). However, the model does not exhibit a common form of the maximum retention function after the laboratory-data adjustment.

Thus, the advantages of the slow-particle model over the delay-release model are the smaller number of tuned parameters and common form of the revealed maximum retention function.

The general model has five independent coefficients, which is lower than the six degrees of freedom of the laboratory dataset. The agreement coefficient is also very high. The obtained delay periods have the same order of magnitude as do those observed in laboratory tests. The model exhibits a common form of the maximum retention function.

The slow-fines-migration model with four free parameters already exhibits very close agreement with laboratory data. Adding the delay factor into the slow-fines model does not change its accuracy.

The proposed interpretation of the model-parameter variations with the salinity decrease includes several competitive factors. It is impossible to declare a priori which factor dominates. Therefore, the proposed explanations must be verified by micro-scale modelling.

4 Fines Detachment and Migration at High Temperature

This section discusses the temperature dependency of fine particle detachment and migration in geothermal reservoirs (Rosenbrand et al. 2015).

As previously discussed, the DLVO theory is used for calculating the electrostatic forces. Because the electrostatic forces are temperature-dependent, fines mobilisation is also a function of temperature. The temperature-dependent parameters of the DLVO forces are listed in Table 10.

Figure 27 presents the effect of temperature on critical particle size according to Eq. (6). Because electrical attraction decreases with temperature increase, particles can be mobilised at a lower velocity if the temperature is increased (illustrated by the curve for 25 °C being above the curve for 80 °C).

4.1 Experimental Results and Model Prediction

The experimental study was undertaken to help analyse formation damage due to fines migration in the Salamander-1 geothermal well (Pretty Hill Formation, Otway Basin, South Australia). However, there is no core from the Salamander-1 well, and only drilling cuttings are available. Thus, a core with analogous mineral characteristics from the same formation and basin (Ladbroke Grove-1 well) was used for this study. This core was taken from depth 2557.12 m and has porosity of 17.2%. The core is 6.33 cm long and has a diameter of 3.92 cm.

In order to characterise the mineralogy of fines present in the core sample, the produced fines were collected by filtering the effluent fluid through a 0.45 μm Nylon filter. The collected volume of produced fines was insufficient for performing an XRD analysis. Thus, SEM-EDX analyses were performed on the produced fines, the results of which are shown in Fig. 28. The plate-like ‘booklets’ on the SEM image show the typical characteristic of kaolinite fines (Fig. 28a). The ‘peak height ratio’ (ratio of relative molar proportions) for Al and Si are shown in the EDX spectrum (Fig. 28b). The similar ratios between Al and Si indicate that the observed booklets on the SEM image are kaolinite, where the compound Al2(Si2O5)(OH)4 is typical.

A coreflood test with piecewise salinity (ionic strength) decrease was performed using the Ladbroke Grove-1 core, using the methodology given in Sect. 3.

Figure 29a presents the normalised permeability of the core for each salinity versus time (black circles). Figure 29b shows that reduction in injection fluid salinity resulted in decrease of the core permeability and production of fine particles. As expected, the graph shows a similar trend as those presented in Figs. 20, 23 and 25. The core permeability drops instantly after each salinity reduction, implying that a significant fraction of attached fine particles are mobilised when salinity is reduced. The mobilised particles then plug pore throats gradually.

Results of tuning the laboratory data from corefloods with varying fluid ionic strength at T = 25 °C, using the analytical model and prediction for Salamander geothermal field (T = 129 °C): a decrease of core permeability during tests with piecewise-decreasing ionic strength. b Cumulative breakthrough concentration at different fluid ionic strengths

The analytical model presented in Sect. 2.3 (rows 12 and 13 in Table 1) was used to treat the experimental data from the Ladbroke Grove-1 core. A typical log-normal distribution of particle sizes is assumed.