Abstract

Nitrogen should be strictly limited in wastewater to control the eutrophication of water bodies. Nitrate and nitrite need to be efficiently removed from groundwater and surface water due to their toxicity to human and animal health. Bioelectrochemical system (BES) is a promising technology for sustainable wastewater treatment, which aims not only water reuse but also nutrient recovery and management. For nitrogen removal and recovery, BESs exhibit great potential with the advantage of oxidizing organics at the anode integrating denitrification at the cathode as well as recovering energy simultaneously. This review summarized the most recent development in versatile nitrogen removal using BESs, including denitrification via biocathode, coupling with nitrification via bioanode, and photosynthetic process. The denitrification principles driven by electro-active bacteria are addressed from the view of microbiology, following the detailed descriptions focusing on the key elements related to nitrogen transformation in BESs, including environmental factors, methodologies for electrode modification, reactor configurations, and operational parameters. In addition, ammonium recovery could be realized in the BES coupling with physicochemical processes such as struvite precipitation and blowing-stripping. This review aims to summarize the current development in this field and to provoke more thoughts on further development of efficient BES-based processes for nitrogen pollutant removal and recovery.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Background

Nitrogen is the most abundant chemical element in the Earth’s atmosphere, and a crucial component of biomolecules. The increased availability of inorganic nitrogen in the environment has boosted biotic production and primary productivity. Ammonium (NH4+), nitrite (NO2−), and nitrate (NO3−) are the most common forms of inorganic nitrogen in the terrestrial environment [1]. These ions can be generated naturally, for example, via nitrogen fixation by prokaryotes (cyanobacteria and rhizobium), atmospheric deposition, and dissolution of nitrogen-rich geological deposits [2]. The total rate of nitrogen production via these natural processes is in the range of 300–500 Tg N year−1, and 25–50% of which is fixed on land [3,4,5].

During the past two centuries, particularly in recent decades, human activities have substantially accelerated the global nitrogen cycle. By 2000, the rate of anthropogenic inorganic nitrogen production was ~165 Tg N year−1. This increased the total rate of reactive nitrogen formation by 33–55%, which exceeded the needs of industry and agriculture [6]. If these high levels of inorganic nitrogen cannot be assimilated by the functioning of ecological systems, there will be serious adverse effects on the natural environment, especially aquatic ecosystems. There are several ways in which inorganic nitrogen derived from human activities can enter aquatic ecosystems. The largest sources of nitrogen pollution are crop farming, animal farming, municipal sewage, and industrial sewage (Table 7.1). Among them, human and animal wastes contribute 60% of nitrogen pollution. In addition, nonpoint sources of nitrogen such as acid rain are generally more damaging than point sources because they occur on a larger scale and are more difficult to control.

Inorganic nitrogenous pollutants in groundwater and surface water have significant negative effects on many aquatic organisms, thus contributing to the degradation of aquatic ecosystems. In the past few decades, there has been a massive increase in eutrophication on a global scale. Eutrophication is the process in which additional nutrients stimulate the rapid growth of phytoplankton, resulting in widespread hypoxia and anoxia, changes in the food-web structure, habitat degradation, and loss of biodiversity [6]. Inorganic nitrogen pollution also markedly increases the concentration of hydrogen ions in freshwater, resulting in acidification of those ecosystems. Furthermore, nitrate in drinking water with high concentrations (>10 mg N L−1) can be converted into nitrite in animal intestines, which could result in methemoglobinemia of the animal and possible death [10, 11]. Therefore, effective methods to reduce nitrogen pollution are urgently required.

The existing biological treatments (nitrification and denitrification) to remove nitrogen require energy and a carbon source, which greatly increase the costs of wastewater treatment [12, 13]. These biological denitrification methods also produce large amounts of waste sludge, which presents a new environmental problem to be solved. In recent years, MFC have been widely used as an alternative technology to reduce nitrogen pollution. The advantages of MFC are that they do not require energy or a carbon source, generate less sludge, and have a flexible electron transfer process [14,15,16,17]. In this chapter, we summarize recent research on nitrogen removal/recovery in BES focusing on wastewater treatment. We describe the nitrogen removal pathways, reaction mechanisms, and new developments in these technologies and discuss the challenges in creating BES that efficiently and effectively remove nutrients from wastewater.

7.2 Nitrate Removal and Recovery

Nitrate concentrations in the environment have increased worldwide because of the increased use of nitrogen fertilizers and increased emissions of industrial and domestic wastewater. Nitrate is a health risk to both animals and humans and can cause methemoglobinemia (blue-baby syndrome) when it is absorbed by infants [10]. Therefore, many researchers have focused on developing biological and physicochemical processes to remove nitrate from water.

7.2.1 Autotrophic Denitrification at Biocathodes

Biological denitrification can remove almost 100% of nitrate from water, so it is an excellent choice for nitrogen removal. There are four stages in the conversion of nitrate to nitrogen gas (N2) during this process:

Since denitrification is a microbial metabolic process, an oxidizable substrate or electron donor is necessary. There are two types of biological denitrification [12]: autotrophic and heterotrophic. Heterotrophic denitrification bacteria can use carbon-containing compounds like ethanol, methanol, acetate, or insoluble carbon sources such as wheat straw as oxidizable substrates [18,19,20]. The disadvantage of heterotrophic denitrification is that it produces biomass. Autotrophic denitrification bacteria utilize hydrogen, iron, or sulfur chemical compounds as sources of carbon dioxide and power, or bicarbonate as the carbon source. The biotic process involving ferrous ions (Fe2+) decreases nitrate to nitrite autotrophically in low-iron surroundings [21]. Based on this reaction, researchers proposed that the cathode could serve as the electron source.

In 1992, successful denitrification was achieved at the cathode of BES [22]. From that study, most researchers believed that nitrate moved from the bulk mass into the cathode biofilm and was reduced to nitrogen gas biologically using the hydrogen generated from the electrolysis of water in the biofilm. It was proposed that the efficiency of hydrogen production was 100% and that the hydrogen generated by the electrolysis of water was used completely in the denitrification process. In 2005, Park et al. obtained a maximal denitrification rate of 434.78 mg NO3-N h−1 (2.16 × 10−5 mol H2 h−1) in their biological cathode denitrification system [23]. However, they obtained a maximal hydrogen production rate of 1.38 × 10−7 mol H2 h−1 (with an applied current of 200 mA), which was 100-fold lower than the nitrate reduction rate. Those results demonstrated that hydrogen is not needed to drive complete cathode denitrification. Different from conventional denitrification that relies on hydrogen, hydrogenotrophic denitrifying bacteria can directly accept electrons from the cathode of BES. This discovery would advance denitrifying process at biocathode in MFC technology, as it led to the development of systems with effective nitrate removal and simultaneous electricity generation.

7.2.1.1 Electron Transfer Between Biocathodes and Denitrifying Bacteria

Higher removal efficiencies can be achieved by autotrophic denitrification. The power conversion and efficiency of nitrogen pollution treatment are determined by electron transfer between microbes and electrodes. Studies in recent decades have revealed details of the anode electron transfer process, but the electron transfer process between the cathode and microorganisms is still poorly understood. Researchers have proposed two mechanisms of autotrophic denitrification at the cathode (Fig. 7.1) [24]:

Proposed cathode extracellular electron transfer mechanisms and associated energy gains for biocathode microorganisms: (right) DET involving c-type cytochrome electron transfer chains; (left) mediated electron transfer. [Cyt], c-type cytochrome; [MV], methyl (redox mediator); [H2ase], hydrogenase; Q/MQ, functional enzyme. (This schematic is modified from [24])

The first proposed mechanism of autotrophic denitrification is DET. In this process, hydrogen is not needed to drive complete cathode denitrification, and hydrogenotrophic denitrifying bacteria can directly accept electrons from the cathode of BES in the absence of organic substances [23, 25]. So far, the best-researched anode DET is the extracellular respiration of dissimilatory metal-reducing Shewanella and Geobacter bacteria. In these bacteria, electrons are transferred via a chain of c-type cytochromes (heme-type proteins) across the cell envelope to extracellular electron acceptors [26]. Similarly, c-type cytochromes are involved in direct cathode DET. The uptake of electrons from electron donors by c-type cytochromes is a common process in nature, especially in acidic situations such as drains in mines, where chemolithotrophic iron II and sulfur oxidization are the dominant microbial actions [27,28,29]. For example, Yarzabal et al. showed that Acidithiobacillus ferrooxidans can accept electrons directly from Fe (II) minerals (pyrite) through the outer membrane Cyc2 (+0.560 V; the highest potential recorded for a c-type cytochrome). Then, Cyc2 further transfers the electrons to an electron transport chain with oxygen reduction as the final reaction step. Cytochrome (Cyt572) has been abundantly found in iron (ΙΙ) oxidation conditions, where its role is to carry the heme that ultimately binds to c-type cytochromes [29].

The c-type cytochrome of cathodic microorganisms may also have the similar function for electron transfer. The process mainly depends on the redox potential, which affects cytochromes and their eventual association with the electron transfer chain. In bioelectrochemical denitrification systems, the final reaction is nitrate reduction, which has broad potential to provide electrons for uptake by microorganisms [30,31,32]. The potential difference generated in this process may be sufficient to power the energy-conserving reactions between the electrode and the electron acceptor such as nitrate, oxygen, or chlorinated organic compounds [30,31,32]. Hence, the immobilization of denitrifying bacteria on the cathode surface is necessary for electron exchange.

Artificial redox mediators can be used to facilitate electron transfer between the cathode and microorganisms, as the cathode itself cannot transfer electrons. The most commonly used redox mediators are neutral red, anthraquinone-2,6-disulfonate, and methyl viologen [33,34,35,36]. The results of several studies have suggested that artificial mediators not only enhance electron transfer but also promote microbial growth and metabolism at biocathodes. However, more research is required to confirm this additional role of redox mediators in the bioelectrochemical denitrification process.

The second proposed mechanism of autotrophic denitrification is IET, in which hydrogen gas is used as a general electron donor. However, in traditional biological denitrification systems, the crucial hydrogen concentration appeared to be 0.2 mg L−1, because incomplete denitrification occurred at lower hydrogen concentrations [11]. During bioelectrochemical denitrification, denitrifying bacteria are immobilized on the cathode surface and utilize the hydrogen gas produced from the electrolysis of electrolytes. The effective contact area between bacteria and cathode is much larger than that of traditional hydrogen diffusion [37], so the electron transfer process is relatively straightforward.

In addition, some bacteria contain hydrogenases that can catalyze the reversible consumption (oxidation) and production (reduction) of hydrogen. Tatsumi et al. and Lojou et al. firstly reported hydrogen gas production by bacterial electrocatalysis [38, 39]. They showed that Desulfovibrio vulgaris Hildenborough produced hydrogen gas with a carbon electrode as the electron donor in the presence of a low-potential redox mediator (methyl viologen) (E = 446 mV). The hydrogen requirement of the autotrophic denitrification process may be more easily met by bacterial electrocatalysis than by direct electrolysis of an electrolyte. However, further research is required to test this idea.

7.2.1.2 Factors Controlling Denitrification at the Biocathode

The main factors that influence the biocathode denitrification are cathode potential, electrode material, reactor configuration, pH, ionic strength, initial nitrate concentration, and the carbon source.

7.2.1.2.1 Cathode Potential

During the DET denitrification process, an applied cathode potential below 150 mV is theoretically sufficient for autotrophic denitrification (Table 7.2). However, the potential should be more negative in practice because of the loss of overpotential [40]. Pous et al. reported an increase in the nitrate reduction rate as the cathode potential decreased from 0 to −300 mV [41]. In their study, 93.9% of the nitrate was converted into nitrogen gas or absorbed by bacteria at −300 mV, but 6.1% was converted into nitrous oxide (N2O) as an intermediate. Their results also showed that the production of nitrous oxide and nitrite, two undesirable denitrification intermediates, varied with cathode potential and was lower at potentials lower than about −500 mV. This phenomenon may have resulted from competition for electrons among different denitrifying enzymes. Therefore, an unlimited source of electrons from the electrode to denitrifying bacteria can avoid the accumulation of nitrite and nitrous oxide.

The hydrogen formation rate at the cathode is also controlled by the cathode potential, which plays a critical function because hydrogen is necessary in the mediated electron transfer denitrification process (Table 7.3). The standard hydrogen evolution potential (pH = 7) is −611 mV, that is, a more negative cathode potential is required for autotrophic denitrification [44]. However, the higher current density resulting from a lower cathode potential will increase the denitrification rate but decrease the current–denitrification efficiency because of the incomplete consumption of hydrogen gas [45]. In addition, when the cathode potential is too low, the hydrogen gas yield by electrolysis increases, leading to effervescence. The resulting gas bubbles form a dry space on the surface of the electrode. This blocks electron transfer and inhibits biofilm formation, thus lowering denitrification performance [46].

7.2.1.2.2 Electrode Substrate

The electrode functions as both the electron acceptor and the carrier for microorganisms. Therefore, electrodes directly affect the power output, bacterial attachment, hydrogen production, and nitrogen removal efficiency of a system. A summary of the types of cathode materials used in MFC and their nitrogen removal performance is provided in Table 7.4.

Carbon-based materials are the most versatile anode materials because of their high specific surface area and excellent biocompatibility. Li et al. developed an integrated shortcut nitrification and autotrophic denitrification MFC with carbon cloth as the cathode [47]. The removal efficiency of total nitrogen (50 mg N L−1) was 99.9%, and the power output was 294.9 mW m−2. Zhang et al. built a two-chamber BES consisting of heterotrophic denitrifying microorganisms immobilized on a cathode with a plain carbon paper surface [48]. The concentration of NO3−–N in the wastewater was 60 mg N L−1. The applied voltage was controlled by another MFC. With voltage outputs ranging from 500 to 700 mV and a maximal power output of 502.5 mW m−2, nitrate removal was significantly accelerated, with almost no accumulation of intermediates. Although carbon-based materials are the most extensively used electrodes in MFC, they have limited use in practical situations because of their high capital cost and poor ductility (low current density) [49].

Consequently, metal-based electrodes, such as gold, silver, copper, nickel, cobalt, stainless steel, and titanium, have been tested as electrodes. Among them, stainless steel is a widely used industrial metal with excellent mechanical properties, sufficiently unusual electrical conductivity, and long-term resistance to corrosion, as well as being commercially available. In 1998, Cast and Flora compared heterotrophic denitrification rates between two cathode materials (a stainless steel rod wrapped with stainless steel mesh and a graphite rod wrapped with polypropylene) in a water treatment experiment [50]. They found that both electrode substances were suitable for microbial attachment and showed similar denitrification efficiencies. Sakakibara compared porous and expanded stainless steel multi-electrode systems in a continuous denitrification experiment [51]. The hydraulic retention times and electric currents ranged from 6 to 2 h and from 80 to 960 mA, respectively. When the electrical current was increased, the effluent nitrite concentration was decreased to less than 0.5 mg N L−1 (influent nitrite concentration was 20 mg N L−1). However, the use of metals as electrodes for denitrification is limited by their poor biocompatibility. In the past few decades, there have been very few reports on the use of metal electrodes as cathodes in bioelectrochemical denitrification systems. Instead, there has been increasing interest in the discovery and design of inexpensive, stable, and effective electrode substances for BES.

Some active metals such as iron, nickel, zinc, and copper have been used in electrochemical denitrification systems. This non-biological approach has been shown to effectively remove nitrate at a broad range of initial concentrations (up to 100 g/L) from diverse wastewaters. The reaction in which zinc and sulfamic acid reduce nitrate to nitrogen gas is as follows (7.2) [52]:

The Zn2+ ions produced in (7.2) reform into solid zinc on the cathode via electrolysis. Consequently, the zinc metal itself is not consumed in the reaction and is reusable afterward as a metal catalyst, whereas the sulfamic acid is consumed in the reaction.

Several recent studies have focused on boron-doped diamond (BDD) [53, 54] as a high-performance anode substrate for removal of emerging pollutants and other refractory pollutants and for electrochemical disinfection. This substance has excellent electrochemical properties including its wide functional potential, its stable and low voltammetric background drift, its unusual overpotential to form oxygen and hydrogen in aqueous electrolytes, and its stability. Ghazouani et al. [53] studied non-biological denitrification in a system with a BDD anode/cathode and found that the current efficiency was higher and the energy consumption was lower than those of other systems. Therefore, the use of BDD may be a fresh approach in the engineering of bioelectrochemical denitrification systems.

7.2.1.2.3 Electrode Modifications

Modifications to the surface of the anode can enhance the current densities of BES. Such modifications include carbon particle coating, conductive polymer coating, mediator grafting, heat treatment, and hydrophilic modification of graphite or metal electrode substrates. Similarly, the cathode surface can be modified to improve its performance in bioelectrochemical denitrification (Table 7.4). To increase the microbial load on the electrode surface, Abbas et al. used a carbon felt cathode modified with a multi-wall carbon nanotube (CF/MWCNT) to enhance the efficiency of bioelectrochemical denitrification [59]. The highest nitrate removal efficiency in the CF/MWCNT system under optimum conditions was 92.7% within 4 h, compared with a nitrate removal efficiency of 76.4% within 4 h with an unmodified cathode. In another study, carbon felt modified with a polypyrrole film (CF/PPy) was used as a cathode in a bioelectrochemical denitrification system [61]. The CF/PPy films formed evenly and stably on the CF electrode using the potentiostatic electropolymerization method. Compared with the unmodified electrode, the CF/PPy electrode showed a 24.7% enhancement in the nitrate removal rate. More biomass was attached to the CF/PPy electrode than to the unmodified electrode, indicating that this modification could improve bacterial adhesion on the cathode.

The low extracellular electron transfer rate between the cathode and bacteria is a major limitation in bioelectrochemical denitrification. To accelerate electron transfer, melted electron shuttles can be added to the cathode. However, electron shuttles are toxic and/or unstable and consequently are a poor fit for these systems environmentally. Thus, it is important to use fixed electron shuttles for denitrification in BES. In this context, Xiao et al. showed that a graphite cathode merged with solid-phase humin supported electron transfer to Pseudomonas stutzeri for denitrification in BES [60]. The solid-phase humin served as a redox mediator to donate electrons to the denitrifying bacterium at −700 mV. Nitrogen gas as the final product accounted for 94.6% of the initial nitrate, and no nitrous oxide accumulated.

Several modifications that enhance cathode denitrification performance have also been reported. Studies have shown that electron exchange between the microbe and the cathode can be improved by introducing a positive charge at the electrode surface, for example, by treatment with cyanuric chloride, ammonia gas, chitosan, 3-aminopropyltriethoxysilane, melamine, or polyaniline [61, 62]. Thin layers of nickel, gold, or palladium catalysts were shown to reduce the activation energy threshold for electron transfer from electrodes to bacteria [62]. Fabrics coated with carbon nanotubes provide open, three-dimensional, matrices that are conducive to microbial growth. Among such materials, carbon cloth modified with thin layers of gold, palladium, or nickel nanoparticles were shown to increase electrosynthesis rates by 4.5-, 4.7-, or sixfold, respectively, in microbial electrosynthesis systems [63], compared with the unmodified carbon cloth. These modifications led to significant increase in cathode performance. Consequently, the design, discovery, and optimization of cheap and stable modifications may increase the efficiency of denitrification in BES.

7.2.1.2.4 Electrode Structure

Brushes, rods, and plates are the most popular structures of carbon-based electrodes [64]. The typical electrode system is a flat-parallel configuration of plate electrodes. Its advantages are the uniform current and readily available materials [65], but its disadvantage is its small surface area that severely limits biofilm formation. By contrast, carbon felt and carbon brushes have larger surface areas for immobilizing denitrifiers.

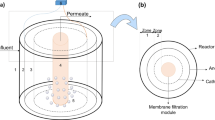

A multi-cathode biofilm electrode provides a large surface area for immobilizing denitrifiers. Prosnansky et al. developed a multi-cathode biofilm-electrode reactor merged with microfiltration and used it to treat nitrate-contaminated water in a laboratory-scale experiment (Fig. 7.2) [45]. The multi-cathode electrodes consisted of multi-granular activated carbon that provided a large surface area for the attachment of bacteria. The denitrification rate was enhanced by 3–60 times in comparison with those reported in previous studies.

Multi-cathode biofilm-electrode reactor combined with microfiltration. (Reprinted from [45], Copyright 2002, with permission from Elsevier)

The use of three-dimensional (3D) cathodes in BES has led to higher efficiency as a result of the increased surface area for hydrogen production and the growth of denitrifying microbes, as well as the larger contact area with contaminants. Generally, 3D cathodes are constructed by adding conductive filler between the anode and the cathode. Zhang et al. designed a 3D BES [66] equipped with a stainless steel anode and cathode and added functional polyurethane foam (specific surface area, 35,000 m2 m−3) and activated carbon to immobilize microorganisms in the cathode chamber. Compared with a traditional two-dimensional (2D) reactor, this 3D system enhanced the removal efficiencies of both organic matter and nitrate and significantly reduced the formation of nitrite as a by-product. In the 3D reactor constructed by Zhou et al., the denitrification rate was about 2.4-fold higher than that of a 2D reactor. Furthermore, it showed excellent and stable performance in a range of conditions, indicating its suitability for use in wastewater treatment systems.

7.2.1.2.5 Reactor Configuration

In the review of Kelly et al., the reactor configuration for nutrient removal and recovery has been summarized in detail [64]. The specifications of reactor design play a significant role in the denitrification rate. The double chamber is one of the most common reactor configurations, and its superior features are its biofilm selectivity and uniform current [65]. In this system, the anode generates electricity from biodegradable organic matter in an anaerobic environment. The cathode works anaerobically and consumes electrons to reduce nitrate to nitrogen gas via the activity of hydrogenotrophic denitrifying bacteria. However, since most wastewaters contain ammonia rather than nitrate, most reactors focus on the removal of total nitrogen. Therefore, the conversion of ammonia to nitrate will facilitate the subsequent bioelectrochemical denitrification.

The first report of complete nitrogen removal in BES involved a separate biofilm-based aerobic reactor (Fig. 7.3a) [67]. In this system, the organic pollutant was efficiently metabolized by microbes in the anode chamber, and this reaction provided electrons for the cathode reduction reaction. Then, the anode effluent with a high ammonia concentration moved into a separate aerobic reactor for the nitration reaction in which ammonia was oxidized to nitrate. Finally, the secondary effluent flowed into a cathode chamber in which nitrate was reduced to nitrogen gas. This system developed by Virdis et al. achieved a high nitrogen removal rate of 0.41 kg m−3 day−1 and a maximum power density of 34.6 W m−3. However, its main disadvantage was that a high concentration of ammonium could enter the cathode chamber via diffusion through the CEM.

BES designed for complete nitrogen removal by nitrification and bioelectrochemical denitrification: (a) BES plus an external nitrifying bioreactor. (Reprinted from [67], Copyright 2008, with permission from Elsevier). (b) SND at the cathode of BES. (Reprinted from [68], Copyright 2010, with permission from Elsevier). (c) Single-chamber air-cathode MFC. (Reprinted from [71], Copyright 2012, with permission from Elsevier). (d) Tubular MFC with dual cathodes. (Reprinted from [72], Copyright 2012, with permission from Elsevier). (e) UBER with palm shell activated carbon as cathode material. (Reprinted from [73], Copyright 2009, with permission from Elsevier). (f) SMDDC to remove nitrate from groundwater in situ. (Reprinted from [74], Copyright 2013, with permission from Elsevier)

To solve this problem, Virdis et al. designed a simultaneous nitrification and SND in which integrated aerobic nitrification occurred in the cathode chamber (Fig. 7.3b) [68]. In this system, the cathode biofilm included two layers: nitrifying bacteria in the outer layer and denitrifying bacteria in the inner layer. The outer biofilm could consume DO, thereby creating a micro-anoxic environment on the surface of the cathode for the denitrification process. To reduce the cost and internal resistance of reactors associated with ion-exchange membranes, several studies focused on SND in simplified single BES. In such systems, the denitrification process is similar to that of a cathode SND, which relies on an oxygen gradient (oxygen concentration decreasing from the anode to the cathode) to produce aerobic and anoxic zones in a single reactor. The aerobic zone is located in the anode chamber, where oxygen is produced by anode oxygen evolution or active aeration. Ammonia is reduced to nitrate in the anode chamber, and nitrate moves to the cathode for the next denitrification reaction. Although such systems can remove nitrogen, the residual DO severely restricts bioelectrochemical denitrification. In addition, the spread of organic compounds into the cathode chamber can lead to serious heterotrophic denitrification.

Because SND reactors have a high prerequisite for DO, several kinds of BES systems have been designed (dual-cathode MFC) with discrete anoxic and aerobic cathodes for denitrification and nitrification, respectively [69]. These systems have an anoxic cathode and an aerobic cathode on each side of the anode chamber. First, the nitrogen-containing wastewater flows into the anode chamber of both BES. Then, the anode effluent is collectively fed into the aerobic biocathode chamber. Finally, the cathode effluent moves into the anoxic biocathode chamber. To explore the engineering applications of this system, Liang et al. designed a 50-L MFC comprising an oxic-anoxic two-stage biocathode and activated-semicoke-packed electrodes [70]. This system simultaneously generated power and removed nitrogen and organic substances. The nitrogen removal efficiency was higher than 84% in continuous mode, and the average maximum power density was 43.1 W m−3.

A single-chamber BES with an air cathode pre-enriched with a nitrifying biofilm can also achieve denitrification and simultaneous nitrification, without additional power input for aeration. In a single-chamber MFC, the nitrifying biofilm adheres to the surface of the air cathode and then oxidizes ammonia to nitrate via the activities of nitrifying bacteria. The nitrate is further reduced to nitrogen gas by heterotrophic denitrifiers (Fig. 7.3c) [71]. Nitrogen removal is further enhanced by increasing the gas diffusion area. Although this system removes nitrogen, the process is not necessarily relevant to current output.

There are many other special designs of BES for nitrogen removal. The tubular configuration appears to be the most extensively studied reactor structure. In such systems, an individual anode is located at the reactor’s axial center and is encircled by the cathode; this is the best configuration to maximize the area of cathode in a volume-limited reactor. Zhang et al. developed a system with a tubular batch-operated dual-cathode configuration (Fig. 7.3d) [72]. The wastewater moved from the anode to the aerobic cathode and finally to the anoxic cathode. The ion-exchange membranes in the system consisted of a CEM between the aerobic cathode and the anode, and an AEM between the anoxic cathode and the anode.

When scaling up BES, UBER may be an appropriate configuration to slow mass transfer in an enormous cathode zone (Fig. 7.3e) [73]. Such systems use particulates such as granular activated carbon as the cathode and biocarrier and contain hydrogenotrophic denitrifying bacteria. Wastewater flows into the cathode zone and contacts the 3D cathode with a large surface area (granular activated carbon). The wide distribution of nitrate is spontaneous in the cathode zone, because of the velocity of the influent. However, the increase in pH at the cathode zone inhibits nitrite reduction, and so nitrite is not reduced to satisfactory levels. This is the common disadvantage of all single-chamber reactors.

Several studies have focused on the removal of nitrogen from groundwater using BES. Nitrate is one of the pollutants in groundwater that poses a threat to human and animal health but is difficult to remove in situ. The uses of BES to treat groundwater require a pump, which requires energy input. Angelidaki et al. designed a SMDDC to remove nitrate from groundwater in situ (Fig. 7.3f) [74]. The reactor included an anode chamber and a cathode chamber on opposite sides of a polycarbonate plate. A CEM and an AEM were placed against the outer side of the cathode chamber and anode chamber to insulate the interior of the chambers against the outside environment. The whole reactor was submerged below the groundwater surface. Wastewater flowed into the anode and the effluent was directly fed into the cathode. Under the action of an electric field force, nitrate was transferred to the anode chamber and then to the cathode chamber for the denitrification reaction.

7.2.1.2.6 pH Control

The pH of wastewater is unstable, and this is one of the main factors affecting the performance of hydrogenotrophic denitrification. Therefore, to increase biocatalytic denitrification, the pH must be maintained at an appropriate level because the microorganisms that catalyze these reactions deteriorate in the conditions that result from their activities [64]. In many autotrophic denitrification systems, the denitrification reaction can significantly slow or even stop under lower (<6) or higher pH (>9) conditions. The pH in the cathode chamber will increase significantly because of proton consumption during the denitrification process [75]. Villano et al. found that the biocathode pH increased rapidly from 8.40 to 11.43 during the first 15 days of operation [76]. Clauwaert et al. reported that only 26% of nitrate was reduced without pH adjustment, but nitrate removal increased under a stable neutral pH [77]. Therefore, the pH at the cathode must be continuously adjusted during the denitrification process. A pH between 6.5 and 8.0 is optimal for denitrification systems.

The pH affects denitrification performance mainly via its effects on the microbial community [78]. Wang et al. reported that the Clostridia community was the most significant nitrate remover at pH 7.0–8.0, followed by members of α-Proteobacteria, γ-Proteobacteria, and Bacilli. Lee et al. showed that Clostridia was the principal community in autotrophic denitrification and that Clostridia displayed denitrifying activity in the cathode chamber of BES. At pH 9.0, Bacilli was the most abundant class, since its members grow well under alkaline conditions. γ-Proteobacteria was the main class at pHs below pH 6.0, indicating that acidic conditions favor this class.

The pH of the electrolyte is normally adjusted by phosphoric acid during a batch denitrification process [50]. The pH is also adjusted by the carbon dioxide produced during the denitrification process [79], as the carbon dioxide gas dissolves in water to produce carbonic acid. This reacts with hydroxyl radicals (OH−) to form bicarbonate (HCO3−), which buffers against the increase in pH [45].

7.2.1.2.7 Ionic Strength

Several studies have shown that nitrate removal is promoted at high ionic strength. Zhang et al. studied the effects of conductivity on BES performance and showed that the nitrate removal efficiency was higher at a high ionic strength (99%; 2200 μS cm−1; added 1000 mg L−1 NaCl) than at a low ionic strength (91%; 900 μS cm−1) [74]. The higher denitrification efficiency at high ionic strength was likely caused by the decrease in internal resistance, which resulted in higher current density and coulombic efficiency. This is the main reason why nitrate removal from groundwater is incomplete. Zhang et al. found that anionic species like chloride ions (Cl−) did not negatively affect the performance of denitrification systems. These results indicated that the addition of exogenous electrolytes (2000–11,000 μS cm−1) is an effective way to increase denitrification efficiency at the cathode [74].

Incomplete nitrate removal is caused by the accumulation of denitrification intermediates (NO2− and N2O). With regard to high conductivity, the electrons produced by the oxidation of organic substances in the anode chamber move to the cathode, where they are used to reduce nitrogen-containing compounds. Nitrogenous gases (NO and N2O) are formed as intermediates at low conductivity. These gases increase resistance in the system, thus limiting proton and electron transport and promoting the accumulation of denitrification intermediates.

7.2.1.2.8 Initial Nitrate Loadings

Biological denitrification has been used to treat wastewater with comparatively low nitrate concentrations (10–200 mg N L−1). However, the nitrate concentrations in wastewater frequently exceed this level, especially wastewater from industries in small- and medium-sized communities (150–12,500 mg N L−1) [80]. Very high nitrate concentrations can be toxic to denitrifying bacteria [81, 82]. Zhang et al. showed that, at an initial nitrate concentration of 100 mg N L−1, nitrate was nearly completely reduced within 21 h, and the denitrification process was similar to that occurring at a lower initial nitrate concentration (70 mg N L−1). However, at a much higher initial nitrate concentration (150 mg N L−1), denitrification was slightly inhibited, and the denitrification rate was significantly decreased [83]. Another study showed that denitrification was completely inhibited when the initial nitrate concentration was higher than 1350 mg N L−1 [80].

7.2.1.2.9 Carbon Source

Organic compounds are the most abundant pollutants in wastewater. Bioelectrochemical denitrification accepts electrons from the cathode and from organic compounds at the cathode [13]. In the cathode of BES fed with organic substances, both autotrophic and heterotrophic denitrifying bacteria exist simultaneously, and the nitrogen reduction pathway varies depending on the carbon source. The carbon/nitrogen ratio (C/N) affects the electron supply and, hence, affects the nitrogen removal rate and pathways. In previous studies [84], heterotrophic denitrifying bacteria were dominant if organic matter was abundant (C/N >1), but autotrophic denitrifying bacteria were dominant when the C/N was below 0.75. To avoid secondary pollution produced by the incomplete use of methanol, the C/N ratio ought to lower than 0.75. The nitrate removal efficiency can be enhanced by the cooperation of autotrophic denitrification and heterotrophic microorganisms.

Three kinds of carbon sources have been used in previous studies: inorganic (e.g., sodium bicarbonate, NaHCO3), simple (e.g., methanol, glucose, and acetate), and complex/refractory (e.g., starch and phenol) (Table 7.5). Inorganic carbon sources are more favorable for autotrophic denitrification than for heterotrophic denitrification. Feng et al. found that BES fed with sodium bicarbonate accumulated nitrite and showed lower nitrogen removal efficiency than those of systems with other organic carbon sources [85, 86]. In this system, most of the nitrogen removal was attributed to hydrogenotrophic denitrification. However, a different nitrogen removal mechanism operated when organic carbon sources were added. In BES fed with simple carbon sources, the carbon sources were direct electron donors for heterotrophic denitrification [87].

However, in BES fed with complex carbon sources, the specific nitrogen pathways are probably different. For example, soluble microbial products and nitrite accumulated in BES which is fed with starch [85, 86], but not in BES fed with simple carbon sources. Further research is required to explore the mechanisms operating in each system. Phenol, another refractory carbon source, cannot be degraded by denitrifying bacteria. Therefore, the concomitant removal of phenol and total nitrogen can be achieved by the combined activities of phenol-degrading bacteria and denitrifying bacteria [88]. In such systems, small-molecule metabolites are the direct electron donors for heterotrophic denitrification. In addition, bioelectrochemical denitrification accepts electrons from direct cell-cell electron transfer.

7.2.1.2.10 Microbial Communities in Cathode Biofilm

Denitrifying bacteria belong to taxonomically and biochemically diverse categories of anaerobic bacteria, which obtain energy for biosynthesis and upkeep from electrons transported from donors to acceptors (NO2−, N2O, and NO3). Many studies have focused on the microbial ecology of biocathode denitrification systems in which the cathode microbial community is separated from mixed cultures of hydrogenotrophic microorganisms. The microbial community is complex and comprises species involved in denitrification and other species with different functions (e.g., species that consume organic compounds synthesized during autotrophic denitrification) [64]. Nitrosomonas sp. is a denitrifying bacterium that can oxidize ammonia to nitrite or reduce nitrite to nitric oxide [93]. The active denitrifying bacterial community in biocathodes was compared between an MFC with an annular association (anode effluent moved into the cathode) and a dual MFC with separate cathode and anode chambers. The loop MFC showed higher performance in both its nitrogen removal rate and current generation; this was probably because of its evenness and greater bacterial richness and the dominance of members of the Firmicutes and Proteobacteria in the cathode biofilm [94,95,96,97,98]. The main participants in the bioelectrochemical denitrification process are Proteobacteria, Firmicutes, and Clostridia. Wrighton et al. found that Proteobacteria and Firmicutes were the dominant phyla in a denitrification system, indicating that these classes have strong potential for nitrate removal. Sotres et al. also found that members of the Firmicutes, Proteobacteria, and Actinobacteria displayed efficient denitrification activities in a biocathode denitrification system.

Proteobacteria are typical hydrogen-oxidizing denitrifiers. Paracoccus denitrificans, which belongs to the α-subclass of Proteobacteria, is one of the most widely studied denitrifying microorganisms [11, 99]. β-Proteobacteria such as Thauera sp., Hydrogenophaga sp. [100], and Rhodocyclus [101] have also been isolated from mixed microbial communities. In IET denitrification, Proteobacteria may dominate the biofilm during the start-up and substrate limitation (hydrogen) phases. However, in DET denitrification, denitrifiers must be able to transfer extracellular electrons through a chain of c-type cytochromes. Previous studies have shown that c-type cytochromes are present in Halochromatium salexigens and other Proteobacteria [101] and in some purple denitrifying microorganisms, including Rhodocyclus [102]. Wodara et al. identified two c-type cytochromes and a flavoprotein in P. denitrificans [103]. These results indicated that most denitrifying microorganisms on the cathode are able to transfer electrons extracellularly.

The difference in degradation efficiency among different denitrifying microorganisms may be due to differences in the expression patterns of genes in the denitrification pathway. The main nitrate reductase genes are napA and narG, the main nitrite reductase genes are nirS and nirK, and the main NO and N2O reductase genes are norB and nosZ, respectively [78]. napA is a periplasmic nitrate reductase that can easily link to the outside electron flow because of its short distance to the outer membrane. Doan et al. reported that the expression of napA and narG was unaffected by increasing current density [104], whereas those of nirS and nirK slowly increased to reach a peak in expression as the current density increased. The rate-limiting step in the denitrification pathway was found to be that catalyzed by NO and N2O reductases (encoded by norB and nosZ). Expression of these two genes was shown to increase rapidly as the current density increased, and denitrification intermediates other than N2O did not accumulate. Finally, N2O accumulation and the low expression of nosZ supported the conclusion that the NO-to-N2O transformation is the rate-limiting step in the denitrification pathway.

7.2.1.2.11 Influence of Other Pollutants

As well as nitrogenous and organic compounds, wastewater contains many other types of pollutants, such as heavy metals, surfactants, sulfides, and nanoparticles. Heavy metal ions and surfactants can inhibit the self-purification of soil and groundwaters in nature [105]. Surfactants are widely used to create emulsions of various compounds such as lubricants and oils. However, the amount of surfactants seeping into the environment has increased. These substances may lead to the accumulation of secondary pollutants and dissolve pollutants that are usually insoluble in polar solvents [106]. As an example, the denitrification rate of a standard medium containing APDA (N-N-Bis (3-aminopropyl) dodecylamine – disinfectant and cleaning agent, a biocide used in the food and cosmetics industry) at 2 mg L−1 by Bacillus licheniformis was similar to that of the standard medium without APDA. However, the denitrification rate decreased with increasing APDA concentrations (inhibiting concentration 2–8 mg L−1). At the toxic concentration of APDA (8 mg L−1), the denitrification process almost completely stopped.

Unlike surfactants, heavy metals can be reduced and detoxified at the surface of the cathode. Thus, the inhibitory effects of heavy metals probably differ between bioelectrochemical denitrification and biological denitrification. Watanabe et al. attempted to use a bioelectrochemical reactor to treat nitrogen pollutants directly in wastewater containing copper [107]. The copper ions and nitrogen pollutants could be removed simultaneously during a continuous operation by applying electric current and supplying acetate. In addition, wastewater containing high concentrations of nitrogen pollutants and hexavalent chromium was successfully treated by a laboratory-scale expanded granular sludge bed reactor [108]. Almost all nitrates were removed, even from wastewater containing a high level of hexavalent chromium (120 mg L−1).

The treatment of nitrate-containing wastewater by the sulfur autotrophic denitrification process using BES has been studied for decades. In this process, sulfur autotrophic and hydrogen autotrophic steps are integrated for the following reasons: bioelectrochemical hydrogen denitrification consumes the protons produced during sulfur denitrification to attain neutralization; and the sulfate concentration in the effluent can be controlled by adjusting the nitrogen load in the sulfur autotrophic denitrification step [109]. Using such a system, Cai et al. achieved nitrate and sulfide removal efficiencies of >90% when influent nitrate and sulfide concentrations were 780 mg L−1 and 135.49 mg N L−1, respectively [110]. These processes are also strongly affected by pH; the sulfur autotrophic denitrification process is weaker than hydrogen denitrification in acid conditions, while hydrogen denitrification is enhanced under alkaline conditions.

Nanomaterials such graphene oxide, zinc oxide, nano-silver, and ferric oxide are used widely in industry and are potential pollutants in wastewater because of their strong dispersity [111]. Such nanomaterials have been shown to be toxic to microorganisms in the wastewater biochemical treatment process [112]. Chen et al. [113] designed a 3D bioelectrochemical denitrification system (3D-BEDS) to treat wastewater containing a high nitrate concentration and various concentrations of graphene oxide (GO; 0–150 mg L−1). As the GO concentration increased (<100 mg L−1), the nitrate removal efficiency decreased slightly from 99.52% to 94.81%. However, the denitrification efficiency dramatically decreased to 74.95% when the GO concentration increased to 150 mg L−1. The authors also found that high GO concentrations changed the dominant bacterial communities and decreased community abundance.

Refractory organic pollutants are another class of hazardous contaminants that affect the nitrate removal efficiency of BES. Chen et al. found that an increase in the p-nitrophenol concentration (0–100 mg L−1) in wastewater led to a decrease in denitrification efficiency (to 74.51%) [114]. Therefore, a high concentration of p-nitrophenol may be harmful to denitrifying microorganisms.

7.2.2 Denitrification at Bioanodes

As mentioned above, most previous studies have focused on SND in the limited-aeration cathode chamber of BES. The DO that is not consumed during nitrification will be harmful to denitrifying bacteria. The anode denitrification MFC (AD-MFC) is a novel type of MFC that removes nitrate and simultaneously generates electricity in the anode chamber [115, 116]. In these systems, SND occurs in separate anode and cathode chambers, rather than in the same cathode chamber. In an MFC that cathode nitrification was coupled to anode denitrification for nitrogen removal, an AEM allowed nitrate to move from the aerobic cathode chamber to the anaerobic anode chamber. Zhang et al. used an AD-MFC system to remove nitrate at various initial concentrations [116]. When the initial nitrate concentration in the anolyte was increased from 50.02 ± 0.03 to 3560 ± 36.80 mg L−1, it was completely removed within 4.2–171.8 h. The results demonstrated that the AD-MFC was capable of treating wastewater containing nitrate, even at very high concentrations, while simultaneously generating electricity.

In anode exoelectrogen systems, the electron output from the anode is due to their ability to directly convert organic waste into electrical energy, and the final electron acceptor is oxygen. Such systems have been used to remove nitrogen, but they are not suitable for power generation because the denitrification process competes for electrons with biological electricity generation in the anode biofilm. In addition, high nitrate concentrations in the anolyte can inhibit or even stop electricity generation in this type of MFC [117].

7.2.3 Nitrate Removal by Constructed Wetland Coupled with MFC

CWs have been widely used to treat municipal sewage, livestock and agricultural wastewater, and leachates and mine drainage. The popularity of CWs has increased in the last 20 years because of their low installation, operation, and maintenance costs. Systems combining an MFC and CW-MFC are a new development in ecosystem wastewater treatment technology (Fig. 7.4) [118]. Such systems are considered to be a cost-effective and environmentally friendly method for generating bioenergy while simultaneously biodegrading organic matter and nitrate. Most CW-MFC has an upflow construction with the cathode buried below the surface layer or in the plant rhizosphere. This arrangement minimizes DO in the anode zone. In CW-MFC, plants play two roles: they provide organic chemical compounds in the rhizosphere and harbor microorganisms that generate power from those organic chemical compounds. The reported current output of a plant-MFC was 18-fold higher than that of a freshwater sediment MFC.

Schematic diagram of simultaneous carbon and nitrogen removal in a CW-MFC. (Reprinted from [118], Copyright 2015, with permission from Elsevier)

The average COD and nitrate removal efficiency of a CW-MFC were 8.3% and 40.2% higher, respectively, than those of the original CW [119]. The relative abundance of β-Proteobacteria, nitrobacteria, and denitrifying bacteria was significantly increased in a closed-circuit CW-MFC, and dissimilatory nitrate reduction to ammonium, microbial immobilization, and plant uptake were all minor mechanisms of nitrate removal. Matheson et al. evaluated the relative importance of competing nitrate removal processes by measuring the degradation pathway of 15N-labeled nitrate in a surface-flow CW [120]. They found that most of the nitrate was permanently removed through denitrification, while smaller proportions were removed by plant uptake (11%) and microbial immobilization (13%).

7.3 Ammonia Removal and Recovery

Ammonium pollution of water is a serious environmental problem because it causes eutrophication, which leads to the death of aquatic species. Kim et al. used an MFC to treat ammonia in wastewater containing organic pollutants [121]. The system removed ammonia while simultaneously generating electrons to produce energy, in a process completely different from traditional ammonia removal processes. Recently, there has been increasing interest in using MFC for ammonia recovery [122]. There are two mechanisms of ammonia removal in MFC. The first mechanism is the transfer of ammonium ions from the anode to another chamber (through ion-exchange membranes) under pressure generated by an electric field force. Then, the ammonium ions can be removed by various methods such as struvite precipitation (MgNH4PO4·6H2O) and blowing-stripping. The second mechanism is biological nitrification/denitrification, in which ammonium ions are oxidized to form nitrogen gas in a water-based bioelectrode mechanically supplied with oxygen.

7.3.1 Nitrification at Bioanodes

There are three biological oxidation steps in the nitrification process (Eq. 7.3) [123]. The limiting step is oxidation of ammonium ions to form nitrite, which is catalyzed by ammonium-oxidizing bacteria. Then, nitrite is rapidly oxidized to nitrate by nitrite-oxidizing bacteria in the presence of molecular oxygen:

The reduction of ammonium ions to nitrite is a two-step reaction with hydroxylamine (NH2OH) as the main intermediate product. In the first step, ammonia rather than ammonium ion is the real substrate; ammonia is oxidized to hydroxylamine by AMO. In the second process, hydroxylamine is further oxidized to nitrite by HAO [124].

Whereas oxygen is required for conventional nitrification, nitrifying bacteria can directly accept electrons from the anode in bioelectrochemical nitrification systems. Min et al. were the first to report the removal of ammonium at high concentrations from swine wastewater in an MFC under anaerobic conditions [125]. The maximum power density generated from swine wastewater was about 45 mW m−2 in a dual-chamber MFC but increased to 261 mW m−2 in a single-chamber MFC. This system removed approximately 83% of ammonia and 88% of soluble COD. Detailed analyses indicated that many extra ammonia elimination processes such as anaerobic ammonia oxidization and denitrification occurred in the system. However, the results did not clarify whether ammonia oxidation was coupled to electricity generation.

Later, Kim et al. tried to generate electricity from ammonia oxidation by intermittently injecting ammonia into the anaerobic anode chamber as the sole electron donor. No power was produced, indicating that ammonia could not serve as a substrate for electricity generation under anaerobic conditions [121]. In contrast, He et al. showed that ammonium could serve as the sole substrate for electricity generation as it could be used directly as an electron donor in anode chamber or indirectly as the substrate for nitrifiers to produce organic compounds for heterotrophs in a rotating-cathode MFC [126]. At present, there is no unanimous agreement as to whether ammonium is a substrate for electricity generation.

In 2013, Xie et al. further investigated the effects and mechanism of DO on nitrification and electricity generation in an AO-MFC [127]. In that system, the electrons originated from ammonia and flowed to AMO (which catalyzes the conversion of ammonia to hydroxylamine), Cyt aa3 oxidase (which catalyzes the reduction of oxygen), and the anode, which were used for triggering ammonia oxidation, synthesizing ATP, and generating electricity. Molecular oxygen was found to play a key role in distributing electrons among these three acceptors. Concentrations of DO that were too high (>6.45 mg L−1) or too low (<0.5 mg L−1) negatively affected electricity generation. However, the ammonia oxidation rate gradually increased as the DO concentration increased. Those results indicated that the electrons derived from ammonia simultaneously flow to oxygen and the electrode. The ammonia-electrode electron transformation was favored under low-DO conditions. However, since oxygen is a substrate for not only AMO but also Cyt aa3 oxidase, low-DO conditions can inhibit the activity of ammonia-oxidizing microorganisms.

7.3.1.1 Electron Transfer Between Bioanodes and Nitrifying Bacteria

Although many studies have focused on electron transfer mechanisms between the anode and bacteria, this process is still poorly understood. The current understanding is that, like in the cathode denitrification process, there are two mechanisms of electron transfer between the anode and bacteria: direct and mediated electron transfer (DET and MET, respectively). In the DET process, electrons are transferred through flavin, conductive pili, and c-type cytochromes. In the mediated electron transfer process, electrons are transferred through external electron mediators between the electrode and microorganisms [128].

To date, three pathways have been proposed. In the first possible pathway, electrons released from ammonium oxidation and nitrite oxidations by nitrifying bacteria are transferred from the microbial cells to the anode to generate electricity [127]. As shown in Fig. 7.5, four electrons are produced from the conversion of hydroxylamine to nitrite by HAO. In traditional nitrification, half of those electrons are used to convert ammonia to hydroxylamine by AMO, and the other two are used to reduce oxygen by Cyt aa3 oxidase [129]. A different process occurs in anode nitrification, where the electrons for oxygen reduction are transferred to the anode via c-type cytochromes [127].

Proposed cathode extracellular electron transfer mechanisms and associated energy gains for bioanode microorganisms. Cytc c-type cytochrome, AMO ammonia monooxygenase (which catalyzes conversion of ammonia to hydroxylamine), HAO hydroxylamine oxidoreductase (which catalyzes conversion of hydroxylamine to nitrite). (Reprinted from [127], Copyright 2013, with permission from Elsevier)

In the second possible pathway, nitrite is electrochemically oxidized into nitrate to generate electricity [130], and ammonia is oxidized in the same way as in the first pathway. In the third possible pathway, ammonium is assimilated by microorganisms into organic compounds, which serve as fuel to generate electricity.

7.3.1.2 Factors Controlling Nitrification at Bioanodes

7.3.1.2.1 pH Control

Both biological and electrochemical pathways depend on the anode pH. The electrochemically active bacteria in the anode chamber can be inhibited or even inactivated in acidic or alkaline conditions. In addition, in an alkali environment, ammonium ions are converted into free ammonia, which inhibits microbial activity. Therefore, the ammonia removal efficiency depends on the anode pH of MFC systems [131]. Kim et al. investigated the pH dependence of ammonia removal in an MFC system (pH 7.0, 8.0, and 8.6) [132, 133]. In this MFC system, 23.3% (30.2 mg N L−1) of total ammonia nitrogen (TAN) was removed via the electrochemical pathway during 192 h at a neutral pH. More ammonia was removed by biological pathways than by electrochemical pathways, and Anammox were the main functional bacteria. However, at the initial pH of 8.6, the proportion of free ammonia increased to 22.8%, which strongly inhibited ammonia removal by biological pathways. Therefore, a neutral pH was identified as being optimal for AO-MFC.

7.3.1.2.2 Initial Ammonia Loadings

Denitrifying systems have been tested using various types of wastewater, e.g., fermented wastewater, swine wastewater, leachates and wastewater from paper and brewing industries, and recycling wastewater [134]. The ammonia concentration in most real wastewaters far exceeds the capacity of the nitrifying process. Nam et al. studied the effect of free ammonia concentration on electricity generation in MFC and found that electricity generation was significantly inhibited by high concentrations of TAN (>500 mg N L−1) [134, 135]. Further increases in TAN significantly inhibited AOB and NOB, resulting in a continuous decrease in maximum power density.

At low concentrations, ammonia functions as a sustainable proton shuttle. Therefore, a low concentration of ammonia can effectively stabilize the anolyte pH and enhance the current output of an MFC [136]. In these systems, the cathode remains anaerobic, thereby facilitating abiotic hydrogen gas formation. When the anolyte is neutral (pH 6.5–7.5), ammonia mainly exists as ammonium ions through combining with the protons produced by the biofilm on the anode. The ammonium ions are transferred into the cathode chamber through a CEM, and free volatile ammonia is produced in the catholyte (pH > 10).

7.3.1.2.3 Inhibition by Primary Intermediates

Ammonium is the original substrate of AO-MFC. The intermediates of nitrification, hydroxylamine, and nitrite, which can also donate electrons, may also serve as substrates in AO-MFC [137]. Chen et al. showed that hydroxylamine at concentrations lower than 3.0 mg L−1 promoted electricity generation in an AO-MFC but inhibited it at a higher concentration (7.2 mg L−1). Since very little hydroxylamine accumulates during nitrification, its contribution to electricity generation will be negligible. Nitrite at concentrations lower than 100 mg N L−1 was shown to promote electricity generation in an AO-MFC but inhibited it at a higher concentration (150 mg N L−1) because of its severe biotoxicity. The addition of nitrate to an AO-MFC was shown to decrease electricity generation.

7.3.1.2.4 Carbon Source

Organic compounds are the most abundant pollutants in wastewater and serve as electron donors. Therefore, there is competition for electron input between organic compounds and ammonium in the anode chamber [72]. Jadhav et al. found that ammonia and organic matter could be removed simultaneously under different COD/ammonium ratios (COD/NH4+ ratios of 1:1, 10:1, and 5:1) [138]. About 63% and 33% of NH4+-N was removed with a COD/ammonium ratio of 1:1 and 10:1, respectively. However, the highest volumetric power density (0.7 W m−3) was in the MFC system with a COD/ammonium ratio of 10:1, indicating that COD benefited current output but inhibited ammonia removal.

7.3.1.2.5 Microbial Communities in Anode Biofilm

In the presence of ammonium and the absence of microbes, a chemical cell failed to generate electricity (ammonium in the anolyte; potassium permanganate in the catholyte). However, in the presence of ammonium and microbes, an AO-MFC system generated electricity. In other words, functional bacteria play a pivotal role in generating electricity in AO-MFC [139].

In the review of Ge et al., the detection of nitrifiers for wastewater treatment has been summarized in detail [12]. The AOB can be distinguished by their cell morphologies and Gram-negative multilayered cell walls, and some of them are motile (with flagella). Since the first isolation of AOB in 1890, five recognized genera of AOB in two phylogenetically distinct groups, the γ- and β-subclasses of Proteobacteria, have been reported [140]. Four genera of AOB, including clusters of Nitrosomonas (e.g., Nitrosococcus mobilis), Nitrosolobus, Nitrosovibrio, and Nitrosospira, are grouped in the β-subclass [141], and one Nitrosococcus cluster is in the γ-subclass [142]. To date, 25 AOB species have been cultured from various environments, and Nitrosomonas and Nitrosospira are the most extensively studied genera [143]. The majority of AOB obtain energy for growth from aerobic oxidation. However, some special AOB species can grow under both aerobic and anaerobic conditions. In high-DO conditions (DO > 0.8 mg L−1), the main aerobic oxidation product of Nitrosomonas eutropha was nitrite, while nitrogen gas, nitrite, and nitric oxides were produced under low-DO conditions (DO < 0.8 mg L−1) [144]. In the anode chamber, N. eutropha may play an important role in oxidizing ammonia and releasing electrons to the anode. Schmid and Bock demonstrated that Nitrosomonas europaea was able to anaerobically oxidize ammonia using nitrite as the acceptor, suggesting that oxygen is not indispensable for ammonia oxidation [145, 146]. He et al. showed that N. europaea could transfer electrons to the anode [147]. Zhan et al. found that N. europaea dominated the microbial community on the anode surface of BES [139].

The conversion from ammonia to nitrite via hydroxylamine is catalyzed by two key enzymes: AMO and HAO. The former is a membrane-bound heterotrimeric copper-containing enzyme, with a broad substrate range and an acetylene-inhibitor profile [148]. The three subunits of AMO are encoded by amoC, amoA, and amoB, but only a portion of amoA performs as a functional gene in AOB [149, 150]. Although AMO is inactivated upon cell breakage, its activity can be tested in vitro. Compared with AMO, HAO has been characterized more extensively. The HAO enzyme is located in the periplasm and comprises multi-c-heme and homotrimer subunits [151]. It is encoded by the gene cluster hao (hydroxylamine oxidoreductase), which is highly conserved, especially in the β-subdivision [143]. N. europaea was found to contain three copies of hao, which were separate but identical (except for one nucleotide) and constituted 40% of the c-type heme [152].

Compared with AOB, NOB is more phylogenetically distinct and widespread among the Proteobacteria. Eight species of NOB have been cultured, and four phylogenetically distinct groups have been described. The genera Nitrococcus and Nitrobacter are assigned to the α-subclass and γ-subclass of Proteobacteria, respectively. The Nitrospira genus, which is in its own subdivision (phylum Nitrospira), groups closely with the δ-subclass. Candidatus Nitrospira defluvii was the first NOB to have its complete genome sequence determined. Nitrospira are the dominant and more specialized NOB in most wastewater treatment plants, including drinking water and soil water treatment plants [153,154,155,156]. Fukushima et al. found that Nitrospira was dominant in high inorganic carbon conditions, while Nitrobacter was dominant in low inorganic carbon conditions [157]. Moreover, Nitrospira was found to be a K-strategist (high substrate affinities and low maximum activity for nitrite and oxygen), while Nitrobacter were γ-strategists under substrate-limited conditions. Nitrococcus and Nitrobacter are able to utilize organic sources as they are facultative autotrophs and anaerobes [158].

The NOB obtains energy from the oxidation of nitrite to nitrate. Nitrite oxidoreductase (NXR) is the key enzyme in the nitrite-oxidizing systems of Nitrobacter, Nitrococcus, Nitrospina, and Nitrospira. An active form of the membrane-bound NXR isolated from Nitrobacter hamburgensis was shown to oxidize nitrite to nitrate in the presence of ferricyanide [159]. The NXR enzyme comprises two to three subunits (α-subunit, NorA, and β-subunit, NorB) containing various cofactors (iron, molybdenum, sulfur, and copper). It is thought that NorA contains the NOR catalytic site and NorB functions as an electron-channeling protein between NorA and the membrane-integrated electron-transport chain [159]. The molecular masses of NorB differ among NOB species, e.g., 65 kDa in Nitrococcus and Nitrobacter, 48 kDa in Nitrospina, and 46 kDa in Nitrospira. Analyses of NXRs have revealed their subcellular location and phylogenetic position as a monophyletic lineage in the tree of type II enzymes in the DMSO reductase family [154].

However, Nitrobacter have never been found in AO-MFC systems. Some studies have demonstrated that the nitrite in the anolyte and potassium permanganate in catholyte can establish a chemical cell to generate electricity, suggesting that biotic nitrite reduction may be negligible and that nitrite may be electrochemically oxidized into nitrate.

7.3.2 Ammonia Removal in Photosynthetic Algae MFC

The possibility of using light to promote electricity production in MFC has received more attention in the last decade, with the development of new systems to convert light into bioelectricity [160]. These systems, which are known as PMFC, can utilize free solar radiation to generate energy. The most widely studied concept is the use of microalgae in the cathode chamber to produce oxygen for the cathode reaction (photosynthetic algae MFC; PA-MFC) [161]. Typically, bacteria at the anode oxidize organic compounds and produce protons and electrons. The electrons are transferred from bacteria to the anode, and then to the cathode through an external circuit. At the cathode, microalgae use light and carbon dioxide to produce oxygen via photosynthesis. The oxygen combines with protons and electrons (from the anode compartment) to form water, thus completing the cathode reaction. The advantage of these systems is that they can treat biodegradable wastes (by bacteria in the anode), consume carbon dioxide, and fix nitrogen and phosphorus (by microalgae in the cathode) while simultaneously producing electricity.

Photosynthesis is a complex biological redox process that occurs in algae and plants. In this process, solar power is used to produce oxygen and carbohydrates via multiple redox reactions. Other chemical compounds produced during photosynthesis can also be used to produce power or to synthesize other molecules [162]. Microalgal growth depends on several parameters, such as light, temperature, nutrients, and pH. Light (quality, intensity, and dark/light regimes) is one of the most important parameters controlling the growth and composition of microalgae biomass (fatty acid and pigment profiles). Nutrients also affect the growth and composition of microalgae. Under nutrient-limited conditions (particularly nitrogen limitation), microalgae increase the production of lipids, carbohydrates, and/or pigments.

7.3.2.1 Electron Transfer Between Electrode and Microalgae

There are four possible electron transfer mechanisms between the electrode and microalgae: DET through the cathode to algae, direct carbon dioxide reduction at the cathode, reduction of oxygen generated by photosynthesis, and electron transfer via self-produced mediators (Fig. 7.6) [163]. Unfortunately, only the oxygen reduction mechanism has been thoroughly studied. First, a phototrophic biofilm comprising cyanobacteria, algae, and other bacteria develops at the cathode. Illumination provides photosynthetically manufactured oxygen as the last electron acceptor for the microbial-catalyzed cathode oxygen reaction [161]. During photosynthesis, nutrients such as nitrogen and phosphate are simultaneously consumed, but DET has not been detected in this mechanism.

Possible cathode reaction mechanisms in microbial carbon capture cells: direct carbon dioxide reduction (a), DET from cathode to algae (b), mediator-assisted electron transfer (c), and oxygen reduction (d). (Reprinted from [163], Copyright 2010, with permission from Elsevier)

Based on theoretic thermodynamic determinations, power output is impossible with end products such as acetate or glucose. The voltage only slightly increased by about 60 mV by directly injecting pure carbon dioxide into the cathode. Cao et al. studied the direct reduction of carbon dioxide in an MFC [164]. Their DO measurements indicated that no oxygen was produced, but there was an obvious reduction peak at around −40 mV, indicating that carbon dioxide was reduced at the biocathode. However, there was no peak before the Chlorella vulgaris biofilm formed on the biocathode. These results indicated that the biofilm is the main functional region for extracellular electron transfer [165].

7.3.2.2 Factors Controlling Photosynthesis

7.3.2.2.1 Light Intensity

Among the environmental factors affecting the growth rate of unicellular algae, light is the most important and is often supplied at abnormal levels. In essence, the intensity of natural light is much higher than the saturation point of the microorganism and may even inhibit growth. The inhibition by light depends on other factors such as temperature, carbon dioxide levels, and nutrient supply. Therefore, in PA-MFC, a low light intensity (lower than that of sunlight, ~100 mW m−2) is sufficient for photosynthesis [166]. In the appropriate range of light intensity, photosynthetic activity, microalgae biomass, and the oxygen production rate were shown to increase with higher light intensity, thereby maximizing the voltage output of the MFC [161]. In addition, the power coulombic efficiency of a PA-MFC was shown to be higher under low light than under high light, indicating that high light should be avoided if algal photosynthesis is the only source of oxygen in the cathode chamber.

7.3.2.2.2 Reactor Configurations

In the review of Elmekawy et al., the reactor configuration of PBR has been summarized in details [162]. An early photosynthetic microbial cathode cell was developed using Chlorella vulgaris as a direct electron acceptor at the surface of the cathode (Fig. 7.7a) [165, 167]. This design has been tested as a bioethanol-producing device and consists of an MFC coupled to an existing industrial yeast bioreactor as the anode chamber. This dual-benefit integrated system has been used to generate electricity in bioethanol plants while reducing carbon dioxide emissions. In this system, the carbon dioxide is used to produce biofuel via the photosynthesis of microalgae growing in the cathode PBR half-cell. In addition, biodiesel is produced as a by-product of microalgal growth. To obtain all the benefits of the system, a chemical mediator must be added to the anode half-cell to allow electrons to travel between the yeast cells and the electrodes. The cathode half-cell is supplied with air containing 10% carbon dioxide, which is injected directly into the cell culture. The PBR is irradiated by sunlight to promote microalgal photosynthesis.

Schematic configuration of coupled PA-MFC: (a) PBR-based design; (b) upflow MFC-based design; (c) dual-chamber PA-MFC; and (d) photosynthetic sediment MFC. (Reprinted from [162], Copyright 2014, with permission from Elsevier)

This concept can be altered by connecting a glass PBR to the MFC to form a PA-MFC (Fig. 7.7b) [168]. Algal growth is initiated in the illuminated PBR, which is supplied with air pumped by the nebulizer in the reactor. The MFC has a double electrode separated by a CEM. The growing microalgae are converted to chemical energy in the form of biomass, while electrochemically active bacteria proliferate in the anode chamber of the MFC. Jiang et al. proposed a similar design [169], in which an upflow-type MFC coupled with a PBR simultaneously treated wastewater and generated power. The upflow MFC consisted of a plastic cylinder with a carbon fiber brush electrode and a glass wool/bead delamination between the anode and the cathode chamber. The outer-column PBR was coupled to the upflow MFC, and the effluent from the cathode chamber of the upflow MFC was pumped continuously into the column PBR. The microalgae culture was grown under continuous irradiation and supplied with air mixed with carbon dioxide (MFC effluent).

So far, the dual-chamber PA-MFC is the most common design. In this configuration, algal photosynthesis directly supplies oxygen in the cathode chamber (Fig. 7.7c) [170,171,172,173], and the two chambers may be separated by an ion-exchange membrane. Typically, activated sludge is used as the inoculum in the anode chamber. The anode chamber is covered during operation to block the light so that algae cannot grow. The cathode compartment containing the microalgae culture is irradiated for a certain period, e.g., 12 h per day. In systems with this configuration, the carbon dioxide produced in the anode chamber moves through a funnel-shaped gas collector at the top of the chamber through a tube to the cathode chamber, where it is used for algal photosynthesis and biomass production. Alternatively, microalgae can be used as a bioanode catalyst in a dual-chamber PA-MFC with an ion-exchange membrane separating the anode from the chemical cathode catalyst [174]. In general, the dual-chamber configuration requires the separate production of bacterial and microalgae cultures, microbial culturing instead of mechanical aeration, and a dynamic light/dark cycle for microalgal growth.

By using an anode buried in a deposit and a cathode in the water at the top of the deposit, energy can be generated by exploiting the naturally occurring potential difference [175]. This kind of system is known as a SMFC (Fig. 7.7d) [176]. The microorganisms obtain energy from the sediment through directly oxidizing organic matter or other inorganic complexes (i.e., sulfur-containing complexes). The cathode reaction of SMFC consists of the reduction of electron acceptors, such as oxygen dissolved in water. In photosynthetic SMFC, the cathode chamber contains microalgae and a biogenic substance [177]. The carbon dioxide generated by the anode bacteria is used by algal cells, and the oxygen generated by algae is used in the cathode chamber to generate the current output. Such systems are composed of an anode in a sediment layer, a sand layer, and a cathode chamber filled with microalgae culture medium. A light source is normally used to drive photosynthesis in photosynthetic SMFC.

7.3.2.2.3 Microbial Community of Anode Biofilm

Chlorella vulgaris is the most common microalgae species used in biological cathodes of PA-MFC. Powell et al. [165] tested the ability of Chlorella vulgaris to capture carbon dioxide as an electron acceptor in the cathode chamber of a PA-MFC. The maximum cell growth rate (3.6 mg L−1 h−1) and a power density of 2.7 mW m−2 were obtained with a carbon dioxide concentration of 10%. Wang et al. [163] focused on reducing carbon dioxide emissions using a novel type of PA-MFC, a microbial carbon capture cell. All the carbon dioxide produced at the anode was moved into the catholyte, and the soluble inorganic carbon was converted to algal biomass. A PA-MFC with a co-culture of Chlorella and Phormidium was also tested.

A large proportion of the sequences (up to 50% of each sample) extracted from green algae (organellar DNA) at MFC cathodes was identified as “chloroplast.” The combination of bacterial metabolic activities and algae in PA-MFC systems provides conditions that favor the growth of certain bacterial taxa. Xiao et al. found that 68–90% of the bacterial sequences identified in samples from a PA-MFC were from α-, β-, and γ-Proteobacteria and Acidobacteria_Gp3 [178].

7.3.3 Ammonia Recovery Through Struvite Precipitation in BES