Abstract

The aberrant use of fossil fuels and greenhouse gases impact on the environment made researchers leverage efforts into renewable energy generation from organic resources such as wastes. Researchers and scientists searched and studied for years so as to find an alternative fuel sources. Recent studies have supported anaerobic digestion (AD) as alternative and efficient technology that combines biofuel production and sustainable waste management. Laboratory-scale and field studies have proved kitchen waste and animal manure as feasible sources of substrate for methane generation. The effects of parameters and pretreatment affecting the co-digestion of kitchen waste and animal manure in different scientific databases within 2001–2020 were searched, and related information was obtained. Animal manure has 72–93% volatile solid, low total solid (TS) content which ranges between 5 and 9%, and high water content, while kitchen waste contains 85–96% volatile solid (VS) and high amount of water content. These characteristic properties indicate that these wastes can be efficient sources for biofuel/biogas production. This article constitutes a comprehensive review that compares and summarizes studies concerning anaerobic co-digestion of kitchen waste and animal manure, factors and inhibitors that affect the process as well as empirical studies of pretreatment techniques for co-digestion of kitchen waste and animal manure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Problems of environmental pollution are becoming increasingly prominent due to rapid economy development as a result of increase in agricultural practices (such as livestock production) and improvement in people’s living standard in most nations of the world [1]. Increase in livestock production leads to generation of huge amount of animal waste/manure while people’s standard of living results into an increase in number of kitchen waste (KW) which pose a threat to animal and human lives [1, 2]. According to Mirmohamadsadeghi et al. [3], approximately one-third of human food which is about 1.3 billion tonnes is wasted annually as reported by global food waste published in 2019 by the Food and Agriculture Organization of the United Nations (FAO). These wastes, if not properly managed, can result in unhealthy environment and emission of greenhouse gases [4]. Due to growing concerns on energy crisis in most parts of the world in recent years, biochemical conversion of these wastes to energy via anaerobic digestion (AD) with the help of methanogenic bacteria in the absence of air could reduce environmental pollution and emission of greenhouse gases [5,6,7]. Wang et al. [8] reported that AD has received great attention both in practice and scientific research, and efficiently is used in western China. The suitability of AD for waste treatment is due its limited environmental impacts and its great potential for recovery of energy [9].

According to Esposito et al. [10], AD technology does not only minimize the volume of wastes disposed, but also produces biogas which is a renewable and inexpensive energy source. Biogas, when used to produce energy, is capable of generating 20–300kWh of electricity [11]. Kemausuor et al. [12] reported that Nigeria with the highest population in Africa produces biogas with an estimated volume of 6,800,000 m3/day from animal manure and over 0.9 million tonnes of methane from municipal solid wastes (MSW). There is an additional source of income from the semi-solid by-product of AD called digestate, which contains high nutrients content that can be directly applied as fertilizer in agriculture [10]. Based on several studies that were carried out in the past [7, 13,14,15], efficient biogas production relies strongly on several operating and inhibiting factors such as temperature, pH, carbon–nitrogen ratio (C-N ratio), volatile fatty acids (VFAs), and mixing.

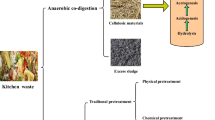

Over the years, different wastes which include municipal solid wastes, sewage sludge, kitchen wastes, and animal manure have been used for biogas generation via AD by different researchers [16,17,18,19,20]. But recently, attention is being shifted to co-digestion of kitchen wastes and animal manure to enhance biogas yield. Anaerobic co-digestion is a process where two or more biodegradable wastes are digested simultaneously in a reactor so as to enhance biotransformation efficiency [21]. Co-digestion process greatly supports recycling a wide spectrum of waste and synergetic effect of microbial activities through the improvement of nutrient balance which consequently bring about process stability [22]. Sayara and Sanchez [22] stated further that for process performance efficiency, it is essential to select adequate co-substrate with appropriate mixing ratio, suitable organic loading rate (OLR), and co-substrate characteristics during anaerobic co-digestion. Bharathiraja et al. [23] stated that co-digestion of kitchen/food waste (which is carbon-rich substrate or substrate with fewer nitrogen content with the exception of meat waste) with animal manure (nitrogen-rich substrate) can overcome the disadvantage presents by animal manure in order to enhance biogas yield. According to them, co-digestion of animal manure with food waste is being practiced in most European nations using community digestion facilities. It is also practiced in some parts of California with about 1.7 million cows generating dry manure of about 3.6 Mt.

Though, digestion has been widely accepted globally and seems to have a great future when compared with other waste treatment technologies. However, low overall bio-digestion efficiency of the process as well as long retention time of 20–30 days results in low efficiencies [24]. To improve the performance efficiency of digestion process, hydrolysis of organic matter/waste which is a rate-limiting stage is accelerated using pretreatment methods to increase soluble chemical oxygen demand (COD) and consequently increase biogas yield [25, 26]. According to Ariunbaatar et al. [9], hydrolysis is the rate-limiting step for complex substrates due to toxic by-products and non-desirable VFA formations, while methanogenesis is the rate-limiting step for biodegradable substrates. Substrate biodegradability and hydrolysis rate of digestion determine the yield of the biogas [24]. Application of pretreatment methods facilitates biogas production by conquering the limitation of hydrolysis including solubilization and biodegradation of lignin and hemicellulose present in the substrates [27].

In the past, several review works [6, 22, 28] have been published with the common aim of examining the effect of pretreatment methods most especially on complex substrates (such as lignocellulosic biomass) and food waste, but there is a limited review on recently growing interest of pretreatment methods to enhance biogas production from anaerobic co-digestion of kitchen waste and animal manure. Furthermore, optimum operating conditions are also essential to increase biogas yield. Therefore, it is necessary to set operating conditions accurately with proper monitoring during anaerobic co-digestion of kitchen waste and animal manure to avoid unwanted conditions or process instability and enhance the efficiency of the process. Therefore, the aim of this current study is to present AD operating and inhibiting parameters and confront it with possibility of the anaerobic co-digestion of kitchen waste and animal manure. This study summarizes and compares the empirical studies on effects of operating, inhibiting parameters and pretreatment on the anaerobic co-digestion of kitchen waste and animal manure.

2 Principle of anaerobic digestion of wastes

Substrates can either undergo thermal or biological gasification for the production of methane. Most often biological gasification is usually referred to as anaerobic digestion process. It combines different activities of anaerobic bacteria for the production of biogas [29]. Anaerobic digestion takes place between temperature range of 25–60 °C [30], while solid contents commonly used during the process are ˂ 10% for wet solid or ˃ 20% for dry solid [31]. Generally, there are four different types of metabolic reactions that occur during the full process of anaerobic digestion. Complete anaerobic digestion process depends on the interaction between different micro-organisms that perform the four stages of metabolic reactions [32]. Pramanik et al. [33] also stated that stability and efficiency of anaerobic digestion depend on moisture content, parameter operating conditions, reactor feeding mode, and configurations. The reactor’s configurations include single-stage, two-stage and multi-stage. Out of these different configuration systems, single-stage configuration which has less technical failure due to its design simplicity and recirculation adaptability is widely used to produce biogas from organic wastes. When substrate/waste is fed into a single-stage digester, all the four stages of reaction (hydrolysis, acidogenesis, acetogenesis, and methanogenesis) occur inside the digester simultaneously [31]. As a result of biogas production from the degradation of waste, compost (bi-slurry) is produced.

The chain of anaerobic digestion is commenced by bacteria responsible for the hydrolysis of complex organic matter (biomass) to simple organic matter. The simple organic matter produced is further broken down to volatile fatty acids (VFAs) and then to acetic acid, CO2 and H2. The final stage of digestion includes activity of methanogens producing methane. Acetoclastic methanogens degrade acetic acid into methane and CO2, while hydrogenotropic methanogens consume hydrogen to produce methane [34]. All methanogens have the ability to consume hydrogen to produce methane, but only few species can transform or convert acetate to methane [23]. The different stages of metabolic reactions and bacteria involved in anaerobic digestion are shown in (Fig. 1).

Stages of metabolic reactions and bacteria involved in anaerobic digestion process [34]

3 Material and method

All journal articles used in this study were review, laboratory, and field studies which were examined according to keywords such as animal manure, kitchen/food waste, anaerobic digestion, and co-digestion, pretreatment, inhibiting and operating parameters from Scopus database period of 2001 to 2020.

4 Discussion

Several studies have been conducted in laboratory, pilot, and full scales on the effect of parameters and pretreatment on biogas production from anaerobic co-digestion of kitchen waste and animal manure. Studies on anaerobic co-digestion of kitchen waste and animal manure were examined. Furthermore, based on this studies parameters are divided into operating and inhibiting parameters as discussed in Sects. 4.2 and 4.3.

4.1 Anaerobic co-digestion of kitchen wastes with animal manure

Either excess of nitrogen or carbon nutrients, heavy metal concentrations, VFA accumulation, as well as low organic matter content inhibit digestion process and subsequently reduce biogas yield. The efficiency of the AD process can be improved upon through the addition/mixing of compatible co-substrate to establish nutrient balance and buffering capacity of the process so as to obtain maximum biogas yield through co-digestion [35]. Anaerobic co-digestion process which is cost-effective and efficient offers solution to lack or insufficient nutrients in substrates [22]. Anaerobic co-digestion is the digestion of mixture of two or more substrates with characteristics that complement one another so as to improve biogas production [36]. Yang et al. [37] defined anaerobic co-digestion as digestion of two or more substrates in a single reactor simultaneously. Co-digestion of different types of wastes by anaerobic process is commonly applied in wastes management practice. It helps to improve the nutrient balance in substrates and improves digester performance [17]. Anaerobic co-digestion is not just mere substrate treatment technique for mixture of two or more different types of wastes, its success depends on choosing the best mixing ratio in order to prevent inhibition, adjust C-N ratio, and allow synergistic effect of micro-organisms [11]. Minale and Worku [17] reported that kitchen waste has high percentage of organic carbon and low percentage of nitrogen. Therefore, co-digestion of kitchen waste with nitrogen rich substrates such as cattle manure and poultry droppings is recommended. According to Sayara an Sanchez [22], the range of C-N ratios for kitchen waste, cattle dung, and poultry manure are respectively 26–30, 15–26, and 4–16. Summary of the results of empirical studies of co-digestion of kitchen waste with animal manure are presented in Table 1.

4.2 Operating parameters affecting biogas production from anaerobic co-digestion of kitchen waste and animal manure

There are several operating conditions which must be studied for proper biodegradation of organic matters. The activities of the micro-organisms are determined by these variables and, thus, influence the efficiency of the anaerobic digestion.

4.2.1 Temperature

During anaerobic digestion, any of the three temperature regimes which include psychrophilic, mesophilic, and thermophilic can be employed. Morales-Polo et al. [43] reported that microbes grow within the range of 10–30 °C in psychrophilic regime, 30–40 °C in mesophilic, and 50–70 °C in thermophilic. The optimum temperature range for mesophilic is 30–35 °C, while thermophilic is between 50 and 55 °C [44]. In operating anaerobic digester, the temperature in the digester has to be monitored and kept constant so as to avoid thermal shock of the micro-organisms and instability of the process. According to Kundu et al. [45], either of mesophilic or thermophilic temperature regimes favors methanogens’ growth. They also stated that bacteria in thermophilic regime have a growth rate that is twice or thrice that of mesophilic bacteria. They also possess higher decay rate when compared with decay rate of mesophilic. Digesters operated at thermophilic condition are more effective in terms of organic loading rate, retention time, and biogas production. Despite all these advantages, thermophilic condition is more problematic than mesophilic because it requires large amount of heat and is more sensitive to changes in process operating parameters [19].

Some studies on anaerobic digestion of wastes were carried out at mesophilic while some at thermophilic condition. Zamanzadeh et al. [46] studied the performance and microbial structure of an individual digestion and co-digestion of cow manure and food waste at both the mesophilic temperature (37 °C) and thermophilic temperature (55 °C). The results obtained showed that co-digestion of cow manure and food waste at mesophilic temperature yielded methane which was 26% more than the methane produced by each digestion of cow manure and food waste separately. Wang et al. [7] investigated the effects of temperature on the anaerobic co-digestion of diary manure, chicken manure, and rice straw. Increased temperature from mesophilic condition (30–40 °C) to thermophilic condition (50–60 °C) improved methane potential. Iqbal et al. [18] conducted an experiment to investigate the effect of room temperature (25–30 °C) and mesophilic temperature (37 °C) on co-digestion of kitchen waste and cattle manure. The result showed that maximum biogas was obtained at 37 °C (about 200 mL) than at room temperature (about 70 mL). Effects of temperature on anaerobic co-digestion of vegetable wastes and swine manure was investigated by Ren et al. [47]. Psychrophilic (20 °C), mesophilic (32 °C and 37 °C), and thermophilic (55 °C) conditions were considered to enhance performance of co-digestion. The result showed that the optimal temperature for co-digestion was mesophilic condition of 32 °C with highest biogas and methane yields were respectively 463.16 L/kg VS and 256.24 L CH4/kg VS. Blasius et al. [48] studied anaerobic digestion of mixture of food waste under both mesophilic (37 °C) and thermophilic (55 °C) conditions. The maximum methane yield of 869 mL of CH4g TVS−1 was obtained at mesophilic condition. Based on the above review works, mesophilic condition happens to be the most adequate for co-digestion of kitchen waste and animal manure.

4.2.2 pH

pH is an important parameter with significant influence on anaerobic digestion process. It affects directly both the progress of digestion and products [49]. The pH of an anaerobic digestion affects the growth rate of micro-organisms [50]. Kwietniewska and Tys [11] stated that the most favorable pH in an anaerobic digestion process for maximum biogas production is within the range of 6.8–7.2. According to Lohani and Havukainen [51], hydrolytic bacteria, fermentative bacteria (acid-forming bacteria), and methane-producing bacteria (methanogens) are the three major types of bacteria involved in biogas production. Methanogens prefers a pH range of 5.5–8.5; beyond this range, their activity is hindered and leads to reduction in the performance of the digester. The optimal pH range for methanogens is 6.5–8.0, though due to their sensitivity to acidic medium, they prefer pH around 7 [11, 51]. Furthermore, the acid-forming bacteria are less sensitive and tolerate a pH range of 4.0–8.5 while, the optimal pH range is between 5.0 and 6.0 [4, 51]. The effect of different initial pH was investigated by Zhai et al. [52] during the anaerobic co-digestion of kitchen waste and cow manure. At initial pH 7.5, the maximum methane production of 8579 mL and volatile solid (VS) degradation rate of 179.8 mL/g VS were obtained. Paramaguru et al. [53] examined the effect of pH 6, 7 and 8 on biogas production from anaerobic digestion of food waste, and the results showed that maximum biogas yield was obtained at pH 7. Ojikutu and Osokoya [54] evaluated biogas yield from different food wastes such as yam peels, plantain peels, orange rind, and fish waste. The results obtained showed that food waste component has effect on pH. Out of all the food waste types, fish waste has the highest pH (7.04) with lowest C-N ratio (5.01). Low C-N ratio causes inhibition in the digester as a result of ammonia accumulation which could lead to total failure of anaerobic digestion process.

4.2.3 Organic loading rate (OLR)

Another parameter which influences biogas production is organic loading rate. It is the amount of waste needed to be introduced into a digester per day under continuous feeding [30]. The actual organic loading rate into a digester depends on the types of wastes. Whenever a digester is underloaded or overloaded, biogas production reduces [55]. Increase in loading rate leads to increase in microbial activity and hence increase in biogas production to some extent; beyond the optimal OLR, biogas production reduces [11]. Overloading (addition of very huge amount of feedstock) of a digester causes upset in the system through the accumulation of volatile fatty acids (VFAs) which inhibit the activity of methane-forming bacteria (methanogens) since they cannot survive in acidic environment and subsequently leads to low biogas production. Underloading (very small amount of feedstock) of a digester results in an alkaline condition that is not favorable to methanogens and hence leads to low biogas production [56]. Agyeman and Tao [57] studied the effect of food waste particle size during anaerobic co-digestion of food waste and dairy manure at different organic loading rates 0.67, 1.0, 2.0, and 3.0 g VS/L/d. The results showed that OLR 3 g VS/L/day gave the highest methane yield (1.40–1.53 L CH4 /L/day) without ammonia inhibition and 67% of VS reduction. Babaee and Shayegan [58] investigated biogas yield from vegetable wastes at different loading rates of 1.4, 2 and 2.75 kg VS/(m3d). At OLR 1.4 kg VS/(m3 d), there was stability in the digester with highest methane yield (64%). The optimum range for OLR depends on the substrate types introduced into the reactor, since the activity level of biodegradation that will occur in the reactor is determined by the substrate.

4.2.4 Hydraulic retention time (HRT)

HRT is the average time required for degradation of organic material completely, and it is connected with microbial growth rate [11]. Complete degradation is achieved whenever substrate stays longer in the reactor under proper conditions. Hence, with longer residence time, the rate of reaction decreases [59]. Long HRT means that large volume of reactor will be needed and this results in increase in capital cost while short HRT leads to washing away of active micro-organisms [60]. Therefore, at optimal value of HRT, maximum biogas is produced. If HRT is less compare to optimal value, there will be accumulation of VFAs which inhibit bacteria activity and results into low biogas production. Also, when there is increase in HRT above the optimal, components of digester will not be effectively utilized, and it results in low biogas production [11, 55]. The retention time required for the complete degradation of any waste in anaerobic digestion depends on feedstock type and environmental conditions such as temperature [59]. Mahanta et al. [56] reported that HRT depends on the temperature of the digester. According to them, the higher the temperature of the digester, the shorter the HRT vice versa. Depending upon the operating temperature and digester design, HRT ranges between 20 and 120 days. According to Imeni [11, 44], the average retention time for the treatment of waste under mesophilic condition is between 15 and 30 days but shorter under thermophilic condition. Dennehy et al. [61] studied the effect of HRT on methane yield during anaerobic co-digestion of pig manure and food waste. According to them, as HRT decreased from 41 to 21 days, there was a decrease in methane yield. Performance of 160 L anaerobic bio-film single-stage reactor for the treatment of food waste was studied by Pramanik et al. [33]. The reactor was operated at three different HRTs (124, 62, and 35 days) under mesophilic conditions. At HRT 124, the maximum biogas and methane yields obtained were respectively 0.934 L/g VSadded and 0.607 L CH4/g VSadded.

4.2.5 Mixing/agitation/stirring

An important factor which speeds up anaerobic digestion process is mixing. Mixing in AD speeds up the process by exposing the substrate with bacteria and also brings about homogeneous temperature distribution in the reactor [4]. Mixing is also referred to agitation or stirring. Other importance of mixing according to Alfa [19] are as follows:

-

i.

It improves the contact between the substrate and micro-organisms.

-

ii.

It improves the ability of micro-organisms to obtain nutrients.

-

iii.

It prevents scum formation.

Proper mixing can be done mechanically or by recycling biogas produced [4]. Thorough mixing of substrate increases biogas production by 50% provided that all others operating parameters are constant. Excessive mixing of substrate disrupts the micro-organisms; therefore, slow mixing is recommended [19]. Rusin et al. [62] studied anaerobic digestion of cattle slurry inoculated by liquid digestate from the 1st stage of wet system in mesophilic biogas plant with and without batch agitation under thermophilic condition. The rates of cumulative methane production for agitated and unagitated are 0.121 and 0.095 mN3 kgvs−1 respectively. The agitation increased methane yield by 28.5%. During an anaerobic digestion of diary manure, Rico et al. [63] carried out mixing through recycling process with a mono pump. Mixing by recirculation has little influence on rate of biogas production at HRT of 10 days and did not improve digester performance. Also, at HRT of 20 days, mixing did not affect performance of the digester. Abdullah and Pandebesie [64] used a variable of stirring time (8 times/day for 5 min and 4 times/day for 5 min) for co-digestion of vegetable wastes and cow manure. The stirring time of 8 times/day gave the highest biogas production at stirring period of 5 min. Ratanatamskul and Saleart [65] investigated effects of sludge recirculation and mixing time on anaerobic digestion of food waste. It was obtained that at 100% recirculation and mixing time of 60 min/day, the highest biogas yield was obtained. Aworanti et al. [66] carried out investigation on the effect of agitation on biomethanization of the mixture of cattle manure, pig manure, and poultry manure (mixed animal wastes) co-digested with pineapple fruit waste and content of chicken gizzard. The result obtained showed that the cumulative biogas yield and biomethane content achieved with agitation speed of 30 to 70 rpm was respectively higher than the biogas yield and biomethane content achieved without agitation.

4.2.6 Moisture content

Moisture is required for microbial activities and metabolism in anaerobic digestion [3, 60]. There are two classes of anaerobic system based on the amount of moisture present: dry (solid-state) system and wet (submerged) system. Dry or solid-state AD system occurs at dry matter ˃ 15%, while wet or submerged system occurs at dry matter ˂ 15% [3]. Mirmohamadsadeghi et al. [3] stated that wet system has lower retention time, higher volatile solid reduction, lower inoculum requirement, and most importantly higher methane production, while dry system requires less energy and can handle digestate easily. Kwietniewska and Tys [11] reported that high methane production rate occurs at 60–80% of humidity. Teklehaimanot [60] stated that excessive moisture in the feedstock reduces the rate of biogas production per unit volume of feedstock, while the inadequate moisture causes inhibition of digestion process due to accumulation of acids. Mousa et al. [67] investigated the effect of ratio of water on the mixed organic solid waste (mixture of kitchen waste and chicken manure). The result showed that when the ratio of mixed solid waste to water was 1:1, volatile solid content was 78%, and more biogas was produced.

4.2.7 Total and volatile solids

Both the total solid (TS) and volatile solid (VS) give useful information on biogas production and process efficiency. Total solid (TS) can be described as the measurement of dry content (or matter) in a substrate. It is achieved by drying an amount of substrate at 105 °C until its moisture content is zero or until no further change in the weight of substrate is observed [68]. The total solid content of substrate affects biogas and methane production efficiency. The three main classes of AD technologies based on TS content of substrate include conventional wet (≤ 10% TS), semi-dry (between 10 and 20% TS), and dry (≥ 20% TS). In most literature, semi-dry or dry technologies are recommended due to lower water demand during the process and smaller size of the digester’s chamber that lowers production cost [69]. Sathish et al. [70] stated that when large amount of total solid is introduced into a digester, it leads to the formation of large amount volatile acids in the same digester. According to them, volatile acids have high impact of alkalinity and pH value of the reactor. Meegoda et al. [32] reported that continuous dry (or high-TS) anaerobic digester improved biogas yield when compared with wet (or low-TS) digester operating at the same retention time. Sun et al. [71] studied influence of raw materials and total solids (TS) on biogas production. They discovered that under the same condition when TS increased from 7.4 to 10%, biogas production also increased. Wang et al. [72] investigated the effect of TS (5%, 10%, 15%, and 20%) on anaerobic co-digestion of pig manure and food waste. There is no significant difference in methane yield (278.8–291.7 NmL/g VSadded) for TS ranging 5–15% TS. But there was a reduction in methane yield (259.8 NmL/g VSadded) when the TS was increased to 20%. The higher the TS content, the more the accumulated volatile fatty acids (VFAs) such as acetic acid [70]. Therefore, reduction in methane yield at 20% TS was a result of accumulation of VFAs. The performances of anaerobic digestion of food waste under mesophilic condition with TS contents from 5 to 20% were investigated by Yi et al. [69]. Results showed that as TS increased from 5 to 20%, the biogas production rate also increased.

Volatile solid (VS) concentration can be defined as measurement of organic fraction of TS which is commonly measured as a percentage of TS in grams per kilogram. It is the amount of matter that is lost when TS is ignited at 550 °C in a muffle furnace. VS can be employed to assess the efficiency of AD, estimation of biogas potential of any biomass, and degree of decomposition of biomass [68]. The residue left after subjecting to high temperature in a furnace is the inorganic fraction. According to Alemayehu [73], VS represents part or portion of organic matter that can be converted to biogas/methane. The higher the value of VS, the more favorable the anaerobic digestion (higher biogas production). According to Orhorhoro et al. [68], VS concentration can be determined by subtracting weight of the inorganic fraction left after ignition from the weight of the dried substrate and then divided by the weight of dried substrate. Investigation carried out by Orhorhoro et al. [68] showed that there was a gradual rise in in the quantity of biogas yield as the percentage of VS concentration was increasing, while reduction in quantity of biogas yield was observed as the percentage of VS concentration decreased.

4.3 Factors inhibiting microbial activity during anaerobic co-digestion of kitchen waste and animal manure

There are some factors that inhibit microbial population in the digestion of wastes. They cause adverse effect on microbial growth. Reduction in the rate of biogas production and accumulation of organic acids are indication of inhibition [11]. Lack of balance between hydrolysis and methanogenesis rates is major cause of inhibition. To achieve higher biogas production rate, then a suitable balance between hydrolysis rate and methanogenesis rate is essential. Quick methanogenesis process is required for prevention of accumulation of organic acids which reduces the pH to an extent of inhibiting methanogenic activities [74]. Co-digestion with other substrate and pretreatment of substrate are some of the operations that lowered the effect of inhibiting factors.

4.3.1 Ammonia

The degradation of protein (or nitrogen-rich organic waste such as manure) results in the formation of ammonia (NH3). It occurs mostly as free ammonia or ammonium (NH4+) forms. Ammonia improves the buffering capacity of a reactor through neutralization of organic acids to prevent inhibition by volatile fatty acids (VFAs). Micro-organisms can consume ammonia as a macro-nutrient [3]. Although ammonia is a good source of nutrient for microbial growth during anaerobic digestion, unwanted increase in ammonia concentration may occur during the degradation of protein in the substrate. This unwanted increase in ammonia concentration inhibits the process performance [75]. Inhibition by high ammonia concentration is responsible for digester failure and high economic losses [76]. According to Chen et al. [77], inhibition of the process is mainly caused by free ammonia because it can easily diffuse into cell membrane and result into imbalance of the proton (H+) and potassium deficiency. It is imperative that the concentrations of ammonia should be less than 200 mg/L to be beneficial to anaerobic digestion process since nitrogen is essential for anaerobic micro-organisms [78]. The inhibitory effect of ammonia affects methanogenesis process more than hydrolysis, acidogenesis, and acetogenesis [79]. According to Morales-Polo et al. [43], ammonia concentration which ranges between 400 and 5700 mg/L results in 56% loss of methanogen activity but acidogens are not affected. Out of the two groups of methanogens, acetoclastic methanogens were more sensitive to ammonia concentration than hydrogenotrophic methanogens [77, 79]. Free ammonia concentration depends on the concentration of total ammonia nitrogen (TAN), pH, and temperature [76]. Akindele [80] reported that instability of AD process caused by ammonia inhibition results in accumulation of VFAs which in turn leads to decrease in both pH and free ammonia concentration. The interaction between free ammonia (FA), VFAs, and pH may cause what is called “inhibited steady state process” (a process whereby the running is stable but with a decrease in biogas production and methane yield).

Zeshan et al. [81] studied the effect of ammonia-N accumulation in a dry anaerobic digestion using pilot scale reactor under thermophilic condition. Food, fruit, vegetable, and paper wastes were the substrates co-digested to attain C-N ratios of 27 and 32 with varying OLR and digestate recirculation rates under different time intervals. The results showed that C-N ratio 32 had about 30% less ammonia in digestate when compared with C-N ratio 27. It was suggested that the effect of inhibition caused by ammonia can be overcome by altering C-N ratio, higher OLR, and digestion recirculation. Chen et al. [82] observed inhibition effects of ammonia on semi-continuous anaerobic digestion of food waste. Seven lab-scale anaerobic bottles were used as reactors with different ammonium concentrations (0, 0.5, 1, 2, 3, 4, 5 g/L). After the first 5 days, methane content slowly increased and became stable. NH4Cl was fed on the 54th day to the concentrations (0–5 g/L) in the reactors. Methane yield was seriously inhibited in reactor with 5 g/L concentration on that day that TAN was increased. In the reactors with ammonium concentrations of 2–4 g/L, methane yields remained stable between 5 and 10 days, and after 10 days, it gradually declined. However, methane yield in reactors with concentrations 0–1 g/L was still at 400 mL/g VSadded. Inhibition was observed when the concentration of total ammonia in the reactor exceeded 2 g/L. Garcia and Angenent [83] operated four anaerobic reactors for a period of 988 days to evaluate the effect of ammonia on methane yield. Within 0–378 days during digestion of animal wastes (faeces, urine, wasted swine food, and flush water), at temperature 25 °C and ammonium-N level of approximately 1200 mg NH4+-N/L, methane yield was 0.31 L CH4/g Vs for all reactors. Within the period of 379–745 days, there was a decrease in methane yield by 45% at 25 °C when the TAN was increased to a level greater than 4000 mg NH4+-N/L and FAN to a level greater than 80 mg NH3-N/L for two of the four reactors. Lastly, for the period of 746–988 days, when temperature was increased from 25 to 35 °C, there was decrease in inhibition from 45 to 13%, while the free ammonia was increased.

4.3.2 C-N ratio

Carbon–nitrogen (C-N) ratio is the ratio of carbon and nitrogen contents present in organic matter. The anaerobic digestion process is highly sensitive to C-N ratio which reflects the nutrient levels of substrates. Low solubilization rate of protein in organic matter brings about low TAN and FA concentrations within a system as a result of a high C-N ratio. An optimal balance between C and N is highly needed for the proper growth of bacteria in anaerobic digestion [43]. Optimization of C-N ratio is one of the methods for reducing or avoiding ammonia inhibition in the anaerobic digestion process [50]. The optimum C-N ratio is 20–30 carbon atom: 1 nitrogen atom [13, 55, 84]. When C-N ratio is higher than the optimum, it means insufficient nitrogen (or under utilization of carbon) which will be consumed rapidly by methanogens and leads to low biogas production [50]. In such a situation, nitrogen-rich substrates such as cow dungs and poultry droppings can be added to improve biogas production. On the other hand, when the C-N ratio is lower than the optimum, the risk of ammonia inhibition which is toxic to methanogens increases. Low C-N means insufficient carbon content or under utilization of nitrogen which will result into ammonia accumulation. Accumulation of ammonia will raise the pH of the slurry in the digester more than 8.5 which will be toxic for methanogens (methane-forming bacteria) and definitely reduces biogas production [13]. Carbon-rich substrates such as kitchen waste, rice bran, and corn flour can be added to improve biogas production [84]. Table 2 shows C-N ratios range for kitchen waste and animal manure. Tanimu et al. [85] co-digested food waste mixture of C-N ratio 17 with meat, fruits, and vegetable wastes so as to increase its C-N ratio to 26 and 30 before anaerobic digestion respectively. The results showed that biogas yield of 0.352, 0.447, and 0.679L/gVS were obtained for C-N ratios 17, 26, and 30 respectively. Maximum food waste efficiency (85%) was achieved at C-N ratio 30. Jos et al. [86] studied the effect of C-N ratio on biogas yield from carica solid waste with rumen cow fluid as inoculum. The experiment was conducted by making total solid variation of 7%, 9%, 11%, 13%, 19%, and 21% and C-N ratio of 25 and 30. The results showed that the optimal rate of biogas production from carica solid waste (1.7825 ml/gTS day) was obtained in liquid state anaerobic digestion (LS-AD) at C-N ratio 25. Wang et al. [7] investigated effect of C-N ratio on anaerobic co-digestion of dairy manure, chicken manure, and rice straw. Lower C-N ratios of 15 and 20 at 35 and 55 °C respectively resulted into low methane potentials due to significant ammonia inhibition. At C-N ratios of 25 and 30, maximum methane potentials were obtained, while there was reduction in ammonia inhibition.

4.3.3 Volatile fatty acids (VFAs)

The products of acidogenesis stage of AD of organic matter include VFAs, alcohol, hydrogen, and carbon dioxide, and their ratios can significantly be differed depending on AD process conditions [23]. VFAs together with by-products such as ammonia (NH3) and hydrogen sulfide (H2S) are produced by acidogenic bacteria (also known as fermentative bacteria) [23, 88]. VFAs are also called short chain fatty acids (SCFAs) or carboxylic acids, and they contain 2–7 carbon atoms [88]. Report from Xu et al.’s [89] study stated acetic acid as the main component of VFA during anaerobic digestion of kitchen waste which inhibits methanogenesis while the concentrations of other VFAs present such as formic acid, butyric acid, and propionic acid remained stable in each stage. Formic, butyric, and propionic acids had little correlation with accumulations during biogas production. Furthermore, during co-digestion of cow manure and food waste under mesophilic and thermophilic conditions by Zamanzadeh, et al. [46]. The major VFA under mesophilic condition for mono- and co-digestions was acetic acid, while propionic acid and acetic acid were the major VFAs for thermophilic mono-digestion and propanoic acid as the only VFA during thermophilic co-digestion. Table 3 shows the names, formula, and structure of VFAs found during anaerobic digestion of kitchen waste and cow dungs. According to Meegoda et al. [32], the conditions of the reactor/digester determine the concentrations of VFAs produced during acidogenesis. They stated further that whenever digesters are operated at different pH, the result is always fluctuation in VFA concentrations, with different studies providing contradictory results. VFAs are produced during the digestion process in the digester and used up in the same digester as nutrients. A rapid increase in VFA concentration (due to accumulation) inhibits the activity of methanogens, lowers the pH value to undesirable level, causes instability of the AD system [11, 44], and subsequently leads to low biogas production rate. Kwietniewska and Tys [11] reported that the ratio of propionic acid to acetic acid greater than 1.4 and acetic acid content greater than 800 mg/L indicates reactor failure. The ratio of VFA to alkalinity characterizes AD process; the lower the VFA/alkalinity ratio, the higher the biogas yield. Currently, addition of trace elements, focusing on C-N ratio, and application of a two-stage reactor for separation of methanogenesis from hydrolysis and acidogenesis stages are the main methods for reducing inhibition caused by VFAs [89].

Effect of VFA concentration was investigated on anaerobic co-digestion of food leachate and animal manure by Lee et al. [14]. The result obtained showed that the volatile solid removal rate (56.4%) was achieved during digestion process which was unable to meet the Korea standard (65%) of volatile solid removal rate. This is due to the presence of high VFA concentration (> 4000 mg/L) in the co-substrate which inhibited the activities of microbes. Xu et al. [89] investigated the influence of VFAs on biogas production from kitchen wastes by anaerobic digestion under different organic loads. The results showed that the maximum specific methane was 328.3 mL.g/TS and that increase in organic loads made acetoclastic methanogens to be more sensitive to acetic acid than hydrogenotrophic methanogens.

4.3.4 Heavy metals (HMs)

Heavy metals are metals or metalloids with density ˃ 5 g/cm3 and mostly associated with pollution and toxicity [92]. Anaerobic digestion process can degrade agricultural wastes to generate close to two billion cubic meters of biogas yearly, but the presence of heavy metals can interfere with biogas production. Although treatment of wastes containing heavy metals is possible by AD process, it has also been reported that heavy metals can inhibit the process [93]. Some heavy metals, when present in small quantities, increase the rate of biogas production because they are used as part of enzyme structure of the bacteria, while some metals (light metals) such as magnesium, sodium, calcium, and potassium can be toxic to microbes in anaerobic digestion if present in large quantities [11]. Similarly, copper, nickel, chromium, zinc, and lead (heavy metals) when present in small quantities stimulate bacteria growth but have a toxic effect when they are present in large quantities [56]. The mechanism of inhibition of heavy metals is by disrupting the structure and function of enzymes. Mirmohamadsadeghi et al. [3] reported that the inhibitory effect of heavy metals is not a concern during anaerobic digestion of food wastes. This is because heavy metal concentrations are always below threshold in food wastes. However, in food wastes according to Mirmohamadsadeghi et al. [3], there are presence of high concentrations of sodium ion (Na+) and potassium ion (K+), and it is a concern. Therefore, concentrations of sodium and potassium should be determined in food waste so as to avoid AD inhibition. Sahu et al. [94] carried out elemental analysis of heavy metals present in the spices added to kitchen waste. It was shown that there was high concentration of metals in the spices which together with other bioactive components could inhibit biomethanation process. Table 4 shows the heavy metal contents of animal manure and vegetable wastes.

Although, researchers had in the past looked at the effect of different operating/inhibiting parameters on anaerobic digestion of kitchen waste and animal manure. However, literatures show that there is dearth information on effect of heavy metals on anaerobic mono and co-digestion of kitchen waste and animal manure. This area needs to be explored.

4.3.5 Effect of spices

One of the major challenges of using kitchen waste as substrate during anaerobic digestion is the compositional variations in kitchen waste which include types and quantities of spices used for preparing food which may affect the digestion process due to their antimicrobial activities [94]. Spices are plant substances (such as mint, rosemary, garlic, onion, red chili, black pepper, cumin, and ginger) from indigenous or exotic origin used for the enhancement of food taste. Sahu et al. [94] stated that spices have antimicrobial and antioxidant properties as their presence in kitchen waste inhibit digestion process. Antimicrobial activity of spices depends on factors which include kind of spices, composition and concentration of spices, substrate composition, process conditions, and storage [95]. Yang et al. [37] also stated that too much of additives/spices in food waste can significantly affect the performance of the AD system. Antimicrobial properties of spices are due to the presence of specific biochemical components (such as thymol in thyme, allicin in garlic, vanillin in vanilla) that inhibit the growth of bacteria [96]. In literature, few works had been done on the effect of spices on biogas production from kitchen waste. The only description of the microbial activities of spices was carried out by different researchers [95,96,97]. The major work on effect of spices on biogas production from kitchen waste in literature was carried out by Sahu et al. [94]. The results showed that different spices come with different magnitude of inhibition of the AD process. Furthermore, microbial examination carried out on digestate revealed that there was a decrease in the population of fermentative and methanogenic bacteria due to presence of spices.

Regular monitoring and controlling of operating parameters within optimum values to improve performance efficiency of the digester is somehow difficult due to intermittent changes in parameters. However, according to Mirmohamadsadeghi et al. [3], it is essential to gradually and slowly allow changes in parameters because drastic changes could cause failure and instability in the process.

4.4 Pretreatment of anaerobic co-digestion of kitchen waste and animal manure for biogas production enhancement

It has also been shown that pretreatment methods when applied can enhance the rate of biogas production, increase volatile solids reduction, and ultimately increase biogas yield [23]. Pretreatment speeds up hydrolysis which is the rate-limiting step (this is the first step in anaerobic decomposition where complex organic matters/substrates are converted into smaller molecules for further degradation) and reduces HRT for the anaerobic digestion process [3]. Kondusamy and Kalamdhad [28] stated that pretreatment effects on substrate biodegradability vary depending on substrate characteristics. According to Li et al. [98], pre-treatment methods could be physical (or mechanical), which most times could increase the capital costs due to additional energy reqiured, biological (or microbial), which is enviromental friendly and cosumes lower energy or chemical pret-treatment that employs chemicals for maintaining conditions of reaction. Szlachta et al. [99] investigated the effect of mechanical pretreatment on nine different agricultural biomasses. The biomasses were minced into 1.5 mm, 5 mm, and 10 mm particle sizes. The results showed that highest biogas was produced at optimum particle size of 10 mm. Rafique et al. [27] obtained 28% increase in biogas and 25% increase in methane content at 100 °C for thermally pretreated dewatered pig manure. At temperature above 100 °C, most bacteria are killed and hence resulted in a decrease in biogas yield. This shows that at temperatures above 100 °C, thermal pretreatment had no positive influence on the degradability of dewatered pig manure.

Due to limited success achieved in improving biogas production using individual pretreatment methods, two or more pretreatment techniques can be combined with the aim of achieving more efficient conversion of organic matter into biogas [100]. Three different pretreatment techniques mechanical (milling), chemical (addition of NaOH and NH4OH), and biological (fungal addition) were combined by Ali and Sun [101] for treatment of park wastes (fresh and dry leaves) and cow dung substrate before anaerobic digestion. A 2.5% NaOH was mixed together with 2.5% NH4OH for 2 weeks (15 days) then followed by biological treatment through the addition of A. terreus and T. viride. At interval of 7 days, substrate pretreatment was studied from 0 to 70 days. Results showed that 102.6 L/kgVS and 125.9 L/kgVS biogas was produced from untreated and pretreated substrate respectively. Likewise, 61.4 L/kgVS and 79.8 L/kgVS methane were produced from untreated and pretreated substrate respectively. When chemical pretreatment with NaHCO3 was applied to improve the performance of the digestion process of agricultural solid waste and cow manure by Almomani [102]. There was an improvement in the biodegradability of the substrate which subsequently increased the cumulative methane production by 43%. Summary of effect of different pretreatment approaches applied to anaerobic co-digestion of kitchen wastes and animal manure is presented in Table 5.

Thermal, chemical, and thermo-chemical are the commonly used pretreatment methods for animal manure in some past studies [27, 104, 105]. Solubilization of wastes was achieved through all these pretreatment methods. However, hydrolysis and acidogenesis could result into accumulation of ammonia and VFAs due to overstimulation as a result of excessive particle size reduction. Microwave pretreatment increases the risk of organic acid accumulation and process inhibition [3], while autoclave pretreatment may reduce biogas yield if the proteins in the substrate are denatured [106]. Therefore, caution should be taken, and prior investigations must be carried out before the selection of appropriate pretreatment methods for kitchen waste and animal manure before co-digestion.

5 Current trend and recent issue and future prospect of biogas production

According to Mata-Alvarez et al. [36], choosing the best blending or mixing ratio for co-substrates improves methane production. Success of anaerobic co-digestion of different wastes depends on balancing C-N ratio, nutrient contents of the given wastes, increasing buffering capacity of the pH, and right combination of other parameters present in the co-substrate mixture [36, 37]. Recent research initiatives have chosen and tested different mixing/blending ratios during co-digestion of wastes to improve biogas yield. Some researchers mixed/blended different wastes based on their VS ratios, while some used TS ratios [107]. But according to them, mixing wastes based on their volatile and total solids ratios would not give optimal result. Therefore, future researchers should consider the application of optimization techniques such as response surface methodologies (RSM) (simplex-centroid mixture design (SCMD) and central composite design (CCD)); artificial neural networks (ANN); linear programming, and adaptive linear programming to obtain the optimal mixing ratio for co-digestion of kitchen waste and animal manure so as to enhance biogas yield. Furthermore, factors such as reactor design, operating conditions, and substrate characteristics affect biogas yield during AD process and, if not within the optimal range, could cause reduction in biogas yield. Hence, for improvement in biogas yield, there is a need to determine the optimized values of these factors. Some previous researches employed convention technique where a single variable factor will be varied and other factors are kept constant at a given condition. These techniques are laborious and time-consuming and bring about zero interaction between variables. Optimal conditions are very difficult to reach due to lack of interactions between variables when conventional method is employed. Future works should focus on the use of response surface methodology (RSM) and artificial neural network (ANN) to determine influence of different factors and their effects on biogas yield from anaerobic co-digestion of kitchen waste and animal manure.

AD as a mature waste management technology can be employed for kitchen waste and animal manure treatment to produce energy. It has gained recognition in most nations of the world for the past two decades for treatment of agricultural wastes (animal manure or crop residues), municipal solid waste (MSW) and industrial and commercial wastes [108] and is widely practiced due to its simplicity, cost-effectiveness, and environmental friendliness. Biogas from anaerobic digestion comprises mainly 50–70% methane content with high heating value. It can be used to generate power for heating and cooking and as transportation fuel when upgraded. However, distributors and consumers of biogas desire sustainability indices that is related to socio-economic performance. Therefore, it has become highly imperative to establish a capital and operating cost profile in order to determine the viability of the biogas production process from the anaerobic co-digestion of kitchen waste and animal manure economically. This will be very important when developing biogas production technology and also assisting with investment so as to avoid unnecessary expenses. A number of techno-economic assessments have been carried out to evaluate the economic feasibility of biogas production from anaerobic digestion of different wastes. But there is dearth of information on techno-economic assessment of anaerobic co-digestion of kitchen waste and animal manure for biogas production most especially at a full-scale level. Therefore, future researchers should look into the techno-economic assessment of anaerobic co-digestion of kitchen and agricultural wastes. The main research gaps and recent issues are discussed in Table 6.

6 Conclusions

Waste treatment by anaerobic digestion is an effective and promising process for the management of kitchen waste and animal manure and gives quite good methane/biogas yield as shown in a few empirical studies presented. However, there are associated problems of getting a substrate free of contaminants so as to increase its biodegradability and instability of the process due to VFA accumulation due to nutrients imbalance whenever any of them is used as lone substrate. Moreover, there are crucial factors or parameters that influence the overall efficiency of the biogas production technology. Operating and inhibiting parameters that affect biogas production performance of anaerobic co-digestion of kitchen waste and animal manure include pH, temperature, mixing ratio, hydraulic retention time, ammonia, heavy metals, C-N ratio, and VFA just to mention but a few. For maximum biogas production, it is very essential to study the effects of these operating and inhibiting parameters. If any of these parameters exceeds the optimal range values, conditions become unfavorable to methanogens, and the process becomes slow and less efficient. This study reviews effect of different operating and inhibiting parameters on biogas yield from anaerobic co-digestion of kitchen waste and animal manure. Furthermore, suitable pretreatment methods for kitchen waste and animal manure to increase methane content in biogas are also summarized. Despite recent reports on biogas production from co-digestion of kitchen waste and animal manure, many gaps are still left to be investigated. Future investigations should focus on optimization of biogas production from co-digestion of kitchen waste and animal manure using RSM, CCD, ANN, and adaptive linear programming techniques instead of conventional technique. Optimal mixing ratio and operating conditions which will maximize biogas yield without compromising process stability can be achieved through these techniques. Finally, economic feasibility of biogas from co-digestion of kitchen and animal manure should receive major attention too.

Abbreviations

- AD:

-

Anaerobic digestion

- TS:

-

Total solid

- VS:

-

Volatile solid

- TVS:

-

Total volatile solid

- FAO:

-

Food and Agriculture Organization

- VFAs:

-

Volatile fatty acids

- C-N:

-

Carbon nitrogen ratio

- kWh:

-

Kilowatt-hour

- MW:

-

Megawatt

- OLR:

-

Organic loading rate

- COD:

-

Chemical oxygen demand

- KW:

-

Kitchen waste

- CD:

-

Cattle dung

- CM:

-

Cow manure

- FW:

-

Food waste

- MSW:

-

Municipal solid waste

- WS:

-

Wheat straw

- PW:

-

Poultry waste

- RSM:

-

Response surface methodology

- SCMD:

-

Simplex-centroid mixture design

- CCD:

-

Central composite design

- ANN:

-

Artificial neural networks

- HRT :

-

Hydraulic retention time

- TAN:

-

Total ammonia nitrogen

- H+ :

-

Proton

- FA:

-

Free ammonia

- FAN:

-

Free ammonia nitrogen

- LS-AD:

-

Liquid state anaerobic digestion

- SCFAs:

-

Short chain fatty acids

- CSTR:

-

Continuous stirred tank reactor

- kHz:

-

Kilohertz

- MHz:

-

Megahertz

- CL:

-

Chicken litter

References

Ke X, Zhao X, Sun Y, Zhang Y (2013) Study on the kitchen residues and cattle manure anaerobic co-digestion in bench-scale laboratory test. Appl Mech Mater 260-261:621-626. https://doi.org/10.4028/www.scientific.net/AMM.260-261.621

Dąbrowska M, Świętochowski A, Lisowski A (2019) Physicochemical properties and agglomeration parameters of biogas digestate with addition of calcium carbonate. Agron Res 17(4):1568–1576

Mirmohamadsadeghi S, Karimi S, Tabatabaei M, Aghbashlof M (2019) Biogas production from food wastes: a review on recent developments and future perspectives. Bioresource Technology Reports 7:1–10. https://doi.org/10.1016/j.biteb.2019.100202

Majd S, Abdoli M, Karbassi A, Pourzamani H, Rezaee M (2017) Effect of physical and chemical operating parameters on anaerobic digestion of manure and biogas production: a review. Journal of Enviromental and Health and Sustainable Development (JEHSD) 2(1):235–247

Adelekan B, Bamgboye I (2009) Effect of mixing ratio of slurry on biogas productivity of major farm animal waste types. Journal of Applied Biosciences 22:1333–1343

Chiu S, Lo I (2016) Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environ Sci Pollut Res 23:24435–24450

Komilis D, Barrena R, Grando RV, Sanchez A, Font X (2017) A state of the art literature review on anaerobic digestion of food waste: influence operating parameters on methane yield. Rev Environ Sci Biotechnol 16:347–360. https://doi.org/10.1007/s11157-017-9428-z

Wang X, Lu X, Li F, Yang G (2014) Effects of temperature and carbon-nitrogen (C/N) ratio on the performance of anaerobic co-digestion of dairy manure, chicken manure and rice straw: Focusing on ammonia inhibition. PLoS ONE 9(5):1–7. https://doi.org/10.1371/journal.pone.0097265

Ariunbaatar J, Panico A, Esposito G, Pirozzi F, Lens P (2014) Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl Energy 123:143–156. https://doi.org/10.1016/j.apenergy.2014.02.035

Esposito G, Frunzo L, Giordano A, Lotta F, Panico A, Pirozzi F (2012) Anaerobic co-digestion of organic wastes. Rev Environ Sci Biotechnol. https://doi.org/10.1007/s11157-012-9277-8

Kwietniewska E, Tys J (2014) Process characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on microalgal biomass fermentation. Renew Sustain Energy Rev 34:491–500. https://doi.org/10.1016/j.rser.2014.03.041

Kemausuor F, Adaramola M, Morken J (2018) A review of commercial biogas systems and lessons for Africa. Energies 11(2984):1–21. https://doi.org/10.3390/en11112984

Orhorhoro O, Orhorhoro E, Ebunilo O (2016) Analysis of the effect of carbon/nitrogen (C/N) ratio on the performance of biogas yields for non-uniform multiple feed stock availability and composition in Nigeria. IJISET - International Journal of Innovative Science, Engineering & Technology 3(5):119–126

Lee D, Lee S, Bae J, Kang J, Kim K, Rhee S et al (2015) Effect of volatile fatty acid concentration on anaerobic degradation rate from field anaerobic digestion facilities treating food waste leachate in South Korea. J Chem 1-9. https://doi.org/10.1155/2015/640717

Martí I (2008) Study of the effect of process parameters on the thermophilic anaerobic digestion of sewage sludge, evaluation of a thermal sludge pre-treatment and overall energetic assessment. PhD Chemical Engineering, Escola Universitària Politècnica del Medi Ambient, Universitat Autònoma de Barcelona, Bacelonia.

Sendaaza C (2018) Anaerobic digestion of organic waste: a kitchen waste case study. Msc Thesis, The American University, Mechanical Engineering Department, Cairo.

Minale M, Worku T (2014) Anaerobic co-digestion of sanitary wastewater and kitchen solid waste for biogas and fertilizer production under ambient temperature: waste generated from condominium house. Int J Environ Sci Technol 11:509–516

Iqbal S, Rahaman S, Rahman M, Yousuf A (2014) Anaerobic digestion of kitchen waste to produce biogas. Proc Eng 90:657–662. https://doi.org/10.1016/j.proeng.2014.11.787

Alfa M (2013) Comparative study of biogas production from cow dung, chicken droppings and Cymbopogon citratus as alternative Energy sources in Nigeria. Ahmadu Bello University, Department of Water Resources and Enviromental Engineering, Zaria, Nigeria

Zhang T, Liu L, Song Z, Ren G, Feng Y, Han X et al (2013) Biogas production by co-digestion of goat manure with three crop residues. PLoS ONE 8(6):1–7

Mat Saad M, Abdul Rahman N, Mohd Yusoff M (2019) Hydrogen and methane production from co-digestion of food waste and chicken manure. Pol. J. Environ. Stud 28(4):2805–2814. https://doi.org/10.15244/pjoes/83670

Sayara T, Sanchez A (2019) A review on anaerobic digestion of lignocellulosic wastes: pretreatments and operational conditions. Appl Sci 9(4655):1–23

Bharathiraja B, Sudharsana T, Jayamuthunagai T, Praveenkumar R, Chozhavendhan S, Iyyappan J (2018) Biogas production – a review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew Sustain Energy Rev 90:570–582. https://doi.org/10.1016/j.rser.2018.03.093

Baredar P, Suresh S, Kumar A, Krishnakumar P (2016) A review on enhancement of biogas yield by pre-treatment and addition of additives. MATEC Web of Conferences 62:1–5. https://doi.org/10.1051/matecconf/2016620

Quiroga G, Castrillon Y, Fernandez-Nava Y, Maranon E, Negral L, Rodriguez-Iglesias J et al (2014) Effect of ultrasound pre-treatment in the anaerobic co-digestion of cattle manure with food waste and sludge. Biores Technol 154:74–79. https://doi.org/10.1016/j.biortech.2013.11.096

Deepanraj B, Sivasubramanian V, Jayaraj S (2017) Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int J Hydrogen Energy 1-7. https://doi.org/10.1016/j.ijhydene.2017.06.178

Rafique R, Poulsen T, Nizami A-S, Asam Z (2010) Effect of thermal, chemical and thermo-chemical pre-treatments to enhance methane production. Energy 1-6. https://doi.org/10.1016/j.energy.2010.07.011.

Kondusamy D, Kalamdhad A (2014) Pre-treatment and anaerobic digestion of food waste for high rate methane production - a review. Journal of Enviromental Chemical Engineering 2:1821–1830

Jingura R, Matengaifa R (2009) Optimization of biogas production by anaerobic digestion for sustainable energy development in Zimbabwe. Renew Sustain Energy Rev 13:1116–1120. https://doi.org/10.1016/j.rser.2007.06.015

Sandhu S, Kaushal R (2019) Anaerobic digestion of vegetable, fruit and cafeteria wastes with cow dung by chemical pretreatment for biogas production in batch digester. J. Phys.: Conf. Series 1240:1–8. https://doi.org/10.1088/1742-6596/1240/1/012132

Karellas S, Boukis I, Kontopoulos G (2010) Development of an investment decision tool for biogas production from agricultural waste. Renew Sustain Energy Rev 14:1273–1282. https://doi.org/10.1016/j.rser.2009.12.002

Meegoda J, Li B, Patel K, Wang L (2018) A review of the processes, parameters, and optimization of anaerobic digestion. Int J Environ Res Public Health 15(2224):1–16

Pramanik S, Suja F, Porhemmat M, Pramanik B (2019) Performance and kinetic model of a single-stage anaerobic digestion system operated at different successive operating stages for the treatment of food wastes. Processes 7(600):1–16

Goswami R, Chattopadhyay P, Shome A, Banerjee S, Chakraborty A, Mathew A et al (2016) An overview of physico-chemical mechanisms of biogas production by microbial communities: a step towards sustainable waste management. 3 Biotech 6(72):1–12.

Vats N, Khan A, Ahmad K (2020) Options for enhanced anaerobic digestion of waste and biomass— a review. Journal of Biosystems Engineering. https://doi.org/10.1007/s42853-019-00040-y

Mata-Alvarez J, Dosta J, Macé S, Astals S (2011) Codigestion of solid wastes: a review of its uses and perspectives including modeling. Crit Rev Biotechnol 31(2):99–111

Yang Q, Wu B, Yao F, He L, Chen F, Ma Y et al (2019) Biogas production from anaerobic co-digestion of waste activated sludge: co-substrates and influencing parameters. Rev Environ Sci Biotechnol. https://doi.org/10.1007/s11157-019-09515-y

Li R, Chen S, Li X, Lar J, He Y, Zhu B (2009) Anaerobic codigestion of kitchen waste with cattle manure for biogas production. Energy Fuels 23:2225–2228. https://doi.org/10.1021/ef8008772

Eyalarasan K, Tewelde S, Yohannes A, Habteslasie T, Karthikeyan K (2013) Anaerobic co-digestion of cafeteria wastes and cow dung mixtures for biogas production. International Journal of Engineering Research & Technology (IJERT) 2(3):1–6

Nehra M, Sanjeev PH (2016) Effect of different mixtures of kitchen waste and cattle dung on biogas production. International Journal of Engineering Research & Technology (IJERT) 4(03):1–7

Paranjpe A, Saxena S (2015) Co-digestion of MSW, with cow manure and poultry waste: an innovative approach for biogas production. International Journal of Recent Development in Engineering and Technology 4(9):46–48

Li R, Chen S, Li X (2009) Anaerobic co-digestion of kitchen cattle waste and cattle manure for methane production. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 31(20):1848–1856

Morales-Polo C, Clederal-Castro M, Soria B (2018) Reviewing the anaerobic digestion of food waste: from waste generation and anaerobic process to its perspective. Appl Sci 8(1804):1–35

Imeni S (2019) Techno-economic assessment of anaerobic co-digestions of livestock manure with agro-industrial by-products. University of Vic-Central University of Catalonia, Bioscience, Vic, Barcelona, Spain, PhD

Kundu K, Sharma S, Sreekrishnan T (2016) Influence of process parameters on anaerobic digestion microbiome in bioenergy production: towards an improved understanding. Springer Science+Business Media, New York

Zamanzadeh M, Hagen L, Svensson K, Linjordet R, Horn S (2017) Biogas production from food waste via co-digestion and digestion- effects on performance and microbial ecology. Sci Rep 7(17664):1–12. https://doi.org/10.1038/s41598-017-15784-w

Ren H, Mei Z, Fan W, Wang Y, Liu F, Luo T et al (2018) Effects of temperature on the performance of anaerobic co-digestion of vegetable waste and swine manure. Int J Agric & Biol Eng 11(1):218–225

Blasius J, Contrera R, Maintinguer S, Alves de Castro M (2020) Effects of temperature, proportion and organic loading rate on the performance of anaerobic digestion of food waste. Biotechnology Reports 27:1–9. https://doi.org/10.1016/j.btre.2020.e00503

Cioabla A, Ionel I, Dumitrel G, Popescu F (2012) Comparative study on factors affecting anaerobic digestion of agricultural vegetal residues. Biotechnol Biofuels 5(39):1–9

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev 45:540–555

Lohani S, Havukainen J (2018) Factors affecting anaerobic digestion process. In anaerobic digestion. Springer Nature, Singapore.

Zhai N, Zhang T, Yin D, Yang G, Wang X, Ren G et al (2015) Effect of initial pH on anaerobic co-digestion of kitchen waste and cow manure. Waste Manage. https://doi.org/10.1016/j.wasman.2014.12.027

Paramaguru G, Kannan M, Lawrence P (2017) Effect of pH on biogas production through anaerobic digestion of food waste. Journal of Advanced Engineering Research 4(1):59–62

Ojikutu A, Osokoya O (2014) Evaluation of biogas production from food waste.The International Journal of Engineering and science (JES) 3(01):1–7.

Sunny S, Joseph K (2018) Review on factors affecting biogas production. International Journal For Technological Research In Engineering 5(9):3693–3697

Mahanta P, Saha U, Dewan A, Kalita P, Buragohain B (2005) Biogas digester: a discussion on factors affecting biogas production and field investigation of a novel duplex digester. Journal of the Solar Energy Society of India 15(2):1–12

Agyeman F, Tao W (2014) Anaerobic co-digestion of food waste and dairy manure: effects of food waste particle size and organic loading rate. J Environ Manage 133:268–274. https://doi.org/10.1016/j.jenvman.2013.12.016

Babaee A, Shayegan J (2011) Effect of organic loading rates (OLR) on production of methane from anaerobic digestion of vegetables waste. World Renewable Energy Congress. Bioenergy Technology, Linkoping, Sweden. pp. 411–417.

Ray N, Mohanty M, Mohanty R (2013) Anaerobic digestion of kitchen wastes: “biogas production and pretreatment of wastes, a review.” Int J Sci Res Publ 3(11):1–6

Teklehaimanot T (2018) Biogas generation and main factors affecting in the production of biogas: review. International Journal of Advanced Technology and Innovative Research 10(1):22–25

Dennehy C, Lawlor P, McCabe M, Cormican P, Sheahan J, Jiang Y et al (2017) Anaerobic co-digestion of pig manure and food waste; effects on digestate biosafety, dewaterability, and microbial community dynamics. Waste Manage. https://doi.org/10.1016/j.wasman.2017.10.047

Rusin J, Chamradova K, Grycova B (2017) The influence of biomass agitation on biogas and methane production using the high-solids thermophilic anaerobic digestion. Green Process Synth 6:273–279

Rico C, Rico J, Munoz N, Tajero I (2011) Efffect of mixing on biogas production during mesophilic anaerobic digestion of screened dairy manure in a pilot plant. Eng Life Sci 11(5):476–481

Abdullah N, Pandebesie, E (2018) The influence of stiring and cow manure added on biogas production from vegetable waste using anaerobic digester. IOP Conf. Series: Environmental Science. 135:1–7, Bristol, United Kingdom: IOP Publishing Ltd. DOI: https://doi.org/10.1088/1755-1315/135/1/012005.

Ratanatamskul C, Saleart T (2016) Effects of sludge recirculation rate and mixing time on performance of a prototype single-stage anaerobic digester for conversion of food wastes to biogas and energy recovery. EnvironSci Pollut Res 23:7092–7098. https://doi.org/10.1007/s11356-015-4448-0

Aworanti O, Agarry S, Ogunleye O (2017) Biomethanization of cattle manure, pig manure and poultry manure mixture in co-digestion with waste of pineapple fruit and content of chicken-gizzard- Part I: kinetic and thermodynamic modelling studies. The Open Biotechnology Journal 11:36–53

Mousa H, Obaidat A, Khaled H, Alawaneh A, Tarawneh A (2016) Experimental investigation of biogas production from kitchen waste mixed with chicken manure. The Journal of Engineering Research (TJER) 13(2):115–123

Orhorhoro E, Ebunilo P, Sadjere G (2017) Experimental determination of effect of total solid (TS) and volatile solid (VS) on biogas yield. American Journal of Modern Energy 3(6):131–135

Yi J, Dong B, Jin J, Dai X (2014) Effect of increasing total solids contents on anaerobic digestion of food waste under mesophilic conditions: performance and microbial characteristics analysis. PLoS ONE 9(7):1–10

Sathish S, Chandrasekaran M, Solomon G (2017) Effect of total solids and agitation time on biogas yield, using rice husk. Int J Ambient Energy. https://doi.org/10.1080/01430750.2017.1372815

Sun Y, Huang X, Kang Y (2018) Effects of different material total solid on biogas production characteristics. E3S Web of Conferences:1–5. https://doi.org/10.1051/e3sconf/20183802006.

Wang Z, Jiang Y, Wang S, Zhang Y, Hua Y, Hue Z et al (2020) Impact of total solids content on anaerobic co-digestion of pig manure and food waste: insights into shifting of the methanogenic pathway. Waste Manage 114:96–106. https://doi.org/10.1016/j.wasman.2020.06.048

Alemayehu G (2016) Co-digestion of municipal organic wastes with night soil and cow dung for biogas production: a review. Afr J Biotech 15(2):32–44. https://doi.org/10.5897/AJB2015.14705

Rabii A, Aldin S, Dahman Y, Elbeshbishy E (2019) A review on anaerobic co-digestion with a focus on the microbial populations and the effect of multi-stage digester configuration. Energies 12(1106):1–25

Yenigun O, Demirel B (2013) Ammonia inhibition in anaerobic digestion: a review. Process Biochem. https://doi.org/10.1016/j.procbio.2013.04.012

Bonk F, Popp D, Weinrich S, Sträuber H, Kleinsteuber S (2018) Ammonia inhibition of anaerobic volatile fatty acid degrading microbial communities. Front Microbiol 9:1–3

Chen Y, Cheng J, Creamer K (2008) Inhibition of anaerobic digestion process: a review. Biores Technol 99(10):4044–4064

Sheng K, Chen X, Pan J, Kloss R, Wei Y (2013) Effect of ammonia and nitrate on biogas production from food waste via anaerobic digestion. Biosystem Engineering 116:205–212

Calli B, Mertoglu B, Inanc B, Yenigun O (2005) Efffects of high free ammonia concentrations on the performances of anaerobic bioreactors. Process Biochem 40:1285–1292

Akindele A (2016) The Effects of Ammonia on anaerobic digestion of the organic fraction of municipal solid wastes. Master of Applied Science (M.ASc), University of Ottawa, Department of Civil Engineering, Ottawa, Ontario, Canada.

Zeshan KOP, Visvanathan C (2012) Effect of C/N ratio and ammonia-N accumulation in a pilot-scale thermophilic dry anaerobic digester. Biores Technol 113:294–302

Chen Y, Wang W, Xue L, Chen C, Liu G, Zhang R (2016) Effects of ammonia on anaerobic digestion of food waste: process performance and microbial community. Energy Fuels 30:5749–5757

Garcia M, Angenent L (2009) Interaction between temperature and ammonia in mesophilic digestes for animal waste treatment. Water Res 43:2373–2382

Noviadi R, Zairiful CAA (2017) Improvement of carbon-to-nitrogen (c/n) ratio by making cassava leaf silage and its implications in digestibility in goat. Bangl J Vet Med 15(2):127–132

Tanimu M, Mohd Ghazi T, Harun R, Idris A (2014) Effect of carbon to nitrogen ratio of food waste on biogas methane production in a batch mesophilic anaerobic digester. International Journal of Innovative, Management and technology 5(2):116–119

Jos B, Hundagi F, Wisudawati R, Budiyono SS (2018) Study of C/N ratio effect on biogas production of carica solid waste by SS-AD method and LS-AD. MATEC Web of Conferences 156:1–5. https://doi.org/10.1051/matecconf/201815603055

Singh G, Jain V, Singh A (2017) Effect of temperature and other factors on anaerobic digestion process, responsible for biogas production. International Journal of Theoretical and Applied Mechanics 12(3):637–657

Siedlecka E, Kumirska J, Ossowski T, Glamowski P, Gołębiowski M, Gajdus J et al (2008) Determination of volatile fatty acids in environmental aqueous samples. Polish J of Environ Stud 17(3):351–356

Xu Z, Zhao M, Miao H, Huang Z, Gao SR (2014) In situ volatile fatty acids influence biogas generation from kitchen wastes by anaerobic digestion. Biores Technol. https://doi.org/10.1016/jbiortech.2014.04.037

Fernández R, Dinsdale R, Guwy A, Premier G (2015) Critical analysis of methods for the measurement of volatile fatty acids. Crit Rev Enviro Sci Technol 1-26. https://doi.org/10.1080/10643389.2015.1073493.

Rössle W, Pretorius W (2001) A review of characterisation requirements for in-line prefermenters Paper 1: Wastewater characterisation. Water SA 27(3):405–411

Mudhoo A, Kumar S (2013) Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. Int. J. Environ. Sci. Technol. https://doi.org/10.1007/s13762-012-0167-y .

Guo Q, Majeed S, Xu R, Zhang K, Kakade A, Khan A et al (2019) Heavy metals interact with the microbial community and affect biogas production in anaerobic digestion: a review. J Environ Manage 240:266–272

Sahu N, Sharma A, Mishra P et al (2017) Evaluation of biogas production potential of kitchen waste in the presence of spices. Waste Manage. https://doi.org/10.1016/j.wasman.2017.08.045

Souza E, Stamford T, Lima E, Trajano V, Filho J (2005) Antimicrobial effectiveness of spices: an approach for use in food conservation systems. Braz Arch Biol Technol 48(4):549–558

Bensid A, El Abed N, Houicher A, Regenstein J, Ozogul F (2020). Antioxidant and antimicrobial preservatives: properties, mechanism of action and applications in food - a review. Crit Rev Food Sci Nutr 1-17. https://doi.org/10.1080/10408398.2020.1862046.

Gottardi D, Buckvicki D, Prasad S, Tyagi A (2016) Benefit effects of spices in food preservation and safety. Front Microbiol 7:1–20. https://doi.org/10.3389/fmicb.2016.01394

Li P, He C, Li G, Ding P, Lan M, Gao Z et al (2020) Biological pretreatment of corn straw for enhancing degradation efficiency and biogas production. Bioengineered 11(1):251–260. https://doi.org/10.1080/21655979.2020.1733733

Szlachta J, Prask H, Fugol M, Luberanski A (2018) Effect of mechanical pre-treatment of the agricultural substrates on yield of biogas and kinetics of anaerobic digestion. Sustainability 10(3669):1–16. https://doi.org/10.3390/su10103669

Zhang L, Loh C, Zhang J (2018) Enhanced biogas production from anaerobic digestion of solid organic wastes: current status and prospects. Biteb. https://doi.org/10.1016/j.biteb.2018.07.005

Ali S, Sun J (2015) Physico-chemical pretreatment and fungal biotreatment for park wastes and cattle dung for biogas production. Springer Plus 4(712):1–14. https://doi.org/10.1186/s40064-015-1466-9

Almomani F (2020) Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network. Fuel 280(118573). https://doi.org/10.1016/j.fuel.2020.118573.

Ahamed J, Raiyan M, Hossain M, Rahman M, Salam B (2016) Production of biogas from anaerobic digestion of poultry droppings and domestic waste using catalytic effect of silical gel. International Journal of Automotive and Mechanical Engineering (IJAME) 13(2):3503–3517, https://doi.org/10.15282/ijame.13.2.2016.17.0289.