Abstract

Global energy security is a major goal for rapid industrial progress. However, meeting the demand of energy and continuing the pace of industrial growth in future would depend on the sustainable economic development and simultaneously addressing the global climate change concerns. It is, therefore, necessary that alternate energy sources with reduced environmental footprints are discovered and developed on a commercial scale. In this scenario, shale gas could clearly be a “game-changing” resource that could transform the global energy market and contribute significantly to the national energy security of different countries. Various countries are considering the shale gas as a means to strengthen their energy security as well as an opportunity to reduce greenhouse gas emissions. However, the unconventional shale gas is present in low permeable rock formations. The extraction and production of shale gas as an economically profitable venture had so far, been difficult, with only the United States exploiting it at large scale. With the innovations in technology, and continuous improvements and advancements in production techniques such as hydraulic fracturing and horizontal drilling, shale gas is emerging as an attractive futuristic source of energy. The advanced technology has, therefore, made it possible to explore the shale reserves and its commercial extraction safe. Nonetheless, the worldwide development of shale gas-based energy production units would depend on collaboration and cooperation among different countries. The stakeholders having common energy goals can harness this futuristic energy resource after formulating a comprehensive framework that addresses various social, legal, environmental, geophysical, engineering, and technological challenges.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Shale gas

- Unconventional energy

- Fracturing technologies

- Geophysical reservoir characterization

- Environmental challenges

1 Introduction

The natural gas trapped within the pores of sedimentary geological rock formations (known as shale plays) and produced by employing horizontal drilling and hydraulic fracturing technologies is commonly known as shale gas. Shale plays are both source and reservoir for unconventional shale oil or gas or both in combined form. The shale gas is found as adsorbed on the organic matter (kerogen), mostly thermogenic in origin (Löhr et al. 2015). The type of hydrocarbon would depend on the organic matter from which the deposits have been formed, and to the extent of maturation level. It can also be present as the free gas within the fractures or voids naturally found in the rocks. Shale deposits are largely found in fluvial, marine, and lacustrine environs, and are capable of holding a high amount of organic substances such as algae plants and marine organisms, which are cracked to generate hydrocarbons. In contrast, conventional natural gas reservoirs are formed by partial migration of these hydrocarbons below the structural and stratigraphic traps. The natural thermal processes carried over the buried organic substances lead to the maturation of these matters to unconventional oil or gas deposits. The unconventional shale gas, which is predominantly methane, is different from the conventional hydrocarbons with respect to the rock sources from which it is obtained. In addition to dominant methane, small volumes of ethane, propane, and butane can also be present in the shale gas. The structural complexities determining the shale matrices play a role in making these rocks either as seal, or reservoir. The shale gas thus formed is evaluated with respect to certain geological parameters; the important ones are thickness and areal extent of shale rocks, organic matter, thermal processes, mineralogy, natural faults, and adjacent underground water containing formations (Löhr et al. 2015).

The shale rocks are widely spread on the Earth’s surface. The gas obtained from shale rocks is different from the conventional natural gas in the sense that shale formation rocks are dense sedimentary clay stones with low porosity and permeability compared to natural gas formations. Porosity in the shale rocks, in general ranges from 2 to 8%, rarely going beyond 14%, whereas permeability falls in the nanodarcy range (https://www.thomaswhite.com/wp-content/uploads/2012/08/img-shale-gas-the-fuel-for-future.jpg. Accessed on Feb 18, 2018). Due to the low porosity and very low permeability, extraction and production of gas from shale reservoirs is possible only after mechanically stimulating these dense rocks. With the applications of novel drilling and fracturing methods, the commercial production of gas from shale formations has become economically beneficial, thereby ushering an era of gas-based energy demands, that is being regarded as the game changer in the energy market (Shaffer et al. 2013). Since sustainable economic and industrial growth in future would depend on meeting the demand of energy and simultaneously addressing the global climate change concerns, it is necessary that alternate energy sources are discovered and developed on a commercial scale. With improvements in production technology, shale gas is emerging as an attractive future energy resource and by the year 2035, it is estimated to be nearly 90% of the total gas production in the United States of America (US) (Rahm and Riha 2012). As per the report published by The U.S. Energy Information Administration (USEIA), it is estimated that shale gas reserves throughout the world add 47% to the global technically recoverable natural gas resources; with 7299 TCF of shale gas and 345 billion barrels of shale oil in 41 countries (Brittingham et al. 2014). This huge shale deposit has the potential to achieve a drastic reduction in toxic emissions from conventional energy resources. The major countries such as US, China, and EU nations have been embarking on projects to extract the trapped gas from underground reservoirs. The profitable extraction of shale gas, however, depends on effectively addressing the concerns of negative environmental impacts that are associated with the commercial production. The energy policy drafted by a leading European think tank analyzes the possibility of adopting shale gas as a tool to transit into the era of low-carbon emission (Helm 2011).

2 Historical Perspective

As early as nineteenth century, shale gas production was attempted, however because of huge costs involved, the commercial production had to wait till the emergence of hydraulic fracturing techniques that could attain huge production volumes. The United States (US) is the pioneer country to extract shale gas for commercial use. William Hart is regarded as the pioneering person who drilled the first commercial gas well in 1821 in the shale formations located in the state of New York in the US. Floyd Farris and J. B. Clark were the two engineers who initiated the hydraulic fracturing technology in the year 1920 (https://www.thomaswhite.com/wp-content/uploads/2012/08/img-shale-gas-the-fuel-for-future.jpg. Accessed on Feb 18, 2018). The technology soon enabled large-scale gas production, and with further research and improvement, the shale gas field development was initiated in the states of Kentucky, Michigan, Ohio, and Indiana. With an average production ranging from 5 to 6 billion m3 per year, these locations became the primary source of gas by the end of the twentieth century with gas occurring at shallow levels (Fig. 1).

Sedimentary shale rock (https://www.thomaswhite.com/wp-content/uploads/2012/08/img-shale-gas-the-fuel-for-future.jpg. Accessed on Feb 18, 2018)

During the 1940s decade, exploration and extraction were carried out at large scale in America. Hydraulic fracturing technique was employed in the Klepper play in Kansas State, and also in Oklahoma and Texas by several companies, followed by large-scale fracking in the decades to follow. Comprehensive research was also conducted in the subsequent years to enhance the production efficiencies of these plays. The “Eastern Project” conceived by the Energy Research Center (Morgantown) and supported by the US Department of Energy in 1976, conducted investigations on hydraulic fracturing to explore the various unconventional hydrocarbon resources (https://www.thomaswhite.com/wp-content/uploads/2012/08/img-shale-gas-the-fuel-for-future.jpg. Accessed on Feb 18, 2018). The starting of Mitchell Energy & Development Company in the 1980s by George P. Mitchell was a significant milestone in the commercial production of shale gas. The other prominent corporations during that period that were engaged in the exploration and production of shale gas included BP, Royal Dutch Shell, Total, Statoil, Apache, Devon Energy, and Noble Energy. The leader of these corporations was Chesapeake Energy of Oklahoma. The company possessed several plays and was a shareholder in Barnett, Fayetteville, Bossier, Haynesville, and also Marcellus Shales (https://www.thomaswhite.com/wp-content/uploads/2012/08/img-shale-gas-the-fuel-for-future.jpg. Accessed on Feb 18, 2018).

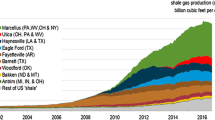

3 Shale Gas Production: Current Status

Various estimates and projections report that in the US the gas is so abundant that it will soon replace the natural gas, and make the US a gas exporter from her current status of fossil fuel importer. There is enough resource in the US that can last for this century. The immediate outcome would be on energy prices globally, with implications on European and Chinese energy supplies. It is estimated that beyond the year 2020, global energy players such as Europe, Russia, and India would also become leading gas producers besides the US. Shale gas is expected to add 7299 trillion cubic feet (TCF) to the global gas deposits by the year 2035 when the consumption would increase threefold. This figure is much higher with respect to the projected 6614 TCF of gas obtainable from conventional reserves. Except for the US which has become self-sufficient in gas production, other countries are dependent on exports to meet their energy needs. This leads to fluctuations in global energy prices. However, many of these countries have their own shale reserves which are at various stages of exploitation, and product development. The US with considerable shale gas reserves is undoubtedly the current global leader with significant impact on gas market prices. In the year 2013, the shale gas made up to 35% of the total natural gas production in the US. The main shale plays (geographic production regions) in the US are located in Barnett, Eagle Ford, Fayetteville, Haynesville, Marcellus, and Woodford (Shaffer et al. 2013; Brittingham et al. 2014). The production from these plays has led to the generation of a large number of jobs and have made huge contributions to the nation’s GDP (Cooper et al. 2016). This has also resulted in the decline of energy prices over the world and turned the country from a gas importer to its exporter. With the falling prices of gas positively impacting the overall economic prospects, the new industrial and investment opportunities came up in the US and significant investments were achieved in chemicals and manufacturing sectors. It is projected that the country would become a leading hub of commodities manufacturing with $72 billion of investment by 2020, and creation of one million jobs by 2025 (Brittingham et al. 2014; Cooper et al. 2016).

In China, a government study estimates that the country has the largest shale gas reserves in the world (Chang et al. 2012). It is projected that the total gas reserves—at 25.08 trillion m3, are nearly 200 times the annual consumption. A large part of China’s shale gas reserves is located in the geographic regions of Sichuan and Tarim (Xinjiang) basins in the southwestern and northwestern China (Chang et al. 2012). The country has set a target of 60 billion m3 of shale gas production by 2020. Once exploited, this gas can drastically reduce the Chinese import burdens and her dependence on coal. In Europe, the rocky geographic region extending from Poland across the planes of Northern Europe, and from under the North Sea to Britain comprises of shale gas reserves (Helm 2011). However, there are some key issues to be resolved before Europe matches to US production level of shale gas. The European regions have not been extensively seismically surveyed with regards to shale gas exploration. Moreover, a complex regulatory framework is required prior to its commercial extraction which can address the issues of land ownership, property rights, resource planning, and utilization of water resources. It is expected that Europe would become a major player in shale gas production beyond 2020 (Helm 2011).

4 Technologies for Shale Gas Production

The most widely used method for shale gas production is hydraulic fracturing which is employed for extracting the gas from shale plays. A combination of several techniques—high volume fracturing, horizontal drilling, and slickwater fracturing using chemicals, which are generally adopted in American shale plays, have made the commercial production viable and profitable. Formation stimulation is another fracturing technique that does not use water-based fracturing fluids. These stimulation techniques use explosives, or foams instead of water. In this section, we briefly discuss the common hydraulic fracturing technique which is predominantly used by major companies over the world.

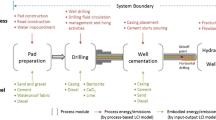

4.1 Hydraulic Fracturing

In this technique, a liquid is employed to fracture the geological rock formations underneath which the gas is trapped. The fracturing fluid is pumped into the borewell at sufficiently high pressure so that the rock gets fractured at the end of the borehole. The pressure should be high enough to overcome the strength of the rock. Water is commonly employed as the pumping liquid, however, gelled crude oil, and gelled kerosene have also been used in the past. With the development of clay stabilizing agents, foams, and gelling agents, water-based aqueous fluids such as brine have become the choice for base fracturing fluid in the vast majority of fracturing operations. In high-temperature wells, gel stabilizers, and cross-linking agents are added to increase the viscosity of aqueous fracturing fluids.

The properties of shale plays vary with respect to their location, exhibiting unique characteristics for each play. This makes imperative to design and develop specific fracture technology for a particular play, which can be achieved by introducing a fracturing fluid into a specific composition suitable with regards to the operational characteristics of the play. Fracturing techniques using slickwater (see Sects. 4.2, 4.3), CO2, N2, or carbon dioxide foam have also been used in the plays across North America. Often a solid material, mainly consisting of sand, or ceramic is added to the fluid. This solid material is known as proppant and it is added to achieve the desired permeability. Slickwater is suitable for brittle rocks, whereas proppant addition is required for ductile reservoirs. Carbon dioxide fluids are also used in place of water to enhance the energy of gas expansion, which reduces the flowback time. In general, the frac fluid is made up of base fluid, additive chemicals, and proppant, with sometimes compressed N2 or CO2 added to enhance its energy to recover the fluid and reduce water consumption. In several places, water is not preferred as a base fluid because, in certain formations, it can be a disadvantage to gas production because of the specific mineral composition in that play. In several plays, the interaction between the rock and water-based fluid softens the rock which leads to embedment of the proppant and its reduced conductivity. In other rocks, excess water from the frac fluid can get trapped in the under-saturated formations because of the capillary retention (Gandossi and Estorff 2015). This phenomenon, known as water blocking, results in the loss of gas production due to the decrease in the gas permeability.

4.2 Hydraulic Fracturing Employing Water as the Base Fluid

Since water-based fluids are dominantly used for hydraulic fracturing, the technique is discussed in detail here. In this technique, water is mixed with friction reducing compounds. The technique called as slickwater fracturing is the widely adopted common method for good stimulation in shale gas production. Water is mixed with silica sand and other chemical additives to enhance the resistance to friction, and bacterial growth. A description of fluid additives is given in Table 1 (Arthur et al. 2008). Water makes to 98% or more in the frac fluid, with an overall concentration of additives in the range 0.5–2% (Fig. 2).

Source U.S. Department of Energy website—https://energy.gov; USDW––Underground source of drinking water

Representation of stimulation of a shale gas reservoir by hydraulic fracturing technique.

4.3 Slickwater Fracturing

Slickwater with low viscosity would form low width fractures. This results in long fractures with complex network and enhanced reservoir-to-wellbore connectivity (Gandossi and Estorff 2015). However, there is some drawback associated with slickwater. This fluid has the problem of settling of proppants, as it is a poor proppant carrier. Therefore, high pumping rates are required to maintain the necessary flow velocities in order to minimize the settling problem. Settling of proppant sand inside the equipment, or pipes may cause termination of fracturing process prematurely, leading to a loss in production. To overcome the problem of proppant settling, linear gel and cross-linked systems are added, however, this can decrease the required fracture complexity. In contrast, the advantages of slickwater fluids include lower damage of gel, higher stimulated reservoir volume, reduced cost with improved fracture containment (Mohanty et al. 2012).

In many cases, polymers are added to enhance fluid viscosity, friction reduction, and improving the properties of linear gels added to the fluid. High viscosity fluids are known as “linear fracturing fluids”. Different types of polymers are added to water. These polymers are in dry powdered form. When these are added to water they get swelled producing a viscous gel. The rationale for forming the gel is to enhance the transport properties of proppant carrying frac fluid. Guar, hydroxypropyl guar, hydroxyethyl cellulose, carboxymethyl hydroxypropyl guar, and carboxymethyl hydroxyethyl cellulose are some common polymers used for gel formation (NSCEP 2004). Linear gels form thick filter cakes over the lower permeability rocks and are very effective in controlling the fluid loss. However, these gels are ineffective in high permeable rocks. To improve the overall fracturing performance cross-linked fluids are employed. Borate ions are used to crosslink the hydrated polymers. Such fluids have shown considerably improved performances in low, as well as high permeable shale formations, exhibiting high proppant transport, stable fluid rheology at high temperatures (300 °F), reduced loss of fluid, and improved cleanup (Gandossi and Estorff 2015).

4.4 Fracturing Using Viscoelastic Surfactant Gel Fluids

In viscoelastic surfactant (VES) gel fluids, surfactants are added and mixed with inorganic salts, to offer improved viscosity, proppant transport, and elasticity. The VES technology is further classified into sub-categories—worm-like micelles, lamellar structures or vesicles depending on the structure formed in the system (Gandossi and Estorff 2015). Micelles are formed in the fluid with the increase in surfactant concentrations in water. These micelles interact with each other because of the ionic forces. The ionic forces can further be increased with the addition of electrolytes or other salts and surfactants. Biocides, as well as additional clay control compounds and flow back surfactants, are not required in the VES technology.

Several new fracturing technologies such as zipper fracturing, cavitation hydro-vibration fracturing, hydra-jet fracturing, exothermic hydraulic fracturing, hydraulic fracturing enhanced by water pressure blasting have also been developed and described elsewhere (Gandossi and Estorff 2015; Yu and Sepehrnoori 2013; East LE Jr et al. 2004; Al-Nakhli et al. 2013; Huang et al. 2011).

5 Geophysical Characteristics of Shale Plays

The geophysical characterization of shale gas resource plays is quite different from the conventional reservoir characterization (Chopra et al. 2012). Shale gas formations are both the source rocks and reservoir rocks, and, therefore, migration is not necessary. Due to nearly zero permeability, it forms its own seal. In general, the shale gas is trapped in the form of free gas in natural fractures and intergranular porosity, in the form of sorbed gas into kerogen and clay particle surfaces, or in the form of dissolved gases in kerogen and bitumen (Curtis 2002). However, in the conventional reservoir, there exists a trap where the hydrocarbons are migrated but they develop at a different place. On the contrary, shale gas plays cover larger areas and contain varying amounts of hydrocarbons throughout that area. This is the reason that shale gas reservoirs require wider characterization (Duey 2012).

In order to map the geological surfaces and seismic stratigraphic relationships, and major faults and subtle structural trends, standard or conventional geophysical workflows continue to be significant in unconventional plays as well. The shale gas reservoir characterization workflows follow the similar methodology, for example, poststack attributes, such as coherence and curvature, are being successfully applied for mapping discontinuities and structural trends that may impact drilling, completion, or production (Close et al. 2012). Seismic is not only used as a tool for mapping structures in shale gas and unconventional plays. Its functioning has evolved far more than that. This is the only remotely sensed predrill data available, therefore 3D seismic data can be utilized in the planning of well sites by locating the intersect zones or “sweet spots” that are expected to have good gas storage. A well-defined well location allows optimal stimulation (i.e., the appropriate combination of lithological compressibility and rigidity, and an absence of major barriers to stimulated fracture propagation) (Close et al. 2012).

Well, logs contribute significantly to shale gas production since it links geology, geophysics, and petroleum engineering. Well, logs are utilized in the exploration phase for the identification of lithology, mineral types and compositions, total organic carbon (TOC), porosity, permeability, gas content, and the potential resources quantity. However, in the development stage, well logs data are used to calculate various parameters of geological and engineering purposes for horizontal drilling and production. These are used in hydraulic fracturing stimulation by estimation of the mechanical properties and determining the orientation and magnitude of the in-situ stress (Zhang et al. 2015).

The logging curves belonging to shale gas reservoirs indicate “three high and two low” phenomenon (Deng and Wang 2015). Acoustic wave and resistivity cross-plot method is the key technique for evaluation of shale gas by the application of logging curve combination technique. Due to the presence of rich hydrocarbons, dual laterolog resistivity logging of shale gas shows a low value. Higher values are indicated in acoustic time curve for shale gas. Acoustic time for shale is between sandstone and mudstone. In the presence of cracks and rich organic matter, the acoustic time curve shows even higher values. Natural gamma-ray and neutron porosity logs show high value for shale. The presence of organic matter enhances the radioactivity, which is indicated as high values in gamma-ray log curve. Furthermore, the shale consists of huge amount of clay shale, high irreducible water saturation, rich kerogen and natural gas as indicated in neutron porosity log. The density log curve indicates a low value for shale gas, however, in presence of cracks and rich organic matter the density log values are even smaller. The shale density is higher than coal and lower than sandstone.

The productivity of shale gas reservoir depends on the organic richness (TOC), maturation (R0%), thickness, gas-in-place, permeability, mineralogy, brittleness, and pore pressure of shale gas reservoirs (Chopra et al. 2012). Along with this the depth of the shale gas formation also plays a significant role as it will influence the economics of the gas recovery.

The core analyses for some reservoirs indicate a different correlation of TOC for silica-rich and clay-rich rocks. In such situations, two probable interpretations are being considered. For silica-rich rocks, TOC indicates a positive correlation with quartz content and a negative correlation with clay content. On the contrary, clay-rich rocks have a poor and negative correlation with clay and quartz contents, but positive correlation with calcite content (Zhu et al. 2011). Sample analysis results are used to predict the level of maturity (LOM) by computing the vitrinite reflectance (R0%). The LOM values vary from 6 or 7 to 12 depending on the type of organic matter. The reservoirs having LOM values close to 7 indicates the onset of maturity for an oil-prone kerogen and 12 points toward the onset of overmaturity for oil-prone kerogen.

6 Challenges and Issues

This is fundamentally important that a new energy resource should be environmentally clean, affordable, safe, and should be competitive in the market. Shale gas is projected to be the dream fuel of the future. Such debates have been carried out to discuss the sustainability criterion that is necessary for the shale gas to qualify as a futuristic clean source of energy. The development of new engineering methods for extraction has significantly reduced the production costs. The gas extraction has been made possible by applying sophisticated seismic mapping techniques to locate the gas spots, precisely followed by horizontal drilling and fracking process. During the fracking process, a huge amount of fresh water and toxic chemicals are required leading to depletion of water resources, and generation of wastewater. Other problems include leakage of methane from the underground rocks and adverse effects on the drinking water table. Shale gas is, however, regarded as a benign energy source compared to the currently dominant coal-based power plants. Coal exploitation is energy intensive and is associated with larger toxic emissions such as methane, ash, SOx, and NOx. The thermal efficiency of coal-fired power plants is low, require huge capital expenditure in mining and transportation of coal, and the loss of energy during transmission is high (Cooper et al. 2016). The huge shale gas deposits worldwide offer a vast opportunity to tap this resource to the benefit of society. The exploration and extraction techniques for producing shale gas should, therefore, be developed in such a way so that the risks associated with conventional energy resources can be minimized.

6.1 Water Management Issues

Production of shale is associated with a large number of threats to the environment because a huge amount of nearby fresh water is required for fracturing the shale to allow hydrocarbons reach the surface. A study conducted by World Resources Institute (WRI) in several countries estimated that nearly 38% of the area of shale reserves is located in arid regions, with 386 million people inhabiting these regions (Reig et al. 2014). The report further states that 19% reserves are located in areas of high or extremely high seasonal variability. Nearly 15% areas of shale reserves are exposed to high or extremely high drought severity. The major environmental and social challenges would be crucial in framing policies for the commercial production of shale gas. Moreover, the limited freshwater availability for shale gas production would also have to compete with the irrigational, municipal, and industrial demands in many countries. Variations in hydrological conditions with respect to spatial and seasonal changes across shale plays, or within plays, occur throughout the year and can lead to uncertainties in predicting the demand for freshwater for hydraulic fracturing and drilling (Reig et al. 2014). These uncertainties can adversely affect the business of the companies. Public concerns and stress on freshwater resources can also threaten a company’s social license to operate. Furthermore, because of social and environmental impacts government regulations can change thereby affecting the short- and long-term investments.

Shale gas production leads to the generation of high salinity water that comes to the surface from the underground formations. Flowback water from the hydraulic fracturing, as well as the formation water, comprise the waste stream of water called as produced water (Shaffer et al. 2013). Flowback water generally returns during the initial weeks of fracturing whereas formation water is continuously obtained during a well’s lifetime. Approximately 8000–15,000 m3 of water may be consumed during drilling and fracturing of a shale gas well, e.g., as per historical data, median water use during good development in Texas region of US can range over 11,000–22,000 m3, whereas in Marcellus shale region this can range over 8000–27,000 m3. There are many factors which govern the management of water during good development. Depending on the volume and water quality, legal framework of the region, geological characteristics of shale play, and the availability of resources the management of water can be carried out. In the US where large-scale production of shale gas has been achieved, currently, a huge amount (~98%) of produced water is injected underground. This is done in order to maintain pressure within the geological formations. Small portions (of higher quality) are also discharged to surface water sources, for livestock watering, and for irrigating the farmlands. More recently, this water can be cleaned and employed for reuse in the good development.

The quality of produced water during good development is very poor. For carrying out hydraulic fracturing of shale formations, a fracturing fluid is prepared by mixing water with certain chemicals, and sand. The chemicals used in this fluid are highly toxic and corrosive (see Sect. 4). Moreover, certain bacterial killing compounds are also added to the fluid which is highly hazardous and is a concern from the perspective of public health. If the shale plays are located near to drinking water sources, or if the produced water is disposed of without proper treatment, there is a likelihood of contamination of water sources meant for public consumption. Conventional wastewater treatment plants are inadequately equipped to control a number of toxic compounds such as bromides, naturally occurring radionuclides (NORMs), biocides (glutaraldehyde and quaternary ammonium chloride), etc., contained in produced water. In such plants, various chemical treatment agents can unwantedly react with dissolved impurities resulting in the formation of undesirable byproducts. Besides huge chemical doses can lead to overloading of these plants and finally to the improper quality of treated water. The discharge of such water to natural streams can adversely affect the marine ecosystem, and increase the toxicity levels of natural water. Moreover, during hydraulic fracturing, the fracturing fluid can leak through fissures and find a way to the underground water reservoirs, or surface water. The chances of surface water contamination through this route are very low because the shale plays are located very deep.

6.2 Geotechnical Issues

Shale plays and reservoirs can often be located close to groundwater aquifers. Hazardous chemicals are used during fracture stimulation which can contaminate the aquifer water (Cooke 2012). Methane can seep into groundwater sources through leaks in the fracture-stimulated wells. It can also leak through fugitive emissions from flowback water, or through equipment and pipeline leakages. There can also be natural thermogenic emissions of methane from the hydrocarbon sources across faults within the earth. There are other issues of induced seismicity—because of the injection of huge amounts of fracturing fluid. The high water volumes penetrating near “critical fault”, can cause the fault to slip thereby resulting in an earthquake. The injected water should be flowed backward from the fractures prior to the occurring of gas flow. The flowback fracturing water dissolved may be contaminated with methane and salts, as well as traces of radioactive substances. This water needs to be disposed of as per existing environmental regulations. Another geological issue pertains to tectonic stresses. Several shale plays exist in regions known for extensional tectonic stresses (Cooke 2012). This can affect the development of shale wells because a higher level of stresses adversely impacts the stimulated reservoir volumes resulting in high costs of well. Various geological parameters and techniques of drilling and fracturing should be evaluated by the exploration groups in the regions of shale formations.

6.3 Environmental Issues

Since the year 2009, many environmental impact studies have been conducted to assess the direct impact of hydraulic fracturing. Shale gas (a source for electricity generation) is considered as an attractive replacement for coal-based power plants with expected reductions in greenhouse gas (GHG) emissions. The coal-fired power plants generated 1514 TWh electricity in the year 2012 in the US, which is significantly lesser compared to 2016 TWh generated in 2007. In the same period, gas-based generation rose from 897 to 1226 TWh which included power generated from shale gas as well as natural gas, with CO2 emissions during electricity production decreasing to 2029 Mt from 2426 Mt (Stamford and Azapagic 2014). Researchers generally agree on the lower life cycle GHG emissions and related effects on climate for shale gas electricity, compared to coal-fired power plants (Cooper et al. 2016). Global warming potential, which is an indicator of climate change impact, has been reported in the range 412–1102 g CO2 eq. per kWh in different studies, for shale gas-based electricity generation. The same value of the potential for coal-based electricity generation has been reported in the range 837–1130 g CO2 eq. per kWh (MacKay and Stone 2013).

Methane emission is a potential threat that can increase the climate impact of shale gas. Fugitive emissions of methane occur during shale gas production. The sources of methane can be leakage from various production machinery and equipment, pipelines, and produced water, as well as venting of the gas during the gas development process. Methane is regarded as a menace during shale gas production because as per some studies, emissions nearing to 12% of total gas produced can nullify the benefits obtainable from shale gas compared to coal (Howarth et al. 2011). There are, however, certain mitigation strategies that can be employed to reduce methane emissions. The fugitive methane gas can be separated from wastewater without it being vented away for further use. Leakages can be located by the use of sophisticated cameras (BP p.l.c 2012).

Besides methane, there are several other emissions associated with shale gas production. These pollutants include NOx, few hydrocarbons, and other volatile organics. Some fine silica particles are also released in the atmosphere. One of the major hazardous gases released is hydrogen sulfide (H2S). The corrosive H2S can corrode equipment and pipelines and is also a potential threat to human health. It is speculated that chemicals used in the fracturing fluid, and activity of some microorganisms in the formations could be the possible reason behind the H2S release. Another environmental problem that has been identified during shale gas extraction relates to photochemical oxidants creation potential (POCP). This problem of photochemical smog, is primarily the result of VOC emissions, either during the sweetening process or from equipment. This drastically reduces the environmental benefits of using shale gas as it can possibly be 98 times worse than natural gas and 18 times worse than the coal power in the extreme scenario (Cooper et al. 2016).

During the gas development process, large chunks of land covered with natural vegetation are subjected to a land-use change which can increase the climate change impact of shale gas (Bond et al. 2014). As per an estimate, the development of shale gas production units on grassland can release 1.21 g CO2 eq. per MJ of gas, compared to 13.41 g CO2 eq. per MJ emissions from developments on peat soil (Cooper et al. 2016). Moreover, the huge amount of land area is required to establish a production unit which may lead to the possible destruction of natural forests, and adversely affecting the local ecosystem.

7 Conclusion

Shale gas as an alternative energy resource can have useful effects on the national economy with regards to benefits for industries, and generation of employment. This can lead to the development of fracturing and stimulating technologies, which, however, require huge capital inflow and technical know-how. It is imperative that the governments invest high expenditures on research prior to commercializing the extraction of shale gas and establishing it as an unconventional resource that is economically viable with profitable revenue earnings. The major environmental challenges have to be addressed before commissioning of production. However, other conventional energy resources such as coal, and oil are also associated with the issues of ecological contamination, air pollution, and seismic effects, and therefore environmental impacts of shale gas exploration and extraction have to be evaluated with respect to existing conventional energy production methods. The national government would be required to frame detailed and comprehensive policy and regulatory structure to address the various challenges.

Shale gas is an abundantly available energy resource with huge potential benefits for future energy security goals, but the diverse nature of the geography and geology of shale sources, as well as different energy needs of various countries, make it difficult to formulate a standard worldwide policy framework. However, considering the potential benefits of the unconventional resource and its positive effects on global energy security, proper collaboration and cooperation between countries as well as other stakeholders, such as industries, academic research groups, local inhabitants, and environmental groups can lead to the development of long-term standard procedures that can be implemented in different countries. The key to successful establishment of shale gas as a viable and futuristic energy resource would depend on international collaboration which is required to implement a comprehensive strategy for creating research and development infrastructure, addressing geophysical, and engineering issues for developing sustainable and cost-effective extraction technologies, as well as meeting the various social and environmental challenges in order to ensure unhindered long-term energy production.

References

Al-Nakhli AR, Abass HH, Al-Ajwad HA, Kwak HT, Al-Harith AM, Al-Otaibi A (2013) Unconventional gas stimulation by creating synthetic sweetspot. In: SPE unconventional gas conference and exhibition. Society of Petroleum Engineers, Muscat, Oman

Arthur JD, Bohm B, Coughlin BJ, Layne M (2008) Hydraulic fracturing considerations for natural gas wells of the fayetteville shale. In ALL Consulting: Tulsa, OK, US. https://steinlevy.com/files/20120606155241-NYLJ%20Reprint.pdf. Accessed on 18th Feb 2018

Bond CE, Roberts J, Hastings A, Shipton ZK, João EM, Kyzy JT, Stephenson M (2014) Life-cycle assessment of greenhouse gas emissions from unconventional gas in Scotland. ClimateXChange, Glasgow, Scotland, UK

BP p.l.c (2012) Unconventional gas and hydraulic fracturing: issue briefing. BP p.l.c., London

Brittingham MC, Maloney KO, Farag AM, Harper DD, Bowen ZH (2014) Ecological risks of shale oil and gas development to wildlife, aquatic resources and their habitats. Environ Sci Policy 48:11034–11047

Chang Y, Liu X, Christie P (2012) Emerging shale gas revolution in China. Environ Sci Technol 46:12281–12282

Chopra S, Sharma RK, Keay J, Marfurt KJ (2012) Shale gas reservoir characterization workflows. In: SEG Las Vegas 2012 annual meeting, Las Vegas, US

Close D, Perez M, Goodway B, Purdue G (2012) Integrated workflows for shale gas and case study results for the Horn River basin, British Columbia, Canada. Lead Edge 31(5):556–569

Cooke D (2012) A brief review of geoscience issues associated with shale gas development in Australia. University of Adelaide/Australian School of Petroleum, and ZDAC Geophysical Technologies, Australia

Cooper J, Stamford L, Azapagic A (2016) Shale gas: a review of the economic, environmental, and social sustainability. Energy Technol 4:772–792

Curtis JB (2002) Fractured shale gas systems. AAPG Bull 86:1921–1938

Deng X, Wang X (2015) Research status of shale gas evaluation methods. IOSRJEN 5(6):52–54

Duey R (2012) Geophysics has a role in shale plays. In: Center for wave phenomena. Department of Geophysics, Colorado School of Mines, Colorado, US

East LE Jr, Grieser W, McDaniel BW, Johnson B, Jackson R, Fisher K (2004) Successful application of hydrajet fracturing on horizontal wells completed in a thick shale reservoir. In: SPE eastern regional meeting. Society of Petroleum Engineers, Charleston, West Virginia

Gandossi L, Estorff UV (2015) An overview of hydraulic fracturing and other formation stimulation technologies for shale gas production. Joint Research Centre: European Union

Helm D (2011) Shale gas and the low carbon transition in Europe. demosEUROPA–Centre for European Strategy: Warsaw, Poland

Howarth RW, Santoro R, Ingraffea A (2011) Methane and the greenhouse-gas footprint of natural gas from shale formations. Clim Change 106:679–690

https://www.thomaswhite.com/wp-content/uploads/2012/08/img-shale-gas-the-fuel-for-future.jpg. Accessed on 18th Feb 2018

Huang B, Liu C, Fu J, Guan H (2011) Hydraulic fracturing after water pressure control blasting for increased fracturing. Int J Rock Mech Min Sci 48(6):976–983

Löhr SC, Baruch ET, Hall PA, Kennedy MJ (2015) Is organic pore development in gas shales influenced by the primary porosity and structure of thermally immature organic matter? Org Geochem 87:119–132

MacKay DJC, Stone TJ (2013) Potential greenhouse gas emissions associated with shale gas extraction and use. In: Department of energy & climate change, G. O. UK., Ed. London

Mohanty KK, Gaurav A, Gu M (2012) Improvement of fracturing for gas shales 07122-38 FINAL, Austin, Texas

NSCEP (2004) Evaluation of impacts to underground sources of drinking water by hydraulic fracturing of coaled methane reservoirs. In: N. S. C. f. E. P., Ed. United States Environmental Protection Agency, Washington, DC

Rahm BG, Riha SJ (2012) Toward strategic management of shale gas development: Regional, collective impacts on water resources. Environ Sci Policy 17:12–23

Reig P, Luo T, Proctor JN (2014) Global shale gas development: water availability and business risks. Washington, DC, USA

Shaffer DL, Chavez LHA, Ben-Sasson M, Castrillón SR-V, Yip NY, Elimelech M (2013) Desalination and reuse of high-salinity shale gas produced water: drivers, technologies, and future directions. Environ Sci Technol 47:9569–9583

Stamford L, Azapagic A (2014) Life cycle environmental impacts of UK shale gas. Appl Energy 134:506–518

Yu W, Sepehrnoori K (2013) Optimization of multiple hydraulically fractured horizontal wells in unconventional gas reservoirs. J Pet Eng 1–16

Zhang Y, Jin S, Jiang H, Wang Y, Jia P (2015) Review of well logs and petrophysical approaches for shale gas in Sichuan Basin, China. Open Pet Eng J 8(Suppl 1: M9):316–324

Zhu Y, Liu E, Martinez A, Payne MA, Harris CE (2011) Understanding geophysical responses of shale-gas plays. Lead Edge 30(3):332–338

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Agrahari, G.K., Agrahari, S. (2018). Shale Gas: A Futuristic Non-conventional Energy Resource. In: Sharma, A., Shukla, A., Aye, L. (eds) Low Carbon Energy Supply. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-10-7326-7_19

Download citation

DOI: https://doi.org/10.1007/978-981-10-7326-7_19

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7325-0

Online ISBN: 978-981-10-7326-7

eBook Packages: EnergyEnergy (R0)