Abstract

Ethanol fuel is leading the transition towards a post-petrol era in the transport sector worldwide. Ethanol is produced via sugar fermentation processes by yeasts or bacteria. Although the current industrial production of ethanol mainly involves the use of starch- and sugar-based feedstocks, lignocellulosic biomass is expected to play a key role as renewable, carbohydrate-rich raw material. With the aim of placing lignocellulosic ethanol into the market, the scientific community has made great efforts to develop and implement efficient conversion technologies. Prior to fermentation, lignocellulosic biomass must be pretreated and hydrolysed to obtain the fermentable sugars. Biomass processing is, however, a major limiting step since it is hindered by the native structure of lignocellulose and generates different biomass-derived compounds that are inhibitors of the subsequent microbial conversion. In this context, different pretreatment, delignification and detoxification methods have been investigated to produce less inhibitory pretreated materials. Furthermore, several strategies such as working at high gravity conditions, high temperatures and/or different process configurations, have been shown to maximize ethanol production from lignocellulosic materials. The development of robust microbial strains tolerant to inhibitory compounds and capable of converting sugar mixtures is also needed for cost-effectiveness of the process. This chapter compiles recent advances in lignocellulosic ethanol production processes, from novel raw materials or fermenting microorganisms to new processing technologies addressed to commercialization.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Pretreatment

- Lignocellulosic ethanol

- Enzymatic hydrolysis

- Detoxification

- Delignification

- Sugar fermentation

- Process integration

- Microbial robustness

1 Introduction

The implementation of a sustainable bio-based economy is considered a priority in today’s society. To reach such a goal, lignocellulosic biomass – the major renewable organic matter in nature – has been recognized as a valuable raw material for the production of biofuels and several chemical building blocks within the biorefinery concept. Among lignocellulosic biofuels , bioalcohols are very attractive and promising alternatives for the transport sector, as they can share current fuel distribution systems and are easily stored and handled, in comparison to biogas and biodiesel [1].

With a long history, ethanol is the most widespread alcohol fuel . It has a low boiling point (78 °C), a high research octane number (RON ; 107) and its energy content is comparable to that of gasoline (two thirds of the gasoline energy content) [1, 2]. Direct use of ethanol as fuel is possible in neat form (100% pure) or in blends with gasoline (e.g. E85: 85% ethanol and 15% gasoline ). Ethanol can be converted to ethyl tert-butyl ether (ETBE ), which is used as fuel additive.

Traditionally, bioethanol has been produced from sugar - and starch -based feedstocks such as sugarcane juice and molasses , and corn. Since January 2013, bioethanol also started to be produced from lignocellulosic feedstocks at commercial scale [3]. However, current prices for lignocellulosic ethanol are 0.57–1.20 USD/L, while conventional ethanol cost about 0.40–0.45 USD/L [4, 5]. To ensure a competitive lignocellulosic industry, some challenges both in biomass processing (such as having a good balance between biomass hydrolysability and biomass degradation ) and microbial conversion processes (including the increase of the tolerance of fermenting microorganism to lignocellulose -derived compounds and the conversion of all lignocellulosic sugars into ethanol with high rates and yields ) still need to be addressed. The present chapter reviews the current advances for a cost-effective lignocellulosic bioethanol production , from the use of novel raw materials and the development of new pretreatment technologies , to the investigation and engineering of fermentative microorganisms.

1.1 Lignocellulosic Bioethanol : A Process Overview

Ethanol production is based on sugar fermentation processes. With about 75% carbohydrate content on dry weight basis, lignocellulose represents an interesting feedstock for ethanol production [6]. However, in contrast to conventional bioethanol production technology, lignocellulosic ethanol production is very challenging due to the highly recalcitrant structure of lignocellulose . Lignocellulosic biomass is composed of three polymers : cellulose, hemicelluloses and lignin . The structural polymer , cellulose, is bonded with both hemicelluloses and lignin , forming a difficult to disrupt complex matrix .

Lignocellulosic ethanol production consists of pretreatment, enzymatic hydrolysis and fermentation steps. Pretreatment is needed to alter the structural characteristics of lignocellulose and increase the accessibility of cellulose and hemicelluloses to hydrolytic enzymes that are responsible for the hydrolysis of polysaccharides into fermentable sugars . Pretreatment is an important process since it has a great impact on final conversion yields and contributes to 30–40% to the overall process costs [7]. As it is further discussed in Sect. 12.3, there is no best pretreatment technology although dilute-acid pretreatment, steam explosion or certain ammonia-based technologies are effective methods that can be applied to a wide range of lignocellulosic feedstocks [8,9,10]. In pretreatment, high temperatures and pressures and/or the addition of solvents and chemical catalysts are required, which leads to biomass degradation , generating different enzymatic and microbial inhibitors that limit the subsequent saccharification and fermentation steps [11, 12]. Different physical , chemical, and biological detoxification methods have been evaluated with the aim of decreasing the inhibitory power of pretreated materials. Another important limiting factor is the residual lignin , which can unspecifically bind hydrolytic enzymes , decreasing saccharification yields . In a similar way to detoxification methods, different biological and chemical delignification processes have been also studied as complementary steps to enhance saccarification yields .

Considering the steps required for lignocellulosic ethanol production , different process configurations can be proposed as depicted in Fig. 12.1. There are three main process configurations, which are explained in detail in Sect. 12.4: separate hydrolysis and fermentation (SHF ), simultaneous saccharification and (co)fermentation (SSF /SSCF) and consolidated bioprocessing (CBP ) [13]. In these processes, different yeast, bacterial or fungi strains have been used for ethanol production as discussed in Sect. 12.5. However, microbial conversion processes are highly dependent on the composition of pretreated materials. The use and development of more robust fermentative microorganisms is therefore of the utmost importance and represents an interesting alternative to the aforementioned detoxification methods. Several metabolic and evolutionary engineering strategies have been used to obtain fermentative strains with increased capacity to convert and/or tolerate high concentrations of inhibitory compounds [14,15,16]. The ability of tolerating high temperatures and osmotic pressures , and converting the full range of sugars present in lignocellulosic feedstocks are important traits to take into consideration [17].

2 Novel Promising Lignocellulosic Feedstocks

Lignocellulosic biomass has an estimated annual production of more than 1010 MT worldwide [18]. The most commonly used lignocellulosic sources include forestry woody feedstocks (spruce , eucalyptus , birch, etc.) and agricultural residues (cereal straw , sugarcane bagasse , corn stover , etc.). However, materials such as energy crops (poplar , switch grass, giant reed , elephantgrass, Miscanthus giganteus, etc.), industrial residues (brews’ spent grains, paper mill residues, cheese whey, etc.), municipal solid wastes and marine algae ( Saccharina latissima , Laminaria sp. , Gracilaria sp., etc.) are considered attractive alternatives with high potential for biofuel production [19,20,21].

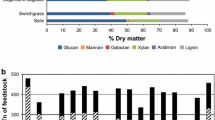

From the chemical point of view, lignocellulose is a highly heterogeneous material. Glucose , xylose , mannose or arabinose are the main sugar units in cellulose and hemicelluloses , while lignin is formed by guaiacyl, syringyl and p-hydroxyphenyl phenylpropanoid units. As no other class of material in nature, such a versatile composition of lignocellulose offers the possibility of its revalorization into a wide range of products with tremendous applicability.

The specific composition of the plant cell wall and its components varies depending on plant species, tissue type, and developmental state of the tissue [22]. Altering the qualitative traits of lignocellulosic biomass, including reducing recalcitrance to degradation or optimizing sugar composition for better fermentability is highly desired for optimal biofuel production . Specific genetic engineering approaches such as (1) reducing/altering the lignin polymer , (2) lowering the endogenous components that exert an inhibitory action on enzymes and fermentative microorganisms, and (3) increasing the abundance of sugars that are easily fermentable , have been investigated in several plants with the aim of enhancing the conversion of lignocellulose into biofuel [23].

Modifying the amount of lignin and its composition is one of the preferred approaches for reducing biomass recalcitrance . Yang et al. [24] were able to reduce about 20% lignin content in Arabidopsis thaliana by exchanging the promoter responsible for the expression of the cinnamate 4-hydroxylase with a vessel-specific promoter, without compromising plant cell growth. On the other hand, Wilkerson et al. [25] incorporated a feruloyl-CoA monolignol transferase in poplar for introducing monolignol ferulate esters that are more label towards a mild alkaline pretreatment .

Lignocellulose is also composed of acetyl esters, methyl esters and ethers. These groups of compounds act as inhibitors for the fermentation and enzymatic hydrolysis steps once they are released from biomass [11, 12]. Decreasing the concentration of those compounds in plant cell walls is therefore beneficial for the conversion of pretreated materials. For instance, the acetyl content or ferulate esters in biomass can be reduced by genetically interfering with the synthesis of the acetylated polysaccharides or reducing feruloylation, respectively [26, 27].

Another crucial engineering strategy that is being considered to enhance biomass conversion is to alter pentose content in lignocellulose . Pentoses such as xylose are fermented with lower efficiencies than hexoses . Thus, increasing the hexose:pentose ratio in raw materials would be of interest. Adjusting carbon partitioning from cell primary metabolism to wall glucan biosynthesis has been successful in poplar by the overexpression of a sucrose synthase [28]. Also, engineering glycan synthases and glycosyltransferases (which are directly involved in wall polymer synthesis) is a promising option. However, attempts to increase cellulose accumulation by overexpressing the multiple transmembrane spanning protein CesA in poplar results in a reduction of cellulose content instead [29].

Algal biomass is also considered a very interesting alternative since they do not require arable lands and can use seawater and wastewater instead of synthetic media [30]. In contrast, the low carbohydrate content and its complex composition (alginate, laminarin), and the low biomass density hamper its conversion into ethanol and makes imperative the discovery of new hydrolytic enzymes and fermenting microorganisms.

To make lignocellulosic biomass a suitable raw material for biofuel production , new engineering strategies and techno-economical modeling must be devised for genetically modifying plants/algae and obtaining the desired structural and chemical properties.

3 Important Aspects and Limitations of Biomass Processing

Different technologies have been evaluated for lignocellulose -to-ethanol conversion, with the biochemical platform being the most advantageous for scale-up [19]. However, biochemical processes are hindered by the high recalcitrant structure of lignocellulosic biomass that limits the accessibility of cellulose and hemicelluloses to the hydrolytic enzymes and prevent the release of sugars.

Pretreatment of biomass is essential to alter its composition and structure so that efficient and rapid enzymatic hydrolysis of carbohydrates can occur [31]. Since different lignocellulosic materials have different physicochemical characteristics, it is necessary to adopt suitable pretreatment technologies based on the properties of each raw material.

Another critical step in lignocellulosic ethanol production is the enzymatic hydrolysis of cellulose and hemicelluloses into fermentable sugars . This stage is affected by several factors including the composition and structure of feedstocks, the pretreatment technology applied, the type of enzymes used and the enzyme loadings [32]. Costs and catalytic efficiencies of enzymes represent a major bottleneck for improving the economy of the bioethanol industry. Optimization of enzyme cocktails for enzymatic hydrolysis is therefore crucial to make the lignocellulosic ethanol production economically viable.

3.1 Pretreatment and Hydrolysis of Lignocellulosic Biomass

Cellulose, hemicelluloses and lignin are strongly intermeshed and bonded through non-covalent and covalent cross-linkages, forming a lignocellulosic matrix . These structural characteristics make lignocellulosic materials very recalcitrant to the action of hydrolytic enzymes . To alter the structure of lignocellulose and facilitate the production of fermentable sugars , a suitable pretreatment process is needed [31]. The main goal of pretreatment is to break down lignin polymer and disrupt the crystalline structure of cellulose. Factors such as lignin and hemicelluloses content [33], degree of polymerization of cellulose [34], and porosity level of lignocellulosic materials [35] are among the main parameters to consider when subjecting lignocellulose to pretreatment processes .

The effectiveness of pretreatment determines the overall efficiency of the ethanol production process, and there are factors both upstream and downstream of the pretreatment step that should be taken into consideration. In the upstream steps, pretreatment can be considered by the selection of the raw material, since biomass harvesting and storage may affect pretreatment conditions such as residence time , temperature and/or the addition of chemical/biological catalysts. On the downstream processing steps, pretreatment highly influences enzymatic hydrolysis and microbial fermentation by affecting enzyme loadings and enzymatic hydrolysis rates , and cell viability and final ethanol yields and productivities , respectively [36].

As mentioned previously, lignocellulose pretreatment has a high impact on the economy of biochemical ethanol production . In fact, Lynd [2] calculated pretreatment costs to be about one third of the total costs, while Mosier et al. [31] described it as one of the most expensive processing steps in the lignocellulose -to-ethanol conversion. Cost-effectiveness of pretreatment is dependent on factors such as sugar release , biomass degradation , byproduct formation, energy demand, addition of chemical and/or biological catalysts, feedstock particle size and moisture content [8].

In addition to pretreatment, enzymatic hydrolysis represents another technological and economical bottleneck in lignocellulosic ethanol processes [37]. During enzymatic hydrolysis , carbohydrates are depolymerized into soluble sugars . This process is influenced by both enzyme-related and substrate -related factors [38]. Enzyme-related factors include end product inhibition , thermal stability , synergism between different enzyme activities and the unspecific adsorption of enzymes to lignin . On the other hand, crucial substrate-related factors are cellulose crystallinity and its degree of polymerization , the available surface area of cellulose and the lignin and hemicelluloses content.

Complete hydrolysis of lignocellulose requires the action of different enzyme activities , grouped in cellulases, hemicellulases and ligninases (Fig. 12.2). Cellulases (endoglucanases , cellobiohydrolases and β-glucosidases) are needed to hydrolyze cellulose into glucose monomers, while hemicellulases (xylanases , β-xylosidases , α-L-arabinofuranosidases, esterases, etc.) and ligninases (laccases , ligninolytic peroxidases, oxidases generating extracellular H2O2, reductases, etc.) are involved in breaking down hemicellulose and lignin polymers , respectively. A novel group of non-hydrolytic enzymes called polysaccharide monooxygenases (LPMOs ) have been discovered that are highly promising enzymes for improving the efficiency of cellulases. Although their action mechanisms have not been completely elucidated, these LPMOs can oxidize crystalline regions of cellulose, creating new reducing and non-reducing ends for cellulases [39]. Finally, non-catalytic proteins such as swollenins and expansins have attracted some attention for enzymatic hydrolysis of lignocellulose . These proteins do not catalyze hydrolytic reactions but aid in disrupting the crystalline structure of cellulose, making it more accessible to hydrolytic enzymes [40].

Schematic representation of the enzymes involved in cellulose (a), hemicellulose (b; adapted with permission from Ref. [38], Copyright © 2013 Springer), and lignin (c) biodegradation . L lignin

Enzyme production costs have great impact on the overall process costs. Thus, different programs have funded studies to improve the enzyme production and make it affordable from the economic point of view. Also, combining and incorporating new enzyme activities in commercial preparations is required to provide an appropriate enzyme mixture. Significant advances have been achieved towards this aim. However, enzymatic mixtures still need to be optimized and adapted to different feedstocks and pretreatments [38]. Enzyme cocktail optimization involves different strategies such as engineering of cellulolytic microorganisms and/or their specific enzymes , screening of novel enzyme-producing microorganisms, enzyme recycling (enzyme immobilization, insoluble solids recycling, enzyme ultrafiltration , enzyme re-adsorption ) and/or the addition of surfactants to avoid unproductive adsorption of hydrolytic enzymes to residual lignin .

3.1.1 Recent Development in Pretreatment Technologies

Pretreatment research has been focused on identifying, evaluating, developing, and demonstrating promising approaches to enhance enzymatic hydrolysis of pretreated biomass, lowering enzyme dosages and shortening process times. Over the years, a large number of pretreatment technologies have been investigated on a wide variety of feedstocks [8, 32]. Pretreatment methods can be roughly divided into physical , chemical, physicochemical and biological processes . Some advantages and disadvantages of pretreatments processes are summarized in Table 12.1.

Combinations of pretreatment methods are usually needed to improve efficiencies . The complexity of lignocellulosic matrix depends very much on biomass feedstock. In this context, pretreatment effectiveness varies greatly among raw materials, and pretreatment optimization is therefore a must for each individual type of biomass. In the following sections, the most important pretreatment processes are summarized, and the most recent developments are highlighted. The impact of pretreatment methods on lignocellulosic materials and their effect on the subsequent enzymatic hydrolysis are discussed.

3.1.1.1 Physical Pretreatment

Physical pretreatment is aimed to increase the accessible surface area of lignocellulose to hydrolytic enzymes by reducing its particle size or disrupting the structure regularity. Such effects can be produced by a combination of shear stresses. Typical physical pretreatment includes chipping, grinding or milling processes [41]. However, the high energy input required in milling and refining processes makes them economically unfeasible.

Extrusion has been applied to improve the enzymatic hydrolysis of lignocellulosic materials . This technology is based on subjecting lignocellulosic biomass to shearing and heating stress factors, resulting in physical and chemical modifications (defibrillation, fibrillation and shortening of the fibers). In contrast to milling processes, extrusion represents a promising method for lignocellulosic biomass pretreatment due to its adaptability to process modifications (it can be combined with chemical and/or biological catalysts such as alkali or enzymes ) and its versatility regarding the use of different raw materials [9, 42].

Irradiation with microwave , electron beam or gamma rays is also considered within physical pretreatments. These pretreatment methods are usually combined with alkalis, acids, ionic liquids (ILs) or salts for improving the digestibility of lignocellulosic materials [51, 52].

3.1.1.2 Chemical Pretreatment

Chemical pretreatment uses different reagents to modify the structure and composition of lignocellulosic biomass. The main chemicals used are acids, alkalis, ILs, oxidant agents and organic solvents.

Of the chemical pretreatment methods , dilute-acid technology is very favorable for industrial applications . It has been studied to pretreat a wide range of lignocellulosic feedstocks including herbaceous crops, hardwoods and softwoods [41]. This technology is based mainly in hemicelluloses hydrolysis and solubilization , and can be performed at high or low temperatures with different residence times . Nonetheless, it promotes extensive biomass degradation , which generates several inhibitory compounds from both sugar degradation and partial lignin solubilization [43]. Mineral acids such as H2SO4 or HCl are the most used acid catalysts. However, organic acids including acetic acid, fumaric acid or maleic acid are appearing attractive alternatives [53].

In contrast to acid pretreatment, alkaline reagents increase cellulose digestibility by lignin removal [44]. Alkaline pretreatment can be performed at room temperature , with residence times ranging from seconds to days, and have shown to be more effective on agricultural residues than on woody materials [45]. Although some inhibitory compounds are generated during the process, alkaline pretreatments cause less sugar degradation than acid pretreatments. Among alkali catalysts, NaOH, KOH, Ca(OH)2 and NH4OH and NH3 are the most widely used [45]. Alkali-pretreated feedstocks usually show saccharification yields of about 50–70%. However, higher saccharification yields (up to 95%) can be obtained by combining alkali-based processes with other pretreatment methods (e.g. mechanical or biological pretreatments) or with oxidant agents such as H2O2 or copper-catalyzed alkaline hydrogen peroxide [12, 50, 54].

Oxidative delignification is a pretreatment method that uses ozone, oxygen, hydrogen peroxide, chlorine dioxide or elemental chlorine as oxidation reagents, causing a remarkable oxidative fragmentation and lignin removal [32]. Oxidative delignification is, in contrast, quite costly and it is normally used in combination with other traditional acid or alkaline pretreatments for removing residual lignin [32].

Organic solvents have also shown to be effective for pretreating lignocellulosic feedstocks . Pretreatment such as organosolv , COSLIF (cellulose and organic solvents-based lignocellulosic fractionation ) or CELF (co-solvent enhanced lignocellulosic fractionation) are attractive technologies [46,47,48]. These processes can partially solubilize sugar components. However, the main action of these technologies is delignification , resulting in the recovery of a rather pure lignin fraction that can be used for further revalorization.

Pretreatment with ILs is a novel and promising alternative to improve ethanol production [32]. ILs are salts which exist as liquids at relatively low temperatures . Imidazolium salts are very common ILs [49]; however, tertiary amines derived from lignin and hemicellulose polymers (also called bioionic liquids) have also recently applied to pretreat lignocellulosic biomass [55]. One of the major advantages of ILs, is that their solvent properties can be adjusted in different ways for producing a simultaneous solubilization of sugars and lignin . Also, it should be highlighted that generation of inhibitory byproducts is avoided. In contrast, ILs can act as inhibitory compounds themselves, and an energy -efficient recycling method is required to compensate the high costs of these compounds.

3.1.1.3 Physicochemical Pretreatment

Physicochemical pretreatment has been used for lignocellulosic ethanol production [8, 32, 56]. Of the developed types of physicochemical pretreatment, steam explosion , liquid hot water , ammonia fiber explosion/expansion (AFEX ), extractive ammonia (EA), wet oxidation , and CO2 pretreatment are the most important. Among them, steam explosion is the most widely used pretreatment technology and is one of the methods applied on the commercial scale. During steam explosion pretreatment, biomass is subjected to saturated steam at high temperatures and pressures, where acetyl groups are solubilized , promoting the autohydrolysis of hemicellulosic sugars [57]. Afterwards, there is a sudden depressurization that provokes a mechanical fiber deconstruction . Steam explosion has been successfully used for ethanol production from a wide range of agriculture residues [58, 59] and hardwoods [60]. In contrast, acid catalysts are needed for steam pretreating softwoods feedstocks, which have a lower content of acetyl groups [61]. The major drawback of steam explosion pretreatment is the extended biomass degradation , which limits the subsequent hydrolysis and fermentation steps [8, 32].

Ammonia-based pretreatments such as AFEX and EA are very promising pretreatment technologies , since ammonia is an inexpensive commodity chemical with easy recycling. AFEX technology is similar to steam explosion pretreatment [62]. It uses temperatures around 60–100 °C and high pressures (1.7–2.1 MPa). During AFEX pretreatment biomass composition is not very much altered and biomass accessibility is enhanced by a swollen effect that increases the water retention values in pretreated biomass [50]. EA is a novel pretreatment technology that uses liquid ammonia at elevated temperatures to solubilize lignin polymer [10]. EA can also alter crystallinity of cellulose, allowing the better hydrolyzability of pretreated materials. Although process conditions have to be optimized, EA pretreatment represents a very promising technology since it requires about 60% lower enzyme loadings to reach similar saccharification yields than those obtained with AFEX technology. A high purity lignin with a native-like structure is recovered after EA pretreatment, which offers a good possibility for lignin revalorization.

3.1.1.4 Biological Pretreatment

Several microorganisms and/or their enzymes have been used to pretreat lignocellulosic materials before enzymatic hydrolysis [63,64,65,66,67,68]. Some brown-, white-, and soft-rot fungi are capable of degrading lignin , hemicelluloses and small amount of cellulose. White-rot fungi are the most effective ligninolytic microorganisms due to their ability to produce enzymes (laccases and peroxidases), which can partially degrade lignin and/or modify its molecular structure [69]. White-rot basidiomycetes such as Phanerochaete chrysosporium , Trametes versicolor , Panus tigrinus , Ceriporiopsis subvermispora , Pycnoporus cinnabarinus , Irpex lacteus , Ceriporia lacerata , Stereum hirsutum , Polyporus brumalis, Ganoderma austral and Pleurotus ostreatus have been examined on different lignocellulosic feedstocks, showing high delignification efficiencies [12]. Although only white-rot basidiomycetes can degradade lignin extensively, some ascomycetes can also colonize lignocellulosic biomass and consequently improve saccharification yields [67]. Besides fungi, certain bacterial strains such as Bacillus macerans, Cellulomonas cartae, Cellulomonas uda and Zymomonas mobilis have also shown delignification abilities [12].

The use of ligninolytic enzymes (especially laccases ) instead of microorganisms is another feasible alternative. Those enzymes show high reaction rates and are substrate specific, which offer the possibility to reduce the overall process time from weeks to hours without any loss in the sugar content [12].

The main advantages of biological pretreatment are their low capital costs, low energy demand and mild reaction conditions. Furthermore, these processes do not require the addition of chemical catalysts and do not release inhibitory byproducts. In contrast, major drawbacks include longer reaction times in comparison to other pretreatment technologies and the high enzyme production costs [8, 12].

Biological pretreatments can be combined with a mild acid/alkali pretreatment, organosolv , hydrogen peroxide, and thermal pretreatments to increase sugar recovery yields and reduce reaction times [67].

3.2 Inhibitory Compounds and Residual Lignin

Current pretreatment technologies still present several drawbacks that significantly influence saccharification and fermentation steps. Among them, residual lignin and biomass-degradation products are the most significant factors to consider for downstream processing .

Residual lignin promotes the unspecific adsorption of hydrolytic enzymes in pretreated materials, thus decreasing saccharification yields . It has been shown that the chemical and physical structure of residual lignin plays a large role in determining hydrolysis yields , which in turn, is heavily dependent on pretreatment conditions . Cellulases have been proposed to adsorb to residual lignin via hydrophobic, electrostatic and hydrogen bonding interactions [35]. Taking into account this negative role of residual lignin , a delignification process can be of benefit for increasing saccharification yields in pretreated materials.

On the other hand, lignocellulosic -derived compounds released during pretreatment process can act as inhibitors of the hydrolytic enzymes and fermentative microorganisms [11, 70,71,72,73]. Inhibitory compounds include furan derivatives (furfural and 5-hydroxymethylfurfural (5-HMF)), aliphatic acids (acetic acid, formic acid and levulinic acid ), and phenolic compounds (4-hydroxybenzoic acid, 4-hydroxybenzaldehyde, vanillin , p-coumaric acid, ferulic acid, dihydroconiferyl alcohol, coniferyl aldehyde, syringaldehyde, syringic acid, and Hibber’s cetones, etc.) [70]. Also, inorganic compounds and extractives (terpenes, fats, waxes and phenolics) can cause inhibitory effects . The nature and concentration of all these products is strongly dependent on the feedstock and pretreatment process [73]. Similar to delignification methods, several detoxification methods have been proposed to reduce the inhibitory power of pretreated substrates and increase saccharification and fermentation yields .

3.2.1 Delignification of Pretreated Materials

Different chemical and biological processes have been investigated to reduce the lignin content in pretreated materials. In comparison to the chemical delignification methods previously described as pretreatment processes (alkaline pretreatment , oxidative pretreatment, organosolv , EA, etc.), biological delignification is a promising technology due to the lower environmental impact and higher product yields .

Among the different biological strategies, the application of laccases has gained considerable attention in the last years [12]. Laccases are multicopper oxidases that catalyze the oxidation of substituted phenols , anilines and aromatic thiols to their corresponding radicals. The low redox potential of laccases only allows the direct oxidation of phenolic lignin units (Fig. 12.3), which represent only a small percentage of the whole lignin polymer [74]. However, in the presence of low molecular weight compounds (also called mediators) laccases can also oxidize non-phenolic lignin units (Fig. 12.3) [75]. In general, fungal laccases and laccases -mediator systems (LMS) have shown to be effective in modifying and/or partially removing lignin , increasing final hydrolysis yields of different pretreated materials [12, 65, 68]. Nevertheless, enzyme production costs and the use of costly synthetic mediators are still considered major drawbacks for the proper integration of these biological delignification methods in the current ethanol production process.

3.2.2 Inhibitors Removal and Detoxification of Pretreated Materials

One way of reducing the amount of inhibitory compounds released from pretreatment is by using milder pretreatment conditions . However, mild pretreatment conditions usually lead to lower hydrolysis yields [73]. Therefore, a good balance between the accessibility of biomass to hydrolytic enzymes and biomass degradation is required during pretreatment processes . Another possibility to reduce the concentration of inhibitory compounds is to physically remove inhibitors or to perform a detoxification step prior to enzymatic hydrolysis and/or fermentation processes. Filtration and washing have been the most common methods employed to remove inhibitory compounds from pretreated materials. However, these processes involve the need of extra equipment, additional and expensive steps, loss of soluble sugars , waste of freshwater and production of wastewater [76].

Other methods developed to overcome the effects of inhibitory compounds include either physical , chemical or biological processes (Table 12.2). Vacuum evaporation for reducing volatile compounds such as furfural, acetic acid and vanillin is probably the most commonly applied physical method [77]. Ion-exchange resins or activated charcoal can adsorb different inhibitors [78, 79], while ethyl acetate and other solvents can extract them from hydrolysates [80]. Overliming processes with Ca(OH)2 is among the most common chemical detoxification methods and can partially remove phenolic compounds , furfural and 5-HMF, improving hydrolysate fermentability [77].

Combination of different detoxification methods have also been used to detoxify pretreated materials [11]. For instance, chemical detoxification with Ca(OH)2 has been combined with activated charcoal or ion-exchange resins, being one of the most efficient combinations [77].

Similar to biological delignification processes, biological detoxification methods with microorganisms or enzymes offer many advantages such as mild reaction conditions, no chemical addition, fewer side-reactions and less energy requirements [12, 81]. Among different microorganisms, fungi such as Trichoderma reesei have been mostly studied for this purpose [77, 82]. Moreover, this fungus can produce hydrolytic enzymes while detoxification take places [82].

Bacteria and yeasts have also been used for detoxification purposes [12]. For instance, most of Saccharomyces cerevisiae strains can convert furan derivatives into less inhibitory compounds (furfural to furfuryl alcohol and 5-HMF to 5-(hydroxymethyl)furfuryl alcohol). This yeast also possesses the capacity to metabolize several phenolic compounds and can convert some aromatic carboxylic acids to the corresponding vinyl derivatives [12, 81].

The most common enzymes used for enzymatic detoxification are laccases and peroxidases, which derive from diverse white-rot fungi (T. versicolor, Trametes villosa, Coriolopsis rigida, P. cinnabarinus, Coltricia perennis, Cyathus stercoreus) and bacteria [12, 81]. These enzymes act selectively to remove phenolic compounds and generate unstable phenoxy-radicals that polymerizes into less toxic aromatic compounds (Fig. 12.3) [83]. After laccase treatment, glucose consumption rates, ethanol volumetric productivity and ethanol yields are usually improved [77, 84,85,86]. Nevertheless, as discussed above, enzyme costs can limit the use of these biocatalysts.

For better economy in these processes, enzyme detoxification methods can be combined with robust fermenting microorganisms to reduce enzyme dosages . Also, the cloning of these enzymes into cellulase-producing microorganisms or their reutilization can reduce the costs of producing these detoxifying biological agents .

4 Process Integration

Pretreatment, enzymatic hydrolysis and fermentation steps need proper integration to achieve an efficient industrial ethanol production process. Strategies and conditions employed for each step have an important influence on the rest, making the process configuration crucial in each particular case.

The main configurations used have typically been SHF and SSF [6, 87]. Nevertheless, other configurations such as integrating pretreatment and hydrolysis in a bioextrusion process [9], or the combination of enzyme production , enzymatic hydrolysis and microbial fermentation in a single step (CBP ) [88,89,90] have been developed.

4.1 Separate Hydrolysis and Fermentation (SHF )

SHF processes have been the strategy traditionally used in bioethanol production . In SHF , enzymatic hydrolysis and fermentation are performed in separate and sequential steps. The main advantage of this approach is the possibility of running both steps at optimal conditions of pH and temperature . Optimal temperature for fungal hydrolytic enzymes is in general higher (45–50 °C) than the optimal temperature for fermenting microorganisms (30–37 °C). Another advantage of SHF processes is the possibility of removing the insoluble solids after enzymatic hydrolysis . This allows performing liquid fermentation , facilitating the reutilization of the fermentative microorganisms [13].

The main disadvantage of SHF is the accumulation of sugars (free and oligomeric forms) during enzymatic hydrolysis . Sugar accumulation promotes end-product inhibition on hydrolytic enzymes and consequently reduces enzymatic hydrolysis yields [91, 92]. The in situ removal of sugars by dialysis has been proposed as an attractive option to solve this problem [93].

4.2 Simultaneous Saccharification and Fermentation (SSF )

In SSF , enzymatic hydrolysis (saccharification ) and fermentation are performed simultaneously in the same vessel. This implies a cost reduction and a great advantage of an integrated process [94]. Another advantage of SSF in comparison to SHF is the reduction of end-product inhibition during the enzymatic hydrolysis step (sugars are simultaneously consumed by fermenting microorganisms). This results in higher hydrolysis yields , shorter reaction times and the possibility of reducing enzyme loadings [87, 95]. Furthermore, contamination risks are lower, since glucose is converted to ethanol as soon as it is released.

SSF processes require, in contrast to SHF processes, compatible fermentation and saccharification pH and temperature conditions. Thus, the main disadvantage of SSF process is the necessity of running enzymatic hydrolysis at suboptimal temperatures . The utilization of thermotolerant yeasts such as Kluyveromyces marxianus capable of fermenting at temperatures above 40 °C, involves a relevant advantage and has been evaluated in bioethanol production [96, 97]. Using high temperatures in SSF processes also implies other advantages such as less risk of contaminations and the reduction in cooling costs. In contrast, higher temperatures may involve fluidification of cell membranes (the physical protective barrier), reducing the tolerance of fermentative microorganisms towards inhibitory compounds [98].

When combining pentose -rich feedstocks and pentose -fermenting microorganisms, the process is called simultaneous saccharification and co-fermentation (SSCF) [15, 99]. As it is detailed later in this chapter, the use of native and engineered strains with the capacity of co-fermenting hexoses and pentoses represents a great advantage with higher potential for increasing ethanol production [96, 100].

In general, the choice between SHF and SSF approaches depends strongly on the process conditions: type of biomass, pretreatment method , solids loading , hydrolytic enzymes and fermentative microorganism. As an example of this variability, it has been recently reported that using pretreated wheat straw at high solids loading and applying an older generation of enzyme cocktails (Celluclast + Novozym188), a SSF process resulted in significant higher yields in comparison to SHF [101]. Interestingly, using new generation of improved enzymatic cocktails (Cellic CTec 2), SHF resulted in 20% higher final ethanol yield compared to SSF [101].

4.3 Consolidated Bioprocessing (CBP )

CBP involves the integration of enzyme production , enzymatic hydrolysis and fermentation in a single bioprocessing system. The integration of all these biological processes needed for ethanol production entails great potential to save capital and operational costs [100, 102]. Different cellulolytic and non-cellulolytic microorganisms have been proposed as candidates for CBP processes, being bacteria from genus Clostridium (such as Clostridium thermocellum or Clostridium phytofermentans ) the most studied [88,89,90]. These anaerobic bacteria display extracellular enzymatic systems or cellulosomes, which are attached to the cell surface and can degrade cellulose into soluble sugars [103]. Other bacteria including Escherichia coli, Thermoanaerobacterium saccharolyticum or Caldicellulosiruptor bescii have been also engineered and/or studied as CBP systems [104,105,106].

As an alternative to bacterial strains , genetically modified yeasts displaying cellulolytic mechanisms, can be also used in CBP processes. Examples of this strategy have been developed in S. cerevisiae [107, 108], K. marxianus [109] or Yarrowia lipolytica [110] strains .

CBP processes seem the logical endpoint in the evolution of ethanol production from lignocellulosic biomass. Application of CBP implies no operating cost or capital investment for dedicated enzyme production (or purchase), reduced diversion of substrate for enzyme production or compatible enzyme and fermentation systems. Nevertheless, most CBP organisms identified and developed up to date have limited overall performance when using real lignocellulosic substrates, either because they still need supplementation of exogenous enzymes , or because they show low ethanol titers , low tolerance to ethanol or limited growth [100, 111].

4.4 Operational Strategies

In general, SHF , SSF and CBP processes can be performed in batch, fed-batch or in continuous mode. In addition, other operational strategies such as including a prehydrolysis step or the use of immobilized cells or membrane bioreactors have been studied for ethanol production .

Being a very simple method, batch processes (a closed culture system which contains an initial amount of substrate that is subjected to fermentation ) are the most common fermentation strategies [111]. However, fed-batch processes (where substrate, culture medium and other required components and nutrients are loaded at specific time points) have shown to be effective for improving ethanol production when working at high substrates concentrations, mainly due to a better mixing and the presence of low concentration of inhibitor compounds, which facilitates their conversion by the fermenting microorganism. Combining substrate, enzyme and yeast feed in SSF processes, Koppram and Olsson [112] obtained 40 g/L of ethanol from a non-detoxified slurry (steam-exploded spruce ) at a final substrate concentration of 20% (w/w) WIS (water insoluble solids), which showed to be totally inhibitory in a normal batch SSF process. Similarly, a multi-feed SSCF strategy was used by Wang et al. [113], increasing the final substrate (steam-exploded wheat straw ) concentrations up to 22% (w/w) WIS (water insoluble solids) without observing mixing problems, both in a standard bioreactor and DEMO scale (10 m3), and reaching ethanol concentrations as high as 57 g/L. Another variation of SSF /SSCF processes when using high solids loading is the introduction of a prehydrolysis or a presaccharification step (also known as Semi-Simultaneous Saccharification and Fermentation, SSSF). This presaccharification step allows a rapid liquefaction of the medium, offering more suitable conditions for fermentation and allowing higher ethanol yields [114, 115]. In the absence of cells, the prehydrolysis is performed at optimal conditions for enzymes for 1–80 h, after which the fermentative microorganism is inoculated. In a recent approach, a two stage hydrolysis configuration involving a quick liquefaction with strong mixing and a longer saccharification with no mixing was proposed to reduce the power required for mixing at high substrate loadings [116].

The use of immobilized cells by encapsulation has also been tested for lignocellulosic ethanol production . This strategy allows a better inhibitory tolerance of the fermenting strains and an optimal co-utilization of glucose and xylose [117]. A better inhibitory tolerance can be also obtained by working at high cell densities in membrane bioreactors. In this context, Ylitervo et al. [118] designed a membrane bioreactor with a cross-flow membrane to allow cell retention during a continuous process (substrate , culture medium and other required components and nutrients are loaded continuously), which enabled continuous ethanol production in the presence of high concentrations of acetic acid (up to 20 g/L).

5 Fermenting Microorganisms for Lignocellulosic Ethanol Production

In the biochemical conversion of lignocellulose , sugars contained in raw materials are converted to ethanol by microbial fermentation . Ethanologenic microorganisms ferment the glucose released during enzymatic hydrolysis into ethanol via glycolysis, with the consequent production of ATP and CO2. The stoichiometric conversion of glucose to ethanol is 0.51 g/g. However, it is very difficult to reach such conversion yield, since microorganisms divert a certain part of the consumed carbon into cellular metabolism and growth.

In contrast to the conventional ethanol production processes from starchy/sugary feedstocks, lignocellulosic sugars are converted in a highly challenging environment. This fact, together with other inherent characteristics of the process, demands robust fermenting microorganisms with high tolerance to biomass-derived inhibitors , ethanol and/or mechanical and osmotic stress. Also, they must be able to ferment the wide range of lignocellulosic sugars and/or tolerate relatively high temperatures .

The yeast S. cerevisiae is the most commonly employed microorganism for industrial alcoholic fermentation . The most attractive characteristics of S. cerevisiae, are: (1) it is generally recognized as safe (GRAS), (2) it can consume all kinds of hexoses , (3) it reaches ethanol yields close to the theoretical and (4) it can produce ethanol at concentrations as high as 18% (v/v) [119]. Apart from monosaccharides, some strains of S. cerevisiae are also able to utilize disaccharides such as sucrose and maltose, or trisaccharides like maltotriose and raffinose [120]. Furthermore, the resistance of S. cerevisiae to lignocellulose -derived inhibitors is high and therefore it is the preferred microorganism for lignocellulosic ethanol production . In spite of showing all these interesting features, the main drawback of S. cerevisiae is its inability to ferment xylose , which is the second most important sugar after glucose in lignocellulose .

More than 2000 yeast species have been studied in the literature so far. Some of them show very interesting characteristics in overcoming the limitations inherent to S. cerevisiae . In this sense, researchers are exploring new alternatives in non-conventional yeasts or bacteria to boost the lignocellulosic ethanol production . Non-conventional yeasts are usually isolated from extreme environments in which they develop specific mechanisms to survive under harsh conditions. This makes these non-conventional yeasts incorporate relevant industrially attractive traits such as the ability to utilize complex substrates and/or having high tolerance to different stress factors [17].

Besides yeasts, other microorganisms like ethanologenic bacteria have shown promising results in terms of xylose fermentation and thermotolerance, which motivates researchers to explore the benefits of using these organisms in lignocellulosic ethanol production processes.

The following sections describe different fermentative microorganisms with interesting traits for lignocellulosic ethanol production and discuss advances in the development of novel strategies for strain engineering.

5.1 Hemicellulosic Sugars Fermentation

Efficient fermentation of all sugars present in lignocellulosic materials is crucial to increase the profitability of biological conversion of lignocellulose into ethanol . Since xylose is the second most abundant carbohydrate in nature, its commercial fermentation is essential to improve the global economy of the process.

A small number of native xylose -fermenting yeasts has been identified. Candida tropicalis , Candida shehatae, Pachysolen tannophilus , Scheffersomyces stipitis and Spathaspora passalidarum are among the xylose-utilizing yeast. These yeast species, however, present low ethanol yields , low tolerance to ethanol and inhibitors , require microaerophilic conditions and are very sensitive to pH changes, which limit their application on the industrial scale. Notwithstanding, advances have been made towards the improvement of these yeast species for their utilization in lignocellulosic ethanol production [121, 122].

As previously discussed, the yeast S. cerevisiae is one of the preferred microorganisms for lignocellulosic ethanol production as it has demonstrated to be highly tolerant towards lignocellulose -derived inhibitors and the end product ethanol . However, since wild-type S. cerevisiae strains are not able to ferment pentoses, hard efforts have been addresses to develop efficient engineered xylose -fermenting S. cerevisiae strains .

Among the three different metabolic pathways for xylose assimilation, only two of them have been introduced in S. cerevisiae : the oxidoreductive pathway, which involves xylose reductase (XR) and xylitol dehydrogenase (XDH) enzymes ; and the xylose isomerase (XI) pathway. The product of both pathways, xylulose, is phosphorylated by the action of a xylulose kinase (XK) and metabolized via the pentose phosphate pathway (PPP) . The XYL1 and XYL2 genes (mainly from S. stipitis) involved in the XR/XDH pathways have been cloned in several S. cerevisiae strains . However, these two enzymes have a different co-factor preference, which is translated in co-factor imbalance and xylitol accumulation. In this context, altering the co-enzyme preference of the XR and XDH has been one of the most effective approaches to decrease xylitol formation and enhance ethanol yields [123, 124]. The expression of XI from bacteria, which directly converts xylose into xylulose, does not present limitations regarding xylitol accumulation. In both pathways, the over expression of the endogenous XKS1 gene encoding for XK enables S. cerevisiae to ferment xylose to ethanol more rapidly [125].

Besides xylitol accumulation, other constrains regarding xylose fermentation by recombinant S. cerevisiae strains have been ascribed to poor xylose uptake and limitation in the PPP and other metabolic fluxes. Thus, big efforts have been recently addressed to overcome these challenges by means of metabolic engineering techniques [126,127,128].

Directed adaptation or evolutionary engineering of yeast in the presence of xylose has been proven as one interesting strategy to develop more efficient xylose-fermenting strains . In this context, evolutionary engineering of xylose-fermenting S. cerevisiae strains to lignocellulosic hydrolysates not only led to an increase in xylose fermentation capacity but also in better results in terms of tolerance to inhibitors and ethanol yields , when compared with non-adapted cells [15, 129]. Furthermore, as it is detailed latter in this chapter, short-term adaptation of recombinant S. cerevisiae cells to hydrolysate rich in xylose and inhibitors during the propagation phase, also resulted in increased xylose fermentation in the subsequent ethanol production process [130, 131].

Apart from yeasts, xylose fermentation has also been reported with some fungi such as Fusarium oxysporum , Mucor circinelloides and Rhizopus oryzae [132, 133]. In comparison to xylose-fermenting yeasts, filamentous fungi are more tolerant to the inhibitors but they show slow fermentation rates for a competitive industrial process [134]. The ethanologenic xylose-fermenting bacteria that show the most promising characteristics for lignocellulosic ethanol production are E. coli and Klebsiella oxytoca. Both organisms utilize also a wide spectrum of sugars; however, they are inhibited at low sugar and ethanol concentrations, and the fermentation processes lead to considerable by-product formation.

5.2 Increased Tolerance to Inhibitors

The use of fermenting microorganisms that can cope with the inhibitory compounds released during pretreatment is crucial for achieving a cost-competitive production process. Several strategies to develop robust S. cerevisiae strains with improved tolerance to inhibitors have been described. The overexpression of genes that encode enzymes which confer resistance to specific inhibitors has improved the tolerance of S. cerevisiae to these degradation compounds [135, 136].

A significant increase in furfural tolerance has been observed by disrupting the SIZ1 gene in S. cerevisiae [137]. The genome shuffling technique has also been used with success to improve the acid tolerance of S. cerevisiae [138]. Among non-metabolic engineering techniques, evolutionary engineering has been proposed as an effective method to improved tolerance to inhibitors in S. cerevisiae strains [129, 139]. During evolutionary engineering, microorganisms are subjected to high inhibitor concentrations over extended periods, which provoke random genetic changes that confer increased tolerance to the stress factors. Besides the long-term adaptation gained during evolutionary engineering, short-term adaptation of yeast to lignocellulosic hydrolysate during propagation has also been proven to increase detoxification rates of furfural and 5-HMF, reduce the lag phase of microorganisms and increase sugar consumption rates and ethanol yields in the subsequent fermentation step [130, 131, 140]. As introduced before, since tolerance to inhibitors is affecting sugar consumption rates, these strategies are very interesting for producing more efficient xylose -consuming strains , highly tolerant to lignocellulose -derived inhibitors .

In addition to all efforts addressed for increasing yeast tolerance to lignocellulose -derived inhibitors , little is known about the superior inhibitor tolerance detected in certain non-conventional yeasts. Among non-Saccharomyces species, Pichia kudriavzevii has been reported as an extremely robust microorganism, coping with up to 7 g/L of 5-HMF [141] and about 8 g/L of acetic acid [142]. Zygosaccharomyces bailii is the most acetic acid-tolerant specie described so far, showing the same growth rate reduction at 24 g/L of acetic acid than S. cerevisiae at 9 g/L [143].

Besides the described evolution and genetic engineering approaches, different alternatives such as cell retention, encapsulation, and flocculation of fermentative microorganisms have been developed to increase the intrinsic tolerance or the inherent detoxification capacity of some microorganisms [12, 81].

5.3 Ethanol Tolerance

S. cerevisiae has been described as the most ethanol -tolerant yeast species [141]. Similar to S. cerevisiae, Dekkera bruxellensis have shown to have similar ethanol tolerance levels. The common trait for the high ethanol tolerance in these two mentioned yeast species is reported to be the duplication of their alcohol dehydrogenase encoding genes. D. bruxellensis strains isolated from wine fermentation have demonstrated ethanol tolerance to concentrations ranging from 10 to 16% (v/v) [144]. In spite of the very promising features present in this yeast, genetic modification of this species is very difficult, which slows down the progress in using this organism for bioethanol production . Other highly ethanol -tolerant yeast species are P. kudriavzevii , and Wickerhamomyces anomalus which are able to tolerate 13% and 11% (v/v) ethanol concentrations , respectively [141].

5.4 Thermotolerance

The employment of thermotolerant yeasts in ethanol processes from lignocellulose is advantageous when applying SSF configurations, since the optimal conditions for enzymatic hydrolysis and fermentation are different. As mentioned before in this chapter, most hydrolytic enzymes perform better at 50 °C while most fermenting microorganisms have an optimum temperature of 30–37 °C. Thus, hydrolysis yields are increased when using thermotolerant microorganisms, owing to the higher temperature of SSF processes. There are other advantages that could be exploited when running SSF processes at higher temperatures , such as energy savings through a reduction in cooling costs, a significant reduction in contamination risks and the possibility of continuous ethanol removal by evaporation. Some studies conclude that an increase of 5 °C in the SSF temperature could considerably reduce the ethanol production costs [98].

Thermotolerant yeast strains of Saccharomyces, Kluyveromyces and Fabospora can grow at temperatures above 40 °C and produce ethanol at temperatures of 40 °C, 43 °C and 46 °C, respectively [98]. K. marxianus grow well at temperatures as high as 45–52 °C and can efficiently produce ethanol at temperatures of between 38 °C and 45 °C. Several strains belonging to the yeast species K. marxianus have been successfully employed in SSF processes from lignocellulose such as wheat straw [145], barley straw [146], eucalyptus [147], switchgrass [148] or even recycled paper sludge or waste [149, 150]. Apart from K. marxianus, some thermotolerant strains of S. cerevisiae and K. fragilis have also been successfully employed in SSF processes [151, 152].

Ogataea polymorpha is a yeast species able to grow at temperatures higher than 50 °C. This fact, together with its ability to ferment xylose and cellobiose to ethanol , makes O. polymorpha an interesting microorganism with high potential for use in SSF processes.

The use of thermophilic bacteria with broad substrate range and high yields may be another good option for ethanol production from lignocellulosic biomass. Highly ethanologen thermophilic bacteria are typically members of the genera Thermoanaerobacterium, Thermoanaerobacter, Clostridium or Caldanaerobacter [153]. Most thermophilic strains within the genus Clostridium have an optimum temperature in the range of 45–65 °C. On the other hand, Thermoanaerobacterium species have an optimum temperature ranging from 55 to 65 °C and have demonstrated good ethanol yields on lignocellulosic substrates. Thermoanaerobacter species have slightly higher optimum temperatures (65–75 °C) than Thermoanaerobacterium. Both Thermoanaerobacter ethanolicus and Thermoanaerobacter J1 have been proven to produce ethanol with high yields from lignocellulosic sugars [154, 155]. Other very promising ethanol producing thermophilic bacteria are the wild type strains of Caloramator boliviensis that have already been used in SSF processes from cassava starch [156].

5.5 Osmotolerance

Running the bioethanol production process at high substrate concentrations (>15% (w/w)) results in improved overall productivity, reduced capital costs and lower energy input, when compared to processes at lower consistencies [157]. The high initial sugar concentrations in the broth may cause an increase in the osmolarity of the fermentation medium, which can lead to water loss and cell shrinking. S. cerevisiae can grow and ferment in media containing as much as 400 g/L glucose, which is one important advantage of this microorganism for producing ethanol at high substrate loading [158].

Two non-Saccharomyces yeast species isolated from sugar rich habitats (floral nectar and sugar beet juice) [141] show even higher osmotolerance than S. cerevisiae . Candida bombi grows well on rich media with 70% glucose. In the same study, Starmerella bombicola reached the same growth level as that of C. bombi on 60% glucose.

The application of extremely osmotolerant non-conventional yeast has recently appeared as interesting options in this kind of processes. Zygosaccharomyces rouxii is one of the most halotolerant and osmotolerant yeast species since it can cope with up to 90% (w/v) sugar concentration [159]. Studies have suggested that this extreme osmotolerance could rely on two plasma membrane transporters (ZrFfz1 and ZrFfz2) phylogenetically distant from any other fungal transporter [160].

Some attempts have been made to engineer new bacterial strains to cope with increased osmotolerance in ethanol production processes at high substrate loading. This is the case of recombinant E. coli strain FBR 5, which is able to ferment acid-treated wheat straw hydrolysates with 150 g/L total sugars. In this study, E. coli FBR5 was able to ferment both xylose and glucose with a final ethanol yield of 0.47 g/g [161].

6 Conclusions and Future Outlook

There is no doubt on the importance of developing and implementing a cost-effective lignocellulose -based industry, which will place into the market several renewable biofuels and other value-added products. Lignocellulosic ethanol is leading such scenario and quite a few commercial lignocellulosic ethanol plants have been opened in the last 3–4 years (BetaRenewables, Abengoa, Raizen, GranBio, Poet-DSM, and DuPont). However, there are still some challenges that should be addressed for establishing a competitive lignocellulosic ethanol industry.

The highly recalcitrant structure and the heterogeneous chemical composition of lignocellulosic materials hinder their utilization as sugar sources. Interesting approaches regarding the development of novel genetically modified feedstocks such as those having lower lignin content and/or a higher proportion of easily fermentable sugars have been reported.

During biomass processing , pretreatment is one of the most important steps in both process and economic terms. Different pretreatment processes have been developed to overcome the recalcitrant structure of lignocellulose and increase biomass digestibility . An optimal pretreatment process would be able to guarantee a proper balance between the increase in biomass digestibility and the extension of biomass degradation . Also, it would facilitate the recovery of a highly pure lignin fraction, thus offering possibilities for its revalorization. Methods such as steam explosion , dilute-acid pretreatment, extrusion, EA, CESF or ILs represent promising processes with high potential for industrial applications .

Enzymatic hydrolysis is another important process in biomass processing . Recent studies in saccharification processes have elucidated the need of incorporating new enzyme activities in the hydrolytic cocktails for the complete hydrolysis of lignocellulose . Some of these activities are LPMOs , hemicellulases , ligninases and other non-hydrolytic enzymes such as swollenins and expansins.

The development of more robust fermentative strains with abilities to cope with all the different stresses is also needed for the optimal conversion of the highly challenging hydrolysates. Different delignification and detoxification methods have been developed for increasing the hydrolyzability and fermentability of hydrolysates. However, promoting the in situ conversion and/or the tolerance of the inhibitory compounds present in hydrolysates would be economically beneficial. In addition, all lignocellulosic sugars must be converted during fermentation processes for increasing final ethanol concentrations and conversion yields . Strains with high pentose -conversion efficiencies are therefore very interesting options for lignocellulosic ethanol production .

Finally, although each process should be individually studied and optimized, proper process integration should be also evaluated in considering the selected pretreatment method , the enzyme cocktail and the fermentative microorganism. In this context, the development of an efficient CBP process where enzyme production , enzymatic hydrolysis and fermentation are integrated in one single step would be convenient for cost-effectiveness of lignocellulosic ethanol production .

In brief, it can be concluded that the breakthrough of key technologies both in biomass processing and fermentation processes, and the optimal integration of all the steps involved, are among the crucial aspects to overcome for the realization of a global bio-based economy, where lignocellulosic ethanol plays a key role.

References

Imran A, Varman M, Masjuki HH, Kalam MA. Review on alcohol fumigation on diesel engine: a viable alternative dual fuel technology for satisfactory engine performance and reduction of environment concerning emission. Renew Sust Energ Rev. 2013;26:739–51.

Lynd LR. Overview and evaluation of fuel ethanol from cellulosic biomass: technology, economics, the environment, and policy. Annu Rev Energy Environ. 1996;21(1):403–65.

Balan V, Chiaramonti D, Kumar S. Review of US and EU initiatives toward development, demonstration, and commercialization of lignocellulosic biofuels. Biofuels Bioprod Biorefin. 2013;7(6):732–59.

Yu Y-S, Giles B, Oh V. State of the market report – uncovering the cost of cellulosic ethanol production. Luxresearch; 2016.

Statistics NEO. Fuel prices: Nebraska Energy Office; 2016. Available from: http://www.neo.ne.gov/statshtml/66.html. Access date: Nov 2016.

Sun Y, Cheng J. Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol. 2002;83(1):1–11.

Tomás-Pejó E, Alvira P, Ballesteros M, Negro MJ. Pretreatment technologies for lignocellulose-to-bioethanol conversion. In: Pandey A, Larroche C, Ricke SC, Dussap C-G, Gnansounou E, editors. Biofuels. Alternative feedstocks and conversion processes. Amsterdam: Academic Press; 2011. p. 149–76.

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol. 2010;101(13):4851–61.

Vandenbossche V, Brault J, Vilarem G, Hernández-Meléndez O, Vivaldo-Lima E, Hernández-Luna M, Barzana E, Duque A, Manzanares P, Ballesteros M, Mata J, Castellón E, Rigal L. A new lignocellulosic biomass deconstruction process combining thermo-mechano chemical action and bio-catalytic enzymatic hydrolysis in a twin-screw extruder. Ind Crop Prod. 2014;55:258–66.

da Costa SL, Jin M, Chundawat SPS, Bokade V, Tang X, Azarpira A, Lu F, Avci U, Humpula J, Uppugundla N, Gunawan C, Pattathil S, Cheh AM, Kothari N, Kumar R, Ralph J, Hahn MG, Wyman CE, Singh S, Simmons BA, Dale BE, Balan V. Next-generation ammonia pretreatment enhances cellulosic biofuel production. Energy Environ Sci. 2016;9(4):1215–23.

Taherzadeh MJ, Karimi K. Fermentation inhibitors in ethanol processes and different strategies to reduce their effects. In: Pandey A, Larroche C, Ricke SC, Dussap C-G, Gnansounou E, editors. Biofuels. Alternative feedstocks and conversion processes. Amsterdam: Academic Press; 2011. p. 287–311.

Moreno AD, Ibarra D, Alvira P, Tomás-Pejó E, Ballesteros M. A review of biological delignification and detoxification methods for lignocellulosic bioethanol production. Crit Rev Biotechnol. 2015;35(3):342–54.

Olsson L, Jørgensen H, Krogh KBR, Roca CFA. Bioethanol production from lignocellulosic material. In: Dumitriu S, editor. Polysaccharides: structural diversity and functional versatility. New York: Marcel Dekker; 2005. p. 957–93.

Martín C, Marcet M, Almazan O, Jönsson LJ. Adaptation of a recombinant xylose-utilizing Saccharomyces cerevisiae strain to a sugarcane bagasse hydrolysate with high content of fermentation inhibitors. Bioresour Technol. 2007;98(9):1767–73.

Tomás-Pejó E, Ballesteros M, Oliva JM, Olsson L. Adaptation of the xylose fermenting yeast Saccharomyces cerevisiae F12 for improving ethanol production in different fed-batch SSF processes. J Ind Microbiol Biotechnol. 2010;37(11):1211–20.

Hasunuma T, Sanda T, Yamada R, Yoshimura K, Ishii J, Kondo A. Metabolic pathway engineering based on metabolomics confers acetic and formic acid tolerance to a recombinant xylose-fermenting strain of Saccharomyces cerevisiae. Microb Cell Factories. 2011;10(1):1–13.

Radecka D, Mukherjee V, Mateo RQ, Stojiljkovic M, Foulquie-Moreno MR, Thevelein JM. Looking beyond Saccharomyces: the potential of non-conventional yeast species for desirable traits in bioethanol fermentation. FEMS Yeast Res. 2015;15(6).

Sánchez OJ, Cardona CA. Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour Technol. 2008;99(13):5270–95.

Ballesteros M, Sáez F, Ballesteros I, Manzanares P, Negro MJ, Martínez JM, Castañeda R, Oliva JM. Ethanol production from the organic fraction obtained after thermal pretreatment of municipal solid waste. Appl Biochem Biotechnol. 2010;161(1–8):423–31.

Limayem A, Ricke SC. Lignocellulosic biomass for bioethanol production: current perspectives, potential issues and future prospects. Prog Energy Combust Sci. 2012;38(4):449–67.

Milledge J, Smith B, Dyer P, Harvey P. Macroalgae-derived biofuel: a review of methods of energy extraction from seaweed biomass. Energies. 2014;7(11):7194–222.

Pauly M, Keegstra K. Plant cell wall polymers as precursors for biofuels. Curr Opin Plant Biol. 2010;13(3):305–12.

Loque D, Scheller HV, Pauly M. Engineering of plant cell walls for enhanced biofuel production. Curr Opin Plant Biol. 2015;25:151–61.

Yang F, Mitra P, Zhang L, Prak L, Verhertbruggen Y, Kim JS, Sun L, Zheng K, Tang K, Auer M, Scheller HV, Loque D. Engineering secondary cell wall deposition in plants. Plant Biotechnol J. 2013;11(3):325–35.

Wilkerson CG, Mansfield SD, Lu F, Withers S, Park J-Y, Karlen SD, Gonzales-Vigil E, Padmakshan D, Unda F, Rencoret J, Ralph J. Monolignol ferulate transferase introduces chemically labile linkages into the lignin backbone. Science. 2014;344(6179):90–3.

Schultink A, Naylor D, Dama M, Pauly M. The role of the plant-specific ALTERED XYLOGLUCAN9 protein in Arabidopsis cell wall polysaccharide O-acetylation. Plant Physiol. 2015;167(4):1271–83.

Bartley LE, Peck ML, Kim SR, Ebert B, Manisseri C, Chiniquy DM, Sykes R, Gao L, Rautengarten C, Vega-Sanchez ME, Benke PI, Canlas PE, Cao P, Brewer S, Lin F, Smith WL, Zhang X, Keasling JD, Jentoff RE, Foster SB, Zhou J, Ziebell A, An G, Scheller HV, Ronald PC. Overexpression of a BAHD acyltransferase, OsAt10, alters rice cell wall hydroxycinnamic acid content and saccharification. Plant Physiol. 2013;161(4):1615–33.

Coleman HD, Yan J, Mansfield SD. Sucrose synthase affects carbon partitioning to increase cellulose production and altered cell wall ultrastructure. Proc Natl Acad Sci U S A. 2009;106(31):13118–23.

Joshi CP, Thammannagowda S, Fujino T, Gou JQ, Avci U, Haigler CH, McDonnell LM, Mansfield SD, Mengesha B, Carpita NC, Harris D, Debolt S, Peter GF. Perturbation of wood cellulose synthesis causes pleiotropic effects in transgenic aspen. Mol Plant. 2011;4(2):331–45.

Nguyen THM, Vu VH. Bioethanol production from marine algae biomass: prospect and troubles. J Viet Env. 2012;3(1):25–9.

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol. 2005;96(6):673–86.

Sun S, Sun S, Cao X, Sun R. The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour Technol. 2016;199:49–58.

Pan X, Xie D, Gilkes N, Gregg DJ, Saddler JN. Strategies to enhance the enzymatic hydrolysis of pretreated softwood with high residual lignin content. Appl Biochem Biotechnol. 2005;121-124:1069–79.

Mansfield SD, Mooney C, Saddler JN. Substrate and enzyme characteristics that limit cellulose hydrolysis. Biotechnol Prog. 1999;15(5):804–16.

Chandra RP, Bura R, Mabee WE, Berlin A, Pan X, Saddler JN. Substrate pretreatment: the key to effective enzymatic hydrolysis of lignocellulosics? Adv Biochem Eng Biotechnol. 2007;108:67–93.

Mussatto SI, Dragone GM. Biomass pretreatment, biorefineries, and potential products for a bioeconomy development. In: Mussato SI, editor. Biomass fractionation technologies for a lignocellulosic feedstock based biorefinery. Amsterdam: Elsevier; 2016. p. 1–22.

Viikari L, Vehmaanperä J, Koivula A. Lignocellulosic ethanol: from science to industry. Biomass Bioenergy. 2012;46:13–24.

Alvira P, Ballesteros M, Negro MJ. Progress on enzymatic saccharification technologies for biofuels production. In: Gupta VK, Tuohy MG, editors. Biofuel technologies: recent developments. Berlin/Heidelberg: Springer; 2013. p. 145–69.

Martínez AT. How to break down crystalline cellulose. Science. 2016;352(6289):1050–1.

Jørgensen H, Kristensen JB, Felby C. Enzymatic conversion of lignocellulose into fermentable sugars: challenges and opportunities. Biofuels Bioprod Biorefin. 2007;1(2):119–34.

Taherzadeh MJ, Karimi K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci. 2008;9(9):1621–51.

Duque A, Manzanares P, Ballesteros I, Negro MJ, Oliva JM, Gonzalez A, Ballesteros M. Sugar production from barley straw biomass pretreated by combined alkali and enzymatic extrusion. Bioresour Technol. 2014;158:262–8.

Saha BC, Iten LB, Cotta MA, Wu YV. Dilute acid pretreatment, enzymatic saccharification and fermentation of wheat straw to ethanol. Process Biochem. 2005;40(12):3693–700.

Carvalheiro F, Duarte LC, Gírio FM. Hemicellulose biorefineries: a review on biomass pretreatments. J Sci Ind Res. 2008;67(11):849–64.

Kumar P, Barrett DM, Delwiche MJ, Stroeve P. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res. 2009;48(8):3713–29.

Zhang YH, Ding SY, Mielenz JR, Cui JB, Elander RT, Laser M, Himmel ME, McMillan JR, Lynd LR. Fractionating recalcitrant lignocellulose at modest reaction conditions. Biotechnol Bioeng. 2007;97(2):214–23.

Zhao X, Cheng K, Liu D. Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol. 2009;82(5):815–27.

Nguyen TY, Cai CM, Osman O, Kumar R, Wyman CE. CELF pretreatment of corn stover boosts ethanol titers and yields from high solids SSF with low enzyme loadings. Green Chem. 2016;18(6):1581–9.

Brandt A, Gräsvik J, Hallett JP, Welton T. Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem. 2013;15(3):550.

Akhtar N, Gupta K, Goyal D, Goyal A. Recent advances in pretreatment technologies for efficient hydrolysis of lignocellulosic biomass. Environ Prog Sustain Energy. 2016;35(2):489–511.

Duarte CL, Ribeiro MA, Oikawa H, Mori MN, Napolitano CM, Galvão CA. Electron beam combined with hydrothermal treatment for enhancing the enzymatic convertibility of sugarcane bagasse. Radiat Phys Chem. 2012;81(8):1008–11.

Moretti MMS, Bocchini-Martins DA, Nunes CCC, Villena MA, Perrone OM, da Silva R, Boscolo M, Gomes E. Pretreatment of sugarcane bagasse with microwaves irradiation and its effects on the structure and on enzymatic hydrolysis. Appl Energy. 2014;122:189–95.

Kootstra AMJ, Beeftink HH, Scott EL, Sanders JPM. Comparison of dilute mineral and organic acid pretreatment for enzymatic hydrolysis of wheat straw. Biochem Eng J. 2009;46(2):126–31.

Bhalla A, Bansal N, Stoklosa RJ, Fountain M, Ralph J, Hodge DB, Hegg EL. Effective alkaline metal-catalyzed oxidative delignification of hybrid poplar. Biotechnol Biofuels. 2016;9:34.

Socha AM, Parthasarathi R, Shi J, Pattathil S, Whyte D, Bergeron M, George A, Tran K, Stavila V, Venkatachalam S, Hahn MG, Simmons BA, Singh S. Efficient biomass pretreatment using ionic liquids derived from lignin and hemicellulose. Proc Natl Acad Sci U S A. 2014;111(35):E3587–95.

Ruiz HA, Rodríguez-Jasso RM, Fernandes BD, Vicente AA, Teixeira JA. Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: a review. Renew Sust Energ Rev. 2013;21:35–51.

Pan X, Arato C, Gilkes N, Gregg D, Mabee W, Pye K, Xiao Z, Zhang X, Saddler J. Biorefining of softwoods using ethanol organosolv pulping: preliminary evaluation of process streams for manufacture of fuel-grade ethanol and co-products. Biotechnol Bioeng. 2005;90(4):473–81.

Ballesteros I, Negro MJ, Oliva JM, Cabañas A, Manzanares P, Ballesteros M. Ethanol production from steam-explosion pretreated wheat straw. Appl Biochem Biotechnol. 2006;129-132:496–508.

Cara C, Ruiz E, Ballesteros M, Manzanares P, Negro MJ, Castro E. Production of fuel ethanol from steam-explosion pretreated olive tree pruning. Fuel. 2008;87(6):692–700.

Oliva JM, Sáez F, Ballesteros I, González A, Negro MJ, Manzanares P, Ballesteros M. Effect of lignocellulosic degradation compounds from steam explosion pretreatment on ethanol fermentation by thermotolerant yeast Kluyveromyces marxianus. Appl Biochem Biotechnol. 2003;105-108:141–53.

Galbe M, Zacchi G. A review of the production of ethanol from softwood. Appl Microbiol Biotechnol. 2002;59(6):618–28.

Laureano-Perez L, Teymouri F, Alizadeh H, Dale BE. Understanding factors that limit enzymatic hydrolysis of biomass. Appl Biochem Biotechnol. 2005;124(1):1081–99.

Mendonça RT, Jara JF, González V, Elissetche JP, Freer J. Evaluation of the white-rot fungi Ganoderma australe and Ceriporiopsis subvermispora in biotechnological applications. J Ind Microbiol Biotechnol. 2008;35(11):1323–30.

Salvachúa D, Prieto A, López-Abelairas M, Lu-Chau T, Martínez AT, Martínez MJ. Fungal pretreatment: an alternative in second-generation ethanol from wheat straw. Bioresour Technol. 2011;102(16):7500–6.

Gutierrez A, Rencoret J, Cadena EM, Rico A, Barth D, del Rio JC, Martinez AT. Demonstration of laccase-based removal of lignin from wood and non-wood plant feedstocks. Bioresour Technol. 2012;119:114–22.