Abstract

Glucosamine (GlcN), an amino sugar, is a compound derived from substitution of a hydroxyl group of a glucose molecule with an amino group. GlcN and its acetylated derivative, N-acetylglucosamine (GlcNAc), have been widely used in food, cosmetics, and pharmaceutical industries and are currently produced by acid hydrolysis of chitin (a linear polymer of GlcNAc) extracted from crab and shrimp shells. In this review, distribution and production of GlcN and GlcNAc, their chemistry and determination in the complex samples will be treated first. This review will describe the procedure to identify a high-quality glucosamine product for Glucosamine/chondroitin Arthritis Intervention Trial (GAIT) and to clarify confusing product information and nomenclature. GlcN is a precursor of the glycosaminoglycans and proteoglycans that make up articular cartilage. Glucosamine sulfate and glucosamine hydrochloride have used for the treatment of osteoarthritis for more than 30 years, with no major known side effects. The notion that augmenting the intake of the precursor molecule, glucosamine, may directly stimulate articular proteoglycan synthesis to modulate osteoarthritis has provided the rationale for its widespread use. Theoretically, exogenous glucosamine may augment glycosaminoglycan synthesis in cartilage. There is a simultaneous theoretical concern that it might also induce insulin resistance in insulin-sensitive tissues. While the efficacy of glucosamine was published in the definitive medical journals, there were views against it. This concern will be also discussed. While glucosamine was not effective without combination with chondroitin sulfate in the some trial, glucosamine alone was effective in the other trial. Some concerns about these trials will be discussed together with the mechanism of action of glucosamine and chondroitin for antiarthritic potential. Finally, the review will focus on the biomedical and other application of the glucosamine and chitosan oligosaccharide. Such biomedical applications include wound healing, bone regeneration, antibacterial effect, and oral hygiene. It also discusses the role of chitosan oligosaccharide as a drug carrier for molecular therapies, such as the drug and the gene delivery systems and the role in imaging for tumor and cancer detection.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Chitin is the most abundantly available polysaccharide on earth after cellulose, and chitin is a main constituent of cell walls of fungus, insect exoskeletons, and crustaceans. It is one of the most ample renewable biopolymer on earth [1]. Accordingly, a very huge number of applications of D-glucosamine and N-acetyl D-glucosamine like food technology, biomaterial science, microbiology, agriculture, techniques for wastewater treatment, drug delivery, tissue engineering, bionanotechnology had been earlier described. The structure of chitin is a biopolymer of N-acetyl-D-glucosamine (NAG) allied by beta-glycosidic bonding. Polysaccharides, oligosaccharides, and monosaccharides are the main derivatives of chitin, which also includes several therapeutic activities such as immunomodulation [2, 3], antitumor [4] osteoarthritis treatment [5], wound healing, tissue engineering, drug delivery, and for regenerative medicines [6–10]. Also, in the recent years, NAG, the end hydrolytic product of chitin, has become an attractive biomaterial as food supplements and cosmetics [11–13]. Also, N-acetyl glucosamine has a pure sweet taste that has also been projected to be utilized as a substitute for similar applications [14].

Researchers has investigated about the glucosamine and analyzed that it has two major beneficial properties. First, Glucosamine declines the level of an enzyme that degrades articular cartilages. Secondly, it has also helped in repairing the damaged articular tissues [15].

In recent years Glucosamine sulphate (GS) has been widely studied as a treatment selection for osteoarthritis (OA) which is a great boon in the field of tissue engineering and regenerative medicines. Glucosamine helps efficiently in regenerating the damaged cartilages. Glucosamine is also a natural building block of any of the articular cartilage [16].

1.1 Chemical Structure of D-Glucosamine and N-Acetyl D-Glucosamine

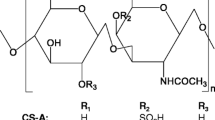

Chitin polysaccharides, which are commonly known as amino sugars with the fundamental structural entity of N-acetyl-β-D-glucosamine are identified for enormous biological functions such as antitumor activity, elicitor action, and anti-inflammatory activity. Chitin is fragmented by endo and exo enzymes called as chitinases (EC3.2.1.14) and β-N acetyl hexosaminidase (EC3.2.1.52), respectively [17]. The degradation of chitin is generally initiated by sudden breakage within the chain of chitin by chitinases to liberate the oligomers of N-acetyl glucosamine chains. The molecular formula of this monosaccharide is C8H15NO6. The chemical structure of glucosamine and N-acetyl glucosamine is shown in Fig. 1. Generally, it’s a whitish and sweetish powder that decays at 221 °C. The solubility of GlcNAc is about 25 % in water and 1 % aqueous solutions are colorless, odorless, and transparent [18]. Apart from the structural constituent of homogeneous polysaccharide like chitin, N-acetyl-D-glucosamine is also a component of heterogeneous oligosaccharides like murein [19], hyaluronic acid (HA) [20, 21].

2 Production of D-Glucosamine and N-Acetyl-D-Glucosamine

GlcNAc and GlcN are the basic constituents for glycoproteins, proteoglycans, glycosaminoglycans (GAGs) and other building units used in connective tissue. [22–27]. Apart from GlcNAc existed in free form in nature, except in human milk [28, 29]. The methods of GlcNAc production summarizes in Fig. 2.

About 150 billion tons of chitin/D-glucosamine is crafted in nature [30–32], which makes chitin a appropriate biomass source for the synthesis of D-glucosamine and GlcNAc. GlcNAc can be synthesized through the procedure that was established on chitin hydrolysis utilizing chitin as feed-stock.

2.1 Preparation of D-Glucosamine and N-Acetyl D-Glucosamine Using Chemical Method

Hydrolysis of chitin using acids such as hydrochloric acid, sulphuric acid etc., which is type of an industrial process for the synthesis of glucosamine hydrochloride salt (GlcNHCl), one of the most popular food supplements, drugs utilized for osteoarthritis and other biomedical applications [33]. The main focus is to understand that the treating temperature and the concentration of the acid should be chosen wisely. All such factors must be highly adequate to degrade only chitin not so high temperature that glucosamine or GlcNAc products are demolished.

Falk et al. discovered that the rates of development of acetic acid and glucosamine were the same but at starting it was less than the rate of N-acetylglucosamine synthesis. From this, it was presumed that the vast majority of the acetic acid was produced by the hydrolysis of N-acetylglucosamine, instead of by hydrolysis of the polymers’ N-acetyl groups. Falk also establish a maximum concentration of N-acetylglucosamine when 10 M HCl was used for hydrolysis of 50 % of the chitin. The authors concluded that controlled acid hydrolysis of chitin did not result best yield of N-acetylglucosamine [34]. There are a few instances which show chemically synthesized D-glucosamine and GlcNAc. Like Kuyama et al. [35] synthesized totally deacetylated chitosan dodecamers started with glucosamine monomer using amino protective group. Aly et al. [36] explained a technique to synthesize fully N-acetylated D-Glucosamine from GlcN monomers using dimethyl maleoyl as an amino protective group for production of two enzymes, i.e.; chitotetraose and chitohexaose. Removal of the amino protective group and N-acetylation was also achieved in a one reaction to provide the required product [37].

The typical procedure for the preparation of glucosamine by direct acid hydrolysis [38]. But this process has a disadvantage of chitin, which includes high cost, lower yield (below 65 %), and acidic leftover which was formed by HCl. The estimated production is 6.42 g/L GlcNAc can be produced in 1 h [39].

Also Varum et al. studied the effect of concentration of hydrochloric acid on hydrolysis of the glycosidic linkages and the N-acetyl linkage of moderately N-acetylated. Hydrolysis of N-acetyl linkage was achieved by SN2 reaction mechanism where water addition in carbonium ion was rate determining stage. It was concluded due to SN2 that in concentrated acid depolymerization in tenfolds higher than de-N-acetylation and in dilute acid it was equal. [40].

Likewise Zhan synthesized an improved method for N-acetylation of Glucoasmine in which he has used pyridine as a solvent in the presence of tributylamine and acetic anhydride. Approximate 99 % pure GlcNAc can be attained after a series of purification methods. The estimated yield of this method had been reported to be higher than 70 % [41].

In another related study, Trombotto et al. [42] prepared homogeneous series of chito-oligomers having 2–12 degrees of polymerization (DP) and different (0–90 %) degrees of N-acetylation (DA) was also obtained via two-step chemical modification. First, they hydrolyzed completely N-deacetylated chitosan followed by selective precipitations to produce glucosamine oligomers. In second step hydro-alcoholic solution of acetic anhydride was used in controlled way for partial N-acetylation glucosamine unit of oligomers. The drawback of this method, as for the enzymatic preparation of chitooligosaccharides,is the heterogeneity of the prepared chitooligosaccharides. Goyal et al. synthesized and screened an innovative class of N-acetyl glucosamine with methoxybenzylidene acetal protective group. This modification did not exert a negative influence on the gelation. On the contrary, it actually enhanced the gelation tendency for many derivatives. The introduction of the additional methoxy group on the phenyl ring led to low molecular weight gelators with a higher pH responsiveness. The resulting gels were stable at neutral pH values but degraded in an acidic environment [43]. Also, Trombotto et al. [44] prepared glucosamine hydrochloride (GluNHCl) from various crustacean shells like Penaeus monodon (Indian shrimp), Portunus pelagicus (blue crab) and Portunus sanguinolentus (three spot crab) of acids through the hydrolysis and its evaluation was analyzed by reversed phase high performance liquid chromatography (RP-HPLC). The results showed that the yield of chitin after demineralization with 0.5 M HCl was 87.83, 89.18 and 51.11 % and deacetylation of chitin with 2 N NaOH resulted in the yield of 68.91, 75.67, and 30 % for P. sanguinolentus, P. pelagicus, and P. monodon, respectively. The HPLC analysis also gives that the obtained glucosamine hydrochloride revealed species of Portunus (21.64 mg g−1 and 21.83 mg g−1) were better source of Glu-HCl than P. monodon (3.32 mg g−1). Although the manufacture of GlcNAc by chemical methods were assessed to be adequately profitable, thus, the product was not reflected as a usual natural polysaccharide due to the chemical alteration of GlcNAc. That is why, GlcNAc prepared using chemicals typically flavors bitter due to these alterations. In addition, the usage of ozone has also been developed [45].

Thus, the use chemically modified GlcNAc and glucosamine covers a wide range of applications like in food additives, cosmetics and pharmaceuticals, and medicines.

2.2 Preparation of D-Glucosamine and N-Acetyl D-Glucosamine Using Enzymatic Method

The drawback of chemical method not only due to practical causes but also because of the other environment interests of producing D-glucosamine and N-acetyl D-glucosamine, this is why synthesis via chemical method is not widely commercialized.

Kuk et al. investigated how a bacteria, GJ18, which are having robust chitinolytic activity which was isolated from soil of coastal areas. Then isolated strain was recognized as A. hydrophila by its structural and biochemical characteristics along with 16S rRNA gene sequences. The results showed up to 45 °C, it was effectually hydrolyzed to GlcNAc by A. hydrophila GJ18 crude enzyme; however the hydrolysis process started decreasing when the temperature is above 50 °C. However, the enzymatic hydrolysis of chitin can synthesize the same under trivial surroundings [46].

They both not only performs physiochemical functions but also utilized in the field of pathological aspects [47–52].

The whole collection of chitinolytic enzymes which consists of endochitinases, exochitinases, chitobiosidases, and acetylglucosaminidases (NAGases) that are synthesized and secreted through a prokaryotic or a eukaryotic entities [53].

Earlier, Muraki et al. separated D-glucosamine oligosaccharides from a chitosan hydrolyzate prepared with the cellulose enzyme derived from Trichoderma viride. The separation was done by using weak ion exchange chromatography with the elution by 0.01 N Hcl. At last titration procedure was used to find the glucosamine content. The results showed that this technique is efficient for the synthesis of highly pure oligosaccharides [7]. In contrasting study, few microorganisms, like Trichoderma hamatum strain or Trichoderma harzianum strain, produced N-acetyl glucosamine in the medium in the absence of chitin or its derivatives [54].

A huge variety of enzymes is sterilized from major production of microorganisms, genetically engineered organisms (GEO) for the purpose of the industrial production of D-glucosamine and N-acetyl glucosamine [55–57].

Setthakaset et al. prepared N-acetyl glucosamine from squid pen β-chitin utilizing Aspergillus species chitinase using hydrolysis process through enzymes. The results showed that the growth of the fungus in the media at pH 3.5 and 40 °C for 5 days which provides the maximum chitinolytic activity of 3.1 U/mL. The crude enzyme achieved from the growth of fungus is used in the hydrolysis process of milled squid pen β-chitin at acidic pH 4 and 45 °C using 22 U of enzyme per gram of chitin [58]. Chen et al. proved to synthesize N-acetyl glucosamine Chitinibacter tainanensis which was isolated from Southern Taiwan soil. The results showed that when Chitinibacter tainanensis was incubated with chitin. Chitin degrading factors was successfully converted to N-acetyl-glucosamine [59].

Recently, Sun et al. produced D-glucosamine by hydrolyzing chitosan with the use of two crude enzymes chitosanase and β-d-glucosaminidase showed that the optimal conditions were temperature 50 °C, substrate conc is 20 mg/mL, the optimum ratio of enzyme to chitosan 1.5 U/60 mg, pH 6.8. Under above conditions, it was completely hydrolyzed in 5 h and thus this method can be used efficiently used for producing D-glucosamine which can be further utilized for other applications [60].

In one study, around 100 % pure N-Acetylglucosamine was synthesized by utilizing enzymes from Aeromonas hydrophila [61], while another enzyme chitobiose was also synthesized using B. chitinases [62]. The study clearly showed that the endochitinases, exochitinases, and N-acetylglucosaminidases are essential for the ample absorption of chitin, and more N-acetylglucosaminidases activity gives a higher and efficient purity of GlcNAc. Thus, chitin crystalline structure and the enzymatic constituents of these reactions are the vital characteristics in the synthesis of GlcNAc through enzymatic reactions.

3 Application of D-Glucosamine and N-Acetyl D-Glucosamine

Glucosamine belongs to a huge section of amino groups of sugars that perform various numbers of vital roles in human system and are also located in the humans. It has become of great interest not only as an under utilized resource, but also as a novel efficient substance with extraordinary ability in enormous fields, and latest progress in chitin or chitosan chemistry is quite remarkable. All the above mentioned properties, together with the very safe toxicity, make them an exciting and promising product to get utilized for various applications such as biomedical applications, tissue engineering, wound healing, cosmetics, etc. The various application of glucosamine is shown in Fig. 3.

3.1 Application in Tissue Engineering

Glucosamine likewise assumes a part during the course of tissue engineering. Regardless of numerous studies in glucosamine and the more endeavors on supramolecular gelators or self-collected nanofibers and other tissue designing applications [15, 35, 63, 64].

Shaunak et al. utilized used anionic, polyamidoamine dendrimers to prepare innovative water-soluble conjugates of D-glucosamine and D-glucosamine 6-sulfate for effective immunogenic and antiangiogenic characteristics, respectively. After various evaluation and clinical trials conducted on rabbits the study showed that specially designed macromolecules such as the dendrimers depicted in this study might be altered to have specific immunogenic and antiangiogenic characteristics, and they utilized collectively to check wound tissue formation which can be majorly utilized in the field for regenerative medicine [65].

Likewise, Wang et al. studied the comparative study between the various outcomes of insulin-like growth factor-I, basic fibroblast growth factor, transforming growth factor beta1, and glucosamine sulphate on temporomandibular joint condylar cartilage and ankle cartilage cells in monolayered culture. The results showed that GS enhanced the cell propagation and synthesis at explicit concentrations and exceed growth elements in definite cases [66].

3.2 Application in Cosmetics

Human skin comprises of stratum corneum and dermis to protect the skin from different extreme natural circumstances like aridness and UV illumination. Stratum corneum assumes an indispensable part in maintaining the solidness of the skin. It additionally comprises of smoothed dead cells, corneocytes and a complex of lipid network, and characteristic dampness properties [67].

Chitin has a high review of UV radiation resistance, purification resistance, and oxidation resistance. Henceforth, it turns into the ideal common beautifiers crude materials. Chitin with saturating, film, and dynamic cell capacity can keep the skin damp, glossy, and adaptable in the readiness of a mixture of healthy skin restorative. It can likewise upgrade the metabolic capacity of epidermal cells, repress free radical oxidation, and wipe out lipofuscinosis quality, age spots, repair skin harm, concealment of bugs, and other harm to the skin. HA is primarily delivered from fibroblasts and keratinocytes and N-acetyl glucosamine are the primary building unit of HA so the last is chiefly included in skin change and assists in treating with skin maturing and detachment. Fitting organization of GlcNAc is utilized to enhance skin quality.

Bisset et al. [68] mulled over that GlcNAc helps in lessening the presence of facial hyperpigmentation in 8 week, which was demonstrated by the twofold visually impaired clinical trial [69]. Utilizing as a part of in vitro genomic trials, the mechanism by which GlcNAc decreases melanin creation has been found to include the up-regulation of a few gene, for example, epidermal turnover qualities and cell reinforcement-related qualities, and the down-regulation of the cytoskeleton qualities included in melanosome transport [70]. It is likewise viewed as that an important fixing in beautifiers for enhancing skin wrinkles and shading due to its flexible properties of GlcNAc [71]. As examined in past segment, glucosamine advances the proliferation of keratinocytes and fibroblasts and builds the creation of HA in the skin, it has likewise been effectively used to recuperate wounds in skin [72, 73].

3.3 Chitin as Drug Delivery Carriers

As chitin is the main constituent of Glucosamine, its important function is to act as a carrier for drug delivery. But the main feature of chitin is that it must not accrue inside the human system nor must it be toxic [74].

Chitin formulations like carboxymethyl chitin, succinyl chitosan [75], chitosan derived hydrogel [76], hydroxyethyl chitin [77] had been clearly mentioned to contain such properties. The colloidal structure of chitosan can easily entrap macromolecules by enormous methods. All such associated molecules have been revealed to transport via mucosa membrane and epithelial cells more effectively. Cationic chitosan when combined with other natural biopolymers have also clearly been indicated to increase the drug encapsulation efficiency of liposomes through layer by layer self-assembly method [78]. Nanoparticles prepared from chitosan/chitin with polyethylene oxide which has widely utilized as an effective carrier for proteins as well. Furthermore, an oral route for delivering drugs has also been established by using chitosan and tripolyphosphate, alginate, etc., In such system, microparticles and nanoparticles were get entrapped inside the beads which are synthesized from chitosan in solution of tripolyphosphate, etc.,

3.4 Application in Regenerative Medicine- Treatment of Osteoarthritis

Osteoarthritis (OA) is the most widely recognized manifestation of joint inflammation, is a general wellbeing issue all through the world. A few elements have been painstakingly examined for the symptomatic and auxiliary administration of OA. This review provides published studies regarding the effect of GS and chondroitin sulfate synthesis on the development of knee or hip OA. Since 1969, when first clinical trial of glucosamine conducted in Germany, various studies have contrasted glucosamine sulfate and nonsteroidal anti-inflammatory agents or with placebo. In the early 1980s, a little number of controlled human trials was directed in Europe and in Asia to evaluate the clinical utilization of glucosamine sulfate in the treatment of OA [79]. Glucosamine along with chondroitin sulfate are successfully utilizing in treat of osteoarthritis. Glucosamine and chondroitin sulfate, when combined, are found efficient in the subclass of patients with moderate-to-severe knee pain. In North America, glucosamine hydrochloride or sulfate along with chondroitin sulfate are measured as nutraceuticals (nutrition + pharmaceutical), although in maximum European nations they are promoted as pharmaceuticals and hence preparation, manufacture and marketing of glucosamine are watched more precisely in Europe [80]. Laverty et al. investigated that in maximum clinical related outcomes in Glucosamine/chondroitin Arthritis Intervention Trial (GATI) a perfect blend of sodium chondroitin sulfate and glucosamine hydrochloride were taken due to enhance the bioavailability of sulfates [81]. Clegg et al. showed the Glucosamine/chondroitin Arthritis Intervention Trial (GAIT) for 24 week, randomized, double blind, placebo and celecoxib controlled, multicenter trial to estimate severely the worth and protection of glucosamine-chondroitin sulfate, and the two in combination in the handling of pain because of the knee osteoarthritis [82].

Alindon et al. conducted a 12 week study and the consequences of this study recommended that glucosamine was no more viable than placebo in treating the indications of knee OA. Be that as it may, it ought to be observed that this study was intended for an alternate reason than evaluation of glucosamine [83, 84].

Hochberg et al. conducted a compare study of the effectiveness and safety of chondroitin sulfate and glucosamine hydrochloride against celecoxib over 606 patients in France, Germany, Poland, and Spain having knee osteoarthritis and severe pain. It was concluded that in comparison with glucosamine + chondroitin sulfate was reducing pain, stiffness, functional limitation, and joint swelling/effusion after 6 months in patients and having a decent safety outline [85].

3.5 Application in Cancer/Tumor Imaging

Tada et al. prepared 2-deoxy-2-[18F] fluoroacetamido-d-glucopyranose via amide bond formation with 18F labeled carboxylic acid [Fig. 4]. Rediochemical yield and purity was 9.1 and 98 %, respectively. The compound utilized in diagnosing tumor through imaging [86]. After an hour of injection of 2-deoxy-2-[18F] fluoroacetamido-d-glucopyranose, a high uptake were measured in tumor cells which were used to diagnosed and visualized by positron emission tomography (PET) [87].

Qi et al. designed and synthesized 99 % pure N-(2-[18F] fluoro-4-nitrobenzoyl) glucosamine, a glucosamine derivative, via many step reaction and their performance were checked by in vivo and in vitro study. Results showed that tumor/blood ratio of glucosamine derivative was 4.40 and tumor/muscle ratio of glucosamine derivative was found 4.84. The prepared 18F derivative can showed it importance in tumor imaging using by positron emission tomography (PET) technique [88]. Carroll et al. designed 18F-labeled glucosamine analogs because glucosamine had a role in the biochemical production of glycosylated proteins and lipids and this property was used for imagining of cancer cells. They design three 18F labeled glucosamine by exploring 18F radiochemistry imine formation via aldehyde condensation, alkylation, and copper mediated click chemistry reaction. The three synthesized 18F labeled glucosamine were verified in vivo in mice by using HEY Rab25 tumors (human ovarian carcinoma cell-line. Figure 5c displayed favorable in vivo characteristics, with no bone uptake, quick clearance and most significantly noticeable tumor uptake [89].

18F labeled glucosamine a, b, and c are prepared by Carroll et al. for imaging of cancer cells [89]

Yang et al. [90] labeled glucosamine derivative with gallium 68 (68Ga) to design a radiotracer for diagnosing tumor cells using micro-positron emission tomography (μPET). Glucosamine was first modified with 1,4,7,10-tetraazacyclododecane-1,4,7,10-tetraacetic acid (DOTA) by reaction of D-glucosamine hydrochloride and 2-(4-isothiocyanatobenzyl)-DOTA. Microwave irradiation of 25 W for 5 min and 50 W for 5 min were used for labeling of 68Ga on DOTA-D-glucosamine derivative. After an hour of incubation of 68Ga labeled glucosamine treated human epithelial carcinoma cells (A431), 15.7 % uptake was observed. μPET images of A431 tumors bearing mice displayed acceptance of 68Ga labeled glucosamine in the tumors [91]. Igawa et al. [92] studied uptake of D-glucosamine conjugate carboxylated QDs into cultured osteoblastic cells. Size of the core carboxylated QDs and D-glucosamine conjugated QDs were calculated around 3 nm and 20–30 nm, respectively. Glucosamine modified QDs adhere on cell surface and conveyed into the cytoplasm in three hours of incubation and the process was confirmed by using specific fluorescent staining [93].

4 Concluding Remarks

Glucosamine has always shown low cytotoxicity, biodegradable, and biocompatible in nature which makes them utilized for various biomedical applications. It also consists of chitinases which is widely available in nature and found almost in all the bacteria, fungi as well as in plants, and in the digestive systems of various animals. D-glucosamine and N-acetyl D-glucosamine is synthesized using substrate, i.e.; chitin by various chemical, enzymatic methods. New methods using glucose as a substrate can also be applied to obtain n acetyl glucosamine using genetically engineered microorganisms. D-Glucosamine and N-acetyl D-glucosamine has a wide application in regenerative medicine like for osteoarthritis through which the damaged cartilages can be replaced by using Glucosamine. At last, the versatile characteristics of both enhance its usage as a novel candidate for utilization not only in regenerative medicine but also for drug development and other biomedical applications.

Abbreviations

- GlcN:

-

Glucosamine

- GlcNAc:

-

N-acetylglucosamine

- NAG:

-

N-acetyl-D-glucosamine

- GS:

-

Glucosamine Sulphate

- OA:

-

Osteoarthritis

- GAGs:

-

Glycosaminoglycans

- GlcNHCl:

-

Glucosamine hydrochloride

- RP-HPLC:

-

Reversed phase high-performance liquid chromatography

- HCl:

-

Hydrochloric acid

- NaOH:

-

Sodium hydroxide

- rRNA:

-

Ribosomal ribonucleic acid

- GEO:

-

Genetically engineered organisms

- IGF-I:

-

Growth factor-I

- bFGF:

-

Basic fibroblast growth factor

- TGF-b1:

-

Transforming growth factor bea1

- TMJ:

-

Temporomandibular joint

- HA:

-

Hyaluronic acid

- QD:

-

Quantum Dots

- GAIT:

-

Glucosamine/chondroitin Arthritis Intervention Trial

References

Flash J, Pilet PE, Jolles P (1992) What’s new in chitin research? Experientia 48:701–716

Shibata Y, Foster LA, Metzger WJ, Myrvik QN (1997) Alveolar macrophage priming by intravenous administration of chitin particles, polymers of N-acetyl-D-glucosamine, in mice. Infect Immun 65:1734–1741

Shibata Y, Honda I, Justice JO, Van Scott MR, Nakamura RM, Myrvik QN (2001) The adjuvant N-acetyl-D-glucosamine polymer up-regulates Th1 immunity but down-regulates Th2 immunity against a mycobacterial protein (MPB-59) in interleukin-10-knockout and wild-type mice. Infect Immun 69:6123–6130

Suzuki K, Mikami T, Okawa Y, Tokoro A, Suzuki S, Suzuki M (1986) Antitumor effect of hexa-N-acetylchitohexaose and chitohexaose. Carbohydr Res 151:403–408

Creamer P (2000) Osteoarthritis pain and its treatment. Curr Opin Rheumatol 12:450–455

Aam BB, Heggset EB, Norberg AL, Sorlie M, Varum KM, Eijsink VG (2010) Production of chitooligosaccharides and their potential applications in medicine. Mar Drugs 8:1482–1517

Yang CJ, Liu YK, Liu CL, Shen CN, Kuo ML, Su CC, Tseng CP, Yen TC, Shen CR (2009) Inhibition of acidic mammalian chitinase by RNA interference suppresses ovalbumin-sensitized allergic asthma. Hum Gene Ther 20:1597–1606

Shen CR, Juang JH, Tsai ZT, Wu ST, Tsai FY, Wang JJ, Liu CL, Yen TC (2011) Preparation, characterization and application of superparamagnetic iron oxide encapsulated with N-[(2-hydroxy-3-trimethylammonium) propyl] chitosan chloride. Carbohydr Polym 84:781–784

Chen JK, Shen CR, Liu CL (2010) N-acetylglucosamine: production and applications. Mar. Drugs 8:2493–2516

Jain T, Dutta PK (2011) Chitin nanoparticles for drug delivery: preparation, characterization and evaluation. Asian Chitin J 7:13–18

Salvatore S, Heuschkel R, Tomlin S, Davies SE, Edwards S, Walker-Smith JA, French I, Murch SH (2011) A pilot study of N-acetyl glucosamine, a nutritional substrate for glycosaminoglycan synthesis, in pediatric chronic inflammatory bowel disease. Aliment Pharmacol Ther 14:1567–1579

Kumar H, Srivastava R, Dutta PK (2013) Highly luminescent chitosan-l-cysteine functionalized CdTe quantum dots film: synthesis and characterization. Carbohydr Polym 97:327–334

Kimball AB, Kaczvinsky JR, Li J, Robinson LR, Matts PJ, BergeCA Miyamoto K, Bissett DL (2011) Reduction in the appearance of facial hyperpigmentation after use of moisturizers with a combination of topical niacinamide and N-acetyl glucosamine. Int J Mol Sci 12:1194–1198

Dutta PK, Dutta J, Tripathi VS (2004) Chitin and chitosan: Chemistry, properties and applications. J Sci Ind Res 63:20–31

Rath P, Sanya K, Kamontip K, Mongkol S, Seiichi A (2002) Quantitative production of 2-acetamido-2-deoxy-D-glucose from crystalline chitin by bacterial chitinase. Carbohydr Res 337:557–559

Dutta PK, Tripathi S, Mehrotra GK, Dutta J (2009) Perspectives for chitosan based antimicrobial films in food applications. Food Chem 114:1173–1182

Dutta J, Chattopadhyaya MC, Tripathi VS, Dutta PK (2004) Chitin & Chitosan: novel biomaterials waiting for future developments. J Polym Mater 21:321–332

Fasbender MH (1994) Glucosamine sulfate compared to ibuprofen in osteoarthritis of the knee. Osteoart Cart 2:61–69

Hackman RH, Goldberg M (1974) Light-scattering and infrared-spectrophotometric studies of chitin and chitin derivatives. Carbohydr Res 38:35–45

Jollès P, Muzzarelli RAA (eds) (1999) Chitin and Chitinases. Birkhauser Verlag publishers, Basel Switzerland

Tanaka T, Fujiwara S, Nishikori S, Fukui T, Takagi M, Imanaka TA (1999) Unique chitinase with dual active sites and triple substrate binding sites from the hyperthermophilic archaeon pyrococcus kodakaraensis KOD1. Appl Environ Microbiol 65:5338–5344

Mao JS, Liu HF, Yin YJ, Yao KD (2003) The properties of chitosan-gelatin membrane and scaffolds modified with hyaluronic acid by different methods. Biomaterials 24:1621–1629

Talent JM, Gracy RW (1996) Pilot study of oral polymeric N-acetyl-D-glucosamine as a potential treatment for patients with osteoarthritis. Clin Ther 18:1184–1190

Angelis PL (1999) Molecular directionality of polysaccharide polymerization by the pasteurella multocida hyaluronan synthase. J Biol Chem 274:26557–26562

Turely EA, Bowman P, Kytryk MA (1985) Effects of hyaluronate and hyaluronate binding proteins on cell motile and contact behaviour. J Cell Sci 78:133–145

Alho AM, Underhill CB (1989) The hyaluronate receptor is preferentially expressed on proliferating epithelial cells. J Cell Biol 108:1557–1565

Toole BP, Jackson G, Gross J (1972) Hyaluronate in morphogenesis: inhibition of chondrogenesis in vitro. Proc Natl Acad Sci 69:1384–1386

Brecht M, Mayer U, Schlosser E, Prehm P (1986) Increased hyaluronate synthesis is required for fibroblast detachment and mitosis. J Biochem 239:445–450

Dube B, Luke HJ, Aumaille M, Prehm P (2001) Hyaluronan reduces migration and proliferation in CHO cells. Biochim Biophys Acta 1538:283–289

Kobata A, Ginsburg V (1969) Oligosaccharides of human milk: isolation and characterization. Arch Biochem Biophys 130:509–513

Miller JB, Bull S, Miller J, McVeagh P (1994) The oligosaccharide composition of human milk: temporal and individual variations in monosaccharide components. J Pediatri. Gastroenterol Nutr 19:371–376

Tharanathan RN, Kittur FS (2003) Chitin—the undisputed biomolecule of great potential. Crit Rev Food Sci Nutr 43:61–87

Howard MB, Ekborg NA, Weiner RM, Hutcheson SW (2003) Detection and characterization of chitinases and other chitin-modifying enzymes. J Ind Microbiol Biotechnol 30:627–635

Kurita K (2006) Chitin and chitosan: functional biopolymers from marine crustaceans. Mar Biotechnol 8:203–226

Hitoshi S, Shizu F, Naoko Y, Norioki K, Atsuyoshi N (2002) Production of N-acetyl-D-glucosamine from α-chitin by crude enzymes from aeromonas hydrophila H-2330. Carbohydr Res 337:761–763

Falk M, Smith DG, McLachla J, McInnes AG (1966) Studies on chitin (Beta-(1-]4)-Linked 2-Acetamido-2-Deoxy-D-Glucan) fibers of diatom thalassiosira fluviatilis hustedt. J Canad Chem 44:2269–2281

Kuyama H, Nakahara Y, Nukada T, Ito Y, Ogawa T (1993) Stereo controlled synthesis of chitosan dodecamer. Carbohydr Res 243:1–7

Aly MRE, Ibrahim E, Ashry ESH, Schmidt RR (2001) Synthesis of chitotetraose and chitohexaose based on dimethylmaleoyl protection. Carbohydr Res 331:129–142

Aly MRE, Castro-Palomino JC, Ibrahim ESI, El-Ashry FSH, Schmidt RR (1998) The dimethylmaleoyl group as amino protective group-application to the synthesis of glucosamine-containing oligosaccharides. Eur J Org Chem 8:2305–2316

Bohlman JA, Schisler DO, Hwang KO, Hennling JP, Trinkle JR, Anderson TB, Steinke JD, Vanderhoff A, (2010) N-Acetyl-D-glucosamine and Process for Producing N-Acetyl-D-glucosamine. US Patent NO. 6693188B2

Sashiwa H, Fujishima S, Yamano N, Kawasaki N, Nakayama A, Muraki E, Aiba S (2001) Production of N-Acetyl-D-glucosamine from β-Chitin by enzymatic hydrolysis. Chem Lett 31:308–309

Vårum KM, Ottoy MH, Smidsrod O (2001) Acid hydrolysis of chitosans. Carbohydr Polym 46:89–98

Zhan WS (2007) Process for Preparing Refined N-Acetyl-D-aminoglucose. CN Patent NO 1907993

Trombotto S, Ladavière C, Delolme F, Domard A (2008) Chemical preparation and structural characterization of a homogeneous series of chitin/chitosan oligomers. Biomacromolecules 9:1731–1738

Goyal N, Mangunuru HPR, Parikh B, Shrestha S, Wang S (2014) Beilstein synthesis and characterization of pH responsive D-glucosamine based molecular gelators. J Org Chem 10:3111–3121

Sibi G, Dhananjaya K, Ravikumar KR, Mallesha H, Venkatesha RT, Trivedi D, Bhusal PK, Gowda K (2013) Preparation of glucosamine hydrochloride from crustacean shell waste and It’s quantitation by RP-HPLC. American-Eurasian J Sci Res 8:63–67

Seo S, King JM, Prinyawiwatkul W (2007) Simultaneous depolymerization and decolorization of Chitosan by ozone treatment. J Food Sci 72:522–526

Kuk JH, Jung WJ, Jo GH, Kim YC, Kim KY, Park RD (2005) Production of N-acetyl-β-D-glucosamine from chitin by Aeromonas sp. GJ-18 crude enzyme. Appl Microbiol Biotechnol 68:384–389

Gooday BW (1977) Biosynthesis of the fungal wall—mechanisms and implications. the first fleming lecture. J Gen Microbiol 99:1–11

Fuchs RL, McPherson SA, Drahos DJ (1986) Cloning of a serratia marcescens gene encoding chitinase. Appl Environ Microbiol 51:504–509

Abeles FB, Bosshart RP, Forrence LE, Habig WH (1971) Preparation and purification of glucanase and chitinase from bean leaves. Plant Physiol 47:129–134

Cohen-Kupiec R, Chet I (1998) The molecular biology of chitin digestion. Curr Opin Biotechnol 9:270–277

Zhu Z, Zheng T, Homer RJ, Kim YK, Chen NY, Cohn L, Hamid Q, Elias JA (2004) Acidic mammalian chitinase in asthmatic Th2 inflammation and IL-13 pathway activation. Science 204:1678–1682

Gooday GW (1990) The ecology of chitin degradation. Adv Microb Ecol 11:387–430

Muraki E, Yaku F, Kojima H (1993) Preparation and crystallization of D-glucosarnine oligosaccharides with dp 6-8. Carbohydr Res 239:227–237

Mori T, Ichikawa W, KitaY, Tetsuka Y (2010) Method for fermentative production of N-Acetyl-D-glucosamine by microorganism. US Patent NO. 20100055746

Roberts RL, Cabib E (1982) Serratia marcescens chitinase: one-step purification and Use for the determination of chitin. Anal Biochem 127:402–412

Oppenheim AB, Chet I (1992) Cloned chitinase in fungal plant—pathogen control strategies. Trends Biotechnol 10:392–394

Pan CH, Rim SL, Kim SI (1996) Expression of two cDNAs encoding class I chitinases of rice in Escherichia coli. Biosci Biotech Biochem 60:1346–1348

Setthakaset P, Pichyangkura R, Ajavakom A, Sukwattanasinitt M (2008) Preparation of N-acetyl-D-Glucosamine using Enzyme from Aspergillus sp. J Metals, Mater Minerals 18:53–57

Chen JK, Shen CR, Yeh CH, Fang BS, Huang TL, Liu CL (2011) N-Acetyl Glucosamine obtained from chitin by chitin degrading factors in chitinbacter tainanesis. Int J Mol Sci 12:1187–1195

Sun Y, Zhang J, Wua S, Wang S (2013) Preparation of d-glucosamine by hydrolysis of chitosan with chitosanase and β-d-glucosaminidase. Int J Biol Macromol 61:160–163

Estroff LA, Hamilton AD (2004) Water gelation by small organic molecules. Chem Rev 104:1201–1218

Kiyonaka S, Sada K, Yoshimura I, Shinkai S, Kato N, Hamachi I (2004) Semi-wet peptide/protein array using supramolecular hydrogel. Nat Mater 3:58–64

Silva GA, Czeisler C, Niece KL, Beniash E, Harrington D, Kessler JA (2004) Stupp SI (2004) selective differentiation of neural progenitor cells by high-epitope density nanofibers. Science 303:1352–1355

Zhang SG, Holmes TC, Dipersio CM, Hynes RO, Su X, Rich A (1995) Self-complementary oligopeptide matrices support mammalian cell attachment. Biomaterials 16:1385–1393

Shaunak S, Thomas S, Gianasi E, Godwin A, Jones E, Teo I, Mireskandari K, Luthert P, Duncan R, Patterson S, Khaw P, Brocchini S (2004) Polyvalent dendrimer glucosamine conjugates prevent scar tissue formation. Nat Biotechnol 22:977–984

Wang L, Detamore MS (2009) Effects of growth factors and glucosamine on porcine mandibular condylar cartilage cells and hyaline cartilage cells for tissue engineering applications. Arch Oral Biol 54:1–5

Wertz PW, Bergh VB (1998) The physical, chemical and functional properties of lipid in the skin and other biological barrier. Chem Phys Lipids 91:85–96

Bissett D, Robinson LR, Raleigh PS, Miyamoto K, Hakozaki T, Li J, Klem GR (2007) Reduction in the appearance of facial hyperpigmentation by topical N-Acetyl Glucosamine. J Cosmet Dermatol 6:20–26

Bissett D, Farmer T, McPhail S, Reichling T, Tiesman JP, Juhlim KD, Hurley GJ, Robinson MK (2007) Genomic expression changes induced by topical N-acetylglucosamine in skin equivalent cultures in vitro. J Cosmet Dermatol 6:232–238

Riordan NH (1999) Skin Treatment System. US Patent NO 5866142

Hwang JI, Kim KS (2005) Cosmetics Composition Comprising Extract of Natural Materials for Improving Acne and Skin Wrinkles and Whitening Skin. KR Patent NO 20050004355 A

Minami S, Okamoto Y (2007) Drug for Remedy or Treatment of Wound. EP Patent NO 1749532

Flessner MF, Lofthouse J, Williams A (2002) Chronic alteration of sub-peritoneal tissue and peritoneal transport. Adv Perit Dial 18:12–14

Dev A, Mohan JC, Sreeja V, Tamura H, Patzke GR, Hussain F, Weyenet S, Nair SV, Jayakumar R (2010) Novel carboxymethyl chitin nanoparticles for cancer drug delivery applications. Carbohydr Polym 79:1073–1079

Kamiyama K, Onishi H, Machida Y (1999) Biodisposition characteristics of N-succinyl-chitosan and glycol- chitosan in normal and tumor-bearing mice. Biol Pharm Bull 22:179–186

Ishihara M, Obara K, Nakamura S, Fujita M, Masuoka K, Kanatani Y, Takase B, Hattori H, Morimoto Maehara T, Kikuchi M (2006) Chitosan hydrogel as a drug delivery carrier to control angiogenesis. J Artif Organs 9:8–16

Zhao Y, Chen G, Sun M, Jin Z, Gao C (2006) Study on preparation of the pH sensitive hydroxyethyl chitin/poly (acrylic acid) hydrogel and its drug release property. Sheng Wu Yi Xue Gong Cheng Xue Za Zhi 23:338–341

Haidar ZS, Hamdy RC, Tabrizian M (2008) Protein release kinetics for core-shell hybrid nanoparticles based on the layer-by-layer assembly of alginate and chitosan on liposomes. Biomaterials 29:1207–1215

Drovanti A, Bignamini AA, Rovati AL (1980) Therapeutic activity of oral glucosamine sulfate in osteoarthritis: a placebo-controlled double-blind investigation. Clin Ther 3:260

Russell AS, Aghazadeh-Habashi A, Jamali F (2002) Active ingredient consistency of commercially available glucosamine sulfate products. J Rheumatol 29:2407–2409

Laverty S, Sandy JD, Celeste C, Vachon P, Marier JF, Plaas AH (2005) Synovial fluid levels and serum pharmacokinetics in a large animal model following treatment with oral glucosamine at clinically relevant doses. Arthritis Rheum 52:181–191

Clegg DO, Reda DJ, Harris CL, Klein MA, O’Dell JR, Hooper MM, Bradley JD, Bingham CO 3rd, Weisman MH, Jackson CG, Lane NE, Cush JJ, Moreland LW, Schumacher HR Jr, Oddis CV, Wolfe F, Molitor JA, Yocum DE, Schnitzer TJ, Furst DE, Sawitzke AD, Shi H, Brandt KD, Moskowitz RW, Williams HJ (2006) Glucosamine, chondroitin sulfate, and the two in combination for painful knee osteoarthritis. N Engl J Med 354:795–808

McAlindon T, Formica M, LaValley M, Lehmer M, Kabbara K (2004) Effectiveness of glucosamine for symptoms of knee osteoarthritis: results from an internet-based randomized double-blind controlled trial. Am J Med 117:643–649

McAlindon T, Formica M, Kabbara K, LaValley M, Lehmer M (2003) Conducting clinical trials over the internet: feasibility study. BMJ 327:484–487

Hochberg MC, Martel-Pelletier J, Monfort J, Möller I, Castillo JR, Arden N, Berenbaum F, Blanco FJ, Conaghan PG, Doménech G, Henrotin Y, Pap T, Richette P, Sawitzke A, du Souich P, Pelletier JP (2015) Combined chondroitin sulfate and glucosamine for painful knee osteoarthritis: a multicentre, randomised, double-blind, non-inferiority trial versus celecoxib. Ann Rheum Dis 2014:206792

Tadal M, Oikawal A, Iwata R, Fujiwara T, Kubota K, Matsuzawa T, Sugiyama H, Ido T, Ishiwata K, Sato T (1989) An efficient, one-pot synthesis of 2-deoxy-2-[18F]fluoroacetamido-D-glucopyranose (N-[18F]fluoroacetyl-D-glucosamine), potential diagnostic imaging agent. J Labelled Compd Radiopharm 27:1317–1324

Fujiwara T, Kubota K, Sato T, Matsuzawa T, Tada M, Iwata R, Itoh M, Hatazawa J, Sato K, Fukuda H, Ido T (1990) N-[18F] fluoroacetyl-D-glucosamine: a potential agent for cancer diagnosis. J Nucl Med 31:1654–1658

Yang Z, Xiong C, Zhang R, Zhu H, Li C (2012) Synthesis and evaluation of 68 Ga-labeled DOTA-2-deoxy-D-glucosamine as a potential radiotracer in μPET imaging. Am J Nucl Med Mol Imaging 2:499–507

Qi CM, He Y, Wang X, Feng M, Xu JL, Ding R, Liu H, Chen YR, Li F, Zhu ZH, Dang YH, Zhang ST, Xie Y (2011) Synthesis and evaluation of N-(2-[18F]fluoro-4-nitrobenzoyl)glucosamine: a preliminary report. J Radioanal Nucl Chem 287:913–920

Igawa K, Xie MF, Ohba H, Yamada S, Hayashi Y (2014) D-glucosamine conjugation accelerates the labeling efficiency of quantum dots in osteoblastic cells. Biomed Res Int 2014:821607

Carroll L, Witney TH, Aboagye EO (2013) Design and synthesis of novel 18F-radiolabelled glucosamine derivatives for cancer imaging. Med Chem Commun 4:653

Acknowledgments

Tanvi Jain and Hridyesh Kumar gratefully acknowledged the research support both from Institute and TEQIP-II, MNNIT Allahabad.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer India

About this chapter

Cite this chapter

Jain, T., Kumar, H., Dutta, P.K. (2016). D-Glucosamine and N-Acetyl D-Glucosamine: Their Potential Use as Regenerative Medicine. In: Dutta, P. (eds) Chitin and Chitosan for Regenerative Medicine. Springer Series on Polymer and Composite Materials. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2511-9_11

Download citation

DOI: https://doi.org/10.1007/978-81-322-2511-9_11

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2510-2

Online ISBN: 978-81-322-2511-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)