Abstract

One of the many environmental challenges faced by Extraction field is the widespread use of organic solvents. With a solvent based extraction the solvent necessarily has to be separated from the final extract. A large number of these solvents are toxic that pose a risk to workers and community members and virtually all of them are classified as volatile organic compounds (VOCs) that contribute to smog. In this context, the development of solvent-free extraction processes is of great interest in order to modernize classical processes making them cleaner, safer and easier to perform. This chapter presents a picture of current knowledge on innovative solvent-free methods of natural products extraction. It provides the necessary theoretical background and some details about extraction using the most innovative, rapid and green techniques such as microwaves, instant controlled pressure drop (DIC) process and Pulsed Electric Field (PEF): the technique, the mechanism and some applications.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Pulse Electric Field

- Pulse Electric Field Treatment

- Vacuum Tank

- Natural Product Extraction

- Plant Food Tissue

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

2.1 Introduction

In a typical chemical or extraction process, solvents are used extensively for dissolving reactants, solvating molecules, extracting products, separating mixtures. However the major part of the organic solvents currently found in industry, in spite of a large number of well-known advantages, are characterized by several dangerous effects for the human health and the environment. Many organic solvents are Volatile Organic Compounds (VOCs), and it means that they are highly volatile, very useful for industrial applications, contribute both to increase the risks of fire and explosion, and to facilitate the release in the atmosphere in which these solvents can act as air pollutants causing ozone depletion and global warming. Moreover, many conventional solvents are highly toxic for human beings, animals and plants, and often their toxicological properties are completely unknown.

For example, n-hexane, solvent of choice for extraction of oils, can be emitted during extraction and recovery; it has been identified as an air pollutant since it can react with other pollutants to produce ozone and photochemical oxidants [1, 2]. Precautions to minimize the effects of these solvents by improved recycling have limited success and cannot avoid some losses into the environment. Moreover, the risk connected to potential accidents is still present.

During the last years, a central objective in extraction field of natural products has been set to develop greener and more economically competitive processes for the efficient extraction of natural substances with potential application in the cosmetic or agrochemical industries. In this context, the development of solvent-free alternative processes is of great interest in order to modernize classical processes making them cleaner, safer and easier to perform.

Therefore the following benefits could be mentioned for solvent-free conditions: (1) Avoid large volumes of solvent which reduces emission and needs for distillation; (2) The absence of solvents which facilitates scale-up; (3) Extracts are cleaner without residues; (4) Safety is enhanced by reducing risks of overpressure and explosions.

Extraction of olive oil using mechanical pressing is recognized as a solvent-free alternative. Virgin olive oils are extracted from olive fruits by using only physical methods, which include crushing of olives, malaxation of resulting pastes and separation of the oily phase. Because of its location in mesocarp of cells and the use of purely mechanical pieces of apparatus for its extraction, virgin olive oil does not require further treatment before its consumption (Fig. 2.1).

This chapter presents a picture of current knowledge on innovative solvent-free methods of natural products extraction. It provides the necessary theoretical background and some details about extraction using the most innovative, rapid and green techniques such as microwaves, instant controlled pressure drop (DIC) process and Pulsed Electric Field (PEF): the technique, the mechanism and some applications.

2.2 Solvent-Free Microwave-Assisted Extraction

The use of microwave energy was described for the first time in 1986 simultaneously by Gedbye [3] in organic synthesis and by Ganzler [4] for extraction of biological samples and analysis of organic compounds. Since then, numerous laboratories have studied the synthetic and analytical possibilities of microwaves as a non-classical source of energy. Several classes of compounds such as essential oils, aromas, pigments, antioxidants, and other organic compounds have been extracted efficiently from a variety of matrices mainly and plant materials. Advances in microwave extraction have given rise to solvent-free microwave technique namely Microwave Hydrodiffusion and Gravity.

2.2.1 Principle

Microwave hydrodiffusion and gravity (MHG) [5] is a new and green technique for the extraction of biomolecules patented in 2008. MHG was conceived for laboratory and industrial-scale applications in the extraction of pigments, aroma components, and antioxidants from different kind of plants. Based on a relatively simple principle, this method also involves placing the plant material in a microwave reactor, without adding any solvent or water. The internal heating of the in situ water within the plant material distends the plant cells and leads to the rupture of cells. The heating action of microwaves thus frees secondary metabolites and in situ water, which are transferred from the inside to the outside of the plant material. This physical phenomenon, known as hydrodiffusion, allows the extract, diffused outside the plant material, to drop by gravity out of the microwave reactor and fall through the perforated Pyrex disk.

A cooling system outside the microwave oven cooled the extract continuously. The crude extracts are collected in a receiving flask for further analysis (Fig. 2.2). MHG not only appeared as an efficient and economical technology but its chief advantage is its environmental friendly approach as it works without using any solvent just under effect of microwaves and earth gravity at atmospheric pressure.

2.2.2 Instrumentation

A Milestone NEOS-GR microwave laboratory oven (900 W maximum), as shown in (Fig. 2.2), is used to perform the microwave hydrodiffusion and gravity (MHG) extraction: this is a multimode microwave reactor of 2.45 GHz. Temperature is monitored by an external infrared (IR) sensor. MHG could also be used to produce larger quantities of extracts by using existing large-scale microwave extraction reactors called “MAC-75” (Fig. 2.3).

2.2.3 Application

The feasibility of microwave process in the preparation of samples has been investigated on different matrices, as shown in the Table 2.1. This process was applied to many kinds of plants such as aromatic plants and citrus for an essential oil extraction [6–8]. The first example is the menthe pulegium L. extraction [6], where 0.95 % of essential oil was obtained by the heating of 500 g of matrix at 500 W during 20 min at atmospheric pressure. For Citrus limon L. [7], 500 g of matrix were also treated at 500 W for 15 min and two respective yields of 0.7 and 1.6 % of essential oil were obtained at atmospheric pressure. Another example with Rosmarinus Officinalis L. [8] was tested by taking 500 g of plant at 500 W during 15 min, which provided 0.33 % of essential oil.

Zill-e-Huma et al. reported MHG as a novel technique for extracting flavonoids from onion. The plant tissues were strongly disrupted by microwave irradiation through the microscopic observation of extracts, so that target compounds could be efficiently extracted and detected by HPLC and other analysis [9, 10]. MHG was also applied to extraction of flavonoids from sea buckthorn by-products, producing a little lower yield of flavonol in a very short time (15 min) in comparison to classic methods but a higher content of reducing compounds contained in MHG extracts [11].

2.3 Instant Controlled Pressure Drop Process (DIC, “Détente Instantanée Contrôlée”)

The instant controlled pressure drop process, abbreviated DIC for ‘Détente Instantanée Contrôlée’, was developed by Allaf et al. in 1988 [12]. DIC extraction is based on fundamental studies with respect to the thermodynamics of instantaneity [13].

2.3.1 Principle

It consists of a thermo-mechanical process induced by subjecting the product to a fast transition from high temperature/high pressure to a vacuum. DIC extraction usually starts by establishing this high temperature/high pressure by injecting steam, microwaves, hot compressed air, etc. for some seconds, proceeding then to an abrupt pressure drop toward a vacuum (about 5 kPa with a rate higher than 0.5 MPa.s−1). By instantly dropping the pressure, rapid autovaporization of the moisture inside the material will occur. It will swell and lead to texture change which results in higher porosity as well as a greater specific surface area and reduced mass-transfer resistance through Darcy’s vapor transfer instead of Fick’s similar law. The short time – high temperature operation (few seconds) and the immediate drop in temperature (to be lower than 30 ºC) thanks to the pressure drop prevent further thermal deterioration and provide a final extract of great quality.

2.3.2 Instrumentation

DIC equipment is in the main part divided in three components: (1) the autoclave with heating jacket also named the processing vessel where the product is placed, (2) the vacuum tank linked to a vacuum pump, and (3) the instant valve enabling the abrupt connection between (1) and (2). The vacuum tank is cooled through a double jacket in order to condensate the extracts. Other devices are part of the DIC process such as a steam generator, an air compressor (for the electro-pneumatic actions) and the vacuum pump. A schematic diagram of the DIC apparatus and the pressure profile are presented in Figs. 2.4 and 2.5.

In order to undergo a DIC cycle, the raw material is placed within the autoclave where a vacuum is subsequently applied. This will facilitate the contact between the steam and the product enabling a homogenous heating of the product. It is afterward filled with saturated steam set and maintained at a required pressure for an optimized time. After this thermal treatment the steam is cut off and the spherical instant valve is opened in less than 0.2 s inducing an abrupt pressure drop towards a vacuum in the autoclave. After a vacuum period, the atmospheric pressure established in order to recover the solid material. The extracts are collected from the vacuum tank.

2.3.2.1 Applications

The feasibility of DIC process in the preparation of samples has been investigated on different matrices (Table 2.2).

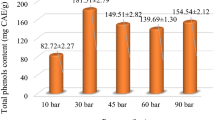

Benamor et al. [14] have studied extraction of anthocyanins from Roselle calyces using DIC. This work has demonstrated that DIC increases kinetics and extraction yield of these compounds. The same authors have also noticed the impact of DIC treatment on the oligosaccharides (stachyose and ciceritol) extraction from the seeds of the Indian Tephrosia purpurea plant [15]. DIC was shown to be an effective extraction method in terms of processing time (1 h of extraction time instead of 4 h for conventional processes). DIC could be also used for the extraction of oil from various plants. One of its advantages compared to other extraction processes is the short-time contact of the oil with the apparatus heated zones to avoid the harmful thermal reactions of the different molecules, combined to an abrupt pressure variation that allows a rapid release of essential oil due to the rupture of the oil-containing glands. The DIC process is more efficient in terms of rapidity (several minutes versus several hours), essential oil yield (comparable even higher), and higher content of oxygenated compounds.

2.4 Pulsed Electric Field (PEF)

Pulsed Electric Field (PEF) technology was invented in the 1960s in order first to offer the possibility to preserve food by replacing traditional pasteurization. Electrotechnologies based on effects of PEF are currently gaining a real interest regarding food processing especially in the field of extraction [20–23].

2.4.1 Principle

Exposing a biological cell (plant, animal and microbial) to a high intensity electric field (kV/cm) in very short pulses (μs to ms) induces the formation of temporary or permanent pores on the cell membrane [24]. The cell membranes are charged and pores are formed in the membranes fostering the extraction. This phenomenon, named electroporation, causes the permeabilization of cell membrane i.e. an increase of its permeability and if the intensity of the treatment is sufficiently high, cell membrane disintegration occurs [25] (Figs. 2.6 and 2.7).

Many fields are developing cell membrane disintegration such as biotechnology, medicine and food industry [24, 26–28]. Cell membrane acts as a physical barrier in removing the intracellular substances from plant food tissues in solid–liquid extraction. The disintegration or permeabilization of the cell membrane in a plant food tissue causes the release of intracellular water and solutes (secondary metabolites) to migrate in an external medium. Thus, this method enables enhancing extraction from food plants; it enhances mass transport out of the cell.

2.4.2 Instrumentation

A PEF treatment chamber consists of at least two electrodes and insulation that forms the treatment volume (i.e. volume where the foods receive pulses). The final distance between the electrodes can be optimized and fixed. The product exposure to a pulsed voltage can hence be done in a batch or continuous treatment chamber. Different pulse-forming networks can be used; their main components include selected voltage power supply, one or several capacitor banks, inductors or/and resistors [24]. Besides pulses of different shape can be generated, including simplest exponential decay pulses and square wave pulses should be limited for exclusion of any significant temperature elevation.

Electric field treatment is applied by a PEF generator which power is also determined depending on the needs. Shape and polarity are criterion of the generator itself. Trains of pulses are usually used for PEF treatment. An individual train consisted of n pulses with pulse duration ti and pulse repetition times Δt. A pause Δt 1 can be set after each train, N being the number of trains. The total time of electrical treatment during PEF treatments are calculated as t 1 = N tot t i where N tot is the total number of pulses N tot = Nn.

These different parameters, whether temperature T, electric field strength E (V/cm), electric energy W (kJ/kg), number of impulsion n and duration of an impulsion t i can be modified regarding the needs.

Some indications regarding PEF parameters:

-

Permeabilisation of plant cells 0.3–1.5 kV/cm 1–10 kJ/kg

-

Inactivation of microorganisms 10–30 kJ/cm 50–200 kJ/kg

2.4.3 Applications

PEF whether direct treatment or as a pre-treatment facilitate the extraction of vegetable oil, active molecules such as anthocyanins, flavonoids, etc. The application of electroporation through PEF offers a great potential for extraction purposes. It improves kinetics extraction and enhances extraction yields. PEF treatment is suitable for thermolabile fragile molecules since the extraction can be done at low temperature.

Temperature contribution to electroporation efficiency is important, which reflects the synergetic effect of the simultaneous thermal and PEF treatment and it increases at small fields [29].

PEF treatment, or pre-treatment noticeably accelerates diffusion even at low temperature (20–40 °C), which enable the “cold” soluble matter extraction [30].

When PEF is employed it is possible to regain antioxidant substances from plant processing residual material, potential of pectin recovery is enabled [31]. Regarding juice pressing with high polyphenol content, the choice of appropriate regime of pressing is required. PEF application allowed decreasing of the applied pressure and pressing time. PEF is very promising for enhancing juice and polyphenol extraction [31–33]. PEF is a promising enological technology to obtain wines with the high phenolic content necessary for the production of high quality oak aged red wines [34].

For extraction both membrane of the cell and the vacuole have to be opened. The releasing efficiency of ionic components, enzymes, proteins and other bio-products can dramatically depend on the applied method of disruption. The PEF treatment removes membrane barriers and accelerates release of the extract contents; it however has practically no influence on the cell walls. As regards to electroporation, pores resealing is possible after the pulse application. If sufficient energy is applied, the pores are electroporated irreversibly (Table 2.3).

References

Wan PJ, Hron RJ, Dowd MK, Kuk MS, Conkerton EJ (1995) Alternative hydrocarbon solvents for cottonseed extraction: plant trials. J Am Oil Chem Soc 72:661–664

Hanmoungjai P, Pyle L, Niranjan K (2000) Extraction of rice bran oil using aqueous media. J Chem Technol Biotechnol 75:348–352

Gedye R, Smith F, Westaway K, Ali H, Baldisera L, Laberge L, Rousell J (1986) Tetrahedron Lett 27:279–282

Ganzler K, Salgó A, Valkó K (1986) J Chromatogr A 371:299–306

Chemat F, Abert Vian M, Visinoni F (2010) Microwave hydro-diffusion for isolation of natural products. United States Patent, US 0,062,121

Abert Vian M, Fernandez X, Visioni F, Chemat F (2008) Microwave hydrodiffusion and gravity, a new technique for extraction of essential oils. J Chromatogr A 1190:14–17

Bousbia N, AbertVian M, Ferhat MA, Meklati BY, Chemat F (2009) A new process for extraction of essential oil from citrus peels: microwave hydrodiffusion and gravity. J Food Eng 90:409–413

Bousbia N, AbertVian M, Ferhat MA, Peticolas E, Meklati BY, Chemat F (2009) Comparison of two isolation methods for essential oil from rosemary leaves: hydrodistillation and microwave hydrodiffusion and gravity. Food Chem 14:355–362

Zill-e-Huma M, Abert-Vian JF, Maingonnat FC (2009) Clean recovery of antioxidant flavonoids from onions: optimising solvent free microwave extraction method. J Chromatogr A 1216:7700–7707

Zill-e-Huma, Abert-Vian M, Fabiano-Tixier AS, Elmaataoui M, Dangles O, Chemat F (2011) A remarkable influence of microwave extraction: enhancement of antioxidant activity of extracted onion varieties. Food Chem 127:1472–1480

Périno-Issartier S, Zill-e-Huma, Abert-Vian M, Chemat F (2010) Solvent free microwave-assisted extraction of antioxidants from sea buckthorn (Hippophae rhamnoides) food by-products. Food Bioprocess Technol 4:1020–1028

Allaf K, Vidal P (1989) Feasibility study of a new process of drying/swelling by instantaneous decompression toward vacuum of in pieces vegetables in view of a rapid re-hydration. Gradient Activity Plotting, University of Technology of Compiegne UTC N° CR/89/103, industrial SILVA-LAON partner

Allaf K, Louka N, Parent F, Bouvier J, Forget M (1999) Method for processing materials to change their texture, apparatus therefor, and resulting materials. United States Patent, US 5,855,941

Ben Amor B, Allaf K (2009) Impact of texturing using instant pressure drop treatment prior to solvent extraction of anthocyanins from Malaysian Roselle (Hibiscus sabdariffa). Food Chem 115(3):820–825

Amor BB, Lamy C, Andre P, Allaf K (2008) Effect of instant controlled pressure drop treatments on the oligosaccharides extractability and microstructure of Tephrosia purpurea seeds. J Chromatogr A 1213(2):118–124

Berka-Zougali B, Hassani A, Besombes C, Allaf K (2010) Extraction of essential oils from Algerian myrtle leaves using instant controlled pressure drop technology. J Chromatogr A 1217(40):6134–6142

Besombes C, Berka-Zougali B, Allaf K (2010) Instant controlled pressure drop extraction of lavandin essential oils: fundamentals and experimental studies. J Chromatogr A 1217(44):6807–6815

Kristiawan M, Sobolik V, Allaf K (2008) Isolation of Indonesian cananga oil using multi-cycle pressure drop process. J Chromatogr A 1192:306–318

Allaf T, Allaf K (2014) Instant controlled pressure drop (D.I.C.) in food processing. Springer, New York

Puértolas E, López N, Condón S, Álvarez I, Raso J (2010) Potential applications of PEF to improve red wine quality. Trends Food Sci Technol 21(5):247–255

Grimi N, Praporscic I, Lebovka N, Vorobiev E (2007) Selective extraction from carrot slices by pressing and washing enhanced by pulsed electric fields. Sep Purif Technol 58(2):267–273

Toepfl S, Heinz V, Knorr D (2005) Overview of pulsed electric field processing for food. In: Emerging technologies for food processing. Academic, London, pp 69–97

Corrales M, Toepfl S, Butz P, Knorr D, Tauscher B (2008) Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: a comparison. Innov Food Sci Emerg Technol 9(1):85–91

Lebovka N, Vorobiev E, Chemat F (eds) (2011) Enhancing extraction processes in the food industry. CRC Press, Cambridge

Vorobiev E, Lebovka N (eds) (2008) Electrotechnologies for extraction from food plants and biomaterials. Springer, New York

Jaeger H, Schulz A, Karapetkov N, Knorr D (2009) Protective effect of milk constituents and sublethal injuries limiting process effectiveness during PEF inactivation of Lb. rhamnosus. Int J Food Microbiol 134(1–2):154–161

Roodenburg B, Morren J, (Iekje) Berg HE, de Haan SWH (2005) Metal release in a stainless steel pulsed electric field (PEF) system: part II. The treatment of orange juice; related to legislation and treatment chamber lifetime. Innov Food Sci Emerg Technol 6(3):337–345

Roodenburg B et al (2010) Conductive plastic film electrodes for Pulsed Electric Field (PEF) treatment – a proof of principle. Innov Food Sci Emerg Technol 11(2):274–282

Grimi N, Lebovka NI, Vorobiev E, Vaxelaire J (2009) Effect of a pulsed electric field treatment on expression behavior and juice quality of chardonnay grape. Food Biophys 4(3):191–198

Loginova KV, Shynkaryk MV, Lebovka NI, Vorobiev E (2010) Acceleration of soluble matter extraction from chicory with pulsed electric fields. J Food Eng 96(3):374–379

Schilling S et al (2007) Effects of pulsed electric field treatment of apple mash on juice yield and quality attributes of apple juices. Innov Food Sci Emerg Technol 8(1):127–134

Boussetta N, Lebovka N, Vorobiev E, Adenier H, Bedel-Cloutour C, Lanoisellé J-L (2009) Electrically assisted extraction of soluble matter from chardonnay grape skins for polyphenol recovery. J Agric Food Chem 57(4):1491–1497

Turk MF, Baron A, Vorobiev E (2010) Effect of pulsed electric fields treatment and mash size on extraction and composition of apple juices. J Agric Food Chem 58(17):9611–9616

Puértolas E, Saldaña G, Alvarez I, Raso J (2010) Effect of pulsed electric field processing of red grapes on wine chromatic and phenolic characteristics during aging in oak barrels. J Agric Food Chem 58(4):2351–2357

Loginova KV, Vorobiev E, Bals O, Lebovka NI (2011) Pilot study of countercurrent cold and mild heat extraction of sugar from sugar beets, assisted by pulsed electric fields. J Food Eng 102(4):340–347

Yin Y, Cui Y, Ding H (2008) Optimization of betulin extraction process from Inonotus Obliquus with pulsed electric fields. Innov Food Sci Emerg Technol 9(3):306–310

Guderjan M, Tepfl S, Angersbach A, Knorr D (2005) Impact of pulsed electric field treatment on the recovery and quality of plant oils. J Food Eng 67(3):281–287

Fincan M, DeVito F, Dejmek P (2004) Pulsed electric field treatment for solid-liquid extraction of red beetroot pigment. J Food Eng 64(3):381–388

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Vian, M.A., Allaf, T., Vorobiev, E., Chemat, F. (2014). Solvent-Free Extraction: Myth or Reality?. In: Chemat, F., Vian, M. (eds) Alternative Solvents for Natural Products Extraction. Green Chemistry and Sustainable Technology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-43628-8_2

Download citation

DOI: https://doi.org/10.1007/978-3-662-43628-8_2

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-43627-1

Online ISBN: 978-3-662-43628-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)