Abstract

The process of extraction is well-known and widely used in numerous fields. Until recently, it has been performed in its basic level both in laboratory and industry. However, increased environmental concerns, development of environmental chemistry and wish to get safe products imposed new trends in extract production. The basic goals which have to be achieved are elimination of harmful solvents and increase of extraction yield. Different modern techniques can be used in order to accomplish these aims, but the special focus has been put on these one which rely on “green” solvents, such as subcritical water or supercritical carbon-dioxide. These techniques could be great alternative for the extraction of compounds of different polarity by setting operational parameters i.e. by varying solvent polarity. Obtained extracts do not contain residue of organic/toxic solvents and there is no need for their further purification. This makes such techniques economically acceptable from the industrial point of view. Yet, there is a question, which are the limitation of these techniques? Are they really so good? This review tends to show all advantages and disadvantages of novel extraction techniques and to give the comprehensive overview of all challenges in the process of developing of new environmentally-friendly techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The process of extraction is one of the oldest separation techniques and even today it is the most commonly used in numerous fields and industries. Generally, it is a transfer of compounds from their sources into the fluid phase, followed by separation of the fluid phase and recovery of the target components from the fluid [1]. Traditional approaches for the extraction involve utilization of organic solvents and show a numbers of disadvantages. Usage of organic solvents (very often toxic and hazard) lead to their present in atmospheric as pollutants. Additionally, they remain in the raffinate, as well as in the extracts, detracting from their purity. This imposes a need for additional purification which requires significant energy consumption, making traditional processes uneconomical [1, 2]. Apart of this, in traditional extraction processes low selectivity occurs as a serious drawback, which further lead to the presence of unwanted components in the obtained extracts thus reducing their biological potential.

Increased environmental concerns, development of environmental chemistry and wish to get safe products imposed new trends in extract production [3]. Moreover, there is an increasing need for the new advanced techniques or to upgrade conventional ones in order to overcome all disadvantages of well-known conventional techniques [4]. One of the basic goal which have to be achieved is elimination of harmful solvents with keeping or even increasing the extraction yield. Eliminating organic solvents is the demand from the environmentally point of view but also the demands that come from different industries and consumers. The latest trends in technology (food technology, cosmetic technology, etc.) are promoting products with plant extracts as functional ingredients [5, 6]. In the products of new generation, the extracts may have the role of additives influencing the product quality thus eliminating synthetic additives [3].

The aim to eliminate organic solvents from the process of extraction of biomolecules from plants with increasing extraction efficiency and economy could be accomplished by using modern techniques and especially those one which rely on “green” solvents [7].

In this paper an overview of the advantages of some of the modern techniques for extracting bioactive compounds from plant material has been given. In the first place, the work promotes the use of pressurized fluids as solvents (supercritical carbon dioxide and subcritical water). Special attention is devoted to the subcritical water as the cutting-edge technique which has shown numerous advantages for use both in the laboratory and in the industry. However, despite the numerous advantages of this technique, the number of industrial plant for its application is rare, which can be due to insufficient data on its characteristics, relationships between extraction parameters, and its possible restrictions [8]. This paper attempts to summarize the latest discovery regarding advantages and disadvantages of subcritical water, referring to its green character and security as a solvent. Also, great accent is given to the fact that this technique enables obtaining of high quality extracts.

2 Supercritical Fluid Extraction (SFE)

Among the all pressurised fluid extraction, supercritical fluid extraction (SFE) is the most commonly used. This technique represents the first environmentally-friendly technique suitable for many chemical process. Extraction with supercritical fluids is a process of mass-transfer which rely on the fact that some gasses can became extremely powerful solvents under the specific operational conditions [9]. Namely, by changing operational parameters (in the first place temperature and pressure) during the extraction process and by bringing the gases near to/above their critical point, their physico-chemical properties are drastically changed.

The gas becomes a fluid with good mobility and solvating properties, but in the same time it is a fluid in which mass-transfer process can be much faster. In other words, supercritical fluids combined the properties of both liquids and gases thus becoming gases and liquids in the same time. The values of their viscosity are lower than viscosity of liquids, but the diffusion coefficients are higher than in case of liquids. These unique characteristics of supercritical fluids allows their better penetration into the pores of matrices. As a consequence, the velocity of extraction becomes higher and the process could be done in a much shorter period in comparison to conventional techniques [8].

The commonly used supercritical fluid is carbon-dioxide (Sc-CO2). Some of its advantages are its non-toxicity, non-flammability, chemical-inactivity, physiologically inactivity. Special convenience for its utilization is their low critical parameters. Critical temperature of 31.1 °C allows extraction of thermo-labile components. Furthermore, obtained extracts do not contain residue of organic/toxic solvents and there is no need for their further purification.

From this point, such extracts can be directly used or incorporated in myriad of products. Furthermore, avoiding purification makes this process economically acceptable from the industrial pint of view.

Sub/supercritical carbon dioxide is suitable for the extraction of non-polar compounds, which are usually extracted by organic solvents such as, benzene, toluene, etc. In this way supercritical carbon dioxide could be excellent green substitute of organic solvents non-acceptable from the green chemistry point of view. However, it has limitation when it comes to more polar compounds. This can be overcome by using the modifiers/co-solvents. Although the fact that different solvents can be used as modifiers, ethanol is the most commonly used in case of the extraction of bioactive compounds, such as polyphenols [4].

The technique was encountered in industrial applications, and through the Europe there are more and more industries which involve this emerging extraction technique.

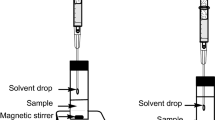

3 Subcritical Water Extraction (SCW)

Still now water represent the first-choice green solvent. However, due to the high polarity it is suitable for the extraction of high-polar compounds and its usage as a solvent is limited. Nevertheless, by bringing the water in its subcritical conditions its solvating properties can be drastically changed as a consequence of the changes in its physico-chemical properties. Basically, subcritical water (SCW) is a water in its liquid form at the temperature between its boiling (100 °C) and critical point (374 °C) under the pressure which is high enough to keep it in liquid phase. Under these operational conditions the characteristics of this “green” solvent becomes remarkably different. The first and probably the most important characteristics of water which succumb to the changes is its dielectric constant. Under subcritical conditions dielectric constant of water sharply decreases from the value of around 80 to the value similar to that of methanol or even lower. Thus subcritical water becomes suitable for the extraction of non-polar and moderately polar compounds under the controlled experimental conditions. Apart of its dielectric constant, many other characteristics of water are drastically changed by bringing water in its subcritical state. Temperature effects on surface tension and viscosity reflect the efficiency of pores filling and the contact between the solvent and sample matrix. Moreover, pH value of water decreases three orders of magnitude with a temperature increase to 250 °C, thus providing more H3O+ ions for acid-catalysed reactions [7]. On the other hand, extraction at too high temperature may cause degradation of thermolabile compounds. Thus, it is very important to define the optimal temperature for target compounds in a tested matrix. Novel scientific research proved the relationship between chemical structure and temperature during subcritical water extraction. In case of bioactive molecules, such as polyphenols, it was confirmed that the presence of conjugated double bonds, side chains, glucose moieties or ether moiety in molecules influence the efficiency of their extraction in subcritical water [10]. Table 1 shows the optimal extraction temperatures in SCW process depending on chemical structure of particular compound [10].

In case of total extracted phenols optimal temperature was proved between 130–140 °C depending on the plant material. For example in case of chamomile, extraction at 130 °C led to extracts rich in polyphenolic components [11] while in case of lotus seed epicarp (Nelumbo nucifera) this effect was achieved at 140 °C [12]. This can be explain by different structure of plant matrices and by different bound between these components and different matrices.

Apart of the temperature, which influence has been thoroughly explored, other parameters could also affect solubility capabilities of SCW but they have not been investigated in detailed. High pressure is obligatory in SCW process but it was believed that maintain water in its liquid form is the main role of this parameter. However, the latest research has disproved these assertions by proving that the change in pressure during the process significantly influences the content of bioactive ingredients in the obtained extracts, but also has an influence on their activity. Thus, now the pressure has been recognized as the second parameter which significantly affects the efficiency of the process. The value of applied pressure during the extraction depends on the target analyte. For the majority of bioactive compounds, extremely high pressures are unfavourable because of the possible interaction and aggregation of molecules or even by their re-adsorption. On the other hand, utilization of low pressures results in low extraction yield. Thus, moderate pressures in the range 30–45 bar offers the extracts opulent with bioactive molecules like polyphenols [11, 13]. Our previous study showed the influence of this parameter on the total phenols content in extracts obtained from chamomile (Fig. 1) [11].

Data from the Fig. 1 clearly show that pressure of 30 bar provides the highest phenols yield (181.51 mg CAE/g). Statistical analysis showed that increases of pressure from 45 to 60 bar and from 60 to 90 bar caused significant difference between yield of phenolic compounds (p = 0.003109 and p = 0.000251, respectively). However, results of performed statistical analyses suggested that there were insignificant differences in yields obtained at 45 and 90 bar (p = 0.13363) [11]. The results impose the significance of the pressure in SCW extraction and suggests that for each group of compounds this parameter should be optimized. For example, our other study [13] showed that in case of aglycones, the presence of double bounds as well as different substituents in the molecules affect their solubility in SCW under different pressures. In case of glycosides, presence of sugar moiety has strong influence on their extraction making them more soluble under the lower pressure in SCW process. In case of pressure optimization, it should take into account that at higher pressure interaction and aggregation of molecules could be appeared influencing the efficiency of the process. Additionally, position of particular analyte in matrix, as well as bounds between matrix and target analyte should be considered [13].

So far, subcritical water extraction has been used for the extraction of different molecules from different matrices and numerous advantages of this technique over traditional and modern were observed [1]. A brief summary of the various extraction methods used for natural products extraction and the advantages of subcritical water extraction for their recovery is shown in Table 2.

Table 2 clearly shows the advantages of using SCW for the extraction of both phenols and flavonoids from plant matrices. Taking into account the fact that these groups of natural biomolecules are considered as a carrier of bioactivities of natural products, extract with their higher concentration should be more bio-potent. Different studies have compared the bioactivity of SCW extracts and bioactivity of extracts obtained by other modern and conventional techniques (Fig. 2) [14,15,16].

Histograms from the Fig. 2 demonstrate improved antioxidant activity of SCW extracts in case of three different plant matrices by using three different assays (results are expressed as IC50 values, i.e. half maximal inhibitory concentration). The ability of the SCW extracts of Satureja hortensis, Lavatera thuringiaca and Chamomilla recutita to act as scavengers of DPPH and OH radicals was stronger than ability of extracts obtained by maceration, microwave, ultrasound and Soxhlet extraction. Moreover, SCW extracts were proven as better protectors of cells against the process of lipid peroxidation [14,15,16].

Due to the relationship among antioxidant activity and many other bio-abilities, plant extracts made with SCW express high level of other bioactivities. Lately, special focus of researchers have been put on cytotoxic activity in order to find safe way for protecting the cells from the cytogenetic illnesses. Table 3 shows cytotoxic potential of plant extracts obtained by different extraction techniques indicating advantages of SCW.

Taking into account high influence of extraction parameters during the process, in the first place temperature and pressure, it should always taking into account that small changes in their values could make significant differences in bioactivity of the extracts. Figure 3 illustrate changes in antioxidant activity of chamomile extracts depending in applied pressure [13]. As it can be seen, the changes of a pressure in the range 10–60 bar influence a significant changes in antioxidant ability of the extract, but increasing the pressure from 60 to 90 bar lead to the insignificantly influence on biological activity. The highest influence is between 45 and 60 bar, but the highest efficiency is obtained by using the pressure of 30 and 45 bar.

Apart of hydrophilic components from plant material, SCW could be used for the extraction of volatile compounds, as well. In the study conducted by Pavlic et al. [19] was demonstrated that yield of volatile fraction of coriander seeds obtained by SCW at 150 °C is comparable with the yield obtained by standardized hydrodistillation technique. Also, it was noticed that increasing in temperature from 100 to 200 °C led to increases of volatile components yield. Content of lipophilic compounds in obtained extract at 200 °C was even higher than those one obtained by SFE at 100 bar [19].

Potential thermal degradation together with high investment cost could be limitation for this technique. Moreover, the obstacle that must be overcome is extremely difficult analysis of obtained extract. Namely, subcritical water represents a medium suitable for different reactions, thus neo-formed compounds could be occur during the extraction process. Analysis of obtained extracts thus require complex analytical protocols and sophisticate analytical tools. It should be highlighted that the efficiency of SCW can be additionally improved by combining it with others modern techniques, in the first place with ultrasound and microwave. All of these advantages and disadvantages should be taken into account before the selection of extraction process and before scale-up it.

4 Conclusion

Environmentally-friendly techniques proven as excellent choice in terms of its solvating properties and selectivity. Almost in all cases, these techniques provided extracts richer in bioactive components. Obtained extracts are safe and could be applied directly in myriad of functional preparations. Bearing in mind a priori knowledge, present requirements, potential risks and principals of green chemistry, enhanced extraction techniques represent high-potential techniques benign for environmental. Nevertheless, development of such techniques faces with different challenges. Contemporary analytical approach and validation of selected methods are needed for new solutions in order to protect human.

References

Mutalib LY (2015) Comparison between conventional and modern methods for extraction of Rosmarinus officinalis leaves. Zanco J Med Sci 19:1029–1034

Chemat F, Huma Z, Kamran Khan M (2011) Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochemistry 18:813–835

Wang L, Weller CL (2006) Recent advances in extraction of nutraceuticals from plants. Trends Food Sci Technol 17:300–3012

Buszewski B, Rafinska K, Cvetanović A, Walcyak J, Krakowska A, Rundicka J, Zeković Z (2019) Phytochemical analysis and biological activity of Lupinus luteus seeds extracts obtained by supercritical fluid extraction. Phytochem Lett 30:338–348

Prakash B, Kujur A, Pratap Singh P, Kumar A, Yadav A (2017) Plants-derived bioactive compounds as functional food ingredients and food preservative. J Nutr Food Sci 2:1–7

Ribeiro A, Caleja C, Barros L, Santos-Buelga C, Barreiro MF, Ferreira IC (2016) Rosemary extracts in functional foods: extraction, chemical characterization and incorporation of free and microencapsulated forms in cottage cheese. Food Funct 18:2185–2196

Cvjetko Bubalo M, Vidović S, Radojčić Redenković I, Jokić S (2018) New perspective in extraction of plant biologically active compounds by green solvents. Food Bioprod Process 109:52–73

Švarc-Gajić J (2011) Samples and sample preparation in analytical chemistry. Nova-Publishers, New York

Nikolovski B (2009) Kinetics and modeling of extraction of oil from Junipers (Juniperus communis L.) and pumpkin seeds (Cucurbita pepo L.) by supercritical carbon-dioxide. Doctoral thesis, University of Novi Sad

Cvetanović A, Švarc-Gajić J, Zeković Z, Jerković J, Zengin G, Gašić U, Tešić Ž, Mašković P, Soares C, Fatima Barroso M, Delerue-Matos C, Đurović S (2019) The influence of the extraction temperature on polyphenolic profiles and bioactivity of chamomile (Matricaria chamomilla L.) subcritical water extracts. Food Chem 271:328–337

Cvetanović A, Švarc-Gajić J, Gašić U, Tešić Ž, Zengin G, Zeković Z, Đurović S (2017) Isolation of apigenin from subcritical water extracts: optimization of the process. J Supercrit Fluids 120:32–42

Yan Z, Luo X, Cong J, Zhang H, Ma H, Duan Y (2019) Subcritical water extraction, identification and antiproliferation ability on HepG2 of polyphenols from lotus seed epicarp. Ind Crops Prod 129:472–479

Cvetanović A, Švarc-Gajić J, Zeković Z, Gašić U, Tešić Ž, Zengin G, Mašković P, Mahomoodally MF, Đurović S (2018) Subcritical water extraction as a cutting edge technology for the extraction of bioactive compounds from chamomile: influence of pressure on chemical composition and bioactivity of extracts. Food Chem 266:389–396

Cvetanović A, Švarc-Gajić J, Zeković Z, Mašković P, Đurović S, Zengin G, Delerue-Matos C, Lozano-Sánchez J, Jakšić A (2017) Chemical and biological insights on aronia stems extracts obtained by different extraction techniques: from wastes to functional products. J Supercrit Fluids 128:173–181

Mašković P, Veličković V, Mitić M, Đurović S, Zeković Z, Radojković M, Cvetanović A, Švarc-Gajić J, Vujić J (2017) Summer savory extracts prepared by novel extraction methods resulted in enhanced biological activity. Ind Crops Prod 109:875–881

Mašković P, Veličković V, Đurović S, Zeković Z, Radojković M, Cvetanović A, Švarc-Gajić J, Mitić M (2018) Biological activity and chemical profile of Lavatera thuringiaca L., extracts obtained by different extraction approaches. Phytomedicine 38:118–124

Cvetanović A, Švarc-Gajić J, Mašković P, Savić S, Lj Nikolić (2015) Antioxidant and biological activity of chamomile extracts obtained by different techniques: perspective of using superheated water for isolation of biologically active compounds. Ind Crops Prod 65:582–591

Zeković Z, Cvetanović A, Švarc-Gajić J, Gorjanović S, Sužnjević D, Mašković P, Savić S, Radojković M, Đurović S (2017) Chemical and biological screening of stinging nettle leaves extracts obtained by modern extraction techniques. Ind Crops Prod 108:423–430

Pavlic B, Vidovic S, Vladic J, Radosavljevic R, Zekovic Z (2015) Isolation of coriander (Coriandrum sativum L.) essential oil by green extractions versus traditional techniques. J Supercrit Fluids 99:23–28

Acknowledgements

The author would like to acknowledge the Serbian Ministry of Education, Science and Technological Development (Project no. TR31013) for the funding support of the research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cvetanović, A. Extractions Without Organic Solvents: Advantages and Disadvantages. Chemistry Africa 2, 343–349 (2019). https://doi.org/10.1007/s42250-019-00070-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-019-00070-1