Abstract

Stone masonry is one of the oldest “structural materials” known to man. It is made by the superposition of stones, mortar and, very often, with infill material between leaves. The components present complex links and interactions and, in most cases, unknown geometry and high variability of their mechanical properties. These characteristics make stone masonry a highly heterogeneous material for which it is difficult to define realistic behaviour laws, a challenge that still demands further research, either through laboratory or onsite experimental campaigns. In reality, the mechanical characteristics of a stone masonry element strongly depend on the geometry and geometrical distribution of the stones along the façade and cross-section of the element and, therefore, on the layout of the interfaces, i.e. the joints. Studies developed in Italy have defined a series of parameters that try to quantify the level of fulfilment of good practice constructions rules with the expectable performance of a stone masonry wall under static and dynamic loading, in particular under seismic type loadings. This chapter discusses construction typologies and materials, assessment methodologies, earthquake induced failure mechanisms and strengthening intervention techniques on stone masonry structures, in particular walls.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Stone masonry is one of the oldest “structural material” known to man that resisted time. It has been widely used, mainly up to the middle of the twentieth century, on a large variety of constructions, either common or monumental, some of them being today classified as local, national, or even world cultural heritage.

Stone masonry is a composite structural material made of the superposition of stones, mortar and, very often, with infill material, presenting complex links and interactions, for which the definition of realistic behaviour laws remains a big challenge; by nature, it is a heterogeneous material, whose components present, in most cases, an unknown geometry and a high variability of the mechanical properties. Thus, a great effort has been, and still is being done to gather information on this type of structures, either through laboratory [1–9] and onsite experimental campaigns [10–14] and/or including Non Destructive Techniques (NDT) and Slightly Destructive Techniques (SDT) using flat-jacks, sonic equipment, dynamic identification procedures, among other techniques [7, 15–17].

Studies carried out in Italy after major earthquakes have also allowed characterizing and classifying stone masonry walls through the assessment of the elevation and cross-section of the walls and the mechanical state of its components [18, 19]. However, and although a series of common “good construction practices” have been followed in different countries, the definition of a complete classification of the existing masonry typologies is difficult. In Portugal, some work has been done on the survey of stone masonry constructions in different regions [20], and a first attempt to create a database was done through the study of stone walls from buildings of the town of Tentúgal [21].

The next points establish and discuss construction typologies and materials, assessment methodologies, earthquake induced failure mechanisms and strengthening intervention techniques on existing masonry structures.

2 Masonry Typologies and Quality

Stone masonry is a composite structural material made of more or less regular layers of stones defining, approximately, horizontal (continuous) and vertical (discontinuous) interface lines, commonly referred to as joints, which may be filled in with mortar, small stones (wedges) and (or) other stiff material: pieces of brick, ceramics… In the case of a multi-leaf stone masonry, apart from those elements, there could be infill material within leaves, being also part of the masonry structure. This element, often considered to be secondary, is usually made of a mix of different materials, from earth to stones, broken bricks, natural fibres, etc., and placed without any particular compaction.

According to the natural resources of a specific geographical area, masonry structures were erected using the available materials and following the local constructive tradition. The construction techniques within a certain territorial ambit were established by the builders’ empirical knowledge, successively transmitted through oral tradition, which afterwards became rules for that territory. Thus, since different building typologies can be found within different regions, it becomes difficult to find a complete and unique classification of the existing stone masonry. Nevertheless, the contact between cultures allows common features to be present in the different construction traditions. Since ancient civilizations, like the Hellenic one, the diffusion of this technical knowledge was supported by experts in the construction field. The treatises of architecture that appeared during the Roman Empire, or the work promoted by these and other cultural centres and present in the libraries of the mediaeval convents and monasteries are examples of that knowledge circulation. Thus, each civilization that reached a certain cultural hegemony left the traces of their technical capabilities through written or oral evidences.

A common tradition for masonry walls was developed by the Romans: from the Mediterranean coasts to the Northern regions of Europe, the Romans learnt the local building traditions and taught their own technical knowledge. During their domination, they imposed shared rules for the construction of masonry structures. In the first book of his treatise, Palladio [22] recalls Vitruvius’s classification for Roman stone masonry walls, remarking that some of those building techniques were still used at his time. Five main typologies are described through short indications and graphic layouts, as follow:

-

a.

Opus isodomum, presenting a regular texture formed by squared stones displayed along horizontal settings. Due to the variation of the proportion between the shaped stones used in the different courses, this masonry typology was also known as opus pseudo-isodomum (see Fig. 1a);

Fig. 1 Examples of the main Roman stone masonry typologies: a opus pseudoisodomum; b Roman concrete; c infill wall (emplecton); d opus reticolatum with infill; e opus incertum; f opus mixtum (layouts from Table 11 of [23])

-

b.

Roman concrete, constituted by irregular stones having limited dimensions (pebbles) bound by mixtures with pozzolanic properties (see Fig. 1b);

-

c.

Infill walls, created through the so called Roman concrete, a composite material obtained by irregular stones of various dimensions bound by pozzolanic mixtures. The infill could be contained through regular (see Fig. 1c) or irregular external masonry texture;

-

d.

Opus reticolatum, composed by squared stones displayed along diagonal laying planes and regularly crossed by Roman bricks forming horizontal settings (see Fig. 1d);

-

e.

Opus incertum, dry walls formed by irregular stones without any horizontal settings; (see Fig. 1e).

Theses masonry typologies, still recognizable in the main Roman monuments and ruins in Europe, North Africa and Middle East, were adopted also after the Roman Empire: the mixed type with infill walls (Fig. 1f), for example, is a building technique that was largely used in Middle Age for the construction of Romanic and gothic cathedrals. Regular stones textures with an internal infill were also typical of defensive structures, like fortresses.

According to the past experience of masonry constructors, the geometry of a stone masonry, namely the distribution and superposition of the stones should respect a series of procedures that are usually referred to in the bibliography [24] as “good practice rules”. The respect of such rules contributes, unquestionably, to a better distribution of forces through the masonry elements and to a better global structural behaviour. In particular, stones should be disposed along regular horizontal layers, should create discontinues vertical interfaces and, in case of a multi-leaf masonry, should guarantee a good connection and (or) interlock between different leaves.

When dealing with ordinary buildings (also known as diffused architecture), the classification appears to be more complex, since more differences are usually found due to a greater influence of more local building traditions, which, sometimes, even correspond to the introduction of new masonry typologies. The changes produced by certain historic events (like the Arabic domination in North Africa and in the Iberian Peninsula) determined a diversification of the classic masonry building techniques. Moreover, natural cataclysmic have also promoted the progressive development of the construction techniques, by showing the ineffectiveness of certain structures and forcing the investigation of more suitable building solutions. The introduction of timber frames in masonry walls (as in some seismic areas of Portugal, Greece or south Italy) was an example of a technical response meant to contrast earthquake effects.

The studies of experts, like Giuffrè [25] and De Felice [26], on diffused architectonic heritage outlined that masonry structures may present defects in the connections between their layers. With respect to the masonry walls built by the Romans, the walls constructed in further periods were characterized by infill mixtures with poorer binding properties. In fact, the monolithic behaviour of Roman walls was obtained through binding mixtures having hydraulic properties and good resistance. These characteristics were rarely obtained during the further centuries, due to the use of mixtures with low quality. As a result, multi-leaf walls are deeply influenced by the organization of their masonry sections: their mechanical behaviour is not interpretable through a simple evaluation of the external masonry texture, but it should be based on the study in depth of the characteristics of the cross-section. Considering large typological classes [27], common stone walls can be divided in:

-

one leaf solid wall, composed by one stone per thickness [2] or stones well connected (usually by headers) and organized in horizontal or sub-horizontal courses (see Fig. 2a);

Fig. 2 Examples of different masonry typologies classification based on the characteristics of their sections (courtesy of C. Almeida and L. Binda and G. Cardani). a Single leaf wall. b Double leaves wall without connections. c Double leaves wall with connections. d Multi leaves wall (3 layers). e Dry wall without mortar joints

-

two leaves wall, formed by two separate layers connected by an infill made by small rubble materials bound with mortar (Fig. 2b), or through the periodical overlapping of the stones (Fig. 2c);

-

multiple leaves wall, usually constituted by external layers with a regular texture and one or more internal leaves composed by an irregular infill (Fig. 2d);

-

dry stone wall, usually composed by irregular shaped blocks jointed by small stone or brick detritus and in some cases by stone wedges (Fig. 2e).

According to research carried out by Binda [28] and Borri [29] on Italian historical centres in seismic area, the quality of the stone masonry walls can be evaluated through the following combination of visual inspections and limited investigations:

-

geometry: the dimension of the material components (the proportions of the stones; the height of the mortar joints, etc.), the disposal of the courses, the vertical joint staggering, the presence of headers, etc. [30];

-

decay status of the materials: identification of the pathologies causing the reduction of the mechanical properties of the structure [31];

-

physical and chemical analysis on sampled mortar: the mortar used in the structure should be investigated for different depths and the identification of certain impurities (like hygroscopic saults or other sinterizing composts) allows to classify the mortar quality [32];

-

Direct sonic tests provide qualitative indications on the connections between the components and can indicate the presence of headers [18];

-

Single and double flat jack tests are able to identify quantitative parameters: respectively, the local state of stress and the deformability characteristics [33];

-

Local dismantling: the direct observation of a limited area of the masonry section (usually 1/3 of its depth) allows recognizing the presence of multiple leaves and the technique used for assembling the components (regular mortar joints, rubble materials, etc.) [34].

The above mentioned study-methodology is the synthesis of the guidelines for the evaluation of the masonry quality promoted by the Italian institutions after recent seismic events. These recommendations provide indications for the interpretation of the mechanical behaviour of historical masonry structures introducing abacus of the main stone masonry textures and abacus showing the most common masonry cross sections (see Fig. 3). According to the characteristics of each stone masonry type, their quality can be evaluated according to the adequacy of the real structures to the characteristics described in the corresponding model.

Examples of different masonry typologies [35]. a Regular shaped stone blocks. b Irregular blocks and pebbles mixed type. c.Irregular blocks and pebbles mixed type with brick courses. d Mixed irregular blocks, pebbles and flakes of rocks

2.1 Masonry Mechanical Behaviour

Studies developed in Italy have created a series of parameters that (try to) quantify the level of fulfilment of good practice constructions rules through the measurement of the deviation of the geometrical and physical characteristics of the walls from ideal conditions [36, 37]. Moreover, the Italian codes [38–40], present tables that link the fulfilment of these rules to the expectable performance of a stone masonry wall under static and dynamic loading.

In reality, strength and stiffness of a stone masonry element depend on the geometry and geometrical distribution of the stones along the façade and cross-section of the element and, therefore, on the layout of the interfaces, i.e. the joints. This means that the mechanical parameters of a stone masonry depend on the mechanical characteristics of the stones, which are usually the most resisting elements, but also on the physical and mechanical characteristics of the joints and of the infill.

The contribution of the infill to the behaviour of stone masonry depends on its mechanical characteristics and on the characteristics of the cross-section, namely on the roughness of the inside face of the leaves and on the existence of transversal stones connecting the leaves. Notice that the compression of the infill induces its horizontal expansion (Poisson effect) that pushes the leaves to the outside. If the external leaves are not well connected and (or) do not present a good interlock, this phenomenon promotes an out-of-plane behaviour that may induce the vertical instability of the leaves. On the contrary, if the connection between leaves is efficiently ensured, the expansion of the infill may be avoided by the external leaves, which induces a confinement state that improves the infill mechanical response and, therefore, promotes a better global performance of the stone masonry.

In general, the mechanical characteristics of a stone masonry with mortar joints are associated to the mechanical characteristics of the stones and of the mortar, in particular to the strength and stiffness of the two materials. Many authors suggest empirical based expressions that link the compressive strength of the two materials to the compressive strength of the masonry. In particular, the following equation has been proposed [41–43]:

where \( \sigma_{cm} \), \( \sigma_{cs} \) and \( \sigma_{cj} \) represent, respectively, the compressive strength of the masonry, of the stones and of the mortar, and \( \gamma \), \( \alpha \) and \( \beta \) the parameters that should be calibrated to take into account the specific characteristics of each type of stone masonry. However, the mechanical properties of a stone masonry tend to have a high scatter; the mechanical parameters depend on the particularities of the masonry that are hardly repeatable. This is particularly true for stone masonry with irregular textures, which can be considered the more general situation. Nevertheless, attempts have been made by different authors to propose ranges of values for different types of stone masonry [2, 10, 44].

As for the stiffness, in particular for the Young modulus of stone masonry (E m ), empirical based expressions have also been proposed to estimate this mechanical property, in particular through a direct proportion to the compressive strength [42, 45]:

Also in this case the proposed ratio can have a very high scatter, and different values for the coefficient k have already been found, or suggested. Although most of the authors point out values for k between 500 and 1000, being the last the one usually used for stones and mortar, tests made on one-leaf irregular stone masonry walls at the Laboratory of Earthquake and Structural Engineering (LESE) of the Faculty of Engineering of Porto University (FEUP) [2] have found values between 80 and 140.

Notice that stones have, in general, high stiffness and compressive strength when compared to mortar joints. This is particularly true when dealing with old stone masonry structures with lime mortar type joints. Values of compressive strength and stiffness of, respectively, 1 MPa and 1 GPa are usually found for this type of mortar, while stones, even with some degradation, present values that are easily greater than 20 MPa and 20 GPa, respectively. This difference makes the initial behaviour of stone masonry to be mostly controlled by the mechanical characteristics of the joints, which may crush under compression forces, open under tensile forces and slide under shear forces, defining, in most cases, the main rupture lines.

However, the contribution of the stones to the mechanical properties and behaviour of the masonry is not restricted to the definition of its texture, i.e. to the delimitation of the joints through the stones interfaces. To understand the role of stones in stone masonry, firstly one should be aware that stones have a tensile fragile behaviour with a tensile strength that is commonly more than ten times lower than the compressive strength. Therefore, while crushing of stones is seldom achieved, or is confined to limited areas where localized concentration of forces occurs, cracking of stones happens more frequently and it interferes with the configuration of the rupture lines. In particular, and apart from any instability phenomenon that may occur due to slenderness and (or) the influence of infill expansion, the stones tensile rupture is the main factor that controls and restrains the compressive strength of a stone masonry. Nevertheless, the importance of the tensile strength of the stones is often neglected and the compression strength is the property that is usually underlined in the literature, even though the ultimate value of compression strength depends, itself, on the tensile strength of the stone. Notice that, although tensile strength and compression strength of the stones is related, the ratio between the first and the second depends on the quality of the stones, and a large scatter can be found even for the same type of stones. Nevertheless, typical values for this ratio are found between 0.04 and 0.10.

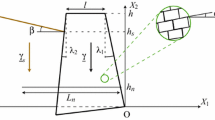

In reality, when a stone masonry wall is loaded by a set of vertical (perpendicular to the horizontal interface layers) and in-plane transversal forces (perpendicular to the previous), the forces flow to the basement through a set of preferential compression lines that depend mostly on the geometrical characteristics of the masonry, in particular on the way the stones are supported on each other. If a set of more or less homogeneous and continuous horizontal layers, i.e. joints, exists in between the stones, the forces flow in a more uniform way and no particular concentration of forces happens on the stones. On the contrary, if the horizontal interfaces between stones are made of small stones, or other stiff material and (or) present different mortar thicknesses, i.e. if the joints are not uniform, presenting a very heterogeneous and discontinuous stiffness distribution, the forces flow through the stiffer areas, promoting a concentration of forces in those areas and inducing a flexural behaviour on the stones between stiffer points. Since stones have a tensile fragile behaviour with a low tensile strength, especially when compared to the compressive strength, this phenomenon promotes the tensile rupture of the stones, which ends up being one of the most important factors that controls the global performance of a stone masonry wall.

Notice that stone masonry is a material that is not meant to be submitted to tensile forces. Moreover, the behaviour and performance of a stone masonry strongly depends on the level of compression force applied to the masonry. In particular, high compression axial forces induce an instable behaviour that should be avoided. However, under ordinary static conditions, stone masonry is usually submitted to levels of axial compression force that are far below its compressive strength and, therefore, these forces have a stabilizing role, in particular when transversal forces are also applied to the masonry. As an example, laboratory tests made on a three-leaves irregular stone masonry wall panel, 1.2 m high per 1.0 m wide and 0.5 m thick, have shown a quite nonlinear plastic behaviour with a vertical axial strength and an initial Young modulus of around 3.0 MPa and 2.4 GPa, respectively [4]. Notice that the high plastic behaviour is one of the main characteristics of stone masonry and that is mainly due to the crushing of the joints, a deformation that is mostly unrecoverable.

Stone masonry is, therefore, a material that is not meant to be submitted to out-of-plane forces. But loads of this type may occur due to natural, or accidental phenomena (wind, earthquakes, explosions, impacts, etc.), or static lateral impulses from the contact with other elements, and stone masonry should be prepared to face them. Exceptional dynamic load events, like earthquakes, can induce important fluctuations of the compressive axial force that may vary from zero, exposing the masonry to a very critical situation where a small lateral force could be enough to overturn the masonry, to very high values that can overcome the compressive strength of the masonry and may cause the crushing of the material. Figure 4 shows the compression behaviour curve of a three-leaf stone masonry wall.

Simple compression test on a three-leaf stone masonry wall [4]: test apparatus and vertical compression behaviour curve

3 The Seismic Behaviour of Existing Masonry Buildings: Morphology of Damages and Failure Mechanisms

The developments that have been implemented and tested concerning stone masonry structures, in particular walls, arches and vaults, are mainly linked to the improvement of the behaviour of that type of masonry elements under seismic type actions. In fact, throughout history, earthquakes have represented one of the main causes of damage and losses of stone masonry buildings. The post-earthquake damage surveys carried out after earthquakes affecting areas where masonry buildings had an important presence came out to be an important source of information on the recurrent damage patterns. These observations showed that one of the main sources of vulnerability for such structures is associated to local failure modes that can be essentially interpreted on the basis of two fundamental collapse mechanisms [46–53]. According to Giuffrè definition [24, 52], the most vulnerable failure mode, referred to as the “First Damage Mode” (Fig. 5) is activated by seismic actions perpendicular to the wall, i.e. out-of-plane actions that cause the overturning of the whole panel, or of a significant portion of it. The building seismic response can be governed by such mechanisms when connections between orthogonal walls and between walls and floors are particularly poor. This is often the case of stone masonry buildings, with lack of interlocking at the connection of intersecting walls, presence of simply supported wooden floors and thrusting roofs. Only if connections are improved by proper devices, as for example tie-rods, the walls can be contained and this failure mechanism can be prevented. The second failure mode, referred to as the “Second Damage Mode” (Fig. 5), which can occur simultaneously, or not with the first one, is activated by seismic in-plane actions that cause the shear cracking of the panels.

Deformation of a building and typical damage of structural walls due to a seismic action. Example of first and second damage mode collapse mechanisms [54]

Under horizontal type actions, such as those impose by earthquakes, the external masonry walls of a house can typically be subjected to out-of-plane mechanisms. This “first mode” could be considered as one the most frequent and ruinous mechanisms, as it implies the complete collapse of the wall and consequent ruin of all supported elements. The way in which it develops depends on the quality of the masonry itself and of the connections with the other structural elements [55]. In the case that the structure is not strengthened and (or) well connected to other structural elements, such as floors and roofs, the only means to restraint the overturning mechanism is the friction produced on the contact surface between the wall and the elements to which it is connected. Notice that, if the structure is strengthened, for example, by introducing ties or ring beams, then usually the simple overturning is prevented, while mechanisms relying on arch effect start to develop [56].

Out-of-plane mechanisms of masonry panels are often associated with in-plane mechanisms, either developing within the same panel, or in different panels. In fact, not only constructions have masonry walls distributed along orthogonal directions, as horizontal actions, as earthquakes, introduce horizontal loads coming from different directions. As described before, this “second mode” is caused by forces acting in the plane of the wall and it is usually characterized by diagonal cracks associated with shear forces that often result in an “X” pattern, but hardly reaching total collapse. However, when a full shear crack occurs during an earthquake, the triangular sections of the panel can become unstable, leading to collapse.

Observation of seismic damage of stone masonry walls, as well as laboratory experimental tests on stone masonry panels, showed that masonry walls subjected to in-plane loading may have two typical types of behaviour, to which different failure modes are associated:

-

Flexural behaviour: this may involve two different modes of failure. If the applied vertical load is low with respect to the masonry compressive strength, the horizontal load produces tensile flexural cracking at the corners and the pier begins to behave as a nearly rigid body rotating around the toe (rocking). If no significant flexural cracking occurs, due to a sufficiently high vertical load, the pier is progressively characterized by a widespread damage pattern, with sub-vertical cracks oriented towards the more compressed corners (crushing). In both cases, the ultimate limit state is obtained by failure at the compressed corners, Fig. 6a.

Fig. 6 Identified masonry failure mechanism [57]

-

Shear behaviour: this may produce two different modes of failure: (i) sliding shear failure, where the development of flexural cracking at the tense corners reduces the resisting section; failure is attained with sliding on a horizontal plane bed joint, usually located at one of the ends of the pier, Fig. 6b; (ii) diagonal cracking, when failure is attained with the formation of a diagonal crack, which usually develops at the centre of the pier and then propagates towards the corners, Fig. 6c. The crack may pass prevailingly through mortar joints (assuming the shape of a ‘stair-stepped’ path in the case of a regular masonry pattern), or through the blocks.

The occurrence of different failure modes depends on several parameters such as: (a) the geometry of the pier; (b) the boundary conditions; (c) the acting axial load; (d) the mechanical characteristics of the masonry constituents (mortar, blocks and interfaces); (e) the masonry geometrical characteristics, namely the block aspect ratio and the in-plane and cross-section masonry pattern. In the past, many experimental tests have been carried out in order to analyse the influence of these parameters on the failure mode of masonry piers. In general, it has been assessed that rocking tends to prevail in slender piers, while bed joint sliding tends to occur in very squat piers [58, 59]. In moderately slender piers, diagonal cracking tends to prevail over rocking and bed joint sliding, for increasing levels of vertical compression [60].

For increasing levels of vertical compression [61], and increasing ratios of mortar to stone strength [62, 63], diagonal cracking propagating through stones tends to prevail over diagonal cracking propagating through mortar joints. Crushing, in general, occurs for high levels of vertical compression and is related to the compressive strength of the material [60].

It is worth pointing out that it is not always easy to distinguish the occurrence of a specific type of mechanism, since many interactions may occur between them. The damages observed in various countries due to recent earthquakes, particularly in Europe where the use of this material is very diffused in construction, (e.g. Umbria-Marche—Italy (1997-98), Azores—Portugal (1998), Andravida—Greece (2008), Abruzzo—Italy (2009), Lorca—Spain (2011), Van—Turkey (2011), Reggio-Emilia—Italy (2012), etc.—[64]) have shown that, although much knowledge already exists, and important investigation is still being carried in this field, there is still much to do, in particular in the implementation of strengthening and (or) retrofitting solutions in old stone masonry constructions to improve their performance under this type of actions. Besides, the fact that there are several buildings that were retrofitted and (or) strengthened prior to earthquakes also allowed assessing the performance, in particular the effectiveness of the applied intervention techniques; not always the adopted structural models were adequate and, therefore, the retrofitting techniques provided the expected effects. In particular, the effects of the earthquakes revealed the existence of incompatibilities between the stone masonry constructions (materials, structural systems…) and the applied intervention techniques, Fig. 7. Many failures were mainly related: to analyses performed on the basis of limited or inadequate information regarding the original structural system and the mechanical properties of the materials, to the use of unsuitable analytical tools and to the adoption of behaviour models developed for modern structures.

Although these observations call for regulatory documents that provide technicians with adequate guidance, it is very complex to define general rules and operative modalities, as it was tempted in the past. This is mainly related to the complexity of the structural typologies of existing buildings, in particular those with masonry bearing structures, but also to the fact that it is an issue that often involves social, historic, aesthetic, technical and economic aspects.

The observation of failures due to incompatibility between the original structure and the repair intervention, showed the need for developing new structural models for assessing the behaviour old stone masonry buildings, and code requirements for the intervention procedures [50, 65]. Formerly, the code requirements were oriented to the seismic adequacy of structures. In the case of cultural heritage constructions, namely those classified or protected by national or international directives, the new Italian seismic code moved from the imposition of “adequacy” to “improvement” [38–40, 66], which means more flexible, compatible and respectful interventions on existing structures. Such codes promote the improvement of the performance of old constructions through a series of intervention procedures, but without imposing the fulfilment of the (too demanding) code requirements for new constructions.

Several studies based on onsite observations after seismic events were carried out in order to define the real structural behaviour of old masonry buildings. These studies allowed creating abacuses with the typical damages occurring to the different typologies (buildings, churches, etc.), which led to the systematization of the mechanical models able to describe their specific behaviour by kinematics models, both for in-plane and out-of-plane mechanisms.

4 Methodologies and Tools for the Assessment of Stone Masonry Structures and Control of Strengthening Interventions

Characterization of old stone masonry structures is a very complex task, which requires specific multidisciplinary methodologies of evaluation that have been improved and applied, in particular to historical constructions or constructions with high cultural value [18]. Such methodologies allow designers, such as engineers and architects, to assess the materials and structural systems of the constructions, as well as their geometry and damage state. Such information is indispensable to calibrate and assess the representativeness of the numerical models that were selected for the simulation of the construction, and that will help to understand the processes that contributed to the actual state of the construction and to measure the actual performance of the recommended intervention solutions.

These evaluation methodologies are present in the Eurocode 8 [67] and in the Italian Technical Norms for Construction [40], and specified for Cultural Heritage in the Italian Guidelines [68]. These norms define different levels of knowledge, correlated to the extent of application of the methodologies, which are then related to different confidence factors. These factors are of great importance to designers for defining retrofitting and (or) strengthening interventions.

The evaluation methodologies can be divided into two main phases: (1) knowledge phase (historical research; assessment of the structure—geometry and material; damage survey; onsite and laboratory tests) and (2) analysis phase (selection of the type of analysis, model and tools).

The knowledge phase is characterized by several steps with the ultimate goal of characterizing in a complete and detailed, as much as possible, way the structural system. This phase is essentially composed by five steps: (1a) historical investigation, paying special attention to the transformations and structural interventions performed to the structure throughout time: assessment of the efficiency of those actions and discussion on their influence to the behaviour of the structure; (1b) description of the building, through the detailed analysis of each of the architectural and structural elements and the survey of the geometrical and material characteristics of the structure; (1c) characterization of the composing material properties (physical, chemical and mechanical) through onsite (flat-jacks, sonics, etc.) and laboratorial experimental tests; (1d) characterization of the more global behaviour of the structure through onsite tests, in particular by using dynamic identification tools, a technique that is becoming more and more diffuse, allowing the identification of higher and lower resistance areas, but also to assess, indirectly, the effectiveness of applied reinforcement solutions; (1e) description and definition of possible causes to the overall state of the structure. The use of different techniques and the comparison of the different results allow a more reliable and effective assessment.

The level of depth and detail involved in this 1st phase depends on the proposed objectives established for each particular case. If it intends a simplified analysis, or the analysis of only a certain part of the structure, it may not be reasonable to implement all the five steps with the same detail, or to apply them to the whole structure. This depends largely on the experience of the technicians involved in the study; a less experienced person may: (1) be extremely conservative (2) or totally neglect the knowledge phase.

The 2nd phase is characterized by a single step: (2a) define a modelling strategy for the assessment of the structures based on the previously gathered information. Within this step, and based on the objectives defined for each case, different matters have to be decided, such as the most effective: (i) modelling type analysis (limit analysis, analysis with numerical models, in particular using finite elements, etc.) and (ii) material type behaviour (linear or nonlinear).

The two phases are not always applied in a unidirectional way, i.e., after the definition of the 1st phase, and after passing to the analysis and modelling of the structure, it is often necessary to reassess the input information, entering into an iterative process.

5 Strengthening Techniques

Recent seismic events showed the ineffectiveness of some past interventions on masonry structures and, therefore, of the approaches/methodologies and tools adopted on its conception. The intervention solutions have to be designed taking into account its functional purpose, the real onsite conditions and should be validated guaranteeing the fulfilment of certain criteria [69–71], such as the requirement for: (i) structural authenticity; (ii) structural reliability; (iii) compatibility; (iv) durability; (v) non-intrusiveness (non-invasive); (vi) non-obtrusiveness; (vii) removability/reversibility, or repeatability; (viii) monitorability and controllability, all converging to (ix) a minimum intervention approach. These criteria should not be understood as absolute requirements, but as recommended conditions to achieve efficient, respectful optimal solutions, consistent with conservation principles. In fact, the fulfilment of all the criteria may be impossible in most cases, and some prioritization or choice, based on engineering judgment, is necessary.

On this validation process, the experimental studies constitute an important source of information, in particular for the development and calibration of analytical and numerical tools capable of predicting the behaviour of these structures. Having in mind that there is not a unique way of repairing, consolidating, strengthening, etc., the optimal solution should be selected among the different available techniques that respond to the safety and serviceability needs of a construction, pointing to the most friendly intervention, i.e. guaranteeing, as much as possible, the accomplishment of the previous criteria, within the available budget. At the same time, maintenance and monitoring programs should be also setup to follow the performance and physical state of the intervention solution in the long term.

As mentioned before, an important requirement to be considered in the selection of any material or technology used for repair or strengthening is the compatibility (chemical, physical, mechanical, thermal, rheological, etc.) between the new and the existing elements. A choice, regarding compatibility, is usually posed in the selection of traditional materials and techniques against modern (or innovative) ones. The first ones present, normally, longer term compatibility with the original elements due to the combination of similar properties and the absence of undesirable side-effects, as observed through past experience.

Modern and innovative materials and techniques may be considered for repair and strengthening purposes provided that sufficient scientific research and experience are available on their adequate performance and compatibility with the original elements. Some of these techniques have already shown severe incompatibility problems when used to restore or strengthened stone masonry structures. In other cases, more experience has to be gathered still before it can be said for certain that no damaging side effects may occur in the long term. The Venice Charter [69] refers directly to this subject; where traditional techniques prove inadequate, the consolidation of a monument can be achieved by the use of any modern technique for conservation and construction, provided its efficacy has been shown by scientific data and proved by experience. In turn, the ICOMOS/ISCARSAH Recommendations [70], mention that “the choice between “traditional” and “innovative” techniques should be determined on a case-by-case basis, with preference given to those that are least invasive and most compatible with heritage values, consistent with the need for safety and durability”.

There is a large number of intervention techniques that have direct application to stone masonry, aiming to improve its performance under static and dynamic loadings. Among those, a set of three that have been widely used in the recent years was selected: (i) grout injection; (ii) deep re-pointing of mortar joints and (iii) application of transversal ties. These techniques can be used either independently, or combined. Nevertheless, their effectiveness continues to be studied and analysed due to the involvement of different materials and methodologies, in combination with the complexity and in-homogeneity of the masonry.

Grout Injection

The repair and strengthening by grouting of brick and stone masonry walls, Fig. 8, has been largely applied in Italy on historic buildings and dwellings in the seventies and eighties, after the main earthquakes of Friuli and Irpinia; nevertheless, no great effort was done in advance to test the effectiveness of this technique.

Grout injection on stone masonry walls [4]: a drilling holes for the injection; b cleaning the drilled holes by blowing compressed air; c injection pump machine; d injection of a wall; e grout mixture leaking from a “control” hole; f sealing of the hole with mortar

Even if experimental and analytical research has been carried out in the past decades on these techniques, the effectiveness was mostly assessed in terms of strength increase, rather than in terms of compatibility with the original masonry [17, 72, 73]. However, some research was carried out on the effectiveness of grout injections [6, 74–80], and more recently the research works carried by Mazzon [3] and Silva [4].

These studies on stone masonry walls injected with grout, which involved cement or polymer-based grouts [9, 81–83] and lime-based grouts [3, 7, 83–85], allowed improving the knowledge regarding the mechanical characteristics and the structural effects of the injection technique. The conclusions recommended a careful approach and suggested a previous knowledge of the masonry wall morphology and of the masonry characteristics, since some types of walls are not injectable. Furthermore, it is a non-reversible technique and its use can raise durability and compatibility questions.

This type of intervention should be applied when there is weak cohesion between the different elements of the masonry and (or) there is an important amount of voids in the masonry cross-section, sufficiently interconnected to allow the mixture to penetrate and spread through the wall, providing a more homogeneous structural element. The technique is particularly appropriate for multi-leaf stone masonry, since a higher percentage of inner voids is expected when compared to other type of masonry. Nevertheless, the technique has been also used with success in single-leaf walls from the city of Porto, Portugal [1], although, in this case the use of this technique can be understood as deep re-pointing.

The choice of the mixture to inject is done by selecting the best characteristics for the type of wall on which to intervene, for example, the mechanical strength of the mixture and its deformation characteristics should be similar to those of the original wall. Therefore, the effectiveness of a repair by grout injection depends not only on the characteristic of the mixture used, but also on its mechanical properties, on the injection technique adopted and, once again, on the information on the wall characteristics. The technical improvements of the last years have developed new grouts with specific properties, such as low salt content and ultra-fine aggregates, and they have shown how to optimize the injection methodology, namely the injection pressure, or the distance between the injectors in function of the masonry characteristics.

The main problems connected to the grout injection technique can be summarized as follows: (i) lack of knowledge on the size distribution of voids in the wall; (ii) difficulty of the grout to penetrate into thin cracks (2–3 mm), even if micro fine binders are used; (iii) presence in the wall of fine and large size voids, together, which make difficult choosing the most suitable grain size of the grout; (iv) segregation and shrinkage of the grout due to the high rate of absorption of the material to be consolidated; (v) difficulty of grout penetration, especially in presence of silty or clayey materials; (vi) need for sufficiently low injection pressure to avoid air trapping within the cracks and fine voids, or even wall disruption.

Sometimes, in the case of disastrous events such as earthquakes, an apparent ineffectiveness of the consolidations using injection is observed. In fact, in these cases there is an inhomogeneous result of the intervention mainly due to: (1) poor design of the injection mixtures, (2) rough and uncontrolled execution of the intervention and (3) punctual distribution of the mixture due to an excessive distance between the injection holes. In fact, in most cases the ineffectiveness of the interventions injection is due to a poor execution of the technique, and not to the technique itself. Surveys after the 1997 earthquake in Umbria on damaged walls have often showed the difficulty of diffusion of the grout injection within stone masonry sections [86].

Deep Re-pointing of Mortar Joints

Deep repointing is a widely applied technique in all types of masonry, Fig. 9. This intervention consists on the partial replacement of the mortar joints with better quality mortar. It is meant to improve the masonry mechanical characteristics and it should be applied if deterioration is localized only in the mortar. This technique can increase the masonry strength for both vertical and horizontal loads, but the best results are obtained especially in terms of stiffness, which is greatly increased due to the confinement effect of the joints. Actually, strength enhancement is expected only when a significant percentage of the initial weak or deeply damaged mortar is replaced by a new more compact and rather stiffer one, but still not excessively rigid and resistant to avoid creating areas in the masonry with inhomogeneous behaviour.

Deep re-pointing procedure [7]

The main aims of deep repointing, provided that it is carried out with very good workmanship, are multiple: (i) to connect, in a rather thin section, the stones of the external leaf, substituting the original mortar in the joints when it is damaged, cracked and (or) very poor; (ii) to confine the wall at a less extent than the jacketing, but with better results, since the bond with the existing stones and mortar can be better assured; (iii) to confine better the injected material when grout injection is carried out; (iv) to provide a better penetration and distribution of the mortar compared to the random penetration and distribution of a grout injection.

Before deciding the application of the deep repointing technique an onsite investigation should be carried out in order to provide the crack pattern of the walls, the thickness of the section (it should be no more than 45.0 or 60.0 cm), the morphology of the masonry (number of leaves and stone arrangement) and the physical and chemical characterisation of the materials. Attention should be given to the choice of the mortar to avoid unwanted chemical, physical and mechanical incompatibilities. In general, cement based mortars are used, as they provide higher strength. However, this type of mortars may trigger unwanted chemical reactions in the masonry.

Sometimes, repointing is ineffective in cases where there is a poor execution of the intervention. In particular, it is frequent to found a malfunction of this technique because it wasn’t well applied in depth, but limited to an aesthetic improvement of the surfaces. Furthermore, much attention must be paid not only to the depth to remove, but also to the total elimination of the original layer of mortar that is in contact with the resistant elements (stones) in order to allow the new mortar to develop bond/adherence with the elements.

In the case of consolidation using repointing, the inability to maintain the original plaster must be taken into account. As so, this type of intervention cannot be used in the presence of fine plaster or frescos, i.e., in the case of buildings with historical and artistic importance.

Often, in conjunction with the repointing operations, it is necessary to intervene on the walls also with injections and (or) transversal steel ties, to increase the effect of the improvement due to the solely introduction of new mortar in the joints. This can be particularly efficient in the case of two or three leaves stone walls reaching a thickness not higher than 60 cm.

Transversal Ties

The technique of inserting metal tie-rods perpendicular to the walls facades, a technique that is used only on multi-leaf wall panels, has the main purpose of linking the different leaves to promote a more monolithic structural element. Thus, it improves the global behaviour of the masonry, preventing the out-of-plane instability of the leaves, Fig. 10, not only under vertical compressive forces, but also under in-plane and out-of-plane horizontal forces, increasing the masonry global strength and stiffness. This technique has as main advantages: (i) high velocity of implementation; (ii) low cost of execution; (iii) good performance and (iv) it can be (partially) removed, in case a better consolidation solution is found.

Application of transversal ties in multi-leaf stone masonry walls [7]

The ties consist on simple steel bars with improved adherence, or placed inside a sleeve that is injected with grout afterwards, or treated bars with a bolted head. The holes to insert the ties are done with a rotating probe, preferably at the mortar joints. Eventually it is possible to insert the bars by hammering, taking advantage of the lesions present in the walls.

When using simple steel bars, they are fixed to the masonry by bending or injection. In this case, the action of consolidation is noticeable only when the deformation of the wall tends to increase, putting the steel bar under tensile load. When using treated bars, a slight tightening can be performed by warming the bar; the contraction that occurs due to the cooling process immediately puts the bar under tensile forces, imposing an immediately compressive transversal action on the wall leaves. To apply these contrast actions, the tie-rods can be placed not only orthogonal to the facades of the wall, but also along diagonals. For the technique to be efficient, 4 ties should be inserted per square meter, with a minimum of 2 per square meter.

In the case of pre-stressed tie-rods, special attention should be paid to the application of the actions to the bars and to guarantee that the pre-stress effect is maintained in the long term. If the holes are not injected and the anchoring systems are accessible, it is possible to perform a periodical control of the state of tension in the bars. Furthermore, in particularly aggressive environments, the protection of the bars against the corrosive action of external agents has to be ensured.

6 Final Remarks

This section discusses construction typologies and materials, assessment methodologies, earthquake induced failure mechanisms and strengthening intervention techniques on existing stone masonry structures.

The characterization of existing stone masonry structures is a very complex task. It requires specific multidisciplinary methodologies of evaluation to provide the necessary information that allows understanding the processes that contributed to the actual state of the construction, and to select the most adequate intervention solutions.

Post-earthquake damage surveys carried out after earthquakes showed that one of the main sources of vulnerability for such structures is associated to local failure modes that can be essentially interpreted on the basis of in-plane and out-of-plane collapse mechanisms. These events showed the ineffectiveness of some past interventions on masonry, in particular due to their incompatibility, in most cases physical/mechanical, with the original structure.

In this context the applicability, advantages, and limitations of some intervention techniques that have been widely used in the recent years are discussed, in particular grout injection, deep re-pointing of mortar joints and application of transversal ties, which can be used either independently, or combined.

References

Almeida, C., Guedes, J., Arêde, A., Costa, A.: Shear and compression experimental behaviour of one leaf stone masonry walls. In: 15th World Conference Earthquake Engineering, Lisbon, Portugal (2012)

Almeida, C., Guedes, J.P., Arêde, A., Costa, C.Q., Costa, A.: Physical characterization and compression tests of one leaf stone masonry walls. Constr. Build. Mater. 30, 188–197 (2012)

Mazzon, N.: Influence of grout injection on the dynamic behaviour of stone masonry buildings. Ph.D. thesis, Università degli Studi di Padova: Scuola di Dottorato in Scienze dell’Ingegneria Civile e Ambientale (2010)

Silva, B.: Diagnosis and strengthening of historical masonry structures: numerical and experimental analyses. Ph.D. thesis, University of Padova, Italy (2012)

Silva, B., Guedes, J., Arêde, A., Costa, A.: Calibration and application of a continuum damage model on the simulation of stone masonry structures: Gondar church as a case study. Bull. Earthq. Eng. 10(1), 211–234 (2012)

Tomaževič, M.: Laboratory and in situ tests of the efficacy of grouting and tying of stone masonry walls. In: International workshop on effectiveness of injection techniques and retrofitting of stone and brick masonry walls in seismic arean, pp. 95–116 (1992)

Valluzzi, M.R.:. Comportamento meccanico di murature consolidate con materiali e tecniche a base di calcea. Ph.D. thesis, University of Trieste, Trieste, Italy (2000)

Vasconcelos, G.: Experimental investigations on the mechanics of stone masonry: characterization of granites and behavior of ancient masonry shear walls. Universidade do Minho, Guimarães (2005)

Vintzileou, E., Tassios, T.P.: Three-leaf stone masonry strengthened by injecting cement grouts. J. Struct. Eng. 121(5), 848–856 (1995)

Corradi, M., Borri, A., Vignoli, A.: Experimental study on the determination of strength of masonry walls. Constr. Build. Mater. 17(5), 325–337 (2003)

Costa, A.A., Arêde, A., Costa, A., Oliveira, C.S.: Out-of-plane behaviour of existing stone masonry buildings: experimental evaluation. Bull. Earthq. Eng. (2011). doi:10.1007/s10518-011-9332-9

Artioli, G., Casarin, F., Dalla Benetta, M., da Porto, F., Secco, M., Valluzzi, M.R.: Restoration of historic masonry structures damaged by the 2009 Abruzzo earthquake through injection grouts. In: 9th Australasian Masonry Conference, Queenstown, New Zealand (2011)

Costa, A.A., Arêde, A., Costa, A., Guedes, J., Silva, B.: Experimental testing, numerical modelling and seismic strengthening of traditional stone masonry: comprehensive study of a real Azorian pier. Bull. Earthq. Eng. 10(1), 135–159 (2012)

Modena, C.: Interpretazione dei risultati ottenuti dalle prove in sito nell’ambito delle tre convenzioni con gli istituti di ricerca di Firenze e Milano e modellazione del comportamento strutturale dei componenti rinforzati. Convenzione di ricerca tra la Regione Toscana e il Dipartimento di Costruzioni e Trasporti dell’Università degli Studi di Padova (1999)

Dalla Benetta, M.: Qualificazione di murature storiche: procedure sperimentali in sito e calibrazione in laboratorio. Ph.D. thesis, University of Padova (2012)

Miranda, L., Rio, J., Guedes, J., Costa, A.: Propagation of elastic waves on stone masonry walls. In: Proceedings of the Eighth International Masonry Conference. Dresden, Germany (2010)

Binda, L., Modena, C., Baronio, G., Abbaneo, S.: Repair and investigation techniques for stone masonry walls. Constr. Build. Mater. 3, 133–142 (1997)

Binda, L.: Caratterizzazione delle murature in pietra e mattoni ai finidell’individuazione di opportune tecniche di riparazione. CNR-Gruppo Nazionale per la Difesa dai Terremoti – Roma (2000)

Binda, L., Saisi, A.: State of the art of research on historic structures in Italy. Department of Structural Engineering, Politechnical of Milan, Italy (2001)

Casella, G.: Gramáticas de Pedra. Levantamento de Tipologias de Construção Muraria. Centro Regional de Artes Tradicionais (2003)

Pagaimo, F.: Caracterização Morfológica e Mecânica de Alvenarias Antigas: Caso de estudo da Vila de Tentúgal. Faculdade de Ciências e Tecnologia da Universidade de Coimbra, Departamento de Engenharia Civil (2004)

Palladio, A.: I quattro libri dell’architettura. Hoepli Editore, Milano (2000)

Breymann, G.A.: Costruzioni in mattoni ed in pietre artificiali e naturali. Dedalo, Roma (2003). 11

Giuffrè, A.: Letture sulla meccanica delle murature storiche. Rome, Kappa, Italy (1990)

Giuffrè, A., Carocci, C.: Vulnerability and mitigation in historical centres in seismic areas. Criteria for the formulation of a Practice Code. XI World Conference on Earthquake Engineering, Acapulco, Mexico 2086 (1996)

de Felice, G., Giannini, R.: Out-of-plane seismic resistance of masonry walls. J. Earthq. Eng. 5, 253–271 (2001)

Binda, L., Penazzi, D., Saisi, A.: Historic masonry buildings: necessity of a classification of structures and masonries for the adequate choice of analytical models. In: VI International Symposium Computer Methods in Structural Masonry—STRUMAS, Rome, Italy, pp. 168–173 (2003)

Binda, L.: Methodologies for the vulnerability analysis of historic centres in Italy. Keynote lecture, IX International Conference on Structural Studies, Repairs and Maintenance of Heritage Architecture—STREMAH, 22–24 June, Malta, pp. 279–290 (2005)

Borri, A., De Maria, A.: Alcune considerazioni in materia di analisi e di interventi sugli edifici in muratura in zona sismica. XI Congresso Nazionale “L’ingegneria Sismica in Italia”, ANIDIS, Genoa, Italy, pp. 25–29 (2004)

Ferrini, M., Melozzi, A., Pagliazzi, A., Scarparo, S.: Rilevamento della vulnerabilità sismica degli edifici in muratura. Manuale per la compilazione della Scheda GNDT/CNR di II livello, Regione Toscana, Italy (2003)

Binda, L., Saisi, A., Tiraboschi, C.: Investigation procedures for the diagnosis of historic masonries. Constr. Build. Mater. 14(4), 199–233 (2000)

Baronio, G., Binda, L.: Experimental approach to a procedure for the investigation of historic mortars. In: IX International Brick and Block Masonry Conference, Berlin, Germany, pp. 1397–1464 (1991)

Binda, L., Tiraboschi, C.: Flat-Jack method applied to historic masonries. In: Proceedings of the International RILEM Workshop On Site Control and Non-Destructive Evaluation of Masonry Structures, Mantova, Italy, pp. 179–190 (2003)

Anzani, A., Binda, L., Cantini, L., Cardani, G., Saisi, A., Tedeschi, C.: On site and laboratory investigation to assess material and structural damage on some churches hit by an earthquake. XII Conv. Naz. L’Ingegneria Sismica—ANIDIS 2007, Pisa, Italy (2007)

Doglioni, F.: Codice di pratica (linee guida) per la progettazione degli interventi di riparazione, miglioramento sismico e restauro dei beni architettonici danneggiati dal terremoto umbro-marchigiano del 1997. Bollettino Ufficiale Regione Marche (1999)

Borri, A.: Proposta di una metodologia per la valutazione della qualità muraria. Progetto di ricerca No. 1, Valutazione e riduzione della vulnerabilità sismica di edifici in muratura, rendicontazione scientifica 1°anno, Report Reluis (2006)

Regione di Molise, Allegato 3D, Protocollo di Progettazione per la Realizzazione degli Interventi di Ricostruzione Post-Sisma sugli Edifici Privati, Parte I—Edifici in Muratura, 2006—‘Indicazioni per la valutazione della qualità delle murature’ (2006)

LLPP, Italian Ministry of Public Works, Norme Tecniche per le Costruzioni in Zona Sismica. Decreto Ministeriale, 16 January 1996

LLPP, Italian Ministry of Public Works (2009) Istruzioni per l’applicazione delle Nuove norme tecniche per le costruzioni di cui al decreto ministeriale 14 gennaio 2008. Circolare del 2/2/2009, n. 617 del Ministero delle Infrastrutture e dei Trasporti approvata dal Consiglio Superiore dei Lavori Pubblici, Suppl. ord. n. 27 alla G.U. del 26/02/2009 No. 47, Italy

LLPP, Italian Ministry of Public Works, Norme Tecniche per le Costruzioni. Decreto Ministeriale del 14/1/2008, Suppl. ord. n. 30 alla G.U. n. 29 del 4/2/2008, Italy (2008)

Bennet, R.M., Boyd, K.A., Flanagan, R.D.: Compressive properties of structural clay tile prisms. J. Struct. Eng. 123(7), 920–926 (1997)

CEN, EN 1996-1-1: Eurocode 6—Design of masonry structures—Part 1-1: General rules for reinforced and unreinforced masonry structures (2005)

Kaushik, H.B., Rai, D.C., Jain, S.K.: Stress-strain characteristics of clay brick masonry under uniaxial compression. J. Mater. Civ. Eng. 19(9), 728–739 (2007)

Corradi, M., Borri, A., Vignoli, A.: Strengthening techniques on masonry structures struck by the Umbria-Marche earthquake of 1997–1998. Constr. Build. Mater. 16, 229–239 (2002)

Magenes, G., Galasco, A., Penna, A.: Caratterizzazione meccanica di una muratura in pietra XIII Convegno Nazionale—L’ingegneria Sismica in Italia. ANIDIS, Bologna, Italy (2009)

Binda, L., Baronio, G., Gambarotta, L., Lagomarsino, S., Modena, C.: Masonry constructions in seismic areas of central Italy: a multi-level approach to conservation. In: VIII North American Masonry Conference—8NAMC, Austin, USA, pp. 44–55 (1999)

Binda, L., Gambarotta, L., Lagomarsino, S., Modena, C.: A multilevel approach to the damage assessment and seismic improvement of masonry buildings in Italy. Seismic damage to masonry buildings, Balkema, Rotterdam, Netherlands (1999)

Borri, A., Avorio, A., Cangi, G.: Considerazioni sui cinematismi di collasso osservati per edifici in muratura. IX Convegno Nazionale “L’ingegneria Sismica in Italia”, ANIDIS, Torino, Italy (1999)

D’Ayala, D.: Correlation of seismic vulnerability and damages between classes of buildings: Churches and houses, in Seismic Damage to Masonry Buildings. Balkema, Rotterdam, pp. 41–58 (1999)

D’Ayala, D., Speranza, E.: Identificazione dei meccanismi di collasso per la stima della vulnerabilità sismica di edifici nei centri storici. IX Convegno Nazionale—L’ingegneria Sismica in Italia, ANIDIS, Torino, Italy (1999)

Doglioni, F., Moretti, A., Petrini, V.: Le chiese ed il terremoto. LINT, Trieste, Italy (1994)

Giuffrè, A.: Sicurezza e conservazione dei centri storici in area sismica, il caso Ortigia. Laterza, Bari, Italy (1993)

Lagomarsino, S., Brencich, A., Bussolino, F., Moretti, A., Pagnini, L.C., Podestà, S.: Una nuova metodologia per il rilievo del danno alle chiese: prime considerazioni sui meccanismi attivati dal sisma. Ingegneria Sismica 3, 70–82 (1997)

Tomaževič, M.: Some aspects of experimental testing of seismic behaviour of masonry walls and models of masonry buildings. ISET J. Earthq. Technol. 37(4), 101–117 (2000)

Modena, C., Valluzzi, M.R., Zenere, M.: Manuale d’uso del Programma c-Sisma. University of Padova, Padova, Italy (2009)

D’Ayala, D., Speranza, E.: Definition of collapse mechanisms and seismic vulnerability of historic masonry buildings. Earthq. Spectra 19, 479–509 (2003)

Tomaževič, M.: Earthquake-Resistant Design of Masonry Buildings. Imperial College Press, London (1999)

Magenes, G., Calvi, G.M.: Cyclic behaviour of brick masonry walls. In: X World Conference on Earthquake Engineering, Madrid, Spain, pp. 3517–3522 (1992)

Magenes, G., Calvi, G.M.: In-plane seismic response of brick masonry walls. Earthq. Eng. Struct. Dynam. 26, 1091–1112 (1997)

Vasconcelos, G., Lourenço, P.B.: Assessment of the in-plane shear strength of stone masonry walls by simplified models. In: V International Seminar on Structural Analysis of Historical Constructions—SAHC06, New Delhi, India, pp. 843–850 (2006)

Lourenço, P.B., Oliveira, D.V., Roca, P., Orduña, A.: Dry joint stone masonry walls subjected to in-plane combined loading. J. Struct. Eng. ASCE 131(11), 1665–1673 (2005)

Mayes, R.L., Clough, R.W.: A literature survey-compressive, tensile, bond and shear strength of masonry. Report No. EERC 75-15, Earthquake Engineering Research Centre, University of California, Berkeley (1975)

Bosiljkov, V., Page, A., Bokan-Bosiljkov, V., Zarnic, R.: Performance based studies on in-plane loaded unreinforced masonry walls. Masonry Int. 16(2), 39–50 (2003)

NGDC, National Geophysical Data Center, The Significant Earthquake Database. http://www.ngdc.noaa.gov/nndc/struts/form?t=101650&s=1&d=1

Magenes G, Bolognini D, Braggio C. (2000) Metodi semplificati per l’analisi sismica non lineare di edifici in muratura. CNR—Gruppo Nazionale per la Difesa dai Terremoti, http://gndt.ingv.it/Pubblicazioni/Magenes_copertina_con_intestazione.htm, Roma, Italy

OPCM 3274, Ordinanza del Presidente del Consiglio dei Ministri n. 3274 del 20 Marzo 2003. “Primi elementi in materia di criteri generali per la classificazione sismica del territorio nazionale e di normative tecniche per le costruzioni in zona sismica”. GU n. 72 del 8-5-2003, e s.m.i (2003)

CEN, EN 1998-3. Eurocode 8—Design of structures for earthquake resistance. Part 3: Assessment and retrofitting. European Standard. CEN, Brussels (2005)

D.P.C.M. 12-10-2007. G.U. n.24 of 29-1-2008, Guidelines for evaluation and mitigation of seismic risk to cultural heritage. Gangemi Editor. Rome. ISBN 978-88-492-1269-3 (2007)

Venice Charter International Charter for the Conservation and Restoration of Monuments and Sites. II International Congress of Architects and Technicians of Historic Monuments (1964)

ICOMOS/ISCARSAH Committee 2005. Recommendations for the analysis, Conservation and Structural Restoration of Architectural Heritage. ICOMOS International Committee for Analysis and Restoration of Structures of Architectural Heritage

ISO/TC98/SC2, ISO/FDIS 13822—Bases for design of structures—Assessment of existing structures. Final Draft. ISO, Genève (2010)

Modena, C., Binda, L., Anzani, A.: Investigation for the design and control of the repair intervention on historical stone masonry wall. In: VII International Conference and Exhibition, Structural Faults and Repair, Edinburgh, vol. 3, pp. 233–242 (1997)

Modena, C., Zavarise, G., Valluzzi, M.R.: Modelling of stone masonry walls strengthened by RC jackets. In: IV International Symposium on Computer Methods in Structural Masonry—STRUMAS, Florence, Italy, pp. 285–292 (1997)

Bettio, C., Modena, C., Riva, G.: The efficacy of consolidating historical masonry by means of injections. In: VII North American Masonry Conference—NAMC, Notre Dame, USA, pp. 458–471 (1996)

Binda, L., Modena, C., Baronio, G.: Strengthening of masonries by injection technique. VI North American Masonry Conference—NAMC, Philadelphia, USA, vol. 1, pp. 1–14 (1993)

Binda, L., Baronio, G., Tiraboschi, C.: Repair of brick-masonries by injection of grouts: experimental research. J. Struct. Eng. Madras, India 20(1), 29–44 (1993)

Binda, L., Modena, C., Baronio, G., Gelmi, A.: Experimental qualification of injection admixtures used for repair and strengthening of stone masonry walls. In: X International Brick and Block Masonry Conference—I2BMC, Calgary, Canada, vol. 2, pp. 539–548 (1994)

Laefer, D., Baronio, G., Anzani, A., Binda, L.: Measurement of grouts injection efficacy for stone masonry wall. VII North American Masonry Conference—NAMC, Notre Dame, USA, vol. 1, pp. 484–496 (1996)

Modena, C., Bettio, C.: Experimental characterization and modelling of injected and jacketed masonry walls. In: Italian-French Symposium Strengthening and Repair of Structures in Seismic Area, Nizza, pp. 273–282 (1994)

Tomaževič, M., Turnsek, V.: Verification of the seismic resistance of masonry buildings. In: British Ceramic Society: Load bearing Brickwork, vol. 30, pp. 360–369 (1982)

Miltiadou, A.: Contribution Ii l’etude des coulis hydrauliques pour la reparation et Ie renforcement des structures et des monuments historiques en maçonnerie. Ph.D. thesis, Ecole Nationale des Ponts et Chaussecs, Paris (1990)

Tomaževič, M., Apih, V.: The strengthening of stone-masonry walls by injecting the masonry-friendly grouts. Eur. Earthq. Eng. 6(1), 10–20 (1993)

Toumbakari, E.E.: Lime-pozzolan-cement grouts and their structural effects on composite masonry walls. Ph.D. thesis, Katholieke Universiteit Leuven, Belgium (2002)

Valluzzi, M.R., da Porto, F., Modena, C.: Behaviour and modelling of strengthened three-leaf stone masonry walls. Mater. Struct. 37(3), 184–192 (2004)

Vintzileou, E., Miltiadou-Fezans, A.: Mechanical properties of three-leaf stone masonry grouted with ternary or hydraulic lime-based grouts. Eng. Struct. 30(8), 2265–2276 (2008)

Binda, L., Cardani, G., Penazzi, D., Saisi, A.: Performance of some repair and strengthening techniques applied to historical stone masonries is seismic areas. ICPCM a New Era of Building, Cairo, Egypt, vol. 2, pp. 1195–1204 (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Quelhas, B., Cantini, L., Guedes, J.M., da Porto, F., Almeida, C. (2014). Characterization and Reinforcement of Stone Masonry Walls. In: Costa, A., Guedes, J., Varum, H. (eds) Structural Rehabilitation of Old Buildings. Building Pathology and Rehabilitation, vol 2. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-39686-1_5

Download citation

DOI: https://doi.org/10.1007/978-3-642-39686-1_5

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-39685-4

Online ISBN: 978-3-642-39686-1

eBook Packages: EngineeringEngineering (R0)