Abstract

This paper presents results obtained in a MSc thesis (1st author) developed in NOVA School of Science and Technology (FCT NOVA) (Joaquim, in Behaviour of traditional stone masonry walls subjected to blast loading. Master Thesis, Civil Engineering. FCT NOVA, Lisbon, 2021) regarding the blast behavior of traditional stone masonry walls. In order to understand this phenomenon, two types of tests were performed, using two traditional stone masonry specimens (M1 and M2) with dimensions 1.20 m × 1.20 m × 0.40 m (length × width × thickness), produced by Pinho (Ordinary masonry walls—Experimental study with unstrengthened and strengthened specimens. Ph.D Thesis, Civil Engineering. FCT NOVA, Lisbon, 17/out/07, 2007). Firstly, the specimens (walls) were subjected to unconfined explosions—without physical barriers between the explosion and the target/wall. Secondly, after the explosions, the axial compressive strengths of the two walls were evaluated. In this paper, the results and discussion of the first kind of tests are presented.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Experimental Work

Traditional stone masonry walls are usually (external) “resistant walls”. Thus, a testing system was developed to apply a pre-load of 0.25 MPa to each wall, which in turn may simulate a lower floor wall of a traditional Portuguese ancient stone building.

Field tests took place at Campo Militar de Santa Margarida (CMSM), which has safety and optimal and operational conditions to perform this experimental procedure.

Due to the lack of bibliography and knowledge concerning the expected results, the ideal approach would be to reproduce perfect airbursts, firstly, in order to facilitate the study and create data regarding traditional stone masonry walls' blast resistance.

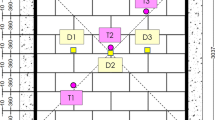

It was not possible to test the walls in the horizontal position, similarly to tests previously performed [1, 2] under the Project PTDC/ECI-EST/31046/2017—PROTEDES, due to their constitution, weight and pre-load applied. Therefore, a different testing system was used, Fig. 1, allowing three types of unconfined explosions on two masonry specimens: perfect aerial, near-surface and surface explosions. Making this system closer to reality also adds difficulty in recording and processing data.

The testing facility of Competence Centre for Infrastructure Protection (CCPI), located in CMSM, comprises a foundation and reinforced concrete walls (0.35 m thick), 1.65 m apart. Additionally, the test system has several steel parts (e.g. brackets and beams) to ensure the assembly of different support systems.

In order to keep the wall perpendicularly to the blast action direction, two UNP300 metal beams were used, with the upper one supported on two metal brackets and the lower one 15 cm off the ground, Fig. 2.

A metallic tripod with a rope weas used to place the explosive and adjust the height and distance to the target.

Two incident pressure transducers and one reflected pressure transducer [(×2) PCB 137B24 and PCB 137B24, respectively] were used.

In order to evaluate the explosion's effects on the wall, transversal displacements of each wall were measured using an expedite system consisting of steel tubes filled with foam. This measurement system was positioned behind the wall, placing six metal bars in contact with the back of the wall, wrapped in foam inside the metal tubes.

Explosive EurodynTM was used in the experimental tests, with 75% of TNT's detonation power. The quantity of explosive used, presented in Table 1, was determined through numerical simulations.

The distances and loads of the first test (specimen M2) were based on previous works performed under the project PTDC/ECI-EST/31046/2017—PROTEDES, allowing future comparisons regarding different constructive solutions. For the second test, using specimen M2 again, it was kept approximately the same incident impulse, varying the distance and the amount of explosive. These variations were performed to cause more damage and analyze the difference between reflected pressures. In the third test (specimen M1), to allow data extraction and axial compression test execution, the explosive quantity was defined to create more damage without leading the rampart to collapse.

For safety reasons, the handling of the explosive was carried out by the EOD (Explosive Ordnance Disposal) team from the 1st Engineering Regiment based in Tancos.

2 Visual Damage Assessment

The first test used 20 kg of explosive at a distance of 5.0 m from the target (M2), and there was no visible damage except a small crack on the face exposed to the blast.

In the second test (M2, again), the incident impulse was kept approximately the same as in the first test, varying the distance and amount of explosive (1.0 m and 1.3 kg, respectively) to cause more damage and analyze the difference between reflected pressures. In this test, the following damage was observed—several cracks (higher width crack of 1.4 mm) and some craters on the face exposed to the blast and the side of the wall; on the face opposite to the blast, there was no visible damage.

In the third test (specimen M1), there was an increase in the amount of explosive relative to the second test, and the damage acquired a greater dimension, with the wall showing cracks (maximum 0.8 mm) on the face opposite to the explosion. However, the wall did not collapse, and there was no spalling on this face. On the other hand, a large part of the mortar on the face exposed to the blast was disintegrated.

3 Results

Firstly, a filtering of the data obtained from the incident and reflected pressures was performed to allow an evaluation by comparing the positive phase of the explosion between the shock wave profiles obtained in the experimental tests and the theoretical profiles obtained through Friedlander's equation. In Eq. (1), where t is the value of time recorded since the arrival to the positive phase, where the incident peak pressure occurs (PS0), and b is a shape constant.

Subsequently, a comparison was made between the values of incident peak pressure (PS0) and reflected peak pressure (Pr) (2) of Kinney and Graham [4], Eq. (3) of Rankine-Hugoniot [5] and the “KINGERY_master” calculation sheetsmaster”.

Parameters given in Eqs. (2) and (3) if it is a surface explosion, the comparative analysis of experimental data used in UFC 3-340-02 [6], reveal that W must be corrected by a multiplication factor of 1.8. Z is the reduced distance obtained by Eq. (4) and P0 is the atmospheric pressure.

Finally, we compared the values of the incident pulses (PS0) and reflected impulses (Pr), obtained in the experimental tests, by numerical integration of the shock wave profiles recorded by the transducers and the theoretical incidents and reflected impulses by Eq. (6) of Kinney and Graham [4], Eq. (7) and the “KINGERY_master” spreadsheets.

3.1 Comparison of Experimental and Theoretical Shock Wave Profiles

In order to study the shock wave profiles obtained experimentally, a comparison was made between these and the curves that would be obtained using Eq. (1).

The values of the curves obtained from each incident pressure transducer were averaged to standardize the values and obtain a global perception of the events in each test. Only the values referring to the positive phase were considered, ignoring the negative phase.

Finally, to obtain the theoretical curve suitable to the profile obtained, some variables were calculated: shape constant (b); positive phase time (t0) and incident peak pressure (Pso). Those were obtained as a function of the minimum value of the sum of the standard deviations (S.D.) between the values obtained by the description of Eq. (2) and the experimental values.

With the results of the first test (wall M2) it was possible to approximate the incident pressure curve, Fig. 3, based on Eq. (1), having been obtained the values b = 0.92; t0 = 2.91 ms and Pso = 0.56 MPa.

Regarding the reflective pressure curve, Fig. 4, due to successive reflections and interference in the sensor reading, it was not possible to obtain the entire curve, only the peak reflected pressure.

In the second test (specimen M2), due to the reflections evidenced in Figs. 5 and 6, the wave prolongation did not allow for a good fit based on Eq. (1). The quick decrease of the peak pressure also contributes decisively to the lack of a better approximation of the profiles. For the minimum value of S.D. (best approximation to the experimental curve) the parameters are not coherent, as shown in Table 2. These reflections occurred due to the proximity of the sensors to the wall and test system, being only 1.00 m away.

Similarly, to the second test, in the third test (specimen M1), the explosive was placed at a distance of 1.00 m from the wall, causing reflections. These reflections did not allow a good approximation of the theoretical and experimental curves for the incident and reflected pressures. The profiles of the shock wave curves of the incident and reflected pressures are represented in Figs. 7 and 8 respectively, as presented in Table 3.

3.2 Comparison of Incident Peak and Reflected Pressures

By comparing the experimental values with theoretical formulations, it can be seen that formers are closer to a surface explosion.

The most significant discrepancies are for the incident pressure, with an error of 87.5% observed in the first test and 41.4% in the second test; however, the error decreases in the third test, observing a value of 10.2%. This can be justified by the experimental test conditions in natural conditions outside the laboratory. In the case of the second test, a sensor recorded a higher peak of 2.58 MPa, and the other one of 1.65 MPa which is closer to the theoretical values.

Regarding the reflected pressure, it has a minor error between its theoretical values and spreadsheets being respectively 10.4%, 3.4% and 15.5% in the first, second and third tests. It is also possible to observe that the values of the positive phase duration and impulses are in greater agreement with the “KINGERY_master” calculation sheets of RD Willcox of CESO(N) (1993).

In Table 4, we can see the results obtained through the experimental tests and compare them with theoretical calculations (Eqs. 2 and 3 and spreadsheet results).

3.3 Comparison of Incident and Reflected Impulses

Impulses, namely the reflected ones, are fundamental in analyzing the blast action because it is the force that effectively acts on the wall, resulting from the incident and reflected pressures, Table 5.

In the first test, it was impossible to experimentally quantify the action reproduced on the wall (reflected impulse) due to an incorrect transducer measurement. Regarding the second and third tests, errors of 24.3% and 148%, respectively, were found by comparing the experimental and the theoretical values of the surface explosion.

On the other hand, comparing the experimental values with the values obtained through the spreadsheet, for the surface explosion, errors of 35.6% and 1.9% are registered, respectively, in the second and third tests.

It can be seen that relevant errors were obtained, probably due to the proximity between the explosive and the wall (only 1.0 m, almost contact blast).

4 Conclusions

For these explosive loads, there was no collapse and projection of aggregates. Thus, it is essential to continue the study, increasing the explosive loads, in order to really know the ultimate load and failure mechanisms, with the purpose of adopting the best strengthening solutions for this constructive solution.

Moreover, concerning studies in the field of out-of-plane actions in traditional stone masonry walls, the information is relatively scarce, so it would be necessary to understand the stiffness, ultimate loads and maximum deflections of this type of wall, in order to obtain more accurate results in the description of the events and effects by an explosion.

The tests performed at a distance of 1.0 m from the target, due to the high proximity, show similar behaviour to the contact explosions, exhibiting localized damage. This distance also leads to the registration of reflections by the sensors, which hinders a good fit to the theoretical curve. This may show that these formulations may not be suitable for short distances.

References

Nabais, D.: Development of an innovative system for the protection of concrete structures against explosions. Master Thesis, Military Engineering. Lisbon, Military Academy/Instituto Superior Técnico (2016). (in Portuguese)

Pereira, V.: Innovative system for explosion protection of buildings—Reinforced concrete facade panels with thin walled steel connectors. Master Thesis, Military Engineering. Lisbon, Military Academy/Instituto Superior Técnico (2017). (in Portuguese)

Pinho, F.F.S.: Ordinary masonry walls—Experimental study with unstrengthened and strengthened specimens. Ph.D Thesis, Civil Engineering. FCT NOVA, Lisbon, 17/out/07 (2007). (in Portuguese)

Kinney, G.F., Graham, K.J.: Explosive Shocks in Air. Springer. ISBN: 978-3-642-86682-1 (1985)

Gomes, G.: Reuse of current buildings for operational purposes—Blast assesment. Collection “ARES”, 13. Lisbon; Instituto Universitário Militar (2016)

UFC 3-340-02 (2008): Structures to resist the effects of accidental explosions; U.S Department of Defense

Joaquim, B.: Behaviour of traditional stone masonry walls subjected to blast loading. Master Thesis, Civil Engineering. FCT NOVA, Lisbon (2021). (in Portuguese)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Joaquim, B., Conceição, J., Pinho, F.F.S. (2023). Experimental Analysis of Traditional Stone Masonry Walls Under Blast Loadings. In: Chastre, C., et al. Testing and Experimentation in Civil Engineering. TEST&E 2022. RILEM Bookseries, vol 41. Springer, Cham. https://doi.org/10.1007/978-3-031-29191-3_11

Download citation

DOI: https://doi.org/10.1007/978-3-031-29191-3_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-29190-6

Online ISBN: 978-3-031-29191-3

eBook Packages: EngineeringEngineering (R0)