Abstract

Recently, low-temperature fermentation has been recognized as a valuable tool to improve the flavor of fermented foods such as alcoholic beverages, e.g., in terms of improved ratios of off-flavor compounds to desirable compounds on total volatiles produced during fermentation. Extremely low-temperature fermentation processes can be made feasible using psychrophilic or psychrotolerant yeasts, combined with cell immobilization techniques and suitable bioreactor design. At research level, many studies deal with the optimization of low-temperature alcoholic fermentation (0–15 °C) in order to improve product quality, produce different products from the same raw material, and create added value. Studies dealing with these aspects also discuss ways to maintain bioreactors when production in the factory ceases, as well as the production of low-cost, ready-to-use dried yeast formulations. The application of extremely low-temperature fermentation in winemaking, brewing, distillates, and other fermented food production, as well as cold-adaptation aspects for food yeasts is discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Fermentation has been used for thousands of years as a natural process to improve quality, nutritional value, and safety of foods. Fermenting microorganisms, mainly yeasts and lactic acid bacteria, are used traditionally and at industrial scale for the production of bread, meat and dairy products, wine, beer and distillates (Steinkraus 1997; Vlieg et al. 2011; Bourdichon et al. 2012; Navarrete-Bolanos 2012). Recently, low-temperature fermentation (below 15 °C) is recognized as a valuable tool to improve the flavor of fermented foods (Kourkoutas et al. 2004; Beltran et al. 2006). Especially, low-temperature fermentation in winemaking is used to produce white wines with minimized losses of aroma volatile compounds, while higher fermentation temperatures (18–30 °C) are preferred in red winemaking to enhance extraction of pigments (Redon et al. 2011). Brewing on the other hand is traditionally carried out at varying temperatures depending on the type of beer. For example, ale beers are brewed at 16–23 °C, while lager fermentation is carried out at lower temperatures (8–15 °C) (Belloch et al. 2008). Special local products such as the Greek wines Vinsanto (sweet dessert wine made from white sun-dried grapes, Santorini Island, Greece) and Zitsa (semi-sparkling white wine, Zitsa, Epirus, Greece) or the famous French sparkling Champagnes are produced by low-temperature secondary fermentation during winter. The improved quality of these wines is attributed to the improved ratios of off-flavor compounds (such as higher alcohols) to desirable compounds (such as short-chain fatty acid esters) on total volatiles produced during fermentation (Bakoyianis et al. 1993; Bardi et al. 1997a; Kanellaki and Koutinas 1999; Beltran et al. 2006; Domizio et al. 2007; Parapouli et al. 2010; Torresi et al. 2011).

Industrial winemaking includes fermentation at low temperatures, usually not lower than 15 °C, using selected psychrotolerant wine yeasts. At research level on the other hand, since it is well established that fermentation temperature affects wine flavor, many attempts have been made to optimize winemaking at very low temperatures (0–15 °C) to (1) improve wine quality in terms of aroma volatiles composition; (2) produce different wine products using the same raw material; and (3) create added value. Good operational stability of extremely low-temperature fermentation processes can be facilitated by the use of psychrophilic or psychrotolerant yeasts combined with cell immobilization techniques and suitable bioreactor design (Kanellaki and Koutinas 1999; Kourkoutas et al. 2004). Research efforts regarding optimization of extremely low-temperature fermentations also propose technologies for low-cost production by using cold-adapted yeasts or for ways to maintain the bioreactors when production in the factory ceases. For the production of yeasts ready-to-use and their commercial distribution, various drying techniques have been developed such as freeze-drying or simple thermal drying, focusing on preservation of cell viability during drying and storage (Bekatorou et al. 2001a, b, 2002a; Iconomopoulou et al. 2000, 2002a, b; Tsaousi et al. 2010, 2011). Viable cold-adapted yeasts have been produced in free-cell formulations or immobilized on various carriers, such as porous inorganic (γ-alumina, glass, kissiris etc.), synthetic, or natural organic materials (cellulose, polysaccharides, hydrogels, proteins, etc.), as well as agro-industrial wastes and by-products (cellulosics, pieces of fruit, cereal residues, etc.) (Kourkoutas et al. 2004) (Fig. 19.1). Finally, a number of investigations deal with chemical analysis and sensorial testing to demonstrate the effect of fermentation temperature on the formation of volatile compounds that strongly affect product flavor (Bakoyianis et al. 1993; Bardi et al. 1997a; Mallouchos et al. 2003a, b, 2007; Tsakiris et al. 2004a; Garruti et al. 2006). All these efforts can contribute to the development of novel and integrated low-temperature fermentation technologies for controlled high-quality winemaking and brewing of distillates production.

Recent developments in the application of low-temperature fermentation processes in winemaking, brewing, and distillates production using cold-adapted yeasts are presented and discussed in this Chapter.

2 Cold-Adapted Yeasts for Low-Temperature Fermentation

2.1 Effect of Growth and Fermentation Temperature on Yeast Performance

Psychrophilic yeasts have a huge biotechnological potential due to their ability to grow and metabolize at low temperatures and can be used in various industrial applications such as (1) production of cold-active enzymes, e.g., lipases for detergents, cellulases for textile and biofuel processing, and in food production; (2) bioremediation of pollutants (e.g. phenolics, hydrocarbons, etc.); (3) production of miscellaneous metabolites of commercial interest (γ-decalactone, extracellular polysaccharides, microbial lipids, etc.); as well as (4) food and beverage fermentations at low temperatures to improve quality, prevent contamination by mesophiles, etc. (Kanellaki and Koutinas 1999; Okuyama et al. 1999; D’Amico et al. 2006; Buzzini et al. 2012).

Metabolic and physiological changes in yeasts are not only induced in psychrophilic species evolved in cold environments, but are also common during growth or fermentation processes at low temperatures. Saccharomyces cerevisiae is naturally found in environments, such as the surface of fruit, which can be subjected to low temperatures. In alcoholic fermentation processes, these yeasts can be exposed to temperatures around 10–12 °C, far below their natural physiological temperature (25–30 °C). Also, industrial strains may be stored at very low temperatures (4 °C) at which viability is maintained but growth is restricted (Aguilera et al. 2007). In S. cerevisiae, low temperatures induce the expression of genes that display a cold-sensitivity phenotype. Cold-inducible genes upregulated as a response to low temperature, including cold-dependent induction of fatty acid desaturases, a nucleolin-like protein involved in pre-rRNA processing and ribosome biogenesis, serine-, and alanine-rich cell wall proteins, etc., have been identified in S. cerevisiae (Kondo and Inouye 1991; Kowalski et al. 1995; Schade et al. 2004). The genetic response to cold stress was found to be time dependent, e.g., genes involved in the metabolism of glycogen and trehalose in detoxifying reactive oxygen species and defending against oxidative stress were induced after 4–6 h of low-temperature incubation (Grant 2001; Sahara et al. 2002; Schade et al. 2004; Murata et al. 2006). The transcriptional response of S. cerevisiae to low temperature comprised of two distinct expression patterns: (1) modifications of membrane fluidity and RNA secondary structures for efficient protein translation during the early phase; and (2) environmental stress response due to altered cell physiological state by decreased transport, accumulation of misfolded proteins, and reduced enzyme activities during the late growth phase (Schade et al. 2004). Low temperature was also found to influence wine yeast transcription profile during second fermentation such as that applied in production of sparkling wines by the traditional Champenoise method (Penacho et al. 2012).

Pizarro et al. (2008) showed that temperature differences (15 and 30 °C) most strongly affect nitrogen metabolism and the heat shock response in laboratory and wine S. cerevisiae strains. These responses were centered on sugar uptake, nitrogen metabolism, and expression of genes related to organoleptic properties. Salvado et al. (2012) conducted functional analysis to identify genes and proteins involved in adaptation to low-temperature fermentations in commercial wine yeast. They identified nine proteins mainly involved in stress response and in glucose and nitrogen metabolism as the most significant change during the first 24 h of fermentation at 13 °C. Redon et al. (2011) studied the effect of growth and alcoholic fermentation temperature (13 and 30 °C) on yeast viability, vitality, fermentation capacity, and lipid composition of different Saccharomyces species with different fermentative origins (wine, beer, baker’s and laboratory strains) showing that at low temperature, in spite of specific responses of the different strains/species, the medium-chain fatty acid and the triacylglyceride content increased, whereas the phosphatidic acid content and the phosphatidylcholine/phosphatidylethanolamine ratio decreased. A similar work was conducted by Torija et al. (2003), who determined the production of volatile compounds and the changes in the membrane fatty acids by GC to show the degree of cell adaptation and performance at 13 °C, with 25 °C as reference. They showed that lipid composition changed with the growth temperature, and the optimal membrane fluidity at low temperatures was modulated by changes in the unsaturation degree in S. cerevisiae strains. In S. bayanus, on the other hand, this change in the unsaturated fatty acid percentage was not observed at different growth temperatures, but the concentration of medium-chain fatty acids at low fermentation temperatures was higher.

Psychrophilic wine yeast strains of the species S. cerevisiae were isolated by Kishimoto et al. (1993) and their viability and fermentation ability at low temperatures (7–13 °C) was found superior compared to mesophilic strains (Kanellaki and Koutinas 1999). These strains also produced higher amounts of malic acid, higher alcohols, isoamyl acetate, β-phenylethyl alcohol, β-phenylethyl acetate and lower amounts of acetic acid. Isolation and characterization of psychrotolerant Saccharomyces strains from grape musts, able to grow well at 6 °C, was also reported by Castellari et al. (1995). However, publications concerning winemaking at temperatures lower than 10 °C are very few, and in practice, industrial winemaking at temperatures lower than 15 °C is not common due to very low productivity (Kanellaki and Koutinas 1999). To deal with this problem, various S. cerevisiae strains were isolated from the Greek agricultural area (the provinces of Achaia and Halkidiki and the Aegean islands Santorini, Samos, and Thasos) and were subjected to cold-adaptation treatments. The psychrotolerant S. cerevisiae strains S. cerevisiae Visanto and S. cerevisiae AXAZ-1 were found suitable for winemaking at low temperatures, by using free or immobilized various solid carriers such as mineral kissiris, delignified cellulosic material (DCM), and gluten pellets (Bakoyianis et al. 1992; Bardi and Koutinas 1994; Argiriou et al. 1996; Bardi et al. 1996a; Kanellaki and Koutinas 1999) (Fig. 19.1). The produced wines had improved flavor and required lower amounts of sulfites for stabilization.

Therefore, regarding alcoholic beverage production, psychrotolerant S. cerevisiae strains possess a number of advantages compared to conventional yeasts. In brewing, they can be used for fermentation at low temperatures (6 °C) for the production of beers of superior quality, and in winemaking, they can be used to ferment low acidity musts to produce more malic and succinic acid, glycerol and β-phenylethanol, and less acetic acid (Kishimoto et al. 1993; Giudici et al. 1995; Caridi and Corte 1997; Kanellaki and Koutinas 1999). However, these processes are not commonly used because low temperatures decrease the rates of yeast growth and fermentation and increase the risk of stuck and sluggish fermentations. The competition for nutrients between the selected psychrotolerant yeast and the wild microflora is higher at low temperature, and fermentation can be particularly problematic in musts from southern Europe, which typically have high sugar contents and low nitrogen availability (Llaurado et al. 2005; Salvado et al. 2011). The contribution of indigenous non-Saccharomyces species is potentially higher in fermentations carried out below 20 °C, reflecting in the chemical composition and sensory properties of the products. Controlled fermentation with selected yeasts in active dry form may involve rehydration with warm water (35–42 °C) prior to inoculation in a colder must, which may cause physiological stress. Therefore, active dry yeast rehydration at lower temperatures was proposed (Llaurado et al. 2005). On the other hand, Argiriou et al. (1996) pre-adapted the psychrotolerant yeast strain S. cerevisiae AXAZ-1 before use to conduct low-temperature fermentation. The yeast was grown in media with gradually increasing amounts of sugar content, while the culture temperature was kept below 20 °C. Improvement of the yeast fermentation performance, faster assimilation of nitrogen, lower acetic acid and fusel alcohol formation and higher glycerol concentrations were obtained (Argiriou et al. 1996; Kanellaki and Koutinas 1999). Fermentation of molasses by S. cerevisiae AXAZ-1 was evaluated in an extremely wide temperature range (3–40 °C). Sequence analysis of the 5.8S internal transcribed spacer and the D1/D2 ribosomal DNA (rDNA) regions assigned the isolate to S. cerevisiae. Restriction fragment length polymorphism of the mitochondrial DNA showed that the strain is genetically divergent compared to other wild strains of Greek origin or commercial yeast starters. Immobilization of the yeast on brewer’s spent grains, the main by-product of the brewing industry, improved the thermo-tolerance of the strain and enabled fermentation at 40 °C. Therefore, the strain S. cerevisiae AXAZ-1 is very promising for the production of ethanol from low-cost raw materials, such as molasses, as it is capable to perform fermentations yielding high ethanol concentrations, good-quality products regarding aroma volatile profiles, at both low and high temperatures (Kopsahelis et al. 2009).

2.2 Genetically Engineered Yeasts for Improved Fermentation Performance and Stress Resistance

Over the last few years, the wine and brewing industry also showed interest for genetically engineered yeasts with specific functions, with emphasis on the development of S. cerevisiae strains with improved fermentation efficiency, biopreservation, and capacities for increased wholesomeness and sensory quality of wine. Genetic modification may involve hybridization, backcrossing, mutagenesis, transformation, and somatic fusion procedures (Kanellaki and Koutinas 1999; Pretorius and Bauer 2002; Pérez-Través et al. 2012; López-Malo et al. 2013). Hybrid strains of S. cerevisiae, Saccharomyces bayanus, and Saccharomyces kudriavzevii are commercially available for wine fermentations (Belloch et al. 2008). Improvement of wine yeasts through genetic engineering has been reported aiming at obtaining certain properties, such as killer activity (Hara et al. 1981), higher yields of glycerol (Eustace and Thornton 1987), enhanced fermentation rate, decreased formation of acetate and improved production of fermentative aroma (Herrero et al. 2008; Cadière et al. 2012), tolerance to SO2 (Thornton 1982), cell flocculation at the end of fermentation (Watari et al. 1989), and enhanced xylose metabolism for conversion of lignocellulosics into biofuels (Kim et al. 2013), etc.

Improvement of yeast stress responses (including low or high temperature) during alcoholic fermentation processes has also been reported. It is well established that heterologous overexpression of proteins is connected with different stress reactions. Especially, the unfolded protein response in S. cerevisiae and other yeasts is well documented. High-cell-density fermentation, the typical process design for recombinant yeasts, exerts growth conditions that deviate far from the natural environment of the cells. Thus, different environmental stresses such as high osmolarity, low pH and low temperature may be exerted on the host. Whereas the molecular pathways of stress responses are well characterized, there is a lack of knowledge concerning the impact of stress responses on industrial production processes. Accordingly, most metabolic engineering approaches conducted so far target at the improvement of protein folding and secretion, and there are only few examples of cell engineering against general stress sensitivity (Mattanovich et al. 2004). Cardona et al. (2007) described a novel genetic manipulation strategy to improve stress resistance in wine yeasts. This strategy involved modification of the expression of the transcription factor MSN2, which plays an important role in yeast stress responses. The modified cells were able to carry out vinifications at 15 and 30 °C with higher fermentation rates during the first days of the process compared to the control strain. Jiménez-Martí et al. (2009) introduced several genetic manipulations in two genes induced by several stress conditions: HSP26, which encodes a heat shock protein, and YHR087 W, which encodes a protein of unknown function in two different wine yeasts. Some of these modifications resulted in strains with higher expression of these genes, better resistance to certain stress conditions, and even improved fermentative behavior. Sato et al. (2002) performed hybridization trials between four top-fermenting S. cerevisiae strains and a psychrophilic yeast S. bayanus in order to improve the fermentability at low-temperature. The hybrids were selected using 5-bromo-4-chloro-3-indolyl-α-d-galactopyranoside and were checked with pulsed-field gel electrophoresis. Their improved brewing performance at 10.5 °C was observed using small-scale fermentation trials.

In brewing, lager beers are fermented with strains collectively known as S. carlsbergensis, which are hybrids of S. cerevisiae and S. eubayanus-like strains, particularly adapted to low-temperature fermentations (Saerens et al. 2010; Sanchez et al. 2012). Selection of new yeast strains with improved properties, or fermentation performance is laborious, due to the allotetraploid nature of lager yeasts. Sanchez et al. (2012) generated new lager yeast and S. cerevisiae hybrids by classical genetics, which were improved regarding growth at elevated temperature and resistance against high osmolarity or high ethanol concentrations. Due to the uncertainty of chromosomal make-up of lager yeast spore clones, they introduced molecular markers to analyze mating-type composition and isolated new hybrids between a lager and an ale yeast by micromanipulation. These hybrids were not subject to genetic modification and showed improved stress resistance including improved survival at the end of fermentation and improved fermentation rates at 18–25 °C.

Achievements in genetic engineering of Saccharomyces yeast strains applied in food and beverage industry (brewing, winemaking and baking) have been reviewed and discussed (Donalies et al. 2008), yet, it is uncertain whether genetic engineering, although promising for the improvement of yeast properties with regard to product quality and fermentation efficiency, can lead to losses of other natural properties or affect yeast metabolic pathways with unexpected undesirable results (Guerzoni et al. 1985; Lee et al. 1995; Kanellaki and Koutinas 1999).

3 Low-Temperature Winemaking, Brewing, and Ethanol Production

A number of studies report the selection or the improvement of cold-adapted yeasts for better fermentation performance and stress tolerance as discussed above, but the largest part of literature reporting the development of low-temperature fermentation processes for alcoholic beverages or ethanol production involves the use of immobilized cell systems. The upsurge of interest in cell immobilization for alcoholic beverages and potable alcohol production is mainly due to the numerous advantages that it offers over free-cell systems, including enhanced fermentation productivity, stress tolerance, feasibility of continuous processing, cell stability and lower costs of recovery and recycling and downstream processing. Nevertheless, industrial use of immobilized cells is still limited and it will depend on the development of processes that can be readily scaled-up (Kourkoutas et al. 2004). Alterations in cell growth, physiology, and metabolic activity may be induced by cell immobilization of both yeast and bacterial species. Comparative studies on immobilized and free cells reported effects on activation of yeast energetic metabolism, increase in storage polysaccharides, altered growth rates, increased substrate uptake and product yield, lower yield of fermentation by-products, higher intracellular pH values, increased tolerance against toxic and inhibitory compounds, and increased invertase activity. Also, the immobilized cells showed increased viability and activity when stored at low temperature for long periods (Kourkoutas et al. 2004).

3.1 Low-Temperature Winemaking

Important improvement of fermentation productivity was achieved by S. cerevisiae immobilized on inorganic materials such as mineral kissiris (porous volcanic mineral found in Greece; 70 % SiO2) and γ-alumina, during batch fermentations of glucose and raisin extracts (Tsoutsas et al. 1990; Kana et al. 1989a, b) at ambient temperatures. These systems were further evaluated in batch as well as continuous winemaking at extremely low temperatures (2–10 °C), leading to important productivities (Bakoyianis et al. 1992, 1993, 1997). γ-Alumina promoted the alcoholic fermentation kinetics but showed lower efficiency at low temperatures compared with mineral kissiris (Bakoyianis et al. 1997). Despite the better fermentation performance of these biocatalysts, γ-alumina and kissiris leave mineral residues (e.g. Al) to the produced wine, therefore, studies to remove them were also carried out (Loukatos et al. 2000, 2003). However, these wines can be used as raw material for distillates production (Bakoyianis et al. 1997; Loukatos et al. 2000, 2003).

To avoid the presence of undesirable residues in wine released by inorganic materials, food-grade organic supports such as DCM and gluten pellets were evaluated as yeast immobilization supports for low-temperature fermentation. DCM was prepared after removal of lignin by alkaline (NaOH) treatment of sawdust, which increased the material’s porosity, and was used for immobilization of the psychrotolerant and alcohol resistant strain S. cerevisiae AXAZ-1. The biocatalyst was found suitable for extremely low-temperature batch fermentation of grape must, with acceptable fermentation rates even at temperatures lower than 5 °C (Bardi and Koutinas 1994). In the same manner, gluten pellets were used for low-temperature winemaking (Bardi et al. 1996a). Both supports presented similar efficiency for grape must fermentation. However, DCM is considered more attractive compared to gluten pellets due to its negligible cost and easier preparation. Wines produced by yeast immobilized on DCM and gluten pellets at extremely low temperature had improved flavor, which was demonstrated by both sensorial tests and chemical analysis of aroma volatiles.

Similarly to DCM, wine fermentations were conducted using free and immobilized psychrotolerant yeast on brewer’s spent grains at 25–10 °C. The operational stability of the biocatalyst was good and no decrease of its activity was observed, even at 10 °C. Ethanol and wine productivities were high, showing suitability for low-temperature winemaking.

Most of the research efforts to optimize low-temperature fermentation using immobilized cells concerned white winemaking. In red winemaking, fermentation proceeds in the presence of grape skins for color extraction. Therefore, new bioreactor design is necessary for low-temperature red winemaking to accommodate the immobilized biocatalyst and the grape skins confined in separate compartments (Tsakiris et al. 2004a).

In seek of new supports for yeast immobilization suitable for low-temperature winemaking, starch containing waste materials such as potatoes (Kandylis and Koutinas 2008), wheat (Kandylis et al. 2010a, b), barley (Kandylis et al. 2012a), and starch gels (Kandylis et al. 2008) were evaluated. These biocatalysts were also found to increase productivities of extremely low-temperature grape must fermentations compared to free cells. Comparing starch with alginates, starch is a more abundant natural carbohydrate and of lower cost, which makes it more attractive for commercialization. The biocatalyst produced by immobilization of the psychrotolerant strain S. cerevisiae AXAZ-1 on whole wheat grains was used for batch fermentations of glucose and grape must at laboratory and larger scale (80 L) at various temperatures (20–2 °C). The biocatalyst retained its operational stability for a long period, and it was proved capable to produce dry wines of fine clarity even at 5 °C. The scale-up process did not affect the fermentative ability of biocatalyst or the quality of the produced wines (Kandylis et al. 2010b). The same strain was immobilized on whole corn grains and was used for batch fermentations of glucose and grape musts at various temperatures. The biocatalyst retained its operational stability for a long period and it proved able to produce dry wines of fine clarity, even at extremely low temperatures (5 °C). A mathematical model to describe sugar consumption and ethanol formation was developed fitting almost perfectly with the experimental results (Kandylis et al. 2012b).

The idea to use fruit pieces as yeast immobilization supports for use in winemaking was also considered attractive because fruits are the natural habitats of yeasts, they can be easily accepted by consumers and can positively affect the product flavor. Cells immobilized on apple, pear, and quince pieces were successfully used for batch and continuous winemaking at extremely low temperatures (0 °C) (Kourkoutas et al. 2001, 2002a, 2003a; Mallios et al. 2004). These biocatalysts were stored at low temperature for long periods of time without loss of their activity (Kourkoutas et al. 2003b), which is an important observation regarding their potential for commercial application. In a similar manner, S. cerevisiae was immobilized on dried raisin berries (Sultanina variety) (Tsakiris et al. 2004b) or grape skins (Mallouchos et al. 2003b) to produce immobilized biocatalyst for use in dry white winemaking 25–15 °C and 25–10 °C, respectively. Raisin berries and grape skins are fully compatible with wine, and consumer acceptance is not an issue. Both biocatalysts were found suitable for good-quality winemaking with good operational stability (more than 4 months in the case of raisin berries). Although the use of fruit in high-volume bioreactors is problematic, such materials could still be employed in low-capacity processes due to the fine quality of the produced wines which can create added value. Table 19.1 shows the major volatiles produced during wine fermentations by cells immobilized on various natural carriers and by free cells of a psychrotolerant yeast (S. cerevisiae AXAZ-1) and a mesophilic commercial yeast (S. cerevisiae Uvaferme 299) at temperatures of 0–30 °C.

To industrialize a batch or continuous process employing immobilized cells, high operational stability is required. The improvement of biocatalytic stability and productivity of immobilized yeast cells was attempted by successive preservations at 0 °C of a psychrotolerant strain leading to a stability of productivity for at least 2.5 years (Argiriou et al. 1996). This result showed that the biocatalyst in the bioreactor could be maintained without need for emptying, sterilizing, recovering, and refilling, which can reduce the production cost and make handling easier when the factory is out of operation.

3.2 Low-Temperature Brewing

In brewing, research during the last 30 years has mainly focused on immobilization techniques in order to apply continuous processes, reduce maturation time, and produce alcohol-free beer (Masschelein et al. 1994; Kourkoutas et al. 2004). Brewing requires long fermentation times (6–7 days), large-scale fermentation, maturation at low temperature and storage capacities and is a highly energy-consuming process. Diacetyl is a key compound in beer maturation as it has an undesired butter flavor. It is produced by an oxidative non-enzymatic reaction from α-acetolactate and converted to acetoin by yeast metabolism during the maturation stage (diacetyl rest). These reactions are time-consuming and energy demanding since they are occurring at very low temperatures to avoid product quality degradation. The combination of yeast immobilization and low-temperature fermentation can reduce process times and improve product quality in the brewing industry, leading to significant reduction in production costs (Kourkoutas et al. 2004).

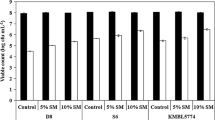

Traditionally, industrial brewing processes involve fermentations at low temperatures (13–15 °C) to obtain beer with quality that mainly depends on the yeast strain. Low-temperature fermentation of wort below common brewing temperatures (0–12 °C) produced beers of improved quality due to alterations in the chemical composition, mainly of aroma volatiles. Likewise, the combination of low-temperature fermentation and cell immobilization was found to lead to reduction in fermentation times and elimination of the maturation stage due to faster reduction in diacetyl (Bardi et al. 1996b; Bekatorou et al. 2001a, 2002a, b). The use of immobilization for the removal of diacetyl and therefore controlling flavor and reducing maturation time and production costs in brewing has been reported as a promising technological application.

As in the case of low-temperature winemaking, DCM was used as support for yeast immobilization for use as biocatalyst in low-temperature fermentation of wort (Bardi et al. 1996b). Beers were produced in batch or continuous processes with important productivities even at very low temperatures. Beers had lower pH, and lower diacetyl and phenolic compounds contents, and reduced bitterness compared with those of free cells. Beers produced by the DCM biocatalyst also had higher ethanol content (about 15 % higher) than those made with free cells, which can be attributed mainly to lower conversion of sugar to cell biomass. The lower pH of beers increases resistance to spoilages, while the lower diacetyl content improves beer flavor and reduces maturation time. The decreased phenolics content reduces the possibility of haze formation in the bottle. Sensorial tests showed important improvement of beers produced by a psychrotolerant yeast strain immobilized on DCM. Gluten was also employed as support for cell immobilization for extremely low-temperature brewing (Bardi et al. 1997b) and the obtained results were similar with those of the DCM biocatalyst.

Extremely low-temperature brewing (7–3 °C) with yeast immobilized on dried pieces of fruit (dried figs) was also investigated (Bekatorou et al. 2002b). Dried figs, which are rich in pectins, cellulose as well as protein, were found suitable for yeast immobilization and brewing, as shown by improved fermentation efficiency and product quality compared to free cells.

For low-temperature brewing, breweries, especially small production capacity units, require suitable isolated psychrophilic strains available for sale in the market. Consequently, the development of dried brewing yeasts was necessary. Freeze-dried S. cerevisiae immobilized on DCM and gluten pellets was examined for its efficiency for glucose fermentation (Iconomopoulou et al. 2000; Bekatorou et al. 2001b) and subsequently for extremely low-temperature brewing (Bekatorou et al. 2001a, 2002a), exhibiting all those important attributes, which are necessary for commercial application (increased productivities and improved product quality).

3.3 Low-Temperature Ethanol and Distillates Production

Most of the works describing winemaking or brewing using cold-adapted yeasts, free or immobilized on various carries, as described above, include studies with synthetic media (e.g. glucose) or waste effluents such as whey, to evaluate use of these biocatalyst for potable or fuel ethanol production. Distillates are produced through single or double distillation of fermented liquids or by fractional distillation in columns. The quality of distillates depends on the quality of the fermented raw materials, which is improved in the case of low-temperature fermentations by immobilized cells, due to improved ratios of esters to higher alcohols on total volatiles. In distillates production, inorganic materials such as γ-alumina pellets and kissiris can particularly be useful as immobilization supports, since they are cheap, abundant and can be easily reused. Mineral residues in the fermentation broth from such materials are not an issue since they do not distill. Therefore, continuous winemaking using yeast immobilized on γ-alumina, kissiris, DCM and gluten pellets was successfully performed at lower temperatures than the optimal for improved wine distillates production (Loukatos et al. 2000, 2003). Other natural materials have also been used as yeast immobilization carriers for potable alcohol production at ambient and low temperatures such as orange peel (Plessas et al. 2007).

Whey, the main liquid waste of the dairy industry, has also been used as raw material for potable alcohol production by fermentation with lactose fermenting yeasts or mixed cultures such as kefir. Kefir immobilized on DCM was used for batch fermentations at various temperatures in the range of 5–30 °C. The concentration of fusel alcohols was reduced at lower fermentation temperatures. At 5 °C, the content of total volatiles in the product was only 38 % of the volatiles formed during fermentation at 30 °C (Athanasiadis et al. 1999). Kefir immobilized on DCM was also found suitable for continuous whey fermentation supplemented with 1 % raisin extract or molasses. The continuous fermentation system was operated for 39 days, stored for 18 days at 4 °C and operated again for another 15 days without any diminution of the ethanol productivity. Ethanol productivity and residual sugar were at acceptable for the production of potable alcohol and alcoholic drinks at industrial scale (Kourkoutas et al. 2002a). Subsequently, industrial scale-up process of whey alcoholic fermentation, promoted by raisin extracts, using free kefir-yeast cells was successfully developed (Koutinas et al. 2007). The effect of fermentation temperature in the range 30–5 °C, among other parameters, was examined. The scale-up process involved the development of a technology transfer scheme from laboratory-scale experiments to a successive series of increased capacity bioreactors (100, 3000 and 11,000 L).

4 Development of Dried Yeasts for Commercial Low-Temperature Applications

Various commercial yeasts for induced fermentations are available usually in the form of dry active formulations. The most common drying technique used for industrial starter culture production is freeze-drying. Therefore, research works proposing new strains for use in food fermentation processes usually involve optimization of drying techniques to produce viable, active ready-to-use cultures. The efficiency of freeze-dried selected yeast strains, free or immobilized on suitable carriers, for extremely low-temperature fermentations has been reported. Freeze-dried psychrotolerant S. cerevisiae AXAZ-1 strain immobilized on DCM (Iconomopoulou et al. 2000, 2002a; Bekatorou et al. 2002a) or gluten pellets (Bekatorou et al. 2001a, b; Iconomopoulou et al. 2002b) was successfully used for alcoholic fermentation, winemaking, and brewing. Freeze-drying was carried out without the use of cryoprotectants showing suitability of the technique for commercial immobilized dry yeast production. Yet, freeze-drying has a relatively high investment and production cost compared to other drying methods. Therefore, the development of simple and mild processes for commercial dry yeast production was investigated, such as convective drying at low temperatures (e.g. 30–40 °C, under air stream or vacuum). Such techniques were found suitable for dry yeast production with fermentation efficiency similar to that of freeze-dried and wet-weight cells as evaluated by winemaking experiments (Tsaousi et al. 2010, 2011). A freeze-dried biocatalyst produced by immobilization of the psychrotolerant strain S. cerevisiae AXAZ-1 on gluten pellets and subsequent freeze-drying was used in a multistage fixed-bed tower (MFBT) bioreactor for batch and continuous winemaking. The process resulted in higher alcohol productivity compared to fermentations carried out in a single-bed bioreactor and better operational stability even at low fermentation temperature (5 °C) and after storage for 6 months at 4 °C. The good fermentation performance, operational stability and good quality of the product as shown by both chemical analysis and sensory evaluations, indicated potential industrial application of the freeze-dried biocatalyst and the MFBT bioreactor (Sipsas et al. 2009).

5 Flavor of Wine, Beers, and Distillates Produced by Low-Temperature Fermentation

The production and metabolism of compounds such as esters, higher alcohols, aldehydes, vicinal diketones, fatty acids, and sulfur compounds is crucial for the flavor of fermented foods, especially alcoholic beverages. These compounds are mainly associated with the yeast amino acid metabolism (Kourkoutas et al. 2004; Mallouchos et al. 2007). The effect of temperature on fermented food aroma is well established, and it has been shown that low-temperature processes can improve it. The combined effect of low fermentation temperature and use of immobilized cell techniques on wine and beer flavor has also been demonstrated (Bakoyianis et al. 1993; Bardi et al. 1997a; Yajima and Yokotsuka 2001; Mallouchos et al. 2003a, 2007; Kourkoutas et al. 2004, 2005; Kopsahelis et al. 2007). The greatest impact of such technologies is considered to be the improved ratio of esters to alcohols (increased ester and decreased fusel alcohol formation on total volatiles) (Mallouchos et al. 2003a; Kourkoutas et al. 2004, 2005).

Regarding wine, its distinctive aroma is the result of complex associations of varietal and fermentation volatile compounds. Generally, wines produced at low temperatures have aromas with more fruity notes due to increased synthesis or reduced conversion of esters. The use of immobilized cells in very low-temperature fermentation processes (below 10 °C) led to wines of improved aroma due to this effect (Bakoyianis et al. 1993; Jackson 1994; Bardi et al. 1997a; Yajima and Yokotsuka 2001; Mallouchos et al. 2003a, 2007; Kourkoutas et al. 2004, 2005). As described above, the use of natural food-grade supports for cell immobilization such as DCM and gluten pellets proved to be effective for low-temperature winemaking, showing significantly improved fermentation productivity and product quality compared to free cells. To facilitate commercialization of such biocatalyst, freeze-drying techniques were also evaluated for the production of ready-to-use dry formulations (Iconomopoulou et al. 2002a, b).

The production of wine using psychrotolerant yeast immobilized on food-grade materials, fully compatible with wine, such as grape skins and grape berries was also evaluated at 25–10 °C (Mallouchos et al. 2003b, c) and 6–30 °C (Tsakiris et al. 2004a), respectively. Improved fermentation performance of the immobilized biocatalysts was reported compared to free-cell systems and a positive influence on wine aroma, attributed to lower amounts of fusel alcohols which were decreased dramatically at low fermentation temperatures (below 10 °C). Pieces of various fruits like apple, pear, and quince were also proposed as carriers for yeast immobilization. Their use in batch and continuous winemaking processes also had a positive effect on wine flavor (Kourkoutas et al. 2001, 2002a, 2003a; Mallios et al. 2004), with higher ester and lower propanol-1 and isobutanol and amyl alcohol concentrations observed in the range 1–12 °C. Wine fermentations with yeast immobilized on brewer’s spent grains carried out at 15–10 °C also resulted in improved productivity and operational stability, and the combination of immobilization and low fermentation temperature affected significantly the flavor of these wines. The immobilized cells produced wines with higher contents of ethyl and acetate esters and volatile fatty acids at 15 and 10 °C, whereas the opposite was observed for free cells at higher temperatures (Mallouchos et al. 2007). Finally, wines produced at low temperature (5 °C) by psychrotolerant yeast immobilized on inorganic materials such as kissiris had an improved aroma with higher ethyl acetate content and lower higher alcohols on total volatiles (Bakoyianis et al. 1992, 1993, 1997; Kourkoutas et al. 2004), which is important for the production of good-quality wine distillates.

Low-temperature fermentation of fresh cashew juice with free S. bayannus cells was also reported, producing good-quality wines with cashew, fruity, and sweet characters. Headspace analysis of volatiles by Osme/GC–MS identified volatiles including ethyl esters associated with fruit aromas (Garruti et al. 2006).

Beer, on the other hand, is produced by more complex biochemical and technological processes (macromolecule hydrolysis, malting, kilning, fermentation, hops addition, maturation, etc.), which affect its flavor. Carbon dioxide, ethanol, and glycerol are the major compounds that control the organoleptic effect of other minor constituents such as alcohols, esters, vicinal diketones, aldehydes, sulfur compounds, and fatty acids. Yeast (amino acid) metabolism, a key to the development of beer flavor, is affected by process temperatures and use of cell immobilization techniques; therefore, technologies based on these features as well as process conditions and strain selection have been developed to control beer flavor (Kourkoutas et al. 2004; Branyik et al. 2008). Biochemical changes occurring during the secondary fermentation (maturation) of beer, which is usually conducted at very low temperature (0 °C), also affect its flavor. One of these changes is diacetyl rest, i.e., the reduction in diacetyl (buttery flavor) to the flavorless derivatives acetoin and 2,3-butanediol by yeast. The use of immobilized yeast and low-temperature primary fermentation was found to produce beers with low diacetyl amounts, therefore showing potential of low-cost industrial application since maturation is a high energy-consuming process (Kourkoutas et al. 2004). Perpète and Collin (2000) showed that during alcohol-free beer production, the enzymatic reduction in worty flavor (caused by Strecker aldehydes) (Fig. 19.2) by brewer’s yeast was improved by cold-contact fermentation. Also, as in the case of winemaking, biocatalysts prepared by immobilization of a psychrotolerant yeast strain on DCM and gluten pellets were found suitable for batch and continuous low-temperature brewing even at 0–5 °C. The produced beers had lower amounts of diacetyl and polyphenols compared to beers made using free cells. The fruity flavor of these beers was also attributed to the improved ratios of esters to alcohols (Bardi et al. 1996b; Bekatorou et al. 2001a, 2002a; Kourkoutas et al. 2004). Similar results were obtained during brewing at low and ambient temperatures (3–20 °C) by yeast immobilized on dried figs (Bekatorou et al. 2002b). The fine clarity of the produced beers and improved flavor after the end of the primary fermentation, in combination with the abundance, food-grade purity, and low cost of the proposed immobilization carriers, encouraged full-scale application for low-temperature brewing.

6 Conclusions and Perspectives

The isolation of psychrophilic yeasts, selection of psychrotolerant strains, or preadaptation treatments, in combination with techniques that protect cells from stress during fermentation and the development of drying techniques for commercial culture production, as discussed in this Chapter, describe an integrated approach to optimize low-temperature winemaking, brewing, and alcohol production processes. Low-temperature fermentation can improve quality and reduce maturation time, while cell immobilization can increase productivity, stress tolerance, and facilitate continuous processing of such processes. The proposed technology can also lead to the production of various new types of wines, beers, and distillates, without the need for addition of preservatives (e.g. SO2) and possibility for direct bottling of the product after the end of the primary fermentation. This is based on the following observations for low-temperature fermentations, especially those involving immobilized cell biocatalysts: (1) the improved flavor of the products, mainly due to improved ratios of esters to alcohols, lower diacetyl content, etc.; (2) increased fermentation performance of cold-adapted yeasts; and (3) fine clarity of the products after the primary low-temperature fermentation due to precipitation of tartrates in winemaking or chill haze in brewing, avoiding the need for clarification before bottling. Application of the described technology is encouraged by more than 50 original publications discussing results of laboratory and scale-up low-temperature fermentation processes.

References

Aguilera J, Randez-Gil F, Prieto JA (2007) Cold response in Saccharomyces cerevisiae: new functions for old mechanisms. FEMS Microbiol Rev 31:327–341

Argiriou T, Kanellaki M, Voliotis S, Koutinas AA (1996) Kissiris-supported yeast cells: High biocatalytic stability and productivity improvement of immobilized yeast cells by successive preservations at 0°C. J Agr Food Chem 44:4028–4031

Athanasiadis I, Boskou D, Kanellaki M, Koutinas AA (1999) Low-temperature alcoholic fermentation by delignified cellulosic material supported cells of kefir yeast. J Agr Food Chem 49:658–663

Bakoyianis V, Kanellaki M, Kalliafas A, Koutinas AA (1992) Low temperature wine-making by immobilized cells on mineral kissiris. J Agr Food Chem 40:1293–1296

Bakoyianis V, Kana K, Kalliafas A, Koutinas AA (1993) Low-temperature continuous wine-making by kissiris-supported biocatalyst: volatile by-products. J Agr Food Chem 41:465–468

Bakoyianis V, Koutinas AA, Aggelopoulos K, Kanellaki M (1997) Comparative study of kissiris, γ-alumina and Ca-alginates as supports of cells for batch and continuous wine making at low temperatures. J Agr Food Chem 45:4884–4888

Bardi E, Koutinas AA (1994) Immobilization of yeast on delignified cellulosic material for room temperature and low-temperature wine making. J Agr Food Chem 42:221–226

Bardi E, Bakoyianis V, Koutinas AA, Kanellaki M (1996a) Room temperature and low temperature wine making using yeast immobilized on gluten pellets. Process Biochem 31:425–430

Bardi E, Koutinas AA, Soupioni M, Kanellaki M (1996b) Immobilization of yeast on delignified cellulosic material for low temperature brewing. J Agr Food Chem 44:463–467

Bardi E, Koutinas AA, Psarianos C, Kanellaki M (1997a) Volatile by-products formed in low-temperature wine-making using immobilized yeast cells. Process Biochem 32:579–584

Bardi E, Koutinas AA, Kanellaki M (1997b) Room and low temperature brewing by yeast immobilized on gluten pellets. Process Biochem 32:691–696

Bekatorou A, Koutinas AA, Kaliafas A, Kanellaki M (2001a) Freeze-dried Saccharomyces cerevisiae cells immobilized on gluten pellets for glucose fermentation. Process Biochem 36:549–557

Bekatorou A, Koutinas AA, Psarianos C, Kanellaki M (2001b) Low-temperature brewing by freeze-dried immobilized cells on gluten pellets. J Agr Food Chem 49:373–377

Bekatorou A, Soupioni MJ, Koutinas AA, Kanellaki M (2002a) Low-temperature brewing by freeze-dried immobilized cells. Appl Biochem Biotech 97:105–121

Bekatorou A, Sarellas A, Ternan NG, Mallouchos A, Komaitis M, Koutinas AA, Kanellaki M (2002b) Low-temperature brewing using yeast immobilized on dried figs. J Agr Food Chem 50:7249–7257

Belloch C, Orlic S, Barrio E, Querol A (2008) Fermentative stress adaptation of hybrids within the Saccharomyces sensu stricto complex. Int J Food Microbiol 122:188–195

Beltran G, Novo M, Leberre V, Sokol S, Labourdette D, Guillamon JM, Mas A, Francois J, Rozes N (2006) Integration of transcriptomic and metabolic analyses for understanding the global responses of low-temperature winemaking fermentations. FEMS Yeast Res 6:1167–1183

Bourdichon F, Casaregola S, Farrokh C, Frisvad JC, Gerds ML, Hammes WP, Harnett J, Huys G, Laulund S, Ouwehand A, Powell IB, Prajapati JB, Seto Y, Ter Schure E, Van Boven A, Vankerckhoven V, Zgoda A, Tuijtelaars S, Hansen EB (2012) Food fermentations: microorganisms with technological beneficial use. Int J Food Microbiol 154:87–97

Branyik T, Vicente AA, Dostalek P, Teixeira JA (2008) A review of flavour formation in continuous beer fermentations. J Inst Brewing 114:3–13

Buzzini P, Branda E, Goretti M, Turchetti B (2012) Psychrophilic yeasts from worldwide glacial habitats: diversity, adaptation strategies and biotechnological potential. FEMS Microbiol Ecol 82:217–241

Cadière A, Aguera E, Caillé S, Ortiz-Julien A, Dequin S (2012) Pilot-scale evaluation the enological traits of a novel, aromatic wine yeast strain obtained by adaptive evolution. Food Microbiol 32:332–337

Cardona F, Carrasco P, Pérez-Ortín JE, del Olmo ML, Aranda A (2007) A novel approach for the improvement of stress resistance in wine yeasts. Int J Food Microbiol 114:83–91

Caridi A, Corte V (1997) Inhibition of malolactic fermentation by cryotolerant yeasts. Biotechnol Lett 19:723–726

Castellari L, Magrini P, Passarelli P, Zambonelli C (1995) Effect of must fermentation temperature on minor products formed by cryo and non-cryotolerant Saccharomyces cerevisiae strains. Ital J Food Sci 2:125–132

D’Amico S, Collins T, Marx JC, Feller G, Gerday C (2006) Psychrophilic microorganisms: challenges for life. EMBO Rep 7:385–389

Domizio P, Lencioni L, Ciani M, Di Blasi S, Pontremolesi C, Sabatelli MP (2007) Spontaneous and inoculated yeast populations dynamics and their effect on organoleptic characters of Vinsanto wine under different process conditions. Int J Food Microbiol 115:281–289

Donalies UE, Nguyen HT, Stahl U, Nevoigt E (2008) Improvement of Saccharomyces yeast strains used in brewing, wine making and baking. Adv Biochem Eng Biotechnol 111:67–98

Eustace R, Thornton RJ (1987) Selective hybridization of wine yeasts for higher yields of glycerol. Can J Microbiol 33:112–117

Garruti DS, de Abreu FAP, Franco MRB, Aparecida MAP (2006) The influence of fermentation temperature and sulfur dioxide on the volatile composition and flavour profile of cashew wine. Dev Food Sci 43:109–112

Giudici P, Zambonelli C, Passarelli P, Castellari L (1995) Improvement of wine composition with cryotolerant Saccharomyces strains. Am J Enol Viticult 46:143–147

Grant CM (2001) Role of the glutathione/glutaredoxin and thioredoxin systems in yeast growth and response to stress conditions. Mol Microbiol 39:533–541

Guerzoni ME, Marchetti R, Giudici P (1985) Modifications of aroma components of wines obtained by fermentation with Saccharomyces cerevisiae mutants. B OIV 58:228–234

Hara S, Iimura Y, Oyama H, Kozeki T, Kitano K, Otsuka KI (1981) The breeding of cryophilic killer wine yeasts. Agr Biol Chem 45:1327–1334

Herrero O, Ramón D, Orejas M (2008) Engineering the Saccharomyces cerevisiae isoprenoid pathway for de novo production of aromatic monoterpenes in wine. Metab Eng 10:78–86

Iconomopoulou M, Kanellaki M, Psarianos C, Koutinas AA (2000) Delignified cellulosic material supported biocatalyst as freeze-dried product in alcoholic fermentation. J Agr Food Chem 48:958–961

Iconomopoulou M, Kanellaki M, Soupioni M, Koutinas AA (2002a) Freeze dried immobilized cells on delignified cellulosic material in low-temperature and ambient temperature wine making. Appl Biochem Biotechnol 104:23–36

Iconomopoulou M, Psarianos K, Kanellaki M, Koutinas AA (2002b) Low temperature and ambient temperature wine making using freeze dried immobilized cells on gluten pellets. Process Biochem 37:707–717

Jackson RS (1994) Wine science, Principles and applications, 1st edn. Academic Press INC, London

Jiménez-Martí E, Zuzuarregui A, Ridaura I, Lozano N, del Olmo M (2009) Genetic manipulation of HSP26 and YHR087 W stress genes may improve fermentative behaviour in wine yeasts under vinification conditions. Int J Food Microbiol 130:122–130

Kana K, Kanellaki M, Papadimitriou A, Psarianos C, Koutinas AA (1989a) Immobilization of Saccharomyces cerevisiae on γ-Alumina pellets and its ethanol production in glucose and raisin extract fermentation. J Ferment Bioeng 68:213–215

Kana K, Kanellaki M, Psarianos C, Koutinas AA (1989b) Ethanol production by Saccharomyces cerevisiae immobilized on mineral kissiris. J Ferment Bioeng 68:144–147

Kandylis P, Koutinas AA (2008) Extremely low temperature fermentations of grape must by potatoes supported yeast-strain AXAZ-1. A contribution is performed to catalysis of alcoholic fermentation. J Agr Food Chem 56:3317–3327

Kandylis P, Goula A, Koutinas AA (2008) Corn starch gel for yeast cell entrapment. A view for catalysis of wine fermentation. J Agr Food Chem 56:12037–12045

Kandylis P, Manousi ME, Bekatorou A, Koutinas AA (2010a) Freeze-dried wheat supported biocatalyst for low temperature wine making. LWT-Food Sci Technol 43:1485–1493

Kandylis P, Drouza C, Bekatorou A, Koutinas AA (2010b) Scale-up of extremely low temperature fermentations of grape must by wheat supported yeast cells. Biores Technol 101:7484–7491

Kandylis P, Dimitrellou D, Koutinas AA (2012a) Winemaking by barley supported yeast cells. Food Chem 130:425–431

Kandylis P, Mantzari A, Koutinas AA, Kookos IK (2012b) Modelling of low temperature wine-making, using immobilized cells. Food Chem 133:1341–1348

Kanellaki M, Koutinas AA (1999) Low temperature fermentation by cold-adapted and immobilized yeast cells. In: Margesin R, Schinner F (eds) Biotechnological applications of cold-adapted organisms. Springer, Berlin, pp 118–145

Kim SR, Park YC, Jin YS, Seo JH (2013) Strain engineering of Saccharomyces cerevisiae for enhanced xylose metabolism. Biotechnol Adv. doi:10.1016/j.biotechadv.2013.03.004

Kishimoto M, Shinohara T, Soma E, Goto S (1993) Selection and fermentation properties of cryophilic wine yeasts. J Ferment Bioeng 75:451–453

Kondo K, Inouye M (1991) TIP1, a cold shock-inducible gene of Saccharomyces cerevisiae. J Biol Chem 266:17537–17544

Kopsahelis N, Kanellaki M, Bekatorou A (2007) Low temperature brewing using cells immobilized on brewer’s spent grains. Food Chem 104:480–488

Kopsahelis N, Nisiotou A, Kourkoutas Y, Panas P, Nychas GJE, Kanellaki M (2009) Molecular characterization and molasses fermentation performance of a wild yeast strain operating in an extremely wide temperature range. Biores Technol 100:4854–4862

Kourkoutas Y, Komaitis M, Koutinas AA, Kanellaki M (2001) Wine production using yeast immobilized on apple pieces at low and room temperatures. J Agr Food Chem 49:1417–1425

Kourkoutas Y, Koutinas AA, Kanellaki M, Banat IM, Marchant R (2002a) Continuous wine fermentation using a psychrophilic yeast immobilized on apple cuts at different temperatures. Food Microbiol 19:127–134

Kourkoutas Y, Douma M, Koutinas AA, Kanellaki M, Banat IM, Marchant R (2002b) Continuous winemaking fermentation using quince-immobilized yeast at room and low temperatures. Process Biochem 39:143–148

Kourkoutas Y, Komaitis M, Koutinas AA, Kaliafas A, Kanellaki M, Marchant R, Banat IM (2003a) Wine production using yeast immobilized on quince biocatalyst at temperatures between 30 and 0°C. Food Chem 82:353–360

Kourkoutas Y, Kanellaki M, Koutinas AA, Banat IM, Marchant R (2003b) Storage of immobilized yeast cells for use in wine-making at ambient temperature. J Agr Food Chem 51:654–658

Kourkoutas Y, Bekatorou A, Banat IM, Marchant R, Koutinas AA (2004) Immobilization technologies and support materials suitable in alcohol beverages production: a review. Food Microbiol 21:377–397

Kourkoutas Y, Kanellaki M, Koutinas AA, Tzia C (2005) Effect of fermentation conditions and immobilization supports on the wine-making. J Food Eng 69:115–123

Koutinas AA, Athanasiadis I, Bekatorou A, Psarianos C, Kanellaki M, Agouridis N, Blekas G (2007) Kefir-yeast technology: Industrial scale-up of alcoholic fermentation of whey, promoted by raisin extracts, using kefir-yeast granular biomass. Enzyme Microb Tech 41:576–582

Kowalski LR, Kondo K, Inouye M (1995) Cold-shock induction of a family of TIP1-related proteins associated with the membrane in Saccharomyces cerevisiae. Mol Microbiol 15:341–353

Lee S, Villa K, Patino H (1995) Yeast strain development for enhanced production of desirable alcohols/esters in beer. J Am Soc Brew Chem 53:153–156

Llaurado JM, Rozes N, Constanti M, Mas A (2005) Study of some Saccharomyces cerevisiae strains for winemaking after preadaptation at low temperatures. J Agr Food Chem 53:1003–1011

López-Malo M, Chiva R, Rozes N, Guillamon JM (2013) Phenotypic analysis of mutant and overexpressing strains of lipid metabolism genes in Saccharomyces cerevisiae: Implication in growth at low temperatures. Int J Food Microbiol 162:26–36

Loukatos P, Kiaris M, Ligas I, Bourgos G, Kanellaki M, Komaitis M, Koutinas AA (2000) Continuous wine making by γ-alumina-supported biocatalyst. Appl Biochem Biotechnol 89:1–13

Loukatos P, Kanellaki M, Komaitis M, Athanasiadis I, Koutinas AA (2003) A new technological approach proposed for distillate production using immobilized cells. J Biosci Bioeng 95:35–39

Mallios P, Kourkoutas Y, Iconomopoulou M, Koutinas AA, Psarianos C, Marchant R, Banat IM (2004) Low temperature wine making using yeast immobilized on pear pieces. J Sci Food Agr 84:1615–1623

Mallouchos A, Komaitis M, Koutinas AA, Kanellaki M (2003a) Wine fermentations by immobilized and free cells at different temperatures. Effect of immobilization and temperature on volatile by-products. Food Chem 80:109–113

Mallouchos A, Komaitis M, Koutinas AA, Kanellaki M (2003b) Evolution of volatile by products during wine fermentations using immobilized cells on grape skins. J Agr Food Chem 51:2402–2408

Mallouchos A, Skandamis P, Loukatos P, Komaitis M, Koutinas AA, Kanellaki M (2003c) Volatile compounds of wines produced by cells immobilized on grape skins. J Agr Food Chem 51:3060–3066

Mallouchos A, Loukatos P, Bekatorou A, Koutinas AA, Komaitis M (2007) Ambient and low temperature winemaking by immobilized cells on brewer’s spent grains: Effect on volatile composition. Food Chem 104:918–927

Masschelein CA, Ryder DS, Simon JP (1994) Immobilized cell technology in beer production. Crit Rev Biotechnol 14:155–177

Mattanovich D, Gasser B, Hohenblum H, Sauer M (2004) Stress in recombinant protein producing yeasts. J Biotechnol 113:121–135

Murata Y, Homma T, Kitagawa E, Momose Y, Sato MS, Odani M, Shimizu H, Hasegawa-Mizusawa M, Matsumoto R, Mizukami S, Fujita K, Parveen M, Komatsu Y, Iwahashi H (2006) Genome-wide expression analysis of yeast response during exposure to 4 degrees C. Extremophiles 10:117–128

Navarrete-Bolanos JL (2012) Improving traditional fermented beverages: How to evolve from spontaneous to directed fermentation. Eng Life Sci 12:410–418

Okuyama H, Morita N, Yumoto I (1999) Cold-adapted microorganisms for use in food biotechnology. In: Margesin R, Schinner F (eds) Biotechnological applications of cold-adapted organisms. Springer, Berlin, pp 101–115

Parapouli M, Hatziloukas E, Drainas C, Perisynakis A (2010) The effect of Debina grapevine indigenous yeast strains of Metschnikowia and Saccharomyces on wine flavour. J Ind Microbiol Biotechnol 37:85–93

Penacho V, Valero E, Gonzalez R (2012) Transcription profiling of sparkling wine second fermentation. Int J Food Microbiol 153:176–182

Pérez-Través L, Lopes CA, Barrio E, Querol A (2012) Evaluation of different genetic procedures for the generation of artificial hybrids in Saccharomyces genus for winemaking. Int J Food Microbiol 156:102–111

Perpète P, Collin S (2000) How to improve the enzymatic worty flavour reduction in a cold contact fermentation. Food Chem 70:457–462

Pizarro FJ, Jewett MC, Nielsen J, Agosin E (2008) Growth temperature exerts differential physiological and transcriptional responses in laboratory and wine strains of Saccharomyces cerevisiae. Appl Environ Microbiol 74:6358–6368

Plessas S, Bekatorou A, Koutinas AA, Soupioni M, Banat IM, Marchant R (2007) Use of Saccharomyces cerevisiae cells immobilized on orange peel as biocatalyst for alcoholic fermentation. Biores Technol 98:860–865

Pretorius IS, Bauer FF (2002) Meeting the consumer challenge through genetically customized wine-yeast strains. Trends Biotechnol 20:426–432

Redon M, Guillamon JM, Mas A, Rozes N (2011) Effect of growth temperature on yeast lipid composition and alcoholic fermentation at low temperature. Eur Food Res Technol 232:517–527

Saerens SMG, Duong CT, Nevoigt E (2010) Genetic improvement of brewer’s yeast: current state, perspectives and limits. Appl Microbiol Biotechnol 86:1195–1212

Sahara T, Goda T, Ohgiya S (2002) Comprehensive expression analysis of time-dependent genetic responses in yeast cells to low temperature. J Biol Chem 277:50015–50021

Salvado Z, Arroyo-Lopez FN, Barrio E, Querol A, Guillamon JM (2011) Quantifying the individual effects of ethanol and temperature on the fitness advantage of Saccharomyces cerevisiae. Food Microbiol 28:1155–1161

Salvado Z, Chiva R, Roze N, Cordero-Otero R, Guillamo JM (2012) Functional analysis to identify genes in wine yeast adaptation to low-temperature fermentation. J Appl Microbiol 113:76–88

Sanchez RG, Solodovnikova N, Wendland J (2012) Breeding of lager yeast with Saccharomyces cerevisiae improves stress resistance and fermentation performance. Yeast 29:343–355

Sato M, Kishimoto M, Watari J, Takashio M (2002) Breeding of brewer’s yeast by hybridization between a top-fermenting yeast Saccharomyces cerevisiae and a cryophilic yeast Saccharomyces bayanus. J Biosci Bioeng 93:509–511

Schade B, Jansen G, Whiteway M, Entian KD, Thomas DY (2004) Cold adaptation in budding yeast. Mol Biol Cell 15:5492–5502

Sipsas V, Kolokythas G, Kourkoutas Y, Plessas S, Nedovic VA, Kanellaki M (2009) Comparative study of batch and continuous Multi-Stage Fixed-Bed Tower (MFBT) bioreactor during wine-making using freeze-dried immobilized cells. J Food Eng 90:495–503

Steinkraus KH (1997) Classification of fermented foods: worldwide review of household fermentation techniques. Food Control 8:311–317

Thornton RJ (1982) Selective hybridization of pure culture wine yeasts II Improvement of fermentation efficiency and inheritance of SO2 tolerance. Eur J Appl Microbiol Biotechnol 14:159–164

Torija MJ, Beltran G, Novo M, Poblet M, Guillamon JM, Mas A, Rozes N (2003) Effects of fermentation temperature and Saccharomyces species on the cell fatty acid composition and presence of volatile compounds in wine. Int J Food Microbiol 85:127–136

Torresi S, Frangipane MT, Anelli G (2011) Biotechnologies in sparkling wine production. Interesting approaches for quality improvement: A review. Food Chem 129:1232–1241

Tsakiris A, Sipsas V, Bekatorou A, Mallouchos A, Koutinas AA (2004a) Red wine making by immobilized cells and influence on volatile composition. J Agr Food Chem 52:1357–1363

Tsakiris A, Bekatorou A, Koutinas AA, Marchant R, Banat IM (2004b) Immobilization of yeast on dried raisin berries for use in dry white wine making. Food Chem 87:11–15

Tsakiris A, Kandylis P, Bekatorou A, Kourkoutas Y, Koutinas AA (2010) Dry red wine making using yeast immobilized on cork pieces. Appl Biochem Biotechnol 162:1316–1326

Tsaousi Κ, Koutinas AA, Bekatorou A, Loukatos P (2010) Fermentation efficiency of cells immobilized on delignified brewers’ spent grains after low and high-temperature thin layer thermal drying. Appl Biochem Biotechnol 162:594–606

Tsaousi K, Velli A, Akarepis F, Bosnea L, Drouza C, Koutinas AA, Bekatorou A (2011) Low-temperature winemaking by thermally dried immobilized yeast on delignified brewer’s spent grains. Food Technol Biotechnol 49:379–384

Tsoutsas T, Kanellaki M, Psarianos C, Kaliafas A, Koutinas AA (1990) Kissiris: A mineral support for the promotion of ethanol fermentation by Saccharomyces cerevisiae. J Ferment Bioeng 69:93–97

Vlieg JETV, Veiga P, Zhang CH, Derrien M, Zhao LP (2011) Impact of microbial transformation of food on health - from fermented foods to fermentation in the gastro-intestinal tract. Current Opin Biotechnol 22:211–219

Watari J, Takata Y, Ogawa M, Nishikawa N, Kaminura M (1989) Molecular cloning of a flocculation gene in Saccharomyces cerevisiae plasmid DNA purification from E. coli culture. Agr Biol Chem 53:901–903

Yajima M, Yokotsuka K (2001) Volatile compound formation in white wines fermented using immobilized and free yeast. Am J Enol Viticult 52:210–218

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Kanellaki, M., Bekatorou, A., Koutinas, A.A. (2014). Low-Temperature Production of Wine, Beer, and Distillates Using Cold-Adapted Yeasts. In: Buzzini, P., Margesin, R. (eds) Cold-adapted Yeasts. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-39681-6_19

Download citation

DOI: https://doi.org/10.1007/978-3-642-39681-6_19

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-39680-9

Online ISBN: 978-3-642-39681-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)