Abstract

The purpose of this work was to study blast mitigation in a water mist and more specifically the effects of the droplet size and of the water mist loading on blast mitigation. A tunnel has been equipped with a water mist fire suppression system. By using this facility, experiments of detonation were carried out in the air and in different water mists. The blast effects were evaluated by means of four pressure gauges placed on the tunnel walls and one pressure gauge placed at the end of the tunnel. The transmission factor of the initial overpressure in the water mist was around 0.8 when four nozzles were used to produce the mist, whatever the size of the droplets. The transmission factor of the initial overpressure was smaller, about 0.6, with eight nozzles generating the mist, either for small or large droplets. The shock wave was delayed by the presence of the mist. The maximum impulse was reduced by about 20% when four nozzles were used to produce the mist, whether the droplets were small or large. The maximum impulse was more reduced with eight nozzles generating the mist, i.e., by about 30% for both droplet sizes.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

It is well known that explosion effects can be significantly mitigated by surrounding a detonating charge with a layer of water. Water can be used in various physical forms, bulk water [1], spray, or mist [2]. Numerous studies have described the mitigation of dust, hydrocarbon mist, and vapor/gas cloud explosions by using water mist [2,3,4,5]. In contrast, the use of water mist to mitigate the blast effect from a high explosive has been less studied, and only a small number of papers have been published [6,7,8,9,10,11]. Nevertheless, it has been shown that the overpressure, the impulse, as well as the quasi-static pressure of an explosion are reduced by the presence of mist.

It has been assumed in the previous studies [9,10,11,12] that the factors strongly influencing the explosion attenuation are the droplet size and the water load. But most of the time in these studies, the water mist was not characterized precisely and consequently, it was difficult to evaluate the mitigation efficiency according to the type of water mist. Therefore, a facility and a method of evaluating the mitigation properties of a water mist and its characteristics were developed. A tunnel was built and equipped with a water mist fire suppression system. By using this facility, experiments of detonation were carried out in air and in water mists. The water load of the mist in the tunnel as well as the droplet size was varied. The water mists effects on the blast wave overpressure and impulse loading generated by the detonation of Composition B spheres were assessed.

2 Experimental

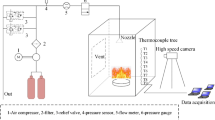

The tunnel has the following dimensions: a length of 4.50 m, a width of 2 m, and a height of 3 m. The tunnel was equipped with a water mist fire suppression system consisting of a high-pressure pump (SEM-SAFE®, Danfoss, 114 liters per minute, 120 bar) and nozzles. Three types of nozzles were used: the first and the second ones (types F500.147.37.04 and F500.143.37.04, DEF, France) generate fine droplets (diameter of the order of 25–100 μm), and the third one (type 17 90 05, DEF, France) generates large droplets (diameter of the order of 200–300 μm). Two arrangements of nozzles in the tunnel were investigated; they are presented in the Fig. 1 (left).

The flow of each nozzle was determined by collecting the whole ejected mass of water in a plastic barrel for a given period of time. The water distribution on the floor was measured in a similar way: an array of 100 × 100 mm plastic boxes collected water for a certain length of time.

The charges used were homogeneous spherical charges of Composition B. The sphere mass was 57 g. They were ignited by means of a high-voltage cap and 5 g of C4. The position of the charge in the tunnel and with respect to the pressure gauges is presented in Fig. 1. Blast effects were evaluated by using four reflected pressure gauges (PCB 113B28) placed on the tunnel walls and one side-on pressure gauge (PCB 137 A 23) placed at the end of the tunnel.

3 Results

3.1 Water Mist Characteristics

It was observed that the nozzles generating small droplets restricted the flow; indeed, for the two nozzle configurations, the nozzle flow was approximately the same. Such was not the case for the nozzles generating large droplets, the nozzle flow being much higher when four nozzles were used, compared with eight. The water distribution on the floor was measured for each configuration. The time of flight (TOF) of droplets from top to bottom in the tunnel was estimated. From these water distributions and from the TOF, it was possible to estimate the water load. First of all it was observed that for small droplets, the water distribution was affected by drafts, which was less the case for large droplets. The small droplets were volatile and escaped from the tunnel. When four nozzles were used, whether for small or large droplets, the water distribution was very inhomogeneous. When four nozzles ejecting small droplets were used, the mean water load was about 200 g/cm3, and with eight nozzles the value increased to 300 g/cm3. When four nozzles ejecting large droplets were used, the mean water load was about 150 g/cm3, but with eight nozzles the value decreased to 120 g/cm3. This is due to the higher flow of the nozzle in the case of a four-nozzle configuration.

3.2 Detonation Tests

Thirty four detonation tests were performed, 8 detonations in the air and 26 in a water mist. Five tests were carried out with four nozzles generating small droplets, and six tests were performed with four nozzles generating large droplets. Eight tests were made with eight nozzles generating small droplets, and seven were performed with eight nozzles generating large droplets. Figure 2 presents the overpressure as a function of time for all the tests obtained with the five gauges. The red curves correspond to blast tests in the air, the light blue ones correspond to blast tests in water mist composed of small droplets generated by four nozzles, the dark blue ones correspond to blast tests in a water mist made of small droplets generated by eight nozzles, the light green ones relate to blast tests in a water mist made of large droplets generated by four nozzles, and the dark green ones correspond to blast tests in a water mist made of large droplets generated by eight nozzles. The overpressure was reduced by the presence of the water mist, and this could be observed on all the gauges. Moreover, the shock wave was delayed by the presence of the mist.

Figure 3 (left) shows the average initial overpressure as a function of the distance to the charge for the tests in the air and the tests in a water mist. The uncertainty of the initial overpressure was estimated at 10%. The transmission factor of the initial overpressure that corresponds to the initial overpressure in a water mist divided by the initial overpressure in the air was computed. It was around 0.8 for this range of distance (from 1 to 2.10 m) when four nozzles were used to produce the mist, whether there were small or large droplets. The transmission factor of the initial overpressure was smaller when eight nozzles were used to generate the mist. Whether for small or large droplets, the transmission factor of the initial overpressure was around 0.6 for a distance ranging from 1 to 2.10 m. Figure 3 (right) presents the average arrival time as a function of the scaled distance for the tests in the air and the tests in the water mist. The value of uncertainty of the arrival time was estimated at 20 μs. The shock wave was delayed by the mist, and this delay increased with the distance to the charge, and thus with the quantity of water mist the shock wave passed through. Moreover, the delay was longer when eight nozzles were used compared with four, and this was also probably due to the greater amount of mist on the shock-wave path.

(Left) Initial overpressure as a function of the distance to the charge for the tests in the air and the tests in a water mist. The transmission factor of the initial overpressure is given. (Right) Arrival time as a function of the scaled distance for the tests in the air and the tests in a water mist. The increase in the arrival time compared to the tests performed in the air is given in percent

Figure 4 shows the impulse versus time obtained with gauges 1, 2, 3, 4, and 5. The impulse corresponds to the overpressure signal integrated over time. The red curves correspond to blast tests in the air, the light blue ones correspond to blast tests in a water mist generated by four nozzles ejecting small droplets, the dark blue ones correspond to blast tests in a water mist generated by eight nozzles ejecting small droplets, the light green ones relate to blast tests in a water mist generated by four nozzles producing large droplets, and the dark green ones correspond to blast tests in a water mist generated by eight nozzles ejecting large droplets. The impulse was reduced by the presence of the water mist, and this was visible on the five gauges. The reduction was less significant on gauge 2, as this gauge was the nearest to the charge and the measurements were affected by the fireball. Moreover, it could also be supposed that if the impulse was less reduced by the presence of mist, this was due to the smaller amount of mist on the shock-wave path. The maximum impulse was averaged over the different tests for each configuration; the results are given in Table 1. The difference in percentage in comparison with the tests performed in the air is also given. The maximum impulse was reduced by about 20% when four nozzles were used to produce the mist, whether for small or large droplets, except for gauge 2 where the decrease was less pronounced. Whether for small or large droplets, the maximum impulse was reduced by about 30% with eight nozzles generating the mist.

4 Conclusion

The aim of this work was to assess the mitigation of an explosion by a water mist generated by a water mist fire suppression system. We attempted to study the mitigation efficiency as a function of the droplet size and the water loading of the mist. For this purpose, nozzles generating two different sizes of droplets were used as well as two nozzle configurations (either four or eight nozzles). The initial overpressure was reduced by the presence of the mist. The transmission factor of the initial overpressure in the water mist was around 0.8 for a distance ranging from 1 to 2.10 m when four nozzles were used to produce the mist, whatever the size of the droplets. The transmission factor of the initial overpressure was smaller, around 0.6, with eight nozzles generating the mist, whether for small or large droplets. The shock wave was delayed by the presence of the mist, and this delay increased with the distance to the charge, and thus with the quantity of water mist, the shock wave passed through. This delay was also longer with eight nozzles, compared with four, and this was due to the greater amount of mist on the shock-wave path. The maximum impulse was reduced by about 20% with four nozzles used to produce the mist, whatever the size of the droplets. The maximum impulse was more reduced with eight nozzles generating the mist, i.e., by about 30% for both droplet sizes. For small droplets, when the number of nozzles increased, the water load increased as well as the mitigation efficiency. Consequently, it may be assumed that the mitigation efficiency increases with the quantity of water contained in the mist and probably with the homogeneity of the mist. By contrast, for large droplets when the number of nozzles increased, the water load slightly decreased. However, the blast mitigation improves with eight nozzles. It can be assumed that the uniformity of the water load has an impact. The shock wave was also more delayed with eight nozzles. With respect to the effect of the droplet size on the mitigation efficiency, we have obtained a similar mitigation with a smaller water load with large droplets, compared with small droplets. It can be supposed that the droplets of a diameter of 200–300 μm are more effective for attenuating the blast produced by a high explosive. This observation has to be confirmed.

The next steps will be first to study the mitigation efficiency when the explosive charge explodes outside the water mist and to close the tunnel ends and to assess the mitigation efficiency in a confined environment.

References

A. A. Buzukov, Combust. Explos. and Shock Waves 36, 395 (2000)

A. Jones, G.O. Thomas, Trans. IChem E 71, 41 (1993)

V.H.Y Tam et al., J. Loss Prev. Process Ind. 16, 81 (2003)

G.O. Thomas, Trans. IChem E 78, 339 (2000)

C.A. Catlin et al., Trans. IChemE 71, 101 (1993)

E. Mataradze, et al., Shock energy absorber for protection underground structure from internal explosions, in 15th International Symposium on Interaction of the Effects of Munitions with Structures Proceedings, Postdam (2013)

R. Tosello, et al., Shock wave attenuation using watermist, in International Symposium on Military Aspects of Blast and Shock Proceedings, Bourges (2012)

R. Ananth et al., Fire. Technol 48, 641 (2012)

H.D. Willauer et al., J. Hazard. Mater. 165, 1068 (2009)

J.L. Bailey, et al., NRL report: NRL/MR/6180- -06-8933 (2006)

A.D. Resnyansky, T.G. Delaney, DSTO report: DSTO-TR-1944 (2006)

D.A. Schwer, K. Kailasanath, NRL report: NRL/MR/6410- -06-8976 (2006)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Schunck, T., Sturtzer, MO., Mory, J., Eckenfels, D., Legendre, JF. (2019). Mitigation of Blast in a Water Mist. In: Sasoh, A., Aoki, T., Katayama, M. (eds) 31st International Symposium on Shock Waves 2. ISSW 2017. Springer, Cham. https://doi.org/10.1007/978-3-319-91017-8_89

Download citation

DOI: https://doi.org/10.1007/978-3-319-91017-8_89

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-91016-1

Online ISBN: 978-3-319-91017-8

eBook Packages: EngineeringEngineering (R0)