Abstract

Water mist system is used widely in confined spaces, where fire protection and suppression efficiency is very important due to limited water and no water damage. Pulsed water mist is a new type of fire extinguishing system that sprays and pauses in cycle during the procedure of fire extinguishment. Focusing on the fire suppression performance of pause water mist system, a series of experiments have been conducted to explore a more effective pause cycle way, fire suppression behavior, and the temperature distribution in a confined space. The results can be found that the best fire extinguishing effect was achieved with a pulse cycle alternating between an 8-s activation and an 8-s deactivation. With the increase in size of the vents, the advantage of the pulse water mist system gradually diminishes. The smothering method is better than the cooling method. The results of the study may provide a reliable reference for the practical application of pulsed water mist system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The water mist fire extinguishing system is a new type of fire extinguishing system, which operates on the basis of an automatic sprinkler system. Through certain atomization methods, extremely small water particles are created and are forced through the nozzles, allowing the user to effectively control, suppress, and extinguish fire. With no environment-related side effects, the water mist fire extinguishing system extinguishes fires more quickly and with lower water usage than more traditional systems. Additionally, the water from this system causes minimal damage to objects in the fires. This system is an ideal substitute for the traditional halon-based fire extinguishers, and it is suitable for fires in any domestic appliances, aircrafts, and so on. However, traditional fire extinguishing methods are not applicable in such cases, which shows its practical significance [1,2,3,4,5].

Pulse water mist refers to a new type of water mist system that employs a pulse jet method. The pulse jet alternates between spraying and pausing. This method has a stronger turbulent effect, which is conductive to the mixture of water mist and smoke plume. As a result, the heat-absorption and vaporization of the fog drop are enhanced, further lowering the temperature of the smoke and fog, diluting combustible air and oxygen, reducing the thermal feedback of the fuel, and eliminating gasification or evaporation. This increases the efficiency of the fire extinguishing effort and reduces the demand for water [6, 7].

Fires include complicated phenomena such as chemical reactions, thermal conduction, and multiphase flow. A large amount of research has been conducted in the mechanism of water mist fire extinguishing in confined spaces. Soonil et al. [8] established a model of water mist and fire plume and researched the influence of the droplet particle size, spray momentum, and water mist flow on fire zones. Parra et al. [9, 10] investigated the performance of water mist for premixed methane–air flames in a confined space. In their study, they emphasize that the fire front is suppressed by the water mist, which slows its spread, and the smaller the fog mist, the stronger its suppressing effect. Liu et al. [11] revealed that the intermittent activation and deactivation of the nozzle of water mist can achieve a better fire extinguishing effect than continuous spraying. They attribute this finding to the cooling and suffocating effect of sprayed mist. However, they did not quantify the effect on the fire extinguishing effect of the water mist pressure and the length of the interval of the intermittent activation and deactivation of the nozzle. Liao et al. [12, 13] studied the influence of the flow rate and droplet size on water mist suppression of oil pool fires.

As a new method of fire extinguishing, the pulse jet water mist system has not yet been widely adopted. Despite the system’s demonstrated advantages in extinguishing fires, several aspects have yet to be examined in detail: the main fire extinguishing mechanism, the pulse jet cycle, the pause time, and its efficacy in limited ventilation conditions. Many accidental fires involve fire sources that consist of various oils whose combustible properties vary. In this present study, experiments were conducted to determine the performance of the pulse jet water mist system in extinguish an oil pool set on fire in a limited space. The main objective of this study is to explore the fire extinguishing effects and mechanisms of the pulse water mist system. The study will be helpful to promote pulse jet water mist techniques and offer recommendations for a new design of the water mist system with enhanced fire extinguishing capabilities.

2 Experimental apparatus

2.1 Water mist

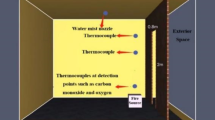

The confined space used in this study had dimensions of 1.5 m × 1.5 m × 1.5 m. The shelf on which the oil plate was supported was made of triangular steel 5 mm thick. The plate of oil had dimensions of 1.5 m × 1.5 m × 0.1 m (length, width, height). Under the shelf, a drainage system was installed on one side. One side of the confined space was made of reinforced glass 5 mm thick, which allowed the researchers during the experiments to observe the burning process and the circulation of the smoke in the confined space. The other walls were made of cement gypsum board for ease of installation and calibration of the measuring equipment. On one side of the confined space, a 1.0 m × 0.5 m sized door was installed, on which an adjustable vent was fixed (maximum size of 45 cm × 45 cm). The water mist nozzle as high as 1.4 m was placed in the central part of the top. The whole setup is displayed in Fig. 1.

A single-phase flow water mist fire extinguishing system was used in the experiment. The water mist system is composed of a water mist nozzle, an air compressor, a proportional pressure-reducing valve, a flow meter, pressure gauge, and a control devise. Four storage tanks with 70 L volume (height 1200 mm, diameter 280 mm, preset pressure 1.5 MPa) were used to store the water to be used by the water mist fire extinguishing system. The working pressure of the system was 0–3 MPa. The pulse control system used a multi-stage digital double-tuning time-limited relay to control the high-pressure solenoid valve, which was made of copper and had a maximum pressure of 5 MPa.

2.2 Method

During the experiments, the working pressure was adjusted through a proportional pressure-reducing valve regulating system. In the pipeline of the system, a flow meter is installed for measuring the variation of the volume of the pipeline during the experiments. A digital pressure-measuring device was installed at the end of the pipeline, which measured the pressure at the end of the nozzle. A circular steel pan with a diameter of 150 mm and 100 mm depth was employed to represent fire in a confined space. Sheathed K-tape thermocouple, with an error margin of ± 0.5 °C, was employed to measure the temperature in the tests, as shown in Fig. 1. The thermocouple placed at the bottom served to measure the surface temperature of the oil tank. The thermocouple with serial number 1 had another thermocouple on top with a 15-cm interval. There were nine thermocouples in total, with serial numbers 1# to 9#. A TOPPIE TP700 multi-channel recorder was used as a data collector. Experiments parameters of water spray nozzle are given in Table 1.

During the initial stages of the experiment, the spread rate of the diesel flame tended to be slow, and its flame shape, heat release rate, and smoke generation fluctuated unpredictably. As burning continued, the flame stabilized, and so did its temperature. To ensure a quasi-steady flame, the diesel tank was left to burn naturally for 60 s before it is extinguished by the activation of the water mist fire extinguisher [14, 15].

For droplets of 150 μm < d < 325 μm, the heat transfer coefficient can be simulated as

where Pr and Re are the Prandtl and Reynolds coefficients, respectively. K is the thermal conductivity.

According to Wighus’s model [16], the spray heat absorption ratio can be expressed in the form:

where Qwater is the ratio of the heart absorbed by the spray and Qfire is the heat released by the fire. For the specific calculation formula, please refer to Ref. [17, 18].

Formally, the governing equation for a confined space can be given as

where U is the total energy, Qvent is the ventilation heat loss rate, and Qwall is the boundary layer heat loss rate.

3 Results and discussions

3.1 The comparison of various fire extinguishing methods

The pulse water mist fire extinguishing system with an alternation of 8-s activation and 4-s deactivation was compared with a continuous water mist fire extinguishing system. The temperature variation curves of the continuous water mist and pulse water mist fire extinguishing process are shown in Fig. 2. When the temperature measured by T1 was significantly higher than that of the other thermocouples during the steady stage, the temperatures measured by T5 to T9 were almost equal to one another. When the continuous water mist system was turned on, the temperature of T1 rapidly declined. When the temperature measured by T1 was stable at 45 °C, the corresponding droplet concentration reached 155 g/m3, so the flame was extinguished. This experimental result can be summarized as follows: During the continuous water mist fire extinguishing process, the temperature variation curve dropped rapidly with the increase in water droplets and then decreased more slowly due to the absence of internal pressure. For example, the temperature of the fire dropped from 594 to 350 °C within 31 s. It then took 148 s for the fire temperature to drop from 350 to 45 °C. Correspondingly, as shown in Fig. 2b, the temperature maintained a high steady state during the pulse water mist fire extinguishing process. After 78 s, the fire was smothered at a high temperature. This indicates that the pulse water mist system performs better than the continuous water mist system. As given in Fig. 2c, the oxygen concentrations during the cycling period were reduced significantly. This is because the suppressed fires recovered and were burned.

3.2 Mechanism of fire extinguishing and activation timing of water mist fire extinguishing system

The different cycles of the pulse water mist fire extinguishing processes are shown in Fig. 3. The fire is extinguished at a high temperature within 8 s of the mist water system’ activation. When the activation time exceeded 10 s, the temperature variation tended to decrease in the temperature. The longer the activation lasts, the more the pulse water mist resembles the continuous water mist. Under such a condition, the temperature of the fire is relatively lower when it is extinguished, which is named “cooling.” The time the pulse water mist takes to extinguish a fire is the shortest when it uses a pulse cycle with an alternation of 8-s activation time and 4-s pause, indicating that this type of pulse water mist is most effective in diluting the oxygen surrounding the fire.

3.3 Influence of pause interval upon fire extinguishing process

In the experiments above, the activation time of the pulse water mist nozzle was set at 8 s, and the pause time varied from 4 to 20 s with an interval value of 4 s. There were five experiments in total, aiming to investigate the influence of pause time upon the effect of the pulse water mist on the fire.

The variation of the fire temperature curves with the pulse water mist fire extinguishing process at different intervals is shown in Fig. 4. As the diagram shows, as pausing time increases, the duration of the pulse water mist fire extinguishing process tends to decrease first and then increase. The most effective pulse water mist fire extinguishing system is the one with an 8-s activation time and an 8-s pause time. When the pause time is relatively shorter, the evaporation of the water mist is limited due to the relatively lower indoor temperature, although lasting spraying can lower the burning rate of the fire. Extremely short pause times make the pulse water mist perform similarly to the continuous water mist: It takes a relatively longer time to extinguish the fire, and the extinguishing mechanism involved is cooling. As pause time increases, the combustion of the fire strengthens, which increases the indoor temperature and facilitates the evaporation of the water mist. As a result, this increased pause time leads to a better fire extinguishing method, as the time to extinguish the fire decreases. When the pause time is 8 s, the temperature of the fire is maintained at a high level, and it is extinguished at 503 °C. This type of process is called “smothering.” An increase in the pause time allowed the intensity of the fire to increase, which prolonged the time required to extinguish the fire. When the pause time is increased to 20 s, the fire continues to burn fiercely with no sign of weakening. (Maximum burning time during experiments is 600 s.) Therefore, 8-s activation and 8-s pause cycle strategy was applied in this study. Figure 5 shows images of the flames at different points during the pauses of the pulse cycles. As the images show, the size of the flame quickly returns to its stable state 8 s after the pause begins.

3.4 Influence of pressure on fire extinguishing process

In order to study the effects of pressure on the pulse water mist fire extinguishing process, different work pressure values were adopted in the experimental. The curve of the temperature fluctuation of the pulse water mist fire extinguishing process at different pressure levels is shown in Fig. 6. With increasing droplet size and nozzle flow, the continuous water mist fire extinguishing process plunges rapidly, whereas the pulse water mist fire extinguishing time shows a concussive trend; that is, the duration of the fire extinguishing process decreases, increases, and then decreases again. This is because the suppressed fires quickly recovered and became lager enough. The temperature of the fire is relatively higher, which shows that the extinguishing mechanism involved is smothering. When the pressure level is at 2.0 MPa or 2.5 MPa, the temperature of the fire is relatively lower.

3.5 Effect of ventilation of fire extinguishing process

The experiments also investigated the influence of ventilation conditions on pulse water mist fire extinguishing system. In the experiments, the sizes of the vents were set to 15 cm × 15 cm, 25 cm × 25 cm, 35 cm × 35 cm, and 45 cm × 45 cm. The average horizontal and perpendicular distance between the vents and the fire was 0.75 m. The temperature variation curves of the pulse water mist fire extinguishing process under different ventilation conditions are shown in Fig. 7. When ventilation is weak, the temperature of the fire and burning zones is relatively higher; as the size of the vents increases, the temperature of the fire and burning zone decreases. This decrease is because relatively smaller vents allow less smoke to leave and less fresh air to enter. The effect on the temperature of the burning zone and the confined space is not significant, and the pulse water mist can still maintain a relatively higher evaporation rate, making effective smothering of the fire extinguishing process possible.

Overall, in a confined space, as the pause time of the system increases and the activation time is fixed, the time taken to extinguishing the first fire decreases and then increases. When the pause time is relatively shorter, the lasting spraying makes the temperature of the confined space relatively lower, which is not conducive to the evaporation of water mist. The mechanism involved with short pause times is cooling. Pausing time that is too long would weaken the suppressing effect on the fire. Once the fire is restored to its flaring state, it takes longer to extinguish. Moreover, compared to the continuous water mist, the pulse water mist produced more water vapor and combustion products, which created a dynamic mixing in a confined space. With support from the dynamic mixing, the steam was redirected back to the fire and diluted the air [19, 20].

3.6 Effect of fuel type on fire extinguishing process

To illustrate the fire extinguishing effects of pulse water mist upon different fuels, petrol, diesel, and methanol were employed in this experiments study. The petrol was 93#-octane petrol with a calorific value of 44,000 J/kg and a flash point under − 30 °C; the diesel was 0# diesel with a calorific value of 40,158 J/kg and a flash point at approximately 55 °C; the methanol was pure methanol (approximately 98%)with a calorific value of 22,703 J/kg and a flashing point around 12 °C. Figure 8 shows the temperatures measured at different heights by thermocouple tree. All the fuels used in the experiments maintain a relatively higher fire temperature after the water mist fire extinguishing system is applied. The evaporation rate of the pulse water mist therefore tends to be higher than that of the continuous water mist fire extinguishing system, which reduces the duration of the fire extinguishing process. Methanol takes a much longer time to be extinguished than either petrol or diesel. This is because the calorific value of methanol is lower, its combustion is relatively more stable, and it creates relatively less smoke, keeping the internal temperature relatively lower. Furthermore, the flash point of methanol is relatively lower, and its water solubility makes it hard for water mist to cool and cover the surface of the fuel. Therefore, the fire extinguishing process tends to be longer. Figure 9 shows the conditions of different fires after the water mist is applied. As can be seen, the methanol fire does not strengthen after the water mist is applied. However, for petrol and diesel, neither of which can be dissolved in water, different extents of strengthening can be observed.

4 Conclusion

In this study, a series of experimental was conducted to investigate the influence of several factors on the effectiveness of the pulse water mist. These factors include the mechanism of the fire extinguishing process (cooling and smothering), the activation and pause time, the working pressure, ventilation conditions, and the different type of fuels. The experimental results are presented and analyzed, and the following conclusions can be drawn:

-

(1)

According to the results of the experiments, the smothering method is better than the cooling method. When optimizing the pulse cycle, the activation of the nozzle should fill the confined space with water mist, and pausing spraying should fully evaporate the floating water mist, maximizing the evaporation rate of the water mist. Under the experimental conditions in this study, the best fire extinguishing effect was achieved with a pulse cycle alternating between an 8-s activation and an 8-s deactivation.

-

(2)

As working pressure increases, the pulse water mist fire extinguishing time shows the trend of decreasing before increasing as pressure grows, and the mechanism involved is cooling instead of smothering.

-

(3)

As the size of the vents is enlarged, the pulse water mist fire extinguishing time increases significantly. The advantage of the pulse water mist system over the continuous water mist system gradually diminishes. When the size of the vents is larger than 35 cm × 35 cm, the pulse fire extinguishing time becomes longer than the continuous water mist fire extinguishing time. However, the pulse water mist system requires less water usage than the continuous water mist.

-

(4)

For fuels that do not dissolve in water, the combustion of the fire would be strengthened during the first stage of applying the water mist, which is attributed to the azeotrope of the water mist and the fuel. For fuels that can be solved in water, however, this phenomenon will not occur.

References

Liu Z, Kim AK (1999) A review of water mist fire suppression systems—fundamental studies. J Fire Prot Eng 10:32–50

Santangelo Paolo E, Tartarini Paolo (2012) Full-scale experiments of fire suppression in high-hazard storages: a temperature-based analysis of water-mist systems. Appl Therm Eng 45–46:99–107

Kim SC, Ryou HS (2003) An experimental and numerical study on fire suppression using a water mist in an enclosure. Build Environ 38:1309–1316

Yang Peizhong, Liu Tao, Qin Xian (2010) Experimental and numerical study on water mist suppression system on room. Build Environ 45:2309–2316

Arvidson Magnus (2014) Large-scale water spray and water mist fire suppression system tests for the protection of RO–RO cargo decks on ships. Fire Technol 50:589–610

Ni X, Chou WK (2011) Performance evaluation of water mist with bromofluoropropene in suppressing gasoline pool fires. Appl Therm Eng 31:3864–3870

Tapscott RE, Sheinson RS, Babushok V, Nyden MR, Gann RG (2001) Alternative fire suppressant chemicals: a research review with recommendations. NIST Technol Note 1443:13

Soonil LM, Yang JC, Cleary TG (2003) On the interaction of a liquid droplet with a pool of hot cooking oil. Fire Saf J 38:651–659

Parra T, Castro F, Mendez C, Villafruela JM, Rodriguez MA (2004) Extinction of premixed methane-air flames by water mist. Fire Saf J 39:581–600

Prasad K, Li C, Kailasanath K, Ndubizu C, Ananth R, Tatem PA (1998) Numerical modeling of water mist suppression of methane-air diffusion flames. Combust Sci Technol 132:325–364

Liu Y, Jiang Z, Wang D, Xiaohui L (2014) Experimental research on the water mist fire suppression performance in an enclosed space by changing the characteristics on nozzles. Exp Therm Fluid Sci 52:174–181

Huang X, Wang XS, Liao GX (2002) Characterization of an effervescent atomization water mist nozzle and its fire suppression tests. P Combust Inst 33:2573–2579

Xiaomeng Z, Guangxuan L, Bo C (2006) Improvement of water mist’s fire-extinguishing efficiency with MC additive. Fire Saf J 41:39–45

Zhou Y, Rongwei B, Gong J, Yan W, Fan C (2018) Experimental investigation on downward flame spread over rigid polyurethane and extruded polystyrene foams. Exp Therm Fluid Sci 92:346–352

Silvani X, Morandini F, Dupuy JL (2012) Effects of slope on fire spread observed through video images and multi-point thermal measurements. Exp Therm Fluid Sci 41:99–111

Liu Z, Andrew KK, Su JZ (1999) Examination of the extinguishment performance of a water mist system using continuous and cycling discharges. Fire Technol 35(4):336–361

Jian L, Changkun C, Bingyin S (2014) Experimental study on gas temperature during fire in a compartment with a sloped roof vent. Fire Technol 50:1483–1498

Varri J (2001) A study of total flooding water mist fire suppression system performance using a transient one-zone computer model. Fire Technol 37:327–342

Honglin X, Xishi W, Yuan L, Pei Z, Haiyong C, Wenxin Q (2017) Experimental investigation of methane/coal dust explosion under influence of obstacles and ultrafine water mist. J Loss Prevent Proc 49:929–937

Liang TS, Liu MJ, Liu ZL, Zhong W, Xiao ZK, Lo SM (2015) A study of the probability distribution of pool fire extinguishing times using water mist. Process Saf Environ 93:240–248

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Mario Eduardo Santos Martins, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lun, P.Y., Zhang, Q. & Li, X.K. Experimental study on the pulse water mist fire suppression system performance in a confined space. J Braz. Soc. Mech. Sci. Eng. 42, 258 (2020). https://doi.org/10.1007/s40430-020-02354-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02354-x