Abstract

Currently, in Vietnam 35 urban WWTPs had been constructed with a total capacity of 850,000 m3/day. Some 40 new WWTPs are in the design or construction phase with a capacity of 1,600,000 m3/day. During operation, a lot of excess sludge must be wasted out of the system. It is well recognized that sludge disposal is one of the most critical issues for WWTPs as the cost of the excess sludge treatment and disposal can account for 50–60% of the operating cost. In Vietnam, sludge discharged from wastewater treatment plants were mostly disposed by the conventional method such as landfill. Therefore, reduction of sludge volume before disposal is very important for sludge transportation and management. In this study, the sludge was disintegrated by alkalis to enhance the sludge biodegradability before adding to the anaerobic digestion. As a result, MLSS reduced from 6600 mg/L down to about 4800 mg/L when alkalis dosage was increased from 1 to 1.8 g/L. Soluble COD was increased from less than 100 mg/L to over 1800 mg/L. The sludge biodegradability enhancement is linearly correlated to COD solubilization. The biogas production of the disintegrated sludge was higher compared to the sludge without the alkali disintegration (358 and 245 mL biogas/g sludge added), representing a 46% increase in the biogas production. The cost of chemical consumption for sludge disintegration was about 0.36 US $/kg TSS. The alkali sludge disintegration combined with anaerobic digestion process could be considered as a potential approach for sludge management of wastewater treatment plants in Vietnam.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Anaerobic digestion

- Biogas production

- Biodegradability

- Disintegration

- Techno-economic

- Waste activated sludge

- Wastewater

1 Introduction

1.1 Waste Activated Sludge

The activated sludge process is the most widely used biological wastewater treatment for both domestic and industrial plants in the world (Grady et al. 1999; Tchobanoglous et al. 2003). The basic function of a wastewater biological treatment process is to convert organics to carbon dioxide, water and bacterial cells. The cells can then be separated from the purified water and disposed of in a concentrated form called excess sludge . It must be realized that the excess sludge generated from the biological treatment process is a secondary solid waste that must be disposed of in a safe and cost-effective way (Liu 2003). The increased excess sludge production is generating a real challenge in the field of environmental engineering technology (Velho et al. 2016). For example, a quasi-exponential growth of excess sludge production in the USA has been reported (Seiple et al. 2017). In the European Union (EU), some 6 million tons of sludge were generated annually in 1998. By the year 2005, within the EU, about 10 million dry tons per year were generated (Christodoulou and Stamatelatou 2016). Vietnam is also facing the challenge of trying to keep pace with the increasing environmental pollution associated with rapid urbanization and industrialization. Over the past 20 years, Vietnam has made considerable effort to develop urban sanitation policies, legislations and regulations and to invest in urban sanitation including wastewater treatment plants (WWTPs) (WorldBank 2013). Most of the domestic wastewater in urban areas is not centrally treated but only treated by household’s septic tank and discharged directly into the environment, such as rivers, lakes and streams. Only a few big cities have centralized wastewater treatment plants (Bao et al. 2013). Currently, in Vietnam 35 urban WWTPs had been constructed in Hanoi, Ho Chi Minh City and Da Nang, Quang Ninh, Vinh, Dong Hoi, Quy Nhon, Nha Trang, Da Lat and Buon Ma Thuot cities with a total capacity of 850,000 m3/day. Some 40 new WWTPs are in the design or construction phase with a capacity of 1,600,000 m3/day (Nga 2017). Industrial parks in Vietnam have developed rapidly since 1986, and there are 289 industrial parks throughout the country (Thuy et al. 2016). Until now there have been about 90% of the industrial parks which have WWTPs that are operated or under constructed (Pham et al. 2016). To date, in Vietnam the wastewater treatment technology has been focused on the use of some form of activated sludge secondary treatment technology, such as conventional activated sludge (CAS) , anaerobic-anoxic-aerobic (A2O), oxidation ditch (OD) and sequencing batch reactor (SBR) technologies (WorldBank 2013, 2014). During operation, a lot of sludge has been discharged. The sludge disposal has been a significant challenge and attracted great attention in both academic and engineering fields. It should be noted that the cost of the excess sludge treatment and disposal can account for 30–40% of the capital cost and about 50–60% of the operating cost of many wastewater treatment facilities (Nowak 2006; Wang et al. 2013). Moreover, the conventional disposal methods such as landfill or ocean dumping may cause secondary pollution problems and are strictly regulated in many countries (Oh et al. 2007). In Europe, sea disposal has not been used since the end of 1998. In 2000, landfill of dewatered sludge became illegal in the Netherlands. Landfilling of sludge has been totally forbidden in Europe since 2015 (Christodoulou and Stamatelatou 2016). However, in Vietnam, sludge discharged from wastewater treatment plants were mostly disposed by the conventional method such as landfill (Uan et al. 2016). Therefore, reduction of sludge volume before disposal is very important for sludge transportation and management. It should be noted that the anaerobic digestion could be used as a common method of sludge stabilization (Appels et al. 2008). Besides, anaerobic digestion is a burgeoning technology and has lately captivated much attention owing to the need for sustainable energy production (Appels et al. 2013; Browne et al. 2014; Kavitha et al. 2015a, b). Therefore biogas produced through anaerobic degradation of sludge in wastewater treatment plants has gained much more attention as it is a renewable energy resource (Appels et al. 2008; Yu et al. 2016).

1.2 Anaerobic Digestion of Waste Activated Sludge

Basically, sludge was thickened before introducing to anaerobic degradation process in order to reduce the sludge volume. Besides, hydraulic retention time is identical to solid retention time, leading to a larger volume of anaerobic digester (Wang et al. 2013). Anaerobic digesters have retention times in the range of 20–30 days, and approximately only half of the organic material fed to anaerobic digestion could be degraded and subsequently transformed to methane (Uma Rani et al. 2014). In the anaerobic degradation systems, Proteobacteria and Bacteroidetes were the two most predominant phyla in the digested sludge samples (Chouari et al. 2005). Proteobacteria are able to degrade a wide range of macromolecules (Chouari et al. 2005; Costa et al. 2017). Bacteroidetes, known to be proteolytic bacteria, are involved in protein degradation and able to ferment amino acids to acetate (Riviere et al. 2009; Świątczak et al. 2017; Yang et al. 2014). Analysis of microbial community structure suggested Bacteroidetes and Firmicutes were the dominant species when ozone pretreatment was applied (Li et al. 2017b). However, conventional anaerobic degradation process needs substantial improvements, especially for the treatment of sludge with low solids content and poor anaerobic biodegradability (Appels et al. 2008; Carrère et al. 2010; Jimenez et al. 2014; Jin et al. 2004). Besides, recently, anaerobic degradation of sludge has been enhanced by using the submerged anaerobic membrane bioreactor (Baêta et al. 2016; Yu et al. 2014, 2016). Co-digestion of wastewater sludge and food waste has been also applied in full scale anaerobic digesters for biosolids management and biogas generation (Amha et al. 2017; Fitamo et al. 2017; Nghiem et al. 2017). The anaerobic degradation process is achieved through several stages: hydrolysis, acidogenesis, and methanogenesis. For sludge degradation, the rate-limiting step is the hydrolysis. It should be noted that the initial phase of anaerobic degradation, hydrolysis, is considered to be the rate-restricting phase (Chen et al. 2013). Hence, sludge disintegration has to be done prior to the anaerobic degradation in order to increase the hydrolysis rate.

1.3 Sludge Disintegration Methods

It should be noted that in anaerobic degradation process, sludge hydrolysis leads to the rupture of cell walls and the release of extracellular polymeric substances, which provides soluble organic substrates, such as dissolved organic matter, for acidogenic microorganisms (Appels et al. 2008). It was observed that pretreatment has to be done prior to anaerobic degradation to enhance the biogas generation. The most attractive way to enhance anaerobic degradation performance is by pretreating the waste to convert insoluble organic polymers into soluble components (monomers) (Nazari et al. 2017). By doing this it is possible to enhance hydrolysis rate, which subsequently increase the biogas generation, as well as reduce the digestion time and the amount of final residuals (Banu and Kavitha 2017). There are various sludge disintegration techniques attracted attentions as promising alternatives to reduce sludge production. Sludge disintegration techniques have been reported to enhance the biodegradability of sludge. Sludge disintegration methods reported in the literature include both physical methods such as ultrasound (Han et al. 2013; Hirooka et al. 2009), ball mill, and homogenizer treatments and chemical methods such as ozone (Muz et al. 2014; Sallanko and Okkonen 2009; Vlyssides and Karlis 2004; Aquino and Pires 2016), acid (Velho et al. 2016) and alkali treatments (Do et al. 2009; Oh et al. 2007). Besides, thermal treatment (Higgins et al. 2017; Kim et al. 2016), cell lysis-cryptic growth (Romero et al. 2013) and enzyme treatment (Ohsaka 2005; Song et al. 2013) have also been tested. Recently, a novel and energy-efficient radio frequency pretreatment system has been developed for anaerobic digestion of municipal sludge (Barrios et al. 2017; Hosseini Koupaie et al. 2017). The aim of all pretreatments is to disintegrate the sludge flocs, disrupting the cell wall, thus releasing and solubilizing intracellular material into the liquid phase. Several researchers have reported affirmative synergistic upshots of the combined pretreatment methods on subsequent anaerobic digestibility (Feki et al. 2015; Kavitha et al. 2015b; Li et al. 2017a, b; Pilli et al. 2015; Şahinkaya et al. 2012; Tyagi and Lo 2012; Wang et al. 2016b; Zhao et al. 2017; Zhen et al. 2014). In this process, the sludge disintegration enhances transformation of particulate organic compounds into more readily biodegradable substances and subsequently accelerates the process of anaerobic methane production (Do et al. 2009; Hirooka et al. 2009; Li et al. 2017c; Liu 2003; Nowak 2006; Øegaard 2004; Oh et al. 2007; Pérez-Elvira et al. 2006; Wang et al. 2016a; Yu et al. 2016). The disintegration processes are based on mechanical, thermal, chemical or thermochemical and biological techniques shown in Table 1.

Basically, mechanical sludge disintegration methods are generally based on the disruption of microbial cell walls by shear stresses. Cells are disrupted when the external pressure exceeds the cell internal pressure (Banu and Kavitha 2017). Mechanical disruption of sludge has gained acceptance due to its various successful industrial scale applications. The high-energy levels were most probably the reason why the application of mechanical disruption methods is still limited. Heat treatment results in the breakdown of the gel structure of the sludge and the release of intracellular bound water. Thermal hydrolysis involves heating of the sludge. Increased temperature had a major positive effect on the yields of soluble COD (Atay and Akbal 2016). Apparently, the origin of the sludge is of primary importance for the final solubilization to be reached with thermal hydrolysis. In chemical and/or thermochemical hydrolysis techniques, an acid or base is added to solubilize the sludge cells (Ødegaard et al. 2002). Whereas for thermal destruction methods high temperatures are required to achieve acceptable results, the thermochemical treatments are often carried out at lower or ambient temperatures. With respect to alkaline pretreatments, variable results have been found. An additional advantage of alkali instead of acid is that it is readily compatible with subsequent biological treatment (Wang et al. 2016b). Biological hydrolysis can be considered as a partial anaerobic sludge digestion. The biochemical sludge disintegration processes are based on enzyme activity that is either produced within the system. Biological hydrolysis is an easy and inexpensive method for the in situ production of a readily degradable carbon source for nutrient removal (Velho et al. 2016). An additional advantage is that less sludge is produced, compared with a system with external carbon addition.

1.4 Brief Economic Assessment of Sludge Disintegration Methods

The strategies for sludge disintegration should be evaluated and chosen for practical application using costs analysis and assessment of environmental impact. Economic savings from the reduced costs of treatment and disposal of biomass improved operational efficiencies and reduced environmental burden with lower disposal requirements (Atay and Akbal 2016). Other economic, operational and environmental costs may be incurred and these must be considered. The environmental impact, e.g. odour problems, should be assessed (Carrère et al. 2010). The performance of some disintegration methods can be compared with each other using the specific energy, which is defined as the amount of energy that stresses a certain amount of sludge. Müller (2001) has carried out a comparison in terms of five aspects (i.e. rate of sludge degradation, degree of sludge degradation, bacteria disinfection, influence on the dewatering results and odour generation). The author found that the mechanical methods contributed an excellent role in sludge degradation rate. However, the chemical methods using ozone could give the highest degree of sludge degradation compared with other methods. Among the summarized methods, the thermal methods could have a strong effect on bacterial disinfection. It seems that the odour generation was not affected by the sludge disintegration methods. It should be due to the sludge disintegration processes that were mostly carried out in the closed reactors.

It should be noted that the mechanical disintegration has been investigated primarily on laboratory to pilot scale. Problems encountered were the heating of the cell suspension because of the high shear stresses the sludge cells are being subjected to. Moreover, mechanical disintegration often appears to require high capital equipment and is energy intensive (Han et al. 2013). On the other hand, thermal and thermochemical treatments require high temperatures and high pressures to achieve acceptable results. Not only is equipment needed to raise the temperature and the pressure, also expensive construction materials are required in order to prevent corrosion problems (Carrère et al. 2010). Furthermore, odour problems can be encountered in thermal hydrolysis techniques. Most authors mention that acidic or basic conditions should be applied in combination with elevated temperatures, thereby creating quite aggressive reaction conditions (Yang et al. 2013). Moreover, raising or lowering the pH requires the addition of chemicals which increase the ionic strength of the sludge (Fang et al. 2014). If the hydrolysate is used in biological applications, e.g. anaerobic digestion or nutrient removal, subsequent neutralization is required, which again implies the addition of chemicals. In addition, due to high costs caused from ozone production, it is important to decrease the amounts of ozone required for sludge reduction.

It has been reported that one of the most significant inputs, environmentally and financially, is energy. While the cost of treatment may be disposal driven, in energy terms, energy utilized should hopefully match the energy produced by increases in biogas production. The energy input depends heavily on the method and may be a function of sludge composition, operating and ambient conditions and equipment used, among others (Carrère et al. 2010). A comparison of several sludge pretreatments such as stirred ball milling, ozonation, lysate centrifugation and sonication could be classified according to the aspects below (Table 2).

The evaluation of energy balance and cost assessment should be used in the conventional data such as industrial power price of 0.23 USD/kWh, NaOH price of 345.6 USD/ton and sludge treatment and disposal cost of 441.2 USD/ton TS. Meanwhile, energy stored in the increased methane volume as a result of pretreatment reached 378.15 kWh and 751.08 kWh, respectively (Kavitha et al. 2016). An energy balance and cost assessment of the thermo-chemo-sonic disintegrated sludges were performed by Kavitha et al. (2015b). In the study, the three alkalis (NaOH, KOH and Ca(OH)2) were used in the thermo-chemo-sonic disintegrated sludge process. The energy balance and cost evaluation were based on the energy content of the biogas produced from both samples. The energy utilized for the mechanical stirring and pumping of the sludge was taken into account. At the same time, the energy content of the biogas for all three samples was calculated to be 1213 kWh, 1043 kWh and 927 kWh, respectively. Moreover, to evaluate the economic viability of the disintegration process, the present study took into account an estimation of the operational cost (including consumable chemicals) and the decreased amount of the solids to be disposed. It was noted that a positive net profit was achieved in all three samples. The net profit of all three sludges (NaOH, KOH and Ca(OH)2 was calculated to be 42.6 USD, 20.6 USD and 4 USD, respectively. The presently attained net profit was found to be comparatively higher than those obtained in other studies in which Houtmeyers et al. (2014) achieved 2.48 USD and 3.02 USD as net costs for ultrasonic and microwave pretreatment. It should be noted that in low-temperature thermal treatment, it would take from several hours to a few days to achieve the maximal disintegration effect (Şahinkaya et al. 2012). This strongly implies that it was possible to achieve 20% solubilization only in this combined novel process with lesser energy consumption. Table 3 shows a cost comparison of sludge of some combined sludge disintegration methods.

Carrère et al. (2010) have analysed the energy consumption for the various sludge disintegration methods, including non-mesophilic, non-thermophilic, biological, thermal hydrolysis, sonication, ball milling and high pressure. The energy consumption in those methods was mainly electrical and thermal. Electrical requirements are mainly feed and mixing and are approximately 0.1–0.2 kWh/m3 days. The analysis also assumes a hydraulic retention time of 20 days for mesophilic or 15 days for thermophilic. It should be noted that the heating requirements are thermal capacity plus about 10% losses in mesophilic or 20% in thermophilic (Greenfield and Batstone 2005). The authors found that the electrical consumption was varied from 0.03 to 0.04 kWh/kg VS (volatile solids) for the non-mesophilic, non-thermophilic, biological and thermal hydrolysis methods. However, it was much higher in case of sonication (0.37 kWh/kg VS), ball milling (1.04 kWh/kg VS) and high pressure (0.33 kWh/kg VS). Basically, the thermal consumed in most of the methods was in the range of 0.5–1.0 kWh/kg VS, except thermal hydrolysis (2.0 kWh/kg VS) (Carrère et al. 2010).

1.5 General Objectives and Scopes of This Work

It should be noted that among the sludge disintegration methods, chemical hydrolysis using alkaline was the most efficient for inducing cell lysis (Do et al. 2009; Banu and Kavitha 2017). The chemical-combined activated sludge processes would be more efficient for sludge disintegration. The chemical assisted sludge disintegration processes have advantages of easy control, stable performance and high operation flexibility. The minimum effective sludge disintegration index for anaerobic digestion was reported to be 25% (Gayathri et al. 2015; Zhang et al. 2008). However, achieving solubilization in excess of 18% by thermochemical pretreatment was not cost effective (Jang and Ahn 2013) but results in the loss of organics (Chiang et al. 2012). Sonication, a cavitational process, was used by legions of researchers to achieve high degree of solubilization (40–50%). However, the practical applicability of sonic pretreatment was constrained because of its high energy cost (Şahinkaya et al. 2012; Zhang et al. 2008). Thus, in order to overcome the high energy requirement, the sonic pretreatment can be combined with other pretreatments to achieve the desirable solubilization with less energy consumption. Besides, the alkaline treatment is known to be relatively cheap resulting in a significant decrease of the total treatment cost. Therefore, in this study, sludge disintegration using alkalis such as sodium hydroxide (NaOH) and calcium hydroxide (Ca(OH)2) was applied to sludge taken from Yen So and Kim Lien wastewater treatment plants in Hanoi (Vietnam). In particular, the study aimed to examine (i) the sludge solubilization and sludge dewatering ability during treatment, (ii) the change of the biodegradable matter and the particle size distribution and (iii) a brief economic evaluation of the alkali sludge disintegration and (iv) to test the biodegradability of sludge after alkali digestion. The digested sludge is subsequently treated anaerobically to generate biogas, and then the biogas can give long-term economic benefits.

2 Materials and Methods

2.1 Sludge Sources and Collection

In this study, waste activated sludge was collected from Yen So and Kim Lien wastewater treatment plants in Hanoi (Vietnam) (Fig. 1). These sludge samples were taken from oxic tank, SBR tank and sludge storage tank. The Yen So wastewater treatment plant works on the principle of SBR technology with a design capacity of 200.000 m3/day, whereas the Kim Lien wastewater treatment plants work on A2O technology with the capacity of 3500 m3/day. The sludge samples were collected weekly and stored in refrigerator (4 °C) until use within 24 h. General characteristics of sludge samples are presented in Table 4.

2.2 Experimental Setup and Procedure

Sludge disintegration experiments will be carried out at laboratory temperature using a jar apparatus with six paddle stirrers (Model: JLT6, VELP Scientifica, Europe). Alkalis were added under stirring. Rapid mix took place for 1 min at a speed of 200 rpm, followed by slow mix for 3 h at 30 rpm. During digestion, NaOH and Ca(OH)2 were added to the reactor at various dosages, ranging from 0.2 to 2 g/L (Fig. 2).

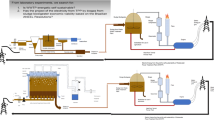

The anaerobic digestion experiments were conducted in a lab-scale anaerobic digestion system (Figs. 3 and 4).

Setup of a simplified test for measuring the biogas production. Notes: 1 Anaerobic reactor (V = 5 L), 2 Heating in water batch, 3 Mixer, 4 Feeding pipe, 5 Valve, 6 Motor, 7 Thermostart, 8 Pressure pipe, 9 Temperature control, 10 Biogas collection pipe, 11 Water addition pipe, 12 Gas volume bottle, 13 Mixing pump in water batch, 14 Temperature sensor, 15 Water batch cover, 16 Water bottle

The anaerobic reactor is a round-bottomed reactor with a working volume of 5 L. The pretreated sludge was inoculated with an active methanogenic bacterial population for the quick startup of the reactor. Sludge from an anaerobic wastewater treatment using a covered lagoon was selected as the inoculum. A slow mixer was used to keep a completely mixed anaerobic digester. Biogas generation was calculated by the liquid displacement method, in which the difference in the water level in a cylinder linked to the reactors was measured. The displaced liquid is therefore considered to have the same volume as the produced biogas. The produced gas was collected in standardized glass cylinders filled with acidified deionized water to evade losses of CO2 due to the formation of carbonates.

2.3 Analytical Methods

Characteristics of sludge (including MLSS, MLVSS, sludge dewatering), and other parameters of the solution such as TP, soluble TP, total COD, soluble COD, BOD, TN, soluble TN, and NO3 - were measured and analysed in accordance with the Standard Methods described in APHA (2012). Sludge disintegration efficiency was calculated as the ratio of the soluble COD (SCOD, mg/L) increase by the disintegration process to the total COD (TCOD, mg/L) of the sludge before disintegration.

\( \alpha =\frac{\mathrm{SCOD}-{\mathrm{SCOD}}_{\mathrm{o}}}{\mathrm{TCOD}-{\mathrm{SCOD}}_{\mathrm{o}}} \) in which SCODo (mg/L) is the soluble COD of the sludge before disintegration.

The biogas composition biogas was taken during experimental tests. The compositions of these samples (CH4, CO2, H2S, O2) were determined using an Optima 7 Biogas Analyzer (MRU Instruments, Inc., Germany).

3 Results and Discussion

3.1 Sludge Source Variation

Sludge used in this study were collected from the Yen So and Kim Lien wastewater treatment plants in Hanoi (Vietnam). It should be noted that the SBR technology with a design capacity of 200,000 m3/day was used in the Yen So wastewater treatment plant, but the Kim Lien wastewater treatment plant used A2O technology with a design capacity of 3500 m3/day. The variation of sludge sample taken from sludge storage tank was presented in Fig. 5. As seen from the figure, the sludge concentration was very different from each other. In Yen So wastewater treatment plant, it was in a range of 4000 to about 10,000 mg/L. In case of Kim Lien wastewater treatment plants, it was around 2500 to over 6000 mg/L.

3.2 Sludge Solubilization

Alkalis added to a cell suspension react with the cell walls in several ways, including the saponification of lipids in the cell walls, which leads to solubilization of the membrane. Disruption of microbial cells then leads to leakage of intracellular material out of the cell. In this study, the collected sludge was tested with different NaOH and Ca(OH)2 dosages. Each 1 L of sludge was added in six glass beakers and put in the jar test system. The first beaker was without added by any alkalis. The mining beakers were added with different NaOH and Ca(OH)2 dosages, from 0.2 to 2 g/L. During digestion, soluble COD will be released out of the sludge. Figure 6 shows the variation of soluble COD during digestion.

It could be seen from Fig. 6 that the soluble COD was increased with the increase of NaOH. However, it was increased very low during adding Ca(OH)2. When alkali agents were added, COD solubilization increased through various reactions such as saponification of uronic acids and acetyl esters, reactions occurring with free carboxylic groups and neutralization of various acids formed from the degradation of particular materials (Liu 2003). During digestion process using Ca(OH)2, calcium ion could bind to the sludge surface through the exopolysaccharide polymer as well as assist in the bioflocculation of the sludge, resulted in reduction of the sludge solubilization (Bruus et al. 1992).

3.3 Sludge Mass Reduction

The reduction of MLSS during digestion was presented in Fig. 7. It was reduced from 6600 mg/L down to about 4800 mg/L when alkali dosage was increased from 1.0 to 1.8 g/L. Besides MLSS reduction, the soluble COD was also increased from less than 100 mg/L to over 1800 mg/L. Alkali treatment is a harsh method. At extremely high pH values of medium, the cell loses its viability, and it cannot maintain an appropriate turgor pressure and disrupts. Alkalis added to the cell suspension react with the cell walls in several ways, including the saponification of lipids in the cell walls, which leads to solubilization of membrane. The high alkali concentrations cause much degradation. Disruption of sludge cells leads to leakage of intracellular material out of the cell (Banu and Kavitha 2017). As a result, the sludge mass was decreased, and the COD was increased. Besides, a relationship between MLSS, MLVSS reduction and soluble COD increasing during digestion for different sludge samples was also measured and presented in Fig. 8. Depending on MLSS concentration, sludge reduction was varied from 10% to 18%.

3.4 Enhancement of Sludge Dewatering

Sludge dewatering ability was tested by measurement of time to filter. At the same volume of digested sample, the filter time between NaOH and Ca(OH)2 was much different (Fig. 9). The filter time of NaOH digested sample was much higher than Ca(OH)2 digested sample, showing that Ca(OH)2 could help improvement of sludge dewatering ability. One reason for the difficulty in activated sludge dewatering is the presence of extracellular polymer (ECP). ECP is present in varying quantities in sewage sludge, occurring as a highly hydrated capsule surrounding the bacterial cell wall and loose in solution as slime polymers (Houghton et al. 2001). One of the main influences on sludge dewaterability is the particle size distribution (Eriksson and Alm 1991). Flocculation changes the particle size distribution of a sludge, binding small particles together, thereby influencing the sludge dewatering characteristics. ECP can therefore be expected to have an influence on sludge dewaterability through the high level of hydration of the polymer surrounding the bacterial cell and its role in flocculation. Bruus et al. (1992) suggested that cations aid in flocculation by bridging negative sites on ECP which promotes an increase in the floc size, floc density and floc resistance to shear. Divalent cations act as a bridge between negatively charged sites on ECP resulted in improvements of sludge settling and dewatering.

Figures 10 and 11 show the settled volumes and SVI changes of various sludge samples before and after digestion. It seems that after digestion, SVI was improved slightly. The alkali disintegration alters sludge floc properties (such as size, water content, etc.); it also modifies its settling and filtering properties. In particular, the alkali disintegration integrated in the wastewater handling units increases the settling rate and could reduce SVI. The SVI determines the settling capability of sludge. The value of SVI for alkali-disintegrated sludge was found to be in the range of 46–113 mL/g, which was comparatively higher than the others. It is known from the literature that the usage of Na+ ions deteriorates the dewatering property of sludge, and it thereby demands the addition of sludge-conditioning aids (Banu et al. 2012).

3.5 Biodegradability of Solubilized COD After Alkali Digestion

The biodegradability of solubilized COD after alkali digestion was measured by BOD (Table 5). The results observed that the biodegradability of the solubilized COD by Ca(OH)2 was low, around 30–35%. This unexpected phenomenon is probably due to the release of part of the sludge material by desorption or floc destructuration while no increase in its intrinsic biodegradability occurs. In case of NaOH digestion, the sludge biodegradability enhancement is linearly correlated to COD solubilization up to 80–83%. Due to its enhanced biodegradability, the supernatant of NaOH sludge digestion would be used as a carbon source to support post-denitrification in the biological nitrogen removal. During sludge disintegration, TN, NO3 −, NH4 +, TP and PO4 3− releases were also monitored. The results were presented in Table 6. It should be noted that the structure of sludge flocs was significantly dispersed after alkali digestion. The average floc size decreased in the range of about 1–50 μm (Uan et al. 2017). Sludge flocculation capacity decreased with microorganism death.

3.6 Anaerobic Digestion of Digested Sludge

In anaerobic digestion process , the organic residues will be transformed by bacteria into the biogas through four sequential phases, i.e. hydrolysis, acidogenesis, acetogenesis and methanogenesis in anaerobic digestion process. The progression of anaerobic digestion has the prospective of transforming recyclable organics into biogas. On the other hand, in lack of a pretreatment, the biogas production potential of anaerobic digestion is inadequate due to the existence of refractory microbial cell walls and other organic materials present in the sludge. As a result, to enhance the biogas augmentation, pretreatment is believed to be the plausible option. Sludge disintegration was extended to boost bioenergy generation by hastening the hydrolysis pace of anaerobic digestion. To increase the biogas production, assorted pretreatment practices are applied. A comparatively current scientific progression which would probably be capable of formulating anaerobic digestion further was the expansion plus concern of preprocessing of wastes prior to anaerobic digestion to hasten the sludge degradability. Pretreatment enhances liquefaction and its rate, which consequently enhance biogas production. All pretreatments bring about the breakdown of sludge biomass, thus solubilizing and discharging substance present inside the aqueous phase and converting obstinate organic substances into recyclable nature consequently creating substances easily accessible to microbes. These entire pretreatments are exposed to enhance the biogas generation in subsequent anaerobic digestion process. Figure 12 presents the digestion curves obtained in the anaerobic digestion tests . It can be observed that the biogas production of the sludge without the alkali disintegration was very slow. As expected, the biogas production of the disintegrated sludge was higher compared to the sludge without the alkali disintegration (358 and 245 mL biogas/g sludge added), representing a 46% increase in the biogas production in case of NaOH disintegration. However, it was only about 10% increase in the biogas production in case of Ca(OH)2 disintegration. The fractioning of the disintegrated sludge showed that the contribution of the enhancement in biogas production and kinetics after the hydrolysis is due to the liquid fraction, remaining the solid fraction difficult to degrade.

The composition of biogas production during anaerobic digestion of the alkaline-disintegrated sludge was sometimes measured by using an Optima 7 Biogas Analyzer (MRU Instruments, Inc., Germany). The results show that the CH4 composition is high at about 73%. It was tried to burn very well in the lab (Figs. 13 and 14). However, it was clearly that the H2S concentration in the biogas is too high at about 1989 ppm. It means the biogas must be purified before using such as for burning or for electricity generation.

3.7 Economic Analysis for Sludge Akali Disintegration

As discussed above, the sludge can be disintegrated by mechanical, physical, chemical or biological processes. The main purpose of the disintegration processes is to improve the anaerobic digestion of the sludge. Therefore, a high degree of disintegration is necessary in order to realize a noticeable acceleration and enhancement of the disintegrated sludge degradation. However, it is not easy to recommend one or the other method to be applied, because of the lack of experience at full scale. A comparison between the capital costs and the operational and maintenance (O&M) costs among treatment processes is needed. Rough cost estimates are between 70 and 150 US$/t TS for capital and O&M costs (Müller 2001). It has been reported that the O&M costs vary considerably among sludge disintegration methods. The O&M costs for sludge disintegration by biological methods were lower compared with others. However, it should be noted that the biological methods required long retention time for the disintegration process, resulted in bigger volume of reactor. The high energy levels were most probably the reason why the application of mechanical disruption methods is still limited. Thermal methods also required high energy for heating. Besides, the thermal treatment time had less impact on sludge solubilization in comparison with temperature (Müller 2001). However, if temperatures are not high enough, several hours to days of heating was required (Zhen et al. 2017). The chemical methods required the chemical costs. During treatment, the corrosion issues should be considered. It is important that the sludge cells can be dissolved by acids of alkalis at low or ambient temperatures. Chemical methods could be realized at low costs if the conditions are appropriate (Uan et al. 2017).

In this study, a preliminary economic analysis was evaluated. In particular, the operating costs for alkali digestion were calculated based on the chemical consumption and TSS concentration or sludge volume. Besides, the costs of dewatering, transportation and landfill should be taken into account. In case of NaOH used for sludge digestion at 1.2 g/L (it means 0.12 kg of NaOH was used for 1 kg of TSS, and the cost of NaOH (99%) of about 0.3 US $/kg), the chemical consumption was estimated about 0.36 US $/kg TSS (about 8,100 VND/kg TSS). In Vietnam, the cost for transportation and treatment of sludge was varied from 0.20 to 0.44 US $/kg TSS (about 4500 to 10,000 VND/kg TSS), depending on the sludge characteristics and services. If the digested sludge is subsequently treated anaerobically to generate biogas, then it can be biogas can give long-term economic benefits.

It should be noted that 1 m3 of biogas could produce hourly 2.14 kWh of electricity and 2.47 kWh of heat energy (Akbulut 2012). Therefore, an economic comparison between chemical consumed and benefits obtained from the anaerobic digestion for sludge without alkalis disintegration and the disintegrated sludge was presented in Table 7.

As seen in Table 7, the alkali disintegration of sludge shows a lot of benefits. Among the sludge disintegration processes, the chemical methods have advantages of easy control, stable performance and high operation flexibility. However, it is expected that the increased operation and capital costs due to chemical addition can be compensated from saving the cost of excess sludge posttreatment. In this sense, the chemical methods for sludge disintegration would be attractive and have great industrial potentials.

4 Conclusions

Sludge disintegration is used as a pretreatment step to enhance the sludge biodegradability before adding to the anaerobic digestion. The results obtained from the present study show that the sludge volume and mass were reduced significantly during digestion. MLSS reduced from 6600 mg/L down to about 4800 mg/L when alkali dosage was increased from 1.0 to 1.8 g/L. Soluble COD was increased from less than 100 mg/L to over 1800 mg/L. NaOH was an efficient reagent for inducing cell lysis and causes sludge solubilization. The sludge biodegradability enhancement is linearly correlated to COD solubilization. Ca(OH)2 used for the sludge digestion could improve the sludge dewatering, but the sludge solubilization by Ca(OH)2 was low. More importantly, sludge dewatering ability was increased much after sludge digestion showing that sludge management was benefited by sludge digestion. The anaerobic digestion tests show that the biogas production of the sludge without the alkali disintegration was very slow. The biogas production of the disintegrated sludge was higher compared to the sludge without the alkali disintegration (358 and 245 mL biogas/g sludge added), representing a 46% increase in the biogas production in case of NaOH disintegration. However, it was only about 10% increase in the biogas production in case of Ca(OH)2 disintegration. The cost of chemical consumption for sludge disintegration was about 0.36 US $/kg TSS (about 8100 VND/kg TSS). Based on the preliminary economic assessment, if the sludge disintegration was carried out with a NaOH dose of 1.2 g/Lg, the increase in the biogas of 46% and 27% of sludge reduction could offset the cost of chemical. Therefore, the alkali sludge disintegration would be considered as a potential method for sludge management of wastewater treatment plants in Vietnam. Further works should be carried out to overcome including the reduction of chemicals and the prevention of corrosion issues.

References

Akbulut A (2012) Techno-economic analysis of electricity and heat generation from farm-scale biogas plant: Çiçekdağı case study. Energy 44:381–390. https://doi.org/10.1016/j.energy.2012.06.017

Amha YM, Sinha P, Lagman J, Gregori M, Smith AL (2017) Elucidating microbial community adaptation to anaerobic co-digestion of fats, oils, and grease and food waste. Water Res 123:277–289. https://doi.org/10.1016/j.watres.2017.06.065

APHA (2012) Standard methods for the examination of water and wastewater, 22nd edn. American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC

Appels L, Baeyens J, Degrève J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34:755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Appels L, Houtmeyers S, Degrève J, Van Impe J, Dewil R (2013) Influence of microwave pre-treatment on sludge solubilization and pilot scale semi-continuous anaerobic digestion. Bioresour Technol 128:598–603. https://doi.org/10.1016/j.biortech.2012.11.007

Aquino S, Pires EC (2016) Assessment of ozone as pretreatment to improve anaerobic digestion of vinasse. Braz J Chem Eng 33:279–285

Atay Ş, Akbal F (2016) Classification and effects of sludge disintegration technologies integrated into sludge handling units: an overview. Clean (Weinh) 44:1198–1213. https://doi.org/10.1002/clen.201400084

Baêta BEL, Lima DRS, Silva SQ, Aquino SF (2016) Influence of the applied organic load (OLR) on textile wastewater treatment using submerged anaerobic membrane bioreactors (SAMBR) in the presence of redox mediator and powered activated carbon (PAC). Braz J Chem Eng 33:817–825

Banu JR, Kavitha S (2017) Various sludge pretreatments: their impact on biogas generation. In: Singh L, Kalia VC (eds) Waste biomass management – a holistic approach. Springer International Publishing, Cham, pp 39–71. https://doi.org/10.1007/978-3-319-49595-8_3

Banu JR, Khac UD, Kumar SA, Ick-Tae Y, Kaliappan S (2012) A novel method of sludge pretreatment using the combination of alkalis. J Environ Biol 33:249–253

Bao PN, Kuyama T, Kataoka Y (2013) Urban domestic wastewater management in Vietnam – challenges and opportunities. WEPA Policy Brief 5:1–10

Barrios JA, Duran U, Cano A, Cisneros-Ortiz M, Hernández S (2017) Sludge electrooxidation as pre-treatment for anaerobic digestion. Water Sci Technol 75:775–781. https://doi.org/10.2166/wst.2016.555

Browne JD, Allen E, Murphy JD (2014) Assessing the variability in biomethane production from the organic fraction of municipal solid waste in batch and continuous operation. Appl Energy 128:307–314. https://doi.org/10.1016/j.apenergy.2014.04.097

Bruus JH, Nielsen PH, Keiding K (1992) On the stability of activated sludge flocs with implications to dewatering. Water Res 26:1597–1604. https://doi.org/10.1016/0043-1354(92)90159-2

Carrère H, Dumas C, Battimelli A, Batstone DJ, Delgenès JP, Steyer JP, Ferrer I (2010) Pretreatment methods to improve sludge anaerobic degradability: a review. J Hazard Mater 183:1–15. https://doi.org/10.1016/j.jhazmat.2010.06.129

Chen Y, Liu K, Su Y, Zheng X, Wang Q (2013) Continuous bioproduction of short-chain fatty acids from sludge enhanced by the combined use of surfactant and alkaline pH. Bioresour Technol 140:97–102. https://doi.org/10.1016/j.biortech.2013.04.075

Chiang K-Y, Chien K-L, Lu C-H (2012) Characterization and comparison of biomass produced from various sources: suggestions for selection of pretreatment technologies in biomass-to-energy. Appl Energy 100:164–171. https://doi.org/10.1016/j.apenergy.2012.06.063

Chouari R, Le Paslier D, Daegelen P, Ginestet P, Weissenbach J, Sghir A (2005) Novel predominant archaeal and bacterial groups revealed by molecular analysis of an anaerobic sludge digester. Environ Microbiol 7:1104–1115. https://doi.org/10.1111/j.1462-2920.2005.00795.x

Christodoulou A, Stamatelatou K (2016) Overview of legislation on sewage sludge management in developed countries worldwide. Water Sci Technol 73:453–462. https://doi.org/10.2166/wst.2015.521

Costa A, Gusmara C, Gardoni D, Zaninelli M, Tambone F, Sala V, Guarino M (2017) The effect of anaerobic digestion and storage on indicator microorganisms in swine and dairy manure. Environ Sci Pollut Res 24:24135. https://doi.org/10.1007/s11356-017-0011-5

Do K-U, Banu JR, Chung I-J, Yeom I-T (2009) Effect of thermochemical sludge pretreatment on sludge reduction and on performances of anoxic-aerobic membrane bioreactor treating low strength domestic wastewater. J Chem Technol Biotechnol 84:1350–1355. https://doi.org/10.1002/jctb.2189

Eriksson L, Alm B (1991) Study of flocculation mechanisms by observing effects of a complexing agent on activated sludge properties. Water Sci Technol 24:21–28

Fang W, Zhang P, Zhang G, Jin S, Li D, Zhang M, Xu X (2014) Effect of alkaline addition on anaerobic sludge digestion with combined pretreatment of alkaline and high pressure homogenization. Bioresour Technol 168:167–172. https://doi.org/10.1016/j.biortech.2014.03.050

Feki E, Khoufi S, Loukil S, Sayadi S (2015) Improvement of anaerobic digestion of waste-activated sludge by using H2O2 oxidation, electrolysis, electro-oxidation and thermo-alkaline pretreatments. Environ Sci Pollut Res 22:14717–14726. https://doi.org/10.1007/s11356-015-4677-2

Fitamo T, Treu L, Boldrin A, Sartori C, Angelidaki I, Scheutz C (2017) Microbial population dynamics in urban organic waste anaerobic co-digestion with mixed sludge during a change in feedstock composition and different hydraulic retention times. Water Res 118:261–271. https://doi.org/10.1016/j.watres.2017.04.012

Gayathri T, Kavitha S, Adish Kumar S, Kaliappan S, Yeom IT, Rajesh Banu J (2015) Effect of citric acid induced deflocculation on the ultrasonic pretreatment efficiency of dairy waste activated sludge. Ultrason Sonochem 22:333–340. https://doi.org/10.1016/j.ultsonch.2014.07.017

Grady CPL, Daigger GT, Lim HC (1999) Biological wastewater treatment, 2nd edn. Marcel Dekker, New York

Greenfield PF, Batstone DJ (2005) Anaerobic digestion: impact of future greenhouse gases mitigation policies on methane generation and usage. Water Sci Technol 52:39–47

Han X, Wang Z, Zhu C, Wu Z (2013) Effect of ultrasonic power density on extracting loosely bound and tightly bound extracellular polymeric substances. Desalination 329:35–40. https://doi.org/10.1016/j.desal.2013.09.002

Higgins MJ et al (2017) Pretreatment of a primary and secondary sludge blend at different thermal hydrolysis temperatures: impacts on anaerobic digestion, dewatering and filtrate characteristics. Water Res 122:557–569. https://doi.org/10.1016/j.watres.2017.06.016

Hirooka K, Asano R, Yokoyama A, Okazaki M, Sakamoto A, Nakai Y (2009) Reduction in excess sludge production in a dairy wastewater treatment plant via nozzle-cavitation treatment: case study of an on-farm wastewater treatment plant. Bioresour Technol 100:3161–3166. https://doi.org/10.1016/j.biortech.2009.01.011

Hosseini Koupaie E, Johnson T, Eskicioglu C (2017) Advanced anaerobic digestion of municipal sludge using a novel and energy-efficient radio frequency pretreatment system. Water Res 118:70–81. https://doi.org/10.1016/j.watres.2017.04.017

Houghton JJ, Quarmby J, Stephenson T (2001) Municipal wastewater sludge dewaterability and the presence of microbial extracellular polymer. Water Sci Technol 44:373–379

Houtmeyers S, Degrève J, Willems K, Dewil R, Appels L (2014) Comparing the influence of low power ultrasonic and microwave pre-treatments on the solubilisation and semi-continuous anaerobic digestion of waste activated sludge. Bioresour Technol 171:44–49. https://doi.org/10.1016/j.biortech.2014.08.029

Jang J-H, Ahn J-H (2013) Effect of microwave pretreatment in presence of NaOH on mesophilic anaerobic digestion of thickened waste activated sludge. Bioresour Technol 131:437–442. https://doi.org/10.1016/j.biortech.2012.09.057

Jimenez J, Gonidec E, Cacho Rivero JA, Latrille E, Vedrenne F, Steyer J-P (2014) Prediction of anaerobic biodegradability and bioaccessibility of municipal sludge by coupling sequential extractions with fluorescence spectroscopy: towards ADM1 variables characterization. Water Res 50:359–372. https://doi.org/10.1016/j.watres.2013.10.048

Jin B, Wilén B-M, Lant P (2004) Impacts of morphological, physical and chemical properties of sludge flocs on dewaterability of activated sludge. Chem Eng J 98:115–126. https://doi.org/10.1016/j.cej.2003.05.002

Kavitha S, Saranya T, Kaliappan S, Adish Kumar S, Yeom IT, Rajesh Banu J (2015a) Accelerating the sludge disintegration potential of a novel bacterial strain Planococcus jake 01 by CaCl2 induced deflocculation. Bioresour Technol 175:396–405. https://doi.org/10.1016/j.biortech.2014.10.122

Kavitha S, Yukesh Kannah R, Yeom IT, Do K-U, Banu JR (2015b) Combined thermo-chemo-sonic disintegration of waste activated sludge for biogas production. Bioresour Technol 197:383–392. https://doi.org/10.1016/j.biortech.2015.08.131

Kavitha S, Rajesh Banu J, Vinoth Kumar J, Rajkumar M (2016) Improving the biogas production performance of municipal waste activated sludge via disperser induced microwave disintegration. Bioresour Technol 217:21–27. https://doi.org/10.1016/j.biortech.2016.02.034

Kim MS, Lee K-M, Kim H-E, Lee H-J, Lee C, Lee C (2016) Disintegration of waste activated sludge by thermally-activated persulfates for enhanced dewaterability. Environ Sci Technol 50:7106–7115. https://doi.org/10.1021/acs.est.6b00019

Li C, Wang X, Zhang G, Yu G, Lin J, Wang Y (2017a) Hydrothermal and alkaline hydrothermal pretreatments plus anaerobic digestion of sewage sludge for dewatering and biogas production: bench-scale research and pilot-scale verification. Water Res 117:49–57. https://doi.org/10.1016/j.watres.2017.03.047

Li X, Xu X, Huang S, Zhou Y, Jia H (2017b) An efficient method to improve the production of methane from anaerobic digestion of waste activated sludge. Water Sci Technol 76:2075. https://doi.org/10.2166/wst.2017.313

Li Y, Hu Y, Lan W, Yan J, Chen Y, Xu M (2017c) Investigation of the accumulation of ash, heavy metals, and polycyclic aromatic hydrocarbons to assess the stability of lysis–cryptic growth sludge reduction in sequencing batch reactor. Environ Sci Pollut Res 24:24147. https://doi.org/10.1007/s11356-017-0042-y

Liu Y (2003) Chemically reduced excess sludge production in the activated sludge process. Chemosphere 50:1–7. https://doi.org/10.1016/S0045-6535(02)00551-9

Müller JA (2001) Prospects and problems of sludge pre-treatment processes. Water Sci Technol 41:121–128

Müller JA, Winter A, Strünkmann G (2004) Investigation and assessment of sludge pre-treatment processes. Water Sci Technol 49:97–104

Muz M, Ak MS, Komesli OT, Gökçay CF (2014) Intermittent ozone application in aerobic sludge digestion. Ozone Sci Eng 36:57–64. https://doi.org/10.1080/01919512.2013.824808

Nazari L et al (2017) Low-temperature thermal pre-treatment of municipal wastewater sludge: process optimization and effects on solubilization and anaerobic degradation. Water Res 113:111–123. https://doi.org/10.1016/j.watres.2016.11.055

Nga TTV (2017) Problems and challenges in nitrogen and phosphorus removal in municipal wastewater in Vietnam in Conference proceeding of “Removal of nitrogen and phosphorus in municipal wastewater in Vietnam: challenges and opportunities”. Hanoi, Vietnam, pp 1–13

Nghiem LD, Koch K, Bolzonella D, Drewes JE (2017) Full scale co-digestion of wastewater sludge and food waste: bottlenecks and possibilities. Renew Sust Energ Rev 72:354–362. https://doi.org/10.1016/j.rser.2017.01.062

Nowak O (2006) Optimizing the use of sludge treatment facilities at municipal WWTPs. J Environ Sci Health A 41:1807–1817. https://doi.org/10.1080/10934520600778986

Ødegaard H, Paulsrud B, Karlsson I (2002) Wastewater sludge as a resource: sludge disposal strategies and corresponding treatment technologies aimed at sustainable handling of wastewater sludge. Water Sci Technol 46:295–303

Øegaard H (2004) Sludge minimization technologies-an overview. Water Sci Technol 49:31–40

Oh Y-K, Lee K-R, Ko K-B, Yeom I-T (2007) Effects of chemical sludge disintegration on the performances of wastewater treatment by membrane bioreactor. Water Res 41:2665–2671. https://doi.org/10.1016/j.watres.2007.02.028

Ohsaka F (2005) Activity to reduce sludge generated from septic tanks to zero using bacterial method FUJITSU. Sci Technol J 41:259–268

Park ND, Helle SS, Thring RW (2012) Combined alkaline and ultrasound pre-treatment of thickened pulp mill waste activated sludge for improved anaerobic digestion. Biomass Bioenergy 46:750–756. https://doi.org/10.1016/j.biombioe.2012.05.014

Pérez-Elvira SI, Nieto Diez P, Fdz-Polanco F (2006) Sludge minimisation technologies. Rev Environ Sci Biotechnol 5:375–398. https://doi.org/10.1007/s11157-005-5728-9

Pham TT, Mai TD, Pham TD, Hoang MT, Nguyen MK, Pham TT (2016) Industrial water mass balance as a tool for water management in industrial parks. Water Resour Ind 13:14–21. https://doi.org/10.1016/j.wri.2016.04.001

Pilli S, Yan S, Tyagi RD, Surampalli RY (2015) Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review. Crit Rev Environ Sci Technol 45:669–702. https://doi.org/10.1080/10643389.2013.876527

Riviere D et al (2009) Towards the definition of a core of microorganisms involved in anaerobic digestion of sludge. ISME J 3:700–714. http://www.nature.com/ismej/journal/v3/n6/suppinfo/ismej20092s1.html

Romero P, Coello MD, Quiroga JM, Aragón CA (2013) Overview of sewage sludge minimisation: techniques based on cell lysis-cryptic growth. Desalin Water Treat 51:5918–5933. https://doi.org/10.1080/19443994.2013.794842

Şahinkaya S, Sevimli MF, Aygün A (2012) Improving the sludge disintegration efficiency of sonication by combining with alkalization and thermal pre-treatment methods. Water Sci Technol 65:1809–1816. https://doi.org/10.2166/wst.2012.074

Sallanko J, Okkonen J (2009) Effect of ozonation on treated municipal wastewater. J Environ Sci Health A 44:57–61. https://doi.org/10.1080/10934520802515350

Seiple TE, Coleman AM, Skaggs RL (2017) Municipal wastewater sludge as a sustainable bioresource in the United States. J Environ Manag 197:673–680. https://doi.org/10.1016/j.jenvman.2017.04.032

Song Y, Shi Z, S-y C, Luo L (2013) Feasibility of using lysozyme to reduce excess sludge in activated sludge process. J Cent South Univ 20:2472–2477. https://doi.org/10.1007/s11771-013-1759-5

Świątczak P, Cydzik-Kwiatkowska A, Rusanowska P (2017) Microbiota of anaerobic digesters in a full-scale wastewater treatment plant. Arch Environ Prot. https://doi.org/10.1515/aep-2017-0033

Tchobanoglous G, Burton FL, Stensel HD (2003) Wastewater engineering: treatment. In: Disposal and reuse, 4th edn. McGraw-Hill, New York

Thuy PT, Tuan PT, Khai NM (2016) Industrial water mass balance analysis. Int J Environ Sci Dev 7:216–220

Tyagi VK, Lo S-L (2012) Enhancement in mesophilic aerobic digestion of waste activated sludge by chemically assisted thermal pretreatment method. Bioresour Technol 119:105–113. https://doi.org/10.1016/j.biortech.2012.05.134

Uan DK, Harada H, Hoang TN, Hong NTN (2016) Application of sludge disintegration to enhance sludge management for wastewater treatment plants in Vietnam proceedings of international conference on environmental engineering and management for sustaninable development, Bach Khoa publishing house, Hanoi, 15 September, 2016. pp 23–27

Uan DK, Harada H, Saizen I (2017) Techno-economic assessment of alkalis sludge disintegration to enhance sludge management for wastewater treatment plants in Vietnam proceedings of the 7th National conference on water resources engineering, the 4th EIT international conference on water resources engineering, the 9th AUN/SEED-net regional conference on environmental engineering “development for sustainable global environment and water resources”, January 23–24, 2017, Chonburi, Thailand. pp 326–330

Uma Rani R, Adish Kumar S, Kaliappan S, Yeom I-T, Rajesh Banu J (2014) Enhancing the anaerobic digestion potential of dairy waste activated sludge by two step sono-alkalization pretreatment. Ultrason Sonochem 21:1065–1074. https://doi.org/10.1016/j.ultsonch.2013.11.007

Velho VF, Daudt GC, Martins CL, Belli Filho P, Costa RHR (2016) Reduction of excess sludge production in an activated sludge system based on lysis-cryptic growth, uncoupling metabolism and folic acid addition. Braz J Chem Eng 33:47–57. https://doi.org/10.1590/0104-6632.20160331s20140207

Vlyssides AG, Karlis PK (2004) Thermal-alkaline solubilization of waste activated sludge as a pre-treatment stage for anaerobic digestion. Bioresour Technol 91:201–206. https://doi.org/10.1016/S0960-8524(03)00176-7

Wang Z, Yu H, Ma J, Zheng X, Wu Z (2013) Recent advances in membrane bio-technologies for sludge reduction and treatment. Biotechnol Adv 31:1187–1199. https://doi.org/10.1016/j.biotechadv.2013.02.004

Wang R, Liu J, Lv Y, Ye X (2016a) Sewage sludge disruption through sonication to improve the co-preparation of coal–sludge slurry fuel: the effects of sonic frequency. Appl Therm Eng 99:645–651. https://doi.org/10.1016/j.applthermaleng.2016.01.098

Wang X, Duan X, Chen J, Fang K, Feng L, Yan Y, Zhou Q (2016b) Enhancing anaerobic digestion of waste activated sludge by pretreatment: effect of volatile to total solids. Environ Technol 37:1520–1529. https://doi.org/10.1080/09593330.2015.1120783

WorldBank (2013) Vietnam urban wastewater review. © World Bank, Washington, DC

WorldBank (2014) Socialist Republic of Vietnam : review of urban water and wastewater utility reform and regulation. © World Bank, Washington, DC

Yang Q, Yi J, Luo K, Jing X, Li X, Liu Y, Zeng G (2013) Improving disintegration and acidification of waste activated sludge by combined alkaline and microwave pretreatment. Process Saf Environ Prot 91:521–526. https://doi.org/10.1016/j.psep.2012.12.003

Yang Y et al (2014) Metagenomic analysis of sludge from full-scale anaerobic digesters operated in municipal wastewater treatment plants. Appl Microbiol Biotechnol 98:5709–5718. https://doi.org/10.1007/s00253-014-5648-0

Yu H, Wang Q, Wang Z, Sahinkaya E, Li Y, Ma J, Wu Z (2014) Start-up of an anaerobic dynamic membrane digester for waste activated sludge digestion: temporal variations in microbial communities. PLoS One 9:e93710. https://doi.org/10.1371/journal.pone.0093710

Yu H, Wang Z, Wu Z, Zhu C (2016) Enhanced waste activated sludge digestion using a submerged anaerobic dynamic membrane bioreactor: performance, sludge characteristics and microbial community. Sci Rep 6:20111. https://doi.org/10.1038/srep20111. https://www.nature.com/articles/srep20111#supplementary-information

Zhang G, Zhang P, Yang J, Liu H (2008) Energy-efficient sludge sonication: power and sludge characteristics. Bioresour Technol 99:9029–9031. https://doi.org/10.1016/j.biortech.2008.04.021

Zhao J et al (2017) Aged refuse enhances anaerobic digestion of waste activated sludge. Water Res 123:724–733. https://doi.org/10.1016/j.watres.2017.07.026

Zhen G, Lu X, Li Y-Y, Zhao Y (2014) Combined electrical-alkali pretreatment to increase the anaerobic hydrolysis rate of waste activated sludge during anaerobic digestion. Appl Energy 128:93–102. https://doi.org/10.1016/j.apenergy.2014.04.062

Zhen G, Lu X, Kato H, Zhao Y, Li Y-Y (2017) Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives. Renew Sust Energ Rev 69:559–577. https://doi.org/10.1016/j.rser.2016.11.187

Acknowledgments

The author would like to thank the supports by the Hanoi University of Science and Technology (T2014-15). The financial supports by the GSGES seeds research funding programme for overseas field campuses (Year 2015–2016) were highly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Do, KU., Harada, H., Saizen, I. (2018). Enhancement of Biogas Production from Anaerobic Digestion of Disintegrated Sludge: A Techno-Economic Assessment for Sludge Management of Wastewater Treatment Plants in Vietnam. In: Chan, HY., Sopian, K. (eds) Renewable Energy in Developing Countries. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-319-89809-4_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-89809-4_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-89808-7

Online ISBN: 978-3-319-89809-4

eBook Packages: EnergyEnergy (R0)