Abstract

Bonneville Power Administration (BPA) was among the first adopters of the synchrophasor technology in the early 1990s. Initial PMUs were installed as stand-alone disturbance recorders at four substations collecting data locally at a rate of 30 times each second. The value of the synchrophasor technology was evident when the synchronized dynamic data enabled detailed analysis of some of the events/outages that happened in 1996. Following the outages, BPA greatly expanded its PMU coverage to monitor large power plants, interties, and load centers. BPA also researched, developed, and prototyped several applications that use wide-area synchronized measurements for power system analysis. This chapter presents BPA’s efforts and contributions in using synchrophasor technology in managing the grid.

Contributors:

BPA Transmission Planning

BPA Transmission Operations

BPA Transmission Engineering

BPA Transmission Innovation

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Phasor measurement units

- Synchrophasors

- Wide-area monitoring

- Wide-area control

- Model validation

- Voltage stability control

- Event analysis

- Oscillation detection

- Island detection

4.1 History of the Synchrophasor Technology at BPA

Synchrophasors are precise time-synchronized measurements of power system quantities—voltages, currents, angles, frequency, active and reactive power, provided by phasor measurement units (PMUs ). The primary benefits of the PMUs are (a) precise time synchronization (data points are time-stamped at the source at the moment of measurement) and (b) high data resolution (30–120 measurements per second compared to one measurement every 2 or 4 s by conventional SCADA ). PMUs provide synchronized wide-area view of the power system dynamic state [1].

Bonneville Power Administration (BPA) was among the first adopters of the synchrophasor technology in the early 1990s. Initial PMUs were installed as stand-alone disturbance recorders at four substations collecting data locally at a rate of 30 times each second. The value of the synchrophasor technology was evident when the synchronized dynamic data enabled detailed analysis of July 2 and August 10, 1996 outages ([2, 3], also see Appendices A and B). Following the outages, BPA greatly expanded its PMU coverage to monitor large power plants, interties, and load centers. BPA also developed a network to stream real-time PMU measurements to its laboratory. In 2001, BPA started exchanging real-time PMU data with Southern California Edison (SCE), and later with California ISO (CAISO) .

BPA also researched, developed, and prototyped several applications that use wide-area synchronized measurements for power system analysis. Power plant model validation using disturbance data was one of the early applications , providing a cost-effective alternative to staged generator tests. BPA’s success with the approach influenced WECC Generating Unit Model Validation Policy developed in 2006, and disturbance-based model validation techniques have been adopted into NERC MOD Reliability Standards. Wide-area oscillation detection and analysis applications are enabled by the synchrophasor data . BPA collaborated with other grid operators and the research community to develop a suite of applications for analysis of disturbance ringdown, forced and ambient oscillations .

In mid-2000s, Vickie VanZandt, then Senior Vice President of BPA Transmission, sets the direction for the synchrophasor technology at BPA, saying, “It is time to move forward from wide-area monitoring to wide-area controls.” BPA researched several analytical methods for using synchrophasor data for response-based voltage stability controls [4]. BPA also initiated a research project on developing control algorithms to dampen inter-area power oscillations . Brian Silverstein, then Senior VP of BPA Transmission, sets a clear guiding principle for synchrophasor -based controls—“First, do no harm”.

4.2 BPA Synchrophasor Investment Project

BPA’s original synchrophasor network was research-grade and was not suitable for real-time control center applications . In 2010, BPA started a capital project to build a secure, reliable, and production-grade synchrophasor infrastructure , as a participant in the Western Interconnection Synchrophasor Project (WISP) co-funded with federal Smart Grid Investment Grant funds. BPA’s project included installations of dedicated “control” PMUs , high-capacity network routers, GPS units, substation telecommunication battery upgrades, and deployment of control center infrastructure and software.

A typical PMU inputs two sets of three-phase voltages and six sets of three-phase currents, and calculates voltage and current phasors in polar form (magnitude and angle), bus frequency, line active, and reactive power. Digital statuses of circuit breakers and disconnects can be also recorded in a PMU message. BPA installed fully redundant “control” PMUs at 46 substations, measuring more than 4,000 power system quantities at a rate of 60 samples per second. “Control” PMUs are treated as Bulk Electric System (BES) Cyber Assets (CA). BPA “control” PMUs are fully redundant—they are connected to separate sets of potential and current transformers, and they stream data over redundant communications networks to separate BPA control centers.

BPA also deployed many non-redundant “data” PMUs , mainly at wind power plants in the Pacific Northwest. The “data” PMUs are used for engineering analysis , but not for real-time controls or operational decision making.

The interconnected nature of power system operations requires real-time data exchange among operating entities. BPA is a partner in the WISP, led by Peak Reliability Coordinator (RC), which deployed an unprecedented interconnection-wide network for real-time data exchange among operating entities in the West. BPA streams most of its synchrophasor data to Peak RC and exchanges a significant amount of real-time PMU data with 14 operating entities in the West.

BPA implemented state-of-the-art control center architecture to handle huge volumes of streaming synchrophasor data and to perform real-time analytics. OSI Soft PI data historians are used to archive more than 200,000 measurements per second. The situational awareness application engine processes over 18,000 measurements per second. BPA deployed several real-time analytics described below. BPA technical staff developed visualization displays using PI Process Book to effectively present analytical information to BPA dispatchers. BPA established PMU data-based alarming for the oscillation detection application, with supporting operating procedures and training sessions. BPA dispatchers use a dedicated situational awareness PMU data historian to support real-time operations , and a similar historian with synchrophasor data and analytical results is available for BPA technical and engineering staff on a separate network. PMU data are also down-sampled to a 2-s SCADA rate and used in EMS applications such as state estimation .

Wide-area control was one of the key objectives of the BPA synchrophasor investment. BPA developed infrastructure to integrate streaming PMU data into a new Remedial Action Scheme (RAS ) controller and developed an off-line environment for monitoring, testing, and validating the new PMU -sourced RAS controller’s performance. BPA implemented a wide-area reactive power switching scheme using synchrophasors , which is currently in a test mode.

In addition to the production system, BPA developed a synchrophasor application laboratory for researching, prototyping, and testing new analytical algorithms and applications . The laboratory has capabilities to extensively back-test algorithms using years of historic data as well as real-time streaming data, thereby accelerating application development. BPA has tested and validated its Mode Meter , oscillation detection , synchrophasor RAS , and voltage stability applications in the synchrophasor laboratory.

BPA synchrophasor investment project received Platt’s Global Energy Award for Grid Optimization in 2013 [5].

BPA continues its commitment to the synchrophasor technology by having a multi-year plan for PMU deployment, implementing operating procedures for control room applications , and supporting research and demonstration of advanced applications using synchronized wide-area data.

4.3 Engineering Applications at BPA

The value of the synchrophasor investment project is unlocked through deployment of applications . BPA has successfully developed and deployed a variety of engineering applications over the past 15 years.

4.3.1 Power Plant Model Validation

Accurate power system models are required for reliable and economic power system operations, and power plants are the most critical part of the power system dynamic model. Following the 1996 cascading outages, which were attributable in part to poor system and power plant models used for system operations, the Western Interconnection instituted a requirement for periodic testing of generators for model verification. In the meantime, BPA greatly expanded its PMU coverage to power plants, with PMUs located at BPA substations looking at the power plant Point-Of-Interconnection (POI). BPA researched and successfully prototyped a disturbance-based model verification process in 2000, seeing the technique as an independent, cost-effective, and lower-risk option for model re-validation . BPA worked with grid simulator developers to add disturbance play-in functionality in their simulation packages. BPA’s success influenced the WECC Generating Unit Model Validation Policy of 2006. The 2016 NERC MOD-026 and 027 Reliability Standards, which superseded WECC Policy, also recognize disturbance-based model verification as an acceptable method of compliance. To complement these Standards, the NERC Synchronized Measurement Subcommittee developed a Reliability Guideline on using PMUs for power plant dynamic model verification [6].

Today BPA has PMUs at the POIs of 13 conventional power plants, 33 interconnection points, and 133 generators, with over 21.5 GW of generating capacity. In addition, PMUs are now installed within BPA’s service area at the POIs of 13 wind power plants with total capacity over 1.2 GW. As the number of power plants monitored grew, it became necessary to develop better ways to manage PMU data and power plant models. Through its Technology Innovation Program (TIP 52 and 274), BPA developed the power plant model validation (PPMV) application for model and data management. BPA also partnered with PNNL to implement advanced capabilities for managing data flow, comparing model performance, and reporting.

Today, the PPMV application is used in two modes of operation:

-

Event analysis : BPA technical staff can compare the actual generator response with expected generator response during a system event for its entire generating fleet. This process helps to find generator performance abnormalities (see next section).

-

Power plant model verification: BPA technical staff compares the actual responses (from recorded PMU data) with model responses for a specific generator over a span of several system events . If there is a good comparison between model and actual data, the model is verified, and the verification report can be used for compliance with the NERC MOD-026 and -027 Reliability Standards. Several BPA customers have used these BPA-provided reports to earn WECC plant model approval certificates.

If examination shows a consistent discrepancy between plant models and actual performance data, BPA will work with power plant operators to re-calibrate the model. BPA’s research indicates that disturbance data can be used, with proper engineering judgment, to complement but not replace baseline model development and calibration.

Disturbance-based model verification and stress-testing are parts of an annual model checkup performed by BPA staff. When we started the process in 2011, about 60% of dynamic models were found to be deficient in their representation of actual plant responses to system events . Since then, the continued use of PPMV has materially improved the quality of power plant models in BPA service territory. Success stories of disturbance-based model verification are reported at NASPI and NERC technical conferences and IEEE publications [7, 8].

The Pacific Northwest experienced unprecedented wind generation development in the late 2000s. However, wind generation model development lagged power plant installation, resulting in incomplete planning requirements and ultimately operational issues, as documented in [9]. BPA has been actively involved in wind generation modeling through leading organization like UVIG, WECC, and NERC. BPA is also actively engaged with wind generation manufacturers, leading researchers at EPRI, NREL, and regional wind power operators to develop and validate wind power plant models.

BPA was one of the first utilities in North America to require new power plants to install “data” PMUs as a part of their interconnection process. Several leading transmission operators in North America have since adopted similar requirements, including ERCOT and PJM Interconnection.

BPA has been also conducting large-scale industry outreach on model validation tools at NASPI, NERC, WECC, and EPRI forums, and also working with individual utilities on technology sharing. BPA is an active member of the EPRI modeling group and a user of EPRI’s Power Plant Parameter Derivation tool.

4.3.2 Power Plant Performance Monitoring and Analysis

Once a good model is developed, representing the desired power plant performance, the PPMV application can then be used as a “clinical” checkup of power plant dynamic performance. Over the years, BPA has used the PPMV application with PMU data to detect several abnormal and unexpected responses of power plants to grid disturbances (i.e., by spotting situations when a power plant model that has been shown to be accurate in several prior grid disturbances predicts plant behavior that does not match the plant’s actual response in a new event).

Examples of PMU -detected control abnormalities are shown below:

-

(a)

Power System Stabilizer (PSS) at a large power plant experienced an internal failure. The PSS status light was indicating normal operation. However, the plant’s actual response to Chief Joseph brake application was much more oscillatory than expected. Further inspection done by plant engineering staff identified internal PSS failure.

-

(b)

The power plant controller response overrides frequency pickup. A large hydro-power plant was expected to provide about a 30 MW of governor response to support system frequency during a system event. However, the plant controller not only entirely negated the governor response, but continued to drive the response 30 MW in the opposite direction.

-

(c)

Multiple occurrences of unexpected reactive power runbacks have occurred at a large hydro-power plant after new digital exciters were commissioned. The events coincide with large system frequency deviation events. Power plant technical staff and BPA operations were advised on the issue.

-

(d)

Power plant controller response attempts to over-ride RAS generation drop. A hydro-power plant participated in BPA RAS. Following an unplanned transmission line outage, the BPA RAS operated, tripping two units carrying about 120 MW of generation. While some governor response from the remaining units was expected (blue line), the actual plant response was significantly higher because the plant controller attempted to restore plant output to its initial schedule. Such response was undesirable as it counteracts RAS action to relieve transmission overload. Plant technical staff was notified to address the issue.

PMU -based disturbance monitoring and the PPMV application help BPA to quickly identify power plant and generator control issues and to initiate corrective actions to address them. BPA’s TIP 350 supports the efforts to advance the suite of power plant monitoring applications .

4.3.3 System Model Validation and Event Analysis

The NERC MOD-033 Reliability Standard requires transmission planners to perform verification of system models used in planning studies. The verification is performed by comparing simulated disturbance events against the actual time-synchronized disturbance data. PMU technology is the best source of time-synchronized disturbance data required for system model validation .

BPA and WECC have extensive experience with performing large-scale system model validation studies, including those for the August 10, 1996 outage, the August 4, 2000 oscillation, several large frequency disturbances during thermal governor model development in early 2000s, the June 14, 2004 Westwing event, and many RAS and large generation loss events [10, 21].

In recent years, WECC Staff, Peak RC, General Electric, BPA and other utilities in the West have made significant progress in bridging operational and planning models, working through the WECC Modeling and Validation Work Group. This team is developing a more complete mapping between operating cases and the dynamic model database, thereby enabling dynamic simulations performed using state estimator models. The group is also developing tools to map a state estimator snapshot onto a planning powerflow case, enabling verification of planning models as required by NERC MOD-033 Reliability Standard.

These improvements allow planning and operating engineers to perform model validations more frequently for a more diverse set of system events (large generation trips, RAS events, Chief Joseph brake tests, local faults), which helps engineers identify more accurate system operating limits [11].

4.3.4 Event Analysis

Wide-area visibility and time-synchronization of PMU data are also essential for reconstructing a sequence of events during complex system disturbances. Event analysis has been one of the earliest applications of the synchrophasor technology , greatly reducing staff time required to sequence the events and find causalities between them. For example, September 8, 2011, Pacific Southwest outage had more than 100 notable events occurred in less than 11 min, mainly clustered around four stages of the event. Having resolution and time alignment of the synchrophasor data turned to be essential to sequence them appropriately. FERC and NERC reports states [20]: “The availability of Global Positioning System (GPS)-time-synchronized PMU data on frequency, voltage, and related power angles made this task much easier than in previous blackout inquiries and investigations.”

BPA technical staff routinely uses time-synchronized PMU data for analysis of system events . Of particular focus are events when RAS operated, when analysis is done to ensure that the operation was appropriate and needed. This type of review helped BPA to improve RAS settings over the years.

Furthermore, BPA has been using the synchrophasor data for analysis and baselining of key power system performance metrics like frequency response, oscillation damping, and voltage sensitivities to variable transfers as described in the following sections.

4.3.5 Frequency Response Analysis

NERC BAL-003-1 Frequency Response Reliability Standard requires each interconnection to provide a certain amount of frequency response following a system frequency deviation event. The interconnection-wide frequency response requirement is then pro-rated among the Balancing Authorities (BAs), who are responsible for compliance with the Standard.

BPA has been using PMU data for frequency response analysis since late 1990s, and supported early attempts to develop Frequency Responsive Reserve requirements in the Western Interconnection through the 2000s. Supporting NERC BAL-003-1 Reliability Standard, BPA worked with the PNNL to develop a comprehensive set of tools and processes for frequency response monitoring and analysis. BPA’s Technology Innovation Program, TIP 313, funded the development of the frequency response analysis tool (FRAT) [12].

The developed process encompasses (a) the assessment of frequency response at multiple levels—Western Interconnection, BPA Balancing Authority, and individual power plants, and (b) the impact of frequency response on transmission loading on major paths. BPA developed a comprehensive baseline of the frequency response performance of the Western Interconnection as a whole, and the BPA Balancing Authority in particular. The developed historic baseline is used for correlation analysis of the frequency responses relative to various system metrics, including total generation, hydro-generation, wind generation, time of day, and season. The FRAT application has helped BPA operations staff better understand BPA’s historic performance as a Balancing Authority, the associated compliance risks, and make more informed decisions on the amount of frequency response available for marketing. NERC technical staff has adopted the FRAT application for their frequency response monitoring in support of BAL-003 Reliability Standard. BPA also has an application for verifying performance of power plants contracted to provide frequency response. BPA is now working on predictive tools to track its BA frequency response inventory based on generators online and their historic performance.

The geographic distribution of governor response following a generation loss or a RAS generation drop affects post-contingency power flows on transmission paths, and in turns affects post-contingency voltage stability . The California–Oregon Intertie (COI) and Pacific DC Intertie (PDCI) are stability-limited transmission paths affected by the post-transient governor response. BPA has been using PMU data to track power pickup on COI since the late 1990s. Governor power flow set-up used in planning and operating is tuned to reproduce the observed historic power pickup.

Appendix D provides step-by-step illustration of a frequency event detection and analysis performed by BPA engineering staff.

4.3.6 Oscillation Event Analysis

Oscillations are always present in power systems. Power oscillations are low amplitude and well-damped most of the time. But when the oscillations grow in magnitude, they may contribute to power system instability (such as occurred on August 10, 1996 in the Western Interconnection) or equipment damage (e.g., sub-synchronous control interaction that occurred in ERCOT in March 2009 [22]).

There are many types and causes of power oscillations . Oscillations can be grouped into two broad categories based on our approach in addressing them: (a) oscillations that we can predict, model, and mitigate by either control design/tuning or by operating procedures, and (b) oscillations that result from equipment failure or forced, that are not generally predictable and have to be dealt as they develop.

Electromechanical oscillation is the most common type of oscillations that can be predicted, modeled, and controlled. Inter-area electromechanical oscillations are of high concern for BPA, and specifically North–South and Montana–Northwest (NW) modes [13]. North–South oscillations involve generators in British Columbia and Upper Columbia oscillating against generators in Desert Southwest and Southern California. The North–South modes are manifested in voltage and power oscillations on the California–Oregon Intertie. The North–South oscillations are typically well-damped; but the oscillation became unstable on August 10, 1996 leading to the large-scale power outage and was very lightly damped during the August 4, 2000 event. The Montana–Northwest oscillation has Colstrip power plant oscillating against generators in Pacific Northwest. Montana-NW oscillation can resonate with British Columbia-NW oscillation. This mode is manifested in power oscillations on the Montana Intertie and voltage oscillations in the Spokane area. The oscillation is typically well-damped, but could be become a problem under outage conditions.

BPA has a long-established history of performing analysis of the inter-area power oscillations , going back to pioneering work by Dr. John Hauer. Analysis of oscillation ringdown events is used for baselining oscillation damping versus system conditions and contingencies, benchmarking simulated damping against actual power system damping, developing operating procedures to address low damping oscillation risks. BPA advanced the state of “ringdown” analysis tools under TIP 050. BPA’s current set of “ringdown” tools include interactive applications developed by PNNL and the University of Wisconsin, and a batch-processing application developed by Montana Tech University. BPA’s planning and operations performed extensive large-scale simulations of a wide range of system conditions and contingencies to identify scenarios when low damping can occur. These studies provided a technical foundation for the development of the operating plans to address low damping conditions.

BPA performs annual system tests to stimulate power oscillations under controlled conditions. The tests usually include insertion of a 1,400 MW Chief Joseph braking resistor to initiate an oscillation ringdown and signal injections in the Pacific HVDC Intertie. Under TIP 349, BPA is developing a baseline of the system performance during these tests to continue improving understanding of the factors impacting inter-area power oscillations .

BPA also participated in DOE-led research on applications to estimate damping of the inter-area power oscillations using ambient data, an application known as the Mode Meter . The goal of the application is to recognize when low damping conditions indicate high system stress. Such application could be used as an early warning of potential oscillation problems. The Mode Meter application has been implemented in the BPA synchrophasor application server and is now in a test mode. Our experience indicates that it is technically challenging to distinguish low damping conditions due to system stress versus low damping condition caused by forced oscillation. BPA is working with researchers at Montana Tech University, University of Wyoming, University of Wisconsin, and PNNL to advance this technical issue with funding from US Department of Energy.

Forced low energy oscillations could provide early indication of equipment health issues, mistuned controllers, or bad operating points. A PNNL team developed signal processing techniques to pick up these low energy oscillations , which are otherwise not visible just by looking at the signals. BPA worked with the PNNL team to prototype these methods in the BPA’s synchrophasor laboratory under TIP 305 and is now developing a structured environment around the analytics and alarming under TIP 350.

Engineering analysis of power oscillation paved the foundation for the control room applications like oscillation detection and Mode Meter described in the later session, including development of operating procedures for dispatchers on how to respond to oscillation events and low damping conditions.

4.3.7 Voltage Fluctuations due to Variable Transfers

Large-scale integration of renewable generation in the Western Interconnection can greatly benefit from expanding the footprint of generation resources used for energy balancing. Over the next decade, the need for flexible generating capacity is expected to increase significantly to support the integration of large amounts of solar generation [14].

The developing western Energy Imbalance Market (EIM) aims to expand the balancing resources by pooling generation resources across multiple Balancing Authorities, thereby reducing the need to build new peaking capacity, lowering operating costs, and improving efficiencies. One of the technical challenges is to make sure that the balancing services can be delivered reliably over the transmission network. Transmission network controls and business processes were designed for relatively slow and predictable power ramps. Faster ramps caused by variable energy resources like wind and solar require greater automation of business processes, more nimble controls, heavier duty switching, and better situational awareness and system assessment tools. BPA transmission is taking steps toward automated arming of its Remedial Action Schemes (RAS ) and has researched concepts of advanced voltage controls and situational awareness under its Technology Innovation Program (TIPs 51, 348, 355, 370).

BPA Technology Innovation supported research to identify the system impacts of variable transfers, including development of methodologies and simulation tools under TIPs 237 and 281. This research found that the acceptable magnitude of voltage fluctuations has been the most limiting factor for variable transfers. BPA Transmission Planning and Operations have used PMU data from disturbances and power ramps to independently validate the results of the powerflow studies performed to establish limits on variable transfers.

Current research under TIP 348 is evaluating measurement-based predictive algorithms using wide-area synchronized measurements, and TIP 370 plans take the concepts from monitoring to controls.

4.3.8 State Estimation

BPA’s synchrophasor system sends 2-second down-sampled data to its Energy Management System (EMS ) applications including state estimation . PMU -measured bus voltages, line active and reactive power measurements typically have better resolution than the existing SCADA measurements . Bus voltage phasor angle is a direct measurement of the power system state. BPA uses a state estimator from GE Grid Solutions (formerly Alstom, Areva, and ESCA) which is capable of using phase angles in its solution.

BPA’s PMU data have very high availability, and data quality is monitored and properly flagged. In contrast, many neighboring transmission owners are sending PMU data with frequent data dropouts, or unflagged bad data. While accurate phasor angles from external system can improve BPA state estimator solution, inaccurate phasor angles can also cause solution issues. Better data quality monitoring is required to ensure that bad measurements are flagged and eliminated from state estimation .

4.3.9 Data Quality Monitoring

BPA deployed applications for monitoring data quality , including data dropouts, data latency , and loss of synchronization. In general, BPA data have very high data availability from its PMUs . BPA is also taking steps in improving data calibration. A simplistic approach is to compare the PMU measurements with SCADA measurements for consistency. A more comprehensive approach is to use linear state estimation for data calibration and system network model validation . If measurements are properly calibrated and network model is correct, the “estimated” measurements will match the actual measurements. Electric Power Group, under a contract with WECC and BPA, implemented and demonstrated a linear state estimator in the BPA synchrophasor laboratory. Good PMU coverage of the BPA 500-kV grid provides required observability for network model verification and PMU measurement calibration.

4.4 Control Room Applications at BPA

Bringing synchrophasor technology into the control room was one of the main objectives of BPA’s original 2010 investment project. BPA developed several operations applications and visualization displays and deployed these on a control room video-wall as early as October 2013. BPA has since held regular dispatcher training sessions, improved the displays, and prepared technical reference documents for these applications . Finally, BPA developed formal operating procedures for the oscillation detection application in June 2016.

4.4.1 Oscillation Detection

BPA implemented and deployed the oscillation detection application in its control room in October 2013. The application’s primary purpose is to detect unanticipated oscillations that result from control system failures, local power plant instability, forced oscillations , excitation of inter-area modes, or a generating unit in an unstable operating region. The oscillation detection application scans multiple signals (power, frequency, voltages) across the grid for indications of growing or sustained high energy oscillations . It monitors large power plants, including BPA wind hubs, load centers, AC interties with Canada, California and Montana, and controlled elements like the Pacific HVDC Intertie and Static VAR Compensators.

The application uses algorithms developed by Dr. Dan Trudnowski at Montana Tech University and Dr. John Pierre at the University of Wyoming. BPA staff developed visualization displays to present the information to dispatchers, planning and operations staff. The oscillation detection display is very effective in identifying a type and magnitude of an oscillation event. Each PMU has four oscillation frequency bands. These bands correspond to various types of oscillations : (i) AGC or local plant controls, (ii) inter-area oscillations , (iii) local plant oscillations or control problems, (iv) voltage control problems at generators and power electronic devices. Forced oscillations can be present in any of the frequency bands. In the display, a status indicator changes color from green to red when an oscillation alarm is triggered for that frequency band, which has proven to be an effective visual indicator of the type of oscillation present. The display also informs a dispatcher whether an oscillation is local or wide-area. If an alarm is indicated at only one site, then the oscillation is local. But if many sites are affected, then the oscillation is wide-area, or it is a high energy oscillation that propagates through the grid (see figure). A dispatcher can click on a site to get further details on the oscillation—such as real-time trends of monitored signals, calculated oscillation energy, and alarm status. This information helps to better diagnose the problem, locate the oscillation source, and ensure appropriate corrective actions are taken.

BPA developed operating procedures for dispatchers to address the oscillation events, developed technical reference documents, and performed several training sessions for BPA dispatchers. The operating procedures and alarming went into effect in June 2016. BPA published a technical paper through a US CIGRE conference on its experience with the development, implementation, and initial operational experience with the oscillation detection application [14].

Here are examples of oscillation events detected, their causes, and actions taken:

-

Multiple instances of high-frequency reactive power oscillations were detected at a large wind generation hub in 2013 and early 2014. These oscillations correlated with high-wind generation output. The oscillation frequency was about 13–14 Hz, close to the resonant frequency of an adjacent series-compensated line. BPA was concerned about the risk of a sub-synchronous control interaction, should a wind power plant become radially isolated on the series-compensated line (similar to an event that occurred in ERCOT in 2009). BPA engineering staff approached the wind power plant owner/operator, and they notified the wind-turbine generator manufacturer. The manufacturer upgraded the control firmware in April 2014, and the oscillations have diminished since.

-

Multiple instances of local power oscillations were detected at The Dalles hydro-power plant in late summer—fall of 2015. Because of drought, hydro-generation was low, transmission loading was low, and system voltages were high. As a result, hydro-generators were absorbing a large amount of reactive power. The oscillation events correlated with times when generators were operating close to their Under-Excited Limiters. Further analysis done by the US Army Corps of Engineers identified control interactions between a generator’s Power System Stabilizers and Under-Excitation Limiters as the cause of the oscillation. The US Army Corps of Engineers retuned the Under-Excitation Limiter controls in January 2016, and performed system tests to confirm that the new controls settings provided a stable response.

-

An event of sustained operation in a rough zone was recorded at John Day hydro-power plant in October 2014. While hydro-power generators regularly cross a rough zone during loading and unloading, sustained operation with oscillations is highly undesirable. The problem was caused by the plant controller, which erroneously dispatched the generator to operate in the rough zone. The BPA’s dispatcher called the power plant and notified a plant operator about the oscillation. The plant operator re-dispatched the unit to a stable operating point; the plant controller error was also fixed.

-

In April 2016, equipment failure near the Sylmar terminal of the Pacific HVDC Intertie caused large active and reactive power variations at the BPA’s Celilo terminal. The oscillation propagated through the Pacific Northwest network. Events like this demonstrate the interconnected nature of the power system.

-

In May 2016, a “rogue” power controller activity was detected at John Day powerhouse line#1. It caused random changes in active power for about an hour. The behavior was attributed to plant controller issues in the John Day plant.

-

The oscillation detection application has detected several local generator instability events caused by transmission losses. Because such oscillations are usually high energy, they propagated several substations away from the source (cause) of the oscillation.

4.4.2 Frequency Event Detection

BPA developed a frequency event detection application and deployed it in the control room in 2014 for monitoring purposes. This application is very practical and useful for dispatchers, technical operations staff, and engineers. It detects an onset of a system frequency deviation from nominal. The application finds the bus frequency measurement with the largest rate of change, typically corresponding to the PMU closest to the location of generation loss. The information is then displayed on a video-wall—the largest dot corresponds to the PMU assumed to be closest to the location of the generation loss. The smaller dot sizes show the propagation of the event through the system.

The trending display includes system frequency as well as power pickup on the interties with Canada, Montana and California. As discussed in the engineering applications section, post-transient frequency response can lead to transmission overloads; therefore, a synchronized view of system frequency and path flows improves situational awareness for the operations staff.

Appendix D describes integrated frequency response analysis deployed at the BPA.

The detection of a frequency event also triggers an automatic update of a MW flow display, showing the dispatchers how MW flow on the grid (based on phase angle differences on paths between PMUs ) get redistributed as result of the event that caused the frequency to change (e.g., a Gen drop).

Following the event, a dual bar chart is shown next to each path that had a voltage angle change of at least 0.5°. The top bar chart shows the relative phase angle difference /MW flow on the path before the event (relative to an historical max), and bottom bar chart shows the relative angle difference/MW flow after the event. It is easy to see how flows on individual paths/lines increased or decreased.

4.4.3 Islanding Detection

Generators in the Western Interconnection operate synchronized, and large-scale power system breakups and islanding events are very infrequent. However, when breakups occur, fast restoration of power service is vital. The objective of the BPA Islanding Detection application is to provide information on power system islands, breakup cut-planes, their frequencies, and angular separation between islands, which dispatchers and technical operations staff can use during the system restoration process. Because of BPA PMU coverage, the phase angle display can be also used during regular line reclosing to ensure the line closing angle is safe.

4.4.4 Mode Meter or Low Oscillation Damping Detection

The Mode Meter application estimates damping of the grid’s natural modes of oscillation from ambient data. The application could be used as an early warning of potential oscillation problems due to high system stress. BPA deployed analytical algorithms co-developed by Montana Tech University, University of Wyoming, and PNNL. The application is implemented for estimating damping of the inter-area modes of oscillations —North–South Mode A, North–South Mode B, Montana Northwest, and British Columbia Northwest. The application calculates frequency, damping, and energy for each oscillation mode, and the results of analytics are archived in the BPA historian. BPA is developing a composite alarm and operating procedures for the application.

Lightly damped oscillations can develop either due to high system stress (e.g., August 10, 1996 and August 4, 2000 on COI) or due to forced oscillations (e.g., November 30, 2005 Nova Joffre event). This distinction matters because dispatchers take different actions depending on the cause of an oscillation. The current algorithm does not differentiate when low damping conditions are due to system stress versus low damping condition caused by forced oscillations . BPA is working with researchers at Montana Tech University, University of Wyoming, University of Wisconsin, and PNNL to advance this technical issue with support from DOE.

4.5 Synchrophasor-Based Controls

BPA’s synchrophasor system was designed and built to enable wide-area stability controls. BPA implemented a synchrophasor -based wide-area voltage stability controller as a part of the investment project, also known as “synchrophasor RAS ”. The control scheme and its implementation have been approved as a safety net by the WECC RAS Reliability Subcommittee. The controller was tested in monitoring mode for two years before becoming operational in May 2017.

BPA researched several algorithms for voltage stability controls in the early 2000s, and prototyped them in its laboratory. This experience was useful and informative for the work done under BPA TIP 051 voltage stability controls, where BPA developed and performed extensive modeling, simulations, and back-testing of new algorithms. BPA also engaged an industry-wide expert panel to review its work.

The synchrophasor RAS has a hierarchical architecture. The master controller receives wide-area synchrophasor measurements to perform a real-time assessment of transient voltage stability risks. The implemented controller includes three phase-plane algorithms to identify potential stability risks; if any of the three algorithms is triggered, the RAS sends a control signal to several BPA substations to trigger local voltage controllers. Should the local voltage drop below a pre-defined threshold, the local controller switches shunt capacitors and reactors with a minimum time delay.

BPA designed the synchrophasor -based control system up to WECC’s RAS standards. BPA’s synchrophasor RAS is fully redundant, including redundant measurements, PMUs , and network equipment (routers, switches, etc.) streaming data to both BPA control centers. BPA also deployed a diversity principle to account for potential data dropouts or bad measurements. Each signal has its primary, secondary, and tertiary options of “like”-measurements, so that if the primary signal is not available or flagged as “bad”, the algorithm will switch to the next available signal. Timing is a critical part of the synchrophasor RAS , as BPA planning required the total response of less than half a second. Synchrophasor RAS receives measurements every cycle to perform voltage stability assessment. BPA has measured statistics on data latency , including signal processing by a PMU , network latencies, RAS controller throughput, and telecom delay from RAS controller output to BPA substations and relaying, to verify that the incoming data speeds do not impede the half second RAS response required.

BPA implemented an innovative approach for testing and verification of the synchrophasor RAS controller. RAS controllers are tested annually or any time when a controller change is made, so it is essential to have automated tools and procedures for efficient RAS testing. Most conventional RAS algorithms are event-driven by line-loss logic, and their testing is event-based. The challenge with testing the synchrophasor RAS is that its algorithm is driven by a time-sequence of analog measurements. BPA had to develop a special RAS test automation unit that streams synchrophasor data and compares actual to expected controller outputs.

BPA prototyped the RAS controller in its synchrophasor laboratory. This environment allowed BPA to back-test algorithms using a wide range of historic data events, such as large generation trips, line faults and outages, power oscillations , and also bad data cases. This testing helped further refine the algorithm performance.

BPA has a replica of the RAS controller algorithm in its situational awareness application engine. It runs the PMU data through the RAS algorithms every 5 s to determine whether the algorithms would have triggered. The results are archived in the BPA historian, and available to BPA operations and planning staff for further analysis and performance assessment .

4.6 Value Realized from the BPA Synchrophasor Project

BPA’s current synchrophasor project investments total about $50 M, comparable to the synchrophasor technology investments made by Pacific Gas and Electric, Southern California Edison, and Peak Reliability Coordinator. These costs include:

-

Cost of field installations (PMUs , telecom, substation upgrades)—about $30 M

-

Cost of control center network, servers, and applications —about $8 M

-

Technology innovation projects—about $10 M

This section describes and quantifies many of the benefits realized from the synchrophasor project investments.

California Energy Commission was one of the first one to perform a study to develop a business case for the synchrophasor technology deployment in mid-2000s [17]. The Western Interconnection Synchrophasor Program (WISP) identified reliability , operational efficiency, and renewable generation integration value streams in its business case for a large-scale synchrophasor SGIG investment in the early 2010s. In 2015, NASPI published the most comprehensive report, “The Value Proposition for Synchrophasor Technology ,” [18] on how to evaluate the benefits of the synchrophasor technology , taking into account experiences with actual technology deployment and value realized. This paper uses the NASPI framework to estimate the value delivered by the BPA synchrophasor investment.

The NASPI Value Proposition study identified many benefits and value metrics from the use of synchrophasor technology (see Tables 1-2 and 3-1 in the NASPI report [18]). Among these benefits, BPA primary benefits are in the reliability and resiliency categories. Over time, BPA will realize increasing benefits from economic benefits such as congestion reduction, labor cost reductions (as from hours saved due to faster event analysis ), and capital savings from early diagnosis of equipment mis-operations, and environmental benefits from better integration of variable energy resource integration.

The value of the synchrophasor investment projects extends beyond BPA. BPA streams its real-time data to Peak Reliability Coordinator, where it is used for the interconnection-wide situational awareness , system performance assessment , and system model validation .

We will use the framework developed by NASPI to highlight examples of value delivered by BPA’s synchrophasor investment. Table 4.1 provides an overall summary of the how applications relate to specific value streams. Specific applications and their benefits are reviewed below:

-

Oscillation Detection—BPA’s oscillation detection application was first implemented in October 2013, and operating procedures were developed and went into effect in June 2016. BPA has since detected numerous oscillation events, and resolved them either operationally or through follow-up control fixes. Oscillations could cause either direct grid instability (as in WECC on August 10, 1996), or transmission and generation equipment damage (as with ERCOT’s 2009 wind oscillation event). Detecting oscillations and acting on them in timely manner improves overall system reliability and equipment safety. In the case of oscillations caused by wind generation controls, early identification of the oscillation and analysis of its causes can reduce the extent of wind plant curtailments.

-

Frequency Event Detection and MW Flow —Frequency response is a key reliability metric for the bulk power system. Frequency response impacts other reliability metrics, as the governor response to frequency deviations affects transmission line loading and voltage stability . An example of this occurred on June 14, 2004, when a delayed cleared fault in Arizona resulted in more than 4,000 MW of generation tripped, pushing the Western Interconnection into under-generation and close to the stability edge [12]. After the system survived the initial power swing, the new challenge emerged: power flow on the COI was far in excess of its SOL, while the system frequency was abnormally low. Navigating the system through such complex events requires comprehensive wide-area situational awareness tools. BPA’s frequency event detection (FED) application provides better situational awareness to BPA dispatchers for similar situations in the future. The FED display provides clear indications where an under-frequency event was initiated, and MW flow display shows how the governor response for all of the generators online affects power transfers on interties and flow gates. This integrated view allows operators to quickly diagnose and mitigate under-frequency problems before they cause a stability collapse.

-

Islanding Detection—Islanding events , which occur when a grid collapse ends up with an portion of the grid in balance between load and generation, are very rare. The existence and boundaries of an electrical island can be determined in real time using PMUs . Streaming PMU data is used for islanding detection . PMU data and phase angle monitoring can be used to re-synchronize and speed system restoration should an islanding event occur in the Pacific Northwest, reducing customer outage time. BPA islanding detection was implemented in the control room in October 2013.

-

Phase Angle Display—BPA phase angle displays were implemented in the control room in October 2013. The application displays either absolute or relative phase angles, selectable by a user, for BPA substations. This information can be used for transmission line reclosing or re-synchronizing parts of the system during an islanding event. After a major grid collapse, operators have to piece the system back together, figuring out a carefully choreographed sequence that balances available generation and load across a wide region. Wide deployment of PMUs across the BPA main grid makes this much easier because operators can use phase angle matching for faster and safer synchronization and line reclosing, reducing total customer outage time with less risk to costly electrical assets.

-

Synchrophasor RAS—BPA’s synchrophasor RAS was approved by WECC in 2015 as a safety net to protect the grid against unplanned contingencies and extreme events, such as June 14, 2004 event described above. Voltage stability is one of the limiting factors for dynamic transfers when COI flows are near its operating limit, or as much as 20% of time as estimated from historic data. BPA is considering whether the synchrophasor RAS can be used to mitigate voltage stability limitations and to enable a wider operating range for dynamic transfers. Synchrophasor RAS helps to advance the environmental policies in the Western Interconnection toward reliable integration of renewable generation by protecting against extreme events and expanding the operating range of dynamic transfers. BPA estimates that using this RAS scheme increases COI voltage stability limit by 100–150 MW without the need to invest additional capital funds.

-

Power Plant Model Validation —BPA’s PPMV application was initially researched and developed in 2000. Numerous enhancements in model and data management have been implemented over the years, and the current application has been in active use since 2014. Regular use of power plant model validation application results in multiple generator model revisions, which ultimately improves grid reliability since the models are used to study operating limits and make grid investments. Thanks to PPMV, better generator models across the Northwest have improved simulated system performance, enabling BPA to increase its export limit on the Northern Intertie from 2,000 to 2,500 MW in 2015 without any incremental capital investment. Higher export capability could become useful during high-water, high-wind, light load conditions, similar to those during 2011 spring runoff, so that Northwest could export power instead of curtailing wind generation.

With synchrophasor -based model validation , BPA is realizing time and money savings by reducing the need for physical generator testing and modeling, with no lost revenue from plant downtime, or risk to equipment damage during staged tests. BPA helped several transmission customers to comply with NERC MOD-026 and -027 by performing PMU -based model verification.

Accurate wind generation models are required to make appropriate system investments and to avoid curtailments due to instability events. Because initial wind generation models were incomplete, BPA and wind developers were unable to foresee voltage stability issues under weak network conditions in some parts of their system. When local instability events occurred, BPA had to curtail wind generation power output until appropriate reinforcements or operational improvements were made. With the use of the PPMV application, BPA and industry experts have improved dynamic models of wind power plants in Pacific Northwest, thereby making sure appropriate reinforcements and controls are in place to reduce the risk of wind curtailments.

-

Power Plant Performance Models Monitoring—With automated PPMV and ongoing plant monitoring, BPA can identify potential equipment failures before they occur, supporting condition-based maintenance that should reduce catastrophic equipment failures and direct maintenance costs. Faster identification of generator problems creates facility efficiencies by reducing equipment downtime and protecting generator revenues. Reducing equipment failures can reduce crew labor costs, including travel time and overtime, and enable more cost-effective equipment acquisition and inventory management.

-

Event Analysis—PMU -based event analysis provides greater insight in the root cause than SCADA data. PMU -based event analysis significantly reduces labor costs and time required to complete an after-event sequence of events and root cause analysis.

-

System Model Validation—Accurate power system models are required for reliable system operations. Periodic model validation ensures that the models are accurate and up to date. NERC MOD-033 Reliability Standard requires Transmission Planners to conduct model validation studies for their footprint. Models are compared against wide-area disturbance data provided by PMUs . BPA collaborated with industry to develop tools to streamline system model validation process. Leveraging its experience with system model validation and event analysis , WECC and BPA developed interactive tools to greatly reduce the staff hour required to prepare model validation cases .

-

Frequency Response Analysis—BPA’s frequency response analysis tool (FRAT) was developed in 2014. BPA uses FRAT for frequency response analysis at the interconnection, BPA BA and power plant levels. The tool allows BPA to assess its historic performance and to identify which generator contributing to its frequency response. BPA used the frequency response baselining in its filings with FERC during the development of NERC BAL-003-1 Frequency Response Standard. BPA also uses FRAT for compliance with NERC BAL-003-1 Reliability Standard, and helping BPA to make decisions on how much of frequency response surplus make available in the power market.

-

Oscillation Analysis Tools—Damping of inter-area power oscillations is a necessity for grid security . BPA has used oscillation analysis tools and wide-area synchronized PMU data to identify and better understand the modes of inter-area oscillations in the Western Interconnection and recognize the conditions when these oscillations can put the system at risk. BPA developed its strategy to address the oscillation damping risks. Forced oscillations could be an indicator of impending control failure or improper tuning. BPA worked with equipment owners to correct forced oscillation issues caused by malfunctioning equipment at wind power plants and hydro-power generators.

-

Voltage Analysis—BPA has developed several tools to analyze voltage fluctuations due to variable energy transfers, as on the California–Oregon Intertie. Variable transfers are limited primarily by voltage fluctuations and secondarily by voltage stability . PMU data were used in baselining historic fast power ramps to validate study results used to set the dynamic transfer limits on California–Oregon Intertie. Increasing dynamic transfer capabilities on COI and PDCI enables the Balancing Authorities in the West to expand balancing footprint to accommodate a larger amount of renewable generation.

4.7 Technology Innovation Pipeline

BPA has a robust pipeline of technology innovation projects to further unlock the value of the BPA investment in the synchrophasor technology .

4.7.1 Synchrophasor Infrastructure

As more solar and wind generation in the West becomes electronically coupled to the grid, those plants’ dynamic response is affected by phase imbalances and point-on-wave phenomena during system faults. The resolution and attenuation of phasor quantities may no longer be adequate for analysis of disturbance performance of electronically coupled generators. A 500-kV fault in Southern California on August 18, 2016 resulted in tripping more than 1,000 MW of electronically coupled generation, even though phasor quantities were within disturbance ride-through envelopes. BPA recognized the need for digital oscillography capabilities at its wind power plants back in 2009, and installed extended digital fault recorders with PMUs at wind power plants. Moving forward, BPA is evaluating multi-functional devices capable of streaming out synchrophasor data at 60 samples per second for real-time applications , and local recording of digital oscillography for engineering event analysis .

BPA uses OSI Soft PI historian to support operational and event analysis functions. However, traditional databases are generally not well suited for big data analytics. BPA is researching advanced computational platforms based on distributed cluster computing for efficient analysis of the high volume of synchrophasor data . BPA has been collaborating with PNNL researchers to deploy a big data analytical system using the Apache Spark cluster computing framework at the BPA synchrophasor lab.

BPA exchanges real-time synchrophasor data with several operating entities in the Western Interconnection. The current method of data exchange is point-to-point, but greater efficiencies could be gained by using a publish–subscribe method instead. BPA is monitoring an ongoing NASPI-PNNL study developing a proposal for next-generation information technology and communications architecture for synchrophasor data exchange.

4.7.2 Engineering Analysis

BPA will continue incremental improvements to the existing tools deployed for ringdown analysis, model validation , and frequency response analysis . As we move forward, the focus is shifting toward system dynamic performance baselining and monitoring. BPA is developing baselining applications for oscillation analysis (TIP 349) to correlate observed damping of power oscillations with system conditions. TIP 313 has developed frequency response baselining capabilities at the interconnection, BPA Balancing Authority, and power plant levels.

Equipment monitoring has emerged as one of the unexpected success stories of the synchrophasor technology , providing capabilities to detect equipment failures and identify control mis-operations and cyber intrusions. BPA will continue research and demonstration of analytics for detecting equipment abnormalities, building on initial work under TIP 305 and TIP 350. This work also ties to developing the capabilities for big data analytics at BPA.

BPA will continue deployment of tools for compliance with NERC MOD Standards. Applications for power plant model verification (MOD-026, -027) are fairly mature and have been in use at BPA for several years. The focus is now shifting on applications for MOD-033 system model validation Reliability Standard. One of such applications is called linear state estimator (see NASPI workshop on linear state estimation [20]). Through collaboration with WECC and Peak RC, BPA has installed and successfully tested a linear state estimator in its synchrophasor laboratory. The application can be used to assess model-data integrity, identify persistent measurement errors, validate network model data, and condition data for use by downstream analytical applications . BPA is also monitoring similar research efforts at other utilities, primarily Dominion Virginia Power.

4.7.3 Control Room Applications

BPA made synchrophasor -based oscillation detection operational in June 2016. The application is simple and effective in detecting and alarming on events of high energy power oscillations . While the oscillation cause and source can be identified in most events, there have been cases when the oscillation origin was not obvious. The problem becomes particularly challenging in instances when a forced local oscillation excites an inter-area mode. BPA is partnering with the research community and other operating entities to improve analytical methods for location of the oscillation source. BPA is also monitoring ISO New England work on locating oscillation source using wide-area measurements.

The Mode Meter application was developed under the DOE-WECC Western Interconnection Synchrophasor Project. The application has run in monitoring mode since October 2013. BPA’s objective is to use the application to identify low damping conditions due to the system stress. As noted earlier, the current version of the application does not differentiate between low damping due to system stress or forced oscillations . BPA is collaborating with the research community on the algorithm improvements.

BPA continues to advance research and demonstration of voltage stability applications , using both model and measurement-based approaches. BPA TIP-325 demonstrated analytical methods for voltage stability assessment using real-time state estimator models and augmenting them with real-time synchronized measurements. Similar applications are deployed by Peak RC and ISO New England. BPA TIP-348 is evaluating measurement-based approaches for predicting voltage changes on the power grid due to reactive switching or variable transfers.

Phasor Angle Monitoring is another application BPA had for several years. BPA installed its first Phasor Angle Monitor in 1997 following the recommendations from August 10, 1996 power outage report. Poor data availability with the original research PMUs made the monitor unusable for real-time operations . BPA deployed a revised version of phasor angle displays in its control room as a part of the synchrophasor investment project in October 2013. Currently, there are no alarming or operating procedures for dispatchers associated with the phasor angle display. BPA is planning to initiate a study to determine on how to make phasor angle information actionable.

4.7.4 Wide-Area Controls

BPA’s wide-area synchrophasor RAS was implemented and approved by WECC as a safety net. BPA continues monitoring the RAS control performance with a goal of making the scheme operational in 2017. The new RAS could be used to remove some of the existing voltage stability constraints on dynamic transfers. BPA will continue researching other algorithms to improve voltage security in Pacific Northwest load centers and interties.

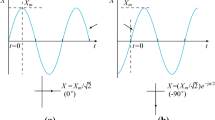

A team of technical staff from Sandia National Laboratories, Montana Tech, and BPA has developed and demonstrated a control system for damping of north–south oscillations in the Western Interconnection. The control system acquires measurements from PMUs located across the Pacific Northwest, and uses them as feedback information in constructing a power command signal. This control signal is used to modulate active power flow on the PDCI by as much as +/– 125 MW (of less than 4% its 3,220 MW-rated capacity). Extensive system studies were done to demonstrate the controller effectiveness in damping power oscillations (see Fig. 4.1), as well as robustness with respect to a wide range of generation patterns and contingencies. A major milestone was achieved in September 2016 when the control system was first tested in closed-loop operation. Tests were done under controlled conditions when the oscillation damping was already good. Still, the controller has shown more than 4% improvement in damping of the primary north–south oscillation mode when the control system was active (see Fig. 4.2). Test results were consistent with the study work performed, validating the effectives and robustness of the developed control system.

This is the first time that wide-area synchronized PMU measurements have been successfully demonstrated in real-time feedback control on a large-scale power grid in North America. Significant engineering effort went into making sure that the controller causes “no harm” to the grid under all possible operating conditions. A “watch dog” supervisory system was developed and implemented to monitor grid conditions, signal quality and latencies, PDCI status, and the controller hardware status. This project was supported by BPA Technology Innovation and the DOE Office of Electricity Transmission Reliability and Energy Storage programs.

Automated Generation Control (AGC) performs generation-load balancing functions. AGC systems in general do not recognize transmission system constraints. BPA suspends AGC during transmission contingencies that initiate RAS operation. Similarly to its synchrophasor RAS , BPA needs to consider adding condition-based rules to suspend/modify its AGC action. On August 10, 1996, AGC action to replace tripped generation at McNary with generation at Upper Columbia contributed to increased transmission system stress [2]. Phasor angles between Upper Columbia and interties were increasing well beyond safe operating levels. Suspending AGC when phasor angles exceed safe operating limits is being considered.

4.7.5 Collaboration and Technology Outreach

US Department of Energy and North American Synchrophasor Initiative have played a vital role in the advancement and deployment of the synchrophasor technology and its applications in North America. The DOE program funds development of new synchrophasor hardware and applications concepts, while NASPI coordinates industry learning, problem-solving, and strategy development to foster synchrophasor technology adoption and value realization. WECC’s Joint Synchronized Information Subcommittee and recently, NERC’s Synchronized Measurement Subcommittee have complemented DOE and NASPI with more hands-on, peer-to-peer synchrophasor deployment advice. BPA is committed to supporting DOE, NASPI, and NERC mission in advancing the synchrophasor technology outreach for grid reliability , resiliency, and adaptability to meet the challenges of large-scale renewable generation integration in the West. BPA will also continue playing a regional role in providing technical support to Northwest utilities with technology implementation and value proposition.

Over the years, BPA has established collaborative relationships with operating entities outside the Western Interconnection, specifically ISO New England, ERCOT, Dominion Virginia Power, and Oklahoma Gas and Electric. This type of collaboration helps BPA to appreciate new diverse perspectives and to learn from other’s operating experiences.

4.8 Synchrophasor Project Team

Executive Sponsors:

-

Jeff Cook, VP of Transmission Planning

-

Mike Miller, VP of Transmission Engineering

-

Michelle Cathcart, VP of Transmission Operations

-

Terry Oliver, Chief Technology Officer

PMU Deployment Project Management:

-

Lawrence Carter

Control Room Applications:

-

Pete Raschio (Manager), Nick Leitschuh (PM), Vincent Minden, Bill Wagner, Jeff Anderson, Kliff Hopson

Synchrophasor RAS team:

-

MayMay Adolf, Carldez Thomas, John Kerr, Gary Swoboda, Ziyuan Zhang, Kerry Bilyeu, Abebe Masho, Karl Knoll

Synchrophasor Laboratory:

-

Greg Stults, Tony Faris, Steve Yang

Technology Innovation:

-

Gordon Matthews

Transmission Engineering:

-

Steve Laslo, Caitlin Martin, Grisel Mendez, Joe Andres

Transmission Operations:

-

Margaret Albright (Manager), Jim Burns, Dan Goodrich, Ashley Donahoo, John Anasis, Eric Heredia, Bart McManus, Rian Sackett

Transmission Planning:

-

Melvin Rodrigues (Manager), Dmitry Kosterev (Editor), Jeff Cutter, Gordon Kawaley, Hamody Hindi, Dave Cathcart, Sergey Pustovit, Christina Lee, Sam Hirsi, Kalin Lee, Jeff Johnson.

4.9 Relevant Technology Innovation Projects

-

TIP-050—Oscillation Damping Controls

-

TIP-051—Voltage Stability Controls

-

TIP-052—Power Plant Dynamic Monitoring

-

TIP-274—Development and Demonstration of Applications for FCRPS Compliance with Model Validation Standards

-

TIP 281—Impacts Due to Dynamic Transfers (Maxisys)

-

TIP 289—Wide-Area Damping Control Proof-of-Concept Demonstration (Sandia, Montana Tech)

-

TIP 299—Synchrophasor Linear State Estimator and PMU Data Validation & Calibration

-

TIP 305—Data Integrity and Situational Awareness Tools (PNNL)

-

TIP-313—Power Frequency Controls

-

TIP 325—Real-Time System Operating Limits (SOL) Computation and Visualization for BPA (V&R Energy)

-

TIP-348—Measurement-Based Voltage Stability

-

TIP-349—Oscillation Baselining Application

-

TIP-350—Power Plant Monitoring Center

-

TIP-352—Development and Demonstration of a Phasor-Driven Tool for Adaptive Stability Model Calibration using GE PSLF (PNNL, General Electric)

Abbreviations

- BPA:

-

Bonneville Power Administration

- CERTS:

-

Consortium for Electric Reliability Technology Solutions

- CAISO:

-

California Independent System Operator

- COI:

-

California–Oregon Intertie

- DOE:

-

US Department of Energy

- EIM:

-

Energy Imbalance Market

- EPRI:

-

Electric Power Research Institute

- ERCOT:

-

Electric Reliability Council of Texas

- FCRPS:

-

Federal Columbia River Power System

- LBNL:

-

Lawrence Berkeley National Laboratory

- NASPI:

-

North American Synchrophasor Initiative

- NERC:

-

North American Reliability Corporation

- NREL:

-

National Renewable Energy Laboratory

- PNNL:

-

Pacific Northwest National Laboratory

- RAS:

-

Remedial Action Scheme

- TIP:

-

(BPA) Technology Innovation Project

- UVIG:

-

Utility Variable generation Integration Group

- WECC:

-

Western Electricity Coordinating Council

References

North American synchrophasor initiative. www.naspi.org

Taylor CW, Erickson DC (1997) Recording and analyzing the July 2 cascading outage. IEEE Trans Comput Appl Power 26–30. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=560830

Kosterev DN, Taylor CW, Mittelstadt WA (1999) Model validation for the August 10, 1996 WSCC system outage. IEEE Trans Power Syst 14(3): 967–979. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=780909

Taylor CW, Erickson DC, Martin KE, Venkatasubramanian V (2005) WACS—wide area stability and voltage control system: R&D and online demonstration. Proc IEEE 93(5):892–906. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=1428005

https://www.bpa.gov/news/newsroom/Pages/Synchrophasor-success-lands-BPA-its-first-Platts-Award.aspx

NERC (Sept 2016) Reliability guideline, power plant dynamic model verification using PMUs. http://www.nerc.com/pa/RAPA/rg/ReliabilityGuidelines/Reliability%20Guideline%20-%20Power%20Plant%20Model%20Verification%20using%20PMUs%20-%20Resp.pdf

Overholt P, Kosterev D, Eto J, Yang S, Lesieutre B (2014) Improving reliability through better models. IEEE Power Energy Mag 44–51. http://magazine.ieee-pes.org/files/2014/04/12mpe03-overholt-2301533.pdf

North American Synchrophasor Initiative (2015) Model validation using phasor measurement unit data: NASPI technical report, March 2015. [Online]. Available: https://www.naspi.org/documents

Federal Energy Regulatory Commission (2012) Comments of the Bonneville power administration under AD12–10, May 2012. http://elibrary.ferc.gov/idmws/file_list.asp?document_id=14023794

Kosterev D, Davies D (2010) System model validation studies in WECC. IEEE Power Eng Soc Meet. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=5589797

Kincic S, Davies, D, Kosterev D, Member H, Zhang B, Thomas M, Vaiman J, Ramanathan RW (2016) Bridging the gap between operation and planning models in WECC. IEEE Power Eng Soc Meet. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=7741091

Kosterev D, Davies D, Etingov P, Silverstein A, Eto J Using synchrophasors for frequency response analysis in the western interconnection

GIGRE 2014 grid of the future symposium, October 2014, http://cigre.wpengine.com/wp-content/uploads/2015/06/Using-Synchrophasors-for-Frequency-Response-Analysis-in-the-Western-Interconnection.pdf

WECC (2013) Modes of inter-area power oscillations in western interconnection Nov 2013. https://www.wecc.biz/Reliability/WECC%20JSIS%20Modes%20of%20Inter-Area%20Oscillations-2013–12-REV1.1.pdf

California ISO Flexible resource adequacy criteria and must-offer obligations. http://www.caiso.com/informed/Pages/StakeholderProcesses/FlexibleResourceAdequacyCriteria-MustOfferObligations.aspx

Kosterev D, Burns J, Lietschuh N, Anasis J, Donahoo A, Trudnowski D, Donnelly M, Pierre J (2016) BPA experience with oscillation detection application, in GIGRE 2016 grid of the future symposium, Oct 2016

IEEE Power System Dynamic Performance Committee (2012) Identification of electromechanical models in power systems. Technical Report PES-TR15, June 2012. http://sites.ieee.org/pes-resource-center/files/2013/11/TR15_Modal_Ident_TF_Report.pdf

Novosel D, Madani V, Bhargava B, Khoi V, Cole J (2008) Dawn of the grid synchronization. IEEE Power Energy Mag 49–60, Jan/Feb 2008. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=4412940

NASPI Technical Report (2015) The value proposition for synchrophasor technology—itemizing and calculating the benefits from synchrophasor technology use, Version 1.0, Oct 9, 2015. www.naspi.org

NASPI technical workshop on synchrophasor data and state estimation, Mar 25, 2015. www.naspi.org

FERC and NERC Report (2011) Arizona-Southern California outages on Sept 8, 2011. https://www.ferc.gov/legal/staff-reports/04-27-2012-ferc-nerc-report.pdf

Agrawal B, Kosterev D (2007) Model validation for a disturbance event that occurred on June 14 2004 in the western interconnection, presented at 2007 power engineering general meeting. Tampa, FL

Adams J, Carter C, Huang S-H (2012) ERCOT Experience with sub-synchronous control interaction and proposed remediation. IEEE PES transmission and distribution conference and exposition, May 2012. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=6281678

Acknowledgements

We gratefully acknowledge BPA engineers who paved the road to the deployment of the synchrophasor technology at BPA. Bill Mittelstadt, John Hauer, Carson Taylor, Jules Esztergalyos, and Ken Martin were among the first visionaries to recognize the value of the technology, develop the first synchrophasor network, research and prototype leading-edge applications. Support from John Haner, Susan Wiess and Don Watkins helped BPA to move through early stages of technology deployment.

BPA executives and management provided strong support and inspiration for the research, development, and deployment of the synchrophasor technology at BPA, including Vickie VanZandt, Brian Silverstein, and Larry Bekkedahl.

BPA synchrophasor investment project was unprecedented for the Agency with a very aggressive timeline. Jim Dow developed the initial project plan, schedule, and cost estimates. Scott Lissit served as a Project Manager during the critical first phase of the project. The successful execution of the synchrophasor investment project is attributed to BPA Project Management Organization.