Abstract

The anesthesia flowmeter is described as having a constant pressure and variable orifice. Gas flows under the float raising it until the bobbin or ball stops as its weight is supported by the pressure difference above and below. Flow tubes are specific to the physical characteristics of each gas. Flow rate is dependent on the viscosity of the gas at low, on laminar flow, and on density at higher turbulent flow. Flow rates are read at the top of a bobbin and the middle of a ball. Flowmeter leaks are downstream from all machine safety devices except the O2 monitor. In the presence of a flowmeter leak, hypoxic mixtures are less likely when the oxygen flowmeter is placed downstream from the others.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

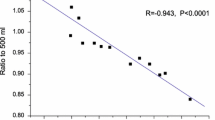

Fig. 80.1 Anesthesia flowmeter

-

1.

What are the physical principles of the anesthesia flowmeter?

-

2.

Describe the components of the flowmeter assembly.

-

3.

What are the concerns about flowmeter leaks?

-

4.

List the causes of inaccuracy in flowmeters.

Answers

-

1.

Operating principles of the conventional flowmeter

-

(a)

The anesthesia flowmeter is described as a constant pressure, variable orifice flow meter. Newer anesthesia machines may have electronic flowmeters; however, auxiliary O2 flowmeters of the conventional type may be present.

-

(b)

The glass flowmeter or Thorpe tube is tapered, smaller at the bottom and wider at the top (Fig 80.1). Gas flows under the float raising it until the bobbin or ball stops as its weight is supported by the pressure difference above and below.

-

(c)

Flow tubes are specific to the physical characteristics of each gas.

-

(d)

Gas flow at low rates is laminar and viscosity of the gas is important. Laminar flow is predicted by the Hagen-Poiseuille formula:

\( Q=\kern0.5em \frac{\pi \Delta \Pr 4}{8\eta l} \)

where Q is flow, ∆P is the pressure gradient (unchanged), R is the radius (variable as tube widens), ῃ is the viscosity (characteristic of each individual gas), and l is the length of the tube.

At higher flow rates, flow becomes turbulent as the Reynolds’ number exceeds 2000. With turbulent flow, the density becomes more important than viscosity:

\( {\mathrm{Reynolds}}^{'}\ \mathrm{number}=\kern0.5em \frac{\upsilon \rho r}{\eta} \)

υ, fluid linear velocity; r, radius; ρ, density; and ῃ, viscosity [1]

-

(e)

Floats are meant to rotate, minimizing friction.

-

(a)

-

2.

Components of flowmeter assembly

-

(a)

The flow control valve is manually controlled, turning counterclockwise. A needle valve disengages releasing the gas flow into the flowmeter. All gas flow from the flowmeter distally to the common gas outlet is in the low pressure circuit of the anesthesia machine.

-

(b)

The oxygen flow control is physically different; it is larger, has a fluted edge, and is color coded.

-

(c)

If a single gas has two flow tubes, they are placed in series and controlled by one valve.

-

(d)

The flow rate is read at the top of a bobbin and the middle of a ball. Float stops at the top and bottom of the tube to keep the float visible at high flows, giving an indication when flow is turned off, and prevent the float from becoming stuck at the top of the gas outlet.

-

(e)

Flowmeter scales are individually calibrated to the specific float and are gas specific. The tube, float, and scale are an inseparable unit [2].

-

(a)

-

3.

Leaks

-

(a)

Flowmeter leaks are downstream from the oxygen failure cutoff valve or “fail safe” valve. Hypoxic gas mixtures from a leak in the flowmeter may be detected by the O2 monitor, which is placed downstream.

-

(b)

Flowmeters are fragile and may leak from cracks or the O rings at either end. In the presence of a flowmeter leak, hypoxic mixtures are less likely when the oxygen flowmeter is placed downstream of the others. This is now the standard position. See Figs. 80.2 and 80.3. A crack in the O2 flowmeter, even placed last, may still result in a hypoxic gas mixture.

-

(c)

Being in the low pressure circuit, specific tests may be necessary to detect leaks. In general, if the machine does not have a check valve at the common gas outlet, the low pressure circuit may be tested with a positive pressure leak test. Machines with a check valve must be tested with a negative pressure leak test [3].

-

(a)

-

4.

Causes of inaccuracy include:

-

(a)

The tube that is not vertical distorts the annular flow.

-

(b)

Back pressure from ventilator may cause the float to drop, measuring less than the actual flow.

-

(c)

A float may become sticky from either a dirty flow tube or static electricity.

-

(d)

Flowmeters are calibrated at 20 °C and 760 mm Hg. The effect of temperature is minor; however at decreased atmospheric pressure, the density will be less, and with higher, turbulent flow, the actual flow will be greater than the set flow.

-

(a)

References

Aitkenhead AR, Moppett IK, Thompson JP. Smith & Aitkenhead’s textbook of anesthesia. 6th ed. Churchill Livingstone Elsevier; 2013.

Morgan EG, Mikhail MS. Clinical anesthesiology, Chapter 4, 4th ed.

Barash PG, Cullen BF. Clinical anesthesiology, Chapter 26, 6th ed. 2009.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Carter, J.B. (2017). Flowmeters. In: Raj, T. (eds) Data Interpretation in Anesthesia. Springer, Cham. https://doi.org/10.1007/978-3-319-55862-2_80

Download citation

DOI: https://doi.org/10.1007/978-3-319-55862-2_80

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-55861-5

Online ISBN: 978-3-319-55862-2

eBook Packages: MedicineMedicine (R0)