Abstract

Induced by the rise of online retailing new storage strategies have evolved, designed to meet the demands of e-commerce warehousing. Although many of these new approaches have established over the last few years, literature on basic planning problems in these environments can be found only rarely. This paper points out the special needs of e-commerce warehousing and details the scattered storage strategy (also known as mixed-shelves storage) where unit loads are unbundled and single items are stored at multiple positions within the warehouse. This way, an item of an ordered product is always close by and the unproductive walking time of pickers is reduced. Based on the paper of Weidinger and Boysen (Scattered storage: how to distribute stock keeping units all around a mixed-shelves warehouse. Working Paper Friedrich-Schiller-University Jena, 2015) [8], the scattered storage assignment problem is presented and the processes in a scattered storage warehouse are described.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

1 Introduction

E-commerce has gained a lot of importance in the recent years. However, consulting today’s literature on warehouse management one has to observe that the revolution of e-commerce is rarely considered. Instead—referring to storage assignment strategies—only the two classical approaches dedicated and shared storage can be found in many cases (see, e.g., [1]). This dichotomy, though, seems to be incomplete nowadays, as the rise of e-commerce has led to an emergence of new storage concepts supporting the needs of e-commerce warehousing much better than classical approaches.

The most important challenges to be tackled managing the logistic processes of an online retailer can be summarized under the following four points [9].

-

Small orders: Typically, consumers order only small quantities of products. According to the personal information of an Amazon warehouse manager, the vast number of orders contains only one or two items.

-

Large assortment: Pursuing the long tail strategy (see, e.g., [2, 5]), most online retailers have an assortment of goods much larger than classical retailers. The revenue of selling niche products often represents a significant part of the total revenue.

-

Scalability: The amount of orders to be processed is highly volatile, since it varies on different levels. Some seasons are more high-selling than others and the same can be observed for differing days of the week.

-

Tight delivery schedules: An important aspect of customer service is a fast delivery. This way, one of the most significant disadvantages of online shopping in comparison with retail shops, the lack of immediateness, is partly compensated. Most online retailers guarantee next day delivery and the percentage of shops offering same day delivery is growing. Amazons program Prime Now even provides a delivery within a 1-h timeframe after submitting the order. In consequence, all processes triggered by a customer order are highly time-critical.

One representative of the new generation of storage strategies tackling these challenges is the scattered storage strategy. Like most of its companions, scattered storage can rarely be found in today’s literature although it is implemented in a vast number of warehouses worldwide, including basically all European Amazon warehouses. This paper, at first, details the basic idea of scattered storage as well as important processes in a scattered storage warehouse (Sect. 2.1). Afterwards, the scattered storage assignment problem by Weidinger and Boysen [8] is described (Sect. 2.2) and their most important findings on scattered storage warehouses are pointed out (Sect. 2.3). Finally, the paper is summarized (Sect. 3).

2 The Scattered Storage Strategy

The basic idea of the scattered storage strategy is to unbundle unit loads in the receiving area and store single items of one stock keeping unit (SKU) at differing positions within the warehouse, furnished with head-high shelves (low-level picking [4]). To use space more efficiently, items of different SKUs are assigned to the same storage bays of so-called mixed-shelves. Having multiple storage positions per SKU tends to always have an item of an ordered SKU close by, irrespective of the position within the warehouse. Based on this concept, highly performant and scalable picking processes especially suited for the needs of online retailers can be implemented. One possible implementation of the picking process in such a scattered storage warehouse is detailed in the following. The example is based on the description of processes in European Amazon warehouses by Weidinger and Boysen [8].

2.1 The Picking Process in a Scattered Storage Warehouse

To use the height of a building although having implemented a low-level picking strategy, Amazon warehouses are often constructed as multi-mezzanine systems. Each level is furnished with head-height shelves arranged in a rectangular layout. However, a picker, typically, remains on a single floor of the system during the picking process and changes stories only in exceptional cases. As the mean order volume is small, batching is implemented to utilize full picker capacity. Avoiding an additional sorting step subsequent to the picking process, each picker is equipped with a small maneuverable cart providing one standardized bin for each order currently picked.

Not having a structured and, consequently, learnable allocation of SKUs, pickers are highly reliant on an information system. Therefore, each picker carries a handheld scanner providing information about the next storage position to be visited as well as the name and quantity of the SKU to be picked. Guided by the device, the picker heads towards the storage position and, once arrived, scans the storage bay as well as the article to be picked before he/she adds it to the corresponding bin. The scanning process ensures that the right article is picked and, additionally, tags the storage position as available for restocking in the underlying warehouse management system.

Once an order is completely picked, the worker can hand off the bin containing all demanded items to a conveyor system, which transports it to the packing and shipping area of the warehouse. Entrances to this conveyor system are available at multiple positions spread all over the warehouse. At each station of this so-called distributed depot system the picker can obtain new empty bins to refresh the capacity of the picking cart, while new picking instructions are made available via the handheld scanner. In consequence, the picking tours are not bound to a central point of the warehouse anymore. Instead, the pickers roam the warehouse continuously, finalizing old and receiving new picking orders as well as empty bins at the distributed depot system. When processing heterogeneous orders of small volume, this strategy leads to a highly performant picking process.

Leaving behind the concept of a central depot, however, classical storage assignment strategies will fail, as they are grounded on a centralized layout. Weidinger and Boysen [8] identify this deficit in research and present a storage assignment strategy especially suited for scattered storage warehouses. Their approach is detailed in the next section.

2.2 The Scattered Storage Assignment Problem

The intention of the storage assignment problem is to support the picking process best. Therefore, classical approaches tend to assign SKUs with a high turnover rate near to the depot and SKUs demanded less frequently to more remote storage positions [1]. This way, SKUs to be picked more often can be found close to the start and end point of each tour, resulting in shorter picking tours on average. Planning the assignment in a scattered storage warehouse, however, the initial position of the picker is not available, as it could be each of the numerous stations of the distributed depot system. Therefore, Weidinger and Boysen [8] suggest maximizing the scatter of items. This way, the average length to reach the nearest item of a given SKU is shortened, irrespective of the actual position of the picker.

To quantify the scatter of an assignment, they introduce so-called measuring points, which could be interpreted as possible start points of a tour. However, these measuring points are not necessarily located at depot stations, but rather at strategically chosen locations. The objective of the presented scattered storage assignment problem is to find a feasible assignment \(\varGamma \) such that the maximum distances to reach the nearest item of each SKU \(i \in I\) starting from an arbitrary measuring point \(\tau \in D\) are minimized. An assignment is feasible if none of the storage positions \(s \in S\) is assigned more than once and all \(n_i\) items of each SKU \(i \in I\) are allocated to compatible storage positions, given by the subsets \(S_i \subseteq S\). Restrictions on storage positions (\(\exists i \in I: S_i \ne S\)) may be caused by product size or weight, for example.

To avoid shortages, not all storage positions have been emptied when planning a new assignment. Therefore, the distance to reach an item of SKU i starting from measuring point \(\tau \) is bounded by the distances to the already assigned items. The bounds are given by problem parameters \(\delta _{\tau i}\), while the shortest distances to newly assigned items are assumed to be returned by the function \(\mathfrak {d}_{\tau i}(\varGamma )\) depending on the storage assignment \(\varGamma \). Based on this notation, the objective value of an assignment \(\varGamma \) is calculated as given in formula 1. Note that Weidinger and Boysen [8] use a weighted sum of maximum distances. A higher weight \(w_i\) of SKU i might represent that it is more time-critical or more fast-moving than other SKUs and, therefore, has to be considered with a higher priority.

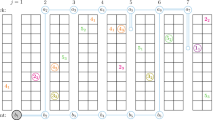

Example: An instance of the storage assignment problem is depicted in Fig. 1. The warehouse has ten storage positions (see Fig. 1a). Four of them are open to be reassigned to two items of SKU 1 and one item of SKU 2 and 3, respectively. SKU 2 is weighted by 2, while the remaining SKUs have a weighting factor of 1. As distances are measured by the number of squares to be crossed to reach the given storage position starting from the considered measuring point, the \(\delta \)-values can be derived from the sketch of the warehouse. Note that the shelves are accessible only via non-cross aisles such that \(\delta _{41}\) is 4 rather than 2. The feasible assignment \(\varGamma _1\) (see Fig. 1b) improves the maximum distances given by the \(\delta \)-values significantly. The objective value of this assignment amounts to \(F(\varGamma _1) = 13\).

Weidinger and Boysen [8] formulate the optimization problem outlined above as a mixed integer model and prove NP-hardness in the strong sense. Additionally, they present suited heuristics to solve instances of real-world size in an adequate quality. Based on this, an extensive simulation study is realized. Its most interesting findings are summarized in the next section.

2.3 Effects of an Optimized Storage Assignment

Storage assignments are not optimized in most scattered storage warehouses. Instead, items are allocated to storage positions in a randomized manner. Weidinger and Boysen [8] show that picking tours are shortened by up to 20% on average and up to 50% in maximum when the storage assignment is planned more carefully using their optimization approach. Note that the picking tours are determined employing a modified nearest neighbor heuristic introduced by Daniels et al. [3]. While picker routing in a rectangular warehouse with single storage positions per SKU is a solvable case of the traveling salesman problem [6], picker routing in a rectangular scattered storage warehouse becomes NP-hard due to multiple available storage positions per SKU [7]. For this reason, a heuristic approach is used in the simulation study.

Furthermore, the replenishment level is identified as an important impact factor in the simulation study. Weidinger and Boysen [8] define it as the percentage of storage positions still occupied when replenishment takes place. Therefore, having a constant pick rate, a lower replenishment level leads to longer time intervals between two replenishment iterations. When using the randomizing assignment strategy, the picking process is supported best when replenishment is performed in short intervals. This way, the average quantity of storage positions per SKU is higher, resulting in shorter picking tours. Naturally, this effect is observable for optimized assignments as well. However, a second (antagonistic) effect is relevant for the optimizing strategy. As the storage assignment is manipulated by the picking process permanently, imbalances regarding the scatter may occur. These imbalances can better be fixed when the replenishment level is lower. This way, more open storage positions are available when planning the assignment and, consequently, a higher degree of scatter can be obtained, resulting in shorter picking tours on average, too. When using the optimizing approach, the replenishment level has to be selected such that both effects are properly traded off against each other, consequently.

Considering the higher effort for replenishment when using the optimizing strategy, Weidinger and Boysen [8] additionally study effects on the total effort including picking and replenishment. Even then the optimizing approach excels in scenarios where using scattered storage is expedient.

3 Conclusion

This paper treats the challenges in e-commerce warehousing, having led to a whole new generation of warehousing strategies. As a representative of these new approaches, the scattered storage strategy is detailed. With the help of the scattered storage assignment problem introduced by Weidinger and Boysen [8] the need for novel approaches for solving classical planning problems (e.g., storage assignment) in those new environments is demonstrated. The basic idea of the storage assignment strategy is outlined and the most important findings are summarized.

References

Bartholdi III, J.J., Hackman, S.T.: Warehouse & Distribution Science. Release 0.96. Supply Chain and Logistics Institute (2014)

Brynjolfsson, E., Hu, Y., Smith, M.D.: Consumer surplus in the digital economy: estimating the value of increased product variety at online booksellers. Manage. Sci. 49, 1580–1596 (2003)

Daniels, R.L., Rummel, J.L., Schantz, R.: A model for warehouse order picking. Eur. J. Oper. Res. 105, 1–17 (1998)

De Koster, R., Le-Duc, T., Roodbergen, K.J.: Design and control of warehouse order picking: a literature review. Eur. J. Oper. Res. 182, 481–501 (2007)

Elberse, A.: Should you invest in the long tail? Harvard Bus. Rev. 86, 88 (2008)

Ratliff, H.D., Rosenthal, A.S.: Order-picking in a rectangular warehouse: a solvable case of the traveling salesman problem. Oper. Res. 31, 507–521 (1983)

Weidinger, F.: Picker routing in rectangular mixed shelves warehouses. Working Paper Friedrich-Schiller-University Jena (2016)

Weidinger, F., Boysen, N.: Scattered storage: how to distribute stock keeping units all around a mixed-shelves warehouse. Working Paper Friedrich-Schiller-University Jena (2015)

Weidinger, F., Boysen, N., Schneider, M.: Picker routing in the mixed-shelves warehouses of e-commerce retailers. Working Paper Friedrich-Schiller-University Jena (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Weidinger, F. (2018). A Precious Mess: On the Scattered Storage Assignment Problem. In: Fink, A., Fügenschuh, A., Geiger, M. (eds) Operations Research Proceedings 2016. Operations Research Proceedings. Springer, Cham. https://doi.org/10.1007/978-3-319-55702-1_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-55702-1_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-55701-4

Online ISBN: 978-3-319-55702-1

eBook Packages: Business and ManagementBusiness and Management (R0)