Abstract

Exploiting full microbial capacities constitutes one of the challenges ahead of fermentation technology. Microbial preservation undoubtedly plays a key role in ensuring maximum production outputs while displaying full structural properties during any fermentative upstream approach. Over the past years, novel techniques have emerged as an alternative to conventional preservation methodologies for maintaining the cellular properties during long-term storage. This chapter addresses the recent advances in the preservation of microbial cultures, highlighting the relevance of emerging methods on maintaining the cellular viability. The key relationship between the cellular fitness and how novel preservation methods can shield the microbial cells from undesired stress responses is also described. Finally, this chapter provides a comprehensive overview on the challenges for the adoption of novel preservation technologies for fermentation, including their latest applications.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

2.1 Introduction

Over last two decades, the maintenance of structural properties and bioconversion abilities of microbial cell factories during long-term storage has become increasingly important in the industrial manufacturing of functional foods , pharmaceuticals , biofuels, and biochemicals. Nowadays, robust upstream cell propagation schemes are essentially needed to achieve cost-competitive and efficient bio-based processes. As microbial preservation constitutes the first step in any upstream bio-production approach, both cellular propagation and subsequent scale-up processes are influenced by the degree of cellular stability achieved during the post-cultivation and storage stages. In fact, the scenario is featured by an ever-growing development of novel strategies with an aim to ensure both higher storage stability and functionality of microorganisms. Among those upstream operations, cell preservation undoubtedly plays a key role in ensuring a complete and efficient microbial cell propagation, while maintaining metabolite titers, yields, and productivities during any scale-up process.

Within the current bio-economy context, exploiting full microbial capacities while implementing robust upstream processes is of prime importance for achieving cost-effective scalable bioprocesses . In fact, productive degeneration may arise due to non-optimized and unsuitable cell preservation approaches. Loss of cellular functionality through the seed propagation trains has thus prompted the development of novel preservation techniques towards ensuring an optimum cellular stability during long-term microbial storage. Such instability and lack of cellular robustness can undoubtedly be translated into reduced fermentation performances accompanied with unpredictable metabolic responses. As a result, the novel preservation technologies developed during the last decade are playing a key role in preventing microbial productive degeneration throughout the fermentation process. Furthermore, cell preservation is one of the main challenges ahead of the development and application of efficient probiotics systems for functional foods (Jankovic, Sybesma, Phothirath, Ananta, & Mercenier, 2010). In particular, industrial starter cultures including lactic acid bacteria are sensitive to stressful conditions and the long-term stability of these microorganisms is strongly compromised during their production, storage, and end use. Industrial operations (e.g., freeze drying , spray drying) can negatively influence on the microorganisms’ viability and their technological properties . Though many attempts have been made to increase microorganisms’ stability during various downstream processing stages, improving the survival rates is still one of the major challenges in industrial starters and probiotics production (Lacroix & Yildirim, 2007). Apart from their long-term storage, cellular stability of probiotics constitutes another challenge to provide beneficial health effects.

Drying and cryopreservation are the most commonly employed techniques for long-term microbial cell preservation. Both preservation strategies entail deleterious impacts on viability, stability, and functionality of microorganisms, hence to achieve balance between stabilization and cell damage is critical in pursuing an efficient cell preservation strategy. Though freeze-drying is widely employed in long-term storage, spray drying has been the chosen technique for microbial dehydration due to its high processing flexibility as well as cost-effectiveness at industrial settings (Schuck, Dolivet, Méjean, Hervé, & Jeantet, 2013). Even though cryopreservation methods are featured by the loss of viability, both cryotolerance and functionality of microbial culture can be improved depending on processing variables employed. In fact, the interaction of factors such as the use of low cooling rates and cryoprotective agents has been the focus of several studies in the last decade with an aim to improve cell viability and long-term stability. Additionally, the use of sophisticated analytical tools has enabled researchers to characterize the physiological cell responses at the single-cell level while understanding the impact of processing strategies on cellular robustness. All these recent advances have contributed to convert microbial cell preservation into an exciting area of research.

This chapter overviews the latest advances in microbial cell preservation along with novel bioprocessing strategies to enhance cellular viability and stability during long-term storage. Technological challenges as well as novel cell preservation methods which can foster the development of functional foods are also discussed.

2.2 Conventional Approaches for Long-Term Microbial Preservation

Efficient drying processes are of prime importance for achieving long-term storage stability since the degree of stabilization of the microbial cultures is directly related to the moisture content. Traditionally, microbial cells have been preserved over long term through cryopreservation or freeze drying (Fig. 2.1). The cryopreservation is the most preferred technique for safeguarding microbial cultures in biological resource centers (Heylen, Hoefman, Vekeman, Peiren, & De Vos, 2012, Peiren et al., 2015). Table 2.1 highlights key advantages and hurdles of some microbial cell preservation techniques.

2.2.1 Freeze-Drying

Freeze-drying is the most frequently employed technique for drying of microorganisms. The freeze-dryin g process is based on sublimation which occurs in three phases involving a freezing step followed by two stage drying processes under a high vacuum. Though it is an expensive technique for preserving microbial cells at industrial scale, freeze-drying confers long-term stability without culture transfers, retaining high cell viability after long-term storage periods (Kupletskaya & Netrusov, 2011). As the process involves a freezing step, cellular damages may arise due to the formation of crystals and osmotic stresses. To protect cells against such damages during the freeze-dryin g a wide range of lyoprotectants, e.g., skim milk , sugars can be added to the drying media before freeze-drying.

When sensitive microorganisms like lactic acid bacteria (LAB) are involved, freeze-drying can even result in the loss of microbial viability and stability in the presence of effective protectants (Carvalho et al., 2004a). To this end, novel methodologies have been sought with the aim of overcoming such limitations. One of those simple approaches combined skim milk and activated charcoal as a carrier material for the long-term preservation of sensitive microorganisms (Malik, 1990). In this way, the good thermal conductive properties of activated charcoal can minimize the freezing degree of the cells during the evacuation process, resulting in a simple methodology to retain a high genetic stability and viability during long-term storage (Malik, 1990).

The choice of the lyoprotectant has a major impact on the storage survival. Thus, standardized freeze-drying protocols for delicate or recalcitrant strains such as Campylobacter, Aeromonas, and Vibrio can result in freeze-dried products of reproducible viability during long-term storage (Peiren et al., 2015). In addition to the importance of the freezing media, characteristics of the cell surface must be taken into account during a freeze-drying process (Otero, Espeche, & Nader-Macías, 2007). Such cell surface features are strain dependent, and are particularly relevant in strong autoaggregative microbial strains. In fact, increased sensibility to a freeze-drying process can be attained due to the large surface area of the cellular aggregates formed when an autoaggregative strain is processed (Otero et al., 2007).

Freezing rate also plays a key role during downstream processes as part of an end-product or to prepare an intermediate product for subsequent freeze-drying process (Volkert, Ananta, Luscher, & Knorr, 2008). The freezing rate affects the location of ice nucleation, size and the growth of crystal, determining the degree of cellular damage of frozen microbial cells (Fonseca, Béal, & Corrieu, 2001). Regardless the low probability of intracellular ice formation, the osmotic-driven migration of water can lead to an increased intracellular solute concentration which can be deleterious for the cells under high freezing rates (Volkert et al., 2008). Generally, higher freezing rates are preferred from economic perspective. Cellular injuries due to the mechanical forces generated by ice crystals can also occur if the freezing rates are high. Feasible alternatives proposed by Volkert et al. (2008) include using spray freezing to produce a controlled spray of high surface area to volume ratio droplets which rapidly cool down below the freezing point or using pressure shift freezing, which avoids ice formation through a supercooling process in which nucleation occurs instantly.

Innovative microbial preservation technologies involving instant drying steps for the long-term storage without requiring freezing processes have also been described for their application in culture collections. Interestingly, a simple storage system involving of a pre-dried activated charcoal cloth-based matrix within a resealable system was developed by Hays, Millner, Jones, and Rayner-Brandes (2005). The adsorption of the microorganism onto the fibers reduced the stresses exerted to the cells thus improving cell viability upon rehydration (Hays et al., 2005). Though the developed approach seems promising, its wider applicability for drying of various microorganisms has not been investigated.

2.2.2 Spray Drying

Spray drying is the most efficient dehydration technique for the preservation of microbial cultures at industrial scale since it can be carried out in a continuous mode (Peighambardoust, Tafti, & Hesari, 2011). Specifically, the technique involves the evaporation of water through the atomization of a homogeneous solution into a drying chamber. The application of high temperatures is necessary to facilitate water evaporation along the process, and to deliver good storage stability by obtaining final moisture content between 4 and 7 % (Peighambardoust et al., 2011). However, one critical factor in spray drying processes is the high temperatures (85–90 °C) applied during the process, which can lead to heat and osmotic cellular stresses with deleterious impacts on sensitive microorganisms (Ananta, Volkert, & Knorr, 2005). Scalable production has been achieved but stresses generated during the process are still recognized as a major drawback in the applicability of this technology for the large-scale production of microbial dried powders (Fu & Chen, 2011). Though feasibility of spray drying technique is strain dependent, spray drying is recognized as a cost-effective technology in probiotics manufacturing with about ten times lower operational costs compared to freeze-drying (Schuck et al., 2013). Over the last few years, several technical innovations including low heat treatments have emphasized the versatility of spray drying processes in the production of starter cultures and probiotics. In terms of cell viability, the outcome of this technique depends on the addition of protective carrier matrices to offer protection against the high drying temperatures. Carrier matrices like skim milk or polydextrose-based prebiotic substances have been demonstrated to have an effective protection capacity, achieving a cell survival rate of 60 % at an outlet temperature of 80 °C (Ananta et al., 2005). However, the long-term stability of the probiotic cells is affected if polyhydroxylated carbohydrate -based substances are not able to replace water molecules effectively (Ananta et al., 2005).

2.2.3 Fluid Bed Drying

To date, fluid bed drying has been underutilized despite its major potential in cell preservation processes. Specifically, fluid bed drying involves the evaporation of water from wet powder or particles using hot air (Aldabran, Chatzifragkou, Khutoryanskiy, & Charalampopoulos, 2015). Among the advantages of fluidized bed drying, rapid heating and a short drying period, low cost, and easy handling convert fluid bed drying into a promising technology for the manufacturing of stable dried probiotic and starter cultures. However, the lack of extensive research on the cell viability limits its current widespread adoption.

2.2.4 Freezing and Frozen Storage

Cryopreservation remains as the main long-term cell preservation method to date due to its high survival rates. Microorganisms can be cryopreserved at low or ultra-low temperature without genetic or phenotypic alterations while maintaining cell viability (Tedeschi & De Paoli, 2011). Whereas cryopreservation of microbial strains at cryogenic temperatures (<−150 °C) generally results in higher survival rates (Heylen et al., 2012) compared to those stored at −20 °C. Cell viability is severely affected due to the formation of large ice crystals at freezing temperature and can lead to mechanical damage of cell membranes (Tedeschi & De Paoli, 2011). Thus, control of ice crystals is important for improved survival rates.

Among the operating conditions, the temperature, freezing rate, and freezing time play a vital role in maintaining the biological activities during storage. In fact, the lower the temperature and the shorter the duration, the higher acidification activity is preserved in probiotics (Fonseca et al., 2001). Fonseca et al. (2001) reported that cell resistance to freezing and frozen storage can be improved by using a high freezing rate (30 °C/min) and a low storage temperature (−70 °C). Specifically, the freezing rate determines the outcome of the freezing process since mechanical damages may arise due to the presence of ice crystals either inside or outside of the microbial cells. Whereas cellular damages are caused by the extracellular ice accumulation at low freezing rates, high freezing rates have the advantage of forming a glassy rather than a crystallization state (Fonseca et al., 2001). The importance of a homogeneous and earlier freezing process in the cryopreservation of fungal strains has been emphasized by Missous, Thammavongs, Dieuleveux, Guéguen, and Panoff (2007). These authors developed an artificial nucleation and temperature downshift control by adding an industrial ice nucleator protein from biological origin which led to enhanced viability of cells, when subjected to freezing-thawing cycles (Missous et al., 2007).

Despite its major industrial relevance, most fungi cultures are still preserved by repeated subculturing in which a continuous growth is attained by serial transfers (Homolka, 2014). However, it does not prevent genetic and physiological alterations during long-term maintenance. As a result, cryopreservation at low temperatures has been proposed as an efficient approach to preserve cell functionality (growth, morphology, production of metabolites) in basidiomycetes (Homolka, 2014). Though the genetic stability has been proved, further research is needed since most of the novel protocols entail partial suppression of growth and metabolism of the fungus (Camelini et al., 2012).

In the beverage industry, the long-term maintenance method used for brewer’s yeast also plays a key role on maintaining yeast vitality and final beer characteristics (Matoulková & Sigler, 2011). To date, subculturing on agar and cryopreservation have been the preferred approaches for long-term yeast maintenance. Other preservation approaches like freeze-drying are not suitable for long-term maintenance of a brewer’s yeast due to the low cell recovery and the viability loss. However, repeated subculturing may lead to time-dependent genetic instability as well as modifications in the flocculation process. Though cryopreservation is the most successful protocol, brewer’s yeast cells are sensitive to freeze-thaw stress. To overcome such hurdle, novel cryopreservation protocols have incorporated different levels and types of cryopreservants as well as appropriate equilibration times and cooling rates to prevent membrane damage and the disturbance of cellular organelles (Matoulková & Sigler, 2011). Though the sedimentation ability and viability were not affected in the long-term storage, desired technological properties like the production of beer flavor compounds were enhanced using cryopreserved cells, suggesting the suitability of cryopreservation as a long-term preservation protocol for brewer’s yeast cells (Matoulková & Sigler, 2011).

Interestingly, a novel freezing technology called Cell Alive System (CAS) has recently been developed for the immediate preservation of environmental samples (Morono et al., 2015). By applying an alternating magnetic field during the freezing process, a super-cooled liquid phase is created, achieving a uniform freezing process with minimal crystal formation. Such methodology offers stability with minimal loss of viability, suggesting its major potential for preserving fastidious microorganisms (Morono et al., 2015).

2.3 Protective Agents Used in Preservation Processes

The main goal behind any microbial culture preservation technique is to ensure greater cell viability after the downstream processes. Though there is no golden rule behind the formulation of preservation media, it is generally accepted that the inclusion of protectants provides shield against the deleterious effects encountered during cell processing operations and subsequent storage. As a result, cell survival after cryopreservation or dehydration processes can be greatly enhanced by adding extra protective components like cryoprotectants or antioxidants to the media.

2.3.1 Cryoprotective Additives

Microbial preservation has traditionally been carried out by reducing the temperature in order to achieve improved stability. As a rule of thumb, higher microbial viability is preserved at lower storage temperature. If the storage temperature is below the freezing point, cryoprotectants are essential to reduce cell damage from the freezing process. Though loss of viability is inevitable, novel commercial solutions and procedures are already available to minimize the impact of the freezing process and further long-term storage.

Cryoprotectants, also known as lyoprotectants in freeze-drying processes, are additives mixed with the microbial suspensions before freezing to minimize the deleterious influence of ice crystal formation and to lower the freezing point during the freezing processes. Glycerol, dimethylsulfoxide (DMSO), and non-permeable additives like polysaccharides are currently used as cryoprotectants in microbial cultures. These cryoprotective additives are adsorbed to the surface of the microorganisms, coat the cells and therefore provide shield from ice crystals formation during long-term storage. Glycerol conversely acts as a membrane permeant and facilitates the vitrification process by replacing the water in the cells and making hydrogen bonds with water molecules to exert a protective effect (Martin-Dejardin et al., 2013).

Most freeze-drying cell preservation protocols include skim milk as drying medium since it stabilizes the cell membrane constituents by creating a protective coating over the cells (Carvalho et al., 2004a). Protein- and carbohydrate -based matrices have also employed as cryoprotectants. However, the ratio of protection is strain dependent (Hubálek, 2003). The synergistic combination of several cryoprotectants can provide higher protective effects than each component separately (Navarta, Calvo, Calvente, Benuzzi, & Sanz, 2011). With the use of rapidly penetrating agents, both osmotic stress and the formation of extracellular ices are prevented (Hubálek, 2003). Likewise, the presence of antioxidants in the media has been shown to display a protective role by reducing the cryoscopic point of the matrix (Fonseca, Béal, Mihoub, Marin, & Corrieu, 2003). In fact, low ice crystal formation is achieved during freezing and frozen storage when binary and multicomponent solutions including antioxidants (e.g., betaine and sodium glutamate) are included in the protective media (Fonseca et al., 2003). Amino acids can also act as cryoprotectors in lactobacilli by increasing the mobility of the fatty acids acyl chains in the membrane core region (Martos, Minahk, Font de Valdez, & Morero, 2007).

The incorporation of unconventional materials to the bacterial suspensions prior to freeze-drying can also help to shield the microbial cells from membrane damage. Recently, in an alternative approach to freeze-drying processes , the use of dry rice cakes has been described as a small-scale and low-tech application for preserving yeasts (Nyanga, Nout, Smid, Boekhout, & Zwietering, 2012). Specifically, the rice starch provided hydroxyl groups for the attachment of the yeast cells, forming a glassing structure and protecting the yeast cells from damage without requiring freeze-drying (Nyanga et al., 2012).

2.3.2 Sugar Preservatives

Sugars have been used for long time as preservatives in freezing and freeze-drying processes due to their ability to replace water during dehydration while maintaining the biological structures in hydrated status (Carvalho et al., 2004a; Hubálek, 2003). In addition to the water replacement ability, sugars are able to form glassy structures which slow down the molecular interactions within the cytoplasm (Hubálek, 2003). Sugars also provide good protection to the microbial cells by replacing the water in the membrane after dehydration and preventing aggregation of proteins by hydrogen bonding with polar groups (Champagne, Gardner, Brochu, & Beaulieu, 1991).

The effect of adding different mixture of ingredients as carriers and thermoprotectants (starch , whey protein concentrate, maltodextrin, etc) in the survival rate is strain dependent. In fact, the intrinsic differences in the glass transition temperatures of such mixtures provide different grade of protection against cell damage (Carvalho et al., 2004a). By using the synergistic combination of skim milk and sugars like sucrose or lactose, the cell viability loss can be reduced after a drying process . In fact, skim milk is responsible to form a protective coating on the cell wall which results in the stabilization of the membrane constituents (King & Su, 1994). Similarly, sugars like trehalose (Li et al., 2011; Nyanga et al., 2012) or lactose (Ananta et al., 2005; Chen, Ferguson, Shu, & Garg, 2011) prevent the formation of ice crystals during drying processes . In addition, the protective effect exerted by polyhydroxylated compounds such as trehalose can be enhanced by adding antioxidants like monosodium glutamate to the carrier medium (Sunny-Roberts & Knorr, 2009). Such synergistic combinations can contribute to maintain not only the membrane integrity and fluidity, but also the enzymatic activity of key metabolic enzymes (Basholli-Salihu, Mueller, Salar-Behzai, Unger, & Viernstein, 2014; Li et al., 2011). However, most of the studies involving the use of cryoprotectants in freeze-drying processes have not demonstrated enough long-term stability (>80 % survival after 1 year) of the freeze-dried bacteria at room or refrigeration temperatures (Corveleyn, Dhaese, Neirynck, & Steidler, 2012). Novel formulations containing alternative cryoprotectants like starch hydrolysate and polyols are being developed to confer long-term stability to the freeze-dried microorganisms (Corveleyn et al., 2012).

In addition to dairy-based carriers such as skim milk , low cost dairy by-products including cheese whey have been proposed as effective growth and protective media. Thus, the formulation of lactobacilli media with cheese whey not only provides a potential low cost growing medium but also acts as a cryoprotectant (Burns, Vinderola, Molinaru, & Reinheimer, 2008; Lavari, Páez, Cuatrin, Reinheimer, & Vinderola, 2014). Cheese whey can be also exploited as growth media and encapsulation matrix within a coupled fermentation and spray drying process which avoids the harvesting and resuspension stages found in multistage processes (Jantzen, Göpel, & Beermann, 2013).

Cryotolerance can be induced by choosing the proper medium formulation for growing the microorganisms. Thus, incorporation of sugars like glucose and fructose , as well as polyols like sorbitol in the formulation of growth medium rather than only in the drying matrix has been found to enhance the protection of lactobacilli (Carvalho et al., 2004b; Siaterlis, Deepika, & Charalampopoulos, 2009). However, ultimate protective effect depends on the sugar uptake capacity of the strain since growth medium will not enhance the cell resistance to drying processes unless sugars are transported inside the cell (Carvalho et al., 2004b).

The composition of the drying matrices also plays a key role during freeze-dryin g of yeast cells. In fact, excipients like maltose and maltodextrins or their mixtures have been found to preserve the viability of Saccharomyces cerevisiae cells (Lodato, Segovia de Huergo, & Buera, 1999). The hydrogen bonding capacity of disaccharides plays a critical role in maintain the membrane integrity and protein structures during freeze-dryin g processes (Lodato et al., 1999).

2.3.3 Galacto-Oligosaccharides and Prebiotic Compounds as Novel Cryoprotectant Agents

Galacto-oligosaccharides (GOS) are polyhydroxylated carbohydrate -based compounds composed by a variable number of galactose units linked to two to eight glucose monomeric units. In addition to their role as prebiotics, GOS have recently gained commercial interest as effective cryoprotectants (Tymczyszyn, Gerbino, Illanes, & Gómez-Zavaglia, 2011). Their protectant capacity is explained on basis to three hypotheses. The first one, known as the vitrification hypothesis, is based on the formation of glassy states which maintains the cells in a vitreous state during storage. The second hypothesis involves the replacement of water by compounds, leading to the interaction between sugars and polar heads of lipids , and decreasing the phase transition temperature of membranes . A third potential mechanism during dehydration-rehydration processes proposes that sugars are excluded from the surface, concentrating water molecules close to the surface and preserving the native structure of the biomolecules (Tymczyszyn et al., 2011). Therefore, the presence of different side chains along GOS structure may present an advantage to interact with biomolecules and to form glassy structures where biomolecules are embedded.

Though the use of polysaccharides with high vitreous transition temperatures does not guarantee appropriate cell preservation. GOS exert great protective capacity due to their high vitreous transition temperatures. In this sense, the synergistic combination of two prebiotic compounds like GOS and lactulose has been found to promote the protection of lactobacilli against freezing processes (Santos, Gerbino, Araujo-Andrade, Tymczyszyn, & Gomez-Zavaglia, 2014). The combination leads to the formation of glassy matrices in which molecular interactions are limited due to the high viscosity and low mobility conditions generated (Santos, Gerbino, et al., 2014; Tymczyszyn et al., 2011). In addition to their protective capacity during the dehydration process, GOS mixtures with high content of tri- and tetra-saccharides can also exert a membrane protective role upon rehydration (Santos, Araujo-Andrade, Esparza-Ibarra, Tymczyszym, & Gómez-Zavaglia, 2014). Upon dehydration, GOS stabilize the membrane native structure through the replacement of water molecules and by forming hydrogen bonds around the polar groups from the phospholipids and proteins (Tymczyszyn et al., 2011). Nevertheless, such protective effect is heavily influenced by the temperature and water content conditions achieved during storage period. In fact, higher survival rates can be attained at lower water content and lower storage temperatures (Tymczyszyn et al., 2012).

In addition to GOS, prebiotics (e.g., inulin and fructo-oligosaccharides (FOS)) have recently been proposed as protective agents of lactic acid bacteria during freeze-drying (Schwab, Vogel, & Ganzle, 2007). In fact, the resulting increased stability and enhanced membrane integrity can be attributed to direct interactions between FOS and the cell membrane, leading to increased membrane fluidity and stability (Schwab et al., 2007). The self-protected symbiotic products generated by supplementing probiotics with compounds like GOS and FOS bear the potential of opening up new commercial applications since such compounds exert both prebiotic and protecting effects.

2.4 Novel Emerging Preservation Technologies

Over the last decade, novel strategies have emerged as complementary approaches to the conventional preservation methodologies. Approaches like microencapsulation or the application of sublethal stresses have emerged as simple and effective strategies to improve cellular properties while preserving the cellular functionality during subsequent processing and storage.

2.4.1 Cellular Immobilization: A Novel Approach for Microbial Preservation

Cellular immobilization has been proposed as an efficient alternative to increase the stability of the microorganisms during the cultivation stage. As opposed to freezing and freeze-dryin g which may entail irreversible protein denaturation and membrane damages with deleterious effects on cell viability (Carvalho et al., 2004a), microencapsulation has become a feasible technique for shielding the cells while increasing their stability during storage. In general, the effectiveness of encapsulation as cell preservation approach depends on the method as well as the type and concentration of the entrapment material employed. Parameters like size, porosity, and texture also affect the grade of protection exerted to the microorganism (Aldabran et al., 2015). In addition, the nature of the coating material can also promote cell protection as well as increase the effectiveness of the encapsulation process.

Over the last years, microencapsulation has been particularly prolific in the probiotics field since the application of this technique may provide a controlled release of probiotic cells in the human gut under favorable conditions. Though there are several available techniques, extrusion, emulsification, and spray drying are the three major entrapping techniques for probiotics encapsulation into a gel matrix using an ionotropic gel forming mechanism (Martín, Lara-Villoslada, Ruiz, & Morales, 2015). Recent studies have also highlighted the high storage stability achieved in probiotic cultures through the combination of microencapsulation and dehydration processes (Aldabran et al., 2015). Thus, fluidized bed dried capsuled displayed higher cell survival rates due to the structural collapse and shrinkage observed upon the storage period. Though the protective mechanisms behind the process are not clearly understood, Aldabran et al. (2015) observed an increased agglomeration of the fluidized bed dried powders compared to freeze-dried powders.

Microencapsulation in calcium alginate has been also proposed as an alternative methodology for entrapping probiotic strains, protecting them against freezing temperatures (Sousa et al., 2012). When stored at −80 °C, encapsulation provided a protective effect upon viability in probiotic strains in absence of cryoprotectants (Sousa et al., 2012). In contrast, encapsulation in alginate was not able to exert protection to the encapsulated probiotic cells at −20 °C since major physical changes including larger particle size, loss of spherical shape, and porous net damages were found after a short-term period (Sousa et al., 2015). Interestingly, such results open up the possibility of incorporating probiotics into food matrix that require storage below freezing temperatures without the use of cryoprotectants (Sousa et al., 2012).

Microencapsulation has also been proposed as a feasible approach to increase the cell viability of probiotic strains like Enterococcus during drying processes , storage, and gastrointestinal transit (Kanmani et al., 2011). As long-term preservation of entrapped microorganisms requires the dehydration of beads, freeze-drying is usually employed to dry the immobilized beads. However, as previously pointed out, dehydration through freeze-dryin g involves an oxidative stress which might induce an osmotic shock to the microbial cells. To increase microbial cell protection during freeze-dryin g, cryoprotective agents are integrated into the entrapment media. As a result, the protective effect exerted by microencapsulation can be also increased by adding trehalose and sucrose (Kanmani et al., 2011) or lactose and trehalose to the entrapment media (Nag & Das, 2013). Moreover, the incorporation of trehalose as cryoprotectant and sodium ascorbate as an antioxidant into the formulation has been found to improve the survival of bifidobacteria after freeze-dryin g (Martin-Dejardin et al., 2013). Thus, the synergistic combination of both compounds leads to replace the water in the cell during the dehydration process while the antioxidant combats the mechanical contraction and osmotic shock during freeze-drying (Martin-Dejardin et al., 2013).

Cell entrapment in inorganic matrices has emerged as alternative methodology for long-term cell preservation without the need for exposing the microorganisms to harsh temperatures. Thus, entrapping cells in a silicon dioxide-derived matrix has been proposed as an effective cell preservation methodology for microorganisms which tend to suffer genetic instability and to lose its metabolite production capabilities during long-term storage (Desimore et al., 2005). Immobilization into a porous hydrophilic polymer which provides a mechanical strength and thermal stability can be an alternative for long-term preservation of genetic unstable microorganisms.

In addition to the conventional microencapsulation methodologies, immobilization using dry biopolymers has recently become an effective approach to maintain cell viability and functionality during long-term storage (Sorokulova et al., 2012, Sorokulova, Olsen, & Vodyanoy, 2015). This novel microbial preservation methodology allows the cells to be entrapped in water -soluble polymers like acacia gum or pullulan through a spontaneous polymerization and water replacement process which results in the formation of a protective stable film (Sorokulova et al., 2015). As a result, the biopolymer-based film generated is able to protect the microorganisms under several humidity conditions without requiring cold storage (Krummow et al., 2009). In particular, acacia gum seems to trap bound water, preventing complete dehydration of the cell cytoplasm and maintaining the water balance of live cells while increasing their viability (Krummow et al., 2009; Sorokulova, Krummow, Pathirana, Mandell, & Vodyanoy, 2008). This novel cell preservation technology appears to be particularly well suited for preserving spore-forming microorganisms like Bacillus without requiring prior time-consuming spore preparation steps (Krummow et al., 2009). Furthermore, spore immobilization in a matrix including acacia gum and porous carriers has led to a 60-fold increase in spore life time at room temperature, suggesting its major potential as long-term spore preservation technique (Sorokulova et al., 2008).

2.4.2 Electrospinning and Electrospraying

High-voltage electrohydrodynamic processes like electrospinning and electrospraying have recently emerged as novel microencapsulation techniques to preserve the viability of sensitive microorganisms. Electrospinning and electrospraying are atomization processes that use an electrically charged jet of polymer solution to form nanoscale and microscale fibers or particles (Fig. 2.2). In addition to their promising food-based applications, both electrospinning and electrospraying have recently emerged as an efficient entrapping methodology for preserving microorganisms due to their high surface area to volume ratios and high permeability (López-Rubio, Sanchez, Wilkanowicz, Sanz, & Lagaron, 2012). Specifically, the thin polymeric fibrous material generated in electrospinning processes allows the entrapped cells to exchange nutrients and metabolic products while retaining their metabolic activity (Liu, Rafailovich, Malal, Cohn, & Chidambaram, 2009) (Fig. 2.2). Both electrohydrodynamic processes can use a wide range of support matrices for cell entrapment, including protein-based materials like whey protein isolate and whey protein concentrate, and polysaccharides like chitosan , cellulose , or alginate (Bhushani & Anandharamakrishnan, 2014). In addition to the versatile use of a wide range of supports, electrohydrodynamic processes offer the advantage of not requiring temperature control, so deleterious impacts on the microbial physiology due to high processing temperatures can be avoided. Such relevant features have converted electrospinning and electrospraying into simple and effective microencapsulation methodologies with potential applications in the development of functional foods (López-Rubio, Sanchez, Sanz, & Lagaron, 2009; López-Rubio et al., 2012).

Recently, electrospinning has been successfully applied for entrapping of bifidobacterial strains by forming electrospun fibers which enabled to maintain high microbial viability despite the drastic osmotic change and electrostatic field generated during the encapsulation process (López-Rubio et al., 2009). Aside from the high cell viability achieved, the incorporation of microbial cells into electrospun nanofibers through electrospinning offers advantages in terms of protein stability and functionally that are hardly achievable with conventional microencapsulation methodologies (Canbolat et al., 2013).

Electrospraying, featured by the atomization of a liquid flow into droplets, has likewise been employed for encapsulating probiotic strains onto protein-based (López-Rubio et al., 2012) or polysaccharide-based matrices (Laelorspoen, Wonsasulak, Yoovidhya, & Devahastin, 2014). Thus, microencapsulation through electrospraying in whey protein concentrate effectively prolonged the survival of bifidobacterial cells even under high relative humidity conditions in comparison to freeze-dried cells (López-Rubio et al., 2012). Microcapsules generated by electrospraying have been able to maintain the viability even under harsh acidic conditions, suggesting an effective probiotics delivery vehicle in the gastrointestinal tract (Laelorspoen et al., 2014).

Though remarkable structural advantages have been obtained by using electrohydrodynamic processes in comparison to conventional dehydration processes, their encapsulation efficiency and long-term stability have not been evaluated so far. Undoubtedly, microencapsulation through electrohydrodynamic processes presents great potential for probiotics in food applications due to their capacity to maintain high cell viability. Nonetheless, further studies on the feasibility for using other probiotic strains and microorganisms as well as optimized operating conditions are required for potential commercial exploitation.

2.4.3 Use of Stressful Bioprocessing Conditions for Enhancing Microbial Preservation

Increasing the cellular robustness during the cell propagation stage is of paramount significance in many cell preservation protocols. The application of sublethal stress bioprocessing strategies has lately emerged as an effective approach to enhance cellular robustness during cultivation and prior to downstream processing . Table 2.2 overviews the main bioprocessing strategies used to increase the cell resistance against downstream processes. Though the concept is not new, significant new advances with a particular focus on probiotics manufacturing have come to the fore in the last years (Muller, Ross, Fitzgerald, & Stanton, 2009). Thus, the exposure of microorganisms to sublethal stresses has shown to increase cell viability and resistance against subsequent downstream processes. When cells are exposed to sublethal stresses, repair mechanisms, morphology changes, and excretion of molecules are involved in the cellular response which leads to a higher tolerance against stressful conditions. The frequency and intensity of the stress shocks eventually determine whether positive cross-tolerance mechanisms are induced or not. In this sense, the application of sublethal stresses during the fermentation stage has become an effective strategy to increase cell tolerance.

Among the potential strategies to enhance post-fermentation viability, the application of heat or cold shock treatments has been found to increase the tolerance of starter cultures against freezing and freeze-drying processes (Broadbent & Lin, 1999). Specifically, heat shock (42 °C for 25 min) and cold shocks (10 °C for 2 h) induced changes in the cell membrane lipid composition which resulted in increased cryotolerance and post-fermentation viability (Broadbent & Lin, 1999).

In an interesting approach, stochastic exposure to a sublethal high temperature has been found to improve the cell survival ability of bifidobacteria to freeze-drying processes (Nguyen et al., 2014). Cells displayed higher cell resistance to freeze-drying when applied to a sublethal heat shock of 42 °C for a period in a range of 100–300 s during cultivation stage. In fact, such heat shock induced a stress resistance in bifidobacteria, featured by the increase in exopolysaccharides synthesis and excretion, which shielded the cells from deleterious impacts during the post-fermentation and subsequent downstream processing stages. As a result, higher cell survival rates upon cell recovery and further freeze-drying steps were obtained in bifidobacteria (Nguyen et al., 2014).

Other bioprocessing approaches to increase cell resistance against spray drying processes include the application of mild stresses during cell cultivation. In particular, the heat and oxidative challenges encountered during spray drying of lactobacilli were counteracted by the application of a mild heat stress (Lavari et al., 2015). Likewise, the application of mild heat treatment processes (52 °C for 15 min) upon cultivation stage has been found to enhance the survival of lactobacilli to spray drying and further post-drying storage (Páez et al. 2013). Such enhanced cell functionality was additionally translated into better endurance to gastrointestinal digestion conditions (Páez et al. 2012, 2013), suggesting that the application of sublethal stresses during the cell cultivation stage may contribute not only to enhance post-drying stability but also to promote the cell resistance of probiotic foods.

Increasing the osmotic stress at the beginning of fermentation has revealed to enhance the cell survival rate of probiotics during storage (Louesdon, Charlot-Rougé, Juillard, Tourdot-Maréchal, & Béal, 2014). Thus, the application of osmotic shocks at the beginning and end of the fermentation can induce the accumulation of osmoprotectants like betaine while maintaining a high acidification activity and survival rate during the storage (Louesdon, Charlot-Rougé, Juillard, et al., 2014). In fact, a 200-fold increase in the viability of freeze-dried lactobacilli was found after applying an osmotic shock with NaCl during cell production stage (Koch, Oberton, Eugster-Meier, Melle, & Lacroix, 2007). Such osmotic shocks not only help to attain a balanced osmotic pressure while preserving the protein functions inside the cells, but also increase membrane fluidity.

In lactobacilli, submitting cells to nutrient starvation conditions after cell cultivation has been found to be positive in inducing cryotolerance (Wang, Delettre, Corrieu, & Béal, 2011). The adaptive responses found against the starvation conditions cross-protected lactobacilli from cold stresses, enhancing therefore their resistance to freezing and frozen storage. Interestingly, such cross-protection phenomenon entailed an increase of membrane fluidity as well as a stress response involving the upregulation of the proteins involved in carbohydrate and energy metabolisms and pH homeostasis (Wang et al., 2011). Analysis of membrane composition and proteome revealed that the cellular adaptive response in lactobacilli starved cells was similar to the freeze-thaw resistance developed by Escherichia coli under starvation conditions (Gawande & Griffiths, 2005). Undoubtedly, a rational compromise between starvation conditions and culture production yield must be established to develop a cross-protection phenomenon against drying processes .

Increased viability of S. cerevisiae upon freeze-drying processes can also be targeted after applying mild acid stresses to yeast cultures (Chu-Ky, Vaysse, Liengprayoon, Sriroth, & Le, 2013). Chu-Ky et al. (2013) found that the viability of the acid-adapted cells (pH = 3.5) was significantly higher than non-stressed cells. Specifically, the induced cross-protection mechanism involved an increase in the fatty acid saturation degree as well as an intracellular accumulation of reserve carbohydrates in the form of glycogen (Chu-Ky et al., 2013). Similarly, the application of an acid adaptation step before freeze-drying has been found to improve the cryotolerance in probiotic cells (Streit, Delettre, Corrieu, & Béal, 2008). The exposure to an acidic condition (pH = 5.25) for 30 min at the end of the fermentation improved the cryotolerance by inducing a cross-protection phenomenon. In such case, the physiological cell responses were featured by the overexpression of proteins involved in energy metabolism and nucleotide synthesis as well as by the decrease in unsaturated to saturated and cyclic to saturated membrane fatty acid ratios (Streit et al., 2008).

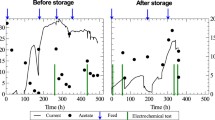

The implementation of specific bioprocessing conditions must be taken into consideration when production and downstream processes are integrated. In fact, cell growth and resistance are strongly affected by the fermentation conditions adopted during the cell production stage (Velly, Fonseca, Passot, Delacroix-Buchet, & Bouix, 2014). Parameters such as pH , harvesting time (e.g., late exponential vs. late stationary growth phase) and fermentation temperature can strongly influence cell resistance upon drying processes . In addition, the nature of the fermentation medium can also include protective compounds. In certain probiotic strains, loss of acidification activity during refrigerated temperature storage can be counteracted by improving the bioprocessing conditions. Thus, the increase in the fermentation temperature along with appropriate pH control strategies and harvesting time at stationary growth phase made possible to reduce the loss of acidification activities during storage at refrigerated temperatures (Velly et al., 2014). Therefore, an enhanced cell resistance can be obtained through a tunable control of the bioprocessing conditions during the production stage.

The harvesting time strongly influences the cell resistance upon processing and storage. In general, cells harvested at the stationary growth phase are more resistant than cells harvested at the exponential growth phase since the former ones develop a general stress resistance . In lactobacilli, increasing the harvesting time from early to the late stationary growth phase did not damage the quality of the culture in terms of biomass concentration or acidification activity, but in turn it did have strong impact on the acidification activity (Broadbent & Lin, 1999). The optimization of cell fermentation stage prior cell concentration can therefore confer an advantage against loss of cell viability during dehydration processes.

In yeasts, drying and rehydration processes may not only induce membrane permeabilization, but also result in the loss of metabolic activity (Pénicaud et al. 2014). Such physiological changes have shown to be ameliorated by harvesting the yeast cells at stationary growth phase (Pénicaud et al. 2014). As a result, stationary growth phase cells displayed increased metabolic activities and higher cell viability than cells harvested at the exponential growth phase.

In addition to the harvesting time, cell cryotolerance in probiotics can be induced through a fine-tune pH control during the fermentation stage. As emphasized in several studies, fermentation pH plays a relevant role on the stability of freeze-dried probiotics. In this sense, the implementation of suboptimal pH conditions during the production stage can trigger beneficial stress-induced physiological responses while improving the stability of lactobacilli upon cell recovery (Saarela et al., 2005). Thus, cell cryotolerance can be induced by culturing lactobacilli at suboptimal pH conditions (pH = 5) in comparison to lower cell functionalities attained under higher pH values (pH = 6) (Rault, Bouix, & Béal, 2010). The impact of combining different fermentation pH control values and harvesting times was also explored by Ampatzoglou, Schurr, Deepika, Baipong, and Charalampopoulos (2010). These authors observed that the acid tolerance and the survival ability of Lactobacillus rhamnosus GG during freeze-dryin g were highly affected by both factors. Whereas late exponential phase cells from pH-controlled fermentations survived significantly better than cells from uncontrolled-pH cultures, late exponential phase cells were more acid resistant regardless of the pH control conditions (Ampatzoglou et al., 2010). Accordingly, fermentation conditions and harvesting time heavily impact on the degree of resistance displayed by the cells upon freeze-drying. In fact, bioprocessing conditions like the accumulation of lactic acid and the reducing conditions reached at the end of lactobacilli fermentations can result in major changes in the membrane composition and therefore enhanced cryotolerance (Louesdon, Charlot-Rougé, Tourdot-Maréchal, Bouix, & Béal, 2014).

In lactobacilli, the cell resistance to freezing and frozen storage conditions can therefore be strongly affected by the cell physiological state resulting from the bioprocessing conditions implemented during the cell production stage. In contrast, harvesting time has shown no significant impact on the storage stability of freeze-dried bifidobacteria (Saarela et al., 2005). Nevertheless, there is supporting evidence that the implementation of sublethal stress strategies as well as optimized bioprocessing conditions can result in enhanced cell cryotolerance.

2.5 Role of Viability in Cell Preservation Techniques

Regardless of the cell preservation technique employed, the maintenance of cell viability across the processing and storage stages is the main goal behind any cell preservation approach. When microorganisms are subjected to dehydration processes, the membrane integrity and fluidity are strongly compromised, leading to a concomitant loss of metabolic activity and viability (Ananta et al., 2005). In freezing processes, the degree of cellular damage including the loss of membrane integrity is influenced by the size of ice crystals as well as location of ice nucleation and crystal growth (Volkert et al., 2008). Membrane damage, and eventually the cell viability, has also been affected by the freezing rate (Cao-Hoang, Dumont, Marechal, Le-Thanh, & Gervais, 2008) or the cold osmotic shock applied during long-term supercooling processes (Moussa, Dumont, Perrier-Cornet, & Gervais, 2008). Therefore, both cell viability and physiological cell responses are intimately linked to the degree of protection achieved during the preservation process.

As both the cell survival ratio and physiological changes play important roles in developing efficient cell preservation protocols, monitoring and characterization such responses at the single-cell level have also been the focus of research in the last decade. Thus, multiparameter flow cytometry has recently appeared as a high-throughput tool to assess metabolic and structural changes at the single-cell level, providing accurate information on injured cell subpopulations that cannot be detected by classical cell counting methods. The application of this technique has therefore enabled not only to quantify the number of viable but nonculturable cells but also to determine the changes in the metabolic activity and the membrane integrity of cells subjected to freezing and frozen storage (Chen et al., 2011, Chen, Cao, Fergusson, Shu, & Garg, 2012; Rault, Béal, Ghorbal, Ogier, & Bouix, 2007). Important aspects like the cell resistance of freeze-dried cells against acid stresses (Chen et al., 2011) or the impact of adding different cryoprotectants to the freezing media (Chen et al., 2012) have also been characterized by using multiparameter flow cytometry . Rault et al. (2007) have also employed this high-throughput analytical technique to evaluate the cryotolerance of LAB cultures after freezing and during frozen storage. In addition, the impact of applying lesser deleterious temperatures during fluidized bed drying in lactobacilli viability has also been assessed through flow cytometry (Bensch et al., 2014). Such better understanding on the physiological responses of lactobacilli at the single-cell level has enabled technical improvements like the use of larger size of fluid nozzles to reduce the mechanical stress during spray drying (Ananta et al., 2005) or the addition of sorbitol to prevent the membrane -associated cell injuries in fluidized bed drying processes (Bensch et al., 2014). Similarly, the information about the membrane damage, depolarization, and metabolic activity of bifidobacteria enabled to decipher the real impact of thermal stresses during spray drying at the single-cell level (Salar-Behzadi et al., 2013).

Maintenance of the cell viability upon cell immobilization is paramount to various applications. Flow cytometry -based protocols have been successfully applied to monitor the cell viability after being microencapsulated (Canbolat et al., 2013) and freeze-dried (Martin-Dejardin et al., 2013). Though cell immobilization can be a useful strategy for cell preservation as it provides a protective microenvironment, the maintenance of high cell viability and high metabolic activity status are not always attained upon cell entrapment (Alonso, Rendueles, & Díaz, 2015).

As previously highlighted, cell viability of lactobacilli can be strongly affected by bioprocessing strategies applied during the fermentation stage. In fact, membrane integrity, cell polarization, and metabolic activity of lactobacilli are strongly reliant on the pH control or the harvesting time conditions adopted (Alonso, Rendueles, & Díaz, 2014; Rault, Bouix, & Béal, 2008). The implementation of enhanced bioprocessing conditions on basis to the information provided by flow cytometry is therefore important in guaranteeing that microorganisms display maximum cell viability ratios before the downstream processes.

2.6 Challenges Associated to Cell Preservation Techniques in Probiotics

One of the main technological challenges encountered during probiotics manufacturing is ameliorating the cell death while maintaining the cellular functionality during the downstream processes and subsequent storage (Lacroix & Yildirim, 2007). Considering that starters are usually supplied in powdered form, the development of novel formulations containing probiotics needs to meet such requirements (Tripathi & Giri, 2014). In particular, both lactobacilli and bifidobacteria are very sensitive to process-related stress conditions. In fact, dehydration processes like freeze-drying entail stressful conditions with deleterious impacts on cellular viability. In addition, fine tuning of operating conditions like the freezing rate during freeze-drying processes has limited influence on retaining the full integrity of the cellular membrane . Balancing the optimal freezing rates along with the incorporation of cryopreservants to the freezing media can therefore arise as potential solutions to ameliorate the deleterious effects encountered during freezing processes.

Another important aspect is the impact of the osmotic response in the cell viability during long-term storage. For that reason, the degree of cryotolerance achieved during the cell production stage may pave the way for enhanced functionality upon storage. Strategies like the addition of complementary cryoprotectants to the growth media or the exposure to sublethal stress levels during the fermentation stage may lead to significant improvements in the cryotolerance ability of probiotic cells. Overall, increasing cell viability through the implementation of novel processing strategies as well as the synergistic combination of protective agents and preservation methods constitutes an important step in developing robust probiotics with attractive technological properties .

2.7 Industrial Biotechnology: Attempts to Increase the Viability During Cell Preservation

One of the main drawbacks of large-scale bio-based production lies in the over-time productive degeneration of the microbial cell platforms which can result in uncompetitive bio-production yields. Cellular degeneration with lower metabolite-producing abilities and unstable production profiles may appear if rationale preservation procedures are not implemented. Effective methodologies for culture preservation are important to ensure that the cellular properties and the biosynthetic pathways are not affected during long-term storage. In fact, such long-term genotypic and phenotypic stability will guarantee an optimum post-preservation recovery (Prakash, Nimonkar, & Shouche, 2013). A proper preservation protocol additionally would ensure a short lag phase, maximizing the success of any resuscitation step after long-term storage.

Loss of stability and productive degeneration are among the reasons for productivity failures during the seed train development in industrial bioprocesses . In addition to the instability and loss of productive metabolic capacity of the microbial cells during storage, undesired phenotypes and physiological states may arise due to wrong preservation approaches. In fact, the loss of desired traits constitutes a common feature found in bioprocesses after several repeated transfer stages, with major detrimental effects in the upstream stage during any up-scaling approach. As a result, long-term failures at industrial scale may arise due to a wrong seed train development (Fig. 2.3). Recently, an interesting approach involving the addition of butanol to the storage solution has been developed to prevent productive degeneration of clostridia involved in acetone-butanol-ethanol fermentation processes (Liu, Gu, Liao, & Yu, 2014). Maintaining the cells in a storage solution containing glycerol and butanol at 37 °C not only prevented productive degeneration but also enhanced the cellular robustness of Clostridium acetobutylicum. The developed 1-butanol-glycerol storage procedure led to enhanced butanol tolerance, cell viability, and biobutanol productivities (Liu et al., 2014). Alternative methodologies involving the use novel protective formulations have been also explored to prevent productive degeneration in recombinant protein-producing (Desimore et al., 2005) or enzyme -producing microbial cell factories (Pinotti, Silva, Zangirolami, & Giordano, 2007). All these approaches have highlighted the importance of optimizing the cell preservation stage as cornerstone to achieve enhanced productive yields during the scaling-up process.

2.8 Concluding Remarks

The maintenance of cell viability remains as one of the most important challenges in food and industrial biotechnology. Novel cell preservation methods, with higher viability as well as higher stability of the genetic material and metabolism during long-term storage, will definitely pave the way for better yields and production outputs. As a result of better cell preservation processes, robust seed train propagation processes will also enable to enhance the metabolite titers while reducing the failure numbers during the large-scale production at industrial settings.

Likewise, the development of functional foods will be benefited by the advances in the cell preservation field. Undoubtedly, the inclusion of cryoprotective additives is increasingly becoming important in the development of robust dehydration processes for probiotics and starters manufacturing. In particular, the application of novel analytical tools will not only enable to study whether the novel cryopreservation approaches involve changes in terms of physiological and functional properties, but also pave the way for the development of innovative formulations for microbial preservation. Though there are already implemented robust preservation protocols, it is necessary to bridge the gap between the most efficient drying methods and the maintenance of cell viability aiming at taking advantage of the great technological potential offered by probiotics and industrial starters.

References

Aldabran, H. A., Chatzifragkou, A., Khutoryanskiy, V. V., & Charalampopoulos, D. (2015). Stability of probiotic Lactobacillus plantarum in dry microcapsules under accelerated storage conditions. Food Research International, 74, 2018–2216.

Alonso, S., Rendueles, M., & Díaz, M. (2014). Physiological heterogeneity in Lactobacillus casei fermentations on residual yoghurt whey. Process Biochemistry, 49, 732–739.

Alonso, S., Rendueles, M., & Díaz, M. (2015). A novel approach to monitor stress-induced physiological responses in immobilized microorganisms. Applied Microbiology and Biotechnology, 99, 3573–3583.

Ampatzoglou, A., Schurr, B., Deepika, G., Baipong, S., & Charalampopoulos, D. (2010). Influence of fermentation on the acid tolerance and freeze drying survival of Lactobacillus rhamnosus GG. Biochemical Engineering Journal, 52, 65–70.

Ananta, E., Volkert, M., & Knorr, D. (2005). Cellular injuries and storage stability of spray-dried Lactobacillus rhamnosus GG. International Dairy Journal, 15, 399–409.

Basholli-Salihu, M., Mueller, M., Salar-Behzai, S., Unger, F. M., & Viernstein, H. (2014). Effect of lyoprotectants on β-glucosidase activity and viability of Bifidobacterium infantis after freeze-drying and storage in milk and low pH juices. LWT--Food Science and Technology, 57, 276–282.

Bensch, G., Rüger, M., Wassermann, M., Weinholz, S., Reichl, U., & Cordes, C. (2014). Flow cytometric viability assessment of lactic acid bacteria starter cultures produced by fluidized bed drying. Applied Microbiology and Biotechnology, 98, 4897–4909.

Bhushani, J. A., & Anandharamakrishnan, C. (2014). Electrospinning and electrospraying techniques: Potential food based applications. Trends in Food Science & Technology, 38, 21–33.

Broadbent, J. R., & Lin, C. (1999). Effect of heat shock or cold shock treatment on the resistance of Lactococcus lactis to freezing and lyophilization. Cryobiology, 39, 88–102.

Burns, P., Vinderola, G., Molinaru, F., & Reinheimer, J. (2008). Suitability of whey and buttermilk for the growth and frozen storage of probiotic lactobacilli. International Journal of Dairy Technology, 61, 156–164.

Camelini, C. M., Pena, D. A., Gomes, A., Steindel, M., Rossi, M. J., Giachini, A. J., et al. (2012). An efficient technique for in vitro preservation of Agaricus subrufescens (=A. brasiliensis). Annals of Microbiology, 62, 1279–1285.

Canbolat, M. F., Gera, N., Tang, C., Monian, B., Rao, B. M., Pourdeyhimi, B., et al. (2013). Preservation of cell viability and protein conformation on immobilization within nanofibers via electrospinning functionalized yeast. ACS Applied Materials & Interfaces, 5, 9349–9354.

Cao-Hoang, L., Dumont, F., Marechal, P. A., Le-Thanh, M., & Gervais, P. (2008). Rates of chilling to 0°C: Implications for the survival of microorganisms and relationship with membrane fluidity modifications. Applied Microbiology and Biotechnology, 77, 1379–1387.

Carvalho, A. S., Silva, J., Ho, P., Teixeira, P., Malcata, F. X., & Gibbs, P. (2004a). Relevant factors for the preparation of freeze-dried lactic acid bacteria. International Dairy Journal, 14, 835–847.

Carvalho, A. S., Silva, J., Ho, P., Teixeira, P., Malcata, F. X., & Gibbs, P. (2004b). Effects of various sugars added to growth and drying media upon thermotolerance and survival throughout storage of freeze-dried Lactobacillus delbrueckii ssp. bulgaricus. Biotechnology Progress, 20, 248–254.

Champagne, C. P., Gardner, N., Brochu, E., & Beaulieu, Y. (1991). The freeze-drying of lactic acid bacteria: A review. Canadian Institute of Food Science and Technology, 24, 118–128.

Chen, S., Cao, Y., Fergusson, L. R., Shu, Q., & Garg, S. (2012). Flow cytometric assessment of the protectants for enhanced in vitro survival of probiotic lactic acid bacteria through simulated human gastro-intestinal stresses. Applied Microbiology and Biotechnology, 95, 345–356.

Chen, S., Ferguson, L. R., Shu, Q., & Garg, S. (2011). The application of flow cytometry to the characterisation of a probiotic strain Lactobacillus reuteri DPC16 and the evaluation of sugar preservatives for its lyophilisation LWT-Food. Science and Technology, 44, 1873–1879.

Chu-Ky, S., Vaysse, L., Liengprayoon, S., Sriroth, K., & Le, T. M. (2013). Acid adaptation for improvement of viability of Saccharomyces cerevisiae during freeze-drying. International Journal of Food Science and Technology, 48, 1468–1473.

Corveleyn, S., Dhaese, P., Neirynck, S., & Steidler, L. (2012). Cryoprotectants for freeze drying of lactic acid bacteria. US 2012/0049853 A1.

Desimore, M. F., De Marzi, M. C., Copello, G. J., Fernández, M. M., Malchiodi, E. L., & Diaz, L. E. (2005). Efficient preservation in a silicon matrix of Escherichia coli, producer of recombinant proteins. Applied Microbiology and Biotechnology, 68, 747–752.

Fonseca, F., Béal, C., Mihoub, F., Marin, M., & Corrieu, G. (2003). Improvement of cryopreservation of Lactobacillus delbrueckii subsp. bulgaricus CFL1 with additives displaying different protective effects. International Dairy Journal, 13, 917–926.

Fonseca, F., Béal, C., & Corrieu, G. (2001). Operating conditions that affect the resistance of lactic acid bacteria to freezing and frozen storage. Cryobiology, 43, 189–198.

Fu, N., & Chen, D. (2011). Towards a maximal cell survival in convective thermal drying processes. Food Research International, 44, 1127–1149.

Gawande, D., & Griffiths, M. (2005). Growth history influences starvation-induced expression of uspA, grpE, and rpoS and subsequent cryotolerance in Escherichia coli O157:H7. Journal of Food Protection, 68, 1154–1158.

Hays, H. C. W., Millner, P. A., Jones, J. K., & Rayner-Brandes, M. H. (2005). A novel and convenient self-drying system for bacterial preservation. Journal of Microbiological Methods, 63, 29–35.

Heylen, K., Hoefman, S., Vekeman, B., Peiren, J., & De Vos, P. (2012). Safe guarding bacterial resources promotes biotechnological innovation. Applied Microbiology and Biotechnology, 94, 565–574.

Homolka, L. (2014). Preservation of live cultures of basidiomycetes—Recent methods. Fungal Biology, 118, 107–125.

Hubálek, Z. (2003). Protectants used in the cryopreservation of microorganisms. Cryobiology, 46, 205–229.

Jankovic, I., Sybesma, W., Phothirath, P., Ananta, E., & Mercenier, A. (2010). Application of probiotics in food products—Challenges and new approaches. Current Opinion in Biotechnology, 21, 175–181.

Jantzen, M., Göpel, A., & Beermann, C. (2013). Direct spray drying and microencapsulation of probiotic Lactobacillus reuteri from slurry fermentation with whey. Journal of Applied Microbiology, 115, 1029–1036.

Kanmani, P., Kumar, R. S., Yuvaraj, N., Paari, K. A., Pattukumar, V., & Arul, V. (2011). Effect of cryopreservation and microencapsulation of lactic acid bacterium Enterococcus faecium MC13 for long-term storage. Biochemical Engineering Journal, 58, 140–147.

King, V. A. E., & Su, J. T. (1994). Dehydration of Lactobacillus acidophilus. Process Biochemistry, 28, 47–52.

Koch, S., Oberton, G., Eugster-Meier, E., Melle, L., & Lacroix, C. (2007). Osmotic stress induced by salt increases cell yield, autolytic activity, and survival of lyophilization of Lactobacillus delbrueckii subsp lactis. International Journal of Food Microbiology, 117, 36–42.

Krummow, A. A., Sorokulova, I. B., Olsen, E., Globa, L., Barbaree, J. M., & Vodyanoy, V. J. (2009). Preservation of bacteria in natural polymers. Journal of Microbiological Methods, 78, 189–194.

Kupletskaya, M. B., & Netrusov, A. I. (2011). Viability of lyophilized microorganisms after 50-year storage. Mikrobiologiya, 80, 842–846.

Lacroix, C., & Yildirim, S. (2007). Fermentation technologies for the production of probiotics with high viability and functionality. Current Opinion in Biotechnology, 18, 176–183.

Laelorspoen, N., Wonsasulak, S., Yoovidhya, T., & Devahastin, S. (2014). Microencapsulation of Lactobacillus acidophilus in zein-alginate core-shell microcapsules via electrospraying. Journal of Functional Foods, 7, 342–349.

Lavari, L., Ianniello, R., Páez, R., Zotta, T., Cuatrin, A., Reinheimer, J., et al. (2015). Growth of Lactobacillus rhamnosus 64 in whey permeate and study of the effect of mild stresses on survival to spray drying. LWT--Food Science and Technology, 63, 322–330.

Lavari, L., Páez, R., Cuatrin, A., Reinheimer, J., & Vinderola, G. (2014). Use of cheese whey for biomass production and spray drying of probiotic lactobacilli. Journal of Dairy Research, 81, 267–274.

Li, B., Tian, F., Liu, X., Zhao, J., Zhang, H., & Chen, W. (2011). Effects of cryoprotectants on viability of Lactobacillus reuteri CICC6226. Applied Microbiology and Biotechnology, 92, 609–616.

Liu, X., Gu, Q., Liao, C., & Yu, X. (2014). Enhancing butanol tolerance and preventing degeneration in Clostridium acetobutylicum by 1-butanol-glycerol storage during long-term preservation. Biomass and Bioenergy, 69, 192–197.

Liu, Y., Rafailovich, M. H., Malal, R., Cohn, D., & Chidambaram, D. (2009). Engineering of bio-hybrid materials by electrospinning polymer-microbe fibers. Proceedings of the National Academy of Sciences of the United States of America, 25, 14201–14206.

Lodato, P., Segovia de Huergo, M., & Buera, M. P. (1999). Viability and thermal stability of a strain of Saccharomyces cerevisiae freeze-dried in different sugar and polymer matrices. Applied Microbiology and Biotechnology, 52, 215–220.

López-Rubio, A., Sanchez, E., Sanz, Y., & Lagaron, J. M. (2009). Encapsulation of living bifidobacteria in ultrathin PVOH electrospun fibers. Biomacromolecules, 10, 2823–2829.

López-Rubio, A., Sanchez, E., Wilkanowicz, S., Sanz, Y., & Lagaron, J. M. (2012). Electrospinning as a useful technique for the encapsulation of living bifidobacteria in food hydrocolloids. Food Hydrocolloids, 28, 159–167.

Louesdon, S., Charlot-Rougé, S., Juillard, V., Tourdot-Maréchal, R., & Béal, C. (2014). Osmotic stress affects the stability of freeze-dried Lactobacillus buchneri R1102 as a result of intracellular betaine accumulation and membrane characteristics. Journal of Applied Microbiology, 117, 196–207.

Louesdon, S., Charlot-Rougé, S., Tourdot-Maréchal, R., Bouix, M., & Béal, C. (2014). Membrane fatty acid composition and fluidity are involved in the resistance to freezing of Lactobacillus buchneri R1102 and Bifidobacterium longum R0175. Microbial Biotechnology, 8, 311–318.

Malik, K. A. (1990). A simplified liquid-drying method for the preservation of microorganisms sensitive to freezing and freeze-drying. Journal of Microbiological Methods, 12, 125–132.

Martín, M. J., Lara-Villoslada, F., Ruiz, M. A., & Morales, M. E. (2015). Microencapsulation of bacteria: A review of different technologies and their impact on the probiotics effects. Innovative Food Science & Emerging Technologies, 27, 15–25.

Martin-Dejardin, F., Ebel, B., Lemetais, G., Minh, H. N. T., Gervais, P., Cachon, R., et al. (2013). A way to follow the viability of encapsulated Bifidobacterium bifidum subjected to a freeze-drying process in order to target the colon: Interest of flow cytometry. European Journal of Pharmaceutical Sciences, 49, 166–174.

Martos, G. I., Minahk, C. J., Font de Valdez, G., Morero, R. (2007). Effects of protective agents on membrane fluidity of freeze-dried Lactobacillus delbrueckii ssp. bulgaricus. Letters in Applied Microbiology, 45, 282–288.

Matoulková, D., & Sigler, K. (2011). Impact of the long-term maintenance method of brewer’s yeast on fermentation course, yeast vitality and beer characteristics. Journal of the Institute of Brewing, 117, 383–388.

Missous, G., Thammavongs, B., Dieuleveux, V., Guéguen, M., & Panoff, J. M. (2007). Improvement of the cryopreservation of the fungal starter Geotrichum candidum by artificial nucleation and temperature downshift control. Cryobiology, 55, 66–71.

Morono, Y., Terada, T., Yamamoto, Y., Xiao, N., Hirose, T., Sugeno, M., et al. (2015). Intact preservation of environmental samples by freezing under an alternating magnetic field. Environmental Microbiology Reports, 7, 243–251.

Moussa, M., Dumont, F., Perrier-Cornet, J. M., & Gervais, P. (2008). Cell inactivation and membrane damage after long-term treatments at sub-zero temperature in the supercooled and frozen states. Biotechnology and Bioengineering, 101, 1245–1255.

Muller, J. A., Ross, R. P., Fitzgerald, G. F., & Stanton, C. (2009). Manufacture of probiotic bacteria. In D. Charalampopoulos & R. A. Rastall (Eds.), Prebiotics and probiotics science and technology (1st ed., pp. 727–762). New York: Springer.

Nag, A., & Das, S. (2013). Effect of trehalose and lactose as cryoprotectants during freeze-drying, in vitro gastro-intestinal transit and survival of microencapsulated freeze-dried Lactobacillus casei 431 cells. International Journal of Dairy Technology, 66, 162–169.

Navarta, L. G., Calvo, J., Calvente, V., Benuzzi, D., & Sanz, M. I. (2011). Freezing and free-drying of the bacterium Rahnella aquatilis BNM 0523: Study of protecting agents, rehydration media and freezing temperatures. Letters in Applied Microbiology, 53, 565–571.

Nguyen, H. T., Razafindralambo, H., Blecker, C., N’Yapo, C., Thornat, P., & Delvigne, F. (2014). Stochastic exposure to sub-lethal high temperature enhances exopolysaccharides (EPS) excretion and improves Bifidobacterium bifidum cell survival to freeze-drying. Biochemical Engineering Journal, 88, 85–94.

Nyanga, L. K., Nout, M. J. R., Smid, E. J., Boekhout, T., & Zwietering, M. H. (2012). Yeast preservation: Alternatives for lyophilisation. World Journal of Microbiology and Biotechnology, 28, 3239–3244.

Otero, M. C., Espeche, M. C., & Nader-Macías, M. E. (2007). Optimization of the freeze-drying media and survival throughout storage of freeze-dried Lactobacillus gasseri and Lactobacillus delbrueckii subsp. delbrueckii for veterinarian probiotic applications. Process Biochemistry, 42, 1406–1411.

Páez, R., Lavari, L., Audero, G., Cuatrin, A., Zaritzky, N., Reinheimer, J., et al. (2013). Study of the effects of spray-drying on the functionality of probiotic lactobacilli. International Journal of Dairy Technology, 66, 155–161.

Páez, R., Lavari, L., Vinderola, G., Audero, G., Cuatrin, A., Zaritzky, N., et al. (2012). Effect of heat treatment and spray drying on lactobacilli viability and resistance to simulated gastrointestinal digestion. Food Research International, 48, 748–754.

Peighambardoust, S. H., Tafti, A. G., & Hesari, J. (2011). Application of spray drying for preservation of lactic acid starter cultures: A review. Trends in Food Science and Technology, 22, 215–224.

Peiren, J., Buyse, J., De Vos, P., Lang, E., Clermont, D., Hamon, S., et al. (2015). Improving survival and storage stability of bacteria recalcitrant to freeze-drying: A coordinated study by European culture collections. Applied Microbiology and Biotechnology, 99, 3559–3571.

Pénicaud, C., Landaud, S., Jamme, F., Talbot, P., Bouix, M., Ghorbal, S., et al. (2014). Physiological and biochemical responses of Yarrowia lipolytica to dehydration induced by air-drying and freezing. Plos One, 9, 1–12.

Pinotti, L. M., Silva, R. G., Zangirolami, T. C., & Giordano, R. L. C. (2007). Maintenance of penicillin G acylase expression by B. megaterium: Preservation methods and activity recovery. Brazilian Journal of Chemical Engineering, 24, 307–313.

Prakash, O., Nimonkar, Y., & Shouche, Y. S. (2013). Practice and prospects of microbial preservation. FEMS Microbiology Letters, 339, 1–9.

Rault, A., Béal, C., Ghorbal, S., Ogier, J. C., & Bouix, M. (2007). Multiparametric flow cytometry allows rapid assessment and comparison of lactic acid bacteria viability after freezing and comparison of lactic acid bacteria viability after freezing and during frozen storage. Cryobiology, 55, 35–43.

Rault, A., Bouix, M., & Béal, C. (2008). Dynamic analysis of Lactobacillus delbrueckii subsp. bulgaricus CFL1 physiological characteristics during fermentation. Applied Microbiology and Biotechnology, 81, 559–570.

Rault, A., Bouix, M., & Béal, C. (2010). Cryotolerance of Lactobacillus delbrueckii subsp. bulgaricus CFL1 is influenced by the physiological state during fermentation. International Dairy Journal, 20, 792–799.

Saarela, M., Virkajärvi, I., Alakomi, H. L., Mattila-Sandholm, T., Vaari, A., Suomalainen, T., et al. (2005). Influence of fermentation time, cryoprotectants and neutralization of cell concentrate on freeze-drying survival, storage stability, and acid and bile exposure of Bifidobacterium animalis ssp. lactis cells produced without milk-based ingredients. Journal of Applied Microbiology, 99, 1330–1339.