Abstract

Electroactive polymers (EAPs) and coatings (EACs) provide an expanding and progressive frontier for responsive drug delivery and the design of biomedical devices. EAPs possess the distinctive propensity to undergo a change in shape and/or size following electrical current activation. Current interest in EAPs and EACs extends to use in controlled drug delivery applications, where an “on-off” mechanism for drug releases would be optimal, as well as application in a biomedical devices and implants. This chapter explores and molecularly characterizes various EAPs such as polyaniline, polypyrrole, polythiophene, and polyethylene, which can ultimately be incorporated into responsive hydrogels in conjunction with, for example, a desired bioactive, to obtain a stimulus-controlled bioactive release system, which can be actuated by the patient, for enhanced specificity. The institution of hybrids of conducting polymers and hydrogels has also been subjected to increasing investigation as soft EACs, which have been applied, for example, in the improvement of the mechanical and electrical performance of metallic implant electrodes. The various interconnected aspects of EAP-based systems, including their synthesis, proposed modus operandi, physical properties, as well as functionalization approaches for enhancing the performance of these systems, are delineated. The use and comparison of these EAPs and EACs alone, and in conjunction with hydrogels, is further elaborated, together with strategies for integrating electroactive components and hydrogels. Approaches for modeling and explaining the proposed modus operandi of these systems are delineated. A critical review of diverse biomedical systems implementing EAPs and EACs having application in the pharmaceutical and medical industry, specifically, is provided, highlighting their applications, potential advantages, and possible limitations. Ultimately, this chapter illuminates innovative approaches for enabling EAP- and EAC-based systems to attain their full clinical potential.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Electroactive polymers

- Electroactive coatings

- Hydrogels

- Polyelectrolytes

- Dopant

- Drug delivery systems

- Biomedical devices

- Stimulus responsive

3.1 Introduction

Electroactive polymers (EAPs) have been ushered in as a novel generation of intelligent biomaterials enabling direct delivery of electrical, electrochemical, and electromechanical stimulation to cells [1]. EAPs, in some definitions, have been referred to as artificial muscles due to the similarity in functional response, as well as potential to mimic the mechanical performance, of biological muscles. Essentially, they are polymeric materials with the intrinsic ability to change their shape or size following electrical current activation. Actuation via the use of electrical energy is an attractive activation method for causing elastic deformation in polymers, and it offers great convenience and practicality.

More and more, nature provides biologically inspired adaptations in designed biomedical devices and delivery systems. There is a diversity of polymers that have the potential to undergo a change in size or shape in the presence of stimuli, including temperature, light, chemical, magnetic, pneumatic, magnetic, and electrical. The attraction of electrical activation for causing polymeric deformation lies in its convenience and practicality [2, 3].

The reported history of polymers possessing electrically stimulated behavior has extended over more than 100 years, but this fact has received little attention possibly due to the comparatively small response to the stimulus, until recently. In the passing two decades, polymer scientists have achieved the synthesis of EAPs and electroactive coatings (EACs) that have demonstrated more notable elastic deformations and ultimately shape and size changes. These materials have attracted multidisciplinary interests and have had exciting applications as, for example, robotic fish, artificial eyelids, and catheter steering elements [3]. EAPs and EACs provide an expanding and progressive frontier for responsive, controlled drug delivery, where an “on-off” mechanism for drug releases would be optimal, as well as application in biomedical devices and implants.

Encompassed within the family of EAPs are conductive polymers, electrets, and piezoelectric and photovoltaic materials [3]. Electrets and piezoelectric materials enable electrical stimulus delivery in the absence of an external power source; however, stimulus control is limited. Conversely, conductive polymers enable good electrical stimulus control, good electrical and optical properties, and a favorable conductivity/weight ratio and can be rendered biocompatible, biodegradable, and porous [4]. Specific modification of the chemical, physical, and electrical properties of conductive polymers is also possible via incorporation of enzymes, antibodies, or other biological moieties, for particular applications, which are also alterable following exposure to stimuli [1, 5].

Since their inception, more than 25 EAP systems have been reported (Table 3.1), possessing the combined attributes of metals (charge conduction, good electrical and optical properties) and polymers (processing flexibility and ease of synthesis) [6]. The initial “discovery” of conductive polymers was with the observation that the conductivity of polyacetylene (a fairly semiconducting polymer) could have its conductivity increased 10 millionfold upon oxidation via iodine vapor [7]. This also introduced the phenomenon of “doping,” the process through which conductivity is introduced to polymers. It ignited the search for more EAPs, such as the polyheterocycles, which include polypyrrole, polyaniline, and polythiophenes. These examples possess an enhanced stability compared to polyacetylene and good conductance as well [8].

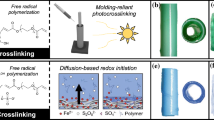

This chapter provides an in-depth discussion on the principles and applications of EAPs, EACs, and their composites while building on concepts introduced in the review of Pillay and co-workers [11]. The use and comparison of these EAPs and EACs alone, and in conjunction with hydrogels, is further elaborated, together with strategies for integrating electroactive components and hydrogels. The various interconnected aspects of EAP-based systems, depicted in Fig. 3.1, including their synthesis, proposed mechanism of operation, physical properties, as well as functionalization approaches for enhancing the performance of these systems, are delineated. A critical review of diverse biomedical systems implementing EAPs and EACs while having application in the pharmaceutical and medical industry, specifically, is provided, highlighting their applications, potential advantages, and possible limitations. Ultimately, this chapter illuminates innovative approaches for enabling EAP- and EAC-based systems to attain their full clinical potential.

Schematic demonstrating the interconnectivity of the various aspects of EAPs. Adapted from Balint et al. [1]

3.2 Classification of Electroactive Polymers

Roentgen essentially made the seminal report of EAP materials in 1880 [12]. This was by subjecting a rubber band (having a fixed end and a mass attached to the free end) to an electric field. This was followed by Eguchi’s discovery and description of electrets in 1925. These are dielectric materials possessing a quasi-permanent electric charge or dipole polarization. In 1969, Kawai described the piezoelectricity of polyvinylidene fluoride (PVDF). EAPs and coatings can be categorized as ionic and electronic (or field activated) [3]:

-

(a)

Ionic EAPs

These include conjugated polymers. Actuators are comprised of an electrolytic polymer film with a 2-electrode coating with activation implicating ion mobility due to electrical excitation [13]. Their advantages include generation of large bending displacement following low-voltage activation; however, there is the maintenance requirement of electrolyte wetness, low efficiency of energy conversion, and limited ability to sustain constant displacement via direct current (DC) voltage activation (except for conducting polymers) [14]. Examples of ionic EAP materials include the ionomeric polymer-metal composites (IPMCs), conducting polymers, carbon nanotubes, and ionic polymer gels. IPMCs are the most widely investigated EAPs in this group, with the base polymer enabling movement of positive ions through its channels of interconnected clusters of fixed network negative ions [13]. Pertinently, IPMCs undergo significant bending in response to a fairly low electrical voltage (1 V); however, the response frequency is slow (<10 Hz) [3].

-

(b)

Electronic (field-activated) EAPs

These include piezoelectric polymers, electrorestrictive polymers, nonionic gels, and dielectric elastomers. Activation is via Coulomb force instigating an alteration in dimension, which may be a result of either direct thickness reduction, seen, for example, in dielectric elastomers, or internal polarization with molecular alignment noted in ferroelectric EAP [15]. A high electric field (>10-V/μm) is commonly required, which can approach the electric breakdown level due to the low dielectric constant. The voltage required can be reduced by employing thin multilayers as a stack and creating a composite incorporating high dielectric constant filler material. This group of EAPs possess a fast response time, maintaining the generated displacement under DC voltage, as well as greater mechanical energy density. The requirement of a high activation field potentially close to electric breakdown level is their main disadvantage [3].

Compared to conducting polymers, redox polymers possess redox sites, with electrostatic or covalent bonds to the polymer, and electronic and spatial localization [16], whereas conducting polymers exhibit delocalization of electronic states [17]. Depending on the synthetic reaction for the polymerization process, the EAP may be an addition or condensation polymer, and this reaction is implicit in defining the electrical properties of the synthesized EAP [18]. A more recently arising novel technique is for the formation of modified EAPs, where the polymer possesses distinct properties from the monomers, is electropolymerization, undertaken on the surface of electrodes [19]. Herein, however, lies its drawback, as the yield from the electropolymerization at the electrode surface is too low for industrial application [20–23].

3.3 The Mechanism of Operation and Conductivity Source of Electroactive Polymers

When an electric charge is applied to an EAP with sufficient mobility, there is charge redistribution within the polymer, with the response either being a change in dielectric properties (either (a) dielectric properties which represent polarization or (b) tangent of dielectric loss angle representing relaxation phenomena) or bulk conductive properties (either (a) dielectric strength representing breakdown phenomena or (b) conductivity representing electric conduction). Additional distinct EAP properties encompass piezoelectric, pyroelectric, ferroelectric, triboelectric, photovoltaic, and photoconductive properties [24].

Charge conduction in EAPs is due to the ease of electron jumping between the polymeric chains on oxidation or reduction of the EAP. This is due to a combination of factors. Within the conjugated polymer backbone, the series of alternating single and double bonds provides both localized σ-bonds, which are chemically strong, and less strongly localized π-bonds, respectively [25, 26] (Fig. 3.2). Overlapping of the p-orbitals of consecutive π-bonds enables easy delocalization and thus free movement of electrons between atoms. As the polymer must be synthesized in its conducting form (i.e., oxidized), a dopant molecule, generally an anion, is essential for charge neutralization and backbone stabilization. Simultaneously, the dopant brings a charge carrier into the system through introduction or removal of electrons into or from the polymer chains, causing their relocalization as polarons or bipolarons (loosely held yet localized electrons enclosed within a crystal lattice distortion) (Fig. 3.3). The application of an electrical potential causes movement of dopant into or out of the EAP, causing polymer backbone disruption, thus enabling the charge to pass through the polymer as the polarons or bipolarons [1, 25, 26].

Depiction of a conjugated backbone indicating alternating single and double bonds. Source: Balint et al. [1]

Schematic illustrating the electrical conductivity of conducting polymers. (a) The dopant removes or adds an electron from/to the polymer chain, creating a delocalized charge. (b) Charge localization is energetically favorable and the charge is surrounded by a local distortion of the crystal lattice. (c) This distortion-engulfed charge is a polaron (a radical ion and the associated lattice distortion). (d) Conduction of electricity is due to the polaron movement along the polymer chain. Source: Balint et al. [1]

In polypyrrole (PPy), the bipolaron (p-type) conduction creates conductivity, with electron hopping and anion and cation movement [6]. The overall conductivity of the EAP depends on the polaron, charge transfer to adjacent molecules, and length of conjugation, which can be varied in accordance with the dopant type and quantity. Conductivity may be limited by defect sites in the EAP backbone, potentially due to exposure to water or oxygen or redox switching [27].

The diffusion coefficient is employed to describe this rate of oxidation or reduction within the EAP and is an indication of the charge percolation efficiency through the polymer, as measured via cyclic voltammetry (CV) or chronoamperometry (CA) [28]. In addition, the type of EAP used also affects the response time. A rapid response time of milliseconds is demonstrated by electronic-based EAPs, but with the requirement of a high actuation voltage. On the other hand, ionic-based EAPs respond more slowly, but at a lower actuation voltage [29].

3.4 Creating an Electroactive Polymer: The Process and Considerations

Certain EAPs have been the focus of intensive investigation as responsive platforms including PANi [30], polythiophene (PTh), and PPy [31]. The advantages, limitations, and various modifications for potential improvement of these commonly employed EAPs are provided in Table 3.2. The versatility of PANi and its derivatives is due to their potential for processing into various redox states and possession of tunable conductivity and stability. The applications of PANi include dental uses (maxillofacial surgery and dental implants), antistatic applications, gas sensors, and artificial muscle design [32–37].

The behavior of EAPs can be tailored via doping with various counterions. This has enabled, for example, the mimicry of basic insect and animal movements by investigators in the field of biomimetics. There has been a shift in focus on EAPs as their actuation ability improves, as well as the availability of a wider selection of biomaterials [11]. However, this brings concerns with regard to the biocompatibility of these new materials [57]. A study specifically assessing the biocompatibility of PANi conjugates investigated the subcutaneous implantation of ethylene vinyl acetate (EVA) copolymer (PE) and PANi (emeraldine, nigraniline, and leucoemeraldine states) in Sprague-Dawley rats over a period of 19–90 weeks with subsequent histological evaluation. No carcinogenic effects were observed on rat tissues, even after the extended periods of time, highlighting adequate biocompatibility [58, 59]. The biocompatibility of the EAP PPy has also been demonstrated in humans, as well as its controllable physicomechanical behavior and chemically or electrochemically enabled synthesis.

The mechanism of polymerization of PPy is followed by most EAPs, with the polymerization commencing via oxidation of the pyrrole monomer (Fig. 3.4). The counterion employed in its synthesis is C-, with its negative charge enabling incorporation into the polymer, which is in equilibrium with the polymer backbone’s positive charge [60]. As highlighted in Fig. 3.4a, incorporation of diverse counterions during the polymerization process is enabled, allowing for alteration of the overall physicomechanical properties. The use of a combination of counterions is also possible for achieving the desired degree of conductivity and physical attributes [61].

Schematic depicting: (a) Polypyrrole (PPy) chemical synthesis. (b) Polymer protonation via protonic acid (acid counterions are not illustrated). (c) Mechanism of an oxidation reaction of PANi (downward arrow represents the oxidation reaction). Source: Pillay et al. [11]

Zhao and co-workers [62] indicated that the transport mechanism within the EAP is controlled by the counterions, most notably, the anions. Following the application of sufficient negative potential, outward anion diffusion occurs and the reaction is reduced. Application of a repetitive pulsed potential waveform to the membrane maintains transport through it. Incorporation of counterions into a polymeric membrane can be achieved through electropolymerization; however, if they are trapped during this process, immobility is a potential concern. Sulfonated aromatic groups have proved suitable [62]. Following expulsion of an anion from the polymeric system, reincorporation is achieved via repetitive pulsed potential waveform; furthermore, if the anion-loaded polymer is placed in a cationic electrolyte solution, these may also be assimilated into the polymeric system. Three criteria must be satisfied for efficacy of this electroactive transport mechanism: (1) a transport system with a rapid on-off switching mechanism, (2) controllable flux and sustainable transport within the polymeric system, and (3) controlled selectivity.

3.4.1 The Electropolymerization Process

Electropolymerization is a specific method originated for the formation of EAPs. Being a more stable approach than chemical synthesis of an EAP, it also yields EAPs with less variation in molecular mass as a result of the exothermic reaction during chemical oxidation of the monomer, with temperature fluctuations impacting the polymer chain length [63]. The process implicates dissolution of the monomer in an appropriate solvent together with a selected anionic doping salt; this is followed by oxidation of the monomer at the anode. Oxidation furnishes free cationic radicals of the monomer, which interact to form oligomers and subsequently the EAP [64]. Factors influencing the elaborate electropolymerization process include the degree of monomeric substitution, choice of electrolyte and solvent, solvent and aqueous medium pH, and the electrochemical method employed [65]. Bearing these factors in mind, there lies the potential for synthesis of a novel synthetic approach or polymer with desirable attributes. Current intensity is influenced by the electrolyte employed, which ultimately affects the EAP quantity formed [65]. Solvents possess various donor numbers influencing cationic monomer radical deprotonation, as well as possessing varying dielectric constants, influencing chain propagation [66]. Solvent choice further depends on it providing a medium with ionic conductivity and on its stability at the monomer’s oxidation potential [64]. Solvent pH is important due to its effect on monomer solubility (via chemical reaction) and on the polymer’s physical attributes [e.g., aniline undergoes polymerization under acidic conditions as a result of PANi protonation, resulting in enhanced conductivity (doping effect)] [67, 68]. Monomers need to dissolve in the solvent for electropolymerization to ensue. Inert materials (e.g., gold, platinum, or glass-like carbon) commonly comprise the anode employed for the polymerization reaction; partially reactive materials may dissolve with polarization of the anode [69, 70]. The physicochemical properties of the synthesized EAP are implicitly based on the electropolymerization method instituted, but generally this approach imparts EAPs with comparable conductivity, for application in research and system design [11].

3.4.2 The Doping Process

The overall goal in EAP synthesis is attainment of the required conductive, mechanical, and sometimes optical properties. Doping implicates introduction of a chemical agent for direct interaction with the polymer chain and has a pertinent impact of the physicomechanical attributes of the EAP. Figure 3.1b demonstrates this; there is protonization of nitrogen atom of the quinoid group in PANi by protonic acid [71]. Commonly, doping is performed with EAP in the base form which is then combined with an acid; the protonated EAP has increased conductivity, due to the protonated imine nitrogen emanating in increased polarons in EAPs (i.e., PANi and PPy) [72]. The preferential synthesis of PANi is thus in an acidic environment, as discussed previously [72]. However, these conditions may be considered harsh and undesirable, possibly necessitating the addition of other solutions to the acid. Mirmohseni and Wallace [73] synthesized PANi films adding doping agents to an acetone: 1M HCl solution, with immersion of the PANi in this solution for 24 h enabling sufficient doping, followed by vacuum drying. Transition metals (e.g., NiCl2, EuCl3, and ZnCl2) represent more progressive doping agents compared to conventional protonic acids where only a dopant change is induced on the polymer, whereas transition metals also elicit a dual effect causing a change in morphology as well [71].

The preparation of EAPs via emulsion polymerization enables the generation of a conducting salt in the absence of a postdoping processing step with acid [74], as investigated by Kinlen and co-workers [75]. They demonstrated the polymerization of PANi salts of hydrophobic acids (e.g., dinonylnaphthalene) in an organic solvent (2-butoxyethanol).

3.5 Redox Reactions in Electroactive Polymers

3.5.1 Conductivity of EAPs via Redox Reactions

The responsiveness of EAPs is intrinsic to their potential for undergoing oxidation and reduction reversibly. The transport of ions through the EAP and subsequent controlled movement of ions from the EAP conducting film is described via redox reactions. Examining PANi as an example of a conducting polymer, the amine groups serve as its redox centers, undergoing oxidation to imine groups; subsequent to oxidative, there is some level of conductivity. PT and PPy may be similarly classified [76]. The site of occurrence of the redox reaction is commonly at the interface of the film and solution, as here there is the potential for the reaction of dissolved ions with the conducting polymer. The steps implicit to the redox switching of an EAP are (noted in Fig. 3.4c for PANi):

-

1.

Change in conformation

-

2.

Solvent molecule entry or exit, potentially altering the swelling state

-

3.

Conformational change of EAP-bound ions

-

4.

EAP electroneutrality balance via ion ejection or injection

3.5.2 Evaluation of Redox Reactions in EAPs

An EAP’s redox potential has pertinent influence on the extent of swelling/deswelling and electroactivity of the polymer. Assessment of the redox reaction of the EAP via the following techniques enables prediction of EAP electroactivity:

-

1.

Linear sweep voltammetry (LSV)—measurement of the current at the working electrode relative to a potential range (i.e., EAP voltammetric response). Peaks and troughs in the generated voltammogram represent oxidation or reduction within the EAP. LSV is also employed for quantification of ions in a sample [77, 78]. Cyclic voltammetry has largely replaced this technique as it provides more data.

-

2.

Cyclic voltammetry (CV)—an extension of LSV where there is an inversion of the working electrode potential on attainment of the end potential and provides a potentiodynamic electrochemical measurement [79]. It enables determination of an analyte in solution [79], as well as the surveillance of oxidation and reduction behavior of the EAP. A cyclic voltammogram plot is generated of the current accumulated at the working probe versus the applied potential difference. The potential is linearly increased in CV, and as it approaches the oxidation potential of the analyte, there is an increase in the current, which ultimately falls as the analyte concentration at the electrode decreases on oxidation. The shortcomings of CV are its low structural resolution; however, it is still a popular redox reaction-determining tool.

-

3.

Impedance spectroscopy (IS)—a nondestructive approach importantly employed for the characterization of the intrinsic electrical properties of a polymer, such as conductivity, dielectric coefficient, static properties (at the interface), and dynamic changes resulting from charge transfer. Its application even extends to the assessment of body makeup, specifically in overweight individuals [80]. IS is employed for gaining information on the kinetics and electrochemical reactions of EAPs and confirmation of a model for diffusion of ions in and out of an EAP in solvent or diffusion of counterions or electrons at the EAP/solvent interface [81, 82]. Disadvantages of this technique are difficulty of data interpretation and that it is essentially a complementary approach.

-

4.

Chronoamperometry (CA)—in this technique, there is maintenance of the potential for a period, followed by stepping up, thus creating a faradic process with the resultant current (resulting from oxidation or reduction) recorded. For analysis, the EAP is applied as a thin-film coating to the electrode. A limitation is that the alternating current can affect the results recorded. The employment of CA is important where determination of the migration flux of charged particles in EAPs is required through analysis in a constant electric field of the concentration distribution and current-time plots of a polymer film [11]. With regard to conductive EAPs, they can be applied in CA as sensors enabling detection of simple and complex electroactive or nonactive substances [83].

3.6 Creating Composites of Smart Hydrogels and Electroactive Polymers

The composition of hydrogels as three-dimensional interconnected hydrophilic networks is well known. They absorb water and swell, retaining their structure due to the presence of cross-links, entanglement, or crystallinity [84]. In their native form, they lack an inherently electroresponsive nature; however, the incorporation of EAPs enables their responsivity in the presence of electrical stimuli [85, 86]. The application of electroresponsive hydrogels is diverse as actuators, separation devices, and responsive, sometimes miniaturized, delivery systems [87–90]. Such hydrogels may also be classified as “intelligent” or “smart” where responsivity to more than one stimulus, including electrical, is present [91–95]. The limitations of EAPs have been discussed, when used in isolation (e.g., the poor solubility and mechanical properties of PANi and PPy). Approaches to addressing these challenges and enhancing the physicomechanical and physicochemical attributes of the EAP include creating an EAP-biomaterial blend with an insulating biomaterial, electrochemical, or chemical oxidative polymerization of the EAP into a polymeric matrix or formulation via codeposition of a composite EAP-insulating polymer [96]. Hydrogels commonly exhibit stimulus-responsive behavior as a conformational change, which could be catalysis, actuation, signaling, movement, or an interaction [97]. The stimuli in question are diverse and include temperature, pH, electric fields, light/UV, chemicals, magnetic fields antigens, etc. [98].

Drug delivery approaches have been developed employing an EAP which has been integrated within the polymeric membrane [99]. As indicated, there is inward and outward movement of counterions when an electrical current is initiated. In certain EAPs (PPy and PANi), a high cation flux occurs upon oxidation. This has been applied, for example, to glutamate and ATP, which have been electrostatically charged to attain their controlled release [100, 101].

As indicated, transport of ions is also enabled during redox reaction switching via changes in conformation, which includes swelling, deswelling, or shape change (i.e., a shape-memory effect, thus embodying the action of an artificial muscle) [102]. This slow relaxation with shape change is exhibited by EAPs such as PANi and those falling within its group. This relaxation effect is absent in certain EAPs [e.g., poly(o-aminophenol), poly(o-phenylenediamine), and poly(benzidine)] [103]. In studies by Silk and Tamm [104] on halogenide-doped PPy films, they reported the effect of cations on this redox switching process in terms of relaxation times.

Hydrogel performance can be enhanced through the inclusion of acidic or basic groups into the structure to create a polyelectrolyte (the solid matrix network, ionic species, and fluid component). Popular polyelectrolyte hydrogels employed include polyacrylic acid (PAA) as sodium and potassium salts [105–108]. Investigators have employed the sodium salt of hyaluronic acid hydrogels, demonstrating its reduction in volume at the anode with consequent drug release [109]. It follows that drug release from hydrogel networks is affected by the monomeric composition, swelling degree, and cross-linking density, which ultimately impact the porosity and network structure. The presence of ionizable groups in the hydrogel elicits chemical and physical changes in the structure, thus enabling drug release [110]. Electrical stimulation of a responsive polyelectrolyte causes drug migration to the oppositely charged electrode, and contraction of the hydrogel, emanating in drug expulsion [111]. This drug movement is represented in Fig. 3.5.

Schematic depicting: (a) Positively charged drug particle migration toward the negatively charged anode. (b) Contraction of the hydrogel with forced drug exudation from the system. Adapted from Pillay et al. [11]

3.6.1 Responsive Hydrogels: Electrocompatible Preparation Approaches

The versatility of hydrogels and their potential application in an electroresponsive system has been introduced [112]. An increase in the degree of cross-linking of the hydrogel enhances the architectural integrity, lowering the amount of water imbibed and thus decreasing the degree of swelling [113, 114]. Hydrogel synthesis may be via blending, copolymerization, grafting, or formation of an interpenetrating polymer network or composite. Blending implicates interaction between two or more agents, for example, through esterification between hydroxyl group of polyvinyl alcohol (PVA) and the carboxyl group of gelatin [115]. Copolymerization occurs via reaction of two monomers. Grafting is similar to copolymerization, except that the polymer employed for hydrogel formation is a graft copolymer (a branched polymer where the main chain and side chain differ) possessing the combined properties of both polymers [111, 116].

With regard to interpenetrating polymer networks (IPNs) , the hydrogel network incorporates a network of a component, where there is polymerization or cross-linking of at least one component in the presence of another. Thus, there can be incorporation of an EAP into a hydrogel to create an IPN, thereby potentially increasing the electrical stimulation conductivity into the hydrogel and the ultimate electroresponsiveness [117, 118].

Formation of a composite hydrogel occurs by embedding a particle into a hydrogel network, where the particle does not interact directly with the hydrogel [119]. All these approaches may be instituted in the synthesis of an electroresponsive hydrogel system, with selection based on swellability, structural integrity, and response required.

3.7 Electroactive Polymer Functionalization for Specific Applications

Various approaches exist for the functionalization of EAPs for the binding of bioactives and optimization of the properties of the device or delivery system (i.e., porosity, hydrophobicity, degradability, conductivity), as represented in Fig. 3.6. This ultimately enhances their potential for numerous biomedical applications. Entrapment and absorption techniques do not involve chemical reactions that could affect bioactive activity and are thus commonly employed for biosensor applications [120].

Approaches to functionalizing EAPs: (a) physical absorption, (b) entrapping, (c) covalent bonding, and (d) exploiting the doping mechanism. Source: Balint et al. [1]

-

1.

Absorption—The EAP is introduced to a solution of the functionalizing agent, enabling its physical adsorption to the polymer matrix via static interactions between the molecule’s charge and the polymer matrix. This is a simple approach; however, it exhibits sensitivity to pH, and outward leaching of the bioactive can occur [121]. Examples include the physical adsorption binding of calf thymus DNA to PPy as a toxicant biosensor [122].

-

2.

Entrapment—The functionalizing molecule, the monomer of the polymer, the dopant, and the solvent are mixed prior to synthesis. Incorporation of the functionalizing agent molecules close to the electrode into the polymeric chain occurs during electrochemical polymerization. Application of this method to the binding of large molecules, such as DNA and enzymes, is common, as their size generally inhibits their escape upon entrapment [120]. Entrapment has been employed, for example, for the binding of glucose oxidase for formation of glucose sensors [123]. DNA has been bound for the detection of aromatic amines, cDNA, and Hep C virus [124].

-

3.

Covalent bonding—The molecule is covalently bound strongly to the monomer of the polymer and the long-term stability of the polymer is enhanced. There is the possibility of a reduction in the EAP’s conductivity. An example is the covalent binding of cysteines via sulfide bonds to the beta-positions of PPy. Additional bioactive molecules can be anchored to the cysteines [125].

-

4.

Exploitation of the doping process—Enables bonding of a wide range of bioactives with the prerequisite that they are charged. The binding of biomolecules such as collagen, growth factors, heparin, and chitosan has been achieved through doping; however, this is limited by the small amount of molecules that can be bound, as well as a notable reduction in the conductivity [25, 126, 127].

Diverse biological molecules of interest have also been employed to functionalize EAPs, thus enhancing their bioactivity. The following have been applied, for example, to PPy [128, 129]:

-

1.

Dermatan sulfate to enhance keratinocyte viability

-

2.

Heparin to promote endothelial cell proliferation

-

3.

Laminin-derived peptide doping to improve neuron and astrocyte adhesion

-

4.

Neural growth factor and poly-l-glutamic acid to enhance neuronal growth

-

5.

Hyaluronic acid and chitosan to promote skeletal myoblast growth and differentiation [130]

3.8 The Diverse Applications of Electroactive Polymers and Coatings to the Pharmaceutical and Biomedical Industry: Controlled Delivery Applications

Application of responsive polymers is divided by application areas, including cardiovascular devices, ophthalmic devices, surgical devices, dental and orthopedic devices, respiratory devices, gastrointestinal devices, urogenital devices, drug delivery devices, and implantable biosensors [131].

3.8.1 EAPs in Controlled Drug Release Applications

The need for the controlled delivery of chemical compounds is a prerequisite for a number of industries, specifically the medical and pharmaceutical disciplines [5]. The institution of EAPs is an exciting avenue for overcoming the challenges in the design of effective controllable delivery devices. The great potential of EAPs lies in the fact that upon application of a negative (reducing) potential, controlled expulsion of molecules bound through doping into EAPs is enabled [5, 132, 133]. EAP devices can be rendered porous, with delocalization of charge carriers facilitating bound molecule diffusion. Successful release of numerous therapeutic agents from EAP-based systems has been demonstrated and reported for 2-ethylhexyl phosphate, dopamine, naproxen, heparin, neural growth factor (NGF), and dexamethasone [132–137]. These and further examples are elaborated on in Fig. 3.7.

The attainment of intelligence in drug release, where the appropriate amount of drug is released at the required site at the correct time, is the main goal of pharmaceutical researchers. The design of such systems is ultimately beneficial to the patient for enhancing compliance and reducing side effects [92]. This is where EAPs as electroresponsive systems have pertinent application. EAP-based hydrogels achieve controlled release as a result of the inward and outward movement of charged particles. Models explicating the mechanism of release are minimal. Murdan [92] described three different scenarios:

-

1.

Gel deswelling resulting in forced drug convection

-

2.

Drug migration due to charged electrodes (drug electrophoresis)

-

3.

EAP hydrogel erosion on electrical stimulation with the consequent release of drug

The limitations of employing EAP-based hydrogels for drug release are that:

-

1.

The drug must be charged to enable electrochemical movement control into and from the hydrogel [138].

-

2.

There is difficulty in the absorption (thus resulting in relatively low drug loading), as well as release of large volumes of drug by the hydrogel [137–139].

-

3.

There is a decreased control over drug release with continued ion exchange between the surrounding medium and drug [138].

-

4.

Rapid drug expulsion (this could also be an advantage in some instances) [137, 139].

-

5.

Diffusional leaching of drug with replacement by other molecules in the EAP’s environment [137, 139].

-

6.

EAP fatigue on repeated electrical stimulation due to irreversible polymeric oxidation, thus limiting EAP lifetime. Swelling and deswelling due to continual doping agent movement cause consequent polymeric degradation [5, 7].

Drug loading can be enhanced through the application of biotin-streptavidin coupling, with biotin acting as a dopant, covalently binding the bioactive, and ultimately providing release kinetics that are more uniform [139].

Zinger and Miller [100] investigated the controlled release of charged particles (the anionic neurotransmitter, glutamate) covalently bound to the polymer backbone of PPy which was coated onto a glass-like carbon electrode. Ferrocyanide was incorporated to enhance PPy conductivity. Controlled release of the drug was successfully achieved [100]. With regard to cationic drug release, Zhou et al. [140] demonstrated the anodic release of protonated dimethyl dopamine from a cationic poly(N-methyl-pyrrole)/polyanion composite. Drug release from bilayered polymers as a dual layer transport system has also been verified by Pyo and Reynolds [141]. A low redox potential inner layer (PPy and polystyrene sulfonate) was separated via insulating film from a high redox potential outer layer [either poly(N-methyl pyrrole) or poly(vinyl ferrocene) (PVFc)]. This intelligent design enabled both the release of charged particles and the reuptake of specified charged particles present in the surrounding medium.

Determination of the behavior of the EAP-based hydrogel requires the correct application of the current. There should be immersion of the hydrogel in the conducting medium, with embedding or contact of one or both electrodes with the hydrogel. Alternatively there can be direct contact of the hydrogel with the electrode in the absence of conducting media, which will ultimately result in a varied release profile compared to institution of the first method, which should be considered on selection of the optimal approach [92]. Investigation of release mechanisms has been undertaken by Kanokpom and co-workers [142], employing a cross-linked PVA hydrogel doped with sulfosalicylic acid. It was demonstrated that release of drug varied linearly with the square root of time. There was dependence of the diffusion coefficient of the hydrogel on the applied electric current and the degree of cross-linking. Institution of polyelectrolytes (water-soluble electrically charged polymers) as the main component of the hydrogel also influences drug release, potentially creating electrical, temperature, and pH-responsive hydrogels, as elaborated in the ensuing section.

3.8.2 EAP-Based Polyelectrolyte Hydrogels in the Delivery of Biologics

The movement and shape of these electrically charged water-soluble polymers are controlled by their charge, as well as by Brownian motion, resulting in either coiling or stretching. Depending on the ionizable groups present such as those that are acidic (e.g., carboxylic, phosphoric, sulfonic) or basic (amino groups), a polyelectrolyte can be classified as a polyacid, polybase, or polyampholyte [143]. The application of polyelectrolytes in the field of EAP-based bioactive delivery is of pertinence based on their structural response to pH, temperature, and electrical current alterations [144]. DNA is a polyelectrolyte, thus indicating the potential for synthesizing biocompatible polyelectrolytes [11].

The incorporation of a polyelectrolyte into a hydrogel creates the potential for swelling, collapse, or even shape change of the system when exposed to solutions of varying pH or charge [145]. Examples of electrically responsive polyelectrolytes include PAA and PVA copolymer membranes, sulfonated cross-linked polystyrene gel, acrylamide/acrylic acid copolymer with PPy/carbon black, and chitosan/carboxymethylcellulose hydrogels [146], which can display good electrical responses at various pH values. As indicated, with electrical stimulation, the kinetic motion is one of hydrogel collapse/contraction of the cationic or anionic polymer at either the anode or cathode, respectively, occurring in two areas. This is due to electrochemical processes following Faraday’s law and is evident first in the area of high gel response. Thereafter there is a possibility for electro-osmotic water release in an area having a low response [145]. In addition to drug release applications, and owing to their biocompatibility and stimulus sensitivity, these EAP-based polyelectrolyte hydrogels also have shown potential as biosensors, microsurgical tools, miniature bioreactors, and for use in DNA hybridization. Polyelectrolyte multilayers may also be employed as fibers or coatings for bioactive and diagnostic agent release [147, 148]. Inoue et al. [149] evaluated the pH-responsive drug release from hydrophobic or cationic polyelectrolyte hydrogels. There were notable variances in the rate of swelling and drug release at different pHs.

Certain hydrogels and EAPs may function as stimulus-actuated systems, which are biodegradable and, when implanted at a target site, begin eroding with release of incorporated drug upon actuation [150]. Natural polymers possessing this potential include gelatin and dextran. Biodegradable EAPs may also achieve controlled release in this manner including multiblock polylactide and aniline pentamer copolymers [45], which were evaluated in rat models. Guimard and co-workers [150] fabricated 5, 5′″-bis (hydroxymethyl)-3,3′″-dimethyl-2,2′:5′,2″:5″,2′″-quaterthiophene-co-adipic acid polyester via incorporation of alternating electroactive quaterthiophene units and biodegradable ester units to create a macromolecular framework. Nanoscale applications of EAPs have also been investigated, with sizes of even 100 nm demonstrating electroactivity [151, 152]. A summative account of EAP-based delivery systems is provided in Fig. 3.7, highlighting the progressive potential of this field for drug delivery. Future investigations could see the application of drug-loaded EAP systems as injectable nanorobots or nanobiosensors, with subsequent activation via electrical and other stimuli, ultimately leading to a more patient-specific treatment approach.

3.8.3 Application of EAPs in Medical Devices

Tanaka et al. [161] developed a stop valve on a microchip. First, a novel stop valve structure was conceptualized with fabrication, and subsequent measurement, of the displacement of the diaphragm in the absence of fluid. Second, the functionality of the stop valve installed on a glass microchip was demonstrated. Figure 3.8 depicts the structure and actuation principles of the stop valve. There is thinning and elongation of the EAP horizontally upon voltage application (Fig. 3.8a). The EAP is held between soft electrodes and mounted on a silicon rubber diaphragm. Elongation in the horizontal direction is inhibited in this structure; thus diagonal elongation occurs upon voltage application in order to close the penetrating hole in a chamber within a microchip (Fig. 3.8b). For valve function demonstration, a linear microchannel with a valve structure in the center of the channel was designed (Fig. 3.8c).

Design and mechanism of operation of a microchip with a stop valve. (a) Deformation of an EAP by an applied voltage. (b) Schematic of the stop valve. (c) Microchip design and observation method of the microchannel fluid flow. Source: Tanaka et al. [161]

3.8.4 The Application of EAPs as Biomimetic Sensors: Electroactive Polymeric Sensors in Hand Prostheses

Biddiss and Chau [162] took on the task of creating a prosthetic hand incorporating EAPs, a daunting undertaking, considering the complexity of the natural human hand (17,000 tactile receptors all of which can access the sensory information generated). EAPs are a suitable choice for such prosthetics as they are diverse, lightweight, shatterproof, and pliable, with adjustable electrochemical properties, and find dual application as an actuator and as a sensor. This has allowed EAPs to be used in numerous sensory applications such as neural and haptic interfaces as well as artificial noses [163], chemical sensing systems [164], and devices for measurement of blood pressure and pulse rates [165]. Table 3.3 summarizes some of the EAPs successfully applied as biomimetic sensors [162].

For their experimental setup (Fig. 3.9), Biddiss and Chau [162] employed a gold-coated IPMC film, having an appropriate geometric fit for the metacarpophalangeal joint of a typical hand prosthesis. Their goal was characterization of the material response to quasistatic and dynamic bending embodied by the prosthetic hand. They ascertained the performance of a calibrated IPMC sensor with regard to prediction errors for various bending rates and angles. Bending was achieved by loading of the sample as a cantilever beam from angles of 0 to 90o. Fixing one end of the IPMC sample was achieved via a stationary clamp fitted with isolated electrodes for measurement of the voltage potential across the polymer, while the opposite end was fixed to a rotating platform. This was operated by a computer-controlled stepper motor working in increments of 0.9o, for reliable variation of bending angles and rates. The angle of rotation of the stepper motor shaft (bending angle) and the shaft angular velocity (bending rate) was the input. The output voltage was amplified 100 times, which was converted by a data acquisition board to a digital signal.

Schematic of experimental setup with rigid mounting of polymer on one end, with anchoring on the opposite end to a stepper motor-driven rotating platform. There is subsequent filtering, amplification, and digitization of the polymer response for signal processing. Source: Biddiss and Chau [162]

Biddiss and Chau [162] indicated that the application of EAP technology to biomimetic sensors is at various stages, with established systems such as conductive rubber pressure sensors, to exceedingly innovative IPMC systems. Through their studies, they found that IPMS sensor errors (3–5° amplitude errors) were in line with those of the natural proprioceptive system in the metacarpophalangeal joints. There is high resolution and accuracy with conventional sensors (e.g., fiber optics, strain gauges, etc.) but lack durability, flexibility, or of sufficiently small size, rendering them with minimal clinical acceptability for prosthetic devices. There is no need for auxiliary mechanisms or an external power source when IPMCs are employed, significantly reducing bulk. The favorable response through enhanced functional and sensory capacity demonstrated by the IPMC sensor in this study renders them as a necessitated alternative for proprioceptive sensory feedback in prosthetics.

3.8.5 EAPs as Nanocomposites

Organic-inorganic material hybrids have gained increasing amounts of recognition, with hybrid nanocomposites furnishing materials with unique physical properties, greatly exceeding the performance of the individual components alone [166]. These hybrid nanocomposites possess diverse applications; hybrids of nanoparticles and conducting polymers (e.g., Pt, Au, Pd, Zr(HPO4)2, MoO3, MnO2, Mo3Se3, γ-Fe2O3, Fe3O4, and IrO2) have been applied to the fields of electrocatalysis, energy storage devices (e.g., supercapacitors), sensors, battery cathodes, microelectronics, magnetic materials, and electrochemical devices [167–175]. As most of the aforementioned hybrids incorporate metals or their oxides, moisture sensitivity may be an issue if not entrapped within an organic material matrix, thus forming a core/shell nanostructure [176].

The biomedical field could also reap rewards from the application of these hybrid structures with application as electrodes in soft tissue implants. Composites of PPy and carbon nanotubes have been employed in chronic implantable neural probes as electrodes for neural interfaces. The application of iridium oxide (IrO2) as the inorganic component of hybrid materials has been used in numerous applications as a substrate for culture, growth, and neural cell electrical stimulation, as well as a medical electrostimulation electrode and sensor coatings [177–179]. The organic component could be comprised of conducting polymers such as PEDOT and PPy. This combination was predicted by Moral-Vico et al. [176] to be suitable for biomedical electrode applications, with the addition of the EAP providing the required flexibility and biocompatibility for implantation in a living organism [176]. Together with potentially enhanced electrochemical intensive properties, they also anticipated a significant increase in charge capacity due to the Faradic properties of both components.

Other industries have also realized the potential of these novel hybrid phases, for example, as coatings or powders, as PEDOT, PPy, and IrO2 all have applications in energy devices (e.g., solar and fuel cells), electrochromic devices, and sensors [179–181].

In the investigation performed by Moral-Vico and co-workers [176], two novel organic-inorganic nanocomposites comprised either of PPy or PEDOT encapsulating IrO2 (i.e., PPy-IrO x and PEDOT-IrO x ) were formulated via a facile hydrothermal reaction in various oxidation states employing a suspension of the IrO2 and the monomer as precursor. Their biocompatibility was ascertained in the presence of cortical neuron cells and compared with IrO2 and PPy-ClO4 single phase toxicity, with a view of potential applications in the neural system [176] (Fig. 3.10). There was encapsulation and entrapment of IrO2 by the polymer film in all instances. Conductivity and electrochemical activity were evident in varying degrees for the resultant material, with dependence on the initial oxidation state and the relative amount of each component. Biocompatibility was demonstrated by the hybrid materials for neuronal growth and differentiation. In terms of the suspension, a limited amount of material could be employed prior to the observance of toxicity, thus indicating that the nanocomposite maintains the biocompatibility in comparison with the non-hybrid-conducting polymers. The composite thus has potential for application as electroactive phases in biological media, when employed as a coating for bioelectrodes or for nanoparticulate delivery [176].

(a) SEM image of hybrid nanocomposite of polypyrrole and iridium oxide (IrO2), (b) corresponding results of a cytotoxic assay. Source: Moral-Vico et al. [176]

3.8.6 EAPs in Shape-Memory Applications

Shape-memory polymers (SMPs) possess the unique potential of deformation and fixing into a temporary shape, with recovery of their initial permanent shape following application of an external stimulus, which includes thermal, light, electrical, and magnetic stimuli to name a few [182]. SMPs have advantages over shape-memory alloys (SMAs), such as nickel titanium, including lightness, flexibility, processability, high shape recovery ratio, and low cost, in addition to high elastic deformation and low recovery temperature [183]. Their industrial applications are vast ranging from clothing manufacture, space structures, morphing aircraft, and biomedical treatments [184, 185]. There are certain limitations to SMPs limiting wider application including the following: low rubbery moduli lead to small recovery; poor thermal conductivity leads to low recovery speed; and the electrical insulation of most polymeric materials renders them inert to electromagnetic stimuli (compared to SMAs). Various investigations have been undertaken to overcome these challenges; specifically, approaches have been developed to enable electrical actuation of SMPs, resulting in the induction of the recovery of SMP composites via electrically resistant joule heating. This is achieved through combination of SMPs with conductive fillers such as carbon black, carbon fibers, nickel, and PPy, which generate heat in accordance with Joule’s law to enable heat transfer for triggering the shape recovery of the SMP matrix [185–188]. This, however, requires high loading amounts of the conductive filler. Lower loading with notable enhancement of shape recovery can be implemented through institution of nanofillers (e.g., surface-functionalized carbon nanotubes) [185, 189].

Most investigations to date have focused on thermoplastic SMP resins such as polyurethane SMP as an electroactive SMP composite. Its invention was basically the inception of biodegradable SMPs as intelligent polymeric materials for biomedical applications [190]. Thermoplastic SMPs, however, possess poor thermal and mechanical attributes. Investigators then looked toward polylactide (PLA) and its copolymers, but its use was limited by brittleness. Hiljanen-Vaino and co-workers [191] then improved the mechanical properties of PLA via polycondensation with ε-caprolactam, ensued by introduction of urethane linkages for chain extension to poly(ester-urethane). Raja and co-workers [185] then proceeded to delve into an investigation on the shape-memory capabilities of polyurethane-polylactide (PU/PLA) blends, which saw the introduction of pristine and modified carbon nanotubes (CNTs) via a melt mixing process. The electroactive and shape-memory properties of the composite were investigated. Modified CNTs loaded into the PU/PLA blend furnished a significant improvement in the mechanical properties (tensile strength, dynamic storage modulus) and glass transition temperature compared to the pristine CNT-loaded system, as enhanced polymer-CNT interactions were enabled. The fine dispersion of the modified CNT in the matrix emanated in the formation of PU/PLA CNT nanocomposites with good electrical and thermal conductivity, which in turn enhanced the electroactive shape-memory behavior of the resultant composite (Fig. 3.11).

Shape-memory effect of pristine and modified CNT-filled PU/PLA nanocomposites. Source: Raja et al. [185]

3.8.7 EAPs as Artificial Muscles

Polymeric actuators can exceed the performance of natural muscle in a number of aspects; hence, their suitability for biomedical devices, medical prostheses, biomimetic robots, and micro-/nano-electromechanical systems. As mentioned, the sandwiched structure of the ionic exchangeable polymeric core and platinum electrode face sheets of IPMCs are the favored EAPs for electrically driven bending actuators. Wang and co-workers [192] developed a novel biomimetic artificial muscle based on a cross-linked ionic networking membrane of sulfonated poly(arylenethioethersulfone) copolymer (SPTES) and PVA. This muscle was designed to demonstrate electrically actuated bending deformation. Synthesis of the SPTES copolymer was via direct copolymerization of the sulfonated monomers. This was followed by cross-linking with PVA via the dehydration approach with the cross-linking mechanism between the polymeric backbones highlighted in Fig. 3.12. There is transformation of the hydrophilic (–OH) and (–SO3H) groups into the less hydrophilic (–OSO2–) sulfonic ester groups during dehydration. The cross-linking of PVA and SPTES molecules’ membranes minimizes swelling, in addition to altering the hydrophilic-hydrophobic balance inside the membranes. Ion-exchange processes and electroless plating achieved the final electroactive PVA/SPTES actuator. Application of an electric field to the IPMC caused cations within the membrane to carry solvent molecules in the direction of the cathode, with the ion movement instigating bending deformation and thus the actuation force. The cross-linked PVA/SPTES membrane demonstrated significantly enhanced proton conductivity and ionic exchangeable capacity compared to a Nafion membrane (a sulfonated tetrafluoroethylene-based fluoropolymer-copolymer with conductive properties). The bending deformation of the PVA/SPTES actuator is larger, in the absence of straightening-back relaxation and harmonic responses under sinusoidal excitations in a wide frequency band [192].

Chemical structure and cross-linking mechanism of PVA/SPTES. Source: Wang et al. [192]

3.8.8 Advances in Electroactive Coatings

Investigations have focused on the formation of hybrids of conducting EAPs and hydrogels as soft electroactive coatings for enhancing the mechanical and electrical performance of metallic implant electrodes. These soft electroactive materials mediate the mechanical mismatch between stiff metals and soft tissues. A challenge encountered is that it is difficult to achieve submicron coatings, using hydrogel fabrication approaches, which results in bulky implants, displacing excessive tissue volumes. Baek et al. [193] addressed this concern by covalently bonding polymer brushes of poly(2-hydroxyethyl methacrylate) (pHEMA) to a gold electrode via surface-initiated atom transfer radical polymerization (SI-ATRP). Electropolymerization, through the brush layer, of the CP poly(3,4-ethylene dioxythiophene) (PEDOT), formed a thin hydrophilic coating (Fig. 3.13). The electrical properties of the hybrid were shown to be superior to homogenous conducting EAPs. The material formed had potential as a hybrid coating for bioelectrode applications and supported the attachment and differentiation of model neural cells.

Schematic of the fabrication of the CP-brush hybrid. 1 Surface initiator self-assembly. 2 Surface-initiated atom transfer radical polymerization of pHEMA. 3 PEDOT/pTS electrodeposition through pHEMA. Source: Baek et al. [193]

3.9 Conclusion

EAPs encompass a novel technology platform that holds pertinent potential with diverse industrial applications. This chapter highlighted their specific impact in the medical and pharmaceutical industries. The key to their success is their extensive versatility, with the choice of dopant being important for definition of the overall properties. In this chapter, an overview has been provided of all the factors implicit to the successful operation of an EAP-based delivery system or device. Stemming from this, a panoply of drug delivery systems and biomedical devices has been developed, demonstrating the intelligence of design inherent in these systems, which can ultimately enable patient-controlled electroresponsive bioactive release for the tailored control of the clinical response. This being said, these developments are not without their limitations. Developments, specifically in the design of hybrid nanocomposites, could see these hurdles overcome. It is clear that the future will bring further examples of EAP-based systems in nanorobotics, nanobiosensors, prosthetics, and responsive miniaturized delivery systems where “smart” capabilities will be the name of the game.

References

Balint R, Cassidy NJ, Cartmell SH (2014) Conductive polymers: towards a smart biomaterial for tissue engineering. Acta Biomater 10:2341–2353

Bar-Cohen Y (2004) Electroactive polymer (EAP) actuators as artificial muscles – reality, potential and challenges, vol PM136, 2nd edn. SPIE Press, Bellingham, WA, pp 1–176

Bar-Cohen Y (2012) Biomimetic muscles and actuators using electroactive polymers (EAP). In: Bhushan B (ed) Encyclopedia of nanotechnology. Springer, Dordrecht, pp 285–290

Lakard B, Ploux L, Anselme K, Lallemand F, Lakard S, Nardin M et al (2009) Effect of ultrasounds on the electrochemical synthesis of polypyrrole, application to the adhesion and growth of biological cells. Bioelectrochemistry 75:148–157

Guiseppi-Elie A (2010) Electroconductive hydrogels: synthesis, characterization and biomedical applications. Biomaterials 31:2701–2716

Ateh DD, Navsaria HA, Vadgama P (2006) Polypyrrole-based conducting polymers and interactions with biological tissues. J R Soc Interface 3:741–752

Zhou DD, Cui XT, Hines A, Greenberg RJ (2010) Conducting polymers in neural stimulation applications. In: Zhou DD, Greenbaum E (eds) Implantable neural prostheses, vol 2. Springer, Berlin, pp 217–252

Guimard NK, Gomez N, Schmidt CE (2007) Conducting polymers in biomedical engineering. Prog Polym Sci 32:876–921

Kirchmeyer S, Reuter K (2005) Scientific importance, properties and growing applications of poly(3,4-ethylenedioxythiophene). J Mater Chem 15:2077–2088

Wan M (2008) Introduction of conducting polymers. In: Wan M (ed) Conducting polymers with micro or nanometer structure. Springer, Berlin, pp 1–15

Pillay V, Tsai T-S, Choonara YE, du Toit LC, Modi G, Naidoo D, Tomar LK, Tyagi C, Kumar P, Ndesendo VMK (2014) A review of integrating electroactive polymers as responsive systems for specialized drug delivery applications. J Biomat Res A 102:2039–2054

Roentgen WC (1880) About the changes in shape and volume of dielectrics caused by electricity, section III. In: Wiedemann G (ed) Annual physics and chemistry series, vol 11, John Ambrosius Barth Publisher. Leipzig, German, pp 771–786 (In German)

Park IS, Jung K, Kim DSM, Kim KJ (2008) Physical principles of ionic polymer-metal composites as electroactive actuators and sensors, special issue dedicated to EAP. Mater Res Soc MRS Bull 33:190–195

Madden JDW, Madden PG, Hunter IW (2002) Conducting polymer actuators as engineering materials. In: Bar-Cohen Y (ed) Proceeding of the SPIE smart structures and materials 2002: electroactive polymer actuators and devices (EAPAD). SPIE Press, Bellingham, WA, pp 176–190. doi:10.1117/12.475163

Cheng Z, Zhang Q (2008) Field-activated electroactive polymers, special issue dedicated to EAP. Mater Res Soc MRS Bull 33:190–195

Inzelt G, Szabo L (1986) The effect of the nature and the concentration of the counter-ions on the electrochemistry of poly (vinylferrocene) polymer film electrodes. Electrochim Acta 31:1381–1387

Bott AW (2001) Electrochemical techniques for the characterization of redox polymers. Curr Sep 19:71–77

History of polymer and plastics for students. American Chemistry Council. http://plastics.americanchemistry.com/Education-Resources/Hands-on-Plastics/Introduction-to-Plastics-Science-Teaching-Resources/History-of-Polymer-and-Plastics-for-Students.html. Accessed on April 7, 2015.

Karyakin AA, Karyakina EE, Schmidt H (1998) Electropolymerized azines: a new group of electroactive polymers. Electroanalysis 11:149–155

Asami R, Atobe M, Fuchigami T (2005) Electropolymerization of an immiscible monomer in aqueous electrolytes using acoustic emulsification. J Am Chem Soc 127:13160–13161

Ali E, Mahmood K, Mansoor K (2006) Electropolymerization of aniline on plastically deformed Pd surface: structure at micro- and nano-scale. Polym J 38:329–334

Wang Z, Kang J, Liu X, Ma Y (2007) Capacitive detection of theophylline based on electropolymerized molecularly imprinted polymer. Int J Polym Anal Charact 12:131–142

Walter MG, Wamser CC (2010) Synthesis and characterization of electropolymerized nanostructured aminophenylporphyrin films. J Phys Chem C 114:7563–7574

Ku CC, Liepins R (1987) Dielectric breakdown in polymers. In: Ku CC, Liepins R (eds) Electrical properties of polymers—chemical principles. Hanser Publishers, Munich, Germany, pp 102–199

Ghasemi-Mobarakeh L et al (2011) Application of conductive polymers, scaffolds and electrical stimulation for nerve tissue engineering. J Tissue Eng Regen Med 5:e17–e35

Ravichandran R, Sundarrajan S, Venugopal JR, Mukherjee S, Ramakrishna S (2010) Applications of conducting polymers and their issues in biomedical engineering. J R Soc Interface 7:S559–S579

Pelto J et al (2010) Electroactivity and biocompatibility of polypyrrolehyaluronic acid multi-walled carbon nanotube composite. J Biomed Mater Res 93A:1056–1067

Lyons MEG, Fay HG, McCabe T, Corish J, Vos JG, Kelly AJ (1990) Charge percolation in electroactive polymer films. J Chem Soc Faraday Trans 86:2905–2910

Bar-Cohen Y (2007) Focus issues on biomimetics using electroactive polymers as artificial muscles. Bioinsp Biomim 2:E01

Bidez PR, Li S, Macdiarmid AG, Venancio EC, Wei Y, Lelkes PI (2006) Polyaniline, an electroactive polymer, supports adhesion and proliferation of cardiac myoblasts. J Biomater Sci Polym Ed 17:199–212

Wang LX, Soczka-Guth T, Havinga E, Mullen K (2003) Poly(phenylenesulfidephenylenamine) (PPSA)—the “compound” of polyphenylenesulfide with polyaniline. Angew Chem 35:1495–1497

Otero TF, Rodriguez J, Angulo E, Santamaria C (1993) Artificial muscles from bilayer structures. Synth Met 55–57:3713–3717

Della Santa A, De Rossi D, Mazzoldi A (1997) Performance and work capacity of a polypyrrole conducting polymer linear actuator. Synth Met 90:93–100

Kincal D, Kumar A, Child A, Reynolds J (1998) Conductivity switching in polypyrrole-coated textile fabric as gas sensors. Synth Met 92:53–56

Lekpittaya P, Yanumet N, Grady BP (2004) Resistivity of conductive polymer-coated fabric. J Appl Polym Sci 92:2629–2636

Lopes A, Martin S, Moraö A, Magrinho M, Gonçalves I (2004) Degradation of a textile dye, C.I. Direct Red 80 by electrochemical processes. Portug Electrochim Acta 22:79–94

Moschou EA, Peteu SF, Bacha LG, Madou MJ, Daunert S (2004) Artificial muscle material with fast electroactuation under neutral pH conditions. Chem Mater 16:2499–2502

Kenji M, Shunzo S, Makoto U, Katsuhiko N (2000) Synthesis of a novel soluble polyaniline using imide super-acid. Nippon Kagakkai Koen Yokoshu 78:114–119

Lindström H, Holmberg A, Magnusson E, Lindquist S, Malmqvist L, Hagfeldt A (2001) A new method for manufacturing nanostructured electrodes on plastic substrates. Nano Lett 1:97–100

McCarthy PA, Juang J, Yang S, Wang H (2002) Synthesis and characterization of water-soluble chiral conducting polymer nanocomposites. Langmuir 18:259–263

Chao D, Lu X, Chen J, Liu X, Zhang W, Wei Y (2006) Synthesis and characterization of electroactive polyamide with amine-capped aniline pentamer and ferrocene in the main chain by oxidative coupling polymerization. Polymer 47:2643–2648

Palaniappan S, Devi SL (2006) Thermal stability and structure of electroactive polyaniline-fluoroboric acid-dodecylhydrogensulfate salt. Polym Degrad Stab 91:2415–2422

Zhang H, Li HX, Cheng HM (2006) Water-soluble multi-walled carbon nanotubes functionalized with sulphonated polyaniline. J Phys Chem B 110:9095–9099

Huang Y, Yu H, Xiao C (2007) pH-sensitive cationic guar gum/poly (acrylic acid) polyelectrolyte hydrogels: swelling and in vitro drug release. Carbohydr Polym 69:774–783

Huang L, Hu J, Lang L, Wang X, Zhang P, Jing X, Wang X, Chen X, Lelkes PI, Macdiarmid AG, Wei Y (2007) Synthesis and characterization of electroactive and biodegradagble ABA block copolymer of polylactide and aniline pentamer. Biomaterials 28:1741–1751

Guo B, Finne-Wistrand A, Albertsson A (2011) Versatile functionalization of polyester hydrogels with electroactive aniline oligomers. J Polym Sci Polym Chem 49:2097–2105

Tsai T, Pillay V, Choonara YE, du Toit LC, Modi G, Naidoo D, Kumar P (2011) A polyvinyl alcohol polyaniline based electro-conductive hydrogel for controlled stimuli-actuable release of indomethacin. Polymers 3:150–172

Yin W, Ruckenstein E (2001) A water-soluble self-doped conducting polypyrrole-based copolymer. J Appl Polym Sci 79:86–89

Bae WJ, Kim KH, Jo WH (2005) A water-soluble and self-doping conducting polypyrrole graft copolymer. Macromolecules 38:1044–1047

Ansari R (2006) Polypyrrole conducting electroactive polymers: synthesis and stability studies. E J Chem 3:186–201

Kim J, Deshpande SD, Yun S, Li Q (2006) A comparative study of conductive polypyrrole and polyaniline coatings on electro-active papers. Polym J 38:659–668

Sutar D, Aswal DK, Gupta SK, Yakhmi JV (2007) Electrochemical actuator from conductive electroactive polymer polypyrrole deposited on gold. Indian J Pure Appl Phys 45:354–357

Fichou D, Ziegler C (1999) Single crystals and thin films. In: Fichou D (ed) Handbook of oligo- and polythiophenes. Wiley-VCH, Weinheim, Germany, pp 185–282

Granstrom M, Harrison MG, Friend RH (1999) Electrooptical polythiophene devices. In: Fichou D (ed) Handbook of oligo- and polythiophenes. Wiley-VCH, Weinheim, Germany, pp 54–58

Gnanakan SRP, Rajasekhar M, Subramania A (2009) Synthesis of polythiophene nanparticles by surfactant-assissted dilute polymerization method for high performance redox supercapacitors. Int J Electrochem Sci 4:1289–1301

Heeger AJ (2001) Semiconducting and metallic polymers: the fourth generation of polymeric materials. J Phys Chem B 105:8475–8491

Bar-Cohen Y, Kwang J, Kim KJ, Choi HR, Madden JDW (2007) Electroactive polymer materials. Smart Mater Struct 16, E01

Kinoshita Y, Kuzuhara T, Kobayashi M, Ikada Y (1995) Reduction in tumor formation on polyethylene by collagen immobilization. J Long Term Eff Med Implants 5:275–284

Sengothi K, Tan P, Wang J, Lee T, Kang ET, Wang HC (1999) Biocompatibility of polyaniline polymers in tissue: Biomaterial surface interactions. In: AIChE annual meetings, Dallas, TX

Zhao H, Price WE, Too CO, Wallace GG, Zhou D (1996) Parameter influencing transport across conducting electroactive polymer membranes. J Membr Sci 119:199–212

Zhao H, Price WE, Wallace GG (1998) Synthesis, characterization and transport properties of layered conducting electroactive polypyrrole membrane. J Membr Sci 148:161–172

Zhao H, Prince WE, Wallace GG (1994) Effect of counter-ions employed during synthesis on the properties of polypyrrole membranes. J Membr Sci 87:47–56

Cirić-Marjanović G, Dragićević L, Milojević M, Mojović M, Mentus S, Dojćinović B, Marjanović B, Stejskal J (2009) Synthesis and characterization of self-assembled polyaniline nanotubes/silica nanocomposite. J Phys Chem B 113:7116–7127

Sadki S, Schottland P, Brodie N, Sabourand G (2000) The mechanisms of polypyrrole electropolymerization. Chem Soc Rev 29:283–293

Pistoia G, Bagnarelli O, Maiocco M (1978) Evaluation of factors affecting the radical electropolymerization of methylmethacrylate in the presence of HNO3. J Appl Electrochem 9:343–349

Yamada K, Tenshima K, Kobayashi N, Hirohashi R (1997) Electropolymerization of aniline derivatives in non-aqueous solution without a proton donor. J Electroanal Chem 394:71–79

Roeder J, Zucolotto V, Shishatskiy S, Bertolino JR, Nunes SP, Pires ATN (2006) Mixed conductive membrane: Aniline polymerization in an acid SPEEK matrix. J Membr Sci 279:70–75

Hatchett DW, Josowicz M, Janata J (1999) Acid doping of polyaniline: spectroscopic and electrochemical studies. J Phys Chem B 103:10992–10998

Kowalski D, Ueda M, Ohtsuka T (2008) The effect of ultrasonic irradiation during electropolymerization of polypyrrole on corrosive prevention of the coated steel. Corros Sci 50:286–291

Shabani-Nooshabadi M, Ghoreishi SM, Behpour M (2009) Electropolymerized polyaniline coatings on aluminum alloy 3004 and their corrosion protection performance. Electrochim Acta 54:6989–6995

Dimitriev OP (2003) Doping of polyaniline by transition metals: effect of metal cation on film morphology. Synth Mater 142:299–303

Taka T, Laakso J, Levon K (1994) Conductivity and structure of DBSA-protonated polyaniline. Solid State Commun 92:393–396

Mirmohseni A, Wallace GG (2003) Preparation and characterization of processable electroactive polyaniline–poly vinyl alcohol composites. Polymer 44:3523–3528

Palaniappan S, Saravanan C, John A (2005) Emulsion polymerization for preparation of polyaniline-sulfate salt, using non-ionic surfactant. J Macromol Sci Part A 42:891–900

Kinlen PJ, Frushour BG, Ding Y, Menon V (1999) Synthesis and characterization of organically soluble polyaniline and polyaniline block copolymers. Synth Mater 101:758–761

Posadas D, Florit MI (2004) The redox switching of electroactive polymers. J Phys Chem 108:15470–15476

Scampicchio M, Lawrence NS, Arecchi A, Mannino S (2007) Determination of sulphite in wine by linear sweep voltammetry. Electroanalysis 20:444–447

Pathiratne KAS, Skandaraja SS, Jayasena EMCM (2008) Linear sweep voltammetric determination of free chlorines in waters using graphite working electrodes. J Nat Sci Found Sri Lanka 36:25–31

Heinze J (2003) Cyclic voltammetry—“electrochemical spectroscopy”: new analytical method. Angew Chem 23:831–847

Fortunato R, Branco LC, Afonso CAM, Benavente J, Crespo JG (2006) Electrical impedance spectroscopy characterization of supported ionic liquid membranes. J Membr Sci 270:42–49

Gabrielli C, Keddam M, Nadi N, Perrot H (2000) Ion and solvent transport across conducting polymers investigated by AC electrogravimetry. Application to polyaniline. J Electroanal Chem 485:101–113

Lyons MEG (1996) Transport and kinetics in electroactive polymers. In: Prigogine I, Rice SA (eds) Advances in chemical physics: polymeric systems, vol 94. Wiley, Hoboken, NJ, Chapter 5

Nguyen TA, Kobot S, Ongarato DM, Wallace GG (1999) The use of chronoamperometry and chemometrics for optimization of conducting polymer sensor arrays. Electroanalysis 11:1327–1332

Peppas NA, Bures CD (2006) Glucose-responsive hydrogels. In: Wnek GE, Bowlin GL (eds) Encyclopedia biomaterials and biomedical engineering. Dekker, New York, NY

Deng K, Zhang P, Ren X, Zhong H, Gou Y, Dong L, Li Q (2009) Synthesis and characterization of a pH/temperature responsive glycine-mediated hydrogel for drug release. Front Mater Sci China 3:374–379

Wang Q, Mynar JL, Yoshida M, Lee E, Lee M, Okuro K, Kinbara K, Aida T (2010) High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 463:339–343

Bikram M, Gobin AM, Whitmire RE, West JL (2007) Temperature sensitive-hydrogel with SiO2–Au nanoshells for controlled drug delivery. J Control Release 123:219–227

Westbrook KK, Qi HJ (2008) Actuator designs using environmentally responsive hydrogels. J Intell Mater Syst Struct 19:597–607

Park C, Orozco-Avila I (2008) Concentrating cellulose from fermented broth using a temperature sensitive hydrogel. Biotechnol Prog 8:521–526

You J, Auguste DT (2010) Conductive, physiologically responsive hydrogels. Langmuir 26:4607–4612

Qui Y, Park K (2001) Environment-sensitive hydrogels for drug delivery. Adv Drug Deliv Rev 53:321–329

Murdan S (2003) Electro-responsive drug delivery from hydrogel. J Control Release 93:1–17

Li H, Yuan Z, Lam KY, Lee HP, Chen J, Hanes J, Fu J (2004) Model development and numerical simulation of electric-stimulus-responsive hydrogels subject to an externally applied electric field. Biosens Bioelectron 19:1097–1107

Li L, Huang C (2007) Electrochemical/electrospray mass spectrometric studies of electrochemically stimulated ATP release from PP/ATP films. J Am Mass Spectrom 18:919–926

Luo R, Li H, Birgersson E, Lam KY (2008) Modeling of electric-stimulus responsive hydrogels immersed in different bathing solutions. J Biomed Mater Res 85A:248–257

Brahim S, Guiseppi-Elie A (2004) Electroconductive hydrogels: electrical and electrochemical properties of polypyrrole-poly (HEMA) composite. Electroanalysis 17:556–570

Ehrick JD, Deo SK, Browning TW, Bachas LG, Madou MJ, Daunert S (2005) Genetically engineered protein in hydrogels tailors stimuli-responsive characters. Nat Mater 4:298–302

Miyata T, Asami N, Uragami T (1999) A reversibly antigen-responsive hydrogel. Nature 399:766–769

Pernaut J, Reynolds JR (2000) Use of conducting electroactive polymers for drug delivery and sensing of a bioactive molecular. A redox chemistry approach. J Phys Chem B 104:4080–4090

Zinger B, Miller LL (1984) Timed release of chemicals from polypyrrole films. J Am Chem Soc 106:6861–6863

Pyo M, Reynolds JR (1994) Electrochemically stimulated adenosine 5′-triphosphate (ATP) release through redox switching of conducting polypyrrole films and bilayers. Chem Mater 8:128–133

Otero TF, Padilla J (2004) Anodic shrinking and compaction of polypyrrole blend: electrochemical reduction under conformational relaxation kinetic control. J Electroanal Chem 561:167–171

Moina YG, Andrade C, Molina EM, Florit FV, Rodríguez Presa MI, Posada MJ (2003) Conformational changes during the redox switching of electroactive polymers. J Argentine Chem Soc 91:119–134

Silk T, Tamm J (1996) Voltammetric study of the influence of cations on the redox switching process of halogenide-doped polypyrrole. Electrochim Acta 41:1883–1885

Li L, Hsieh Y (2005) Ultra-fine polyelectrolyte hydrogel fibres from poly (acrylic acid)/poly (vinyl alcohol). Nanotechnology 16:2852–2860

Wang Y, Shen Y, Zhang Y, Yue B, Wu C (2006) pH-sensitive poly acrylic acid (PAA) hydrogels trapped with polysodium-p-styrenesulfonate (PSS). J Macromol Sci Part B 45:563–571

Adnadjevic B, Jovanovic J (2007) Novel approach in investigation of the poly (acrylic acid) hydrogel swelling kinetics in water. J Appl Polym Sci 107:3579–3587