Abstract

Transgenic plants can be used for molecular farming for the production of recombinant pharmaceutical or industrial compounds. They offer attractive alternatives to produce low-cost recombinant pharmaceuticals or industrially-important proteins on a large scale. The feasibility of precise plant genetic manipulation, high-scale expression of recombinant proteins, rapid and easy scaling up, and convenient storage of raw material and less concern of contamination with human or animal pathogens during downstream processing has attracted biotechnologists to plastid and chloroplast engineering. Crop plants produce large amounts of biomass at low cost and require limited facilities. Molecular farming represents a novel source of molecular medicines, such as plasma proteins, enzymes, growth factors, vaccines and recombinant antibodies, whose medical applications are understood at the molecular level. Edible organs can be consumed as uncooked, unprocessed or partially-processed material, making them ideal for the production of recombinant subunit vaccines, nutraceuticals and antibodies designed for topical application. Based on this prominence, the present chapter is aimed to cover recent advancement for the production of plant pharmaceuticals.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The use of plants for medicinal purposes is not new but genetic engineering of plants to produce desired biopharmaceuticals is quite recent. The growing of plants in agriculture to produce pharmaceutical or industrial compounds instead of food, feed or fiber is called plant molecular farming. The possibilities range from the manufacture of medical products, such as pharmaceuticals (drugs) and vaccines, to the production of products like biodegradable plastics (Kamenarova et al. 2005) and industrial chemicals (Paul et al. 2011; Sahu et al. 2014; Stoger et al. 2014). With the development of efficient genetic transformation methods, transgenic plants are now increasingly being used for the production of a variety of compounds such as monoclonal antibodies (Hiatt et al. 1989), blood substitutes (Magnuson et al. 1998), industrial proteins (Franken et al. 1997), parental therapeutics , pharmaceutical intermediates and antigens/antibodies (Walmsley and Arntzen 2000).

As the demand for biopharmaceuticals is increasing, they should be made available in significantly larger amounts. Currently, the cost of biopharmaceuticals limits their availability (Kayser and Warzecha 2012). Plant-derived biopharmaceuticals are cheap to produce and store. They are easy to scale up for mass production, and safer than those derived from animals (Ma and Wang 2012). Plant molecular farming is the use of genetically-modified plants to produce pharmaceutical products or industrial chemicals. These plants are developed by inserting new genes, usually from other species, so that a plant can produce the desired substance. Substances accumulate in specific parts of the plant, such as seeds or leaves and can be extracted and refined for use. Plants under investigation include potato, banana, wheat, tobacco, rice, soybean, spinach, maize, legumes, tomato and Arabidopsis (Jelaska et al. 2005). These plants could be used to fight diseases like cholera, measles, hepatitis-B, Norwalk virus , rabies virus and enterotoxigenic Escherichia coli (Thomas et al. 2002).

Transgenic plants that express foreign proteins of industrial or pharmaceutical value, represent an economical alternative to fermentation-based production systems (Valkova et al. 2013). The cost of vaccines is one of the factors preventing their wider use in vaccination, leaving thousands of children at risk of preventable diseases. First, the cost of purchasing and administering current vaccines is too high for many developing countries (Fischer et al. 2014). Second, compliance is limited by the inconvenience of needing trained personnel to administer injections and the reluctance of many individuals to receive injections. Third, a small but significant proportion of individuals vaccinated are not protected by current vaccines. The principal costs of most marketable vaccines are in production, packaging and delivery. Other related expenses are disposal of needles and syringes and refrigeration required during storage. These economic factors also prevent widespread vaccination of livestock, poultry and swine against avoidable diseases.

Plant vaccines are generally inexpensive to produce and thus can easily be made available in developing countries. For some vaccine antigens, transgenic plants may provide an ideal expression system in which transgenic plant material can be fed directly to people as an oral dose of recombinant vaccine. Edible plant vaccines are effective as delivery vehicles for inducing oral immunization (Horn et al. 2004; Stoger et al. 2014). This is because production cost is low, effective safety, extraction and purification are not required. In addition, these vaccines are safe to store and transport, reducing the need for medical personnel and sterile injection conditions and dependence on foreign supply (Rathore and Shekhawat 2007). This chapter provides an overview of molecular farming prospects to produce various human health-promoting recombinant subunit vaccines, nutraceuticals and antibodies.

2 Transgenic Approaches

Genetic transformation technology has been proved to be a powerful tool for the production of plants with desired traits in many crops (Fig. 4.1). It promises to overcome some of the substantial agronomic and environmental problems that have not been solved using conventional plant breeding programs. Plant transformation mediated by Agrobacterium tumefaciens , plant pathogenic bacterium, has become the most commonly used method for the introduction of foreign genes into plant cells and the subsequent regeneration of transgenic plants . This soil bacterium possesses the natural ability to transform its host by delivering a well-defined DNA fragment, the transferred (T) DNA, of its tumor-inducing (Ti) plasmid into the host cell. Rapid progress in the area of crop biotechnology is mainly because of the development of efficient regeneration and suitable Agrobacterium-mediated transformation protocols for different crop species. Similar success could also be achieved in medicinal plants, which in turn could be used for the enhancement of secondary metabolite content (Khan et al. 2009). Agrobacterium-mediated gene transfer has the advantage for allowing stable integration of defined DNA into the plant genome that generally results in lower copy number, fewer rearrangements and more stability of expression over generations than other transfection methods. Recent studies have shown that virus -based vectors can be efficiently used for high transient expression of foreign proteins in transfected plants and that non-Agrobacterium bacterial species can be used for the production of transgenic plants , laying the foundation for alternative tools for future plant biotechnology . Non-Agrobacterium species like Rhizobium sp. NGR234, Sinorhizobium meliloti and Mesorhizobium loti, are capable of genetically transforming different plant tissues and plant species (Broothaerts et al. 2005).

Simplified representation of molecular farming (Sahu et al. 2014)

Another method of transformation, particle bombardment, was introduced in 1987, which involves the use of a modified shotgun to accelerate small diameter (1–4 μ) metal particles into plant cells at a velocity sufficient to penetrate the cell wall. There is no intrinsic limitation to the potential of particle bombardment since DNA is governed entirely by physical parameters. Different types of plant materials have been used as transformation targets including callus, cell suspension cultures and organized tissues such as immature embryos and meristems. The results indicate that biolistic transformation can lead to the transfer, expression and stable integration of a DNA fragment into chromosomal DNA. The biolistic method usually results in higher copy-number integration of the transgene than Agrobacterium, which can enhance expression. However, excessive copies or very high level expression of nuclear genes can cause gene silencing , resulting in low expression (Finnegan and McElroy 1994; Hobbs et al. 1993; Vaucheret et al. 1998). Thus it is important to select transgenic lines that carry only 1–3 copies of the transgene. The biolistic method is also used to introduce transgenes into the genome of the chloroplast (Svab et al. 1990). The high chloroplast genome copy number in plant cells contributes to enhanced recombinant protein expression. Some agronomically important plant species (e.g. soybean and most cereal grains) are recalcitrant to Agrobacterium transformation; for these plants, the biolistic method is frequently used (Sanford et al. 1993).

3 History of Molecular Farming

Molecular farming is as old as the first successfully transformed plant, because all of the genes have the potential of giving a protein product (Fischer et al. 2014). Initially human growth hormone and antibody chains were produced using transgenic tobacco and sunflower (Barta et al. 1986; Hiatt et al. 1989). The first marker genes have used in developing a transformation systems in plants is uids (Jefferson et al. 1987), which is now a molecular farming product (Kusnadi et al. 1998; Witcher et al. 1998). During (1988) reported the first human antibodies produced in plants. The first protein produced in plants for the specific purpose of extraction, purification, and sale was avidin . It is an eg g protein with several important properties (Hood et al. 1997). Zhong et al. (1999) detailed the production of aprotinin , one of the first molecularly-farmed pharmaceutical proteins produced in plants. Aprotinin can be used medically for wound closure and to suppress systemic inflammatory responses during surgery.

4 Molecular Farming Systems

Vaccine antigens can be produced in plants using two different systems: stable genetic transformation and transient expression. Stable transformation produces plants that can be propagated either vegetatively, or by seed resulting from sexual reproduction (Tacket et al. 1998, 2000). Transient expression uses a recombinant plant virus that carries the vaccine gene and by systemic infection, causes the plant to express the antigen (Koprowski and Yusibov 2001). The main advantage of transient expression with a plant-virus system is that virus replication amplifies gene copy number, resulting in a much higher level of expression than with stable transformation. However, the plant-virus systems may suffer from instability and loss of foreign genes larger than 1 kb. In addition, the need to individually inoculate each plant makes large-scale production laborious. Stable transformation causes integration of the recombinant DNA i nto the genome of either the nucleus or the chloroplast of the plant cell. Nuclear transformation is most often achieved with a plant pathogen such as Agrobacterium tumefaciens that can efficiently transport DNA into plant cells targeting the nucleus to cause chromosomal integration at random sites (Zambryski 1988). Stable transgene expression was recently described in the chloroplast-derived chromoplasts of tomato fruit (Ruf et al. 2001). A further advantage is that, as the chloroplast genome is inherited maternally in most plants, there is minimal danger of unintended spread of transgenes by pollen.

Currently there are four methods of protein production from plants: (1) nuclear transformation, (2) stable plastid transformation, (3) transient transformation and (4) stable transformation of a plant species grown hydroponically such that the transprotein is secreted into the medium and recovered.

The first and most common method of protein production from plants is nuclear transformation of a crop species. All the products available in the market today are based on this method (Fig. 4.1). The most-commonly used methods for transferring foreign genes into the plant cells, are Agrobacterium tumefaciens or particle bombardment, in which the genes are incorporated stably into the host nuclear genome. In grain crops, the protein product is normally accumulated in the seed (Delaney 2002). Seed can be stored without protein degradation even if unrefrigerated for a long time, and transportation can also be done at ambient temperature. The disadvantage of this type of transformation is higher manual labor requirements and lower yields.

The second method, stable plastid transformation of the genome, was first reported in a higher plant, tobacco, by Svab et al. (1990). The transgenic plastid genomes were products of a multistep process, involving DNA recombination, copy correction and sorting out of plastid DNA copies. Tobacco is the only species in which plastid transformation has been established as routine (Daniell et al. 2002; Svab and Maliga 1993). Plastid genes are not usually transmitted through pollen so that outcrossing is not a major problem. But in this system protein stability will change over time even with refrigeration. Extraction and purification must be performed at very specific times following harvest. Large volume products and edible vaccines would not appear to be feasible using this system.

Transient transformation system, the third method, depends on the ability of recombinant plant viruses such as tobacco mosaic virus (TMV) to infect tobacco plants and then transiently express a target protein in the plant tissue. The protein will accumulate in the interstitial spaces and the interstitial fluid can then be collected by centrifugation under vacuum. TMV can be easily manipulated genetically and the infection process is rapid. Small quantities of the target protein can be obtained within several weeks. But this type of transformation is not suitable for a protein needed in large quantities. The product must be processed immediately as storage will cause degradation of the plant tissue (Stoger et al. 2014).

The fourth method of protein production from plants uses hydroponic systems (floating systems), with transgenic plants containing a gene coding for production of the target protein. It is intermediate between suspension and whole plant cultures, based on the use of whole organisms (micro algae, moss or aquatic plants) that are fully or partly in contact with a culture medium and also have the advantage of being fully contained and allowing the secretion-based recovery of the product (Decker et al. 2014; Mathieu-Rivet et al. 2014; Raskin 2000). Purification of the desired product is considerably easier since no tissue disruption is needed and the quantity of contaminating proteins is low. But this system is also unsuitable to producing large quantities of any protein product. In addition, hydroponic facilities are relatively expensive to operate.

5 Classes of Proteins Within Molecular Farming

Biotechnology involves the efficien t utilization of biological material for rich harvest. Plant biotechnology, especially the genetic engineering of plants, has been developed to such an extent that cloned gene(s) synthesized in the laboratory can be introduced into plants which stably express the genes in the resulting transgenic plants and are also transmitted to the next generations. The transgenic approach has resulted in the release of several superior varieties of different crops for commercial production in many countries of the world. Plants have traditionally been a major source of medicines; for example, the Ayurvedic system depends upon plant-based medicines. With the advent of innovative approaches, plants have been given renewed possibilities to produce preventive drugs. Proteins currently being produced in plants for molecular farming purposes can be categorized into four broad areas: (1) parental therapeutics and pharmaceutical intermediates , (2) monoclonal antibodies (MAbs) , (3) industrial proteins (e.g. enzymes ) and (4) antigens for edible vaccines .

5.1 Parental Therapeutics and Pharmaceutical Intermediates

This group includes all proteins u sed directly as pharmaceuticals. Such proteins include products like thrombin and collagen (therapeutics), and trypsin and aprotinin (intermediates). Many proteins in this category have been expressed in tobacco. However, there are some notable exceptions; for instance, rice has been used for the production of human α-interferon (Zhu et al. 1994), canola for hirudin (Parmenter et al. 1995) and α-1 antitrypsin (Terashima et al. 1999) and maize for bovine aprotinin (Azzoni et al. 2002; Zhong et al. 1999). Recombinant human glycoproteins synthesized in plants show much greater similarity to their native counterparts in terms of N-glycan structure compared to the same proteins produced in yeast, bacteria or filamentous fungi (Obembe et al. 2011). Recent reports indicate that rice is a suitable host for recombinant protein due to its competitive yield of certain recombinant proteins, such as human serum albumin, cytokines compared to other plant expression systems such as tobacco cell cultures and potato tubers (Kuo et al. 2013). One of the first publications involving producing HAS (human serum albumin) using a rice suspension cell system with an inducible promoter αAmy3/RAmy3D, reported a maximum yield of 76.4 mg/l of medium after 4 days of sucrose starvation (Huang et al. 2005). There is more than a sixfold yield advantage compared to HSA produced using tobacco suspension cell, which was 11.88 mg/l (Sun et al. 2011). Alternatively, a high yield of recombinant HSA has also been produced in rice endosperm. An endosperm-specific promoter, Gt13a, and its signal peptide were used to direct expressed protein into protein storage vacuoles, and a maximum yield of 2.75 g/kg of brown rice was obtained (He et al. 2011). This is a significant yield improvement over production of HSA using potato tubers (0.01 g/kg of fresh weight) and well above the threshold for cost-effective industrial production, which was 0.1 g/kg of fresh weight (Farran et al. 2002).

The structural study of HSA shows that recombinant HSA (OsrHSA) produced using a rice expression is structurally equivalent to plasma HSA (He et al. 2011). The first report of human GM-CSF (hGM-CSF) production in rice was in 2003 through suspension cell cultures, and the maximum yield obtained was 129 mg/l (Shin et al. 2003). Since then, improvements have been made in rice suspension cell systems producing hGM-CSF by using methods such as humanizing N-glycan structure and increasing yield by two to threefold through reduction of endogenous α-amylase expression, co-expression of proteinase inhibitor and suppression of cellular cysteine proteinase (Kim et al. 2008a, b, c, d; Shin et al. 2011). The protein is also produced in other expression systems such as rice seeds and tobacco seeds using rice glutelin promoters Gt1 and Gt3. The maximum yields were 1.3 % of total soluble protein in rice seeds and 0.03 % of total soluble protein in tobacco seeds (Sardana et al. 2002, 2007). Mouse GM-CSF (mGM-CSF) was successfully produced using rice suspension cells, with yield of 24.6 mg/l of medium (Liu et al. 2012). The same glycoprotein was also produced in tobacco leaves, and the yield was 19 μg/g of fresh leaves (Gora-Sochacka et al. 2010). Interleukin-10 (IL-10) has been successfully produced in rice seeds using Glub-1 promoter and its signal peptide to localize the protein inside seeds exclusively. The product is determined to be un-glycosylated and the yield of final purified protein was 2 mg per 40 g of rice used (50 μg/g). The biological activity of recombinant IL-10 was confirmed using mouse bone marrow dendritic cells (Fujiwara et al. 2010). The protein was also produced inside tobacco leaves, and the yield was 37.0 μg/g of fresh leaves (Bortesi et al. 2009). Production of class II interferon INF-γ has been performed in rice suspension cells using both constitutive maize ubiquitin promoter and inducible rice αAmy3/RAmy3D promoter, and the biological activity has been confirmed using human A549 cell line against dengue virus . A α-amylase signal peptide was added to both in order to allow for secretion of recombinant INF-γ into the culture medium. The highest yield obtained from the culturing medium of the ubiquitin promoter driven system was 12 and 17.4 ng/mL in αAmy3/RAmy3D promoter driven system, and yield found inside the cell was 699.79 ng/g of fresh cell weight for the ubiquitin promoter driven system and 131.6 ng/g of fresh cell weight for the αAmy3/RAmy3D promoter driven system (Chen et al. 2004).

Production of human α1-antitrypsin (hAAT) in recombinant rice suspension cells was first achieved in 2000, with a yield of 120 mg/l, cultured in 30 mL of medium with 10 % (v/v) of cell density (Huang et al. 2001). Recombinant hGH (human growth hormone) has been successfully produced in rice suspension cells using αAmy3/RAmy3D as a promoter. The maximum yield is 57 mg/l in a culture medium, and the biological activity of the recombinant protein has been confirmed using Nb2 node lymphoma cells, whose proliferation and growth depend on the presence of hGH (Kim et al. 2008f). A fungal immunomodulatory protein (FIP-fve) was isolated from golden needle mushroom (Flarnmulina velutipes) and reported to inhibit allergy reactions in mice and regulate Th2 cytokines (Hsieh et al. 2003). Recombinant FIP-fve fused with the antigen Der p 2 (OsDp2Fve) has been produced using rice suspension cells under a control of α-amylase (αAmy8) promoter, and the yield was about 7.5 μg/mL (10.5 % of total protein) (Su et al. 2012).

5.2 Monoclonal Antibodies

Vaccines for active as well as passiv e immunization have been produced in plants. Plantibodies (plant antibodies) are the human/animal antibodies made by and in transgenic plants. Using antibodies as drugs is not new, but manufacturing them in plants is. So far most have failed, for two reasons. First, many early antibody drugs either did not work or provoked severe allergic reactions. The new drug may be effective, but it will not be cheap; cost is the second barrier these medicines face. Maize is not the only crop that can mimic human cells. Agracetus (Monsanto, USA) is also cultivating soybeans that contain human antibodies against herpes simplex virus 2, a culprit in venereal disease. The concept of passive immunization (application of antibodies) is been explored by producing complete antibodies in the plants. In order to achieve this, independent transgenic plants producing a single chain are crossed to obtain hybrid plant producing complete antibodies consisting of light and heavy chains (Fig. 4.2), (Wycoff 2004). Alternatively, antibody producing plants could directly be generated through cotransformation with genes responsible for light and heavy chain sub units. Transformed plant cells have been found to produce and assemble the antibodies, correctly. An antibody yield of up to 5 % of the total plant protein has been observed in transgenic plants . Agricultural plant production offers the most cost effective and large scale protein production system. It has been estimated that by expressing an antibody in soybean even at the level of 1 % of total protein, 1 kg of antibody could be produced for approximately USD 100.

Schematic showing the sequential crossing of individual plants expressing kappa chain, the chimeric IgA/G heavy chain, J chain and secretory component to produce IgA/G, dimeric IgA/G and secretory IgA/G (Wycoff 2004)

This group includes all antibody forms [immunoglobin G (IgG); immunoglobin A (IgA); immunoglobin M (IgM); secretory IgA; etc.) and antibody fragments (Fv). They can be produced in plants in both glycosylated and non-glycosylated forms. These plant-derived MAbs (plantibodies) have the potential of alleviating the serious production bottleneck that currently exists as dozens of new MAb products attempt to reach the marketplace. Examples of plant-derived MAbs in product development include a-caries for prevention of dental decay and a-herpes for prevention of herpes transmission. Guy’s Hospital London and the Salk Institute (USA) have produced mucosal antibodies against a tooth-decaying bacterium Streptococcus mutans. Tobacco-derived antibodies when applied to mucosal surface, prevented infection. Attempts are now being made to produce these antibodies at a large scale with an aim to incorporate them into toothpaste to battle streptococcal decay. Aracetus (USA) has developed a transgenic soybean that produces a tumor reactive monoclonal antibody called BR96 which can be tried as a drug carrier to treat breast, colon, ovarian and lung cancers. Transgenic plants have been used for the production of antibodies directed against dental caries, rheumatoid arthritis, cholera, Escherichia coli diarrhea, malaria, certain cancers, Norwalk virus, HIV, rhinovirus, influenza, hepatitis B virus and herpes simplex virus (Thomas et al. 2002).

Functional antibodies produced in tobacco plants were first reported over a decade ago (1989). The basic protocol used to generate these plantibodies involved the independent cloning of H and L chains of antibody genes in Agrobacterium tumefaciens vectors followed by transformation of plant tissue in vitro with the recombinant bacterium. The first recombinant proteins produced in plants were progeny of the cross of two individual transgenic plants , tobacco and sunflower , expressing single immunoglobulin gamma and kappa chains (Hiatt et al. 1989). The production of antibodies has been reported by a number of academic laboratories and the subject has been reviewed extensively (Hood et al. 2002; Larrick et al. 2001; Schilberg et al. 2002; Stoger et al. 2002a, b). The progressive improvement of expression vectors for plantibodies, purification strategies, and increase in transformable crop species, lead to almost limitless availability of inexpensive recombinant immunoglobulins free of human pathogens for human and animal therapy.

Klaus described the production of MAbs (During 1988). This work demonstrated expression of the B 1–8 light and heavy chains in transgenic tobacco and then showed assembly of the full MAb. Unexpectedly, a high percentage of MAb of hybrid mouse line (B 1–8) was found in the chloroplasts. Hiatt et al. (1989), then at the Scripps Research Institute (La Jolla, Calif.), crossed transgenic tobacco containing gamma or kappa immunoglobulin chains and obtained progeny having fully functional MAb. Cabanes-Macheteau et al. (1999) reported the specific glycosylation composition of a mouse IgG expressed in tobacco plants. Frigerio et al. (2000) described the vacuolar accumulation of a secretory IgA in tobacco. Verch et al. (1998) used a plant virus vector to infect tobacco and produce a full-length MAb directed towards colon cancer antigen. One of the first plant-derived MAb products expected to reach the market is one directed against dental caries. Designated CaroRx, this secretory IgA (sIgA) inhibits the binding of the oral pathogen Streptococcus mutans to teeth. As reviewed by Larrick et al. (2001), the plant derived MAb was extremely effective in reducing colonization by S. mutans using passive immunization, and even prevented re-colonization for up to 2 years. Another plant-derived MAb product expected to reach the market is one directed against genital herpes. Zeitlin et al. (1998) reported the production of anti-herpes humanized MAb in soybean and compared this MAb with the same MAb produced in mammalian cell culture in a mouse model. The two MAbs protected the mice against herpes simplex virus -2 equally well, proving again that differences in glycosylation of transproteins do not significantly reduce efficacy in many cases. This potential product is now being produced in maize. Recombinant human cytotoxic T-lymphocyte antigen 4-immunoglobulin (hCTLA4Ig) has been successfully produced in rice suspension cells using αAmy3/RAmy3D promoter with maximum yield of 31.4 mg/l in liquid medium (Lee et al. 2007). To optimize sIgA (secretory immunoglobulin A) production in plants, Juarez et al. (2013) tested the combinatorial expression of 16 versions of a human sIgA against the VP8* rotavirus antigen in Nicotiana benthamiana, using the GoldenBraid multigene assembly system. From the analysis of the anti-VP8* activity, it was concluded that those sIgA versions carrying HCα1 and LCλ provided the highest yields. Another antibody, single-chain Fv antibody (ScFvT84.66) under the control of maize Ubiquitin-1 promoter, has also been expressed in the leaves and calli of transgenic rice, and the yields were 29 μg/g and 3.8 μg/g of fresh weight of leaves and calli, respectively (Stoger et al. 2000; Torres et al. 1999).

5.3 Industrial Proteins-Enzymes

Expression of industrial enzymes in transgenic plants offers an alternative system to fungal fermentation for large-scale production. Very high levels of expression are required to make the enzymes cost-effective. Transgenic maize plants were generated using an Agrobacterium-mediated system. This group includes hydrolases, encompassing both glycosidases and proteases (Fischer et al. 2014). Oxido-reductase enzymes such as laccase, a fungal enzyme used in fiber bleaching and bioglue of wood products (Bailey et al. 2004; Hood et al. 2003), represent a separate class of industrial enzymes. Enzymes involved in biomass conversion for the purposes of producing ethanol are candidates for molecular farming. Recombinant egg white avidin and bacterial B-glucuronidase (GUS) from transgenic maize have been commercially produced. High levels of expression were obtained in seed by employing the ubiquitin promoter from maize. The recombinant proteins exhibited activities that were indistinguishable from their native counterparts, (Ma et al. 2003). All of these products are used in very large quantities and must therefore be produced very inexpensively (Hood et al. 1999). A major hindrance to the molecular farming of these products is the large land area needed. One of the most important driving factors has been yield improvement, as product yield has a significant impact on economic feasibility. Strategies to improve the recombinant protein yield in plants include the development of novel promoters, the improvement of protein stability and accumulation through the use of signals that target the protein to intracellular compartments (Schillberg et al. 2013), and the improvement of downstream processing technologies (Menkhaus et al. 2004).

5.4 Antigens for Edible Vaccines

Vaccines have played an appreciable role in controlling several human and animal diseases. Some major human diseases like diphtheria, tetanus, yellow fever, measles, mumps, rubella and polio have been largely controlled by vaccination (Hugh et al. 2002). However, according to the World Health Organization (2013), 16 % of children worldwide are still not fully immunized against diphtheria, pertussis (whooping cough), tetanus, polio, measles and tuberculosis (TB). Moreover, the classic vaccines pose a risk that micro-organism may somehow spring back to life, causing disease again. For that reason vaccine today is produced as a subunit preparation, composed primarily of antigenic protein separated from pathogen genes. On their own the protein are not infectious. Sub-unit vaccines are however very expensive, because they are produced in cultures of bacterial or animal cells and have to be purified before use and also need refrigeration during storage and transport. Expression of antigens as vaccine in transgenic plants is a convenient and inexpensive source for these immunotherapeutic molecules (Kamenarova et al. 2005). Charles Arntzen (the first to use the phrase edible vaccine ), with Hugh Mason and colleagues have pioneered the field with work on hepatitis B and heat labile toxin, B subunit, in tobacco plants and potato tubers (Arntzen et al. 2005).

Active immunization means the expression of antigens in plant parts which can preferably be consumed in a raw form, to avoid denaturation of proteins during cooking. The antigens thus expressed in edible plant parts such as potato tubers and banana fruit can stimulate immune response against a particular pathogen attack and prevent the disease/disorder in humans/animals (Sahu et al. 2014). This idea of edible vaccines was conceived by Charles J. Arntzen of USA in the early 1990s. Since then several antigens have been expressed in plants. Hepatitis B virus surface antigen has been expressed in tobacco, potato and lettuce. Hepatitis B kills more than one million people each year and is a leading cause of liver cancer. Likewise, edible vaccines have been produced against viral and bacterial diarrhea. Viral diarrhea is caused by Norwalk virus (NV), a calicivirus that causes epidemic acute gastroenteritis, a leading cause of food-borne illness in US. The bacterial diarrhea is caused by enterotoxigenic Escherichia coli (ETEC), which upon infection secretes toxins in the gut, which include heat labile exterotoxin (LT). The antigens for Norwalk virus capsid protein and E. coli LT B subunit (LT-B) have been expressed in potato and tobacco. Likewise, antigens for cholera toxin B subunit (CT-B), rabies virus glycoproteins (G-protein) and respiratory syncytial virus have been expressed in potato, tobacco and tomato, respectively. The edible vaccines have also been developed for livestock. The antigens for VPI protein of foot and mouth disease have been expressed in Arabidopsis. Other vaccines in the pipe line include vaccine for transmissible gastroenteritis virus (TGEV) in swine, which is a major cause of sickness and death in young pigs, antigens against mink enteric virus which do not affect humans. Extensive studies on development of edible vaccine against human papilloma virus type 16 (HPV 16) which causes cervical cancer in women has also been done. Until now, no conventional vaccine is available for HPV, so the outcome will be quite rewarding. Moreover, the chickens are being genetically engineered to lay eggs containing anti-cancer drugs. Likewise, in preliminary studies conducted in Bangalore, the rabies vaccine has been expressed in muskmelon. According to World Health Organization, rabies claims 70,000 lives every year and most of the victims are from developing countries. The development of edible vaccine could be a major breakthrough (Hugh et al. 2002).

The main goal of an oral vaccine is the induction of a mucosal immune response (Das 2009) and a subsequent systemic immune response. As a pre-requisite for testing these vaccines in humans, pre-clinical studies have been conducted in mice. Orally immunized mice with transgenic extracts have exhibited a strong mucosal and systemic immune response. Many pathogens enter the body through the nose, mouth and other openings. Hence the first defenses they encounter are those in mucous membranes that line the airways, the digestive tract and reproductive tract. When mucosal immune response is effective, it generates molecules known as secretary antibodies that neutralize any pathogen that it finds in its way. In 1998, the National Institute of Allergin and Infectious diseases (NIAID) demonstrated that an edible vaccine could stimulate an immune response in humans as well, which was a major milestone in active immunization. The volunteers, who ate genetically engineered potatoes containing toxin secreted by Escherichia coli bacterium c.o. of diarrhea, showed fourfold rise in serum and intestinal antibodies. Food vaccines might also help to suppress auto-immunity in which the body’s defenses mistakenly attack normal, uninfected tissues. Among autoimmune disorders that might be prevented are type I diabetes, multiple sclerosis and rheumatoid arthritis. The type I diabetes is severe among children. It results from autoimmune destruction of the insulin producing beta cells, of the pancreas. The loss of beta cells eventually leads to drastic shortage of insulin, a hormone needed to help cells take up sugar from the blood for energy. The loss results in high blood sugar levels. Plant-based vaccines have been developed in potatoes, containing insulin or glutamic acid decarboxylase (GAD). Feeding of vaccines to mice helped to delay the onset of high blood sugar.

Compared to traditional commercial vaccines, edible vaccines have several advantages. They are relatively easy to produce at a low cost, and without the need of fermentation and protein purification steps, which are mandatory for conventional vaccine production. Unlike mammalian-derived rDNA drugs, plant-derived antibodies, vaccines and other proteins are particularly advantageous since they are free of mammalian viral vectors and human pathogens (Schillberg et al. 2013). Edible vaccines are easy to administer, as the plant products e.g. fruits/vegetables are eaten raw and there is no need of painful intramuscular/intravenous injections. Moreover, they are safe compared to conventional vaccines, as there is no risk of infection/contamination from the use of non-sterile needles (Lamphear et al. 2004). Advantageously, the edible vaccines do not need refrigerated storage, so they can be easily and cheaply stored, transported and administered to poor populations in real need of vaccination. The plants proposed thus far for edible vaccine production, like potato and banana, can be grown widely. Thus the development of edible vaccines is timely and useful development.

However, there are some questions which still need to be answered before commercial release of these vaccines. These include standardization of appropriate dosage to be consumed, environmental impact, need for high levels of expression of targeted proteins, ways to overcome possible degradation of expressed proteins during storage of fruits/vegetables, appropriate source of food to be used as edible vaccine and also the appropriate time and tissue of expression of the proteins. Extensive studies are underway to answer all these questions favorably. Moreover, the avenues for commercialization of edible vaccines are being opened worldwide, as evident from the issuing of a US patent to a private firm, Prodigene, for the use of plants to develop oral vaccines that can immunize humans and animals against viral diseases. Thus the production of edible vaccines can be conceived as an attractive and an additional tool for vaccine production, which can relieve humankind of several diseases and disorders.

5.5 Production of Other Proteins of Medical Relevance

Proteins of medical relevance include the milk proteins ß-casein, lactoferrin and lysozyme , which can be used to improve child health, and protein polymers that could be used in surgery and tissue replacement (Ma et al. 2003). Expression of thioredoxin in foods such as cereal grains would increase the digestibility of proteins and thereby reduce their allergenicity (Thomas et al. 2002). It has been shown that human collagen can be produced in transgenic tobacco plants and that the protein is spontaneously processed and assembled into its typical triple-helical conformation. Due to a shortage of plasma and low expression levels of recombinant rbFGF (fibroblast growth factor) in conventional gene expression systems, An et al. (2013) explored the production of recombinant rbFGF in rice grains (Oryza sativa bFGF, OsrbFGF). An expression level of up to 185.66 mg/kg in brown rice was obtained. The functional assay of OsrbFGF indicated that the stimulating cell proliferation activity on NIH/3T3 was the same as with commercialized rbFGF. Wound healing in vivo of OsrbFGF is equivalent to commercialized rbFGF.

6 Host Plant Selection for Edible Vaccines

Potatoes have been frequently used as a convenient model system because transgenic lines can be efficiently produced using Agrobacterium-mediated DNA delivery. However, a more palatable system is preferred, as the vaccine must be consumed raw to prevent heat denaturation of the antigens. The tomato is an attractive alternative. Several plant species (dicot, monocot, food and non-food, leafy crops, cereals and legumes) have been used for the expression of recombinant proteins (Table 4.1). Banana is attractive because it is widely grown in developing countries and an efficient transformation system has been reported (May et al. 1995). From an economic point, soybean, alfalfa and maize are among the most efficient plant systems for recombinant protein production. Kusnadi et al. (1997) reported the production, purification, and characterization of recombinant Escherichia coli GUS and chicken egg-white avidin from transgenic maize seed.

6.1 Vaccine Production in Fruit Crops

Several studies have reported the produ ction of transgenic tomato plants for the expression of viral antigens, including rabies virus, foot-and-mouth disease virus, human papilloma virus, Yersinia pestis and for the production of therapeutic proteins. Many investigations have focused on the development of novel mucosal vaccines against HIV and HBV (Hepatitis B virus) in transgenic tomato plants. These tomato-made vaccines are proposed to be inexpensive, heat stable and easy to administer (Rigano et al. 2013). For example, a fruit-based edible subunit vaccine against RSV was developed by expressing the RSV fusion (F) protein gene in transgenic tomato plants. The F-gene was expressed in ripening tomato fruit. Oral immunization of mice with ripe transgenic tomato fruits led to the induction of both serum and mucosal RSV-F specific antibodies. Serum antibodies showed an increased titer when the immunized mice were exposed to inactivated RSV antigen (Sandhu et al. 2000). Shchelkunov et al. (2006) expressed the synthetic chimeric gene TBI-HBS encoding immunogenic ENV and GAG HIV-1 epitopes and the surface protein antigen (HBsAg) of hepatitis B virus in transgenic tomato plants and demonstrated that in mice oral administration of dried tomato tissues stimulated both serum and secretory HIV- and HBV-specific antibodies. Ramirez et al. (2007) expressed the HIV-1 Tat protein in transgenic tomato fruits and demonstrated that the orally delivered tomato-based vaccine raised mucosal IgAs and induced serum IgGs with neutralizing activity in mice.

Cueno et al. (2010) demonstrated the preferential expression of a Tat-GUS fusion protein produced in tomato plants. Protein extracts intradermally injected into BALB/c mice were found to induce both humoral and cellular immune responses. In addition, Zhou et al. (2008) expressed the HIV antigens p24 and Nef from the plastid genome of tomato. HIV antigen accumulation reached values of approximately 40 % of total leaf protein and 2.5 % of total protein in green tomatoes. Bacterial antigens have also been expressed in transgenic tomato plants. One example is the expression of a plant-optimized synthetic gene encoding the multiepitopic protein sDTP (diphtheria-pertussis-tetanus). The synthetic gene contained six DTP immunoprotective exotoxin epitopes and two adjuvants (Soria-Guerra et al. 2007). After that same group demonstrated that in mice, three oral doses with freeze-dried material from the tomato-derived multicomponent vaccine elicited specific systemic and mucosal antibody responses (Soria-Guerra et al. 2011). Tomato-made vaccines have also been used as a novel strategy for the development of vaccines against cholera. Oral vaccines would be particularly suitable to protect against pathogens that infect through intestinal surfaces since this delivery route best induces a mucosal immune response (Rigano et al. 2003; Salyaev et al. 2010). Some other examples are the production in transgenic tomato plants of: (1) CTB (Cholera toxin B subunit), (2) TCPA (toxin co-regulated pilus subunit A) of Vibrio cholera and its immunogenic epitopes P4 or P6 fused to CTB and (3) ACFA (accessory colonization factor subunit A) of Vibrio cholerae and ACFA fused to CTB (Rigano et al. 2013). Jha et al. (2012) demonstrated the feasibility of using tomato plants for the production of stable, glycosylated and biologically active recombinant human α1-proteinase inhibitor.

In addition, Kim et al. (2012) reported the stable production of human β-secretase in transgenic ripe tomato fruits. The capacity of fleshy fruits to accumulate functional antibody has been demonstrated by Juarez et al. (2012). The authors described the production of transgenic tomato plants expressing a recombinant human immunoglobulin A selected against the VP8* peptide of the model rotavirus strain SA11. Minimally processed fruit-derived products showed anti-VP8* binding activity and strongly inhibited virus infection in an in vitro virus neutralization assay. In addition, their paper dealt with the concerns often raised regarding possible contamination of the food chain with transgenic materials. In order to label the transgenic lines expressing the antibodies, sexual crossing were made with a transgenic tomato line expressing the genes encoding snapdragon (Anthirrhinum majus) Rosea1 and Delila transcription factors . These transcription factors ectopically activate anthocyanin biosynthesis in tomato fruit. The resulting purple-colored extracts from the transgenic fruit contained high levels of recombinant antirotavirus neutralizing human IgA in combination with increased amounts of health-promoting anthocyanins.

6.2 Vaccine Production in Tuber Crops

Transgenic potato tubers as bioreactors offer advantages such as long-term storage tissue, abundant biomass, short growth cycle, high nutritional value and the high stability of recombinant proteins accumulated in the tubers during a long period of storage. Potato has been used in recent years as a model system for the expression of bacterial, viral antigens and autoantigens and preliminary results from human clinical trial studies conducted with potato-based vaccines were promising. In addition, mucosal immunity has been induced by orally administered transgenic potato plants (Rigano et al. 2013). Warzecha et al. (2003) demonstrated that ingestion of transgenic tubers expressing the HPV11 L1 capsid protein activated anti-VLP immune responses that can be boosted by subsequent administration of purified insect cell-derived VLPs. Chen and Liu (2011) produced transgenic potato plants expressing GP5 protein of the porcine reproductive and respiratory syndrome virus (PRRSV) and showed that, in mice, oral administration of crude protein extracts from transgenic tubers elicited both serum and gut mucosal-specific antibodies.

Potato plants have also been used to produce several therapeutic proteins. One example from Tremblay et al. (2011) demonstrated a high-yield of soybean agglutinin (SBA), a specific N-acetylgalactosamine-binding plant lectin, in potato tubers. The recombinant SBA retained its ability to induce hemagglutination, was similarly glycosylated to the native SBA and retained its binding specificity for N-acetylgalactosamine. In addition, the recombinant SBA was highly resistant to degradation in simulated gastric and intestinal fluid. One disadvantage of using transgenic potato for the production of antigenic proteins is the poor expression of the foreign proteins. In this regard, it is of interest to mention Youm et al. (2010) who examined the antibody response in mice orally immunized using various doses of potato-derived major surface antigen of hepatitis B virus (ranging from 0.02 to 30 μg potato-derived antigen).

Approaches to increase the yield of recombinant protein expressed in transgenic plants include down regulation of native proteins within the tubers and targeting the protein to the cell secretory pathway. Tremblay et al. (2011) investigated whether minor interruption of starch biosynthesis can have a positive effect on tuber protein content and on tuber biomass. In order to increase the efficiency of the crop potato as a bioreactor, they used an RNAi approach to knock down ATP/ADP transporter in Solanum tuberosum. The authors identified a new line (riAATP1-10) with reduced starch accumulation, increased biomass yield and increased total protein levels. The potential of this line as a new bioreactor candidate was tested by expressing a human single-chain variable fragment (scFv) antibody. Protein expression in the riAATP1-10 line translated into a nearly fourfold increase in product yield. Kim et al. (2008e) also utilized the RNAi technology to knockdown various patatin isoforms in potato tubers for the development of a more efficient protein expression system. In an attempt to improve the yield, the activity and the stability of recombinant protein , Badri et al. (2009a, b) used protein targeting to produce transgenic potato lines expressing the protein bovine aprotinin targeted to the cytosol, the endoplasmic reticulum (ER) and the apoplast. Using a novel SELDI-TOF MS (surface-enhanced laser desorption ionization time-of-flight mass spectrometry) procedure, the authors were able to demonstrate that the recombinant protein targeted to the ER showed good accumulation levels but was processed in the ER compartment of plant cells (Badri et al. 2009a). In a subsequent paper, the authors used a combination of SELDI-TOF MS and 2-D gel analyses to demonstrate that aprotinin retention in the ER was associated with a decrease of leaf soluble protein content and down-regulation of proteins implicated in protein synthesis and maturation. This suggests nintended metabolic interference in transgenic plants (Badri et al. 2009b).

These data demonstrate the importance in plant-made vaccine design of considering also the possible effects of the foreign protein expression on native protein accumulation and endogenous metabolism of the host plant factory. Additional factors that could limit recombinant protein expression include processes such as silencing, premature polyadenylation, mRNA stability and improper codon usage. Mathew et al. (2011) showed the importance of eliminating spurious polyadenylation signals within the coding sequence of the Narita 104 virus capsid protein. Such an exercise increased foreign protein expression in potato plants. Finally, the variability in antigen expression could depend also on the different plant growth conditions used. For example, Mikschofsky et al. (2011) compared greenhouse and field production of potato-made foreign protein using potato expressing VP60 (structural capsid protein of the rabbit hemorrhagic disease virus), CTB and the marker protein NPTII and concluded that equal or higher expression levels with lower variability of foreign protein could be expected in the fields compared to greenhouse production.

6.3 Vaccine Production in Seed Crops

Oral administration requires about 100 times the amount of vaccine delivered through direct injection. Endotoxins that exist inside plants, such as solanine in potato tubers, also raise safety concerns, as they cannot be easily removed. In cases where further processing, such as cooking, is required, thermolabile proteins will be degraded in the process, further reducing the effective yield. Despite the challenges described, rice remains a competitive candidate for producing and delivering recombinant vaccines for two important reasons. First, rice does not contain endotoxins harmful to the human body. Second, localization of recombinant protein into seeds provides ideal storage due to low protease activity. Several vaccine antigens have been successfully produced in recombinant rice (Kuo et al. 2013). The envelope protein of Japanese encephalitis virus (JEV) has been expressed in rice leaves, and the maximum yield was 1.1–1.9 μg/mg of total protein (Wang et al. 2009). To examine the biological activity of the recombinant vaccine, mice were immunized using both Escherichia coli derived JEV envelope proteins and recombinant proteins from rice through oral administration. The rice-derived vaccine was able to elicit higher IgG and IgA responses compared to the recombinant protein derived from E. coli. Oral administration of Chlamydophila psittaci antigen, MOMP, fused to the B subunit of E. coli LTB produced in rice seeds has also successfully induced mouse immunity to mucosal disease (Zhang et al. 2009). Other vaccines were successfully produced for the intention of oral administration as uncooked rice powder, and biologically activities were examined through animal tests (Suzuki et al. 2011; Takagi et al. 2005). Transgenic rice expressing mouse dominant T cell epitope peptides of Cry j I and Cry j II allergens of Japanese cedar pollen was able to prevent the development of allergen-specific IgE and IgG responses (Takagi et al. 2005). Alternatively, transgenic rice expressing a fragment (pp. 45–145) of mite allergen (Der p 1) containing immunodominant human and mouse T cell epitopes successfully reduced the serum levels of allergen-specific IgE and IgG (Suzuki et al. 2011). It is worth noting that differences in mammalian and plant glycosylation have caused immunogenic response in both mice and human, indicating that further modification may be required for recombinant protein produced using rice expression systems (Kuo et al. 2013).

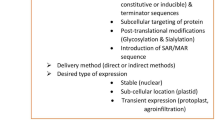

7 Options to Achieve Overproduction of Recombinant Proteins

Several techniques are available to in crease the level of protein expression in plant cells (Egelkrout et al. 2012). Codon-optimization of the transgene, introduction of different regulatory elements and targeting of expressed proteins to special organelles are all factors that can enhance transcription and translational efficiencies and yield of recombinant proteins expressed in plant cells (Rigano et al. 2013). For example, Jha et al. (2012) demonstrated that targeting recombinant human α1-proteinase inhibitor to different subcellular compartments in transgenic tomato plants could influence final yield, biological activity and in planta stability of the recombinant protein. In addition, the level of transgene expression in plants can be affected by the activity and specificity of the promoters. Recently, there has been a vast amount of effort invested in discovering various types of promoters. For example, in tomato several fruit-specific promoters have been recently identified and utilized (Estornell et al. 2009; Guillet et al. 2012; Hiwasa-Tanase et al. 2012; Kim et al. 2012). Targeting recombinant protein expression to the edible parts of the transgenic crop using fruit-specific promoters can be convenient for the production of oral plant-derived vaccines and to avoid non-specific alterations at whole plant levels. The identification of novel promoters expressed in specific tissues or during specific stages of development are proceeds of novel genomic resources and new high throughput sequencing methods such as RNA-Seq that allow evaluation of changes in expression of the transcriptome (Rigano et al. 2013).

The accumulation of recombinant proteins in plant cells is dependent not only on the synthesis of the products but also on its degradation (Rigano et al. 2013). Therefore, the potential of tomato cathepsin D inhibitor as a companion stabilizing agent for the protection of cytosol-targeted recombinant proteins in plants was recently investigated (Goulet et al. 2010). The authors demonstrated a proteome-wide, up-regulating effect of this inhibitor on endogenous leaf proteins in potato and a stabilizing effect in planta improving the accumulation of the cytosol-targeted heterologous protein human α1-antichymotrypsin.

An alternative to conventional nuclear transformation for the expression of high-yield recombinant protein in food crops is stable genetic transformation of plastids (Rigano et al. 2013). The integration and expression of transgenes in the plastid genome presents several advantages including high and stable production levels of foreign protein attainable; precise integration into the host plastid genome that relies on homologous recombination; absence of epigenetic effects; reduced risk of introducing transgenes into the food chain; and the possibility of co-expressing multiple transgenes from prokaryotic-like operons (Bock and Warzecha 2010; Cardi et al. 2010; Scotti et al. 2012). Previously, plastid transformation of species other than tobacco has been limited by low transformation frequencies and low transgene expression usually achieved in non-green plastid. However, today, protocols for stable plastid transformation in tomato and potato have been developed and made available to the scientific community (Ruf et al. 2001; Segretin et al. 2012; Valkov et al. 2011; Wurbs et al. 2007).

The work of Valkov et al. (2011) is noteworthy as it reports an improvement in potato transformation efficiency at levels similar to those obtained for tobacco. This result was achieved by the modification of the selection/regeneration procedure and by using novel vectors containing potato-flanking sequences for transgene integration by homologous recombination in the plastome. In addition, regulatory sequences that could increase protein expression in tomato chromoplasts and potato amyloplasts have been identified and tested (Caroca et al. 2012; Scotti et al. 2011; Valkov et al. 2011). Caroca et al. (2012) used tomato plastid transformation to test a combination of promoters and 5′UTR for their potential to confer active gene expression in chromoplasts. The authors identified chimeric expression elements that trigger high-level protein accumulation in chromoplasts. The best-performing promoter-UTR combinations resulted in accumulation of the reporter protein GFP to 1 % of total cellular protein of the ripe tomato fruit, which is comparable to the GFP accumulation level achievable in chloroplast of green leaves. Tomato transplastomic plants have been used successfully to produce nutraceutical and biopharmaceutical proteins (Wurbs et al. 2007; Zhou et al. 2008). For example, Apel and Bock (2009) introduced lycopene β-cyclase genes from the eubacterium Erwinia herbicola and daffodil (Narcissus pseudonarcissus) into the tomato plastid genome in order to enhance carotenoid biosynthesis inducing lycopene-to-β-carotene conversion.

Hairy root cultures present an alternative system for producing useful pharmacological compounds in crops. In nature, hairy root is a disease of plant tissues infected by the soil bacterium Agrobacterium rhizogenes. This bacterium transfers specific genes (rol genes) from its endogenous root inducing plasmid (Ri plasmid) to alter the auxin/cytokinin perception of the host cells inducing neoplastic root and hair proliferation and growth. Hairy roots provide a genetically-stable transgenic tissue culture system that grows rapidly in simple phytohormone-free media (Rigano et al. 2013). With respect to production of foreign proteins, hairy roots are easily bio-contained in a controlled in vitro environment; they can be scaled up to produce large amounts of biomass in industrial scale bio-reactors (Wilson 1997); and have the potential for rhizosecretion (Gaume et al. 2003). Hairy roots of many different plant species have been utilized to produce various recombinant proteins at varying yields and there have been studies into producing recombinant proteins in hairy roots from crop plants such as tomato and potato. For example, Sunil Kumar et al. (2006) optimized the generation and growth of potato hairy roots for the production of the hepatitis B surface antigen (HBsAg). De Guzman et al. (2011) reported production of the Escherichia coli B-subunit heat labile toxin antigen in tomato hairy root cultures (~10 μg/g blotted weight, BW) and compared the productivity against hairy roots of tobacco (~100 μg/g BW) and petunia (~100 μg/g BW). While tomato yielded the least amount of antigen overall, the antigen accumulation was reasonable when compared to other plant systems producing LT-B (Haq et al. 1995; Kosaki et al. 2008; Walmsley et al. 2003). Unfortunately, oral delivery of vaccine antigens within hairy root tissue has proven less efficient than other plant tissues perhaps due to the cell walls being too thick and not releasing enough antigens from the cells at optimal locations throughout the digestive tract (Pelosi et al. 2011, 2012). Secretion or purification of recombinant proteins from hairy roots may prove to be the more realistic approach for this platform. Lallemand et al. (2015) also focused on the analysis of extracellular proteolytic activities in two production systems: cell cultures and root-secretion (rhizosecretion), in Arabidopsis thaliana and Nicotiana tabacum.

8 Quality Aspects of Plant-Based Vaccines

For developing a plant-based expression system for vaccines, four criteria should be met. First, the major antigen must be sufficiently concentrated to allow for the recommended dose to be delivered in an amount of material that is easily consumed. For example, the standard dose for parenterally delivered hepatitis B vaccines varies from 5 to 40 μg, depending on the specific product, the age of the recipient and whether the recipient is immunocompromised (Streatfield 2005). It is anticipated that oral doses will need to be at least equivalent to parenteral doses, but may need to be up to three orders of magnitude greater in order to achieve comparable efficacy. Also, for the convenience of administration, the amount of material delivered orally as a vaccine should not exceed a few tens of grams. Thus, for a potential oral dose of 10 mg of hepatitis B major surface antigen to be delivered in 10 g of plant material, the recombinant protein must constitute 0.1 % of the material administered. Protein extraction procedures to concentrate the antigen from plant expression hosts are best avoided, because they add significant cost. However, for fresh tissue, some degree of dehydration is necessary to avoid rapid protein degradation following harvest, and this also serves to concentrate the antigen on a weight basis. Also, some inexpensive food processing technologies applied to plant tissues yield protein-rich fractions, and can thus serve to concentrate antigens up to tenfold. Thus, depending on the available processing options for the plant tissue chosen for antigen production, expression level targets should be at least 0.01–0.1 % weight.

A second criteria for a plant-based vaccine is that the antigen concentration should be uniform, allowing for even dosing of subjects. Some degree of processing will likely be required to achieve homogenization. Third, the plant material should be palatable, encouraging uptake. This rules out several plant expression systems such as tobacco and Arabidopsis thaliana used to show the feasibility of expressing antigens in plants (Tacket et al. 2000). Finally, the fourth criterion that should be met is that the antigen should be stable during prolonged storage of the vaccine at ambient temperatures, so avoiding the expense of a cold-storage chain. Grains are particularly suitable in this regard, although fresh tissue may be dehydrated to guard against antigen degradation (Kuo et al. 2013).

There have been several recent developments to improve the efficiency of downstream processing for the production of molecular pharming products. The need for quality and consistency in the manufacturing process has driven researchers to identify novel approaches to remove plant-specific contaminants and to develop models to facilitate purification. For example, flocculation (Buyel and Fischer 2014a) and heat precipitation (Buyel et al. 2014) have been shown to increase the efficiency of depth filtration during the purification of antibodies produced in tobacco leaves, and the filter train can also be optimized to remove plant-derived particulates more effectively (Buyel and Fischer 2014b). The behavior of the target protein and host cell proteins can be modeled to improve the overall efficiency of purification, including the use of quantitative structure activity relationship (QSAR) models to predict how host cell proteins behave during chromatography (Buyel et al. 2013).

9 Examples of Biopharma Products on and Close to the Market

Numerous companies have been involved in molecular farming over the last several years (Table 4.2). There are many products thought to be on and close to reaching the commercial market. Several of these proteins are normally derived from animal organs and, due to the possibility of animal pathogens being carried along with these proteins, there is a need for alternative low-cost supply. Table 4.2 lists these products.

9.1 Aprotinin

Aprotinin is a protein that inhibits serine proteases (including trypsin , chymotrypsin , kallikrein and pepsin). Under the trade name Trasylol and Apronexin, aprotinin was used as an injection to reduce bleeding during complex surgery, such as heart and liver surgery. Its main effect is the slowing down of fibrinolysis, the process that leads to the breakdown of blood clots. The aim of its use is to decrease the need for blood transfusions during surgery, as well as end-organ damage due to hypotension. Native aprotinin is extracted from bovine lungs. Zhong et al. (1999) reported the generation and characterization of transgenic maize lines producing recombinant aprotinin. Immature maize embryos were transformed with the aprotinin gene via particle bombardment. The recombinant aprotinin protein purified from transgenic maize seeds has biochemical and functional properties identical to its native protein. Prodigene Corporation (USA) and Sigma-Aldrich (USA) are marketing aprotinin (AproliZean) from maize and from a transg enic tobacco.

9.2 Avidin

Avidin is a glycoprotein found in avian, reptilian and amphibian egg white. It is used primarily as a diagnostic reagent. The protein is composed of four identical subunits, each 128 amino acids long. The usual source for commercial quantities of avidin is from chicken egg white but the resultant product is relatively expensive due to the cost of maintaining live animals. Hood et al. (1997) produced avidin in transgenic maize seed. The resultant avidin had properties almost identical to those of avidin from chicken egg white. Both the maize-derived and the chicken egg-derived avidin were glycosylated. While the avidin apoproteins were identical, the size of maize-derived avidin was slightly less than chicken egg-derived avidin due to a less complex glycosylation composition. This difference did not alter the binding activity of the mature protein. The production, purification and characterization of chicken egg-white avidin from transgenic maize seed was done by Kusnadi et al. (1998). This product is currently being sold by Sigma-Aldrich (USA).

9.3 Collagen

Collagen is a group of naturally-occurring proteins. In nature, it is found exclusively in animals, especially in the flesh and connective tissues of mammals. It is the main component of connective tissue, and is the most abundant protein in mammals. Based on their structural roles and compatibility within the body, collagen and gelatin are commonly used biomaterials in the medical, pharmaceutical and cosmetic industries. Collagen is used commercially in the areas of bone grafts, corneal implants, drug delivery, incontinence, tissue engineering and as a viscoelastic supplement. Gelatin is used in the stabilization and delivery of vaccines and drugs, in capsules and soft gels, nutraceuticals and as plasma expanders. The first report of human collagen produced in plants was by Ruggiero et al. (2000). They used tobacco plants as a novel expression system for the production of human homotrimeric collagen. Fibrillar collagen cDNAs was inserted into tobacco using Agrobacterium. Large amounts of recombinant collagen were purified from field-grown plant material. The data suggest that plants are a valuable alternative for the recombinant production of collagen for various medical and scientific purposes.

9.4 Edible Vaccines

Vaccine delivery through crops could have signific ant benefits, most notably in the developing world. Vaccines could be grown from seed and then freely distributed without the need for trained medical staff at any stage. Implementation of such schemes would probably require initially-high expenses in terms of education and training, data monitor points out, but thereafter would be relatively cheap. Plant-based vaccines are now edging closer to commercialization. Prodigene Inc. is currently leading the way in developing plant vaccine technology. In the last several years, a novel approach for developing improved mucosal subunit vaccines has emerged by exploiting the use of genetically-modified plants. It has been demonstrated that plant-derived antigens are functionally similar to conventional vaccines and can induce neutralizing antibodies in mammalian hosts. Using genetically engineered plants for the production of immunogenic peptides also provides a new approach for the delivery of a plant-based subunit vaccine, i.e. oral delivery, provided these immunogenic peptides are expressed in an edible plant part, such as the fruit. Thus, food crops can play a significant new role in promoting human health by serving as vehicles for both production and delivery of vaccines (Korban et al. 2002). Charles Arntzen, Arizona State University, has pioneered the field with work on hepatitis B and LT-B in tobacco plants and potato tubers. Vaccines administered using needles do not usually give a good immune response in the mucosal tissues of the vaccine recipient. The laboratory of William Langridge at Loma Linda University, California, is developing multi-component mucosal subunit vaccines and active in developing edible vaccines against diabetes and cholera. Arakawa et al. (1998, 2001) have generated transgenic potato plants that synthesize human insulin, a major insulin-dependent diabetes mellitus autoantigen, at levels up to 0.05 % of total soluble protein. Korban et al. (2002) reported a plant-based oral vaccine against respiratory syncytial virus (RSV) in tomato fruit and are moving the product into apple. Dry grains (maize, rice, wheat) may prove to be a superior delivery system for edible vaccines since the a ntigen will remain at a constant level for an extended period of time without refrigeration (Streatfield 2002). Researchers have to solve the existing disadvantages such as low yields, immunogenicity, accumulation and stability of the transproteins, and obtaining glycosylation; processes that are normally observed in humans.

9.5 β-Glucuronidase

β-glucuronidases are members of the glycosidase family of enzymes . GUS is a homotetrameric hydrolase that cleaves b-linked terminal glucuronic acids in mono and oligo-saccharides and phenols. The protein is composed of four identical subunits, each 128 amino acids long. It is used primarily as a diagnostic reagent as visual marker in transgenic plant research. The usual source for commercial quantities of GUS is chicken egg. It was first produced in transgenic maize (Kusnadi et al. 1998) and its properties were compared with GUS extracted from Escherichia coli, the original source of the protein. While many other investigators have demonstrated the expression of GUS as a scoreable marker, Witcher et al. (1998) have generated transgenic maize seed containing GUS for commercial production. This is one of the first cases where a detailed characterization of the transgenic plants and the protein were performed which are necessary to use this as a commercial source of GUS. Maize-derived GUS has been marketed by Sigma-Aldrich (USA).

9.6 Human Gastric Lipase

Human gastric lipase is involved in exocrine pancreatic insufficiency (EPI). EPI is the inability to properly digest food due to a lack of digestive enzymes made by the pancreas. The current supply of gastric lipase is from bovine pancreatic tissue. A recombinant dog gastric lipase with therapeutic potential for the treatment of EPI was expressed in transgenic tobacco plants (Gruber et al. 2001). Meristem Therapeutics is advancing a maize-derived mammalian lipase through clinical trials.

9.7 Human Lactoferrin

Lactoferrin is secreted in milk, tears and bile. It is elevated by in flammation and some cancers. It has been suggested to have a number of functional properties including anti-cancer, immunomodulation, anti- microbial, anti-viral, toxin binding properties (Legrand et al. 2003). In the work done by Samyn Petit et al. (2001), the human lactoferrin coding sequence was inserted into the pUC18 plasmid under control of the wheat glutenin promoter. Maize was stably transformed and recombinant lactoferrin was purified. N-glycosylation sites of recombinant lactoferrin are mainly substituted by typical plant paucimannose-type glycans, with beta1,2-xylose and alpha1,3-linked fucose at the proximal N-acetylglucosamine, and that complex-type glycans with Lewis(a) determinants are not present in maize recombinant lactoferrin. Studies at the Baylor School of Medicine, Texas USA, were carried out relative to the cloning of lactoferrin and lactoferrin peptides and the expression of recombinate lactoferrin by fungi and bacteria (Conneely et al. 1996a, b, c). It is claimed that the verified cDNA sequence for human, bovine and porcine lactoferrin protein have been used to prepare lactoferrin for therapeutic and nutritional applications. Regions of the cDNA, such as the iron binding sites can be used to produce peptide products. The conversion of these concepts to commercial practice could be competitive with the current production of lactoferrin from whey. Each natural lactoferrin molecule has two iron-binding domains, which reversibly bind iron . Recombinant human lactoferrin has been produced in Aspergillus sp. from which good levels for pharmaceutical have been obtained (Conneely et al. 2001). Lactoferrin was first reportedly produced in tobacco suspension cells by Mitra and Zhang (1994) . A suspension tobacco cell line was transformed to express human lactoferrin. The transgenic calli produced a protein that was signifi cantly smaller than the full-length lactoferrin protein. Total protein extracts made from transgenic tobacco callus exhibited much higher antibacterial activity than commercially available purified lactoferrin.

9.8 Trypsin

Bovine trypsin is a protease that is used in a variety of commercial applications including the digesting or processing of other proteins, including some therapeutic proteins. Trypsin is an aggressive proteolytic enzyme . Recombinant trypsin has been produced in a number of systems, including cell culture, bacteria and yeast. But no system is commercially viable on a large scale. The biopharmaceutical industry is trying to eliminate animal-derived proteins from manufacturing processes due to the possible contamination of these products by human pathogens. Maize-derived trypsin has a significant market potential. The availability of maize-derived bovine trypsin helps to supply the growing market for animal-free reagents. This eliminates animal-source materials and reduces the fears of contamination of products by mammalian viruses. Expression of this enzyme at commercially-viable levels in maize was possible only by expressing the enzyme in an inactive zymogen form. Although the zymogen gene was put into plants, the active enzyme was recovered in extracts from maize seeds (Woodard et al. 2003). Maize derived trypsin (TrypZean) is the first large-scale protein product from transgenic plant technology. Maize-derived trypsin has been marketed by Sigma-Aldrich (USA).

10 Conservation of Developed Cell Lines

Cryopreservation refers to storage of living cells, tissues o r organs at ultra-low temperatures, usually that of liquid nitrogen (−196 °C). When stored at such a low temperature, cellular divisions and metabolic processes of the living cells arrest and therefore, plant materials can be conserved for an indefinite period of time, while maximally maintaining their genetic stability (Xu et al. 2011). Furthermore, cryopreservation occupies little space, eliminates contamination and demands only maintenance. Therefore, cryopreservation has been considered an ideal means for safe and long-term storage of plant germplasm (Wang et al. 2012a). Safe maintenance of transgenic materials has been a serious problem, especially in developing countries. Transgenic materials are frequently maintained either in vitro or in vivo before being analyzed, evaluated and finally released for commercial production. Maintenance of transgenic materials by repeated subculture is time consuming, has high labor cost and may lead to culture loss due to contamination or human error. More importantly, in vitro or in vivo maintenance may create an extra risk of transgene loss or gene flow (Wang et al. 2012b). Therefore, establishment of safe and long-term preservation techniques for transgenic materials, which is capable of ensuring genetic integrity of transgenes and avoiding gene flow, is of significant importance. Successful cryopreservations have been reported for transgenic cell suspensions that expressed human serum albumin (HAS) in Nicotiana tabacum (Schmale et al. 2006), Escherichia coli heat labile enterotoxin (LT) protein in N. tabacum (Van Eck and Keen 2009) and hCTlA4Ig in Oryza sativa (Cho et al. 2007). All results obtained so far indicate that cryopreservation does not affect expression of foreign genes in transgenic materials and the productive ability of cryopreserved cells containing recombinant proteins was similar to that in non-cryopreserved cultures, thus allowing transgenic materials to be stored in a safe manner before being analyzed, evaluated and established as stable seed stocks for commercial production of homologous proteins (Wang et al. 2012b).

11 Future Prospects and Biosafety Challenges

After about two decades production of r ecombinant proteins in plants, only recently has the focus shifted away from technical and basic studies to a serious consideration of the requirements for sustainable productivity and the biosafety regulatory approval of pharmaceutical products (Sparrow et al. 2013). The manufacturing and clinical development of plant-derived pharmaceutical proteins falls under the same safety and good manufacturing practices (GMP) regulations covering drugs from all other sources (Jouzani and Tohidfar 2013). Only recombinant proteins produced by plant cell suspensions in the bioreactor systems may practically observe the GMP guidelines; other plant systems are needed to improve new GMP and biosafety standards and regulations (Fischer et al. 2012).