Abstract

The response of a system to dynamic excitation depends on the interaction between the forcing function and the system. In practice, change in material properties due to aging, fatigue, or the experience of a hazard are major challenges to the designer. This chapter discusses the effect of material deterioration on the dynamic properties of reinforced concrete structures with consideration to strain compatibility. Aging and loss of steel bond to concrete have significant effects on dynamic response. Aging causes a drop in compressive strength, hence in axial and flexural capacity, altering column interaction diagrams, or beam-column joint strength. The effect of aging in standing structures can be measured through coring and lab tests, but loss of bond is harder to evaluate because its mechanism is interior to structural members. Causes of bond deterioration include poor concrete mix, placement, or protection from chemical agents. However, well-designed mixes and placed materials may lose bond when subjected to an earthquake. Steel bond testing was performed and documented in literature, but there is still a gap in field data. A mathematical model is developed to illustrate the relationship between bond loss and concrete frame stiffness. Field assessment and remedial measures are discussed for structures that are suspected of, or diagnosed with, loss of bond. If the structure is salvageable, such effects call for specialized repairs as a preventive measure against subsequent events. But if loss of bond during an earthquake goes into an irreversible deformation range, the possibility of collapse increases or the structure becomes a candidate for disposal.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Concrete behavior is complex due to the development of cracks at low stress levels, weathering, creep, and aging effects. Two major reasons for the deterioration of reinforced concrete are attributed to weather changes, including freezing and thawing, and corrosion of reinforcing steel. The structure becomes more susceptible to weathering if protective finishing works are not completed within a reasonable time frame from the completion of the structural system [1]. Common design considerations make an implicit assumption about compressive strength and concrete mechanical properties without much consideration of material life span and building service life. In the 1940s, early construction materials research addressed the porous nature of concrete and its vulnerability through exposure to exterior agents using hydraulic pressure theory. It was found that susceptibility of concrete to changes in weather, especially when it involves frosting and thawing, increases significantly with porosity [2].

The majority of residential and office buildings in countries around the world are built with reinforced concrete due to its ease of placement and construction. The appeal of using concrete, advances in cement manufacturing technology, and the development of higher strength formulas made reinforced concrete a sustainable construction material [3]. In addition, concrete offers desirable features in terms of low sound and thermal transmission, availability of local expertise and materials in most countries. Whether in residential or office buildings, low noise transmission is one of the typical serviceability requirements. With increasing interest and concern for energy efficiency and environmentally friendly buildings, high thermal insulation properties are sought after [4, 5].

Concrete technology is considered to have made large strides over the last sixty years, which places it today at an advantage over other construction materials such as unreinforced or reinforced masonry, and at almost equal footing with industrial steel for a certain range of buildings. In fact, back in the 1950 s and 1960s research was conducted on the vulnerabilities of concrete as building construction material, emphasizing fatigue combined with loss of material strength. Concrete exhibits different behaviors under different stress states. Under simple compressive stress, concrete exhibits a linear-elastic stress-strain curve until it reaches about one third of its compressive strength because the small cracks remain closed [6–8]. Hydraulic pressure and osmotic pressure theories were used for the purpose of early modeling of concrete behavior [9].

Many researchers attribute the attractiveness of concrete to the fact that it lends itself to almost any desired shape, and may be customized to any loading rate or pattern. For example, it was shown in the mid-sixties that concrete resistance to impact increases with the rate of application of the load and is positively correlated with aggregate size [10]. However, cyclic loading in the range of 50 % of f’c causes a decrease in both the elastic modulus of concrete and its compressive strength and exhibits hysteretic behavior. These findings indicate that concrete is vulnerable to load reversals [11]. While considered a weakness, that same micro-crack formation activates the internal friction in concrete, and its hysteretic behavior provides large energy dissipation throughout the structure, attenuates response to dynamic loading, and curbs motion amplification.

As discussed in the following sections, our interest in the present chapter is mainly about changes in reinforced concrete properties especially those caused by deterioration.

2 Background: Reinforced Concrete in Use

Along with its vulnerabilities, concrete offers several advantages related to sustainability and serviceability. It minimizes noise and vibration transfer, and has relatively favorable thermal characteristics and applications in fire protection. Concrete also offers strength suitable for a wide range of building heights as it has been used in low-rise and high-rise building construction [12]. In 1919, the Japanese Urban Building Law limited the height of reinforced concrete buildings to 100 feet in an attempt to minimize risk emanating from the use of such material. Further, lessons learned in 1924 from Japan’s earthquake that imparted damage to reinforced concrete buildings were rapidly turned into Code upgrades [13]. Almost a century later, reinforced concrete is used in high-rise construction with supporting Codes that provide the design engineer with simplified procedures to perform the necessary calculations while meeting some basic requirements related to ductility, energy dissipation, and resilience in sustaining tremors [14, 15].

In the United States, the leap into skyscraper construction owes it by and large to advances in industrial steel manufacturing, standard shape production, and accompanying design guidelines [16, 17]. Another challenge faced by the steel construction industry was posed by the scarce execution resources; workers, welders, forepersons, and project managers. However, reinforced concrete remained a viable candidate for high-rise construction with and without its combination with structural steel shapes [18–20].

With the advantages of concrete, there are shortcomings related to environmental impact, especially at its manufacturing stages [21]. Cement manufacturing processes, among other industries, came under scrutiny with the increased public awareness about global warming and the negative effects of industrial activity on the environment [22, 23]. But using concrete entails more than just its manufacturing stages. It involves mixing, placement, maintenance, and down the line disposal or recycling [24, 25]. Crushing of recycled concrete has become a source of aggregates and a means of avoiding volumes of dump material that is neither biodegradable, nor suitable as soil. The approach of recycling concrete has also been applied in bridge construction where reclaimed concrete is used [26, 27]. Testing and studies performed on structural elements and sub-assemblages also showed that recycled concrete was a viable construction material [28]. Concrete mixing processes gradually moved from individual mixers that belong to specific construction sites to ready mix concrete factories. Although these factories provide economies of scale catering from one source to various destinations, they pose problems in terms of increased industrial activity. In many, if not most, countries where concrete is mainstream material for the construction industry, factory emissions control is not yet a priority on the environmental agenda [29, 30].

3 Effect of Aging of Concrete on Strength

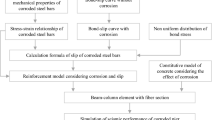

A dimension of great interest in construction material science is the durability and performance of concrete [31, 32]. What factors affect its life time? How does it age? How does concrete aging affect its strength and interaction with other materials? Deterioration through exposure to weather conditions, effect of chemicals, and crack formation are related in an intricate cause-and-effect [33, 34].

Concrete aging comprises a broader range of effects than chemical or mechanical deterioration. Such effects which include creep and shrinkage have been researched extensively in the 1950s and the 1960s and were found to have direct impact on strength and serviceability [35, 36]. More recently, shrinkage effects were studied further with the inclusion of recycled aggregates [37]. Aged concrete tends to deteriorate and to exhibit hairline cracks, which may grow and allow weather agents to infiltrate and attack reinforcing steel causing loss of strength [38]. Loss of strength may be dormant until it manifests itself in case of excessive loading beyond safety margins. For this reason it is important to differentiate the effects of aging on static from the effects on dynamic properties [39]. There are distinctive loading types that cause fatigue and cyclic deformation which in turn contribute to the acceleration of concrete aging, hence deterioration and drop in strength [40].

Conversely, overloading causes damage, crack formation, and hence deterioration that accelerates aging of concrete. In both cases, aging is an important aspect of reinforced concrete performance, especially in seismic zones where structural elements are expected to sustain reversal in loading, fatigue, and peak stress levels that may exceed design levels dictated by Codes [41, 42]. Past research on aging of concrete addressed deterioration at a material level, including transformation of the microstructure. However, there is a need to address the cumulative effects on overall structural response taking into consideration changes in material properties such as compressive strength or splitting strength due to aging [43, 44].

American and European Codes have explicit criteria related to the control of cracking and to the repair of damaged concrete [45, 46]. A question precedes a repair proposal in that does the structure, or a structural member, lend itself to repair or should it be disposed of, replaced, or re-cast? When this question is posed at the level of the entire building that has undergone severe irreversible damage from an earthquake, and may pose public hazard, demolition may be the only solution [47]. Therefore, any concrete repair proposal, plan, or operation requires a priori a meticulous assessment of the structural member and a detailed recommendation of a course of action [48]. To reach a reasonable repair recommendation, an assessment needs to reach tangible results such as the extent to which compressive strength \(f^{\prime }_{c }\) has dropped, or permeability has changed, or porosity has increased by orders of magnitude, among other parametric studies [49, 50]. To answer these questions, it has been common place to take cores out of an existing structure and test the cored samples at the lab. The challenge in this case is threefold. First, coring is an intrusive testing methodology whereby cylinders have to be cut out of members. Second, cores may not fully describe the structural health . Third, even the most professionally clustered cores do not accurately reveal to what extent the structure has been subjected to loss of bond between the reinforcing steel and the surrounding concrete [51, 52].

Loss of bond is therefore one of the most difficult phenomena to field-test realistically, and therefore it is critical to develop new methodologies that reflect how much a bond has weakened or total detachment has occurred between the reinforcing steel and the surrounding concrete [53]. It is also critical to relate this type of damage to other properties of the building whether physical, or dynamic, such as the natural frequency and equivalent viscous damping.

One of the well-documented consequences of de-bonding between steel and concrete is a significant drop in stiffness. So considering an unchanged mass—of course unless substantial shake-off of concrete occurs—the frequency expressed as \(\sqrt{k/m}\) clearly drops. This drop leads to a clear downwards shift in the building response to a given earthquake. Such shift may create a discrepancy between the assumed or anticipated structural performance during its design phase, and its actual real life performance.

4 Basic Assumptions

Due to its anisotropic nature and its non-homogeneous mechanical properties, reinforced concrete requires special assumptions in the development of governing equations in design. In reinforced concrete design literature, the step-wise procedures whether in textbooks or Codes adopt similar simplifying assumptions. Some of the assumptions rely on basic mechanics, and others utilize strain compatibility. For example, in the design of members subjected to bending, assumptions from basic mechanics involve the consideration of plane sections remaining plane in flexure. In the design of members subject to axial loads, mechanics assumptions involve the uniformity of stress distribution on the entire cross section.

Assumptions of strain compatibility are not only a means to simplify calculations and to reach coherent procedures for beam flexure, column axial-flexural interaction equations, and other design formulas, but to also reflect a necessity in maintaining that compatibility in real life applications [54]. This differentiation is very important in design because it dictates the strength and serviceability performance once the structure is put in operation. Depending on several factors which include mix design, placement quality and procedures, or operational loads, strain compatibility may not remain applicable throughout the lifetime of the building. Research literature addressed concrete aging and its effect on overall structural performance [55, 56]. Other studies addressed steel-concrete bond theoretically and experimentally and found that it has a great effect on reinforced concrete member behavior. Early research on bond comprised straight pull out tests that confirmed a significant change in capacity with deterioration of bond [57, 58].

5 Effect of Steel-Concrete Bond

5.1 Localized Versus Member Level Bond Effects

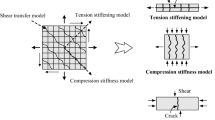

The bond between reinforcing steel and concrete governs the transfer of stress between these two materials. A distinction should be drawn between bond at the localized stress field level, and bond at the reinforced concrete member level. The first category addresses the micro-structure interface whereby the concrete is crushed by the steel lug edge [59, 60]. The second category addresses the cumulative effects of rebar pull-out causing excessive rotation at beam-column joints or crack formation in the tension zone. These effects have a direct effect in the overall stiffness of the structure. They can be modeled directly in the stiffness matrix and found mathematically to impact eigenvalues yielding lower frequencies [61, 62]. Cyclic loading causes alternation between tension and compression at the same member location, and therefore requires the investigation of reversal of member forces computed from static analysis.

5.2 Bond Deterioration at the Local Bar Level

Bond requires development length. If bond resistance deteriorates, reinforcing bars are likely to slip and destroy the steel-concrete composite action. A severe loading such as impulse or earthquake may cause brittle failure. Therefore, bond has multiple functions including overall strength and ductility. It is affected by many factors including concrete cover, rebar spacing, bundling, and position. Depending on the manufacturer, certain bars have ribs at an angle that influences bond and pull-out behavior. It was shown in early research and testing that for the same configuration, bond resistance to straight pull-out is greater under dynamic loading than it is under static loading [63]. This conclusion may not hold under dynamic cyclic loads [64].

Research showed that bond strength decreases as bar diameter increases. This conclusion shed light on the selection of reinforcing steel in practical design, following the determination of a total required steel area [65]. For example a choice of #9 versus #6 bars would not only be affected by placement, but also by increasing the contact surface, or the frictional interface. In this case, smaller bar diameters would be favored, all other design parameters being equal.

Development length of bars was also studied with the effect of confinement. Other factors being constant, ultimate bond stress varies as a function of \(f_{c}^{'}\) because it is related to concrete tensile strength [66]. From traditional tri-axial stress relationships, confinement causes an increase in \(f_{c}^{'}\) and provides larger normal stress between steel and concrete.

Rebar placement, spacing, member width and anchorage also affect bond strength in terms of concrete splitting failure [67]. Studies considering a variety of deformed bar surface properties established a relationship between concrete cracking and slippage along the embedment length. Results helped formulate resistance to pull-out along embedment length [68]. Related research showed that since confinement increases normal stress around the bar, it has a significant effect on bond [69].

5.3 Bond Slip Effects at the Member Level

The cumulative effects of localized bond slip result in overall drop in performance at the reinforced concrete member level. In particular, beam-column joints would undergo additional rotation beyond the level captured by linear elastic analysis [64]. Once reinforcing steel starts to move relative to concrete, the members connected at the joints go through additional rotation relative to each other. Areas in the vicinity of beam-columns joints in moment-resisting frames subjected to dynamic loading are affected the most [62]. This result is expected because the energy imparted into the superstructure by the earthquake is dissipated through ductile behavior at the joints [70].

6 Model Development

6.1 Mathematical Derivation

We develop a mathematical model that represents the bond slip behavior. Consider the ring of concrete in touch with the bar in between two consecutive lugs. Denote by \(\sigma \) the normal stress exerted by the lug on the concrete. Consider the lug as having an angle \(\theta \) with the longitudinal axis of the rebar where \(45^{\circ }\le \theta \le 90^{\circ }\). Let \(d_{b}\) denote bar diameter and \(t_{l}\) the height of the lug above the steel surface. The area on the wedge of the steel lug concentric to the bar axis is:

For an embedment length \(l_{d}\), the resultant is:

The projected lug area concentric to the rebar axis is:

The component of \(\sigma \) exerted on this area contributes to concrete splitting effect. Its resultant is:

The concrete shear area adjacent to the lugis:

If \(f_{cv}\) is the concrete shear strength, shear resistance is:

The area of an infinitesimal element around the circumference of the steel segment within the clear spacing of two consecutive lugs is:

where \(d\alpha \) is an infinitesimal angle about the rebar centroid, and dx is an infinitesimal distance parallel to the longitudinal rebar axis. Among the range of deformed bar patterns, the simplest pattern has lugs that are parallel to each other, spaced at about \(1/2^{\prime \prime }\) to 1\(^{\prime \prime }\) and orthogonal to the bar axis.

To express the frictional resistance mathematically, we consider that the confinement stress, denoted \(f_{1}^{'}\) contributes to frictional resistance to motion, at both the concrete-concrete interface and the steel-concrete interface. Denote \(\mu \) the friction coefficient, which depends on the pull-out displacement rate, \(\dot{x}=dx/dt\) and on the angular location around the rebar periphery, \(\alpha \). The differential force due to friction can be expressed as:

The resultant is a double integral over \(\alpha \) and x, over the inter-lug segment, summed over the embedment length:

The inclusion of \(\alpha \) in the expression of \(\mu \) is due to the fact that there may be localized imperfections around the rebar such as air pockets, or a large aggregate instead of bonding mortar, which may cause an uneven frictional resistance around the circumference of the bar. Such local imperfections and their effects can be accounted for separately through a safety reduction factor related to concrete mix and placement quality. As for the relative pull-out displacement rate or velocity range expected at incipient bond slip, we consider that the steel-concrete friction coefficientis constant along the embedment length. Applying these two simplifications to expression (11), performing double integration, and summing over the development length, we have:

The derivation sheds light on the difference between reversible and irreversible effects of loading. For a steel bar whose strength exceeds the bond slip load level, the effect is considered reversible. However, if bond slip occurs at a load level below the development of the bar strength the effect becomes irreversible.

6.2 Application to Static Equilibrium

The stress resultants in expressions (2), (5), (8) and (12) can be used in equilibrium equations in the longitudinal direction. As discussed earlier, (2), (5) and (12) could be extended into a dynamic equilibrium where the rate of change of the friction coefficient, inertia effects, and other related factors, are accounted for. However, the dynamic equilibrium is treated undera separate scope. Several cases could be identified, which we simplify under two main conditions that are most relevant to our scope. Case 1 pertains to the rebar reaching its full development function, while Case 2 corresponds to a pull-out prior to reaching yield. An optimal equilibrium would be reached under strength and economic conditions simultaneously. Denoting by \(T_{s}\) the tensile force applied to the bar:

where \(A_{st}\) is a single bar steel section and \(f_{s}\) is the stress applied to that section. If there is no bond slip, we have:

otherwise, the bar would pull-out under the applied section stresses. In this case, we have:

Once the concrete shear resistance fails at the envelope layer, both the lug resistance and the frictional resistance along the steel segment between the lugs no longer contribute to bond. Research on steel-concrete friction coefficients shows that their values vary between 0.47 and 0.7 depending on finishing parameters and other factors [71, 72]. For the purpose of the present illustrative examples, we use 0.5. However, the same present derivation and resulting formulas could used over a range for values of the friction coefficient.

The relationship between bar tensile force and bond resistance for a No. 5 bar in 4000 psi compression strength concrete is shown in Fig. 1, where tensile resistance is plotted against development length factor. Yield forces in the bar are T\(_\mathrm{y}\) (4) \(=\) 12.4 k and T\(_\mathrm{y}\) (6) \(=\) 18.6 k for \(f_{y}\) \(=\) 40 ksi and \(f_{y}\) \(=\) 60 ksi, respectively. Development length required by ACI is 37 \(d_{b}\), for \(f_{y}=\) 40 ksi, and 57\(d_{b}\) for \(f_{y} = 60\) ksi. For both \(f_{y}\) values, inequality (14) is satisfied and the bar will yield before reaching the pull-out limit. However, shear strengthin the concrete in the vicinity of the bond area is enough to carry the bar to yield for \(f_{y} = 40\) ksi, but bond slip will occur before the bar yields for \(f_{y} = 60\) ksi (Fig. 1). A similar analysis could be performed for various bar diameters, concrete compressive strength, and steel yield stress.

7 Effect on Overall Structural Health

7.1 Effect of Bond Deterioration

Bond deterioration has a significant effect on local critical zones, and it has an influence on the overall structural behavior, especially when subjected to dynamic loading. The additional rotation at the joints due to bond slip exhibits hysteresis behavior represented by a nonlinear curve [64, 70]. The force-deformation curve starts with a straight line over the elastic range then reaches a plateau where the joint rotates at no additional moment. When load reversal occurs, the joint starts rotating in the opposite direction while engaging the bar in friction until it bears against concrete. At that point, the bar on the opposite side of the beam starts its pulling cycle. Theoretically, reversal exhibits equal and opposite values. But if decay is included in the model, cycle \(i+1\) will exhibit deterioration with respect to cycle i, until collapse of the joint, should the cyclic load continue.

7.2 Effect of Aging

Aging of concrete is one of the most determining phenomena in the behavior of structures. Early studies in the 1950s followed by research at the turn of century show continuous interest in long term effects in concrete behavior [32, 35]. There are no standardized direct experimental processes to deliberately age concrete and test it on that basis. For this reason, the most reliable lab for aging would be the outdoors real life situation in cities where reinforced concrete constitutes the vast majority of buildings.

Data collected in various cities in Lebanon was compiled by building age, condition, and ambient environmental effects. A subset of 140 buildings was studied analytically. But coring and compressive strength tests were performed on only 5 buildings that were considered as representative of the others in the sample. The 5 buildings are not statistically significant, but their results were within a coherent range and therefore provided an indication of the state of the concrete in these older buildings. Some of the cylinders gave a compressive strength as low as 790 psi. The detailed field-related experiments were left outside the scope of this paper as a subject of future research [73].

7.3 Effect of Design and Placement Quality

Mix and structural design, and placement quality are very important and have a direct relationship with the two features above; bond deterioration and aging. Concrete that is well proportioned has a superior longevity to concrete that is not. Structural systems that are designed to withstand dynamic loading defined by code, will obviously perform better than the ones that are not. Some of the field challenges that we encountered had to do with all three components; mix, design, and placement. In the present paper, we mention some of those challenges as they cannot be fixed retroactively, but we shall rather provide a rational approach for decision-making in terms of types of actions that could be taken.

A challenge in many less developed countries is the lack of code guidelines. Another challenge is the poor or lack of supervision. Even when designed per European or US codes, the execution leaves room for mismanagement of resources and potential mishaps during construction.

7.4 Remediation Choices

Although extensive research on reinforced concrete damage caused by bond deterioration was performed in the 1960s, interest in bond effects for both steel and fiber reinforced concrete resurged in later decades as seismic codes grew more stringent [74, 75].

For existing buildings, parameters needed to perform calculations may not be easily available. To determine \(f_{c}^{'}\) in an older building, coring and testing may be performed. But results from various parts of the same building may exhibit a large spread [73]. A simpler decision rule involves the overall state of the building. Table 1 provides a set of inspection results, with possible solutions. Three categories are defined for strength, serviceability, and aesthetic requirements (Table 1).

8 Effect on Dynamic Behavior

8.1 Effect on Fundamental Period

Studies conducted on beam-column assemblages attempted to cast complex dynamic behavior in formulas. Approaches proposed in literature account for bond slip effect on overall structural dynamic behavior [64, 76].

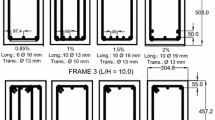

To get a preliminary result on dynamic performance, considera single bay and three degrees of freedom, one translation \(u_{1}\) and two rotations at the joints, \(u_{2}\) and \(u_{3}\), respectively. We have:

where \(k_{11}^{*}\) condenses the \(k_{ij}\) stiffness coefficients (\(i=1, 2, 3\); and \(j=1,2, 3\); \( i \ne 1\), and \(j\ne 1\)) and \(f_{e}\) is the elastic force. The mathematical derivation is under separate scope to focus here on the practical formulas for designers [73]. We define a girder-column stiffness ratio:

where \(E_{cg}\) and \(E_{cc}\) are the moduli of elasticity for the concrete in the girder and in the column respectively, \(I_{g}\) and \(I_{c}\) are the moments of inertia of the girder and column, respectively, and \(L_{g}\) and \(L_{c}\) are the span of the girder and column height respectively. We have:

where a, b, c, and d, are constants that depend on column and girder properties [73]. Degradation in girder-column stiffness ratio is denoted by \(\delta _{\varphi }\). The drop in the condensed stiffness term differs whether the deterioration is occurring in the girder or the column. In both cases, however, it results in a significant drop in natural frequencies of the structural system. Figure 2 shows the drop in stiffness due to degradation in the girder, while Fig. 3 shows results for degradation in the column.

For a stiffness ratio of 5 that decreases 60 % through deterioration of girder moment of inertia, the condensed stiffness drops from 22 to 19.5. While for the same stiffness ratio, 5, that decreases 60 % through deterioration of column moment of inertia, the condensed stiffness drops from 22 to 9 (Fig. 3). These numerical examples support the strong column weak girder approach in the seismic design of RC structures.

The results can be related to linear elastic structural analysis using basic element stiffness coefficients with various boundary conditions. For example, a free standing cantilever column whose top joint is allowed to rotate and translate without any restraints has a lateral stiffness coefficient equal to 3EI/L \(^{3}\), where E, I and L are the modulus of elasticity, moment of inertia, and span, respectively. If the top joint of the column is fixed against rotation, but is allowed to translate horizontally, the lateral stiffness coefficient is 12EI/L \(^{3}\). For a portal, the results in the first case yield a coefficient of 6 and in the second case, a coefficient of 24. Therefore, the worst case scenario of girder failure comprises bond deterioration in the girder at the column face, leaving the joint in the column to rotate freely, or with very low deteriorated rotational stiffness. The worst case scenario of column failure through bond deterioration would be a hinge in the column leading to collapse, which is unacceptable form a reinforced concrete design perspective.

9 Conclusions

Methodologies for predicting earthquake response of a structure based on its known properties and for a given excitation are well established. The challenge resides in the ability to define those properties, especially when the construction material is susceptible to substantial changes through time, or in the wake of a tasking event. For reinforced concrete structures, these two factors are particularly important; aging of concrete is accompanied by shrinkage and creep effects, and events such as earthquakes could drive the members into reversals that change their mechanical properties. What makes the analysis and design of reinforced concrete more demanding is that related formulas are based on strain compatibility assumptions. These assumptions that of steel and concrete deforming in compatible increments as the elements develop nominal strength, do not hold throughout the life of the reinforced concrete member. These assumptions become less applicable to real life behavior when concrete elements age or undergo cyclic loading. Another challenge is related to the possibility of performing tests on various lifetime intervals to ascertain, or adjust, properties in models. The use of field sampling to determine concrete compressive strength may be performed by coring and lab testing. However, field-testing for bond deterioration is much more complex and cannot be determined by sampling an existing structure. Loss of bond between reinforcing steel and surrounding concrete is a complex, internal, often invisible phenomenon that is hard to capture through common sampling techniques. The model developed in the present paper analyzes the structural health of reinforced concrete buildings taking into consideration concrete damage through loss of bond. The analytical model relates steel loading that causes bond distress to design parameters such as development length and bar properties. Potentially, new methodologies for field measurements could be developed to target bond deterioration through the observation of dynamics properties. This is based on the premise that loss of bond leads to reduced stiffness which results in lower natural frequencies. Those reduced or modified stiffness coefficient could be calculated for mass values kept constant. The analytical model could be checked against the dynamic model and could be complemented by field measurements in future research. The diagnosis method presented in this paper discusses the sustainability of the structure and offers a simplified decision rule whether to perform minor fixes, major rehabilitation, or disposal. The model draws a distinction between joint damage in the girder as opposed to the column, and makes the case for weak-girder strong-column design. Plastic joints formed in the girder may potentially lend themselves to concrete repair, while plastic hinges in the column may cause catastrophic collapse, and thus make the structural health condition irreversible. Empirical results were partially used and discussed to illustrate field challenges that are faced when the structure is subjected to earthquake motion or other severe conditions such as impulse loading.

References

Zuber, B., Marchand, J.: Modeling the deterioration of hydrated cement systems exposed to frost action; part 1: description of the mathematical model. Cem. Concr. Res. 30(12), 1929–1939 (2000)

Powers, T.C.: A working hypothesis for further studies on frost resistance of concrete. Research Laboratory of the Portland Cement Association. J. Am. Concr. Inst. 16(4), 245–272 (1945)

Naik, T.R.: Sustainability of concrete construction. ASCE Pract. Period. Struct. Des. Constr. 13(2), 98–103 (2008)

Jacobs, J.B. (ed.): European Concrete Platform: Sustainable Benefits of Concrete Structures. Brussels, Belgium (2008)

Park, S.B., Seo, D.S., Lee, J.: Studies on the sound absorption characteristics of porous concrete based on the content of recycled aggregate and target void ratio. Cem. Concr. Res. 35(9), 1846–1854 (2005)

Nordby, G.M.: Fatigue of concrete: a review of research. J. Am. Concr. Inst. 30(2), 191–219 (1958)

Powers, T.C., Copeland, L.E., Hayes, J.C., Mann, H.M.: Permeability of Portland cement paste. J. Am. Concr. Inst. 51(3), 285–298 (1954)

Powers, T.C.: The physical structure and engineering properties of concrete. Bulletin No. 90. Res. Dev. Lab. Portland Cem. Assoc. 1958, 1–28 (1958)

Powers, T.C., Helmuth, R.A.: Theory of volume changes in Hardened Portland cement paste during freezing. Highw. Res. Board Proc. 32, 285–297 (1953)

Green, H.: Impact strength of concrete. Proc. Inst. Civil Eng. London 28(3), 383–396 (1964)

Ople. F.S., Hulsbos, C.L.: Probable fatigue life of plain concrete with stress gradient. Research report. ACI J. 63(2), 59–81 (1966)

Collins, M.P.: In Search of Elegance: The Evolution of the Art of Structural Engineering in the Western World. ACI, Concrete International 23(7), 55–72 (2001)

Sorensen, A.: The Making of Urban Japan: Cities and Planning from Edo to the Twenty First Century. Routledge, New York (2005)

El-Numeiri, M., Gupta, P.: Sustainable Structure of Tall and Special Buildings. CTBUH 2\(^{nd}\) Annual Special Edition. In: Tall Sustainability, ed. Antony Wind, Wiley, 17(5), (2009)

Smith, B.S., Coull, A.: Tall Building Structures: Analysis and Design. Wiley, New York (1991)

AISC: American Institute of Steel Construction Design Specifications. AISC Manual 13th edn. New York (2010)

Segui, W.T.: Steel Design, 5th edn. Cengage Learning, Stamford (2012)

Ali, M.M., Moon, K.S.: Structural developments in tall buildings: current trends and future prospects. Architect. Sci. Rev. 50(3), 205–223 (2007)

Oldfield, P., Trabucco, D., Wood, A.: Five energy generations of tall buildings: a historical analysis of energy consumption in high-rise buildings. Journal of Architecture 14(5), 591–613 (2009)

Oldfield, P., Wood, A.: Tall building in the Global Recession: 2008, 2020, and beyond. Counc. Tall Build. Urban Habitat (CTBUH) J. 1, 20–26 (2009)

Ann, K.Y., Moon, H.Y., Kim, Y.B., Ryou, J.: Durability of recycled aggregate concrete using pozzolanic materials. Waste Manage. 28(6), 993–999 (2008)

Damineli, B.M., Kemeid, F.M., Aguiar, P.S., John, V.M.: Measuring the eco-efficiency of cement use. Cem. Concr. Composit. 32(8), 555–562 (2010)

Mehta, P.K.: Global concrete industry sustainability. Concr. Int. 31(2), 45–48 (2009)

Al-Mutairi, N., Haque, M.N.: Strength and durability of concrete made with crushed concrete as coarse aggregates. In: Proceedings of the International Symposium on Recycling and Reuse of Waste Materials, pp. 499–506. Scotland, UK (2003)

Katz, A.: Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 33(5), 703–711 (2003)

Gomez-Soberon, J.M.V.: Porosity of recycled concrete with substitution of recycled concrete aggregate. Cem. Concr. Res. 32(8), 1301–1311 (2002)

AASHTO MP 16: Standard specification for reclaimed concrete aggregate for use as coarse aggregate in hydraulic cement concrete. In: American Association of State and Highway Transportation Officials, Washington, DC, US (2010)

Gonzalez-Fonteboa, B., Martinez-Abella, F.: Concretes with aggregates from demolition waste and silica fume: materials and mechanical properties. Build. Environ. 43, 429–437 (2008)

Kayali, O., Haque, M., Khatib, J.: Sustainability and emerging concrete materials and their relevance to the Middle East. Open Constr. Build. Technol. J. 2(1), 103–110 (2008)

Cole, R.J.: Energy and greenhouse gas emissions associated with the construction of alternative structural systems. Build. Environ. 34(3), 335–348 (1999)

Olorunsogo, F.T., Padayachee, N.: Performance of recycled aggregate concrete monitored by durability indexes. Cem. Concr. Res. 32(2), 179–185 (2002)

Alexander, M.G., Ballim, Y., Maketchnie, J.R.: Guide to the use of durability indexes for achieving durability in concrete structures. Collaborative Research by Universities of Cape Town and Witwatersrand. Res. Monogr. 35(2), (1999)

Hasaba, S., Kawamura, M., Torik, K., Takemoto, K.: Drying shrinkage and durability of concrete made of recycled concrete aggregate. Collaborative Research by Universities of Cape Town and Witwatersrand. Trans. Jpn. Concr. Inst. 3, 55–60 (1981)

Bertolini, L.: Steel corrosion and service life of reinforced concrete structures. J. Struct. Infrastruct. Eng. 4(2), 123–137 (2008)

Troxell, G.E., Raphael, J.M., Davis, R.E.: Long-time creep and shrinkage tests of plain and reinforced concrete. Proc. ASTM 58, 1–20 (1958)

Shank, J.R.: Plastic flow of concrete at high overload. ACI J. 20(6), 68–76 (1949)

Hansen, T.C.: Elasticity and drying shrinkage of recycled aggregate concrete. ACI J. 82(5), 648–652 (1985)

Washa, G., Fluck, D.: Effect of sustained loading on compressive strength and modulus of elasticity of concrete. ACI J. 46(5), 693–700 (1950)

Levtchitch, V., Kvasha, V., Boussalis, H., Chassiakos, A., Kosmatopoulos, E.: Seismic performance capacities of old concrete. In: Proceedings, 13th World Conference on Earthquake Engineering, Vancouver, B. C., Canada, 1–6 Aug 2004, Paper No. 2182 (2004)

Levtchitch, V.: Shear fatigue and seismic response of reinforced concrete flexural members. Cyprus J. Sci. Technol. Nicosia 1(3), 22–32 (1997)

Cornelissen, H.A.W., Reinhardt, H.W.: Uniaxial tensile fatigue failure of concrete under constant-amplitude and programme loading. Mag. Concr. Res. 36(129), 216–226 (1984)

Kim, J.K., Han, S.H., Song, Y.C.: Effect of temperature and aging on the mechanical properties of concrete: part I. Experimental results. Cem. Concr. Res. 32(7), 1087–1094 (2002)

Washa, G.W., Wendt, K.F.: Fifty Year properties of concrete. ACI J. Proc. 71–4, 20–28 (1975)

Withey, M.O.: Fifty year compression test of concrete. ACI J. Proce. 58(6), 695–712 (1961)

American Concrete Institute, ACI 224R–90: Control of Cracking in Concrete Structures. ACI Manual of Concrete Practice, Part 3, American Concrete Institute, Detroit, MI (1992)

Base, G.D.: Control of Flexural Cracking in Reinforced Concrete. Civil Engineering Transactions, The Institution of Engineers, Australia, CE 18(1), 20–23 (1976)

Guide to Concrete Repair: Bureau of Reclamation, Technical Service Center, Denver, CO (1996)

American Concrete Institute: Concrete Repair Manual, 4th edn, vol. 1, 2 (2013)

Popovics, S.: New formulas for the prediction of the effects of porosity on concrete strength. Am. Concr. Inst. J. Proc. 82(2), 136–146 (1985)

Chen, X., Wu, S., Zhou, J.: Influence of porosity on compressive and tensile strength of cement mortar. Construct. Build. Mater. 40, 869–874 (2013)

Bartlett, F.M., MacGregor, J.G.: Assessment of concrete strength in existing structures. Structural Report No. 198, Department of Civil Engineering, University of Alberta, Edmonton, Alberta (1994)

American Concrete Institute: Specifications for Structural Concrete—ACI 301–05. Publication SP-15, Field Reference Manual, Farmington Hills (2005)

Saether, I.: Bond deterioration of corroded steel bars in concrete. J. Struct. Infrastruct. Eng. 7(6), 415–429 (2011)

American Concrete Institute, ACI Committee 318–11: Building Code Requirements for Structural Concrete and Commentary. ACI 318–11. MI (2011)

Gulikers, J.: Pitfalls and practical implications in durability design of reinforced concrete structures. In: Proceedings of the 4th International RILEM PhD Workshop on Advances in Modeling Concrete Service Life, Madrid, Spain (2010)

Materials Properties Model of Aging Concrete. Bureau of Reclamation, Technical Service Center, Denver CO (2005)

Shi, Z.: Crack Analysis in Structural Concrete: Theory and Applications. Elsevier, New York (2009)

Hunaiti, Y.: Aging effect on bond strength in composite sections. ASCE J. Mater. Civil Eng. 6(4), 469–473 (1994)

Goto, Y.: Cracks formed in concrete around deformed tension bars. ACI J. 68(2), 244–251 (1971)

Lutz, L.A.: Analysis of stresses in concrete near a reinforcing bar due to bond and transverse cracking. ACI J. Proc. 67(10), 778–787 (1970)

Scott, R.H., Gill, P.A.T.: Short-term distributions of strain and bond stress along tension reinforcement. Struct. Eng. 65B(2), 39–48 (1987)

Filippou, F.C., Popov, E.P., Bertero, V.V.: Modeling of reinforced concrete joints under cyclic excitations. ASCE J. Struct. Eng. 109(11), 2666–2684 (1983)

Hansen, R.J., Liepins, A.A.: Behavior of bond in dynamic loading. ACI J. 59, 563–583 (1962)

Spacone, E., Filippou, F.C., Taucer, F.F.: Fiber beam-column model for non-linear analysis of R/C frames, part 1: formulation. Earthq. Eng. Struct. Dyn. 25(7), 711–725 (1996)

Mathey, R.G., Watstein, D.: Investigation of bond in beam and pullout specimens with high-yield strength deformed bars. ACI J. T. No. 57–50, 1071–1089 (1961)

Ferguson, P.M., Robert, I., Thompson, J.N.: Development length of high strength reinforcing bars in bond. ACI J. T. No. 59–17, 887–922 (1962)

Ferguson, P.M., Breen, J.E., Thompson, J.N.: Pull out tests on high strength reinforcing bars. ACI J. T. No 62–55, 933–950 (1966)

Abrishami, H., Mitchell, D.: Simulation of uniform bond stress. ACI Mater. J. 89(2), 161–168 (1992)

Malvar, L.J.: Bond of reinforcement under controlled confinement. ACI Mater. J. 89(6), 593–601 (1992)

Bazant, Z.P., Bhat, P.D.: Prediciton of hysteresis of reinforced concrete members. ASCE J. Struct. Div. 103(ST1), 153–167 (1977)

Rabbat, B.G., Russel, H.G.: Friction coefficient of steel on concrete or grout. ASCE J. Struct. Eng. 111(3), 505–515 (1985)

Baltay, R., Gjelsvik, A.: Coefficient of friction for steel on concrete at high normal stress. ASCE J. Mater. Civil Eng. 2(1), 46–49 (1990)

Chalhoub, M.S.: Seismic design and dynamic response of reinforced concrete buildings with the effects of deterioration. Working paper, CEM Rep. No. 02–2014 (2014)

Lee, M.G., Chiu, C.T., Wang, Y.C.: The study of bond strength and bond durability of reactive powder concrete. J. ASTM Int. 2(7), 12960 (2005)

Banon, H., Biggs, J.M., Irvine, H.M.: Seismic damage to reinforced concrete frames. ASCE J. Struct. Div. 107(ST9), 1713–1729 (1981)

Emori, K., Schnobrich, W.C.: Inelastic behavior of concrete frame-wall structures. ASCE J. Struct. Div. 107(ST1), 145–164 (1981)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Chalhoub, M.S. (2015). Effect of Reinforced Concrete Deterioration and Damage on the Seismic Performance of Structures. In: Belhaq, M. (eds) Structural Nonlinear Dynamics and Diagnosis. Springer Proceedings in Physics, vol 168. Springer, Cham. https://doi.org/10.1007/978-3-319-19851-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-19851-4_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-19850-7

Online ISBN: 978-3-319-19851-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)