Abstract

In the medical domain, the use of biocompatible materials, such as titanium or titanium alloys is essential to produce individual implants. As a result of this development, it is now possible to generate new patient-specific geometries fitted to the contour. This paper elucidates the process chain to derive individual design variants and to produce patient-specific bone replacement implants for the lower jaw-bone regions by using innovative reverse engineering and manufacturing methods based on CT-data. For this interdisciplinary project, technical scientists, medical scientists at the university hospital and engineers from a product development firm work together.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Purpose

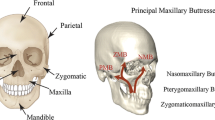

As a result of ongoing globalisation, the greatly expanding market for medical implants made of biocompatible high-performance materials is under ever-increasing pressure from competitors. In this context, the reconstruction of bone defects, in particular in the oral, jaw and facial region, by means of osteosynthetic plates is regarded as a great challenge. Here, special advantages may accrue to a new implant design whose contour and stiffness are tailored to specific geometric and elastic conditions, since in this way it is possible to reduce complications during ingrowth. One objective of the research project is aimed at the development of a process chain that extends all the way from CT layer images of a diseased patient up to the manufacturing of individual bone substitute implants for the patient while taking into consideration a Rapid Manufacturing technique [1–3].

In this context, manufacturing of individualized medical products supported by customized software solutions is becoming more and more important. However, these software tools must be designed so that they are easy to handle and understand. It is not feasible to assume that the surgeon will devote much time to becoming familiar with the software. Also a wide variety of functions may be a liability, in that it is often one reason for the rejection of a product.

Individualised medical products are created in a series of carefully synchronised and mutually interlocking process steps. In this process, doctors, designing engineers and production planners work together in an interdisciplinary team. Consequently, project work within the process chain has to be supported and optimised through customised software tools in order to create an immediate interface for communication and data exchange.

One example that illustrates the need for such special solutions is that of the creation of patient-specific lower jaw implants. They are designed based on CT data processed in a CAD system. Therefore auxiliary geometries have to be defined by the surgeon. Design and manufacture are thus performed on the implant producer’s site. Our goal is to develop a software tool with which the doctor can define the auxiliary geometries after recording the CT data and can make these geometries directly available to the designing engineer.

2 Methods

The design of individualized lower jaw implants made of pure titanium is the subject of a current project financed by the Saxon Bank for Reconstruction and Development (SAB). The authors’ partners in this interdisciplinary endeavor are doctors from the University Clinical Center Dresden and designing engineers from a product development firm. New technologies from medical image processing, Direct Manufacturing (generative manufacturing) and Reverse Engineering are thus brought together. Below, we list the principal steps needed to create individualized implants (Fig. 1):

-

(1)

Recording of the lower jaw region by means of computer tomography (CT) and generation of a surface model by means of the “marching cubes” algorithm

-

(2)

Alignment of the lower jaw model in a defined co-ordinate system and definition of cutting planes (marking of the damaged area), fixing screws and dental implants

-

(3)

Geometry reconstruction of removed part from the lower jaw; there are no limitations in any anatomical situation

-

(4)

Surface representation of the lower jaw contour with follow-up design of implant and cutting templates (marking of the cutting position during operation)

-

(5)

Preparation for generative production by means of LaserCUSING® [4] with subsequent manufacture of the implant and the cutting templates (Fig. 2)

-

(6)

Preparation for generative production by means of LaserCUSING® with subsequent manufacture of the implant and the cutting templates.

3 Results

The product developed is the software tool “Kontito” (Fig. 3). Visualisation is based on XNA technology by Microsoft. This technology makes it possible to develop the tool quickly and simplifies its extension to applications that might be necessary in the future.

The functions are activated using a command manager, following a linear sequence of functions. Patient data are read in from the CT layered images (DICOM) or image data (TIFF, RAW etc.). Image artifacts of due to preexisting dental prostheses in the region of interest can corrupt the results of CT. After processing of the model data (such as cutting and clearing of triangles), the cutting planes are roughly aligned using three fixed surface points. Afterwards one can finely align the planes through shifting and rotation via mouse control. The accuracy depends from the resolution of the layered images during CT-procedure. In clinical situations the voxel size is between 1 and 2 mm. The error of design and manufacturing process is less than 0.01 mm.

For the attachment of the mounting screws not only the intrinsic position is varied, but also the orientation, for instance in order to cover a greater region of the hard bone bed (corticalis) and thus to achieve better adhesion. Therefore it is possible to cut the model along the previously defined planes to make the inside area of the bone visible.

For broader functional integration into the lower jaw implant, position and orientation for dental implants that will be inserted are defined using the 3D model. To guarantee occlusion, orientation is taken from the arch contour of the lower jaw and the dental position of the upper jaw as well. Screws and tooth implants are shown in a simplified manner; the surgeon can freely select length and diameter. Thus, the surgeon can choose the preferred implant type from the wide variety of products on the market.

4 Conclusion

In the project, we created software for targeted planning of auxiliary geometries. The software is used by the surgeon and is characterized by easy and user-friendly handling. The software tool is integrated seamlessly into the entire process chain and makes possible an efficient exchange of design data between surgeon and designing engineer. The application has already been successfully tested using numerous 3D models of lower jaws taken from living minipigs, 20 cadavers of young pigs and on one human lower jaw. A validation of clinical effectiveness of this software-bridge will be a next step of our work.

In the future, additional auxiliary functions can be integrated. The plan is to simultaneously fade in both 3D model and CT layered images in the cutting region and to integrate algorithms to maintain occlusion between the lower- and upper jaws. Other options for the future are to use this application in the field of Augmented Reality (AR) or to embed other controls, such as a 3D mouse.

References

Schöne, C., Stelzer, R., Sembdner, P., Markwardt, J., Reitemeier, B., Engel, G.: Individual contour adapted functional implant structures in titanium. In: Proceedings of the 21st CIRP Design Conference, KAIST, Korea, 27–29 March 2011. ISBN 978-89-89693-29-1

Schöne, C., Stelzer, R., Sembdner, P et al: Individual contour adapted functional implant structures in titanium. In: Proceedings of the 5th International Conference on Advanced Research and Rapid Prototyping (VRAP), Leiria, Portugal, 28 September–1 October 2011. ISBN: 978-0-415-68418-7

Bertol, L., Kindlein, W., Sembdner, P., Schöne, C., Stelzer, R.: Customized craniofacial implants: design and manufacture. In: Davim, P. (ed.) The Design and Manufacture of Medical Devices. Woodhead Publishing, Philadelphia (2012). ISBN 978-1-90756-872-5

Wohlers, T.: Rapid Prototyping and Manufacturing, State of the Industry. Wohlers Associates Inc, Colorado (2009). ISBN 0-9754429-5-3

Acknowledgments

We acknowledge Dipl.-Ing. Gerd Engel, managing director of the product development company Hofmann & Engel Produktentwicklung GmbH in Boxdorf near Dresden, for his innovative ideas and his forward-looking decision to invest in an advanced laserCUSING® system at an early date. We also acknowledge Dipl.-Ing. Thomas Jahn, project manager in this scientific project in the company. Gerd Engel also contributed to the distribution of this modern technology in an industrial environment – and now for applications in the medical domain as well. We also acknowledge Dr. med. Jutta Markwardt from Department of Oral and Maxillofacial Surgery and Prof. Dr. Bernd Reitemeier from Department of Prosthetic Dentistry in Dresden for their innovative ideas.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this paper

Cite this paper

Schoene, C., Sembdner, P., Holzhausen, S., Stelzer, R. (2014). Forming the Interface Between Doctor and Designing Engineer. In: Erdt, M., et al. Clinical Image-Based Procedures. Translational Research in Medical Imaging. CLIP 2013. Lecture Notes in Computer Science(), vol 8361. Springer, Cham. https://doi.org/10.1007/978-3-319-05666-1_2

Download citation

DOI: https://doi.org/10.1007/978-3-319-05666-1_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-05665-4

Online ISBN: 978-3-319-05666-1

eBook Packages: Computer ScienceComputer Science (R0)