Abstract

Forest biomass used for energy or biofuels can be sourced directly from land-use systems, indirectly from wood-based industries or recovered from other human activities outside the forest sector. The former, referring to primary biomass from forests, includes organic products or residues derived directly from living or recently dead trees or other forest vegetation. It constituted nearly half of the world’s harvested forest biomass in 2021 and holds particular importance in the Global South, where traditional biomass remains a vital energy source for many people. Besides direct wood fuel, secondary wood residues represent another substantial source of forest bioenergy. These organic residues, such as wood chips, sawdust or black liquor, are generated by the industries processing wood, especially primary forest industries. A large amount of these residues is well-suited for further material use and energy generation. However, wood suitable for energy is not solely generated by forest-based industries. Various other activities use wood products that eventually reach the end of their usable life and are discarded, such as wood waste from construction or demolition, furniture waste or end-of-life pallets and packaging used to transport goods. This chapter presents and characterises the different woody biomass streams that can provide feedstock for energy.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Forest biomass is the accumulated mass, above and below ground, of living and dead woody tree and shrub species [1]. It can be grouped in three different categories (Table 1): primary, secondary and tertiary [2], respectively called direct, indirect and recovered in the classification by the Food and Agriculture Organisation, FAO [3]. These three categories reflect the supply source: land-use systems (primary biomass), wood-based industries (secondary biomass) and economic and social activities outside the forest sector (tertiary biomass).

Production technologies used and environmental, economic and social sustainability vary greatly among different production systems (and within each type of production system) [6,7,8]. Therefore, other than the supply source, it is important to distinguish forest biomass from the perspective of the production system (cf. chapter “Stand Structure and Biomass”). Forest biomass can be deliberately cultivated and grown with the purpose of producing biomass for energy in the so-called energy plantations (cf. chapter “Energy Plantations”) or it can be obtained from other sources (e.g., natural forests, forests grown for timber, agroforestry systems, trees outside forests, wood-processing industries or other industries, municipal waste).

In some specific contexts, several non-wood materials are removed from forests or generated by forest-based industries and used as fuels. Examples are pine needles and cones [9], bamboo [10] or cork powder [11]. However, worldwide, wood is the most commonly used forest biomass energy source [12]. Figure 1 presents the woody biomass streams from forests, woodlands and other land uses.

Wood fuel, as defined by FAO, encompasses all wood harvested and removed from forests and from trees outside forests that will be used as fuel. “It includes wood harvested from main stems, branches and other parts of trees (where these are harvested for fuel), round or split, and wood that will be used for the production of charcoal (e.g., in pit kilns or portable ovens), wood pellets and other agglomerates. It also includes wood chips to be used for fuel that are made directly (i.e., in the forest) from roundwood. It excludes wood charcoal, pellets and other agglomerates” [13]. On the other hand, industrial roundwood refers to all wood in the rough (roundwood) other than wood fuel. Therefore, roundwood, a measure of a forest harvest over a given period, is the sum of wood fuel and industrial roundwood.

Forest-based industries use industrial roundwood for the manufacture of a broad range of products. In the process, (secondary) wood residues are generated. Some are used as raw materials by other industries or converted to energy or biofuels, but a part will not be valorised. For example, sawmill residues may be used, not exclusively, for the manufacture of wood-based panels [14], for the production of pellets [15] or simply piled and burned at the sawmill [16] or landfilled [17].

While secondary wood residues are produced in forest-based industries, primary wood residues are generated by forest management, such as thinning and pruning and harvesting and logging. They include branches, tops, bark, stumps, roots, small trees and generally unmerchantable stem wood and are frequently left to decompose naturally [18, 19], burned onsite [19, 20] or converted to energy or fuels [18, 21]. Their conversion into value-added products, such as biomaterials and advanced biofuels, seems to be an attractive solution that still requires further research [22, 23].

Forestry and forest-based industries are important sources of bioenergy, but other socio-economic activities are also sources of wood suitable for energy valorisation. They generate the so-called tertiary wood residues and wood waste, which consist of wood products at their end-of-life and other wood residues or waste generated by activities outside the forest sector, such as construction and demolition wood, packaging and pallets. Wood waste may be used, for example, as feedstock for the production of wood products [24, 25], landfilled [26] or burned to produce energy [25].

Before continuing, it is important to define terms that are used throughout this book and are often used in different contexts and with different meanings (Table 2). Products and co-products are the end-products that a certain process intends to obtain and whose production is elastic to changes in demand (i.e., if demand increases, production also increases). Residues and by-products are not primary products and are inelastic to demand. While residues may or may not have economic value, by-products do. Wastes, on the other hand, are materials that the holder intends to discard.

In the next sections, the three categories of forest biomass (cf. Table 1) will be described in detail, along with statistics that reflect their availability worldwide.

2 Primary Sources of Biomass

Land use is diverse, including agricultural systems, settlements and forest systems (Fig. 2). Forests are distributed worldwide, though with rather high variability in terms of species, stand structure and productivity [30, 31]. Forest systems can be grouped as primarily used for production (frequently timber), multiple uses (e.g., agroforestry systems) and other or non-use (associated with the protection and conservation of forests, habitats, flora and fauna). Alternatively, forest systems can also be divided in primary forests, forests primarily used for production and naturally regrown forests [30]. This is related to management objectives and silvicultural systems and the amount of biomass exported (cf. chapter “Stand Structure and Biomass”).

Land-use systems in the world. (Data source [31])

The share of the world forest area is the largest in Europe (including the Russian Federation, according to FAO’s country groups) followed by South America, North America, Africa, Asia and the smallest in Oceania (Fig. 3 left). Growing stock (in volume, m3·ha−1) is the largest in South America, followed by Europe, North America, Africa, Asia and Oceania (Fig. 3 right). There seems to be a trend towards a decrease in the forest area of the world (Fig. 4 left). Yet, this decrease is mainly observed in African and South American countries, whereas an increase is observed in most European, Asian and Oceanian countries and in the United States of America (Fig. 5). This is also reflected in the share of the world forest area (Fig. 4 right, Table 3), which increased from 1990 to 2020 in Europe (+1.6%), Asia (+1.5%), North America (+0.7%) and Oceania (+0.2%) and decreased in South America (−2.2%) and Africa (−1.8%).

Share of the world forest area (left) and growing stock (right) per FAO’s country groups in 2020. (Data source [32])

Evolution of the forest area in the world (left) and share per FAO’s country groups (right) from 1990 to 2020. (Data source [32])

Forest area variation between 1990 and 2020. (Data source [32])

Growing stock (m3·ha−1) shows a more irregular pattern in time, with a decrease from 1990 to 2010, followed by an increase from 2010 to 2015 (with values similar to those in 2000) and subsequently another decrease by 2020 (Fig. 6 left). The decrease occurs mainly in countries in South America, Africa and North America, but also in a few European and Asian countries (Fig. 7). The share of the world’s growing stock increased continuously in Europe, Asia and North America, was approximately constant in Oceania, and decreased in South America and Africa (Fig. 6 right, Table 4). The largest increase from 1990 to 2020 in the share of the world’s growing stock was observed in Europe (+2.4%), followed by Asia (+1.7%), North America (+1.0%) and Oceania (+0.1%), whereas the strongest decrease occurred in South America (−3.3%) followed by Africa (−2.0%) (Table 4).

Evolution of the growing stock in the world (left) and share per FAO’s country groups (right) from 1990 to 2020. (Data source [32])

Growing stock variation between 1990 and 2020. (Data source [32])

Growing stock is higher than 1000 m3·ha−1 in most of America, Europe, Asia and central Africa, whereas it is lower than 100 m3·ha−1 in most of northern Africa (Fig. 8). Biomass in mass (t·ha−1) is the largest in South America and central Africa, followed by Europe and Asia (Fig. 9).

Classes of growing stock. (Data source [32])

Classes of forest biomass. (Data source [37])

Forests store large amounts of biomass, both above and below ground [33, 34]. Moreover, carbon stored in forests corresponds to more than 80% of the total aerial terrestrial carbon and 70% of the below-ground soil organic carbon ([35] and references therein). Globally, the forests sequester circa one third of the CO2 emissions caused by anthropogenic actions [36].

The amount of biomass (or carbon) stored in forest ecosystems varies according to the biome, site, species, stand structure, silvicultural system and management. The three main world biomes are the boreal, the temperate and the tropical. Due to the interactions between biomes, site (soil and climate) conditions and species (arboreal, shrub and herbaceous), forest systems vary in area and capacity to sequester and store carbon. Management practices also influence biomass (and carbon) sequestration and storage [35]. Furthermore, net production is related to management. Forests with intensive management (in which the management practices envision the highest possible productivity in the shortest possible time, and include a set of silvicultural practices from genetic improvement to site preparation and fertilisation, thinning and pruning) tend to have higher production of biomass than forests with extensive management (in which the emphasis is to lower management intensity and costs, and include thinning and harvests of moderate intensity and long production cycles). The forests with intensive management frequently correspond to pure even-aged stands of short production cycles, while the forests with extensive management correspond to pure or mixed uneven-aged stands and long production cycles [35].

Considering the forest biomes (boreal, temperate and tropical), temperate and tropical biomes have a share of carbon stored in biomass and in the soil of 55% and 45%, respectively, whereas for boreal forest the share is 16% of carbon stored in biomass and 84% in the soil [35]. The share of production efficiency (ratio between net primary production and gross primary production) is 38% for the boreal biome, 46% for the temperate and 34% for the tropical. The harvests of woody products per biome are 0.3 Gt·Cy−1, 0.7 Gt·Cy−1 and 1.8 Gt·Cy−1, for the boreal, temperate and tropical biomes, respectively [35].

The biomass storage and carbon sequestration are related to the species, stand structure, silvicultural system, silvicultural practices, woody products and site (cf. chapter “Stand Structure and Biomass”). For woody products (timber, pulp and paper) with medium to long life cycles (more than 35 years), biomass (and carbon) is partially reallocated from the forests to these woody products. This results in a reduction of CO2 emissions when compared to the use of materials based on fossil fuels [38]. Inversely, the use of biomass for energy releases CO2 into the atmosphere in the short term, both as a consequence of the combustion of biomass [38] and to the decrease of soil organic carbon caused by organic matter decomposition [39]. However, in the medium and long term, forest growth results in the increase of above and below ground biomass (and carbon), as well as the increase of soil organic matter [38, 39], thus compensating for the removal of biomass from the forest stands in the medium and long term, as well as the carbon emissions from the utilisation of the woody products [38, 40]. Moreover, the development of stands and forests is subject to disturbances of different intensities and frequencies. In general, low-intensity and short-frequency disturbances are, most usually (but not always), related to silvicultural practices. These practices result in the export of biomass or its reallocation to deadwood, which incorporates carbon into the soil through decomposition. In a short period after the disturbance, there is the release of carbon into the atmosphere through soil organic matter decomposition, which is compensated by the growth of trees, stands and forests [39,40,41]. On the other hand, disturbances of high intensity and long periodicity (e.g., fires, storms, pests and diseases) tend to originate strong reductions of live biomass, converting it to dead (standing or downed) biomass, which results in an overall biomass loss, whether as live biomass or woody products with market value, or a loss of diversity [30, 42]. Thus, the management of stands and forests enables to balance the exports of woody products and the biomass storage and carbon sequestration, both in the trees and in the soil, and consequently contributing to the mitigation of greenhouse gas emissions [38,39,40]. Overall, the maintenance or promotion of biomass storage or carbon sequestration is related to the sustainability of forest systems. This resulted in a set of approaches that were converted, for example, in forest management strategies towards carbon stocks [41], sustainable biomass harvesting guidelines [43] and adaptation of silvicultural practices to promote biomass and carbon stocks in the forests [35].

The long-term production cycles of forest stands imply that market demand will not be met in the short time; that is, the effect of silvicultural practices, forestations or afforestations will take decades before woody products can be explored. There are silvicultural practices that promote the increase in tree growth (e.g., site preparation, control of spontaneous vegetation, use of species of fast growth, genetic improvement of species, fertilisation, irrigation, control of pest and diseases). Energy plantations (cf. chapter “Energy Plantations”) can increase the supply of bioenergy in a shorter term than stands managed for timberwood and pulpwood [44] and may also release the pressure to provide biomass for energy in stands oriented for timberwood, pulpwood and/or under protection and conservation status [45, 46]. They might be a source of beneficial renewable energy, if established in current agricultural land that can be diverted from food and feed production without further impairing food security [47] or in marginal lands [48]. However, the potential competition of energy plantations with food for agricultural soils has ethical implications and energy plantations at a large enough scale pose environmental risks that need consideration [49,50,51]. This is the reason why several authors consider that energy plantations should be established in set aside agricultural lands and/or forest areas [52, 53].

Stands and forests have long harvesting cycles, in particular those whose management is oriented for sawtimber (>20 years) [44], shorter when oriented for pulpwood (8–12 years), and even shorter when oriented for energy (2–6 years) [54, 55]. According to Egnell et al. [44], most woody products for energy in boreal and temperate forests in the next decades will result from timberwood and pulpwood-oriented stands. Stands oriented for energy (or energy plantations, cf. chapter “Energy Plantations”), though having an important role in the supply of bioenergy, will not be able to fulfil market demand in the near future. Even though they are not the most common source of forest biomass for energy today [56,57,58], energy plantations are projected to become more important with the transition to a low carbon economy while meeting the increasing energy demand [49, 59]. Moreover, it is not expected that the biomass for energy will be the result of harvests in unmanaged stands [44].

The removal of biomass is related to carbon stocks through their use. If used for sawtimber, the carbon stocks are exported from the forest stands, but carbon is not emitted for a long time, corresponding to the lifespan of the objects made from it (e.g., furniture, wooden houses). The pulpwood is transformed into a wide variety of types of paper that can have a shorter (e.g., newspapers) or longer (e.g., books) lifespan. Additionally, if the biomass residues remain in the forest stands, carbon is not lost but rather reallocated mainly to the soil and tree growth [60, 61].

Figure 10 shows the amount of roundwood felled or otherwise harvested and removed in the world in 2021. The United States of America was the country with most of the roundwood production in 2021 (10.5%), followed by India (8.1%), China (7.8%), Brazil (6.2%) and the Russian Federation (5%). In terms of the country groups defined by FAO, Asia produced more roundwood in 2021, followed by Europe (the Russian Federation included) and Africa (Fig. 11). While Europe produced most of its roundwood for industrial production (78.7%), Africa and Asia produced it as fuel (90.2% and 60.5%, respectively).

Global production of roundwood in 2021. (Data source [62])

Share of FAO’s country groups in the production of roundwood in 2021. (Data source [62])

Figure 12 shows the wood fuel, i.e., the part of roundwood that was harvested as fuel, produced in the world in 2021. The top producers are India (14.3%), China (7.4%), Brazil (5.9%) and Ethiopia (5.5%). Africa was where more roundwood was harvested as fuel (36.9%), closely followed by Asia (36.2%) (Fig. 13). Overall, 49% of the roundwood harvested in the world in 2021 was harvested as fuel [62], additionally, part of the industrial roundwood produced was also used as fuel (cf. Section 3). This reflects the importance of wood fuel for human societies and the fact that, still today, traditional biomass remains an important energy source for many people around the world, particularly in rural areas of the Global South where access to modern energy sources may be limited [63].

Global production of wood fuel in 2021. (Data source [62])

Share of the FAO’s country groups in the production of wood fuel in 2021. (Data source [62])

The estimations for the production of roundwood and wood fuel (as well as industrial roundwood and recovered wood wastes presented later on) are those reported by FAO [62]. It is worth mentioning that FAO estimates the wood fuel production for several countries where no official statistics exist (many of these, important producers and consumers of wood fuel). Additionally, even for those countries that report wood fuel statistics, the share of roundwood used for energy may be underestimated because of existing informal ways of getting the biomass (see, e.g., [64]). Data on the informal collection of wood fuel is sparse, and a comparison between FAO estimates and other data suggests that wood fuel production in Africa and Asia will be revised upwards in the future [65].

Forest management should take into account economic, environmental and social issues. The demand of woody and non-woody forest products should be considered along with the sustainability of the stands and forests, as well as sequestration and storage of biomass and carbon [35, 66]. To attain sustainability in stands and forests, their monitoring and planning should be careful ([66] and references therein). According to Ameray et al. [35], maintaining forest system sustainability can be achieved by three (non-exclusive) approaches: (i) maintaining biomass and carbon stocks by low to moderate intensity harvests and long production cycles (old-growth forests); (ii) use extensive forest management where silvicultural practices increase productivity and maintain biomass stocks; (iii) use intensive forest management where productivity is high.

In stand management, economic issues should also be considered. In stands with logs with high market value, financial viability is ensured. Yet, in forest stands where the rate of high-value logs is small, the biomass for energy might be an option to incentivise the prescription and execution of silvicultural practices because of the increase in profitability that results from the biomass for energy [44].

Estimations of forest residues that can be used for energy have been made with the utilisation of rates of biomass that can be collected and used for energy (i.e., the percent of residues in total or aerial biomass). Yet, the amount of residues harvested is not always coincident with the amount of residues that is possible to collect in the stands ([66] and references therein). The biomass residues recovery rate varies from 0 to 80% (for details see chapter Stand Structure and Biomass, Sect. 5.3).

3 Secondary Sources of Biomass

Another significant source of forest biomass for energy and fuels comprises the residues of the forest-based industry, which includes several sub-sectors (the most relevant in terms of residues are the woodworking and pulp and paper industries as will be seen below). The residues produced by the industrial sector, understood as secondary products that are generated during the production of a main product, are mainly black liquor and wood residues, such as bark, slabs, sawdust and wood chips. Their importance is reflected in the fact that more than half of the wood used for energy in the countries of the United Nations Economic Commission for Europe (UNECE) are industrial by-products [67].

Woodworking industries include the production of sawnwood, wood-based panels, wooden construction materials and other wooden products. Sawmills are part of the primary forest industries (i.e., those that process wood directly harvested from forests). They receive industrial roundwood and transform it into various lumber pieces of various sizes and shapes, including planks, beams and boards. While these can be used directly, they are often further processed to create various wood-products, such as furniture or products used in construction.

Another sector that also receives industrial roundwood is the pulp and paper industry. Roundwood is first prepared, followed by mechanical or chemical processes to produce pulp, which is a versatile material used in a wide range of applications, such as the production of paper products, textiles or chemicals.

The potential for industrial roundwood processing, and therefore for the generation of secondary wood residues generated, is not only dependent on the overall roundwood supply, but also on the wood fuel demand, since roundwood is used for these two purposes [5].

Figure 14 shows the global production of industrial roundwood in 2021 and Fig. 15 the percentage of roundwood that was industrial roundwood [62]. The United States of America was the country that produced more industrial roundwood (17.4%), followed by the Russian Federation (9.2%), China (8.2%), Brazil (6.5%) and Canada (6.4%). In these countries, industrial roundwood constituted more than half the roundwood produced in 2021, except in India, where 85.8% of the roundwood was harvested as fuel.

Global production of industrial roundwood in 2021. (Data source [62])

Share of the production of industrial roundwood in roundwood in 2021. (Data source [62])

The production of roundwood, wood fuel and industrial roundwood has increased in the last 60 years [62], as a result of the global population growth and increased demand for wood products (Fig. 16). However, the share of wood fuel in the total roundwood production decreased, which means that proportionally more roundwood was directed to the industrial sector. In 1961, 59.6% of the roundwood was harvested as wood fuel, while in 2021, industrial roundwood constituted roughly half (50.9%) of the roundwood.

Global production of roundwood, wood fuel and industrial roundwood and share of wood fuel in roundwood production from 1961 to 2021. (Data source [62])

The consumption of industrial roundwood in a specific country is calculated by adding the country’s production to its net imports. The countries grouped as Europe in FAO statistics (the Russian Federation included) had the highest share of the world’s industrial roundwood consumption in 2021 (30.7%), followed by Asia (26.5%) and North America (26%) (Figs. 17 and 18). This reflects, in part, the proportion of roundwood that was supplied to the industry (Fig. 18). Europe, northern America and Oceania used, respectively, 78.3%, 87.6% and 81.4% of the roundwood in the industrial sector, while in the other extreme, Africa and Central America (Caribbean and Mexico included) only directed, respectively, 9.3% and 12.7% of the roundwood they consumed to the industry.

Global consumption of industrial roundwood in 2021. (Data source [62])

Consumption of wood fuel and industrial roundwood in 2021 per FAO’s country groups. (Data source [62])

As far as industrial use is concerned, in 2021, most roundwood (57%) was sawn lengthways for the manufacture of sawnwood or railway sleepers (ties) or used for the production of veneer (Fig. 19). The second-most important use of industrial roundwood was the production of pulp, particleboard or fibreboard (35%). The remaining (8%) was used for the manufacture of other products such as poles, posts, fencing, wood wool and tanning [62].

Share of industrial roundwood uses in the world in 2021. (Data source [62])

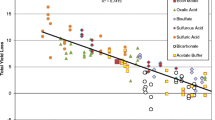

Given a certain amount of industrial roundwood industrially processed in a given region, the availability of secondary residues for energy is dependent on several factors, such as the industrial process itself, the demand for wood residues from other industries and the economic competitiveness and demand for bioenergy [5]. Table 5, based on data provided by [18, 28, 56, 68,69,70,71,72,73,74,75], presents some of the main sources of secondary residues and typical ranges of wood residue generation factors.

Sawmills belong to the primary forest industries and generate large amounts of woody residues in the form of bark, sawdust, slabs, edgings, trimmings and cull logs. Typically, 15 to 60% of the roundwood that enters the mills ends up as residue. The residue generation factor depends on numerous aspects, such as the type, size and quality of the logs being processed and the specific operations and equipment used. The wide range in the residue generation factor in sawmills is related to the sawnwood products (e.g., semi-processed cants, boules and flitches, planned sawnwood) [75] and the use of slab wood [56]. Sawmill residues are generally clean, uniform, concentrated and have a low moisture content (below 20%), which makes them suitable for further use [76]. As such, sawmill residues are frequently sold as raw material for the manufacture of pulp, engineered wood products and fuels (e.g., wood chips for pulp for paper, sawdust for particleboard, pellets), for landscaping applications (e.g., bark mulch), for livestock bedding and as fuel for combustion boilers (e.g., hog fuel).

The residue generation factors of plywood mills are also typically high and, as in sawmills, the residues can be valuable sources of raw materials for various industries. Typically, residues can range from 30 to 60% of the total volume of logs processed, depending on the type and quality of wood being processed, the manufacturing process used and the efficiency of the equipment and operations. Coarser residues (e.g., cores) are mainly used as raw materials for the manufacture of pulp and other fibre products, while bark and fine residues are typically used as fuel [77].

Pulp may be produced by chemical or mechanical processes, although the former dominates (90% of the total production capacity is based on the kraft process, a type of chemical pulping [78]). In mechanical pulping, bark, sludge, ash and screening residues are generated. Typically, residues account for 10 to 30% of the wood input and can be used for various purposes, such as landscaping and energy and fuel production. On the other hand, in chemical pulping, there is a comparatively wider variety of residues produced, including black liquor, bark and sludge [70]. Black liquor is the most important residue in chemical pulp mills. It is usually burned in a recovery boiler to recuperate cooking chemicals contained in the black-liquor and produce steam [79, 80]. Because of this energy recovery, modern non-integrated kraft pulp mills are energy self-sufficient [79]. In certain mills, lignin is extracted from black liquor for biochemical processes and other products [70].

The residue stream generated by the production of primary wood products has been increasingly used as raw material for the production of other wood products, such as wood-based panels (particle-, fibre- and strand board) [69]. The extent to which this is done is dependent on various factors, such as the existence of industries using cascading woody material as raw feedstock, logistics, processing capacity or economic feasibility [5, 81]. The existence of a well-developed bioenergy industry with established infrastructure may affect the cascading use of forest resources [5]. For a discussion on the concepts of circular economy and cascading utilisation refer to Mair et al. [82].

The forest industries that process primary wood products generate additional residues that may be used as an energy source. For example, the production of particleboard generates screening residues and sanding dust, which, typically, account for 5 to 20% of the total volume of the feedstock processed. Because additives (e.g., binders, fillers) are used in the production of wood-based panels, these wood processing residues do not consist exclusively of primary wood fibre [28].

Further processing of wood and engineering-wood for the manufacture of finished products such as furniture, packaging or construction products results in additional residues (e.g., solid timber offcuts, dust, shavings, trims, clippings); some of which may be contaminated with adhesives and coating particles. The amount of residues generated depends on the manufacturing process. For example, Daian and Ozarska [83] assessed the wood residues generated by Australian furniture companies and concluded that the residue generation factor varied significantly, depending on the profile of the manufacture (7% to 49% of the annual supply of wooden raw material ended up as residues).

4 Tertiary Sources of Biomass

Many other industries and economic activities outside the forest-based industries generate wood residues and waste. Examples are the wood waste from the construction of buildings and wooden pallets and packaging used in the transport and storage of goods in various industries. These are classified as tertiary wood residues, along with wood products at their end-of-life.

Tertiary wood residues and waste have a wide range of origins and refer to a very heterogeneous group of materials with different levels of contaminants [84]. They can contain, for example, heavy metals originated from paints and preservatives, polycyclic aromatic hydrocarbons or volatile organic compounds [85]. The source and type of tertiary wood residues and waste determine the appropriate way to handle them. Clean wood can be used for the production of industrial and consumer products or as fuel, while hazardous waste wood requires disposal at special facilities or incineration [86]. In between, treated but non-hazardous wood varies in the level of contaminants.

To date, there is no standardised classification of wood waste streams applied internationally and their management varies among countries, which hinders the reuse of wood waste [87] and leads to different levels of wood waste energy valorisation and recycling. UNECE and FAO present a catalogue of the existing wood waste classifications in the UNECE region, where the different approaches are clearly shown [87].

The valorisation of tertiary wood residues involves (i) their collection at the place where they are generated, (ii) transportation to the place where they are valorised and (iii) subsequent treatment. Different countries have waste management systems with different levels of maturity, with some countries lacking collection and treatment of wood waste [88]. This is somehow reflected in the available FAO data for recovered post-consumer wood, with only a few countries officially reporting values of recovered wood (32 in 2021 [62]).

Wood waste management operations also influence the contaminant level of the waste streams. For example, Faraca et al. [89] analysed wood waste collected for recycling in Denmark and found that contaminant levels varied significantly among the materials analysed, depending on the type and source of the wood waste. The authors suggested that low-quality wood waste should be collected separately from cleaner wood waste to avoid unwanted contaminations with chemicals. Additionally, they recommended that the fractions containing fibreboard, treatments and/or composite materials from construction and demolition should be minimised in recycled material so that the lowest level of contaminants is guaranteed.

Mixed-streams of post-consumer wood pose challenges to recycling wood, and, often, the physical inspection and quality assessment required to avoid possible contaminants re-entering the wood production phase hinder the recovery of such residues [90]. Since sorting technologies are not well developed for most wood-based materials, sorting is manual, which leads to high costs, inconsistent quality and health risks for the workers [90]. Additionally, the fact that tertiary wood waste streams are usually highly dispersed and present irregular patterns also contributes to high recovery costs [5, 90]. Despite these challenges, relative to other woody biomass sources, tertiary wood residues are particularly relevant in regions with small forest production, where wood waste accounts for the largest potential of woody biomass [5].

Figure 20 presents the amount of recovered post-consumer wood that could be recycled or reused for material or energy purposes in 2021, excluding post-consumer wood that would not be reused/recycled (e.g., sent to landfills). Europe accounted for 87.7% (around 31 million t) of the total recovered post-consumer wood reported, while Asia accounted for the rest [62]. Germany was the country that recovered the most post-consumer wood, followed by France and the United Kingdom (UK). These three countries reported more than half of the post-consumer wood recovered in the world. Since in Germany, municipal and industrial solid waste must be sorted and landfilling is restricted to materials with organic matter content that does not exceed 5%, almost no wood waste is disposed of in landfills [91]. Most of it (80%) goes for energy recovery, while a fraction of the least contaminated wood waste is absorbed by the panel industry [91]. However, new waste wood fired power plants are no longer subsidised in Germany and the situation can change in the future. On the other hand, France and the United Kingdom favour material recovery (79% and 70% of the wood waste, respectively), but in France, a substantial part of the wood waste ends up in landfills [91].

Recovered post-consumer wood in the world in 2021. (Data source [62])

5 Final Considerations

Forest biomass for energy and fuels can be classified into three groups, which reflect its origin: primary, directly sourced from energy plantations or other land-use systems (cf. Sect. 2); secondary, corresponding to residues of the wood-based forest industries (cf. Sect. 3); and tertiary, resulting from activities outside the forest sector (cf. Sect. 4).

The availability of primary biomass is dependent on the distribution of the forest area in the world and of the forest systems, including species, site and management (silvicultural systems and practices, harvest and logging). Overall, there seems to be a need for a balance between the biomass maintained in the forest systems (live and dead) and the biomass exported to enable the sustainability of forest systems. In general, disturbances of low intensity and short frequency (e.g., silvicultural practices) tend to maintain biomass stocks in the medium and long term [39, 41], whereas disturbances of high intensity and long periodicity (e.g., storms or fires) tend to reduce biomass storage [30, 42]. Moreover, apart from the maintenance of the sustainability of the forest systems and their productions, the maintenance of the forest area plays a key role in the amount of biomass available for woody products and energy. Forest area and growing stock increased from 1990 to 2020 in Europe, Asia, North America and Oceania, but decreased in South America and Africa (cf. Figs. 4 and 5). This may result, in the future, in a reduction in the availability of woody products (including biomass for energy) in the latter regions.

The availability of secondary biomass depends on various factors within the forest-based industries, including their number, size or type (e.g., woodworking, pulp and paper). The quantity of residues generated by these industries is influenced by factors such as the quality and quantity of the wood received and processed by the industry and the specific industrial process used. Globally, there was an overall increase in the production of roundwood, wood fuel and industrial roundwood from 1961 to 2021. However, the share of wood fuel in roundwood production decreased during this period. Moreover, in 2021, the share of industrial roundwood production in total roundwood production was larger in Oceania, Europe and North America than in South America, Asia and, especially, Central America and Africa, where, respectively, more than 87 and 90% of the roundwood production corresponded to wood fuel (cf. Fig. 15). The consumption of roundwood followed the same pattern of production. The consumption of wood fuel was larger than that of industrial roundwood in Africa, Central America and Asia (cf. Fig. 18). Apart from the quantity of industrial roundwood processed, the proportion of raw materials that become residues per wood-based industry type is also a factor that influences the availability of secondary forest residues for energy purposes. These generation factors are quite variable, spaning from 5 to 60% (cf. Table 5).

Tertiary biomass refers to the wood residues and waste generated by many non-forest industries and economic activities as well as wood products at their end-of-life. This tertiary biomass constitutes a very heterogeneous group of materials that may be clean or contaminated with different concentrations of contaminants. Its use is dependent on the content of contaminants, the available technologies to decontaminate them, logistics and economic factors. Europe reported the largest amount of wood that was recovered and can be recycled or used for material or energy purposes (circa 88%), with Germany, France and the United Kingdom having the largest shares (cf. Fig. 20).

References

Hakkila P, Parikka M (2002) Fuel resources from the forest. Bioenergy from sustainable forestry. Springer, Dordrecht, pp 19–48

Batidzirai B, Smeets EMW, Faaij APC (2012) Harmonising bioenergy resource potentials—methodological lessons from review of state of the art bioenergy potential assessments. Renew Sustain Energy Rev 16:6598–6630. https://doi.org/10.1016/j.rser.2012.09.002

FAO (2004) Unified bioenergy terminology (UBET). FAO, Rome

Hoogwijk M, Faaij A, van den Broek R et al (2003) Exploration of the ranges of the global potential of biomass for energy. Biomass Bioenerg 25:119–133. https://doi.org/10.1016/S0961-9534(02)00191-5

Thiffault E, Gianvenuti A, Zuzhang X, Walter S (2023) The role of wood residues in the transition to sustainable bioenergy—analysis of good practices and recommendations for the deployment of wood residues for energy. FAO, Rome

Hall JP (2002) Sustainable production of forest biomass for energy. For Chron 78:391–396. https://doi.org/10.5558/tfc78391-3

Lattimore B, Smith CT, Titus BD et al (2009) Environmental factors in woodfuel production: opportunities, risks, and criteria and indicators for sustainable practices. Biomass Bioenerg 33:1321–1342. https://doi.org/10.1016/j.biombioe.2009.06.005

Van ‘t Veen H, Eppinga MB, Mwampamba TH, Ferreira Dos Santos MJ (2021) Long term impacts of transitions in charcoal production systems in tropical biomes. Environ Res Lett 16:034009. https://doi.org/10.1088/1748-9326/abe14d

Font R, Conesa JA, Moltó J, Muñoz M (2009) Kinetics of pyrolysis and combustion of pine needles and cones. J Anal Appl Pyrol 85:276–286. https://doi.org/10.1016/j.jaap.2008.11.015

Kumar R, Chandrashekar N (2014) Fuel properties and combustion characteristics of some promising bamboo species in India. J For Res 25:471–476. https://doi.org/10.1007/s11676-014-0478-6

Nepomuceno Pereira R, Malico I, Mesquita P, et al (2017) Energy use of cork residues in the Portuguese cork industry. In: Proceedings of the 12th conference on sustainable development of energy, water and environmental systems—SDEWES2017. Dubrovnik, Croatia, pp 1–20

Mäkelä M, Parkkinen M, Lyytimäki J, Nygrén NA (2020) Futures images of woodchips as an energy source in Finland. Futures 121:102571. https://doi.org/10.1016/j.futures.2020.102571

FAO (2022) Classification of forest products 2022. FAO, Rome

Simal Alves L, da Silva SAM, Dos Anjos AM et al (2014) Particleboard produced with sawmill waste of different wood species. AMR 884–885:689–693. https://doi.org/10.4028/www.scientific.net/AMR.884-885.689

Trømborg E, Ranta T, Schweinle J et al (2013) Economic sustainability for wood pellets production—a comparative study between Finland, Germany, Norway, Sweden and the US. Biomass Bioenerg 57:68–77. https://doi.org/10.1016/j.biombioe.2013.01.030

Sjølie HK (2012) Reducing greenhouse gas emissions from households and industry by the use of charcoal from sawmill residues in Tanzania. J Clean Prod 27:109–117. https://doi.org/10.1016/j.jclepro.2012.01.008

Cambero C, Hans Alexandre M, Sowlati T (2015) Life cycle greenhouse gas analysis of bioenergy generation alternatives using forest and wood residues in remote locations: a case study in British Columbia, Canada. Resour Conserv Recycl 105:59–72. https://doi.org/10.1016/j.resconrec.2015.10.014

Koopmans A, Koppejan J (1997) Agricultural and forest residues-generation, utilization and availability. In: Proceedings of the regional consultation on modern applications of biomass energy. FAO, Kuala Lumpur, pp 1–23

Pergola MT, Saulino L, Castellaneta M et al (2022) Towards sustainable management of forest residues in the southern Apennine Mediterranean mountain forests: a scenario-based approach. Ann For Sci 79:14. https://doi.org/10.1186/s13595-022-01128-w

Hueso-González P, Martínez-Murillo JF, Ruiz-Sinoga JD (2018) Benefits of adding forestry clearance residues for the soil and vegetation of a Mediterranean mountain forest. Sci Total Environ 615:796–804. https://doi.org/10.1016/j.scitotenv.2017.09.301

Díaz-Yáñez O, Mola-Yudego B, Anttila P et al (2013) Forest chips for energy in Europe: current procurement methods and potentials. Renew Sustain Energy Rev 21:562–571. https://doi.org/10.1016/j.rser.2012.12.016

Braghiroli FL, Passarini L (2020) Valorization of biomass residues from forest operations and wood manufacturing presents a wide range of sustainable and innovative possibilities. Curr For Rep 6:172–183. https://doi.org/10.1007/s40725-020-00112-9

Moriana R, Vilaplana F, Ek M (2015) Forest residues as renewable resources for bio-based polymeric materials and bioenergy: chemical composition, structure and thermal properties. Cellulose 22:3409–3423. https://doi.org/10.1007/s10570-015-0738-4

Azambuja RDR, Castro VGD, Trianoski R, Iwakiri S (2018) Recycling wood waste from construction and demolition to produce particleboards. Maderas, Cienc tecnol 20:381–690. https://doi.org/10.4067/S0718-221X2018005041401

Sommerhuber PF, Welling J, Krause A (2015) Substitution potentials of recycled HDPE and wood particles from post-consumer packaging waste in wood-plastic composites. Waste Manage 46:76–85. https://doi.org/10.1016/j.wasman.2015.09.011

Vis M, Mantau U, Allen B (2016) Study on the optimised cascading use of wood. Publications Office, Brussels

EC (2008) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives. European Commission, Brussels, Belgium

Saal U, Weimar H, Mantau U (2017) Wood processing residues. In: Wagemann K, Tippkötter N (eds) Biorefineries. Springer International Publishing, Cham, pp 27–41

ISCC (2020) ISCC CORSIA 201–1 Waste, residues, by-products. ISCC

Schulze K, Malek Ž, Verburg PH (2019) Towards better mapping of forest management patterns: a global allocation approach. For Ecol Manage 432:776–785. https://doi.org/10.1016/j.foreco.2018.10.001

van Asselen S, Verburg PH (2012) A land system representation for global assessments and land-use modeling. Glob Change Biol 18:3125–3148

FAO (2020) Global forest resources assessment 2020. FAO

Pan Y, Hu T, Zhu X et al (2012) Mapping cropland distributions using a hard and soft classification model. IEEE Trans Geosci Remote Sens 50:4301–4312. https://doi.org/10.1109/TGRS.2012.2193403

Pan Y, Birdsey RA, Fang J et al (2011) A large and persistent carbon sink in the world’s forests. Science 333:988–993. https://doi.org/10.1126/science.1201609

Ameray A, Bergeron Y, Valeria O et al (2021) Forest carbon management: a review of silvicultural practices and management strategies across boreal, temperate and tropical forests. Curr Forestry Rep 7:245–266. https://doi.org/10.1007/s40725-021-00151-w

Friedlingstein P, Jones MW, O’Sullivan M et al (2022) Global carbon budget 2021. Earth Syst Sci Data 14:1917–2005. https://doi.org/10.5194/essd-14-1917-2022

Santoro M, Cartus O (2019) ESA biomass climate change initiative (Biomass_cci): global datasets of forest above-ground biomass for the year 2017, vol 1. Centre for Environmental Data Analysis

Baul TK, Alam A, Strandman H, Kilpeläinen A (2017) Net climate impacts and economic profitability of forest biomass production and utilization in fossil fuel and fossil-based material substitution under alternative forest management. Biomass Bioenerg 98:291–305. https://doi.org/10.1016/j.biombioe.2017.02.007

Mäkipää R, Abramoff R, Adamczyk B et al (2023) How does management affect soil C sequestration and greenhouse gas fluxes in boreal and temperate forests?—A review. For Ecol Manage 529:120637. https://doi.org/10.1016/j.foreco.2022.120637

Gouge D, Thiffault E, Thiffault N (2021) Biomass procurement in boreal forests affected by spruce budworm: effects on regeneration, costs, and carbon balance. Can J For Res 51:1939–1952. https://doi.org/10.1139/cjfr-2021-0060

Ontl TA, Janowiak MK, Swanston CW et al (2020) Forest management for carbon sequestration and climate adaptation. J Forest 118:86–101. https://doi.org/10.1093/jofore/fvz062

Vaglio Laurin G, Puletti N, Tattoni C et al (2021) Estimated biomass loss caused by the vaia windthrow in Northern Italy: evaluation of active and passive remote sensing options. Remote Sensing 13:4924. https://doi.org/10.3390/rs13234924

Titus BD, Brown K, Helmisaari H-S et al (2021) Sustainable forest biomass: a review of current residue harvesting guidelines. Energy Sustain Soc 11:10. https://doi.org/10.1186/s13705-021-00281-w

Egnell G, Paré D, Thiffault E, Lamers P (2016) Environmental sustainability aspects of forest biomass mobilisation. In: Thiffault E, Berndes G, Junginger M et al (eds) Mobilisation of forest bioenergy in the Boreal and temperate biomes. Elsevier, London, pp 50–67

Bruckman VJ, Terada T, Fukuda K et al (2016) Overmature periurban Quercus-Carpinus coppice forests in Austria and Japan: a comparison of carbon stocks, stand characteristics and conversion to high forest. Eur J Forest Res 135:857–869. https://doi.org/10.1007/s10342-016-0979-2

Stojanović M, Sánchez-Salguero R, Levanič T et al (2017) Forecasting tree growth in coppiced and high forests in the Czech Republic. The legacy of management drives the coming Quercus petraea climate responses. For Ecol Manage 405:56–68. https://doi.org/10.1016/j.foreco.2017.09.021

Kalt G, Mayer A, Theurl MC et al (2019) Natural climate solutions versus bioenergy: can carbon benefits of natural succession compete with bioenergy from short rotation coppice? GCB Bioenergy 11:1283–1297. https://doi.org/10.1111/gcbb.12626

Schweier J, Molina-Herrera S, Ghirardo A et al (2017) Environmental impacts of bioenergy wood production from poplar short-rotation coppice grown at a marginal agricultural site in Germany. GCB Bioenergy 9:1207–1221. https://doi.org/10.1111/gcbb.12423

Beringer T, Lucht W, Schaphoff S (2011) Bioenergy production potential of global biomass plantations under environmental and agricultural constraints. GCB Bioenergy 3:299–312. https://doi.org/10.1111/j.1757-1707.2010.01088.x

Langeveld H, Quist-Wessel F, Dimitriou I et al (2012) Assessing environmental impacts of short rotation coppice (SRC) expansion: model definition and preliminary results. Bioenerg Res 5:621–635. https://doi.org/10.1007/s12155-012-9235-x

Rösch C, Aust C, Jörissen J (2013) Envisioning the sustainability of the production of short rotation coppice on grassland. Energ Sustain Soc 3:7. https://doi.org/10.1186/2192-0567-3-7

Dimitriou I, Rutz D (2015) Sustainable short rotation coppice a handbook. WIP Renewable Energies, Munich

Hauk S, Gandorfer M, Wittkopf S et al (2017) Ecological diversification is risk reducing and economically profitable—the case of biomass production with short rotation woody crops in south German land-use portfolios. Biomass Bioenerg 98:142–152. https://doi.org/10.1016/j.biombioe.2017.01.018

Arets EJMM, van der Meer PJ, Verwer CC et al (2011) Global wood production: assessment of industrial round wood supply from forest management systems in different global regions. Wageningen, Alterra

Bizerra Barros I, Santos Cavalcante V, Soares Moulin A et al (2021) Integrating forest residue and mineral fertilization: effects on nutrient acquisition, nutrient use efficiency and growth of eucalypt plants. For Ecol Manage 496:119461. https://doi.org/10.1016/j.foreco.2021.119461

Mead DJ (2005) Forests for energy and the role of planted trees. Crit Rev Plant Sci 24:407–421. https://doi.org/10.1080/07352680500316391

Röser D, Asikainen A, Stupak I, Pasanen K (2008) Forest energy resources and potentials. In: Röser D, Asikainen A, Raulund-Rasmussen K, Stupak I (eds) Sustainable use of forest biomass for energy. Springer, Netherlands, Dordrecht, pp 9–28

Stolarski MJ, Krzyżaniak M, Warmiński K et al (2019) Energy efficiency indices for lignocellulosic biomass production: short rotation coppices versus grasses and other herbaceous crops. Ind Crops Prod 135:10–20. https://doi.org/10.1016/j.indcrop.2019.04.022

Daioglou V, Doelman JC, Wicke B et al (2019) Integrated assessment of biomass supply and demand in climate change mitigation scenarios. Glob Environ Chang 54:88–101. https://doi.org/10.1016/j.gloenvcha.2018.11.012

Russell MB, Fraver S, Aakala T et al (2015) Quantifying carbon stores and decomposition in dead wood: a review. For Ecol Manage 350:107–128. https://doi.org/10.1016/j.foreco.2015.04.033

Shannon VL, Vanguelova EI, Morison JIL et al (2022) The contribution of deadwood to soil carbon dynamics in contrasting temperate forest ecosystems. Eur J Forest Res 141:241–252. https://doi.org/10.1007/s10342-021-01435-3

FAO (2023) Forest product statistics. https://www.fao.org/forestry/statistics/84922/en/. Accessed 21 Apr 2023

Vanegas Cantarero MM (2020) Of renewable energy, energy democracy, and sustainable development: a roadmap to accelerate the energy transition in developing countries. Energy Res Soc Sci 70:101716. https://doi.org/10.1016/j.erss.2020.101716

Bailis R, Drigo R, Ghilardi A, Masera O (2015) The carbon footprint of traditional woodfuels. Nat Clim Chang 5:266–272. https://doi.org/10.1038/nclimate2491

FAO (2022) The state of the world’s forests 2022. Forest pathways for green recovery and building inclusive, resilient and sustainable economies. FAO, Rome

Thiel M, Basiliko N, Caspersen J et al (2015) Operational biomass recovery of small trees: equations for six central Ontario tree species. Can J For Res 45:372–377. https://doi.org/10.1139/cjfr-2014-0429

UNECE, FAO (2021) Forest sector outlook study 2020–2040. United Nations, Geneva

da Silva LE, Soares ÁAV, Goulart SL et al (2021) Challenges of the lumber production in the Amazon region: relation between sustainability of sawmills, process yield and logs quality. Environ Dev Sustain 23:4924–4948. https://doi.org/10.1007/s10668-020-00797-9

Ghafghazi S, Lochhead K, Mathey A-H, et al (2017) Estimating mill residue surplus in Canada: a spatial forest fiber cascade modeling approach. Forest Prod J 67:205–218. https://doi.org/10.13073/FPJ-D-16-00031

Hassan MdK, Villa A, Kuittinen S et al (2019) An assessment of side-stream generation from Finnish forest industry. J Mater Cycles Waste Manag 21:265–280. https://doi.org/10.1007/s10163-018-0787-5

Knapic S, Pereira H (2003) Rendimentos industriais de pinheiro bravo em serração. Anais do Instituto Superior de Agronomia 223–241

Murata K, Ikami Y, Tonosaki M (2006) Estimate of material recycling flow in the Japanese wood industry

Najera Luna JA, Sanchez Medrano JA, Mendez Gonzalez J (2013) Lumber yield and production time in sawmilling of pallets in Durango, Mexico. Forest Syst 22:573. https://doi.org/10.5424/fs/2013223-02693

Ogunwusi AA (2014) Wood waste generation in the forest industry in Nigeria and prospects for its industrial utilization. Ivil Environ Res 6:62–69

UNECE, FAO (2010) Forest product conversion factors for the UNECE Region United Nations. United Nations, Geneva

Perlack RD, Wright LL, Turhollow AF, Graham RL (2005) Biomass as feedstock for a bioenergy and bioproducts industry: the technical feasibility of a billion-ton annual supply. United States Department of Agriculture (USDA) and the United States Department of Energy (DOE), Oak Ridge National Laboratory, Oak Ridge, TN

McGraw B (2009) Recycling veneer-mill residues into engineered products with improved torsional rigidity. West Virginia University Libraries, MS

Oliveira RCP, Mateus M, Santos DMF (2018) Chronoamperometric and chronopotentiometric investigation of Kraft black liquor. Int J Hydrogen Energy 43:16817–16823. https://doi.org/10.1016/j.ijhydene.2018.01.046

Suhr M, Klein G, Kourti I, et al (2015) Best available techniques (BAT) reference document for the production of pulp, paper and board. Luxembourg

Teir S (2002) Modern boiler types and applications. Helsinki University of Technology

EC (2018) Guidance on cascading use of biomass with selected good practice examples on woody biomass. European Commission, Brussels

Mair C, Stern T (2017) Cascading utilization of wood: a matter of circular economy? Curr Forestry Rep 3:281–295. https://doi.org/10.1007/s40725-017-0067-y

Daian G, Ozarska B (2009) Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J Clean Prod 17:1594–1602. https://doi.org/10.1016/j.jclepro.2009.07.008

Besserer A, Troilo S, Girods P et al (2021) Cascading recycling of wood waste: a review. Polymers 13:1752. https://doi.org/10.3390/polym13111752

Alakangas E, Koponen K, Sokka L, Keränen J (2015) Classification of used wood to biomass fuel or solid recycled fuel and cascading use in Finland. In: Book of proceeding bioenergy. Jyväskylä, Finland, pp 79–86

WRA (2021) Waste wood assessment guidance for the UK waste wood industry. Wood Recycler’s Association, Inkberrow

UNECE, FAO (2022) Catalogue of wood waste classifications in the UNECE region. FAO, Geneva

Junginger DM, Hennig C, Junginger EM, et al (2019) Transboundary flows of woody biomass waste streams in Europe. IEA Bioenergy

Faraca G, Boldrin A, Astrup T (2019) Resource quality of wood waste: the importance of physical and chemical impurities in wood waste for recycling. Waste Manage 87:135–147. https://doi.org/10.1016/j.wasman.2019.02.005

FAO, UNECE (2021) Circularity concepts in forest-based industries. FAO, Geneva

Cocchi M, Vargas M, Tokacova K (2019) Absorbing the potential of wood Waste in EU regions and industrial bio-based ecosystems—BioReg. EUBIA

Funding

This work is funded by National Funds through FCT—Foundation for Science and Technology, under the Project UIDB/05183/2020, through MED, and Project UIDB/50022/2020, through IDMEC, under LAETA.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Malico, I., Gonçalves, A.C. (2024). Sources and Distribution of Forest Biomass for Energy. In: Gonçalves, A.C., Malico, I. (eds) Forest Bioenergy. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-48224-3_2

Download citation

DOI: https://doi.org/10.1007/978-3-031-48224-3_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-48223-6

Online ISBN: 978-3-031-48224-3

eBook Packages: EnergyEnergy (R0)