Abstract

There has been an increasing global demand for more sustainable production systems, especially in what concerns goods produced from natural tropical forests. The lumber industry in the Brazilian Amazon region produces a significant volume of lumber, and as a consequence of frequent non-optimal procedures, considerable amounts of waste are generated. In order to optimize the timber production and to minimize the environmental damage associated with low yields of sawmills, two features are indispensable: the lumber yield and the quality of the logs. The aim of this research was to analyze the wood quality and lumber yield of logs of tree species harvested from natural stands in the Amazon rainforest. A total of 120 logs from 21 tree species were harvested from natural stands in the state of Pará, Brazil, and analyzed for wood quality. Out of these, 60 logs were evaluated for lumber yield. The most common defects found in the logs were flattening, surface cracks, and eccentricity of the pith. By means of the principal component analysis, the Mezilaurus itauba, Protium decandrum, and Caryocar villosum species stood out. The average lumber yield was 45%. The Bowdichia nitida and C. villosum species presented the highest yield values (average of 63%). There was a trend of correlation between the lumber yield and the quality of the logs. Based on the methodology used to analyze the quality of the logs, inferences can be made on the yield of the logging and, consequently, the sustainability of the timber industries in the Brazilian Amazon.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The production of Amazonian lumber in Brazil has the potential to be a sustainable industry, including the optimization and valuation of forest trees and generation of jobs and income for the region, especially for traditional communities and smallholder (Fortini and Carter 2014; Ribeiro et al. 2014; Waldhoff and Vidal 2015). However, the timber supply of tropical forests has been greatly impacted by growing deforestation associated with restrictive timber harvest laws (Sousa et al. 2016; Lipscomb and Prabakaran 2020). Production of tropical sawnwood in Latin America declined 11% in 2015 to 5.9 million m3, recovering slightly in 2016 to 6.0 million m3. Brazil accounts for 46% of the region’s production (ITTO 2017). Brazil’s tropical roundwood production is mainly concentrated in the northern states of Pará, Amazonas and Mato Grosso (ITTO 2017). Among the challenges for the sector improvement, study of the raw material quality and yield of the sawed wood production can be highlighted.

In the Amazon region, the state of Pará is known for having the largest productive area with native tropical forest in Brazil, and it has the potential for the exploitation of wood from sustainable forest management plans, as well as highlighting the concentration of companies that produce mainly for the production of doors, floors, and furniture (ABIMCI 2016). According to ABIMCI (2016), these tropical forest species are marketed according to a categorization of economic value groups, which are divided into noble, red, mixed, and white. These groups are defined according to the marketing value, availability of the raw material and quality of the wood (Sousa et al. 2020). Within this context, is important to define the volumetric lumber yield per log for tropical tree species in order to ensure stock compatible with consumer requirements.

Thus, for the better use of the logs in the sawmills, some aspects must be taken into account. The quality of the logs, for example, according to Vital (2008) and Melo et al. (2019), affects the yield and efficiency of a sawmill, as it also influences the quality of the lumber and, consequently, the price of the final product. In addition, forest management techniques and silvicultural treatments such as pruning can improve the quality of logs (Nassur et al. 2013). Despite the great potential of timber and the important role of the Amazon in supplying wood to the market, information on Amazon sawmill yields is scarce. This has led to discussions by timber companies wishing to invest in the region, given that the absence data and concrete knowledge makes it difficult to estimate financial returns and, measuring the impacts caused by logging.

According to Li et al. (2016), the investment in models of primary breakdown should be encouraged in sawmill operations to improve lumber yield and enhance the sustainability of the production systems, because, for a given amount of lumber, improving process yield means reduced demand for new areas. Thus, the correlation between the lumber yield and the quality of the logs can improve the use of raw material, which contributes to a more sustainable production in the Amazonian region. The sustainability of sawmills in the Amazon region depends on diversified resource management system in which many tropical species overexploited are replaced with others with similar wood properties and sufficient growth stock (Sears et al. 2007; Reis et al. 2019). In addition, timber industry should integrate strategies for harvesting forest products and generating lumber products in sawmills (Fuentealba et al. 2019) as well to incorporating knowledge and modern technologies to obtain gains regarding primary breakdown, according to the quality of the logs (Bonato Junior et al. 2017).

Recently, some studies have been carried out to quantify logging yield of tropical species (Garcia et al. 2012; Danielli et al. 2016; Melo et al. 2016, 2019; Marchesan et al. 2018; Mendoza et al. 2019; Stragliotto et al. 2019). The latter authors indicated that the small number of commercial forest species, coupled with the heterogeneity of the Amazonian rainforest and the low technological level of the timber industries, make the use of the raw material low, thus generating large amounts of waste (approximately, 30–65% of the initial log volume). On the other hand, the use of waste in sawmills for power generation has the potential to make industries self-sufficient in electricity (Monteiro et al. 2017). This fact makes wood production more sustainable, having less greenhouse gas emissions, especially in countries that use non-renewable energy sources (Gustavsson et al. 2007; Kayo et al. 2015). Once, with the energy use of forest and sawmill wastes, there is carbon emission reduction (Kayo et al. 2015). Thus, the good practices in logging and primary breakdown in the sawmill, e.g., use and minimization of the wood wastes production, are directly associated with the lumber yield. In addition, according to climate change mitigation policies, energy prices at sawmills may change (Packalen et al. 2017).

Therefore, it is of fundamental importance that the quality of the extracted wood is previously analyzed, which will consequently lead to an increase in the yield of the extracted raw material. Considering that according to Asner et al (2009), the intensity of the extraction is interrelated to impacts ecological, which in turn determines that a great deal of the damage is caused during and after the extraction of wood. Therefore, the industrial technological advance is fundamental for the maximum use of the raw material, being directly connected to the conservation of forest resources (Marchesan et al. 2018).

The sustainable production of Amazonian lumber on a large scale can contribute to making the use of this material in civil construction and higher-value products that are environmentally appropriate. This is because wood is considered to be the most ecological material when compared to its substitutes, such as concrete, iron, steel, and aluminum, when considering the materials’ life cycle analyses (Knight et al. 2005; Gustavsson and Sathre 2006; Chiniforush et al. 2018). Despite all efforts to promote sustainable use of timber resources in tropical forests, for example, management criteria at a species level and considering specific growth patterns and ecological features (Andrade et al. 2019); there is a lack of knowledge about lumber yield and tropical logs quality as a subsidy for improving the sustainability indicators of sawmills in the Amazon. One of these indicators is the minimization of waste generated during the processing of logs, but to achieve this goal is necessary establish methods for assessing the quality of logs, analyze the current values of lumber yield, and define the impact of log defects on the sawmill production. Hence, it is necessary know the technical-scientific criteria and apply them in the Amazonian timber industries, to continue to advance economic, social, and environmental benefits through the sustainable use of wood from the world's largest tropical forest (Bila et al. 2016). Finally, the novelty and relevance of the research rely on the assessment of the quality of logs and the volumetric lumber yield of many tropical tree species, definition of scientific criteria for classification of logs to sawmill and, discussions on the relation between process yield, log defects and, sustainability of the timber industries in the Brazilian Amazon. The aim of this study was to analyze the quality of the logs from the Amazon forest and to quantify the yield of the lumber production, aiming at improvements in the sawmills of the Amazon and subsidies for modifications in the standards used to classify the quality of logs of Amazonian species.

2 Materials and methods

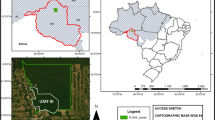

2.1 Log classification

One hundred and twenty logs from 21 native species were collected from an area of natural forest, which was clear-cut for the implementation of a mining project in the Carajás National Forest, Pará, North Brazil (Table 1). Normally, the commercial timber felled in these kinds of projects is primarily destined to the solid wood market, to the manufacture of furniture and parts for civil construction. The logs classification and primary breakdown occurred in a small sawmill in the town of Parauapebas, southeast of the state of Pará, Brazil (06° 03′ 30″ S and 49° 55′ 15″ W).

The species submitted to the quality analysis and primary log breakdown are commonly classified into four categories (noble, red, mixed, and white). The noble woods have high commercial value and small availability in the Amazonian timber market. The red woods are the most commercialized in the state of Pará, have a dark coloration, denser wood and are generally associated with more valuable products then the white woods, which, on the other hand, have lighter coloration and lower density (Sousa et al. 2020). The mixed woods present intermediate quality and value.

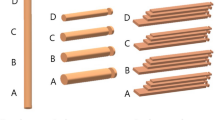

All 120 logs were classified according to defects in the shape, on the rolling surface, and on the logs ends. This was done by using the technical standard for measuring and classifying hardwood logs, as elaborated by the Brazilian Institute of Forest Development (IBDF 1984). The following parameters were analyzed: flattening; conicity; curving; grain slope; diametrical, non-diametrical, annular cracks and cracks reaching the surface; eccentricity of the pith and the net volume.

Considering that the IBDF (1984) standard classifies the log for each defect separately, an improvement of the standard was proposed, so that an overall classification of log quality is determined. The classes established by the IBDF (1984) standard are divided into SU (superior), I, II, III, and IV. For each defect of all 120 logs was hereby proposed the replacement of these categories (Superior, I, II, III, and IV) by the values of 10, 8, 6, 4 and 2, respectively, so that an overall grade can be computed as the average of the assigned defect values (Table 2). Therefore, for each defect evaluated in the logs, a numerical value was assigned (suggested grade). Subsequently, the arithmetic average of the grades attributed to the defects was calculated and, in this context, each log of the tropical species was represented by an average grade. For the proposed classification, five quality classes were suggest based on intervals for this overall grade (grade average per log) as shown in Table 2.

2.2 Lumber yield

Out of the 120 collected logs, 60 logs were submitted to primary breakdown performed using a band saw (Table 1). The successive tangential breakdown was used. The quantification of lumber yield was assessed for these 60 logs, under operational conditions. That is, no cutting standardization was established in order evaluate the suitability of the proposed log classification in the actual conditions of the small sawmills on the Amazon region. The authors sampled 60 logs due the availability of raw material in the sawmill at the time of the assessments for mensuration the volumetric lumber yield and, the operational difficulties of determination this parameter in a high number of logs. We believe that this study is of great importance for sustainability of the small sawmills in the Brazilian Amazon because the author's assessment the volumetric lumber yield per log in the real conditions. Thus, this methodology is representative of small timber industries in the Amazon. In addition, the number of logs evaluated for determining volumetric lumber yield is compatible with the studies by Melo et al. (2019) and Danielli et al. (2016), that is, 48 and 71 logs, respectively. After the primary breakdown, the pieces were separated and measured individually in length, width, and thickness to obtain the volumetric lumber yield per log, according to the procedure used by Danielli et al. (2016). In this research were measurement 1291 pieces (planks, boards, and beams) of the total of 60 logs.

2.3 Statistical analyses

The Shapiro–Wilk test was used to evaluate the normality of the distribution of the volumetric lumber yield data for the primary breakdown and average log quality grades.

Principal component analysis (PCA) was performed using the following variables: diameters of both log ends, length, flatness, conicity, curvature, grain inclination, pith eccentricity, surface cracks, volumetric lumber yield, volume, average quality grade and quantity of sawed pieces. Only the averages of all the variables quantified in the logs for species were used, and the principal component analysis was performed considering the standardized data (with unit variance). Based on the dispersion of the scores of the considered main components, it was possible to evaluate the similarity or dissimilarity of the logs of the tropical species and, thus, to group them in defined subgroups (Mingoti 2005; Ferreira 2008; Lobão et al. 2010). The number of interpreted principal components was determined by scree plot graph, with the principal components in the X-axis and the eigenvalues in the Y-axis, according to Ferreira (2008). The eigenvalues represent the explained variance by principal components. This graph is analyzed to assess the relation between the addition of a principal component and significant changes in the explained variance. This methodology was adopted by Couto et al. (2013) to choose the number of principal components.

In order to understand the relationship between logs quality and tropical sawnwood production and, in order to test for the ability to predict lumber yield based on conicity, surface cracks, flattening and diameter of the thin end, the following multiple linear equations were fit using the ordinary least squares method: VLY = βo + β1*C + β2*Sc + ε and VLY = βo + β1*TED + β2*F + ε; where VLY = volumetric lumber yield (%); C = conicity (%); Sc = surface cracks (%); F = flattening (%); TED = thin end diameter (cm); β0, β1 and β2 = regression coefficients; ε = random error. The conicity, surface cracks, flattening, and thin end diameter were used in the modeling, because presented the highest correlations with lumber yield. The correlations between quality of logs and volumetric lumber yield were determined by the Eq. 1, and the R2 for evaluating the linear models was determined by the Eq. 2.

where \({y}_{i}\) and \({\widehat{y}}_{i}\) are the observed and estimated values, \(\stackrel{-}{{y}_{i}}\) and \(\stackrel{-}{{\widehat{y}}_{i}}\) are their averages respectively; n is the number of observations and p is the number of estimated parameters.

In addition, this research aimed to examine the relationships between the quality of logs and volumetric lumber yield using canonical correlation analysis for 60 logs from 17 native species, under operational conditions (Table 1). The canonical correlation analysis was conducted to investigate the relationships between the group formed by most common logs defects and characteristics (thick end diameter, thin end diameter, conicity, flattening, surface cracks and volume) and, a second group formed by the grade average per log, number of sawed pieces and volumetric lumber yield. The first group represents the independent variables (X), whereas the second group represents the dependent variables (Y). The Hotelling's multivariate test (approximation of the F-distribution) was used to test the significance of the canonical roots jointly. The correlations between dependent variables (Y) and independent variables (X) were interpreted through of the canonical loadings (correlations between the original variables and their respective canonical statistical variables) and, the canonical cross loadings which represent the correlation between an original variable of a given group and the canonical statistical variable of the opposite group. The scores of the canonical statistical variables were utilized to verify the variability of tropical tree species logs and volumetric lumber yield in the context of small sawmills in the Brazilian Amazon. All statistical analyses were carried out using R software version 3.4.3 (R Core Team 2017), package CCA (González and Déjean 2012).

3 Results and discussion

3.1 Quality of logs

The sampled logs presented great variability of results in the quality analysis (Table 3). The flattening was one of the most frequent defects among the logs with a general average for all species of 76.10%. The high frequency of this defect has a significant impact on the production of a sawmill, given that this defect hampers the obtention of a squared central block, which may reduce considerably the lumber yield (Vital 2008).

According to the IBDF (1984) standard, for logs be considered superior with respect to this flattening, values higher than 90% should be observed. In the present study, only 14 of the 120 logs analyzed were considered as superior in the analysis flattening (12% of the logs analyzed). The lowest mean was obtained for Tabebuia serratifolia (63.41%), while the higher mean was 84.09% for Caryocar villosum.

Logs of Toona ciliata obtained from reforestation at 18 years of age presented less flattening with an average value of 87.3% (Nassur et al. 2013). Garcia et al. (2012) observed to logs of Couratari guianensis and Mezilaurus itauba presented higher flattening, with average value superior the 90%. The authors noted that only for C. guianensis the quality of the logs influenced the lumber yield. Although the presence of flattening reduces the quality of the logs, the yield loss may be reduced by the use of simple band saw allows for versatility in the log cutting (Williston 1976) and X-ray logging technologies combined with traceability methods, multivariate models and breakdown simulation software (Lundahl and Grӧnlund 2010).

For all the groups of economic value (noble, red, mixed, and white), the results of the conicity analysis were satisfactory in that 95.3% of the logs were classified as superior for this defect. That is, they had a conicity equal to or less than 3% (IBDF 1984). In the present study, only five, among the 120 analyzed logs, did not fit in the superior class, being divided between classes II and III. The minimum mean for conicity was 0.73% for Bowdichia nitida, and the maximum was 3.01% for Quassia amara. Log conicity not only reduces the breakdown yield (Mendoza et al. 2019), but may modify the physical and mechanical properties of the lumber (Vital 2008). Log conicity can be used to estimate the yield of sawn wood with high reliability. For example, Mendoza et al. (2019) evaluated 19 native species and observed that the logs of Aniba canelilla showed 0.86% of conicity and higher lumber yield (53%). On the other hand, Cedrelinga catenaeformis showed 2.46% of conicity and lower lumber yield (45%). Regarding the grain slope (GS), only seven logs fit in class II (GS ≤ 10%), while the remaining logs were classified as superior for that defect (GS ≤ 3%). The lowest mean was found for Anadenthera macrocarpa with 0.33%, while the largest mean was found for Andira athelmia with 3.00%. The general average for all species was 1.60%. The grain slope can have an important implication on wood quality as it reduces the mechanical resistance of the wood and can cause greater crack formation (Carrasco and Mantilla 2016).

For the curving analysis (Ca), three species presented no curving: A. athelmia, Guatteria poeppigiana, and Eschweilera coriacea. The mean maximum value for this defect was 4.71% for B. nitida, and the overall average was 1.60%. Almost 80% of the logs were classified as superior and I (Ca ≤ 5%). This can be a very good diagnostic since curving limits the log yield and the length of the sawed pieces (Vital 2008). Additionally, curving affects the properties of the wood and induces the formation of reaction wood.

In terms of pith eccentricity (PE), the species with the lowest mean value was A. macrocarpa with 1.90%, and the maximum was M. itauba with 16.67%. Only 30% of the logs were classified in the superior class (PE ≤ 5%), and the rest was classified as class I, II, and III. High eccentricity values are not considered desirable, given that this defect is closely associated with the formation of reaction wood in the trees (Kollmann and Côte Jr 1968; Boschetti et al. 2015). Trunks with eccentric pith are more prone to warping and to the formation of circular cracks between growth rings, in addition to being problematic for mechanical processing because they require proper positioning of logs in the saw (Grosser 1980).

Surface cracks (SC) were the third defect with the lowest quality grades. The amount of 68% of the logs were classified as superior (SC ≤ 5%) and class I (SC ≤ 10%). Some species did not present this defect, such as A. athelmia, T. serratifolia, A. macrocarpa, G. poeppigiana, and C. villosum. On the other hand, some species such as Erisma uncinatum presented significant cracks (26.97%). The surface cracks compromise the lumber quality, generating more waste. This research indicates which the primary breakdown must be performed according to the log quality and at a species level (improved sawmilling or optimized breakdown), for example, knowing the conicity, flattening and surface cracks. According to Fortini and Carter (2014), the financing of startup costs or research leading to improvements in sawmill processing technology could have large impacts in the activity. The impacts of timber products can be minimized in several ways: changes in energy consumption behavior at the sawmill, improved sawing and sawmill practices, proper wood waste management, and, most importantly, use of energy efficient through environment friendly drying techniques and energy sources (Adhikari and Ozarska 2018).

In addition to the aforementioned defects, there were diametrical, non-diametrical, and annular cracks. The results for this type of defects are presented qualitatively, according to the IBDF (1984) standard. These cracks were in smaller proportions in the logs, considering that most of them were grouped between the superior and group I classes, presenting values of 82%, 87%, and 73% for diametrical, non-diametrical, and annular cracks, respectively. Drying stress and contractions are possibly the main causes of these cracks, which can affect wood strength (Kang and Lee 2004). However, the flow of the free and/or adsorbed water, as well as the log diameter (Nascimento et al. 2019), can also affect the intensity of these cracks.

The predominance of classes II and III was observed for all groups of values, representing, respectively, 42% and 45% of the 120 logs subjected to the quality analysis. This indicates that there was, apparently, no relation between these groups with the defects. The frequency of the quality classes was normally distributed (Shapiro–Wilk test’s p value = 0.06458, considering a significance of 0.05) (Fig. 1). The average score obtained for the logs was 7.76 (with standard deviation of 0.71) and, according to the normal distribution, the odds of the logs presenting average grades between 7.0 and 8.9 (values corresponding to classes II and III) is approximately 80%. However, the probability of obtaining scores greater than 9.0, which corresponds to class I, is only 4%. The estimated probability of the logs presenting grades lower than 7.0 (classes IV and V) is only 14%. These results confirm the predominance of classes II and III, stating that the basic raw materials for the present research are, in general, among the middle classes of quality.

This factor may be associated to the storage time of the logs in the company’s yard, which is on average 5 years, and this probably contributed to the wood deterioration. Gerwing et al. (2000), analyzing the yield of sawn and laminated wood in the state of Pará, observed log degradation of up to 13% caused by insect attack or cracking. The authors attributed these defects in the rolling surface and log ends to storage conditions.

3.2 Volumetric lumber yield

The volumetric lumber yield also presented normal distribution (Shapiro–Wilk test’s p value = 0.4717, considering a significance of 0.05) (Fig. 2). The average volumetric yield for the logs submitted to the primary breakdown was approximately 45%, which is greater than the 36% average found by Gerwing et al. (2000) for the sawmills of the state of Pará. In the Amazon, the smallholder produce on average 195 m3 of sawn wood per year with a mean sawmill processing efficiency from logs to lumber of 37%, that is, 63% of log volume is waste of the primary breakdown (Fortini and Carter 2014). The difficulty in obtaining logs because of the increase in inspections in recent years and, consequently, a higher price of the tropical lumber, may have encouraged the adoption of primary log breakdown techniques with a better lumber yield.

The normal distribution indicated that the estimated probability of the volumetric yield of the analyzed tropical species logs is between 35 and 55%, and it is approximately 54%. The probability of that yield being greater than 35% is 78%. These inferences differ from the Brazilian regulation, CONAMA Resolution 474/2016, which reduced the volumetric lumber yield (VLY) to 35%. Thus, the probability of the yield being greater than the VLY established by the current legislation is significantly higher, according to the present study.

Similarly, yields higher than 35% were found in other studies. Garcia et al. (2012) obtained operating income in sawmills ranging from 39 to 51% in the analysis of logging of M. itauba and C. guianensis species. Biasi and Rocha (2001) obtained average yields between species ranging from 53 to 62% analyzing the species E. uncinatum, Qualea albiflora, and M. itauba. Melo et al. (2016) observed an average yield of 52% for the species Qualea. Mendoza et al. (2019) evaluated 19 native species (171 logs) and, observed that the volumetric lumber yield (average for all species of 43.32%), was above the minimum required by current Brazilian regulation (CONAMA Resolution 474/2016). Several factors may influence lumber yield, such as the final size of the pieces, number of cuttings, machinery, the specialized workforce, sawing methods (Ferreira et al. 2004), log dimensions (Vital 2008), in addition to the parameters related to log quality (Garcia et al. 2012), as described in the Standard for Classification of Hardwood Logs (IBDF 1984).

Because the maximum yield established by the official regulation is of only 35%, sawmills that are capable of achieving higher yield values, as demonstrated by the various studies such as this one and the ones cited above, may face barriers in marketing the lumber. These barriers are cause by the fact that the issuance of the official document for the sale of lumber cannot exceed this the maximum lumber yield of 35%, unless there is a formal certification of this yield signed by qualified professional and an authorization of the environmental agency, as defined in CONAMA Resolution No. 474/2016. Therefore, this study suggests which the measurement of lumber yield should be performed at a species level for each sawmill, because the variability of logs quality (see “Volumetric lumber yield” section).

This research indicates that there is need of revision of Brazilian legislation on volumetric lumber yield. The results demonstrate that under operational conditions, the lumber yield was greater than 35% in 88% of tropical species evaluated. These results are fundamentals for the correct planning of timber production and logging with, economic development and sustainability. Based on measured average sawmill daily processing capacity, mean number of days of mill operation per month and, lumber yield, the researchers, engineers and entrepreneurs can define the economic viability of timber production in Amazon (Fortini and Carter 2014). In terms of economic outcomes, the major lumber yield and forest management improves the long-term viability of the Amazon timber industry (Fortini 2019). The integrated model production, that is, sustainable production patterns associated with forest management indicate better prospects for long-term logging (Fortini 2019). We found that sustainable lumber production will only be possible with the increase of process yield, due industrial technological advance, for the maximum use of the raw material, for example optimized breakdown in function of log quality (Bonato Junior et al. 2017).

In Table 4 shows the average quality scores as well as the average lumber yield of the 17 species submitted to primary log breakdown. The average yield of the 60 logs was 45.33% with a coefficient of variation of approximately 30%, which indicates great variability among the yields. In practical terms, there are differences between species that can influence the sustainability of forest management, logging, and sawmills of Amazon region. For example, logs of tropical species with low lumber yield, negatively influence the economic development and efficiency of sawmill. In this context, there is growing concern about fulfilling the need for increasing demand for timber products without deteriorating the world’s forest resources, especially the Amazon forest. Thus, enhanced insight is required into ways of improving the efficiency of timber production process, reducing wood wastage and helping the timber sector to address growing environmental challenges (Eshun et al. 2012). Therefore, study of lumber yield at a species level is important, as can assist in the best industrial practices for sustainable production.

The lowest mean yield values were observed for the species E. uncinatum and E. coriacea with values of 28.88 and 29.92%, respectively. The E. uncinatum and E. coriacea, both white woods, were classified as classes III and V, respectively. All E. uncinatum logs presented surface cracks which, consequently, caused cracks in the lumber and were eliminated in the secondary processing operations. Some of these logs had diametrical, non-diametrical and annular cracks, large proportions of discarded sapwood, internal rot, and compromised central blocks, leading to whole pieces or part of them being discarded (Fig. 3).

The E. uncinatum logs stood out in terms of the initial volume and, generally, for having larger logs. However, at the time of cutting, the sawmill operator preferred its conversion into boards in order to obtain higher commercial value for the lumber production. For this species, 61% of the pieces obtained were boards. This fact may explain the lower average yield when considering that the greater removal of pieces that also results in greater generation of sawdust-like residues.

The E. coriacea logs, which presented the second lowest yield, showed pronounced surface cracks of up to 2 cm thick. There were also diametrical and non-diametrical cracks, which consequently led to the obtaining of pieces with numerous cracks. This log presented termite attack, which contributed to the deterioration of the pieces and, together with the cracks, culminated in the disposal of part of the raw material (Fig. 4). As for the pieces obtained, 75% of the log was converted into boards, generating additional waste in the form of sawdust.

Eshun et al. (2012) identified 19 wood waste sources in Ghana, 3 related to the forestry subsystem and 16 to the timber industry subsystem. The main sources of wood waste were low-quality logs with large defects, bark, off-cuts, sawdust, slabs, and edged trimmings from sawn timber. The authors reported a large amount of wasted wood is often used in the steam production boiler for dry lumbers or is dumped in a site. However, there are new technologies for the utilization of low-quality logs, especially for the species E. uncinatum and E. coriacea, which can significantly reduce wood waste as well as specialized equipment that allows to maximize the wood recovery (Adhikari and Ozarska 2018) and, consequently increase sawmill yield.

The highest average yields were observed for the B. nitida and C. villosum species, classified as classes III and II, with values of 64.77 and 61.54%, respectively. The B. nitida log submitted to the primary breakdown, did not present expressive cracks, however, the defects that led to this log being classified as quality III were the curling and the pith eccentricity. Therefore, considering that this log obtained the highest yield among the 60 analyzed, this may indicate that these defects have no significant effect on the lumber yield.

Of the 5 analyzed logs, 4 presented diametrical cracks; however, they were not very thick, which did not result in the sawn pieces being much worse (Fig. 5).

For the B. nitida and C. villosum species, which presented the highest yields, only 31% and 39%, respectively, were converted into boards. The other products obtained were planks, boards, and beams, which are pieces of greater thickness, resulting in fewer cuts in the logs and, consequently, less sawdust loss.

3.3 Grouping of logs of tropical species

The principal component analysis resulted in three components explaining 74% of the total variance of the data (Table 5). Analyzing the scree plot (Fig. 6), we observed that it was possible to consider only three or four principal components, because, from this value on, there were no major changes in the cumulative percentage of variance. However, the authors decided to consider only three principal components, instead of four, due to the large proportion of the total data variance explained and, to facilitate the visualization the clusters of log of tropical tree species by scores of the principal components (tridimensional graph). This procedure was adopted by Couto et al. (2013) to choose the number of principal components. The researchers observed that the first three principal components explained 72% of the variance in original data of wood quality of Eucalyptus clones. Therefore, these three latent variables were used for the species grouping and assessment of the influence of the logs quality in volumetric lumber yield. By analyzing the eigenvectors of the first principal component, it was noticed that there was a tendency of higher quality grades associated with higher lumber yield. In addition, from the analysis of the eigenvectors of the first principal component, it can be stated that more cylindrical logs, with smaller surface cracks, tend to have higher volumetric lumber yield. Higher scores for the principal component 1 indicate logs with greater number of defects, such as surface cracks and conicity, and consequently, less volumetric lumber yield from the primary log breakdown.

The second component presented significant negative eigenvectors values for the length of the logs and the pith eccentricity. On the other hand, the lower scores are associated with higher values of eccentricity and length, a factor not favorable for the classification of logs in upper classes. Principal component 3 had positive eigenvectors for flattening and curving. Higher scores refer to the species most prone to these defects, and the higher value for the flattening variable indicates more cylindrical logs, which is a beneficial factor for the yield and unfavorable for the bending.

Based on to the eigenvectors values and the scores of the principal components (Fig. 7), E. coriacea segregated from the rest of the species, which lead to its placement as the only species in group I. This species presented the second highest values for conicity and surface cracks, as well as the second lowest yield. Among the analysis of the average quality grades, it was the only species in the lowest quality class (class V). This result may indicate difficulty in the use of this species by sawmills, especially in those conditions where logs are kept in the courtyard for a long time. It may be more suitable for energy generation, considering that, in the research of Moutinho et al. (2011), it was observed that this species presents chemical and physical characteristics superior to the species commonly used as source of bioenergy. Moreover, lumber production has the potential to be self-sufficient in electric energy with the burning of residues (Monteiro et al. 2017), and the use of low-quality logs can increase the production of electric energy in these industries. According to Adhikari and Ozarska (2018), by choosing energy sources for the timber production process, it is necessary to use as much renewable energy as possible, instead of fossil fuel-based energy. Therefore, the energy use from wood waste and logs of species in the lowest quality class (class V) is recommended alternative to minimize the environmental impacts of timber products through the production.

The M. itauba, Protium decandrum, and C. villosum species formed group II, and the most relevant characteristic for this grouping were the best values of flattening, in which the evaluated logs were more cylindrical. This was also associated with the highest yield values of lumber, which classified them as promising species for use in the sawmill.

Group III was formed by logs of the Astronium lecointei and A. macrocarpa species, due to the higher values of conicity and higher quality grades. This indicated that these logs were not affected by other defects, which resulted in a desirable yield and makes them ideal for use in the sawmill.

Group IV was formed by the Dipteryx odorata, E. uncinatum, Balizia pedicellaris, B. nitida, G. poeppigiana, Enterolobium schomburgkii, Bagassa guianensis, Lecythis pisonis, Clarisia racemosa, Buchenavia huberi, and Apuleia leiocarpa species. The most important factor for this grouping was that these species were classified in class III of quality. This indicated that these were the species most affected by the defects of the form, rolling surface, and extremities.

It was observed that there was no standardization of grouping for the noble, red, mixed and white species. Given that, there are species representing the different value groups in all groupings (except for group 1), and this suggests that these groups did not influence the quality of wood.

In Fig. 8, it can be observed that the species that were grouped in the PCA received next quality grades, according to the new classification suggested in the present study. It is observed that the species were divided primarily between classes II and III with the unique exception of E. coriacea species, placed in class V.

There was a linear and positive relationship between the quality score applied to the species with the yield of lumber (r = 0.49, t = 2.166, and p value = 0.04683). The higher grades also result in higher volumetric lumber yield. Together with the standard for measuring and classifying logs made by the Brazilian Institute for Forest Development (1984), this factor may indicate that the classification of logs proposed can be used to make inferences regarding the volumetric lumber yield.

3.4 Correlations between yield of the breakdown and logs quality

The highest correlations were obtained between the volumetric lumber yield and the conicity (r = − 0.64, t = − 3.1801, p value = 0.006212); surface cracks (r = − 0.59, t = − 2.7951, p value = 0.01359); thick end diameter (r = − 0.57, t = − 2.6623, p value = 0.01775), thin end diameter (r = − 0.55, t = − 2.5262, p value = 0.02327) and flattening (r = 0.46, t = 2.0074, p value = 0.06307). This indicates that these variables are the most suitable for model adjustment in order to estimate the lumber yield. These results corroborate with those found by principal component analysis (see Table 5).

In the analysis of the adjustments determined, it was observed that the first model generated more reliable estimates. It presented the lowest standard error of the estimate (Syx = 6.85), as well as the highest coefficient of determination (R2 = 0.53), and therefore, is the most recommended model for estimating the yield of lumber of tropical species (Figs. 9, 10) in the present research. It can also be observed that larger values for surface cracks and conicity were related to lower yield values of lumber. On the other hand, more cylindrical logs with smaller diameters tend to have higher volumetric lumber yield.

Garcia et al. (2012) reported a decline in yield in a tropical species of log that presented conicity and cracking, classifying it as class II. There was a 50% (logs that were classified as superior) to 39% decrease in the yield when the log showed those defects. These values confirm the importance of these defects for the volumetric lumber yield. Therefore, these results indicated that in order to obtain a yield greater than 50%, the logs are ideally less than 1.5% conicity and surface cracking values less than 15% (Fig. 9).

In view of this statistical finding, it is probably not appropriate to place conicity values of up to 3% into the upper class of logs, as suggested by the IBDF (1984) standard. Given this fact, values for this defect above 1.5% have already led to a significant reduction in the yield of lumber in the present study.

As shown in Fig. 10, the yield was influenced by the flatness and diameter of the thin end. The flattening is a characteristic that is a measure of the deviation of the circular shape of the log, and if presented in a marked way, it causes difficulty in forming a square central block, which reduces the lumber yield (Vital 2008). According to the IBDF (1984) standard, it is necessary that the flatness be greater than 90% in order for the log to be classified as superior.

For the present research, all yields that exceeded the average of 50% had the best average flatness values, being in the range of 72.10–86.83%. The highest mean flattening value (86.83%) was found for the C. villosum species, which presented the second best average yield with a value of 61.54%. These results confirm the importance of this analysis for better use of wood and, consequently, less waste generation.

It is expected that larger diameters lead to higher yields of lumber (Dobner Junior et al. 2012). However, in the present study, the logs with the largest diameters did not present this behavior because of the defects that they obtained, mainly, the surface cracks. Melo et al. (2019) stated that there are exceptions to the higher yield associated with larger diameters, emphasizing that this does not occur when there is no total use of the diameters or in the case of defective logs, similar to that observed in the present study. Therefore, it was observed that the better flatness values and the smaller the log diameters presented were related to the higher volumetric lumber yield. Thus, better yields are expected when the logs present more than 75% flattening and fine point diameters ranging from 40 cm to approximately 65 cm (Fig. 10). Timber industries with modern equipment and suitable log breakdown methods find higher lumber yields when processing logs with larger diameters (Williston 1976; Vital 2008). In the Amazon sawmills, these relationships are still little known and scarce. Less precise estimates between the log diameter of Amazonian species and the lumber production were shown in studies (Lima et al. 2019, 2020). Research suggests that log volume should be considered as an important predictor variable for obtaining lumber volume of different Amazonian commercial species (Lima et al. 2019), similar to our study. In addition to this factor, the conicity of the logs is a characteristic that directly affects the lumber yield (Santos et al. 2019).

The canonical correlations and scores of significant canonical functions by Hotelling’s test (p value < 0.0001) demonstrate the relationships between the quality of logs and volumetric lumber yield (Table 6 and Fig. 11). We observed that the logs quality and volumetric yield presented intra-species and inter-species significant variation, according to the scores of canonical function. The heterogeneity of the logs quality observed in this research resulted in a high variation of lumber production (19–74%, see Table 4). For this reason, the canonical R2 was moderate (0.59) and revealed that 59% of the variance between the groups of logs characteristics and volumetric lumber yield was explained by canonical function 1. This is indicative of interdependence between the logs quality, lumber yield and grades for quality classes of the tropical tree species logs present in this research. The results indicate that the higher the grades for quality classes of the tropical tree species logs, higher the volumetric lumber yield and lower the number of sawed pieces per log. The crossed canonical loads indicate that the thick end diameter, thin end diameter, conicity, and volume present negative correlation with volumetric lumber yield and quality grade of logs. The flatness values presented positive correlation with volumetric lumber yield, that is, more cylindrical logs resulted in higher lumber yield, similar to the result found with the multiple linear regression approach (Figs. 9, 10). This information can be of great help in modeling, in understanding the primary breakdown in small sawmill and in ensuring improving the economic, environmental and social indicators of lumber industry in the Amazon.

The lower correlations obtained through multiple linear regressions and canonical correlation analyses are attributed to intra-species and inter-species significant variation and to specific characteristics of the small sawmill studied. Lumber industries in Amazon are characterized by being isolated, by presenting small investment capital and low yield in their procedures and by generating a large amount of waste. These conditions make planning the lumber production difficult. In addition, several factors can make planning this production even more difficult and explain the high variation of the volumetric lumber yield found for the breakdown under operational conditions in the Amazon region. The first factor is old equipment without automation for the primary and secondary log breakdown. In many industries, a single saw is used to cut all logs. The use of tools for the cutting with suitable shapes and angles for each species improves the quality of the cut and, consequently, reduces the generation of waste (Tuset et al. 2007). In addition, software combined with modern log cutting equipment allows to accurately estimate the lumber yield (Wery et al. 2018). The second factor is the absence or low standardization in the method of log sawing and the low qualification of workers. The conventional method of log sawing, in which the saw operator determines how the cuts will be made, still predominates in the Amazon region (Melo et al. 2019). In most cases the decision is random and results in a low yield of sawn wood (Buehlmann and Thomas 2002; Biasi and Rocha 2001). The appropriate log breakdown methods for each species is important to optimize the production of lumber at sawmill (Popadić et al. 2014; Bonato Junior et al. 2017; Santos et al. 2019). Finally, third factor is related to the legislation, which can hinder estimates of lumber production due to the log quality. The requirement of a minimum yield value in the sawmill (i.e., minimum coefficient of volumetric yield of 35% of the CONAMA Resolution No. 474/2016) can result in more cuts in primary and secondary log breakdown for low-quality logs and generate high yield in this raw material.

According to Danielli et al. (2016) and Li et al. (2016), the processing yield of the raw material has a direct influence on the area of forest that needs to be explored, so that the demand for wood is met. Therefore, this process has a high relation with the sustainability of the logging activity, areas of sustainable forest management, and economic development in the Amazon. This research analyzed the wood quality and lumber yield of logs of tree species harvested in the Amazon rainforest and demonstrated that the correlations between yield of the breakdown and logs quality are influenced by intra-species and inter-species variation. However, the results presented contributes to the understanding of the challenges of the lumber production in the Amazon region, especially regarding the relationship between sustainability of sawmills, process yield and logs quality. It is verified that a great quantity of residues is generated in the breakdown and does not have an appropriate use or destination (on average 55% of the initial volume of the logs). The most common use of sawmill waste has been direct burning (Garcia et al. 2012); however, this is not performed in an integral way due to the large volumes or the decentralized location, which ends up being a burden in transportation. For this reason, often the waste is burned in the open. Given this, it is necessary to seek better yield indices in the Amazonian sawmills and to determine the best use of the residual material that is often discarded without adequate destination.

The success of these sawmills is related to the ability to use wastes from timber operations, associated with the optimization lumber yield. The increase of lumber yield has implications for reducing demand for new areas of tropical forest, for a given amount of timber, consequently, with local benefit-sharing considering environmentally rational patterns (Li et al. 2016). In this context, the increases volumetric lumber yield, minimization and use of waste (i.e., construction, floors production or furniture), results in better carbon balance in sustainable forest management and logging (Numazawa et al. 2017). These observations are in accordance to the 2030 Agenda for sustainable development, especially Goal 12 (ensure sustainable consumption and production patterns) and Goal 13 (take urgent action to combat climate change and its impacts). In addition, trees in central Amazon rainforest can be 200 to 1400 years old (Chambers et al. 1998), and present excellent quality of wood for construction and furniture (Sousa et al. 2020); therefore, its rational and sustainable use is essential. Finally, this paper encourages the increase of the volumetric lumber yield, associated with methods for assessing the quality of tropical logs, for improving the economic, environmental and social indicators of sawmills in the Brazilian Amazon.

4 Conclusion

This research explores quality of the tropical logs and quantify the yield of the lumber production of many tropical tree species in a smallholder, aiming at increase the timber production and minimize waste of primary breakdown for improving the economic, environmental and social indicators of sawmills in the Brazilian Amazon.

The logs obtained from natural stands in the Amazon forest presented great variability of quality and were not influenced by the value groups (noble, red, mixed, and white woods). Although the logs concentrated in the middle classes of quality, the studied sawmill presented an average yield of 45%, being 10% higher than that established in Brazilian official regulation, consequently, resulted in lower generation of waste. The probability of lumber yield will greater than 35% was 78%, under operational conditions. The results demonstrate that under operational conditions, the lumber yield was greater than 35% in 88% of tropical species evaluated.

The cut logs with presence of conicity, surface crack and flattening resulted in smaller lumber volumes, and therefore, these defects are important parameters for the analysis of the log quality in the Amazonian sawmills. In addition, it is possible to conclude that the storage time of the logs in the sawmills' yard interferes with the incidence of the defects and the optimization of the lumber production. The correlation between the lumber yield and the quality of the logs, especially with flatness, surface cracks and conicity, can be utilized to improve the use of raw material. The results allowed for fitting of linear models to estimate the lumber yield and, through principal component analysis, it was possible to group the species according to its suitability to sawmill processing, resulting in a more efficient use of raw material, which contributes to a more sustainable production in the Amazonian region.

The classification of logs proposed can be used to make inferences on the volumetric lumber yield. This research indicates which the primary breakdown must be performed according to the tropical logs quality and classification (optimized breakdown). This study contributes to the local society development, where there are many tropical tree species, which can be explored by the sustainable management and, processed aiming at increase the lumber production and indicators of small sawmills in the Brazilian Amazon.

References

Adhikari, S., & Ozarska, B. (2018). Minimizing environmental impacts of timber products through the production process “From Sawmill to Final Products”. Environmental Systems Research, 7(6), 1–15.

Andrade, V. H. F., Machado, S. A. M., Figueiredo Filho, A., Botosso, P. C., Miranda, B. P., & Schöngart, J. (2019). Growth models for two commercial tree species in upland forests of the Southern Brazilian Amazon. Forest Ecology and Management, 438, 215–223.

Asner, G. P., Keller, M., Lentini, M., Merry, F., & Souza Junior, C. (2009). Selective logging and its relation to deforestation. In Amazonia and Global Change, Geophysical Monograph Series, (Vol. 186, pp. 25–42). Washington, DC: American Geophysical Union.

Associação Brasileira da Indústria de Madeira Processada Mecanicamente—ABIMCI. (2016). Estudo Setorial 2016: Ano base 2015. Curitiba: ABIMCI. (in Portuguese).

Biasi, C. P., & Rocha, M. P. (2001). Yield in sawnwood and quantification of residues for three tropical species. Floresta, 37(1), 95–108.

Bila, N. F., Iwakiri, S., Trianoski, R., & Prata, J. G. (2016). Evaluation of quality of the bonded joints of six species of Amazonian tropical timbers. Floresta, 46(4), 455–464.

Bonato Junior, A. I., Rocha, M. P., Juizo, C. G. F., & Klitzke, R. J. (2017). Effect of saw pattern and diametric grades on the yield in lumber of Araucaria angustifolia. Floresta e Ambiente, 24, e00100414.

Boschetti, W. T. N., Paes, J. B., Vidaurre, G. B., Arantes, M. D. C., & Leite, F. P. (2015). Dendrometric parameters and eccentricity of the pith in leaning eucalyptus trees. Scientia Forestalis, 43(108), 781–789.

Buehlmann, U., & Thomas, R. E. (2002). Impact of human error on lumber yield in rough mills. Robotics and Computer-Integrated Manufacturing, 18(3–4), 197–203.

Carrasco, E. V. M., & Mantilla, J. N. R. (2016). Influence of slope of grain in shear strength of wood. Ciência Florestal, 26(2), 535–543.

Chambers, J. Q., Higuchi, N., & Schimel, J. P. (1998). Ancient trees in Amazonia. Nature, 391, 135–136.

Chiniforush, A. A., Akbarnezhad, A., Valipour, H., & Jianzhuangc, X. (2018). Energy implications of using steel-timber composite (STC) elements in buildings. Energy and Buildings, 176, 203–215.

CONAMA. Conselho Nacional do Meio Ambiente. Resolução nº 474 de 06/04/2016. Diário Oficial da União de 02/05/2016, Seção 1, pp. 74–75. (in Portuguese).

Couto, A. M., Protásio, T. P., Trugilho, P. F., Neves, T. A., & Sá, V. A. (2013). Multivariate analysis applied to evaluation of Eucalyptus clones for bioenergy production. Cerne, 19(4), 525–533.

Danielli, F. E., Gimenez, O. B., Oliveira, C. K. A., Santos, J., & Higuchi, N. (2016). Yield modeling in sawing logs of Manilkara spp. (Sapotaceae) in sawmill in the state of Roraima, Brazil. Scientia Forestalis, 44(111), 641–651.

Dobner Junior, M., Higa, A. R., & Rocha, M. P. (2012). Sawmill yield of Pinus taeda logs: Large assortments. Floresta e Ambiente, 19(3), 385–392.

Eshun, J. F., Potting, J., & Leemans, R. (2012). Wood waste minimization in the timber sector of Ghana: A systems approach to reduce environmental impact. Journal Clean Production, 26, 67–78.

Ferreira, D. F. (2008). Estatística Multivariada (1st ed.). Lavras: UFLA. (in Portuguese).

Ferreira, S., Lima, J. T., Rosado, S. C. S., & Trugilho, P. F. (2004). Influence of tangential break down methods on the yield and on the quality of Eucalyptus spp sawn timber. Cerne, 10(1), 10–21.

Fortini, L. B. (2019). Integrated models show a transient opportunity for sustainable management by tropical forest dwellers. Forest Ecology and Management, 438, 233–242.

Fortini, L. B., & Carter, D. R. (2014). The economic viability of smallholder timber production under expanding açaí palm production in the Amazon Estuary. Journal of Forest Economics, 20(3), 223–235.

Fuentealba, S., Pradenas, L., Linfati, R., & Ferland, J. A. (2019). Forest harvest and sawmills: An integrated tactical planning model. Computers and Electronics in Agriculture, 156, 275–281.

Garcia, F. M., Manfio, D. R., Sansígolo, C. A., & Magalhães, P. A. D. (2012). Yield of itaúba (Mezilaurus itauba) and tauarí (Couratari guianensis) logs sawmill according to log quality classification. Floresta e Ambiente, 19(4), 468–474.

Gerwing, J., Vidal, E., Verìssimo, A., & Uhl, C. (2000). O rendimento no processamento de madeira no estado do Pará. Série Amazônica Série Amazônica. Belém: Imazon. (in Portuguese).

González, I., Déjean, S. T. (2012). Canonical correlation analysis. R package version 1.2. Retrieved April 9, 2018, from https://CRAN.R-project.org/package=CCA.

Grosser, D. (1980). Defeitos de madeira. Fupef: Curitiba. (in Portuguese).

Gustavsson, L., Holmberg, J., Dornburg, V., Sathre, R., Eggers, T., Mahapatra, K., et al. (2007). Using biomass for climate change mitigation and oil use reduction. Energy Policy, 35, 5671–5691.

Gustavsson, L., & Sathre, R. (2006). Variability in energy and carbon dioxide balances of wood and concrete building materials. Building and Environment, 41(7), 940–951.

Instituto Brasileiro de Desenvolvimento Florestal—IBDF. (1984). Norma para medição e classificação de toras de madeiras de folhosas. Brasília: Brasiliana. (in Portuguese).

International Tropical Timber Organization—ITTO. (2017). Biennial review and assessment of the world timber situation (2015–2016). Yokohama: Division of Trade and Industry, ITTO.

Kang, W., & Lee, N. H. (2004). Relationship between radial variations in shrinkage and drying defects of tree disks. Journal of Wood Science, 50(3), 209–216.

Kayo, C., Noda, R., Sasaki, T., & Takaoku, S. (2015). Carbon balance in the life cycle of wood: Targeting a timber check dam. Journal of Wood Science, 61, 70–80.

Knight, L., Huff, M., Stockhausen, J. I., & Ross, R. J. (2005). Comparing energy use and environmental emissions of reinforced wood doors and steel doors. Forest Products Journal, 55(6), 48–52.

Kollmann, F. F. P., & Côté, W. A. (1968). Principles of wood science and technology. New York: Springer.

Li, C., Huang, S., Barclay, H., & Sidders, D. (2016). Modeling lumber yield of white spruce in Alberta, Canada: A comparative approach. Journal of Forest Research, 21(6), 271–279.

Lima, R. B., Ferreira, R. L. C., Silva, J. A. A., Guedes, M. C., Oliveira, C. P., Silva, D. A. S., et al. (2019). Lumber volume modeling of Amazon Brazilian species. Journal of Sustainable Forestry, 38(3), 262–274.

Lima, R. B., Ferreira, R. L. C., Silva, J. A. A., Guedes, M. C., Silva, D. A. S., Oliveira, C. P., et al. (2020). Effect of species and log diameter on the volumetric yield of lumber in northern Brazilian Amazonia: Preliminary results. Journal of Sustainable Forestry, 39(3), 283–299.

Lipscomb, M., & Prabakaran, N. (2020). Property rights and deforestation: Evidence from the Terra Legal land reform in the Brazilian Amazon. World Development, 129, 104854.

Lobão, M. S., Chagas, M. P., Costa, D. S. P., Ferreira, A. T. B., Sette Jr, C. R., Carvalho, I. L., et al. (2010). Grouping of forest species by similarity of physical-anatomical characteristics and uses of wood. Cerne, 16, 97–105.

Lundahl, C. G., & Grӧnlund, A. (2010). Increased yield in sawmills by applying alternate rotation and lateral positioning. Forest Products Journal, 60(4), 331–338.

Marchesan, R., Loiola, P. L., Juizo, C. G. F., França, M. C., Rocha, M. P., & Klitzke, R. J. (2018). Yield and quality of lumber from three Amazonian species. Brazilian Journal of Wood Science, 9(3), 143–151.

Melo, R. R., Dacroce, J. M. F., Rodolfo Junior, F., Lisboa, G. S., & França, L. C. J. (2019). Lumber yield of four native forest species of the Amazon region. Floresta e Ambiente, 26(1), e20160311.

Melo, R. R., Rocha, M. J., Rodolfo Junior, F., & Stangerlin, D. M. (2016). Influence of diameter class on lumber yielding of Qualea sp. Pesquisa Florestal Brasileira, 36(88), 393–398.

Mendoza, Z. M. S. H., Borges, P. H. M., Morais, P. H. M., & Elias, M. P. S. (2019). Use of beta regression to estimate the volumetric yield coefficient in logs of native species of the legal Amazon. Nativa, 7(3), 323–329.

Mingoti, S. A. (2005). Análise de dados através de métodos de estatística multivariada: uma abordagem aplicada. Belo Horizonte: UFMG. (in Portuguese).

Monteiro, T. C., Lima, J. T., Silva, J. R. M., Trugilho, P. F., & Barauna, E. E. P. (2017). Energy balance in sawing Eucalyptus grandis logs. BioResources, 12(3), 5790–5800.

Moutinho, V. H. P., Couto, A. M., Lima, J. T., Aguiar, O. J. R., & Nogueira, M. O. G. (2011). Energetic characterization of Matá-Matá wood from the Brazilian rainforest (Eschweilera Mart Ex Dc). Scientia Forestalis, 39(92), 457–461.

Nascimento, T. M., Monteiro, T. C., Barauna, E. E. P., Moulin, J. C., & Azevedo, A. M. (2019). Drying influence on the development of cracks in Eucalyptus logs. BioResources, 14(1), 220–233.

Nassur, O. A. C., Rosado, L. R., Rosado, S. C. S., & Carvalho, P. M. (2013). Variations in log quality of eighteen years old Toona ciliata M. Roem. Cerne, 19(1), 43–49.

Numazawa, C. T. D., Numazawa, S., Pacca, S., & John, V. M. (2017). Logging residues and CO2 of Brazilian Amazon timber: Two case studies of forest harvesting. Resources, Conservation and Recycling, 122, 280–285.

Packalen, T., Kärkkäinen, L., & Toppinen, A. (2017). The future operating environment of the finnish sawmill industry in an era of climate change mitigation policies. Forest Policy and Economics, 82, 30–40.

Popadić, R., Šoškić, B., Milić, G., Todorović, N., & Furtula, M. (2014). Influence of the sawing method on yield of beech logs with red heartwood. Drvna Industrija, 65(1), 35–42.

R Core Team. (2017). R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. R version 3.4.3. Retrieved July 30, 2018, from https://www.R-project.org/.

Reis, P. C. M. R., Souza, A. L., Reis, L. P., Carvalho, A. M. M. L., Mazzei, L., Reis, A. R. S., et al. (2019). Clustering of Amazon wood species based on physical and mechanical properties. Ciência Florestal, 29(1), 336–346.

Ribeiro, R. B. S., Gama, J. R. V., & Melo, L. O. (2014). Sectional analysis for volume determination and selection of volume equations for the Tapajos Nacional Forest. Cerne, 20(4), 605–612.

Santos, M. F., Gama, J. R. V., Figueiredo Filho, A. F., Costa, D. L., Retslaff, F. A. S., Silva-Ribeiro, R. B., et al. (2019). Conicity and yield for lumber from commercial species from the Amazon. Cerne, 25(4), 439–450.

Sears, R. R., Padoch, C., & Pinedo-Vasquez, M. (2007). Amazon Forestry transformed: integrating knowledge for smallholder timber management in Eastern Brazil. Human Ecology, 35, 697–707.

Sousa, K. F. D., Detlefsen, G., Virginio Filho, E. M., Tobar, D., & Casanoves, F. (2016). Timber yield from smallholder agroforestry systems in Nicaragua and Honduras. Agroforestry Systems, 90, 207–218.

Sousa, W. C. S., Barbosa, L. J., Soares, A. A. V., Goulart, S. L., & Protásio, T. P. (2020). Wood colorimetry for the characterization of Amazonian tree species: A subsidy for a more efficient classification. Cerne, 25(4), 451–462.

Stragliotto, M. C., Oliviera, A. C., Pereira, B. L. C., & Freitas, J. M. (2019). Yield in sawn wood and residue utilization of Qualea paraensis Ducke and Erisma uncinatum Warm. Floresta, 49(2), 257–266.

Tuset, R., Duran, F., Berterreche, A., Marius, N., & Daniluk, G. (2007). Manual de Maderas Comerciales, Equipos y Proceso de Utilización: Aserrado de Maderas. 1. v. Montevideo: Hemisferio-Sur.

Vital, B. R. (2008). Planejamento e Operação de Serrarias (1st ed.). Viçosa: UFV. (in Portuguese).

Waldhoff, P., & Vidal, E. (2015). Community loggers attempting to legalize traditional timber harvesting in the Brazilian Amazon: An endless path. Forest Policy and Economics, 50, 311–318.

Wery, J., Gaudreault, J., Thomas, A., & Marier, P. (2018). Simulation-optimisation based framework for Sales and Operations Planning taking into account new products opportunities in a co-production context. Forest Ecology and Management, 94, 41–51.

Williston, E. M. (1976). Lumber manufacturing: the design and operation of sawmills and planer mills (2nd ed.). San Francisco: M. Freeman.

Acknowledgements

This study was financed in part by the National Council for Scientific and Technological Development (CNPq) in Brazil (process 306793/2019-9). The authors are grateful for the comments and suggestions presented by the reviewers during the review process, which contributed to improve the quality of the paper and, COOPMASP (Cooperativa da Indústria Moveleira e Serradores de Parauapebas—Brazil) by provide the raw material. We would also like to thank Michael James Stablein of the University of Illinois Urbana-Champaign for his translation services and review of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

da Silva Luz, E., Soares, Á.A.V., Goulart, S.L. et al. Challenges of the lumber production in the Amazon region: relation between sustainability of sawmills, process yield and logs quality. Environ Dev Sustain 23, 4924–4948 (2021). https://doi.org/10.1007/s10668-020-00797-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-020-00797-9