Abstract

Microfluidics has enabled researchers to explore the physics of fluid in the regions of micro in size. Use of Machine Learning techniques in microfluidics to predict flow behavior and reduce time is an unexplored area. A Y-shaped micromixer was designed and its five design variables were identified. A sample size was designed by general factorial method and the simulation experiments were conducted using a CFD solver. The evaluation criteria was mixing index at the outlet of Y-shaped micromixer. Based on results of 1024 simulations, an Artificial Neural Network (ANN) metamodel was developed. Finally the metamodel was validated against the simulation results for the values of design variables outside the full factorial sample. The results show that the metamodel shows agreement with the simulation results with 0.6% difference.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Microfluidics involve the study of transport of fluids in macro or nanoliters through the micro-components, e.g. micropumps, microchannels and microvalves [1]. It has revolutionized the miniaturization of various chemical, biological and pharmaceutical laboratory tests, famously known as Lab-on-Chip (LOC). Micromixing is essential part of such LOC devices which are used for cell analysis, drug delivery and DNA sequencing [2]. The turbulent mixing is difficult at microscale due to low Reynold number (Re). Chaotic advection and molecular diffusion plays important role in mixing of two or more streams of fluid in such devices, called as Micromixers. The fabrication of these microfluidic devices is carried out by micro-fabrication techniques such as soft lithography, laser engraving, photochemical machining and 3D printing on suitable materials [3]. While is the fabrication can be outsourced from developed laboratories, the design and optimization of these devices involves years of work until a workable prototype is not developed.

Use of Machine Learning (ML) algorithms to develop statistical models that can recognize patterns and predict outcome is gaining importance nowadays [4]. Few examples are face recognition, speech-to-text, weather forecasting and autonomous vehicles. These models can be as easy as simple regression or difficult as Deep Neural Networks (DNN) [5]. The use of ML models in microfluidics has improved processes like cancer screening, cell counting, blood grouping and design of LOC devices.

Numerical simulations has made it possible to study of complex geometries and physics involved in microfluidics. Various commercially available softwares like Fluent, COMSOL MP, etc. are used by researchers to design a microfluidic device before actual prototype [6, 7]. The chaotic mixing at low Reynolds numbers can be easily evaluated with the help of numerical simulations.

The robustness of a numerical study increases if the factors affecting the response function are identified and included in study. Various Design of Experiment (DoE) techniques, viz. Taguchi, RSM, 2 factorial, etc. are used to design the sample size and accordingly experiments are carried out. Analysis of Variance (ANOVA) technique is then used to evaluate the effect of design variables on response function and their interdependence.

The use of numerical simulations to train ML algorithms and develop a robust Metamodel has recently acquired attention of researchers. Wei et al. [8] trained an artificial neural network (ANN) metamodel by a series of CFD simulations of peracetic acid (PAA) disinfection characteristics in a chemical treatment reactor. Naphon et al. [9] analyzed the micro-channel heat sink with nanofluids jet impingement by applying CFD and ANN. The ANN model was trained with the Levenberg–Marquardt Backward propagation (LMB) algorithm.

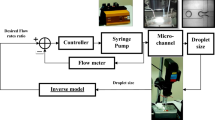

In this paper, an effort is made to develop an ANN Metamodel on the basis of numerical simulations carried out for the sample size which is obtained by full factorial method. Five design variables of a Y-shaped micromixer were identified and varied at four different levels. The trained Metamodel is then validated for a new design of Y-shaped micromixer against its numerical simulation results. The flowchart of the methodology is represented in Fig. 1.

2 Micromixer Model

Micromixers comes in various shapes and are classified as active and passive micromixers [10]. The active micromixers make use of external forces such as acoustic, mechanical, pneumatic for mixing while emphasis is given on geometric shapes and sizes to increase chaotic mixing in case of passive micromixers without the aid of external forces. Various forms of microchannels such as serpentine, parallel and with or without obstacles of different shapes have been a keen area of interest for researchers [11,12,13]. A commonly used Y-shaped serpentine micromixer is represented in Fig. 2 and meaning of abbreviations is shown in Table 1.

3 Design of Simulation Experiments

A general full factorial factorial design is used to measure responses at all combinations of the design parameters. Five design parameters are considered; out of which channel width, entrance angle, planer height and spacing are geometric parameters while velocity at inlet is an operating parameter. These variables are varied at four different levels as shown in Table 2. For given five design parameters at four levels, the general factorial design gives 45, i.e. total 1024 experiments.

4 Numerical Modeling

4.1 Governing Equations

Two-dimensional fluid flow of an incompressible viscous fluid was described by Navier–Stokes equations. For a fluid of density ρ and dynamic viscosity μ, flowing with velocity \(\overrightarrow{V}\) under fluid pressure of p, the continuity equation (Eq. 1) and the momentum equation (Eq. 2) is given by

where is the density of fluid, is the velocity vector, represents fluid pressure, and represents dynamic viscosity of fluid.

The microfluidic mixing phenomena is governed by combination of convection and diffusion processes and its general equation for non-reacting incompressible fluids is given by

where D is the diffusivity and c is the molar concentration.

4.2 Material Properties and Boundary Conditions

The two non-reacting incompressible fluids considered in this study are pure water and ethanol and their physical properties at 25 °C are given in Table 3. Pure Water enters through inlet 2 and ethanol through inlet 1 with concentration of 1 mol/m3, both at velocity of 0.1 m/s under steady state as shown in Fig. 3. Pressure at the outlet is assumed to be atmospheric, i.e. zero static pressure. No-slip wall condition is assigned to other remaining boundaries.

4.3 Grid Test

The numerical results vary upon how well the domain is discretized according to the physics involved. A grid independency test ensures that the model is robust for a certain mesh size and the results are independent of further discretization. For the Y-shaped micromixer, the grid test is carried out with 400 μm channel width, 45° entrance angle, 0.6 mm planer height and 600 μm channel spacing while the velocity at both inlets is 0.15 m/s. The velocity of mixture at the outlet is set as criteria for evaluation of grid independence. The mesh number 3 can be selected as optimum mesh size because the % error in outlet velocity further reduces below 0.5 as shown in Table 4.

4.4 Mixing Index Calculation

The Mixing Index (MI) represents the uniformity of mixing of fluids and a mixure with high MI values is desirable in LOC applications. Mass fractions at the nodes of outlet of Y-shaped micromixer are noted from the simulations and the variance of molar concentration in mixture is expressed as [7]

where N, Ci and Cref are the total number of data points, the concentration of ith point and the concentration of a perfect mix (0.5 mol/m3), respectively.

The Mixing Index is expressed as

The maximum variance (\({\sigma }_{max}\)) of 0.5 represents completely unmixed fluids.

5 Development of ANN Metamodel

The simplicity and flexibility in Artificial Neural Network (ANN) has made it popular among researchers for analysis and prediction of events [9, 14, 15]. In ANN, the information is given to input nodes which is feed forwarded to the network with sigmoid activation function and finally to output nodes as shown in Fig. 4. In the present work, five input parameters, viz. width, entrance angle, planer height, spacing and velocity at inlet and an output parameter, Mixing Index are specified across the test section. In the development of ANN, 20% of simulation data is used for testing and remaining 80% to verify it. The Levenberg–Marquardt backpropagation algorithm with changing weights and biases is used to minimize the error between the test data and predicted results. The ANN model was developed in MATLAB software.

6 Results

Total 1024 simulation experiments were performed for the given sample size from general factorial method. The mixing index at the outlet was calculated in each case and this data was used as input to the ANN model. The highest mixing index of 99.9% was obtained from simulation no. 190 for 200 μm channel width, 45° entrance angle, 10 mm planer height, 800 μm spacing and at 0.1 m/s inlet velocity. On the other hand, the lowest mixing index of 81.41% was obtained from simulation no. 905 for 800 μm channel width, 45° entrance angle, 4 mm planer height, 600 μm spacing and at 0.05 m/s inlet velocity. Small channel width and large mixing length along the direction of flow increase the surface-to-volume ratio and thus mixing performance. While large channel widths and short mixing length along the direction of flow are inefficient for mixing between the fluids. The concentration contours for both cases are shown in Fig. 5a and b respectively. However the pressure drop for the simulation experiment with highest mixing index is 3943.9 Pa and pressure drop for the simulation experiment with lowest mixing index is 100.82 Pa. The mixing performance becomes better at the expense of pressure drop.

Using Levenberg–Marquardt backpropagation algorithm, the ANN model was developed with five input nodes, five hidden layers and one output layer. The accuracy of the ANN model is explained in terms of correlation coefficient (R) and the mean square error (MSE). As shown in Fig. 6, the MSE and R values converge within 87 iterations training.

Figure 7 shows the comparison between the values of Mixing Index across the test section, which were obtained from the ANN model and simulation data set. It can be seen that the ANN model prediction for the Mixing Index yields R = 0.97366 for the training data set and R = 0.97468 for testing data set. The Mixing Index from simulation and ANN show good agreement and falls within ± 0.1%.

7 Validation of Model

The trained ANN Metamodel is then validated against simulation results. A new combination of parameters was designed which was not included in the design sample of general factorial. The Y-shaped micromixer for validation was designed with a channel width of 500 μm, entrance angle of 50°, a planer height of 5 mm and channel spacing of 500 μm. The inlet velocity is 0.12 m/s and other boundary conditions were kept similar as before. The mesh size from the grid test was selected for simulation. Similarly the trained ANN Metamodel was test with these new parameters. The mixing index from simulation is calculated and is equal to 94.17%. The trained ANN Metamodel gives the value of mixing index as 94.85%. The ANN Metamodel shows good agreement with the simulation with 0.6% difference, which is acceptable.

8 Conclusion

The mixing performance of a Y-shaped micromixer from numerical simulation and artificial neural network model is presented for mixing two fluids, viz. water and ethanol. The general factorial method was used to design experiments with five design parameters at four different levels. The mixing performance in each simulation experiment was evaluated and this data was used to train the ANN model. It is seen from the validation study that the ANN metamodel with Levenberg–Marquardt backpropagation algorithm showed good agreement with the simulation results. Therefore, the proposed ANN metamodel can contribute in evaluating mixing performance of micromixers with various configurations.

References

Convery, N., & Gadegaard, N. (2019). 30 years of microfluidics. Micro Nano Engineering, 2(November 2018), 76–91. https://doi.org/10.1016/j.mne.2019.01.003

Nguyen, N. T., & Wu, Z. (2005). Micromixers - a review. Journal Micromechanics Microengineering, 15(2). https://doi.org/10.1088/0960-1317/15/2/R01

Qin, D., Xia, Y., & Whitesides, G. M. (2010). Soft lithography for micro- and nanoscale patterning. Nature Protocols, 5(3), 491–502. https://doi.org/10.1038/nprot.2009.234

McIntyre, D., Lashkaripour, A., Fordyce, P., & Densmore, D. (2022). Machine learning for microfluidic design and control. Lab on a Chip, 22(16), 2925–2937. https://doi.org/10.1039/d2lc00254j

Riordon, J., Sanner, S., Sinton, D., & Young, E. W. K. (2018). Deep Learning with Micro fluidics for Biotechnology, 1–15. https://doi.org/10.1016/j.tibtech.2018.08.005

Carvalho, V., Rodrigues, R. O., Lima, R. A., & Teixeira, S. (2021) Computational simulations in advanced microfluidic devices : A review, 1–14.

Gidde, R. R., Pawar, P. M., Ronge, B. P., Shinde, A. B., Misal, N. D., & Wangikar, S. S. (2019). Flow field analysis of a passive wavy micromixer with CSAR and ESAR elements. Microsystem Technologies, 25(3), 1017–1030. https://doi.org/10.1007/s00542-018-4071-3

Wei, W., Haas, C. N., Asce, F., & Farouk, B. (2020) Development of a CFD-based artificial neural network metamodel in a wastewater disinfection process with peracetic acid, 146(12), 1–11. https://doi.org/10.1061/(ASCE)EE.1943-7870.0001822

Naphon, P., Wiriyasart, S., Arisariyawong, T., & Nakharintr, L. (2019). ANN, numerical and experimental analysis on the jet impingement nanofluids flow and heat transfer characteristics in the micro-channel heat sink. International Journal of Heat and Mass Transfer, 131, 329–340. https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.073

Lee, C. Y., Chang, C. L., Wang, Y. N., & Fu, L. M. (2011). Microfluidic mixing: A review. International Journal of Molecular Sciences, 12(5), 3263–3287. https://doi.org/10.3390/ijms12053263

Yang, J. T., Huang, K. J., Tung, K. Y., Hu, I. C., & Lyu, P. C. (2007). A chaotic micromixer modulated by constructive vortex agitation. Journal Micromechanics Microengineering, 17(10), 2084–2092. https://doi.org/10.1088/0960-1317/17/10/021

Wong, S. H., Ward, M. C. L., & Wharton, C. W. (2004). Micro T-mixer as a rapid mixing micromixer. Sensors Actuators B Chemical, 100(3), 359–379. https://doi.org/10.1016/J.SNB.2004.02.008

Kim, D. S., Lee, S. W., Kwon, T. H., & Lee, S. S. (2004). A barrier embedded chaotic micromixer. Journal Micromechanics Microengineering, 14(6), 798–805. https://doi.org/10.1088/0960-1317/14/6/006

Rizkin, B. A., Popovich, K., & Hartman, R. L. (2019). Artificial neural network control of thermoelectrically-cooled microfluidics using computer vision based on IR thermography. Computers & Chemical Engineering, 121, 584–593. https://doi.org/10.1016/j.compchemeng.2018.11.016

Ghadimi, B., Nejat, A., & Nourbakhsh, S. A. (2018). Multi objective genetic algorithm assisted by ANN metamodel for shape optimization of a centrifugal blood pump, 0–1. https://doi.org/10.1111/aor.13366

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Ronge, D., Pawar, P. (2024). Development of a CFD Based Artificial Neural Network Metamodel for the Design of Micromixer. In: Pawar, P.M., et al. Techno-Societal 2022. ICATSA 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-34648-4_93

Download citation

DOI: https://doi.org/10.1007/978-3-031-34648-4_93

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-34647-7

Online ISBN: 978-3-031-34648-4

eBook Packages: EngineeringEngineering (R0)