Abstract

The great opportunities of the new technology of artificial intelligence and the growing computational capacities together with interacting sensor technology leads to the next industrial revolution called Industry 4.0. In this field the combination of artificial intelligence with numerical simulation to develop a simplified model of a given system can be used for establishing a digital twin of the system for better control and more efficient performance. In this paper, the Artificial Neuronal Network (ANN) methodology is applied as well as a standard interpolation to develop two different simplified models of a 3D cavity flow. The problem is analyzed by Computational Fluid Dynamics (CFD). The CFD simulations are carried out using a commercial software for a case, for which experimental data from the literature exists. In general, the combination of CFD and ANN has been performed in different researches on different applications. Thus, the present paper focuses rather on the comparison of a standard interpolation procedure to ANN, utilizing two different error calculations.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The fields of the Artificial Intelligence (AI) [1,2,3] and Computational Fluid Dynamics (CFD) [4,5,6,7,8] are experiencing a rather parallel development. Both fields exist for decades, and due to the increasing computational capabilities, their impact has been growing rapidly in the recent years. First ideas of combination the technologies of date back a lot of years, e.g. to 1988, when Andrews [9] published the first review on the capabilities and problems in combination of AI and CFD. More recent publications [10,11,12] show different approaches for the AI-CFD interaction. In Ref. [13] a nice overview on the newest AI technologies and frameworks were presented. In problems with more complex physics, the combination of AI and CFD was demonstrated in Refs. [14, 15]

Further investigations on the different aspects of the problem in different areas including digital twins were presented by numerous researches [16,17,18,19,20,21,22,23,24,25].

2 The Test Case

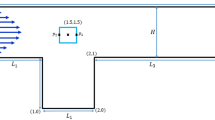

For comparison with realistic data from a three dimensional flow with large velocity variations, a 3D cavity problem is considered. Corresponding experimental was data found in Ref. [26] (Fig. 1, 2).

Sketch of the experimental setup [26]

For the experimental investigations, different Reynolds numbers have been used as shown in Table 1 with the calculated velocities for the working fluid of isopropyl alcohol of density ρ = 0.785 g/cm3 and kinematic viscosity of ν = 0.031 cm2∕s.

Laser image of the velocity field [26]

3 Mathematical and Numerical Flow Modeling

The computational modeling of the flow has been performed using the simulation software ANSYS Fluent [27]. To ensure reliable simulation results, a mesh sensitivity study has been performed and the meshes shown in Fig. 3 are used for the further calculations. Since the Reynolds number was within the laminar flow regime, the simulation was done with no turbulence model, but for a laminar flow simulation setup.

For the inlet boundary condition, a fully developed flow is set by an equation for the velocity.

The Simulation results show fine agreement with the experimental data as shown in Fig. 4.

Flow field Reynolds number 140 (left: simulation, right: experiments [26])

4 Developing a Simplified Model

The numerical simulation following the iterative solution of fluid physics by calculation of the Navier–Stokes equation system can take a lot of computational effort and time. Thus, the common CFD approach may not be feasible in cases, where limitations of resources and time are strict.

On the other hand, if the flow field is prescribed by a set of coefficients as found in interpolations of artificial network, this set of coefficients can be solved within very short time by simple matrix calculations which are very simple for nowadays computational infrastructure.

So the aim of the given study is to develop two different approaches for the calculation of the matrices that represent the flow field and to compare both results for different Reynolds numbers within a given range.

4.1 Simple Interpolation

The first approach is the calculation of a set of coefficients for the solution domain expressing the variables of interest as functions of the inlet condition following a regression function, whose coefficients are extracted from the data exported from the simulations. These coefficients represent the influence of the change of the variable (here the inlet velocity) to the behavior of the system, for different orders, linear, quadratic, and more if necessary.

The equations can be put in matrix form as follows

This system can be solved for the whole domain to get the velocity for a given inlet velocity.

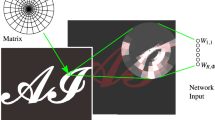

4.2 ANN Model

The next approach is more advanced one, using the ANN framework of Keras with the CFD simulation results, the coordinates and the boundary conditions as an input for the neuronal network with randomized order of the points.

The training is done in a sequential class, the relu activation layer an Adam optimizer with a learning rate of 0.005 and a loss function with Mean AbsouteError.

The architecture was built with four hidden layers with 256 nodes each.

5 Error Estimation

In estimation of the accuracy of the simulation results, next to the qualitative comparison of the flow fields, the given project aimed to also find quantitative error estimation.

Here, it was important to find a method to calculate the error that takes into account the differences of the high velocity zones as well as the differences of the zones with lower velocity also. After some development the decision was made to define two different error calculations as shown in Eqs. (3) and (4).

Since the Error1 takes the differences of each velocity at a certain point from the CFD calculation to the model prediction, here the relative error of the small velocities has a much higher influence compared to the error in the high velocity field. On the other hand for the Error2, the relative error of the differences of the sum of all velocities for the CFD calculation to the sum of all velocities of the model prediction has been calculated and thus, here the differences of the high velocity areas at the flow field plays a major role.

6 Results

In Fig. 5 the comparison of the results of the interpolation to the CFD calculations are shown. It is shown that the prediction of the model shows rather big errors in the area of low Reynolds number but for the higher velocities, the error becomes low and the quality of the predictions is feasible.

The results of the error calculations for the predictions of the ANN in comparison to CFD are shown in Fig. 6. As before, the results of the predictions at the low Reynolds numbers are not good but becomes much better in a range of smaller than 10% at higher Reynolds numbers. It is interesting to notice that the simple interpolation algorithm appears to give better results than the more advanced AI approach.

A further comparison is shown in Fig. 7. As seen in the figure the velocity is plotted along traversal lines (Line 1 in a and d, line 2 in b and e, line 3 in c and f) for two different Reynolds numbers (Re = 15 for a, b, c and Re = 140 for d, e, f) each plot with the direct comparison of the velocity profile for the CFD simulation, the interpolation and the AI model.

It is seen that the prediction of the fully developed pipe flow for the inlet and outlet (at line 1 and 3) is quite well for all cases, just in the middle of the cavity, at line 2, the differences become larger. In b, one can see the difference of the interpolation to the CFD result is smaller than the difference of the AI predictions. For the higher Reynolds number (e) the differences become negligible small for both (Interpolation and AI) in comparison to the CFD simulation.

7 Conclusions

Two different approaches have been developed for using the data of CFD calculations to train different meta models that are able to predict the three dimensional flow field of a cavity flow within very short time. The models were using a simple interpolation model and a more advances AI approach. In this paper both models have been compared among each other and both models show acceptable accuracy in the prediction of the flow field for higher Reynolds numbers but shows difficulty in the lower Reynolds numbers. Here the interpolation shows even better performance than the AI approach.

Following developments will be carried out to develop a supervision tool that performs randomized test simulations and compares them to the predictions and will form smaller submodels for areas where the prediction shows big differences. Here, again both approaches shall be compared.

References

Chollet, F.: Deep Learning mit Python und Keras Das Praxis-Handbuch. MITP Verlag, Frechen (2018)

Vargas, R., Misavi, A., Ruiz, R.: Deep learning: a review. Adv. Intell. Syst. Comput. 2018100218 (2018)

Selle, S.: Künstliche Neuronale Netzwerke und Deep Learning. Lecture in University of Applied Sciences Business School (2018)

Benim, A.C., Iqbal, S., Joos, F., Wiedermann, A.: Numerical analysis of turbulent combustion in a model swirl gas turbine combustor. J. Combust., Article ID 2572035 (2016)

Pfeiffelmann, B., Benim, A.C., Joos, F.: A finite volume analysis of thermoelectric generators. Heat Transfer Eng. 40(17–18), 1442–1450 (2019)

Cagan, M., Benim, A.C., Gunes, D.: Computational analysis of gas turbine preswirl system operation characteristics. WSEAS Trans. Fluid Mech. 4(4), 117–126 (2009)

Benim, A.C., Pfeiffelmann, B., Oclon, P., Taler, J.: Computational investigation of a lifted hydrogen flame with LES and FGM. Energy 173, 1172–1181 (2019)

Benim, A.C., Diederich, M., Gül, F., Oclon, P., Taler, J.: Computational and experimental investigation of the aerodynamics and aeroacoustics of a small wind turbine with quasi-3D optimization. Energy Convers. Manage. 177, 143–149 (2018)

Andrews, A.: Progress and challenges in the application of artificial intelligence to computational fluid dynamics. AIAA J. 26(1), 40–46 (1988)

Wang, B., Wang, J.: Application of artificial intelligence in computational fluid dynamics. Ind. Eng. Chem. Res. 60(7), 2772–2790 (2021)

Usman, A., Muhammad, R., Muhammad, S., Ali, N.: Machine learning computational fluid dynamics. Swedish Artificial Intelligence Society Workshop (SAIS), pp. 46–49. IEEE (2021)

Kochkov, D., Smith, J.A., Aliyeva, A., Wang, Q., Brenner, M.P., Hoyer, S.: Machine learning–accelerated computational fluid dynamics. PNAS 118(21), e2101784118 (2021)

Sadrehaghighi, I.: Artificial intelligence (AI) and deep learning for CFD. Technical Report on ResearchGate. https://doi.org/10.13140/RG.2.2.22298.59847/2

Panwar, V., Vandrangi, S.K., Emani, S.: Artificial intelligence-based computational fluid dynamics approaches. Hybrid Comput. Intell. 8, 173–190 (2020)

Rojek, K., Wyrzykowski, R., Gepner, P.: AI-accelerated CFD simulation based on OpenFOAM and CPU/GPU computing. In: Paszynski, M., Kranzlmüller, D., Krzhizhanovskaya, V.V., Dongarra, J.J., Sloot, P.M.A. (eds.) Computational Science—ICCS 2021, pp. 373–385. Springer, Berlin (2021)

Chinesta, F., Cueto, E., Grmela, M., Moya, B., Pavelka, M., Sipka, M.: Learning physics from data: a thermodynamic interpretation. In: Barbaresco, F., Nielsen, F. (eds.) Geometric Structures of Statistical Physics, Information Geometry, and Learning, pp. 267–297. Springer, Berlin (2021)

Alfaro, I., Gonzalez, D., Zlotnik, S., Diez, P., Cueto, E., Chinesta, F.: An error estimator for real-time simulators based on model order reduction. Adv. Model. Simul. Eng. Sci 2, Article 30 (2015)

Ghnatios, C., El Haber, G., Duval, J.-L., Zoane, M., Chinesta, F.: Artificial intelligence based space reduction of structural nodels. SAFORM 2021 (2021)

Hernández, Q., Badias, A., Gonzalez, D., Chinesta, F., Cueto, E.: Deep learning of thermodynamics-aware reduced-order models from data. Comput. Methods Appl. Mech. Eng. 379(4), 113763 (2021)

Hamzi, B., Owhadi, H.: Learning dynamical systems from data: a simple cross-validation perspective, part I: Parametric kernel flows. Physica D 421(3), 132817 (2021)

Pengzhan, L. et al.: Learning nonlinear operators via DeepONet based on the universal approximation theorem of operators, nature research. Nature Mach. Intell. 3(3), 218–229 (2021). https://doi.org/10.1038/s42256-021-00302-5

Sancarlos, A., Cameron, M., Le Peuvedic, J.-M., Groulier, J., Duval, J.-L., Cueto, E., Chinesta, F.: Learning stable reduced-order models for hybrid twins. ResearchGate (2021). https://doi.org/10.1017/dce.2021.16

Champaney, V., Sancarlos, A., Chinesta, F., Cueto, E., Gonzalez, D., Alfaro, I., Guevelou, S., Duvalm J. L., Chambard, A., Mourguew P.: Hybrid twins—a highway towards a performance-based engineering. Part I: Advanced model order reduction enabling real-time Physics. ESAFORM 2021 (2021)

Cueto, E., Gonzalez, D., Badias, A., Chinesta, F., Hascoet, N., Duval, J.-L.: Hybrid Twins. Part II. Real-time, data-driven modeling. ESAFORM 2021 (2021)

Moya, B., Badias, A., Alfaro, I, Chinesta, F., Cueto, E.: Digital twins that learn and correct themselves. Int. J. Numer. Methods Eng., 1–11 (2020)

Abali, B.E., Savaş, Ö.: Experimental validation of computational fluid dynamics for solving isothermal and incompressible viscous fluid flow. SN Appl. Sci. 2, 1500 (2020)

ANSYS Fluent 18.0, Theory Guide, www.ansys.com

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Diederich, M., Di Bartolo, L., Benim, A.C. (2023). Comparison of Prediction Accuracy Between Interpolation and Artificial Intelligence Application of CFD Data for 3D Cavity Flow. In: Sharma, R.K., Pareschi, L., Atangana, A., Sahoo, B., Kukreja, V.K. (eds) Frontiers in Industrial and Applied Mathematics. FIAM 2021. Springer Proceedings in Mathematics & Statistics, vol 410. Springer, Singapore. https://doi.org/10.1007/978-981-19-7272-0_35

Download citation

DOI: https://doi.org/10.1007/978-981-19-7272-0_35

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7271-3

Online ISBN: 978-981-19-7272-0

eBook Packages: Mathematics and StatisticsMathematics and Statistics (R0)