Abstract

Rotating machines are commonly used mechanical equipment in various industrial applications. These machines are subjected to dynamic and harsh operating conditions over a long time leading to various types of mechanical failures, thereby resulting in undesirable downtime. Consequently, research on fault diagnosis is practically significant to enhance the safety of machinery. Over the years, several fault diagnosis methods have been developed for rotating machines. Of these, artificial intelligence-based diagnosis methods have gained increasing attention due to their reliability, robustness in performance, and capability for adaptation. However, the selection of suitable artificial intelligence methods for specific types of faults or machines is still dependent on the experience of users. The recent research achievements in intelligent fault diagnosis are not reviewed, and future research directions are not clearly stated. To fill these gaps, this paper provides a review of artificial intelligence techniques applied for fault diagnosis of rotating machines, with a special emphasis given to deep learning methods published in the last five years (2017–2022). The research challenges and some possible prospects in this field are discussed to provide valuable guidelines for future research development. The present work can be extended to review the applications of transfer learning for fault diagnosis of rotating machines.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In modern industrial systems, there is an increasing trend toward the need for more reliable machines. Rotating machines are commonly used mechanical equipment in various industrial applications. They accounts for more than 90% of industrial machines [1]. As these machines usually operate under dynamic and harsh conditions for a long time, they often suffer from various types of mechanical failures. Any type of failure in rotating machines, even minor failure, cannot be accepted as it can significantly affect the entire system, and can even lead to undesirable downtime, huge economic losses and serious safety problems [2, 3]. Consequently, research on fault diagnosis is practically significant to enhance the reliability of machines, reduce economic losses, and avoid safety problems [4, 5].

Over the last decades, numerous methods have been presented to diagnose the faults of rotating machines. These methods fall into three broad classes: model-based methods, statistical methods, and artificial intelligence-based methods [6]. Model-based methods are formed based on the physical characteristics of a monitored machine with the necessary assumptions to establish an explicit mathematical model [7]. However, it is challenging to establish an exact mathematical model for complex systems [8]. The high complexity of industrial faults and the cost of model-based methods limit their applicability in fault diagnosis of machines. Statistical methods assume that historical data can be used to establish the fault modes and the future mechanism of machine failure [9]. However, this assumption might not hold in practical scenarios because the failure mechanisms of machines are complex, nonlinear, and involve the coupling of different physical processes. Nowadays, artificial intelligence-based fault diagnosis methods are the focus of academic and industrial research for overcoming the problems in the fault diagnosis of complex industrial machines [10]. The primary reason is that artificial intelligence methods are instrumental if they can be improved as compared with other methods. Artificial intelligence can be easily extended and modified. These methods can also be made adaptive by integrating new data [11].

Motivated by the advantages of artificial intelligence methods, intelligent fault diagnosis methods have gained great attention in recent decades. Therefore, this paper provides a review of artificial intelligence methods applied for fault diagnosis of rotating machines, with a special emphasis given to deep learning methods published from 2017 to 2022. This paper analyzes the strengths and weaknesses of each method, so as to give valuable guidance for researchers in selecting an appropriate intelligent method for specific applications instead of choosing randomly. The research challenges in this field are also discussed to provide possible research directions for further exploration.

The remainder of this paper is organized as follows. Section 2 provides a general overview of intelligent fault diagnosis of rotating machines. Section 3 presents a detailed review of the applications of deep learning methods in the fault diagnosis of rotating machines. Section 4 discusses the observations of the review, research challenges, and future direction in this area. Finally, conclusions are drawn in Sect. 5.

2 Overview of Intelligent Fault Diagnosis of Rotating Machines

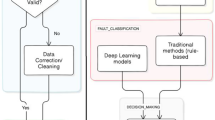

In the last decades, traditional machine learning methods have been widely applied in the intelligent fault diagnosis of rotating machines. These methods mainly comprise three consecutive steps: data acquisition, feature extraction, and fault classification [12, 13]. In the data acquisition stage, a variety of signals such as vibration, acoustic emission, noise, temperature, etc., are acquired from target machines by sensor systems [14]. In the feature extraction stage, fault-sensitive information from sensor signals is manually extracted using different types of signal processing methods [15]. Such processes rely too much on the step of feature extraction, which requires prior signal processing knowledge and diagnosis experience [16, 17]. Finally, the extracted features are fed into the traditional machine learning methods for classification [18, 19]. However, the traditional machine learning methods are designed for specific types of faults or machines and therefore are case dependent and not used for general applications [20]. Moreover, these methods are not efficient for processing high-dimension data [21]. In general, traditional intelligent diagnosis methods have low diagnosis performance for machines that operate under adverse and complex conditions [22]. These reasons can seriously restrict the applicability of traditional machine learning methods for rotating machine fault diagnosis.

Recently, deep learning methods have received great interest and achieved significant successes in machine fault diagnosis, which overcomes the limitations of traditional machine learning methods [23, 24]. Deep learning-based fault diagnosis methods can extract the learnable features from large amounts of sensor data directly by constructing deep network architecture with multiple layers of linear and non-linear transformations and performs an end-to-end fault diagnosis [25, 26]. In the following section, the most common deep learning methods have been discussed.

3 Deep Learning Methods in Fault Diagnosis of Rotating Machines

This section reviews the applications of the most common deep learning methods and their corresponding variants in fault diagnosis of rotating machines.

3.1 Convolutional Neural Network (CNN)

Convolutional neural network (CNN) is a biologically inspired feed-forward neural network used to extract local features from the raw sensor data to perform classification [27]. The typical convolutional neural network model consists of multiple hidden layers, namely, the convolution layer, pooling layer, and fully connected layer [28]. The convolution layer is composed of a series of learnable filters (also known as kernels) that can extract different features of input data to generate new feature maps as the input to the next layer. The pooling layer is the down-sampling layer which decreases the size of the input and the number of parameters, and thus it can decrease the number of computations and prevent overfitting. The fully connected layer is used to compute the class scores [29].

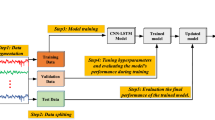

Convolutional neural network (CNN) was originally designed for processing two-dimensional (2D) or three-dimensional (3D) input data such as images and video frames [30]. The traditional CNN is not suitable for fault diagnosis of mechanical equipment since most measured signals are one-dimensional (1D) signals. Thus, the input 1D data needs to be converted into 2D data through some methods to complete the feature extraction and classification [31]. Studies by [32, 33] proposed CNN-based fault diagnosis methods by converting the original 1D signals into 2D images for different machine diagnosis tasks. However, the process of converting the original signal is time-consuming, and may certainly cause the loss of faulty data. The emergence of a one-dimensional convolutional neural network (1D-CNN) provides a feasible solution to avoid the above problems. Compared with 2D-CNN, 1D-CNN has a simpler and more compact network structure, and it can effectively diagnose the faults of machines with limited training data. Using one-dimensional vibration signals as input data, researchers often utilize a 1D-CNN to diagnose the faults of different rotating machine components, such as bearings [12, 20, 34], automobile engines [35], and gearboxes [36]. Abdeljaber et al. [37] used a one-dimensional convolutional neural network (1D-CNN) for structural damage detection based on vibration signals. Yin et al. [38] combined 1D-CNN with self-normalizing neural networks (SNN) to improve the diagnosis accuracy and generalization capability of rotating machine fault diagnosis.

Many researchers have made significant efforts on developing novel CNN-based models and have achieved considerable progress. Jia et al. [39] developed a deep normalized CNN for imbalanced fault classification of machines from mechanical vibration signals. In [40, 41], an adaptive deep CNN model was to diagnose the faults of rolling bearings. Kolar et al. [42] proposed a multi-channels deep CNN model for rotary machine fault diagnosis from the raw vibration data. Sun et al. [43] presented a convolutional discriminative feature learning (CDFL) approach to diagnose the faults of the motor. Dilated CNN methods have been used for bearing fault diagnosis from raw vibration signals [44, 45]. Liu [46] developed a dislocated time series CNN to diagnose the faults of an induction motors. Zhang et al. [47] utilized a CNN model with wide first-layer kernels for rolling bearing fault diagnosis using one-dimensional vibration data. Chen et al. [48] developed a novel deep capsule network with stochastic delta rule (DCN-SDR) for rolling bearing fault diagnosis. Ye and Yu [49] proposed a deep morphological CNN for fault diagnosis of the gearbox. Wang et al. [50] developed a novel multiple-input, multiple-task CNN method for roller bearing fault diagnosis. Studies [51,52,53] proposed a hierarchical convolutional neural network (HCCN) for fault diagnosis of different rotating machine components. Zhang et al. [54] developed an intelligent method based on multi-level information fusion and hierarchical adaptive CNN to diagnose the faults of centrifugal blowers. Jiang et al. [55] developed a multiscale convolutional neural network (MSCNN) for fault diagnosis of wind turbine gearboxes. Wang et al. [56] proposed a cascade CNN with progressive optimization for motor fault diagnosis under dynamic working conditions.

3.2 Recurrent Neural Network (RNN)

Recurrent neural network (RNN) is the deepest neural network with both feedforward connections and internal feedback connections between network layers. Varying from feedforward neural networks like CNN, RNN can exploit temporal information from multiple sequential data because of its internal memory. Neurons of RNN can not only receive information from other neurons but also receive their information to form a network structure with loops. RNN has more advantages in exploiting temporal information. Thus, it has been widely utilized in machine fault diagnosis. Hu et al. [57] utilized an improved deep RNN for rotating machine fault diagnosis. Huang et al. [58] proposed the RNN-based variational auto-encoder (VAE) for motor fault detection. However, RNN has gradient vanishing and exploding problems, thus it has inherent limitations in capturing long-term information [59, 60]. To overcome the limitations of the recurrent neural network, researchers have proposed long short-term memory (LSTM) [61], gated recurrent unit (GRU), and other improved RNN models.

As an improved recurrent neural network, LSTM resolves the problems of gradient vanishing and exploding, and captures long-term dependencies and nonlinear dynamics of time series data [62]. As a result, the LSTM model with memory function has gained increasing attention in machine fault diagnosis. For instance, Yin et al. [63] developed an optimized fault diagnosis method based on the cosine loss LSTM neural network for the wind turbine gearbox. Yang et al. [64] developed an improved long short-term memory model to diagnose the faults of electromechanical actuators. However, LSTM cannot make full use of data since it can only process data in one direction [65]. Furthermore, unidirectional LSTM has a relatively high network complexity, thus the training process takes a long time [66]. Bi-directional LSTM is an improvement of LSTM that can address the limitations of unidirectional LSTM. Bi-directional LSTM can extract features from both forward and backward directions. Cao et al. [67] developed a novel intelligent method based on deep bi-directional LSTM diagnose the faults of wind turbine gearboxes. Han et al. [68] combined Bi-LSTM and a Capsule Network with a CNN for rotating machine fault diagnosis. The bi-directional LSTM was used to complete the feature denoising and fusion, which was extracted by a convolutional neural network and used a capsule network to achieve the fault diagnosis for insufficient training data. Li et al. [69] utilized Bi-LSTM to detect the faults of rolling bearings. Thus, Bi-LSTM has higher diagnosis accuracy and efficiency than unidirectional LSTM.

Compared with the LSTM model, a gated recurrent unit (GRU) can better handle large training data with a simple network structure and fewer parameters, thus it greatly reduces the calculation efficiency [70]. Liu et al. [71] utilized a GRU to diagnose the faults of rolling bearings. Tao et al. [72] utilized a multilayer GRU method for fault diagnosis of spur gear from vibration signals. To verify its superiority, the proposed method was compared with LSTM, multilayer LSTM, and support vector machine (SVM). Besides the most basic GRU structure, Bidirectional GRU (Bi-GRU) has also been employed for fault diagnosis. Bi-GRU can learn information from both forward and backward directions of the input data at the same time. For this reason, Lv et al. [73] proposed a new heterogeneous Bi-GRU method based on fusion health indicators. Zhao et al. [74] utilized a local feature-based GRU network for bearing fault diagnosis. This method used an enhanced bi-directional gated recurrent unit to extract high-level features from vibration data.

Recurrent neural network and its improvement have also been combined with other machine learning methods. Fu et al. [75] combined a CNN with a LSTM to monitor and warn of the fault of wind turbine gearbox bearing using temperature data. Zhao et al. [76] also combined bi-directional LSTM with CNN to address tool wear prediction tasks. In this study, convolutional neural network was used to extract local features from the sequential input, and bi-directional long short-term memory was used to encode the temporal information. Qiao et al. [77] combined a deep CNN with LSTM to complete an end-to-end bearing fault diagnosis under variable loads and different noise interferences. Liao et al. [78] developed a fault diagnosis method for hydroelectric generating units based on one-dimensional convolutional neural network and GRU from the raw vibration signal collected under different operational conditions.

3.3 Generative Adversarial Network (GAN)

In practical engineering scenarios, the faulty data collected from the target machine is usually more limited than the normal data, i.e., the model training data is highly imbalanced. The deep learning method trained with imbalanced data is prone to poor generalization performance. The generative adversarial network is a well-known data generative model inspired by the game theory that can address the data imbalance problem [79]. The generative adversarial network (GAN) model is mainly composed of a Generator and a Discriminator [80]. The generator receives the original data to generate new data that have a similar distribution to the real data, thus expanding the training dataset. The generated new data are imported to the discriminator with the original data to predict whether the input data are real or false data [81]. As a result, GAN has been successfully employed to fault diagnosis. For instance, Liu et al. [82] developed a fault diagnosis method based on global optimization generative adversarial network to solve the unbalanced data problem of rolling bearings. Ding et al. [83] proposed a novel fault diagnosis method for rotating machines based on GAN, and validated the effectiveness through small sample rolling bearing and gearbox datasets.

Recently, researchers have made many improvements and developed a wide variety of generative adversarial network variants. For instance, Yan et al. [84] developed a fault detection and diagnosis method that utilizes the conditional Wasserstein GAN to overcome the imbalanced data problem for air handling units. Zheng et al. [85] proposed a conditional GAN model with a dual discriminator for imbalanced rolling bearing fault diagnosis. Studies by [86,87,88,89] used a deep convolutional GAN for fault diagnosis of rotating machines with imbalanced data. Luo et al. [90] utilized a conditional deep convolutional GAN to address the data imbalance problem in machine fault diagnosis. Shao et al. [91] utilized an auxiliary classifier GAN to generate fake sensor signals to solve unbalanced fault data problems and diagnose the faults of the induction motor. Xiong et al. [92] utilized a Wasserstein gradient-penalty GAN with a deep auto-encoder (DAE) to diagnose the faults of rolling bearing. However, Wasserstein gradient-penalty GAN has the shortcomings of vanishing gradient and mode collapse. As a result, Li et al. [93] proposed a rotating machine fault diagnosis model based on a deep Wasserstein GAN with gradient penalty for the imbalanced data problem. Zareapoor et al. [94] developed a new model named Minority oversampling GAN for class-imbalanced fault diagnosis. Zi et al. [95] proposed a novel multitask redundant lifting adversarial network (MRLAN), and the results confirm its satisfactory performance under sharp speed fluctuation and little data. Liu et al. [96] developed a variational auto-encoding GAN model with deep regret analysis for bearing fault diagnosis. The study by [97] combined an auxiliary classifier GAN with a stacked denoising auto-encoder for fault diagnosis of rolling bearing. Liu et al. [98] proposed a categorical adversarial auto-encoder (CatAAE) for fault diagnosis of rolling bearings under different working conditions and achieved satisfactory performance and high clustering indicators even in different working conditions.

While GAN and its extensions have yielded certain success for the imbalanced training dataset problem, there are still some practical problems that need further exploration. For example, sometimes GAN generates no reasonable data due to the lack of auxiliary information in the deep features of input data. Besides, to create sufficient fault data, a generative adversarial network consumes a huge computing resources and takes a long training time. Consequently, it is practically significant to develop novel fault diagnosis methods based on GAN to overcome these real problems.

3.4 Auto-Encoder (AE)

Auto-encoder (AE) is an unsupervised feed-forward neural network that uses a backpropagation algorithm to learn discriminative features in an unsupervised manner by minimizing reconstruction error between the input data and the output data [99, 100]. The typical AE consists of the input layer, hidden layer, and output layer. The input and hidden layers form the encoder network, whereas the hidden and output layers form the decoder network [101]. The encoder transforms the high-dimensional input data into low-dimensional hidden features and the decoder reconstructs the input data from the learned hidden features [102].

Compared with supervised deep learning methods like CNN and RNN, the auto-encoder possesses the properties of unsupervised learning, high-efficiency training, simple structure, and easy implementation. As a result, auto-encoders had been applied for fault diagnosis of bearings [103], electric motors [104, 105], turbines [106], and other components. However, the standard auto-encoder (AE) has limited feature extraction capability for fault diagnosis tasks due to the lack of label data [107]. Moreover, in most practical situations, the measured signals are always polluted by heavy background noises, which decreases the performance of the standard auto-encoder. To overcome the aforementioned challenges, several variants of the auto-encoder have been introduced into rotating machine fault diagnosis. The common variants are denoising auto-encoder (DAE), sparse auto-encoder (SAE), contractive auto-encoder (CAE), and variational auto-encoder (VAE) [108]. The AE, DAE, SAE, and CAE can be stacked to extract deep features with better representative ability, which are named stacked auto-encoder (SAE), stacked denoising auto-encoder (SDAE), stacked sparse auto-encoder (SSAE), and stacked contractive auto-encoder (SCAE), respectively. The following subsection reviews their applications in machine fault diagnosis.

Stacked Auto-Encoder (SAE).

The structure of the stacked auto-encoder (SAE) is composed of multiple auto-encoders stacked that can extract more implicit features from high-dimensional complex data and reduce the dimensionality of input data than a single auto-encoder [109]. In SAE, the output of the formerly hidden layer is used as the input to the next hidden layer [110]. Since SAE is an unsupervised learning method, it cannot be directly employed for machine fault diagnosis. Consequently, a classification layer is usually added at the end of the network structure of the model. In this context, Liu et al. [111] proposed a stacked auto-encoder (SAE) based deep learning method for gearbox fault diagnosis. Studies by [112, 113] utilized SAE to develop new methods for fault diagnosis of roller bearings. Karamti et al. [114] developed a fault diagnosis method based on stacked auto-encoders for diagnosing rotating system faults with imbalanced samples. An et al. [115] developed a batch-normalized stacked auto-encoder method for intelligent fault diagnosis of rotating machines. The effectiveness of this method was validated through motor bearing and gearbox datasets. Shao et al. [116] also proposed an improved SAE to diagnose the faults of rotating machines, and its effectiveness was validated through sun gear and roller bearing datasets.

Denoising Auto-Encoder (DAE).

The denoising auto-encoder (DAE) is an AE obtained by adding noise to the input data with some statistical characteristics to increase the anti-noise capability [117]. DAE can automatically extract robust features from corrupted and partially destroyed data, so it is more suitable for fault diagnosis of different rotating machines. For instance, studies by [118, 119] employed a DAE to diagnose the faults of rolling bearings. Lu et al. [120] applied the stacked denoising auto-encoder (SDAE) for rolling bearing fault diagnosis. Zhao et al. [121] developed a deep learning method using a SDAE for motor fault diagnosis. Chen and Li [122] applied a deep neural network based on a SDAE to diagnose the faults of the rotor system. J. Yu [123] proposed a manifold regularized SDAE (MRSDAE) for planetary gearbox vibration signals. Zhan et al. [124] also utilized a SDAE combined with a SVM classifier for a permanent magnet synchronous motor used in an electric vehicle. Xu et al. [125] proposed an intelligent fault diagnosis method for metro traction motor bearings based on an improved SDAE. Xiao et al. [126] proposed a noisy domain adaptive marginal SDA for fault diagnosis of gear and motor using acoustic signals. Godói et al. [127] proposed a new denoising convolutional AE method configuration employed to the condition monitoring of rotating machines. Zhao et al. [128] combined a one-dimensional denoising convolutional auto-encoder (DCAE) with a 1D-CNN for rotating machine fault diagnosis under noisy environments. Although DAE can extract robust features and achieve remarkable results in fault diagnosis, it takes more time to select the most suitable corruption level and corrupt the input data into corrupted inputs of the DAE. Moreover, the extracted features by DAE may consist of some useless features for fault diagnosis.

Sparse Auto-Encoder (SAE).

As an extension of AE, the sparse auto-encoder (SAE) is a widely used auto-encoder that introduces the sparse penalty term, adding constraints to the hidden layer for a concise expression of the input data [129]. Compared with other deep learning methods, SAE is superior in extracting sparser features, highly discriminative, and useful for classification. As a result, many researchers have widely used SAE for fault diagnosis of rotating machines. For instance, Xin et al. [130] combined a sparse auto-encoder with softmax regression to diagnose the fault of the attachment on the blades of the marine current turbine. Zhao et al. [131] proposed a semi-supervised deep SAE with local and non-local information for fault diagnosis of rotating machines. Kim et al. [132] utilized a sparse SAE to develop a new fault diagnosis method for the gearbox. Qi et al. [133] developed an intelligent fault diagnosis method based on a SSAE, and its effectiveness was validated through rolling bearing and gearbox vibration datasets. Sun et al. [101] developed a novel intelligent diagnosis method of automatic feature learning and classification of rotating machines based on SSAE. Studies by [134,135,136,137] proposed new fault diagnosis methods based on sparse stacked denoising AE for bearing fault diagnosis. Zhang et al. [138] also developed a stacked pruning sparse denoising AE method for rolling bearing fault diagnosis. Wen et al. [139] proposed a new fault diagnosis method based on stack pruning sparse denoising auto-encoder and CNN to detect and categorized the actuator damage fault of the unmanned aerial vehicle, and showed good fault diagnosis accuracy in an actual high noise environment. Jia et al. [140] developed a local connection network (LCN) constructed by normalized sparse autoencoder (NSAE) for fault diagnosis of rotating machines. The superiority of the proposed NSAE-LCN was verified using gearbox and bearing datasets. However, the accuracy and generalization ability of sparse stacked auto-encoder is affected by its hyperparameter settings and there is no clear rule for determining the optimal hyperparameter values, which heavily depends on experimental experience. Moreover, the standard learning method employed in sparse stacked auto-encoder is time-consuming.

Contractive Auto-Encoder (CAE).

The contractive auto-encoder (CAE) is a well-known AE variant that can automatically learn more robust features and is thus suitable for dealing with noise-overwhelmed signals. The robustness of the data description is obtained by adding a contractive penalty to the error function of the reconstruction. This penalty is used for penalizing the attribute sensitivity in the input variations. CAE can handle noisy data without knowing noise intensity and has been applied successfully for robust feature extraction and fault classification. Qi et al. [141] proposed a new deep fusion network that combined the SSAE and CAE for fault diagnosis of bearing and gearbox. Fu et al. [142] also proposed a deep contractive auto-encoding network (DCAEN) for fault diagnosis of bearing. Shen et al. [143] applied a stacked contractive auto-encoder (SCAE) for feature extraction and fault diagnosis of rotating machines. Gao et al. [144] proposed a new ensemble deep CAE method for machine fault diagnosis under noisy environments. The effectiveness proposed method was verified using bearing, gearbox, and self-priming centrifugal pump datasets. However, CAE still has higher reconstruction errors during the encoding and decoding process of input features to the network that cause difficulty to capture the useful information within the feature space.

Variational Auto-Encoder (VAE).

As a generation model, variational auto-encoder (VAE) can augment the dataset by generating meaningful synthetic data similar to the original real data and has been successfully employed in fault diagnosis of different rotating machines [145]. In [146,147,148], a variational auto-encoder has been employed to create fault data of bearings. Sun et al. [149] developed a novel fault diagnosis method called conditional variational auto-encoder generative adversarial network for planetary gearboxes to solve small sample problems. However, the data augmented by the variational auto-encoder is not always real data. Thus, how to make the data samples generated by variational auto-encoder more real is still a challenge that requires further exploration.

3.5 Deep Belief Network (DBN)

Deep belief network (DBN) is a probability generation model composed of several layers of restricted Boltzmann machines (RBMs), where the output of the previously hidden layer is utilized as the input of the next layer [150] and the last layer is the backpropagation neural network. The training process of DBN comprises two stages: forward unsupervised greedy layer-by-layer pre-training and backward supervised fine-tuning process. The forward pre-training phase is an unsupervised training process that aims to extract features from bottom to top layer-by-layer. After the pre-training of multiple RBMs, the fine-tuning phase is then utilized with a backpropagation algorithm to optimize the parameters and structure of the pre-trained network to further enhance the classification accuracy. In fine-tuning, the weights and biases of every layer are updated continuously until the iteration reaches the limit [151].

Since deep belief network (DBN) is suitable for processing one-dimensional data, its applications in fault diagnosis are reported frequently. For instance, Shang et al. [152] proposed a diagnosis method based on DBN for rolling bearings, which reduces the complicated network structure to some extent. Qin et al. [153] proposed a new fault diagnosis method using a DBN for planetary gearboxes of wind turbines. Yan et al. [154] also proposed a rotor unbalance fault diagnosis method using a multi-deep belief network model with multi-sensor information. Han et al. [155] combined the DBN model with wavelet packet energy entropy and multi-scale permutation entropy to diagnose gear faults. The authors of [156] proposed a new condition monitoring method for rolling bearings by using the DBN model optimized by the multi-order fractional Fourier transform filtering algorithm and the sparrow search algorithm. Zhang et al. [157] applied a DBN algorithm to diagnose the fault of the power system, and enhanced the ability of feature extraction and fault classification by enhancing the network model. Yu et al. [158] proposed a novel fault diagnosis method by hybridizing DBN with Dempster-Shafer theory for diagnosing the wind turbine system.

The performance of deep belief networks in machine fault diagnosis depends heavily on their structure. To obtain an optimal network structure with high performance and training speed, researchers utilized various optimization techniques. In the literature [159, 160], the network structure and learning rate of DBN were optimized by using the PSO algorithm, and the diagnosis accuracy was improved. Wen et al. [161] combined the deep belief network with a fuzzy mean clustering algorithm for rolling bearing fault diagnosis without using data labels. Gao et al. [162] optimized the network architecture of a deep belief network using a salp swarm algorithm and utilized it for rolling bearing fault diagnosis. Similarly, Kamada et al. [163] used the neuron generation annihilation and layer generation algorithm to propose the adaptive structure learning method of restricted Boltzmann machine and deep belief network, and achieved remarkable success. Shen et al. [164] developed an improved hierarchical adaptive DBN optimized by Nesterov momentum (NM) for bearing fault diagnosis.

4 Discussion, Existing Challenges and Future Directions

As seen from the review provided, traditional machine learning methods and deep learning methods are widely applied in intelligent machine fault diagnosis. Intelligent fault diagnosis methods based on traditional machine learning have been widely investigated in the field of fault diagnosis of rotating machines, but they have limitations in processing massive amounts of data as useful features are extracted manually with prior expert experience. Different from traditional machine learning methods, deep learning methods can extract abstract features from massive and heterogeneous mechanical signals with the help of their multilayer nonlinear mapping ability to perform an end-to-end fault diagnosis. Table 1 reveals the strengths and weaknesses of deep learning methods applied in fault diagnosis of industrial machines.

Although deep learning methods have achieved tremendous success in fault diagnosis, there are still some practical problems that need further exploration.

-

1.

Most existing deep learning methods often need a sufficient amount of labeled data for model training, which achieves great results in laboratory experiments since there is sufficient labeled data. However, it is hard to acquire massive data or even impossible in practical industrial scenarios as most machines operate in healthy conditions.

-

2.

Existing deep learning methods can recognize faults accurately with the assumption that the training dataset and the testing dataset are drawn from the same machine under the same working conditions. This assumption may not hold in many real cases due to variations in machine working conditions, interference of environmental noise, etc., which leads to significant diagnosis performance deterioration.

-

3.

In practical industrial applications, the collected sensor signals from rotating machines are usually polluted by various forms of noise, thereby reducing the performance of the existing fault diagnosis methods.

-

4.

For long-term monitoring, it is essential to achieve early fault detection of rotating machines. However, in real practice, it is quite difficult to realize the faults at the earliest stage due to the weakness of impulse signals and the interference of environmental noise.

-

5.

Furthermore, rotating machines operate for a long time under changeable conditions, and compound faults may occur simultaneously. Not only this, multiple rotating machine components may fail at a time. Most existing studies have ignored the existence of simultaneous fault problems.

Therefore, it is of great significance to resolve these practical problems and advance intelligent diagnosis methods for promising employment in modern industrial applications. The following are some possible research directions given to researchers, readers, and engineers who aim to contribute to the advancement of artificial intelligence in the fault diagnosis of rotating machines.

Active research area toward promising results.

-

1.

The emergence of transfer learning provides a feasible solution to overcome the abovementioned gaps. Different from deep learning, transfer learning targets to extract knowledge obtained in the source domain and transfer it to resolve a different but similar problem in another domain task. Therefore, transfer learning is becoming an active research area in the field of intelligent machine fault diagnosis.

-

2.

Based on the review provided, some deep learning methods have strong feature extraction capabilities and others have limitations in fault classification. To break the limitation of a single method, researchers still have great possibilities to propose hybrid deep learning-based fault diagnosis methods for rotating machines.

5 Conclusions

This paper reviewed the applications of artificial intelligence methods for the diagnosis of the faults of rotating machines. The observations, research gaps, and some new research prospects in this research area are discussed. From the review, it is concluded that deep learning methods have better feature learning ability, better adaptability, and a more flexible network structure as compared with conventional machine learning methods. However, their applicability in fault diagnosis is highly restricted by the amount and quality of the training data, the variation of operating conditions, the disturbance of background noise, the weakness of early failure detection, and the occurrence of hidden simultaneous faults. To address these limitations, transfer learning is becoming a hot research topic in machine fault diagnosis. In addition, new intelligent diagnosis methods are needed to be able to combine the advantages of both methods in the future. In the future, the authors will continue to review the applications of transfer learning for the diagnosis of faults of rotating machines.

References

Han, T., Zhang, L., Yin, Z., Tan, A.C.C.: Rolling bearing fault diagnosis with combined convolutional neural networks and support vector machine. Measurement 177, 109022 (2021). https://doi.org/10.1016/j.measurement.2021.109022

Liang, P., Deng, C., Wub, J., Yang, Z.: Intelligent fault diagnosis of rotating machinery via wavelet transform, generative adversarial nets and convolutional neural network. Meas. J. Int. Meas. Confed. 159, 107768 (2020). https://doi.org/10.1016/j.measurement.2020.107768

Youcef Khodja, A., Guersi, N., Saadi, M.N., Boutasseta, N.: Rolling element bearing fault diagnosis for rotating machinery using vibration spectrum imaging and convolutional neural networks. Int. J. Adv. Manuf. Technol. 106(5–6), 1737–1751 (2019). https://doi.org/10.1007/s00170-019-04726-7

AlShorman, O., et al.: Sounds and acoustic emission-based early fault diagnosis of induction motor: a review study. Adv. Mech. Eng. 13(2), 1–19 (2021). https://doi.org/10.1177/1687814021996915

Eren, L., Ince, T., Kiranyaz, S.: A generic intelligent bearing fault diagnosis system using compact adaptive 1D CNN classifier. J. Signal Process. Syst. 91(2), 179–189 (2018). https://doi.org/10.1007/s11265-018-1378-3

You, D., et al.: Intelligent fault diagnosis of bearing based on convolutional neural network and bidirectional long short-term memory. Shock Vib. 2021, 1–12 (2021). https://doi.org/10.1155/2021/7346352

Zhang, Y., et al.: A simultaneous fault diagnosis method based on cohesion evaluation and improved BP-MLL for rotating machinery. Shock Vib. 2021, 1–12 (2021). https://doi.org/10.1155/2021/7469691

Lee, J.-H., Pack, J.-H., Lee, I.-S.: Fault Diagnosis of induction motor using convolutional neural network. Appl. Sci. 9(15), 2950 (2019). https://doi.org/10.3390/app9152950

Wen, L., Li, X., Gao, L., Zhang, Y.: A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 65(7), 5990–5998 (2018). https://doi.org/10.1109/TIE.2017.2774777

Cheng, Y., Lin, M., Wu, J., Zhu, H., Shao, X.: Intelligent fault diagnosis of rotating machinery based on continuous wavelet transform-local binary convolutional neural network. Knowledge-Based Syst. 216, 106796 (2021). https://doi.org/10.1016/j.knosys.2021.106796

Siddique, A., Yadava, G.S., Singh, B.: Applications of artificial intelligence techniques for induction machine stator fault diagnostics: review. In: IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, SDEMPED 2003 - Proceedings, pp. 29–34 (2003). https://doi.org/10.1109/DEMPED.2003.1234543

Peng, D., Liu, Z., Wang, H., Qin, Y., Jia, L.: A novel deeper one-dimensional CNN with residual learning for fault diagnosis of wheelset bearings in high-speed trains. IEEE Access 7, 10278–12093 (2019). https://doi.org/10.1109/ACCESS.2018.2888842

Jiang, H., Li, X., Shao, H., Zhao, K.: Intelligent fault diagnosis of rolling bearings using an improved deep recurrent neural network. Meas. Sci. Technol. 29(6), 065107 (2018). https://doi.org/10.1088/1361-6501/aab945

Tiboni, M., Remino, C., Bussola, R., Amici, C.: A review on vibration-based condition monitoring of rotating machinery. Appl. Sci. 12(3), 972 (2022). https://doi.org/10.3390/app12030972

Zhong, J., Kin, P., Yang, Z.: Fault diagnosis of rotating machinery based on multiple probabilistic classifiers. Mech. Syst. Signal Process. 108, 99–114 (2018). https://doi.org/10.1016/j.ymssp.2018.02.009

Long, Y., Zhou, W., Luo, Y.: A fault diagnosis method based on one-dimensional data enhancement and convolutional neural network. Meas. J. Int. Meas. Confed. 180, 109532 (2021). https://doi.org/10.1016/j.measurement.2021.109532

Chen, Z., Mauricio, A., Li, W., Gryllias, K.: A deep learning method for bearing fault diagnosis based on cyclic spectral coherence and convolutional neural networks. Mech. Syst. Signal Process. 140, 106683 (2020). https://doi.org/10.1016/j.ymssp.2020.106683

Gundewar, S.K., Kane, P.V.: Condition monitoring and fault diagnosis of induction motor. J. Vib. Eng. Technol. 9(4), 643–674 (2020). https://doi.org/10.1007/s42417-020-00253-y

Liang, C., Chen, C., Liu, Y., Jia, X.: A novel intelligent fault diagnosis method for rolling bearings based on compressed sensing and stacked multi-granularity convolution denoising auto-encoder. IEEE Access 9, 154777–154787 (2021). https://doi.org/10.1109/ACCESS.2021.3129061

Chen, C.C., Liu, Z., Yang, G., Wu, C.C., Ye, Q.: An improved fault diagnosis using 1d-convolutional neural network model. Electron. 10(1), 1–19 (2021). https://doi.org/10.3390/electronics10010059

Patil, S.S., Pardeshi, S.S., Patange, A.D., Jegadeeshwaran, R.: Deep learning algorithms for tool condition monitoring in milling: a review. J. Phys: Conf. Ser. 1969(1), 012039 (2021). https://doi.org/10.1088/1742-6596/1969/1/012039

Qiao, H., Wang, T., Wang, P., Zhang, L., Xu, M.: An adaptive weighted multiscale convolutional neural network for rotating machinery fault diagnosis under variable operating conditions. IEEE Access 7, 118954–118964 (2019). https://doi.org/10.1109/ACCESS.2019.2936625

Zhou, F., Sun, T., Hu, X., Wang, T., Wen, C.: A sparse denoising deep neural network for improving fault diagnosis performance. SIViP 15(8), 1889–1898 (2021). https://doi.org/10.1007/s11760-021-01939-w

Hoang, D.-T., Kang, H.-J.: Rolling element bearing fault diagnosis using convolutional neural network and vibration image. Cogn. Syst. Res. 53, 42–50 (2019). https://doi.org/10.1016/j.cogsys.2018.03.002

Inyang, U., Petrunin, I., Jennions, I.: Health condition estimation of bearings with multiple faults by a composite learning-based approach. Sensors 21(13), 4424 (2021). https://doi.org/10.3390/s21134424

Zhang, Y., Zhou, T., Huang, X., Cao, L., Zhou, Q.: Fault diagnosis of rotating machinery based on recurrent neural networks. Meas. J. Int. Meas. Confed. 171, 108774 (2021). https://doi.org/10.1016/j.measurement.2020.108774

Chen, Z., Gryllias, K., Li, W.: Mechanical fault diagnosis using convolutional neural networks and extreme learning machine. Mech. Syst. Signal Process. 133, 106272 (2019). https://doi.org/10.1016/j.ymssp.2019.106272

Kiranyaz, S., Avci, O., Abdeljaber, O., Ince, T., Gabbouj, M., Inman, D.J.: 1D convolutional neural networks and applications: a survey. Mech. Syst. Signal Process. 151, 107398 (2021). https://doi.org/10.1016/j.ymssp.2020.107398

Wang, Q., Zhao, B., Ma, H., Chang, J., Mao, G.: A method for rapidly evaluating reliability and predicting remaining useful life using two-dimensional convolutional neural network with signal conversion. J. Mech. Sci. Technol. 33(6), 2561–2571 (2019). https://doi.org/10.1007/s12206-019-0504-x

Wu, C., Jiang, P., Ding, C., Feng, F., Chen, T.: Intelligent fault diagnosis of rotating machinery based on one-dimensional convolutional neural network. Comput. Ind. 108, 53–61 (2019). https://doi.org/10.1016/j.compind.2018.12.001

Oh, J.W., Jeong, J.: Convolutional Neural Network and 2-D Image Based Fault Diagnosis of Bearing without Retraining. PervasiveHealth: Pervasive Computing Technologies for Healthcare, 134–138 (2019). https://doi.org/10.1145/3314545.3314563

Ding, X., He, Q.: Energy-fluctuated multiscale feature learning with deep ConvNet for intelligent spindle bearing fault diagnosis. IEEE Trans. Instrum. Meas. 66(8), 1926–1935 (2017). https://doi.org/10.1109/TIM.2017.2674738

Yuan, L., Lian, D., Kang, X., Chen, Y., Zhai, K.: Rolling bearing fault diagnosis based on convolutional neural network and support vector machine. IEEE Access 8, 137395–137406 (2020). https://doi.org/10.1109/ACCESS.2020.3012053

Wang, H., Liu, C., Du, W., Wang, S.: Intelligent diagnosis of rotating machinery based on optimized adaptive learning dictionary and 1DCNN. Appl. Sci. 11(23), 11325 (2021). https://doi.org/10.3390/app112311325

Du, C., et al.: Research on fault diagnosis of automobile engines based on the deep learning 1D-CNN method. Eng. Res. Express 4(1), 015003 (2022). https://doi.org/10.1088/2631-8695/ac4834

Qian, W., Li, S., Wang, J., An, Z., Jiang, X.: An intelligent fault diagnosis framework for raw vibration signals: adaptive overlapping convolutional neural network. Meas. Sci. Technol. 29(9), 095009 (2018). https://doi.org/10.1088/1361-6501/aad101

Abdeljaber, O., Avci, O., Kiranyaz, S., Gabbouj, M., Inman, D.J.: Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 383, 154–170 (2017). https://doi.org/10.1016/j.jsv.2016.10.043

Yang, J., Yin, S., Chang, Y., Gao, T.: A fault diagnosis method of rotating machinery based on one-dimensional, self-normalizing convolutional neural networks. Sensors 20(14), 3837 (2020). https://doi.org/10.3390/s20143837

Jia, F., Lei, Y., Lu, N., Xing, S.: Deep normalized convolutional neural network for imbalanced fault classification of machinery and its understanding via visualization. Mech. Syst. Signal Process. 110, 349–367 (2018). https://doi.org/10.1016/j.ymssp.2018.03.025

Fuan, W., Hongkai, J., Haidong, S., Wenjing, D., Shuaipeng, W.: An adaptive deep convolutional neural network for rolling bearing fault diagnosis. Meas. Sci. Technol. 28(9), 095005 (2017). https://doi.org/10.1088/1361-6501/aa6e22

Islam, M.M.M., Kim, J.M.: Automated bearing fault diagnosis scheme using 2D representation of wavelet packet transform and deep convolutional neural network. Comput. Ind. 106, 142–153 (2019). https://doi.org/10.1016/j.compind.2019.01.008

Kolar, D., Lisjak, D., Pająk, M., Pavković, D.: Fault diagnosis of rotary machines using deep convolutional neural network with wide three axis vibration signal input. Sensors 20(14), 4017 (2020). https://doi.org/10.3390/s20144017

Sun, W., Zhao, R., Yan, R., Shao, S., Chen, X.: Convolutional discriminative feature learning for induction motor fault diagnosis. IEEE Trans. Ind. Inform. 13(3), 1350–1359 (2017). https://doi.org/10.1109/TII.2017.2672988

Khan, M.A., Kim, Y.-H., Choo, J.: Intelligent fault detection using raw vibration signals via dilated convolutional neural networks. J. Supercomput. 76(10), 8086–8100 (2018). https://doi.org/10.1007/s11227-018-2711-0

Li, H., Zhang, Q., Qin, X., Yuantao, S.: Raw vibration signal pattern recognition with automatic hyper-parameter-optimized convolutional neural network for bearing fault diagnosis. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 234(1), 343–360 (2020). https://doi.org/10.1177/0954406219875756

Liu, R., Meng, G., Yang, B., Sun, C., Chen, X.: Dislocated time series convolutional neural architecture: an intelligent fault diagnosis approach for electric machine. IEEE Trans. Ind. Inform. 13(3), 1310–1320 (2017). https://doi.org/10.1109/TII.2016.2645238

Zhang, W., Peng, G., Li, C., Chen, Y., Zhang, Z.: A new deep learning model for fault diagnosis with good anti-noise and domain adaptation ability on raw vibration signals. Sensors 17(2), 425 (2017). https://doi.org/10.3390/s17020425

Chen, T., Wang, Z., Yang, X., Jiang, K.: A deep capsule neural network with stochastic delta rule for bearing fault diagnosis on raw vibration signals. Measurement 148, 106857 (2019). https://doi.org/10.1016/j.measurement.2019.106857

Ye, Z., Yu, J.: Deep morphological convolutional network for feature learning of vibration signals and its applications to gearbox fault diagnosis. Mech. Syst. Signal Process. 161, 107984 (2021). https://doi.org/10.1016/j.ymssp.2021.107984

Wang, Y., Yang, M., Li, Y., Xu, Z., Wang, J., Fang, X.: A multi-input and multi-task convolutional neural network for fault diagnosis based on bearing vibration signal. IEEE Sens. J. 21(9), 10946–10956 (2021). https://doi.org/10.1109/JSEN.2021.3061595

Lu, C., Wang, Z., Zhou, B.: Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv. Eng. Inform. 32, 139–151 (2017). https://doi.org/10.1016/j.aei.2017.02.005

Liu, Y.-Z., Zou, Y.-S., Jiang, Y.-L., Hui, Y., Ding, G.-F.: A novel method for diagnosis of bearing fault using hierarchical multitasks convolutional neural networks. Shock Vib. 2020, 1–14 (2020). https://doi.org/10.1155/2020/8846822

Yang, J., et al.: A hierarchical deep convolutional neural network and gated recurrent unit framework for structural damage detection. Inf. Sci. (Ny) 540, 117–130 (2020). https://doi.org/10.1016/j.ins.2020.05.090

Zhang, Y., Li, C., Wang, R., Qian, J.: A novel fault diagnosis method based on multi-level information fusion and hierarchical adaptive convolutional neural networks for centrifugal blowers. Meas. J. Int. Meas. Confed. 185, 109970 (2021). https://doi.org/10.1016/j.measurement.2021.109970

Jiang, G., He, H., Yan, J., Xie, P.: Multiscale convolutional neural networks for fault diagnosis of wind turbine gearbox. IEEE Trans. Ind. Electron. 66(4), 3196–3207 (2019). https://doi.org/10.1109/TIE.2018.2844805

Wang, F., Liu, R., Hu, Q., Chen, X.: Cascade convolutional neural network with progressive optimization for motor fault diagnosis under nonstationary conditions. IEEE Trans. Ind. Informatics 17(4), 2511–2521 (2021). https://doi.org/10.1109/TII.2020.3003353

Li, X., Jiang, H., Hu, Y., Xiong, X.: Intelligent fault diagnosis of rotating machinery based on deep recurrent neural network. In: Proceedings - 2018 International Conference on Sensing, Diagnostics, Prognostics, and Control, SDPC 2018, no. 51475368, pp. 67–72 (2019). https://doi.org/10.1109/SDPC.2018.8664931

Huang, Y., Chen, C.H., Huang, C.J.: Motor fault detection and feature extraction using RNN-based variational autoencoder. IEEE Access 7, 139086–139096 (2019). https://doi.org/10.1109/ACCESS.2019.2940769

Sun, H., Zhao, S.: Fault Diagnosis for Bearing Based on 1DCNN and LSTM. Shock Vib. 2021, 1–17 (2021). https://doi.org/10.1155/2021/1221462

Eltotongy, A., Awad, M.I., Maged, S.A., Onsy, A.: Fault detection and classification of machinery bearing under variable operating conditions based on wavelet transform and CNN. In: 2021 International Mobile, Intelligent, and Ubiquitous Computing Conference, MIUCC 2021, pp. 117–123 (2021). https://doi.org/10.1109/MIUCC52538.2021.9447673

Yang, R., Huang, M., Lu, Q., Zhong, M.: Rotating machinery fault diagnosis using long-short-term memory recurrent neural network. IFAC-PapersOnLine 51(24), 228–232 (2018). https://doi.org/10.1016/j.ifacol.2018.09.582

Wang, P., Zhou, Y., Zhang, L.: Fault diagnosis method of rotating machinery based on CEEMDAN-LSTM model. J. Phys. Conf. Ser. 2173(1), 012057 (2022). https://doi.org/10.1088/1742-6596/2173/1/012057

Yin, A., Yan, Y., Zhang, Z., Li, C., Sánchez, R.-V.: Fault diagnosis of wind turbine gearbox based on the optimized LSTM neural network with cosine loss. Sensors 20(8), 2339 (2020). https://doi.org/10.3390/s20082339

Yang, J., Guo, Y., Zhao, W.: Long short-term memory neural network based fault detection and isolation for electro-mechanical actuators. Neurocomputing 360, 85–96 (2019). https://doi.org/10.1016/j.neucom.2019.06.029

Liu, J., Li, Q., Yang, H., Han, Y., Jiang, S., Chen, W.: Sequence fault diagnosis for PEMFC water management subsystem using deep learning with t-SNE. IEEE Access 7, 92009–92019 (2019). https://doi.org/10.1109/ACCESS.2019.2927092

Ma, S., Cai, W., Liu, W., Shang, Z., Liu, G.: A lighted deep convolutional neural network based fault diagnosis of rotating machinery. Sensors 19(10), 2381 (2019). https://doi.org/10.3390/s19102381

Cao, L., Qian, Z., Zareipour, H., Huang, Z., Zhang, F.: Fault diagnosis of wind turbine gearbox based on deep bi-directional long short-term memory under time-varying non-stationary operating conditions. IEEE Access 7, 155219–155228 (2019). https://doi.org/10.1109/ACCESS.2019.2947501

Han, T., Ma, R., Zheng, J.: Combination bidirectional long short-term memory and capsule network for rotating machinery fault diagnosis. Meas. J. Int. Meas. Confed. 176, 109208 (2021). https://doi.org/10.1016/j.measurement.2021.109208

Li, X., Zhang, W., Ding, Q.: Understanding and improving deep learning-based rolling bearing fault diagnosis with attention mechanism. Signal Process. 161, 136–154 (2019). https://doi.org/10.1016/j.sigpro.2019.03.019

Li, X., Jiang, H., Xiong, X., Shao, H.: Rolling bearing health prognosis using a modified health index based hierarchical gated recurrent unit network. Mech. Mach. Theory 133, 229–249 (2019). https://doi.org/10.1016/j.mechmachtheory.2018.11.005

Liu, H., Zhou, J., Zheng, Y., Jiang, W., Zhang, Y.: Fault diagnosis of rolling bearings with recurrent neural network-based autoencoders. ISA Trans. 77, 167–178 (2018). https://doi.org/10.1016/j.isatra.2018.04.005

Tao, Y., Wang, X., Sánchez, R., Yang, S., Bai, Y.U.N.: Spur gear fault diagnosis using a multilayer gated recurrent unit approach with vibration signal. IEEE Access 7, 56880–56889 (2019). https://doi.org/10.1109/ACCESS.2019.2914181

Chang, Y., Chen, J., Lv, H., Liu, S.: Heterogeneous bi-directional recurrent neural network combining fusion health indicator for predictive analytics of rotating machinery. ISA Trans. (2021). https://doi.org/10.1016/j.isatra.2021.04.024

Zhao, R., Wang, D., Yan, R., Mao, K., Shen, F., Wang, I.: Machine health monitoring using local feature-based gated recurrent unit networks. IEEE Trans. Ind. Electron. 65(2), 1539–1548 (2018). https://doi.org/10.1109/TIE.2017.2733438

Fu, J., Chu, J., Guo, P., Chen, Z.: Condition monitoring of wind turbine gearbox bearing based on deep learning model. IEEE Access 7, 57078–57087 (2019). https://doi.org/10.1109/ACCESS.2019.2912621

Zhao, R., Yan, R., Wang, J., Mao, K.: Learning to monitor machine health with convolutional Bi-directional LSTM networks. Sensors 17(2), 273 (2017). https://doi.org/10.3390/s17020273

Qiao, M., Yan, S., Tang, X., Xu, C.: Deep convolutional and LSTM recurrent neural networks for rolling bearing fault diagnosis under strong noises and variable loads. IEEE Access 8, 66257–66269 (2020). https://doi.org/10.1109/ACCESS.2020.2985617

Liao, G.P., Gao, W., Yang, G.J., Guo, M.F.: Hydroelectric generating unit fault diagnosis using 1-D convolutional neural network and gated recurrent unit in small hydro. IEEE Sens. J. 19(20), 9352–9363 (2019). https://doi.org/10.1109/JSEN.2019.2926095

Li, X., Jiang, H., Liu, S., Zhang, J., Xu, J.: A unified framework incorporating predictive generative denoising autoencoder and deep Coral network for rolling bearing fault diagnosis with unbalanced data. Meas. J. Int. Meas. Confed. 178, 109345 (2021). https://doi.org/10.1016/j.measurement.2021.109345

Fu, Q., Wang, H.: A novel deep learning system with data augmentation for machine fault diagnosis from vibration signals. Appl. Sci. 10(17), 5765 (2020). https://doi.org/10.3390/app10175765

Goodfellow, B.I., et al.: Generative adversarial networks. Commun. ACM 63(11), 139–144 (2014). https://doi.org/10.1145/3422622

Zhou, F., Yang, S., Fujita, H., Chen, D., Wen, C.: Deep learning fault diagnosis method based on global optimization GAN for unbalanced data. Knowledge-Based Syst. 187, 104837 (2020). https://doi.org/10.1016/j.knosys.2019.07.008

Ding, Y., Ma, L., Ma, J., Wang, C., Lu, C.: A generative adversarial network-based intelligent fault diagnosis method for rotating machinery under small sample size conditions. IEEE Access 7, 149736–149749 (2019). https://doi.org/10.1109/ACCESS.2019.2947194

Yan, K., Huang, J., Shen, W., Ji, Z.: Unsupervised learning for fault detection and diagnosis of air handling units. Energy Build. 210, 109689 (2020). https://doi.org/10.1016/j.enbuild.2019.109689

Zheng, T., Song, L., Wang, J., Teng, W., Xu, X., Ma, C.: Data synthesis using dual discriminator conditional generative adversarial networks for imbalanced fault diagnosis of rolling bearings. Meas. J. Int. Meas. Confed. 158, 107741 (2020). https://doi.org/10.1016/j.measurement.2020.107741

Viola, J., Chen, Y.Q., Wang, J.: FaultFace: deep convolutional generative adversarial network (DCGAN) based Ball-Bearing failure detection method. Inf. Sci. (Ny) 542, 195–211 (2021). https://doi.org/10.1016/j.ins.2020.06.060

Sabir, R., Rosato, D., Hartmann, S., Gühmann, C.: Signal Generation using 1d Deep convolutional generative adversarial networks for fault diagnosis of electrical machines. In: 2020 25th International Conference on Pattern Recognition (ICPR), pp. 3907–3914 (2021). https://doi.org/10.1109/ICPR48806.2021.9413119

Zhang, D., Ning, Z.Q., Yang, B., Wang, T.Y., Ma, Y.J.: Fault diagnosis of permanent magnet motor based on DCGAN-RCCNN. Energy Rep. 8, 616–626 (2022). https://doi.org/10.1016/j.egyr.2022.01.226

Xie, Y., Zhang, T.: Imbalanced learning for fault diagnosis problem of rotating machinery based on generative adversarial networks. In: Proceedings of the 37th Chinese Control Conference, pp. 6017–6022 (2018). https://doi.org/10.23919/ChiCC.2018.8483334

Luo, J., Huang, J., Li, H.: A case study of conditional deep convolutional generative adversarial networks in machine fault diagnosis. J. Intell. Manuf. 32(2), 407–425 (2020). https://doi.org/10.1007/s10845-020-01579-w

Shao, S., Wang, P., Yan, R.: Generative adversarial networks for data augmentation in machine fault diagnosis. Comput. Ind. 106, 85–93 (2019). https://doi.org/10.1016/j.compind.2019.01.001

Xiong, X., Hongkai, J., Li, X., Niu, M.: A Wasserstein gradient-penalty generative adversarial network with deep auto-encoder for bearing intelligent fault diagnosis. Meas. Sci. Technol. 31(4), 045006 (2020). https://doi.org/10.1088/1361-6501/ab47df

Luo, J., Zhu, L., Li, Q., Liu, D., Chen, M.: Imbalanced fault diagnosis of rotating machinery based on deep generative adversarial networks with gradient penalty. Processes 9(10), 1751 (2021). https://doi.org/10.3390/pr9101751

Zareapoor, M., Shamsolmoali, P., Yang, J.: Oversampling adversarial network for class-imbalanced fault diagnosis. Mech. Syst. Signal Process. 149, 107175 (2021). https://doi.org/10.1016/j.ymssp.2020.107175

Shi, Z., Chen, J., Zi, Y., Zhou, Z.: A novel multitask adversarial network via redundant lifting for multicomponent intelligent fault detection under sharp speed variation. IEEE Trans. Instrum. Meas. 70, 1 (2021). https://doi.org/10.1109/TIM.2021.3055821

Liu, S., Jiang, H., Wu, Z., Li, X.: Rolling bearing fault diagnosis using variational autoencoding generative adversarial networks with deep regret analysis. Meas. J. Int. Meas. Confed. 168, 108371 (2021). https://doi.org/10.1016/j.measurement.2020.108371

Wu, C., Zeng, Z.: A fault diagnosis method based on auxiliary classifier generative adversarial network for rolling bearing. PLoS ONE 16, 1–21 (2021). https://doi.org/10.1371/journal.pone.0246905

Liu, H., Zhou, J., Xu, Y., Zheng, Y., Peng, X., Jiang, W.: Unsupervised fault diagnosis of rolling bearings using a deep neural network based on generative adversarial networks. Neurocomputing 315, 412–424 (2018). https://doi.org/10.1016/j.neucom.2018.07.034

Shao, H., Jiang, H., Li, X., Wu, S.: Intelligent fault diagnosis of rolling bearing using deep wavelet auto-encoder with extreme learning machine. Knowledge-Based Syst. 140, 1–14 (2018). https://doi.org/10.1016/j.knosys.2017.10.024

Luo, X., Li, X., Wang, Z., Liang, J.: Discriminant autoencoder for feature extraction in fault diagnosis. Chemom. Intell. Lab. Syst. 192, 103814 (2019). https://doi.org/10.1016/j.chemolab.2019.103814

Sun, J., Yan, C., Wen, J.: Intelligent bearing fault diagnosis method combining compressed data acquisition and deep learning. IEEE Trans. Instrum. Meas. 67(1), 185–195 (2018). https://doi.org/10.1109/TIM.2017.2759418

Liu, R., Yang, B., Zio, E., Chen, X.: Artificial intelligence for fault diagnosis of rotating machinery: a review. Mech. Syst. Signal Process. 108, 33–47 (2018). https://doi.org/10.1016/j.ymssp.2018.02.016

Mao, W., Feng, W., Liu, Y., Zhang, D., Liang, X.: A new deep auto-encoder method with fusing discriminant information for bearing fault diagnosis. Mech. Syst. Signal Process. 150, 107233 (2021). https://doi.org/10.1016/j.ymssp.2020.107233

Principi, E., Rossetti, D., Squartini, S., Piazza, F.: Unsupervised electric motor fault detection by using deep autoencoders. IEEE/CAA J. Autom. Sin. 6(2), 441–451 (2019). https://doi.org/10.1109/JAS.2019.1911393

Wang, B., Shen, C., Xu, K., Zheng, T.: Turn-to-turn short circuit of motor stator fault diagnosis in continuous state based on deep. IET Electr. Power Appl. 13(10), 1598–1606 (2019). https://doi.org/10.1049/iet-epa.2019.0101

Zhang, Y., Li, X., Gao, L., Chen, W., Li, P.: Intelligent fault diagnosis of rotating machinery using a new ensemble deep auto-encoder method. Measurement 151, 107232 (2020). https://doi.org/10.1016/j.measurement.2019.107232

Cui, M., Wang, Y., Lin, X., Zhong, M.: Fault diagnosis of rolling bearings based on an improved stack autoencoder and support vector machine. IEEE Sens. J. 21(4), 4927–4937 (2021). https://doi.org/10.1109/JSEN.2020.3030910

Aamir, M., Mohd Nawi, N., Wahid, F., Mahdin, H.: A deep contractive autoencoder for solving multiclass classification problems. Evol. Intel. 14(4), 1619–1633 (2020). https://doi.org/10.1007/s12065-020-00424-6

Shi, C., Panoutsos, G., Luo, B., Liu, H., Li, B.: Using multiple-feature-spaces-based deep learning for tool condition monitoring in ultraprecision manufacturing. IEEE Trans. Ind. Electron. 66(5), 3794–3803 (2019). https://doi.org/10.1109/TIE.2018.2856193

Pan, Y., He, F., Yu, H.: A novel enhanced collaborative autoencoder with knowledge distillation for top-N recommender systems. Neurocomputing 332, 137–148 (2019). https://doi.org/10.1016/j.neucom.2018.12.025

Liu, G., Bao, H., Han, B.: A stacked autoencoder-based deep neural network for achieving gearbox fault diagnosis. Math. Probl. Eng. 2018, 1–10 (2018). https://doi.org/10.1155/2018/5105709

Sun, M., Wang, H., Liu, P., Huang, S., Wang, P., Meng, J.: Stack autoencoder transfer learning algorithm for bearing fault diagnosis based on class separation and domain fusion. IEEE Trans. Ind. Electron. 69(3), 3047–3058 (2022). https://doi.org/10.1109/TIE.2021.3066933

Xiang, Z., Zhang, X., Zhang, W., Xia, X.: Fault diagnosis of rolling bearing under fluctuating speed and variable load. Measurement 138, 162–174 (2019). https://doi.org/10.1016/j.measurement.2019.01.063

Karamti, H., Lashin, M.M.A., Alrowais, F.M., Mahmoud, A.M.: A new deep stacked architecture for multi-fault machinery identification with imbalanced samples. IEEE Access 9, 58838–58851 (2021). https://doi.org/10.1109/ACCESS.2021.3071796

Wang, J., Li, S., An, Z., Jiang, X., Qian, W., Ji, S.: Batch-normalized deep neural networks for achieving fast intelligent fault diagnosis of machines. Neurocomputing 329, 53–65 (2019). https://doi.org/10.1016/j.neucom.2018.10.049

Shao, H., Xia, M., Wan, J., de Silva, C.W.: Modified stacked autoencoder using adaptive morlet wavelet for intelligent fault diagnosis of rotating machinery. IEEE/ASME Trans. Mech. 27(1), 24–33 (2022). https://doi.org/10.1109/TMECH.2021.3058061

Che, C., Wang, H., Fu, Q., Ni, X.: “Intelligent fault prediction of rolling bearing based on gate recurrent unit and hybrid autoencoder. Proc. IMechE Part C J. Mech. Eng. Sci. 235(6), 1106–1114 (2021). https://doi.org/10.1177/0954406220941037

Meng, Z., Zhan, X., Li, J., Pan, Z.: An enhancement denoising autoencoder for rolling bearing fault diagnosis. Meas. J. Int. Meas. Confed. 130, 448–454 (2018). https://doi.org/10.1016/j.measurement.2018.08.010

Yi, G., Cao, J., Song, X., Yao, J.: A denoising autoencoder-based bearing fault diagnosis system for time-domain vibration signals. Wirel. Commun. Mob. Comput. 2021, 1–7 (2021). https://doi.org/10.1155/2021/9790053

Lu, C., Wang, Z.Y., Qin, W.L., Ma, J.: Fault diagnosis of rotary machinery components using a stacked denoising autoencoder-based health state identification. Signal Process. 130, 377–388 (2017). https://doi.org/10.1016/j.sigpro.2016.07.028

Zhao, X., Wu, J., Zhang, Y., Shi, Y., Wang, L.: Fault diagnosis of motor in frequency domain signal by stacked de - noising auto - encoder. Comput. Mater. Contin. 57(2), 223–242 (2018). https://doi.org/10.32604/cmc.2018.02490

Chen, Z., Li, Z.: Fault diagnosis method of rotating machinery based on stacked denoising autoencoder. J. Intell. Fuzzy Syst. 34(6), 3443–3449 (2018). https://doi.org/10.3233/JIFS-169524

Yu, J.: Evolutionary manifold regularized stacked denoising autoencoders for gearbox fault diagnosis. Knowledge-Based Syst. 178, 111–122 (2019). https://doi.org/10.1016/j.knosys.2019.04.022

Xu, X., Feng, J., Zhan, L., Li, Z., Qian, F., Yan, Y.: Fault diagnosis of permanent magnet synchronous motor based on stacked denoising autoencoder. Entropy 23(3), 339 (2021). https://doi.org/10.3390/e23030339

Xu, Y., Li, C., Xie, T.: Intelligent diagnosis of subway traction motor bearing fault based on improved stacked denoising autoencoder. Shock Vib. 2021, 1–9 (2021). https://doi.org/10.1155/2021/6656635

Xiao, D., Qin, C., Yu, H., Huang, Y., Liu, C.: Unsupervised machine fault diagnosis for noisy domain adaptation using marginal denoising autoencoder based on acoustic signals. Measurement 176, 109186 (2021). https://doi.org/10.1016/j.measurement.2021.109186

Godói, L., Nóbrega, E.: Denoising convolutional autoencoder configuration for condition monitoring of rotating machines. J. Braz. Soc. Mech. Sci. Eng. 43(1), 1–13 (2021). https://doi.org/10.1007/s40430-020-02776-7

Liu, X., Zhou, Q., Zhao, J., Shen, H., Xiong, X.: Fault diagnosis of rotating machinery under noisy environment conditions based on a 1-D convolutional autoencoder and 1-D convolutional neural network. Sensors 19(4), 972 (2019). https://doi.org/10.3390/s19040972

Zhang, C., Cheng, X., Liu, J., He, J., Liu, G.: Deep sparse autoencoder for feature extraction and diagnosis of locomotive adhesion status. J. Control Sci. Eng. 2018, 1–9 (2018). https://doi.org/10.1155/2018/8676387

Zheng, Y., Wang, T., Xin, B., Xie, T., Wang, Y.: A sparse autoencoder and softmax regression based diagnosis method for the attachment on the blades of marine current turbine. Sensors 19(4), 826 (2019). https://doi.org/10.3390/s19040826

Zhao, X., Jia, M., Liu, Z.: Semisupervised deep sparse auto-encoder with local and nonlocal information for intelligent fault diagnosis of rotating machinery. IEEE Trans. Instrum. Meas. 70(3501413), 1–13 (2021). https://doi.org/10.1109/TIM.2020.3016045

Nguyen, C.D., Prosvirin, A.E., Kim, C.H., Kim, J.-M.: Construction of a sensitive and speed invariant gearbox fault diagnosis model using an incorporated utilizing adaptive noise control and a stacked sparse autoencoder-based deep neural network. Sensors 21(1), 18 (2021). https://doi.org/10.3390/s21010018

Qi, Y., Shen, C., Wang, D., Shi, J., Jiang, X., Zhu, Z.: Stacked sparse autoencoder-based deep network for fault diagnosis of rotating machinery. IEEE Access 5, 15066–15079 (2017). https://doi.org/10.1109/ACCESS.2017.2728010

Sun, M., Wang, H., Liu, P., Huang, S., Fan, P.: A sparse stacked denoising autoencoder with optimized transfer learning applied to the fault diagnosis of rolling bearings. Measurement 146, 305–314 (2019). https://doi.org/10.1016/j.measurement.2019.06.029

Saufi, S.R., Asrar, Z., MS Leong, MH Lim: Differential evolution optimization for resilient stacked sparse autoencoder and its applications on bearing fault diagnosis. Meas. Sci. Technol. 29(12), 125002 (2018). https://doi.org/10.1088/1361-6501/aae5b2

Shi, P., Guo, X., Han, D., Fu, R.: A sparse auto-encoder method based on compressed sensing and wavelet packet energy entropy for rolling bearing intelligent fault diagnosis. J. Mech. Sci. Technol. 34(4), 1445–1458 (2020). https://doi.org/10.1007/s12206-020-0306-1

Sohaib, M., Kim, J.-M.: Reliable fault diagnosis of rotary machine bearings using a stacked sparse autoencoder-based deep neural network. Shock Vib. 2018, 1–11 (2018). https://doi.org/10.1155/2018/2919637

Zhu, H., Cheng, J., Zhang, C., Wu, J., Shao, X.: Stacked pruning sparse denoising autoencoder based intelligent fault diagnosis of rolling bearings. Appl. Soft Comput. J. 88, 106060 (2020). https://doi.org/10.1016/j.asoc.2019.106060

Yang, P., Wen, C., Geng, H., Liu, P.: Intelligent fault diagnosis method for blade damage of quad-rotor UAV based on stacked pruning sparse denoising autoencoder and convolutional neural network. Machines 9(12), 360 (2021). https://doi.org/10.3390/machines9120360

Jia, F., Lei, Y., Guo, L., Lin, J., Xing, S.: A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines. Neurocomputing 272, 619–628 (2018). https://doi.org/10.1016/j.neucom.2017.07.032

Qi, Y., Shen, C., Zhu, J., Jiang, X., Shi, J., Zhu, Z.: A new deep fusion network for automatic mechanical fault feature learning. IEEE Access 7, 152552–152563 (2019). https://doi.org/10.1109/ACCESS.2019.2948661

Yi, J., Fu, S., Cui, S., Zhao, C., : A deep contractive auto-encoding network for machinery fault diagnosis. In: ISCIT 2018 - 18th International Symposium on Communication and Information Technology, pp. 85–89 (2018). https://doi.org/10.1109/ISCIT.2018.8587983

Shen, C., Qi, Y., Wang, J., Cai, G., Zhu, Z.: An automatic and robust features learning method for rotating machinery fault diagnosis based on contractive autoencoder. Eng. Appl. Artif. Intell. 76(8), 170–184 (2018). https://doi.org/10.1016/j.engappai.2018.09.010

Zhang, Y., Li, X., Gao, L., Chen, W., Li, P.: Ensemble deep contractive auto-encoders for intelligent fault diagnosis of machines under noisy environment. Knowledge-Based Syst. 196, 105764 (2020). https://doi.org/10.1016/j.knosys.2020.105764

Martin, G.S., Droguett, E.L., Meruane, V., das Chagas Moura, M.: Deep variational auto-encoders: A promising tool for dimensionality reduction and ball bearing elements fault diagnosis. Struct. Heal. Monit. 18(4), 1092–1128 (2019). https://doi.org/10.1177/1475921718788299

Yan, X., Xu, Y., She, D., Zhang, W.: Reliable fault diagnosis of bearings using an optimized stacked variational denoising auto-encoder. Entropy 24(36), 1–26 (2022). https://doi.org/10.3390/e24010036

Zhao, D., et al.: Enhanced data-driven fault diagnosis for machines with small and unbalanced data based on variational auto-encoder. Meas. Sci. Technol. 31(3), 035004 (2020). https://doi.org/10.1088/1361-6501/ab55f8

Dixit, S., Verma, N.K.: Intelligent condition-based monitoring of rotary machines with few samples. IEEE Sens. J. 20(23), 14337–14346 (2020). https://doi.org/10.1109/JSEN.2020.3008177

Wang, Y.-r, Sun, G.-d, Jin, Q.: Imbalanced sample fault diagnosis of rotating machinery using conditional variational auto-encoder generative adversarial network. Appl. Soft Comput. 92, 106333 (2020). https://doi.org/10.1016/j.asoc.2020.106333

Zhao, G., Liu, X., Zhang, B., Liu, Y., Niu, G., Cong, H.: A novel approach for analog circuit fault diagnosis based on Deep Belief Network. Measurement 121, 170–178 (2018). https://doi.org/10.1016/j.measurement.2018.02.044

Yan, X., Liu, Y., Jia, M.: Multiscale cascading deep beliefnetwork for fault identification of rotating machinery under various working conditions. Knowledge-Based Syst. 193, 105484 (2020). https://doi.org/10.1016/j.knosys.2020.105484

Shang, Z., Liao, X., Geng, R., Gao, M., Liu, X.: Fault diagnosis method of rolling bearing based on deep belief network. J. Mech. Sci. Technol. 32(11), 5139–5145 (2018). https://doi.org/10.1007/s12206-018-1012-0

Qin, Y., Wang, X., Zou, J.: The optimized deep belief networks with improved logistic sigmoid units and their application in fault diagnosis for planetary gearboxes of wind turbines. IEEE Trans. Ind. Electron. 66, 3814–3824 (2019). https://doi.org/10.1109/TIE.2018.2856205

Yan, J., Hu, Y., Guo, C.: Rotor unbalance fault diagnosis using DBN based on multi-source heterogeneous information fusion. Procedia Manuf. 35, 1184–1189 (2019). https://doi.org/10.1016/j.promfg.2019.06.075

Han, D., Guo, X., Shi, E.: An intelligent fault diagnosis method of variable condition gearbox based on improved DBN combined with WPEE and MPE. IEEE Access 8, 131299–131309 (2020). https://doi.org/10.1109/ACCESS.2020.3008208

Ma, J., Li, S., Wang, X.: Condition monitoring of rolling bearing based on multi-order FRFT and SSA-DBN. Symmetry (Basel) 14(2), 320 (2022). https://doi.org/10.3390/sym14020320

Zhang, Y., Zhang, Y., Wen, L., Cui, Z., He, Y., Liu, G.: Power grid fault diagnosis based on improved deep belief network. J. Phys. Conf. Ser. 1585(1), 012021 (2020). https://doi.org/10.1088/1742-6596/1585/1/012021

Yu, B.: A deep belief network and dempster-shafer theory multiclassifier for reliability of wind turbine system. IOP Conf. Ser. Mater. Sci. Eng. 1043, 032057 (2021). https://doi.org/10.1088/1757-899X/1043/3/032057

Shi, P., Xue, P., Liu, A., Han, D.: A novel rotating machinery fault diagnosis method based on adaptive deep belief network structure and dynamic learning rate under variable working conditions. IEEE Access 9, 44569–44579 (2021). https://doi.org/10.1109/ACCESS.2021.3066594

Niu, G., Wang, X., Golda, M., Mastro, S., Zhang, B.: An optimized adaptive PReLU-DBN for rolling element bearing fault diagnosis. Neurocomputing 445, 26–34 (2021). https://doi.org/10.1016/j.neucom.2021.02.078

Fan, X., Fang, Y.J., Wang, D., Liang, J.Q., Tsui, K.L.: Combining DBN and FCM for fault diagnosis of roller element bearings without using data labels. Shock Vib. 2018, 1–12 (2018). https://doi.org/10.1155/2018/3059230

Gao, S., Xu, L., Zhang, Y.: Rolling bearing fault diagnosis based on intelligent optimized self-adaptive deep belief network. Meas. Sci. Technol. 31, 055009 (2020). https://doi.org/10.1088/1361-6501/ab50f0

Kamada, S., Ichimura, T., Hara, A., Mackin, K.J.: Adaptive structure learning method of deep belief network using neuron generation–annihilation and layer generation. Neural Comput. Appl. 31(11), 8035–8049 (2018). https://doi.org/10.1007/s00521-018-3622-y

Shen, C., Xie, J., Wang, D., Jiang, X., Shi, J., Zhu, Z.: Improved hierarchical adaptive deep belief network for bearing fault diagnosis. Appl. Sci. 9(16), 3374 (2019). https://doi.org/10.3390/app9163374

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 ICST Institute for Computer Sciences, Social Informatics and Telecommunications Engineering

About this paper

Cite this paper

Kibrete, F., Woldemichael, D.E. (2023). Applications of Artificial Intelligence for Fault Diagnosis of Rotating Machines: A Review. In: Woldegiorgis, B.H., Mequanint, K., Bitew, M.A., Beza, T.B., Yibre, A.M. (eds) Artificial Intelligence and Digitalization for Sustainable Development. ICAST 2022. Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering, vol 455. Springer, Cham. https://doi.org/10.1007/978-3-031-28725-1_4

Download citation

DOI: https://doi.org/10.1007/978-3-031-28725-1_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28724-4

Online ISBN: 978-3-031-28725-1

eBook Packages: Computer ScienceComputer Science (R0)