Abstract

The fault monitoring and diagnosis of industrial machineries are very significant in Industry 4.0 revolution but are often complicated and labour intensive. The application of artificial intelligence (AI) techniques have now been an important part of condition monitoring of the mechanical and electrical machines because of its fast computation, higher accuracy, and robustness in performance, reducing the dependence on experienced personnel with expert knowledge. This paper presents a review of applications of AI-based fault diagnosis techniques that have had demonstrated success when applied to various industrial machineries. The important literature published in the last twenty years (i.e., 2000 to 2020) have been reviewed and added. In this work, first, a brief of various AI techniques such as artificial neural networks (ANN), deep learning (DL), fuzzy logic (FL), and support vector machine (SVM) are added. The literature on AI-based diagnostics used for various industrial machines, such as induction motor, bearing, gear, and centrifugal pump, are added and discussed in detail. The observation, research gap, and new ideas have been discussed, followed by a conclusion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Machineries like an induction motor, centrifugal pump, gear, and bearing play a crucial role in driving any machine part and act as the heart of any industry; if they fail, the whole industry has to be shut down for their maintenance and repair. The industry's production process will be affected, and there are chances of huge economic loss to the industry. So in order to avoid this kind of situation, the early detection and diagnosis of the faults in these machines is crucial. Conventionally detecting the faults in these machineries is often a difficult and daunting task for operators and maintainers. Sometimes these machines tend to fail catastrophically, which lead to safety issue in the industry. Without significantly detecting the faults in the machines, one cannot be able to forecast the lead time of failure of machines (Nath et al., 2021).

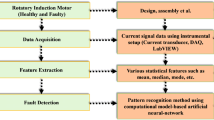

Condition monitoring by the use of AI technique is found to be the best for automated and efficient fault diagnosis of the system and prefers in the industry. Various attempts in the past have been made to improve the accuracy and efficiency of different AI techniques based fault diagnosis of Rotating Machinery. These techniques also free industries to rely on the experts and engineers for the condition monitoring and fault diagnosis of machineries. As the number of industries and machines is increasing day by day, it is impossible to fulfil the requirement of no. of experts and engineers all the time. Therefore, research on AI-based condition monitoring and machines' diagnosis has been getting popularity since last two decades. AI-based fault diagnosis basically includes the following phases: data collection, feature extraction, and fault detection and identification by AI. A flow diagram is added below (Fig. 1) to show AI based fault diagnosis system processes (Hadian et al., 2021; Zhao et al., 2019).

The data acquisition is a process of CBM of collecting and storing useful data or information from the targeted physical assets. The condition monitoring data is very versatile. It may be the vibration, current, acoustic, temperature, pressure, oil analysis data, etc., depending upon the machine. In order to acquire the data, various sensors such as the accelerometer, current probes, acoustic emission sensors, ultrasonic sensors, thermocouples, pressure sensors, etc. have been developed. The data processing includes the process of feature extraction of different faults of a machine. The feature extraction is used to reduce the dimension of data by selecting the important features. The accuracy and effectiveness of signal processing techniques depend on the feature characteristics that can be obtained from the time, frequency, and time–frequency domain (Gangsar & Tiwari, 2020).

The intelligent fault diagnosis is possible by incorporating AI into the online machine condition monitoring. The AI-based diagnoses have shown improved performance over the conventional signal and modeling based approaches. This reduces the direct human–machine interaction for the diagnosis. Moreover, these are data-based techniques; therefore, they do not require any detailed knowledge of the machine model and parameters. These techniques use association, reasoning, and decision-making processes as would the human brain in solving diagnostic problems. These diagnostic techniques involve signal processing methods and classification based on Machine learning (ML) such as the neural network (NN), fuzzy logic (FL), fuzzy neural network (FNN), genetic algorithm (GA), Hidden Morkov model, Bayesian classifier, SVM, Deep Learning (DL) (Gangsar & Tiwari, 2020; Saravanakumar et al., 2021; Zaman & Liang, 2021; Zhao et al., 2019).

The relationship between AI, ML and DL can be understand by Fig. 2. Recently DL is getting popularity because it does not require human intervention for feature extraction. DL consists of huge number of artificial neurons which functions exactly same as the neurons of human brain. DL utilizes Artificial Neural Network (ANN) which is motivated by the biological neural network of the human brain (Saravanakumar et al., 2021). Various types of AI techniques including DL have been used for effectively diagnosing the machine faults in last two decades. The introduction to different AI methods have been added in the subsequent section. Then the research and development in last two decades in AI based fault diagnosis for induction motor, bearing, gear/gearbox and centrifugal pump have been discussed in details. The observation, research gap, ideas have been added at the last followed by conclusions.

Introduction to AI techniques

Artificial neural network/deep learning based technique

The artificial neurons are considered analogous to the biological neurons, where each neuron takes input signal, adds weight to them separately and sums them up and passes this sum through a transfer function to produce an output signal. The start of neural network framework begin with a single layer perceptron which consists of weights, summation processor and activation function. A simple single layers neural network is called as ANN which is developed for performing very simple task of classification. It is actually a feed forward process of computation. However it is not suitable for the problem of non-linearly separable data. After that a multi-layer perceptron is developed with hidden layer of weights between input and output layers. A multi-layer perceptron based on back-propagation rule and with nonlinear activation function can be used for solving complex classification problems (Ali, 2018). A Single Layer Neural Network i.e. Perceptron is shown in Fig. 3.

The network framework includes only three main components i.e., input layer, hidden layer and output layer as shown in Fig. 4. The neurons present in the output and input layer are exactly equal to the size of target function and input attributes of the data frame. The number of hidden layers and neurons in it are the hyperparameters. Every neuron of layer L is connected with each neuron of layer L + 1, assigning some weight to them as per the weight matrix, \({W}_{ab}\). Generally the process of connection happens in a feed forward manner. The equation given below gives us the output generated by the neuron ‘b’ of any layer (Ali, 2018).

where \({\mathrm{X}}_{\mathrm{a}},\) \({\mathrm{W}}_{\mathrm{ab}}\) and \({\mathrm{C}}_{\mathrm{b}}\) are previous layer output, weight assigned between layer ‘a’ and ‘b’ and bias associated with neuron ‘b’, respectively. Non linearity is introduced inside the function with the following nonlinear activation function like tanh, sigmoid, Relu etc. This process continued till the network reaches to its final target value. Finally after predicting the output function the network tries to find the error occurred after training. If the prediction made by the network is wrong then it propagates back through the network using Back propagation (BP) technique. It uses stochastic gradient descent method to find the gradient of error. After that weights are updated with an intention of reducing error at the output layer (Ali, 2018; Khoualdia et al., 2021).

Now based on the error calculated, it calculates the rate of change of error with respect to change in weights

where, \(\beta\; \mathrm{is\; defined\; as\; Learning \;Rate}\). As soon as the change in weight is obtained the new weight is calculated. Since ANN have one or two hidden layers so it took very large computation time for complex problems and was very time consuming also. Therefore, more advanced technique called DL has been developed. DL has more than two hidden layers that are fully connected MLP network as shown in Fig. 5. The performance of DL system can be improved, may be by building it deeper; by preventing problem of over fitting or by collecting more data; by using some powerful optimization algorithm to get improved solution in a given stipulated time. Most of the powerful algorithm used in DL models is derived from stochastic gradient descent (SGD) (Yu et al., 2021).

In DL, techniques like long short term memory (LSTM) which is a recurrent neural network (RNN) has also been developed for fault diagnosis (Chen et al., 2021). In RNN, the present output depends on the present input to detect the pattern in the data and the previous sates that define the previous information. This kind of learning process is especially challenging because of the gradient vanishing and exploding problem. So LSTM was introduced as one of the architecture of RNN to overcome this problem of vanishing gradients and also to reduce our long term dependencies on the data. LSTM is a neuron based neural network that brings in the idea of memory cell. It appoints the gates that controls the flow of value and make decisions about the storage of last computed value and reading, writing of the present data. The flow of information happens with the opening and closing of the gates in the cell. Since the gates are analog therefore they are suitable for back propagation. LSTM needs to remember the past so as to learn which information is passed further or forgotten based on the robustness tuned through the weights. The process of learning of the cells passes through iterative method of estimating, back propagating the error, and adjusting the weights via gradient descent (Chen et al., 2021).

At each time step \(t\),\({s}_{t}\) is defined as hidden state of cell, \({x}_{t}\) is input data, \({s}_{t-1}\) is hidden state at previous time step, \({f}_{t}\) is forget gate, \({o}_{t}\) is output gate,\({i}_{t}\) is input gate and \({y}_{t}\) is memory cell. Each gate is formulated by a sigmoid activation function (\(\sigma \)) and element wise product (*) (Chen et al., 2021; Han et al., 2021).

where, \(W\in {R}^{d\times k}\), \(V\in {R}^{d\times d}\) and \(b\in {R}^{d}:\) are weight matrices and bias to be learned, respectively. \(k\) is hyperparameter that represents the dimensionality of hidden vectors, respectively and tanh is the hyperbolic tangent function.

Fuzzy logic based technique

A fuzzy logic based technique have also been used for classification purpose. For this, fuzzy rules are used in order to do nonlinear mapping of input data vector to a scalar output as shown in Fig. 6. This mapping includes membership functions of input/output, fuzzy logic operators, if–then rules, output sets aggregation and defuzzification (Chouidira et al., 2021). A multi output problem can be solved by combining a no. of multi input, single-output problems. Figure 6 shows basic components of a fuzzy based system such as fuzzifier, inference engine, rule base and defuzzifier. The fuzzifier gets input members and it maps them to corresponding fuzzy membership function. The membership function may be triangular, trapezoidal, and Gaussian. The rule base establishes the rule delivered by experts. The interference engine finds the amount to which predecessor is satisfied with each rule. The aggregation process converts truncated fuzzy sets into combined fuzzy sets. Defuzzfier finally converts the combined fuzzy sets to the crisp value obtained from a defuzzification method such as centroid, height or maximum (Chouidira et al., 2021; Wang & Hu, 2006).

Fuzzy model for fault diagnosis can be built by comparing the data xj in X dataset with certain member yi in Y dataset. Let one feature dataset obtained from any machine is X = {xj} (j = 1,2,….n), where j is the number of features, which may be fuzzified as (Wang & Hu, 2006)

where, Uxj = UX (xj), j = 1,2,……n, is the fuzzy membership of each element xj in X dataset. Membership of yi (i = 1,2,….,m) for different class is UY (yi) and fuzzy vector of the fault may be defined as (Wang & Hu, 2006)

Suppose \(\tilde{R }\) is the fuzzy relation on the set X and Y, can be expressed as

where, 0 ≤ rij ≤ 1, i = 1, 2,….,m, j = 1, 2,……..,n.

From fuzzy logic concept, the relationship between the faults and feature of faults, may be define as

where,‘°’ is fuzzy logic operator, \(\tilde{R }\) is fuzzy diagnosis matrix or relation matrix.

SVM based technique

Support Vector Machine is a soft computing machine learning algorithm that is based on the Statistical Learning Theory (STL). SVM is used for identification and regression analysis. The basic SVM deal with the two class problems. The classification of two classes (+ or -) by SVM is shown in Fig. 7. To classify the data of two classes, SVM first creates a set of hyper plane, then it finds the optimal separating hyper plane by maximizing the margin between the nearest data points of the two classes. The nearest data points of two classes are known as support vectors (SVs). For identification of class of new data, the new data (examples) fed into the same space. Finally SVM classifies the new example in either of the class (Gangsar & Tiwari, 2018a, 2019a).

Let us suppose \({A}_{i}={({a}_{1i} , {a}_{2i} , {a}_{3i}\dots ...{a}_{ni})}^{T}, where i=1,\dots .,M\) be a sample of \((a\in {R}^{n})\) and fit in to any of the two classes i.e. class 1 or class 2. It is easy for the linearly separable classes to determine the hyperplane that exactly split the two classes, one class on either side of the hyperplane. Below equation can help to categorize the plane (Gangsar & Tiwari, 2019a):

where c is a scalar and \(w\in {R}^{n}\) is a weight vector. Both these are responsible determining the separating hyperplane. To define the label for \({a}_{i}\) let us identify \({b}_{i}\), when \({b}_{i}\)=1 then \({a}_{i}\) fit to the class 1, \({b}_{i}=-1\) for class 2. For separating hyperplane satisfying these constraints is extremely important.

For linearly separable case if this inequality holds well then to find the optimal hypeplane we have to optimize this quadratic equation (Gangsar & Tiwari, 2018a):

Consider the case of non-linear classification problem, unlike linear case it is not easy to separate the two classes properly. A non linear mapping is required which helps to create the classification features from original data. The data which is non linearly separable is to be mapped by the use of transformation ɸ(x) onto high dimensional feature space, for converting the data into linearly separable format. Kernel function is used for the mapping. There are many kernel functions that are being used for performing transformation; some popular functions are sigmoid, polynomial function, Gaussian radial basis function (RBF) and Laplace radial basis function. The kernel function is introduced because of the non-linearly separable data which are very difficult to classify by the algorithm. Kernels are a set of mathematical function. The main task of the kernel function is to transform the non-linearly separable data onto high dimensional feature space so that they can easily be separated or structured. There are some major kernel functions that are widely accepted for example RBF. The RBF function canbe expressed as

where \(\sigma \) is RBF kernel width ande \(\gamma \) is kernel parameter. The above formulation is for binary classification by SVM. However, in real life situation, multiclass problems are also exist. To solve a multi class problem, a number of binary class SVMs can be combined. Various multiclass techniques have been developed such as one-versus one, one-versus-all, direct Acyclic graph SVM (Gangsar & Tiwari, 2018a, 2019a).

Application of AI technique for various industrial machines

For induction motor (IM)/bearing fault diagnosis

Various AI-based fault diagnosis has been developed for IM/bearing in the last two decades. In progress of AI-based fault diagnosis of IM, (Caldera et al., 1998) presented short circuit fault detection of stator winding of IM using voltage signal through a hybrid technique called adaptive neuro-fuzzy inference system (ANFIS). It turns out to be effective for diagnosing faults in IM. In a study, Filippetti et al. (2000) used ANN and fuzzy logic (FL) to detect short circuit fault in stator winding and bearing faults with the help of voltage and current signals. They found that fuzzy neural diagnostic system gives better-diagnosing results and minimum computational time. In another study, (Nejjari & Benbouzid, 2000) developed stator voltage imbalance fault detection based on ANN with the help of a current signal. In this, they carefully analyzed the stator current Parks’s vector pattern. Results showed that the developed ANN-based diagnosis with Park's vectors gives accuracy up to 97%.

Han and Song (2003) presented an ANN-based fault diagnosis for various IM faults namely stator fault (inter-turn winding faults), rotor faults (broken rotor bars), bearing faults and air-gap eccentricities. In this work they have used stator current signals, vibration, air gap monitoring, and found a combination of advanced signal processing techniques and A.I techniques gives effective results. Kowalski and Orlowska-Kowalska (2003) advised ANN-based technique for rotor, bearing, and stator winding fault (SWF) detection for IM is one of the best technique. Zeraoulia et al. (2005) successfully introduced a fuzzy logic-based approach to detect the voltage imbalance in IM. They used stator current magnitude to build the fuzzy logic-based diagnosis. Satish et al. (2005) combined the FL and NN to make a hybrid technique and further used to perform diagnosis as well as prognosis of IM for bearing fault and found the hybrid technique to be an effective technique.

Silva and Cardoso (2005) introduced Extended Park’s vector approach (EPVA) for bearing fault in IM by using current and vibration analysis and found the EPVA technique to be most sensitive for bearing fault. Arabacı et al. (2005) diagnosed the number of broken rotor bar (BRB) in IM using current signal analysis and ANN. In this work, they investigated the effects of no. of BRB on the current spectrum by using power spectrum density (PSD) and further used ANN for the successful diagnosis. Satish and Sarma (2005) developed a hybrid approach of fuzzy back propagation network (fuzzy BP) for diagnosing and estimating the RUL of the bearing of induction motor. They combined the fuzzy logic and neural network to form a hybrid approach called fuzzy BP in order to avoid the drawbacks of individual AI technique. For diagnostic and prognostic purpose, stator current and its speed were taken as input for the experiments. The present hybrid method showed better performance than individual NN enough in predicting the RUL of the bearing accurately.

Li and Mechefske (2006) compared the performance of machine current signature analysis (MCSA) and vibration analysis for BRB and bearing fault and found that the stator current is sensitive to broken rotor bar and vibration signal analysis is sensitive to bearing fault. Eldin et al. (2007) discussed external motor faults (e.g., phase failure, unbalanced voltage, locked rotor, undervoltage, overvoltage, phase sequence reversal of supply voltage, mechanical overload) monitoring using current and voltage signals based on neural network (NN) technique. The results showed that a well-trained NN is able to diagnose MATLAB/SIMULINK simulated faults. Rao and Yahya (2008) used an ANN technique called feed-forward back propagation neural network to diagnose SWF, bearing fault and overheating problem in AC motor (synchronous motor). In this work, the resilient error backpropagation (RPROP) algorithm is used for the training. Results showed that the multilayer neural networks are fast and reliable and converges much faster than the conventional back propagation algorithm in the present application.

Nguyen and Lee (2008) combined SVM with GA to diagnose bearing and rotor unbalance in IM and experimentally shows that SVM is an efficient way to improve the system performance. Mahamad et al. (2008) converted vibration data of time into the frequency domain and selected sixteen features from time, frequency, and time–frequency domain out of which nine critical features are selected. Then the fault diagnosis was done with Elman Network by introducing a graphical user interface program to help the user to find the fault in bearing easily. Yang and Widodo (2008) proposed the SVM method to diagnose broken rotor fault in IM and SVM is capable of diagnosing the fault with high accuracy and low computational time.

Ghate and Dudul (2009) presented fault diagnosis of stator in-turn short circuit problem and eccentricity problem by using ANN and SVM approach and finally concluded that if the step size is minimum, then SVM gives you the better result. Mahamad and Hiyama (2009) considered bearing fault detection with Elman Network (EN), which is one of the ANN family. They used frequency-domain features of vibration signals in EN and compared the performance EN with and without a genetic algorithm (GA). GA was used to optimize the weights and biases of EN. The result showed that EN with GA shows better performance than without GA. Jayaswal and Wadhwani (2009) performed bearing fault detection based on A.I techniques like ANN, FL, with wavelet transform. They found that the wavelet transform is good to detect multiple defects. In addition, they showed that the ANN performs better with the minimum data ANN. Arabacı and Bilgin (2010) showed that the error from broken rotor bar and broken end ring detection had been reduced from 18.33% to 1.67% by using current signal and ANN. Dash and Subudhi (2010) developed a hybrid system called ANFIS (adaptive neural fuzzy inference system) for fault detection in stator in-turn short circuit fault using current and voltage signals. The result showed that the hybrid system gives less error compared to NN alone. Bouzid et al. (2010) proposed a feed forward MLP technique for the diagnosis of broken rotor bar fault in IM and showed that the method allows an accurate diagnosis with satisfactory robustness.

Konar and Chattopadhyay (2011) diagnosed one of the critical faults in three-phase induction motor called bearing fault using vibration signals. They used continuous wavelet transform (CWT) and Discrete wavelet transform (DWT) for extracting useful features for SVM and ANN. They showed SVM with CWT features is better as compared to ANN with DWT features. Hamdani et al. (2011) presented a diagnosis of broken rotor bar and dynamic eccentricity with ANN using the current signal. They used fault frequencies and magnitudes as features and showed that the present methodology is very effective in diagnosing a fault in IM. Lee (2011) covered bearing and rotor fault in IM based on ANN and DWT. They showed that the use of DWT features in ANN improves the performances of the present diagnosis. Akar and Cankaya (2012) combined machine current signature analysis (MCSA) and fuzzy logic to prognosis the broken rotor bars in inverter fed induction motor. They extracted the current harmonics as features required to apply fuzzy logic and showed the MCSA in association with FL is very efficient and useful in the prognosis of BRB. Rajeswaran et al. (2012) attempted testing and fault diagnosis of an induction motor under various load conditions. They used the Back Propagation Neural (BPN) Network for calculating the error and correcting/regulating the induction motor. The result showed that a significant improvement in the speed as well as fault diagnosis by using the BPNN hybrid technique. Hussein et al. (2012) presented bearing fault diagnosis based on MCSA and NN. It is one of the efficient and best method for determining the fault in IM. They used harmonic content obtained from the Fast Fourier transform (FFT) analysis and the Levenberg–Marquardt algorithm to train and test the NN. They showed that the present approach is able to detect the bearing faults at their incipient stage. In a work, Tian (2012) developed an approach for the prediction of RUL of the bearing based on ANN with two hidden layers. Vibration signals were collected over the entire degradation of the bearing. They presented that building a single model in a typical degradation process is not an easy task because pattern of changes at different degradation stages differ significantly. They added a comparative study of Modified Wu’s method and ANN method in which they found that average prediction error in ANN is far more less than the Modified Wu’s method. They showed that the ANN predict the RUL of the bearing accurately and comparatively better than Modified Wu’s method.

Silva and Pederiva (2013) compared the performance of three different AI techniques namely SVM, ANN and FL, in diagnosing various motor faults such as unbalance, misalignment, and mech. Looseness, short circuit, phase unbalance, and BRB. They used vibrational fault frequencies as input to these classifiers and finally showed that the SVM has better generalization error and requires less user knowledge as compared to the ANN and the FL. Refaat et al. (2013) successfully used the application of ANN in detection, isolation, and identification of stator turn faults and their severity. It is useful to reduce the propagation speed of the incipient SWF. In addition, they proposed successful remedial operating strategies, which enable a fault-tolerant IM star-connected winding with neutral point earthed through a controllable impedance using ANN. Guedidi et al. (2013) used the amplitude of the current harmonics and the slip value as input to NN and found it effective for BRB. Nyanteh et al. (2013) successfully introduced a detection approach for fault type, fault location, and fault severity of SWF in a permanent magnet synchronous motor. They used Particle Swarm Optimization and extended Kalman network in ANN. The extended Kalman network enables NN to re-train on the data. And Each NN is trained to correlate the zero-current component to the number of short-circuited turns in the SWF.

Wangngon et al. (2014) confirmed that current signature analysis with ANN is capable of detecting BRB effectively at any load condition. Mahamad and Hiyama (2009) combined the Hilbert Transform with using Welch Transform and the SVM for BRB detection in IM and showed maximum accuracy up to 98% through SVM. Bhavsar et al. (2014) presented a mathematical model by taking the current signal as input to diagnose SWF with ANN and found an accuracy of 99%. Gupta and Kaur (2014) presented a review on ANN based diagnostics of rotor related faults like BRB and dynamic eccentricity in IM. The diagnosis of these faults is difficult especially at light load by conventional signal analysis method as these faults generate characteristic frequencies which are close to the fundamental frequency and their magnitudes are small in comparison. Finally they showed that these faults can be effectively detected under light load by quantification method like ANN. Singh and Kumar (2015) used the application of ANN and SVM to diagnose rotor faults and found that computational time in SVM is remarkably less as compared to ANN; however, the accuracy rate is 99.3% using both techniques. Lashkari et al. (2015) used three-phase shifts between the line current and the phase voltage to detect the SWF and supply unbalance in IM. Here the data collected from simulated faulty models and experiments are used as input to NN. They finally verified the simulated results experimentally. Bessam et al. (2015) used discrete wavelet energy features to remedy the problem of classical signal processing techniques (FFT) in fault diagnosis of IM. They trained the feed-forward multilayer-perceptron neural network using back propagation and showed the methodology's effectiveness or detection of the inter-turn short-circuit fault at non-stationary condition.

In a work, (Huang et al., 2015) presented the application of SVM for RUL prediction of bearing and other machine components. They considered vibration signals as the important feature in detecting the degradation rate of the machine. Their main motive behind the discussion was to discuss about the improved SVM algorithm and its effect on RUF life of the components. They showed that SVM is quite good in utilizing some data for estimating RUL of components but also mentioned that since SVM is a data driven algorithm which depends upon enough monitoring information so increase in class of monitoring techniques can be momentous for our future research work. In other work, (Satishkumar & Sugumaran, 2016) developed a predictive modeling technique based on Support Vector Regression method for forecasting the RUL of the bearing. They acquired vibration data of bearing in definite intervals till the bearing fails naturally. Since these many data was difficult to compute so they extracted 12 features out of it and finally selected only 8 features for their study. They concluded that the developed model was utmost par with all other method available. They also suggested that this method was good enough to deploy for the predictive modeling of other mechanical components.

Godoy et al. (2016) compared the four different classifier performance, namely fuzzy ARTMAP (adaptive resonance theory mapping), multilayer perceptron network, k -nearest neighbour, and SVM, in the detection of various severity levels of BRB faults using time-domain stator current. The result showed that classification accuracy is found to be over 95% with all the classifiers. In addition, they also showed that the diagnosis accuracy does not depend on various operating loads and speeds of the motor. Hussein et al. (2016) discussed ANFIS technique to find stator in turn short circuit fault in which they got high accuracy with low fault percentage. Gangsar and Tiwari (2016) classified the mechanical faults of IM at different loading and speed conditions using vibration signal with RBF function and found an increase in the classification accuracy with an increase in speed and loading with MSVM.

Pietrowski and Górny (2017) discussed stator winding fault detection in the motor through MLP and generalized regression neural netwrok (GRNN) and found that GRNN performs better than MLP. Lee et al. (2017) studied the deep neural network (DNN) for the broken rotor bar fault and bearing damage and found that the method is feasible in fault detection in fault diagnosis. Gangsar and Tiwari (2017a) presented a comparative analysis of mechanical faults of IM using vibration signal and electrical faults using a current signal with MSVM. They concluded vibration as well as current signature are both needed for simultaneous fault detection of mechanical and electrical faults together. Gangsar and Tiwari (2017b) compared time, frequency, and time–frequency domain-based features of vibration and current signal for monitoring different mechanical and electrical fault in IM with SVM technique and concluded that the time–frequency domain feature (CWT) gives the best results.

Subha et al. (2018) presented stator winding fault detection using current and voltage signal by using a fuzzy logic approach and found the present methods very effective as it gives the best output without any mathematical model. Al-Deen et al. (2018) considered a mechanical fault in the IM for diagnosis with MCSA and ANN and concluded that it is the cheapest and comparatively correct technique for fault diagnosis in IM. Islam and Kim (2018) introduced cyclic spectrum maps (CMS) of vibration signals with adaptive learning in deep convolution neural network (ADCNN) for bearing health state diagnosis. The CSMs are two-dimensional plots that indicates the distribution of cycle energy across different bands of the vibration spectrum. The present methodology outperforms other available methods in the literature. Rajamany and Srinivasan (2018) diagnosed the stator winding fault by using ANN techniques. In this study, they modelled the IM with stator turn fault and derived instantaneous phase voltages, peak values of phase currents, and parameters from the model which were used to train ANN and found effective performance.

Sheikh et al. (2018) proposed park’s vector approach with the ANN technique to classify the different severity of bearing fault and concluded that the performance of the present approach does not affect by the nonlinear effect of the motor under the fault conditions. Jigyasu et al. (2018) covered bearing, rotor, and stator fault for diagnosis in IM using current and vibration signal with ANN and mentioned that the current time analysis method is better than vibration analysis. Gangsar and Tiwari (2018b) Gangsar and Tiwari (2019b, c) successfully attempted SVM based fault diagnosis of Induction motor for limited data cases using WPT, CWT, and time-domain features, respectively. This study is important on AI-based fault diagnosis because it is not always possible to have data at all the operating conditions of the motor.

In other work, Xiao et al. (2018) performed LSTM based motor fault diagnosis of three phase induction motor by using vibration signals. They considered six fault classes such as one healthy motor, motor with faulty bearing, rotor imbalance, broken rotor bars, voltage imbalance and bowed rotor. After performing the experimentation they found that average classification accuracy of LSTM model was 98.28% with optimum batch size of 8. Furthermore the performance of the LSTM was validated by the comparative study of the following methods like LR, SVM, MLP with different layer sizes and RNN. From this study they concluded that the proposed method shown better accuracy in terms of health condition recognition of the motor.

In a work, Xia et al. (2019) developed the two stage model for the prediction of RUL of the bearing. In stage one, the entire life of the bearing was sub divided under ‘n’ different health stages and a DNN based classifier was used for the classification of the vibration signals. The classification results of different health stages were further optimized by the grid search method to get the optimum number of heath stages for better computation. The optimum health stages which they got were then used for the estimation of RUL of the bearing which is based on the shallow neural network of one or two hidden layer. For the better performance, they constructed ‘n’ ANN models for ‘n’ optimized health stages rather than using an individual ANN model which proved to be a better choice in concluding the prediction accuracy of RUL of the bearing.

Li et al. (2019) presented a methodology of regression model and ANN model for predicting the RUL of rolling element bearing. Root mean square and kurtosis were taken for the failure analysis of bearing. The regression model and ANN model was compared and results showed that ANN has better performance in predicting the RUL of the bearing. The reason is that the mean square error (MSE) value for ANN model was approximately half of the MSE value of regression model. In addition, they also fed output of regression model to Neural Network which had increased the performance of ANN model.

Drakaki et al. (2019) worked on BRB fault detection in Induction motor using a multi-agent system (MAS) approach using intelligent classifiers such as K-NN and feed-forward neural network (FANN). They also compared the proposed methodology with the ANFIS and found it very effective. Gangsar and Tiwari (2020) reviewed the work published on IM fault diagnosis in last two decades. In this study, firstly, they reviewed the various conventional methods used for motor fault diagnosis and their challenges. After that, they added AI-based technique developed for IM fault diagnosis. Finally, they presented the outcome, the research gap, and the future directions in condition monitoring of IM especially based on AI techniques.

The observations from the literature available on AI based fault diagnosis IM are tabulated in Table 1. This table comprise of considered machine and faults, signal and signal processing technique used, AI methods, and results and remarks.

For gear fault diagnosis

Here, important literature on AI-based techniques for gears are added in the last two decades. Wang et al. (2004) studied the neuro-fuzzy system with the combination of three robust signal processing technique (continuous wavelet transform (amplitude) and beta kurtosis based on the overall residual signal, and the phase modulation by employing the signal average) and then compared the performance with other three system (a pure fuzzy system with unity weights, a neuro-fuzzy system with unity weights, trained by the gradient method, a neuro-fuzzy system with constant weights, trained by the gradient method) and found it to be most accurate because of its adaptive capability and robust design. Samanta (2004) used time-domain vibration signal to extract failure features and then compared the performance of SVM and ANN classifier where it is found that the classification accuracy of SVM is better than ANN without GA and with GA comparable.

Zhi-qiang et al. (2005) performed the experiment with multi fault SVM classifier to find outwear and pitting fault in gear and compared with ANN and proved to be more effective because of its simple algorithm, good classification, and high efficiency. Xuan et al. (2005) considered the PSD of vibration signals to construct some original features and also to get useful features for SVM in gear fault diagnosis. In addition, genetic programming (GP) is also used and finally diagnosed the gear faults effectively. Guohua et al. (2006) used vibration signal decomposed into different frequency band through WPT for pitting fault in gear. The energy percentage of each frequency band was used as input to SVM and showed that the method successfully classified the pitting fault in gear with high veracity and reliability. Rafiee et al. (2007) diagnosed broken teeth fault in gear using vibration signal and ANN with 100% accuracy.

Khawaja et al. (2008) presented a diagnosis scheme based on the least square support vector machine (LS-SVM) on crack propagation of planetary gear and compared the result with probabilistic neural network (PNN) and classical two-class SVM. They showed encouraging advantages of LS-SVM because of its low run time overhead and robustness to handle vector features. Chang et al. (2008) performed the fault detection test in gear using PCA and SVM for error and noise reduction. They used PCA for extracting principle features from gearbox. They found extremely satisfying results with PCA-SVM combination with suitable kernel parameters. Zhiyuan et al. (2008) used a wavelet neural network based on the gradient descent optimization algorithm with vibration signals and found the output result very close to the ideal one. Wu and Hsu (2009) discussed applying fuzzy logic approach and DWT and found over 96% success rate. They showed that DWT is suitable to extract useful features from transient signals, which are difficult in time-domain analysis.

Similarly, Saravanan et al. (2009) used a fuzzy technique to identify the fault in bevel gear. The useful vibration features are extracted using a decision tree and then fed into a fuzzy classifier to detect the fault in bevel gear successfully. In other work, (Saravanan et al., 2010) compared the classification capability of ANN with Proximal SVM (PSVM). They used the J48 algorithm to select the suitable wavelength coefficients for input vectors to the classifiers. They found that the classification accuracies are the same for both the classifier; however, the time taken in ANN is more than PSVM. Saravanan and Ramachandran (2010) used the combination of discrete wavelet transform (DWT) for feature extraction and ANN for classification the incipient faults in spur bevel gear. The DWT is applied to extract the suitable features from the vibrational signals produced by bevel gear, describing the various gear conditions. The result showed the potential of the proposed methodology in gear fault diagnosis. Srihari et al. (2010) used multi-layer feed-forward NN to detect the faults in gear. They showed that the selection of NN layers is critical for building an optimal NN model. They found that ANN having two-layer is found to be optimum despite having the same level of accuracy in three-layers consuming more memory.

Liu et al. (2011) used linear discriminant analysis (LDA) and SVM for planetary gear fault diagnosis. In this work, they used LDA for feature extraction. Finally, they compared the performance of SVM with weighted k nearest neighbour and found that the proposed method outperforms in terms of accuracy and processing time. Fu and Fang (2011) studied the back propagation neural network's performance for spiral bevel gear drive for helicopter transmission. In this work, they used the DWT for feature extraction from vibration signals. They found better accuracy of the proposed methodology compared to the ANN alone. They also stated that DWT with BPNN is also suitable for diagnosing slight defects or defects at a very early stage in the gearbox. Hajnayeb et al. (2011) used vibration signals to diagnose broken teeth fault in gear with ANN's help along with GA and utility additive (UTA) method. They showed that the UTA has the advantage of less computation, and it is faster, and gives rough result, but GA has the advantage of the optimized solution.

Li et al. (2011) used bispectrum analysis of vibration signals with radial basis function neural network (RBFNN) to detect different severity of gear fault in the marine propulsion system. They applied RBFNN and BPNN classification methods to detect the fault and found RBFNN better. Zhou et al. (2011) applied the wavelet neural network (WNN) method to diagnose gear fault by de-noising the signals through wavelet packet analysis (WPA). They used an adaptive learning rate adjustment technique and gradient descent technique for parameter optimization. They showed that the WNN error speed had also been improved than others and eliminated the fluctuations in result which author find quick and accurate method.

Zhang et al. (2012) diagnosed gear fault by the application of wavelet transform and ANN. To stop the noise bio, orthogonal wavelet is used for feature extraction, and Levenberg–Marquardt (LM) algorithm is used to train the network. The proposed methodology proved to be accurate and useful. Lei et al. (2012) used an adaptive neuro-fuzzy inference system (ANFIS) technique to detect the fault in planetary gears using vibrational signals from multiple sensors. They compared the results of multi-sensor data fusion technique with other individual sensor techniques and proved to be superior to others in terms of processing time and robustness. Khazaee et al. (2012) used vibration signal in which time domain is converted to the frequency domain by FFT to study the worn tooth faces of planetary and ring gear with the help of least square SVM (LS-SVM) and found accuracy of 95.6% on test which is more significant than previous 85%.

Kang et al. (2012) used the SVM technique for fault classification of spur and helical gears by using wavelet packet coefficients as a feature factor processed by principle component analysis (PCA). In addition, particle swarm optimization (PSO) is used for SVM parameters optimization. Finally, they showed the effectiveness of the present methodology experimentally. Soleimani (2012) compared the performance of ANFIS and MLP NN in gear fault diagnosis by taking time–frequency characteristics extracted using wavelet packet analysis. They used an improved distance evaluation technique to remove unwanted signals. Finally they found ANFIS effective than MLP NN. Jolandan et al. (2012) extracted vibration signals from faulty gear and converted it into frequency domain from time domain by FFT. Then, required features are extracted using the J48 classification decision tree and then using the combination of J48-Fuzzy interface system (FIS) classifier the fault diagnosis found to be effective. They showed that the accuracy is higher at the higher rotational speed of gear.

Chen et al. (2013) used the WNN technique to find the gear damage using vibration features, which are extracted by WPA and convert into useful features. They showed that the proposed method effectively detects degradation of gear damage and gear crack under multiple fault modes. Fang (2013) applied BPNN for diagnosis and found an incremental increase in the accuracy by decreasing the error in test and training data by the use of GA. Zhou (2013) showed the comparison of SVM and ANN with vibration signals decomposed by wavelet transform (WT) into multiple frequency bands. Results showed that the SVM is better than ANN in this work. Han et al. (2013) reviewed different fault diagnosis approaches for gear such as FFT, Hilbert transform, empirical mode decomposition (EMD), and WT. From the literature, they showed the effective condition monitoring techniques can be developed with the help of artificial intelligence methods like ANN, SVM and relevance vector machine (RVM) with other conventional methods.

Bansal et al. (2013) applied SVM technique to find the faults in the gearbox. They showed that higher accuracy is found at higher angular speeds. Bordoloi and Tiwari (2013, 2014a, b) presented a novel technique of interpolation and extrapolation of data in SVM based fault diagnosis for gears based on time, frequency, and time–frequency domain features, respectively. In these studies, they have trained the SVM algorithm at two different speeds and tested at intermediate as well as extrapolated speeds and found significant results even in these cases. In other work, (Bordoloi & Tiwari, 2014a) examined the ability of SVM technique using Grid search method, GA and artificial-bee-colony algorithm (ABCA) and predict the fault at same angular speed, interpolated angular speed and extrapolated angular speed and found the better performance of GA and ABCA with respect to Grid search method using frequency domain data.

Akbari et al. (2014) used DWT and ANN-based fault diagnosis of the spur gear and bearing by considering five feature like RMS, crest factor, kurtosis, standard deviation and skewness of discrete wavelet coefficient. They have used maximum energy to Shannon entropy ratio for selecting suitable wavelet and discrete level. They found 100% accuracy by ANN. Zhang et al. (2014) performed chip fault damage detection through three analysis method are Levenberg–Marquardt backpropagation neural network (LM-BPNN), El-Alfy’s BPNN and Norgaard’s BPNN and found that the LM-BPNN technique is the best one in terms of accuracy and computation which is further validated using Fisher iris data available in the public domain. Fan et al. (2014) extracted characteristic amplitude ratios of frequency bands from the vibration spectrum and used them as a failure feature factor for the SVM classifier for different gear faults and found them encouraging.

Wu et al. (2015) applied a variable fuzzy nearness approach using vibration signals to diagnose gear fault and proved to be more effective and better than other traditional fuzzy approaches because of its multi-tasking ability. Chen et al. (2015) used a deep learning algorithm convolution neural network (CNN) for detecting various faults in gear like pitting, wearing and breakage using vibration signal. They have used various statistical parameters from the time and frequency domain and found significant results. Waqar et al. (2015) successfully used BPNN with power spectrum features of vibration signal for diagnosing the RPM and oil level related gearbox faults. Jedliński and Jonak (2015) compared the performance of SVM and MLP with and without wavelet transform (WT) of vibration signals in gear fault diagnosis. They have used two cases, one with raw vibration data and the second with the processed data using continuous wavelet transform. Results showed that the performance of both the classifiers significantly increases with the wavelet-based features.

Waqar and Demetgul (2016) used multi-layer perceptron neural network (MLPNN) to identify faulty worm gear with the use of sound and vibration signals and found it to be accurate up to 99.88% accurate. They also applied thermal imaging of healthy and faulty gear and found an effective pattern for gear fault diagnosis. Chen et al. (2016) used the fractional wavelet transform (FRWT) method to eliminate noise from useful vibration signals in the time and frequency domain for successful SVM classification of gear faults. Heydarzadeh et al. (2016) applied the deep neural network (DNN) method with three monitoring signals such as vibration, acoustic, and torque for gear fault analysis. They extracted features from DWT and found the present methodology advantageous for various conditions like different modalities, signal variabilities, and load conditions. Er-raoudi et al. (2016) applied MLPNN incorporated with DWT and PCA for feature selection and extraction, respectively. They simulated a gear drive in MATLAB/Simulink, and faults are simulated using meshing stiffness function such as bending, axial, shear, compressive, fillet foundation, and Hertzian stiffness. They used experimental data along with simulated data to show the effectiveness of the present methodology.

Jing et al. (2017) checked the CNN for its automatic feature extraction and selection capability and diagnosis in gear fault diagnosis. For this, they considered two cases, one with frequency data of vibration signals directly fed to CNN, and second, the convenient features are extracted manually from the frequency domain and fed to a fully connected neural network (FNN), SVM, and random forest (RF). They found a remarkable increase in accuracy of CNN-based automatic diagnosis by 10%. Liao et al. (2017) compared the performance on gear fault diagnosis of S-transform-CNN, Short time Fourier transform-convolutional neural network (STFT-CNN), and wavelet transform–convolutional neural network (WT–CNN) method using vibration signal and find out that the WT-CNN takes less iteration time to get the stable results. Tiwari et al. (2017) presented a comparison of SVM and ANN-based fault diagnosis of gears based on time-domain features. They also investigated the speed bandwidth of the training data for which interpolation/extrapolation predictions are reasonably good.

Chen et al. (2017) used vibration signals to extract various time and frequency domain features using deep neural network (DNN) and found that the present approach based on DNN is efficient, reliable, and robust in gear fault diagnosis. In other work, (Cheng et al., 2018) presented a fault prognostic model based on Particle filtering (PF) algorithm and RUL prediction of gearbox in a wind turbine. Fault features extracted from low current signals of the generator were fed to two data driven models for training viz., ANFIS and RNN. Here, RNN models was developed for the comparison purpose with ANFIS. These models were supposed to learn the state transition function of the fault features. Based on the learned state transition function, the PF algorithm was used to predict the RUL of the gearbox. They found that ANFIS performed better than RNN in terms of learning state transition function.

Kim and Choi (2019) compared the performance of the traditional algorithm with CNN based on transmission error (TE) and vibration signals for gear fault diagnosis and showed CNN perform better with TE than the vibration signals. Li et al. 2019 [1029 used current signals pre-processed by modified spectrum analysis in DNN based planetary gear box fault diagnosis. They showed the current signal with DNN showed effective performance but lesser than the vibration signals. Han et al. 2019 (Chen et al., 2016) compared the performance of various methods like fast Fourier transform–deep belief network method (FT-DBN), WT-CNN, Hilbert-Huang transform–convolutional neural network method (HT-CNN), and comprehensive deep neural network (CO-DNN) method. They used vibration signals of gear and found that WT-CNN gives better performance than FT-DBN and HT-CNN. In addition, they concluded that by combining the identification results of three methods, the CO-DNN can significantly improve the performance. Grezmak et al. (2019) compared the performance of DNN and deep convolution neural network (DCNN) with layer-wise relevance propagation (LRP) in gear fault diagnosis. They used the wavelet transform of vibration signals and LRP is used to show which part of the time–frequency signals is in the input of DCNN. The LRP based DCNN improves the performance and adaption of DNN in practical application.

In other work, (Cao et al., 2019) proposed LSTM based intelligent fault diagnosis of gearbox by extracting vibration signals from wind turbine driven test rig. In this study, five different health states, such as missed gear, surface fault gear, chipped gear, root crack gear and a healthy sun gear in planetary gearbox are discussed. The proposed methodology based on LSTM showed an average classification accuracy of 97.2% which is far higher than the mean classification accuracy of 84.2% of SVM model. Author also discussed that LSTM models does not rely on the well preferred features for better classification as they learn features directly from the raw signals. They added that optimizing the hyperparameters involve in the LSTM model can be a future work. Cirrincione et al. (2020) successfully used shallow neural networks i.e., the architectures with only one hidden layer for gear fault diagnosis. They used different features from vibration, torque, acoustic pressure, and electrical signals. They suggested that the DNN be reconsidered in fault diagnosis for their characteristics, not for their depth.

The observations from the literature available on AI based fault diagnosis for Gear are tabulated in Table 2. This table comprise of considered machine and faults, signal and signal processing technique used, AI methods, results and remarks.

For centrifugal pump fault diagnosis

Here, literature published on AI-based fault diagnosis for a centrifugal pump (CP) in the last decade has been added. In a work, (Zouari et al., 2004) described the fault in the centrifugal pump by considering a feature vector of pertinent parameters using signal processing techniques of different faults and classify the fault using a neural network whose limitation was overcome by Neuro-Fuzzy network. In addition, they found effective performance for different severity level of flow and cavitation. Wang and Chen (2007a) applied a fuzzy neural network (FNN) for the diagnosis of critical faults in CP such as cavitation, impeller damage, and unbalance. They applied synthetic-detection index (SDI) to select the best time-domain features. These features are used as input to FNN and found effective performance. Wang and Chen (2007b) considered cavitation, impeller, and misalignment related problems in centrifugal pump for diagnosis. They used the Daubechies wavelet function for the extraction of CWT based time–frequency data from vibration signals. They extracted non-dimensional symptom parameters from decomposed signals and used rough set theory to acquire diagnosis knowledge. Finally, they used a backpropagation neural network (BPNN) for training the data, and then the partially-linearized neural networks (PNNs) are used for testing the learned NNs. Results showed that the present approach quickly diagnose the pump faults with high accuracy.

Rajakarunakaran et al. (2008a) considered a various faults in CP and diagnosed it with two ANN techniques such as feed-forward network with backpropagation and an adaptive resonance network (ART1). They compared the two techniques and found the ART1 to have high fault classification accuracy for unsupervised input. Rajakarunakaran et al. (2008b) could classify twenty faults in CP by ANN technique with a classification accuracy of 100% by extracting effective features by PCA analysis. Ugechi et al. (2009) included the mechanical faults in the CP by using vibration signal as input parameters in the ANN technique and ended with the result that vibration based technique is well suited for the fault diagnosis of CP the output values come under acceptable range. Wang and Chen (2009) used PNN for the pump's fault diagnosis and to extract features, wavelet transform is used. The diagnosis knowledge is acquired by a Rough set for PNN learning, and PNN can quickly converge the relation between symptom and fault type with high accuracy.

Sakthivel et al. (2009) compared SVM's performance, Proximal SVM (PSVM), and other AI techniques for fault diagnosis of CP such as bearing faults, seal faults, impeller faults, cavitation, by using time-domain vibration signal. Convenient features are extracted using the J48 decision tree. They concluded that the SVM is better and both classification methods are better than ANN, Fuzzy Logic, and Rough set data technique. Sakthivel et al. (2010) compared the performance of the decision tree fuzzy method and the rough set fuzzy method by extracting time-domain vibration signals of CP and concluded that the decision tree fuzzy method is a good candidate for fault diagnosis with a 99.33% accuracy rate.

Muralidharan et al. (2010) discussed CP's faults by considering DWT techniques for fault feature extraction and ANN for fault diagnosis. They used different mother wavelets such as haar, Symlets, conflicts, Daubechies, Biorthogonal, reverse biorthogonal, and Meyer for feature selection and found that reverse biorthogonal is the best wavelet for this problem. They found ANN classification accuracy up to 100% with this mother wavelet. Ahonen et al. (2011) considered cavitation in CP for detection based on vibration. In this work, they used frequency converter's estimates for the pump's rotational speed and shaft torque. They set the rotational speed and shaft torque threshold values and concluded that the high flow cavitation could be easily detected by the present methods. Sakthivel et al. (2012) presented a set of rules for CP's fault diagnosis using a Rough set and fuzzy interface system (FIS). They studied the effect of different membership functions on FIS performance. Finally, they showed that the performance of FIS is better as compared to Anti-Miner Algorithm and MLP.

Farokhzad (2013) presented impeller, leakage, and cavitation related fault in CP in which FFT techniques extract transient signals, and then features are fed as an input to ANFIS got accuracy up to 90.67%. Farokhzad et al. (2013a) utilized the pump's vibration features and then every velocity signal is analysed by FFT for effective fault diagnosis of the CP based on regression analysis. Muralidharan and Sugumaran (2013) presented fault diagnostics of CP by using DWT for feature extraction and classify it with the J48 algorithm and found a classification accuracy of 99.84% by reverse biorthogonal wavelet function. Farokhzad et al. (2013b) presented fault diagnosis of CP based on the frequency spectrum analysis. They observed the frequency spectrum of healthy and faulty conditions of the pump and clearly distinguished the fault conditions based on their peak values. Azadeh et al. (2013) considered two CP faults and diagnosed it with SVM and ANN and compare their performance with decision tree and K- Nearest Neighborhood (KNN). The performance of SVM is found to be better than ANN, KNN, and decision tree. The performance of SVM improves when its parameters are optimized using GA and PSO. In addition, they found SVM with GA and PSO robust under noisy and corrupted data.

Sakthivel et al. (2014) compared the dimensionality reduction techniques (such as PCA, Hessian local linear embedding (LLE), isometric feature mapping (ISOMAP), Diffusion MAP, etc.) for the AI-based fault diagnosis of monoblock CP using vibration signals. In this study, they used various classifiers such as decision tree, Bayes Net Naïve Bayes, and kNN classifiers and showed that PCA-decision tree combination gives better accuracy than other combinations.

Nourmohammadzadeh and Hartmann (2015) presented fault classification of a CP in a normal and noisy environment with ANN and SVM enhanced by a genetic algorithm. They showed that GA significantly improves the performance of the classifiers. They also concluded that SVM with Gaussian kernel function gives the best accuracy incorrect fault diagnosis and excellent robustness against noise. Rapur and Tiwari (2016) successfully presented a diagnosis of blockage in CP based on frequency domain vibration signals using SVM. Al Tobi et al. (2017) considered mechanical and hydraulic faults in CP based on MLP in which WT techniques extract features. Features are further selected by GA optimization technique, and then the result is modified by BP technique.

Azizi et al. (2017) proposed the CP's cavitation severity by decomposing time-domain signal into no. of IMD. Finally, the selected features are fed as input to different classification algorithms like GRNN, MLP, and RBF. They concluded that the classifier’s accuracy is increased to 100% through the hybrid feature selection technique. Shervani-Tabar et al. (2018) successfully diagnosed cavitation with varying intensities in CP based on SVM using vibration signals. Hajnayeb et al. (2017) studied the cavitation severity levels and its prediction in CP using vibration signal. They extracted features using EMD and DWT and concluded that the present methodology has high effectiveness and fast computation ability. Panda et al. (2018) considered the cavitation fault and blockage fault in CP for diagnosis with the SVM technique and found it efficient and mentioned that too much data is not required for good results. Dutta et al. (2018) efficiently performed the diagnosis of cavitation based on SVM. In this work, they study how the vibration, variation of speed, and pressure together affects the cavitation. However, the cavitation can be successfully detected by SVM using vibration signals, speed, and flow rate.

Rapur and Tiwari (2017; 2018a, b) presented fault diagnosis of CP based on the time domain, frequency domain, time–frequency domain features, respectively. They successfully attempted the diagnosis for limited operating conditions cases by considering the interpolation and extrapolation cases. In other work, (Rapur & Tiwari, 2019a, b) used current signal in conjunction with vibration signals for diagnosing various mechanical as well as hydraulic faults in CPs based on SVM. In these studies, they successfully used the time domain and wavelet features, respectively. They performed the diagnosis at a very large range of operating speeds of the pump, and the diagnosis found to be independent of the speeds. Li et al. (2019c) presented CP and bearing fault diagnosis based on deep structure and sparse least squares support vector machine (DSLSSVM). In this work, a deep network structure is established through the superposition of a multi-layer SVM and finally showed that the higher performance than the other methods such as SVM and CNN.

Rapur & Tiwari (2020) explored an intelligent and robust fault diagnosis of CP using noisy vibration and current signals. In this work, they used frequency-based features and multiclass SVM. The result showed that the present methodology is very useful in classifying the CP faults even with 3% and 5% noise in the data. Sayed et al. (2020) used eleven vibration features with ANN to detect faults (seal faults and metal chip) in pumps that have leakage with and particles impurities hitting impeller two drops per second leak and one hundred twenty micrometer aluminum chip. They showed that the fault is difficult to detect using conventional signal processing techniques; however, it can be easily detected using data-driven method like ANN, but it comes with the cost of requirement much more data than signal processing techniques.

The observations from the literature available on AI based fault diagnosis for CP are tabulated in Table 3. This table comprise of considered machine and faults, signal and signal processing technique used, AI methods, results and remarks.

Observation, research gap, and ideas

Some important observations are mentioned below from the literature reviewed on fault diagnosis of Industrial Machines:

-

Different types of faults in various industrial machines have been focused in the literature. For example, bearing fault, stator winding fault, broken rotor fault, etc. are the most critical faults in IM; broken tooth, chipped tooth, wear, spalling, etc. are critical fault conditions in Gear, while faults like cavitation, impeller damage, Misalignment, unbalance are crucial in CPs. These machines' faults are considered individually for the diagnosis; however, the combined study of the faults of these machines is still rare. In addition, very few researchers have considered the simultaneous occurrence of these faults in a machine for diagnosis.

-

Different faults with different severity levels may arise in all types of machines in an operational state, so it is essential to consider the fault under progression to detect the fault at the initial stage, which is found very rare in the research work.

-

Different condition monitoring techniques have been used for the fault diagnosis of various industrial machines by using vibration signals, stator current, Magnetic fields, thermal analysis etc. From the literature it is noted that vibration and current signals have been widely used for fault diagnosis of all type of machines as it is easily measurable and gives excellent results compared to other signals.

-

Nowadays AI techniques are getting preference in condition monitoring in all type of industry compared to other conventional techniques. It is noted that AI-based condition monitoring techniques are data-based technique. Therefore, it is always required to have large useful datasets for better diagnosis. The more useful datasets lead to accurate fault detection in the machines.

-

Most of the researchers have considered individual A.I technique for fault diagnosis of machines and found good results; however, Nowadays, Hybrid AI technique like ANFIS (the combination of ANN and Fuzzy logic) and advanced methods like deep learning are getting popularity for fault diagnosis because of their excellent performance compared to an individual AI technique.

-

In AI-based fault diagnosis, the useful fault features can be extracted using different signal processing methods like time, frequency, and time–frequency methods. From the literature, it is observed that wavelets have an immense scope as it can significantly improve the performance of an AI-based technique. There are several other wavelets available that can be used for the fault diagnosis of different industrial machines. So the choice of correct wavelets is still an open discussion in the future.

-

All the AI-based diagnostic systems are based on history or current database available in the industry for different machines. However, it is impossible to have a database at all the operating conditions of machines. Therefore, it is crucial to develop a diagnostic system that can detect the faults at the particular operating conditions for which the AI model is not already trained.

-

Generalization of the AI-based techniques is one of the challenging aspects in fault diagnosis and may be considered on a priority basis in the near future.

-

A single diagnostic system can be developed for the combined fault diagnosis of various industrial machines like a big rotor system consist of a rotor and many bearings, a pump paired with IM, engine consist of rotor, bearing, and gears. This will reduce a big financial burden coming on industries for individual machine fault diagnosis.

Conclusion

This paper has given a general review of the recent developments in the field of AI-based diagnostic systems for various machines like induction motor, bearing, gear, and CP. It has mainly covered the extensive literatures on fuzzy logic, ANNs, SVM, and DL in machine condition monitoring and fault diagnosis. The observations, research gaps and new ideas of using AI in condition monitoring are discussed. In addition, main findings are also added in the tabular form for IM, gear, and CPs. Generalization of the AI-based fault diagnosis is one of the challenging aspects in fault diagnosis and may be considered on a priority basis in the near future. Furthermore, the research and development of AI in the diagnosis of industrial machines is the focus of this work. Following that, the literature published in the field of AI in machine prognosis for discovering the RUL may be reviewed. It is believed that the AI based technique will bring revolution in condition monitoring of machines in the industry which helps in achieving goals of Industry 4.0 revolution.

Abbreviations

- AI:

-

Artificial intelligence

- ABCA:

-

Artificial-bee-colony algorithm

- ADCNN:

-

Adaptive learning in deep convolution neural network

- ANFIS:

-

Artificial neuro fuzzy system

- ANN:

-

Artificial neural network

- ART:

-

Adaptive resonance theory

- ARTMAP:

-

Adaptive resonance theory mapping

- BBS:

-

Best basis selection

- BF:

-

Bearing fault

- BP:

-

Backpropagation

- BRB:

-

Broken-rotor bar

- CART:

-

Classification and regression tree

- CBM:

-

Condition-based maintenance

- CNN:

-

Convolution neural network

- CP:

-

Centrifugal pump

- CWT:

-

Continues wavelet transform

- CV:

-

Cross-validation

- CVA:

-

Common vector approach

- DAG:

-

Direct acyclic graph

- DAQ:

-

Data acquisition system

- DC:

-

Direct current

- DNN:

-

Deep neural network

- DWT:

-

Discrete wavelet transform

- EOP:

-

Emergency operating procedure

- ERM:

-

Empirical risk minimization

- EPVA:

-

Extended park’s vector approach

- EWN:

-

Evolving wavelet network

- FL:

-

Fuzzy logic

- FFT:

-

Fast fourier transform

- FNN:

-

Fuzzy neural network

- GA:

-

Genetic algorithm

- GDA:

-

Generalized discrimination analysis

- HMM:

-

Hidden markov model

- HHT:

-

Hilbert-huang transform

- HOS:

-

Higher order statistics

- HT:

-

Hilbert transform

- IACO:

-

Improved ant colony optimization

- ICA:

-

Independent component analysis

- IM:

-

Induction motor

- IR:

-

Infrared

- ISOMAP:

-

Isometric feature Mapping

- KNN:

-

K- nearest neighborhood

- LDA:

-

Linear discriminant analysis

- LIBSVM:

-

A library for support vector machine

- MCSA:

-

Motor current signature analysis

- MFS:

-

Machine fault simulator

- ML:

-

Machine learning

- MLBS:

-

Multi-level basis selection

- MLP:

-

Multilayer perceptron

- MLPNN:

-

Multi-layer perceptron neural network

- MRA:

-

Multi-resolution analysis

- MSVM:

-

Multi support vector machine

- MUSIC:

-

Multiple signal classification

- OVA:

-

One versus all

- OASYS:

-

On-line operator aid system

- OVO:

-

One versus one

- PCA:

-

Principal component analysis

- PD:

-

Partial discharge

- PDF:

-

Probability distribution function

- PSD:

-

Probability spectral density

- PSWT:

-

Pitch synchronous wavelet transform

- PUF:

-

Phase unbalance fault

- PVM:

-

Park vector machine

- RBF:

-

Radial basis function

- RBFNN:

-

Radial basis function neural network

- RFE:

-

Recursive feature elimination

- RMS:

-

Root mean square

- RUWPT:

-

Recursive un-decimated wavelet packet transform

- RWE:

-

Relative wavelet energy

- SFAM:

-

Simplified fuzzy ARTMAP

- SOM:

-

Self-organizing map

- SRM:

-

Structural risk minimization

- STFT:

-

Short time fourier transform

- SVM:

-

Support vector machine

- SWF:

-

Stator winding fault

- SWPT:

-

Stationary wavelet packet transform

- SVs:

-

Support vectors

- TDA:

-

Time domain averaging

- UMP:

-

Unbalanced magnetic pull

- UTA:

-

Utility additive method

- WNN:

-

Wavelet neural network

- WPA:

-

Wavelet packet analysis

- WPT:

-

Wavelet packet transform

- WT:

-

Wavelet transform

- WVD:

-

Wigner-ville distribution

References

Ahonen, T., Tamminen, J., Ahola, J., & Kestil, J. (2011). Novel method for detecting cavitation in centrifugal pump with frequency converter. Insight-Non-Destructive Testing and Condition Monitoring, 53(8), 439–449.

Akar, M., & Cankaya, I. (2012). Broken rotor bar fault detection in inverter-fed squirrel cage induction motors using stator current analysis and fuzzy logic. Turkish Journal of Electrical Engineering & Computer Sciences, 20(1), 1077–1089.

Akbari, M., Homaei, H., & Heidari, M. (2014). An intelligent fault diagnosis approach for gears and bearings based on wavelet transform as a preprocessor and artificial neural networks. International Journal of Mathematical Modeling & Computations, 4(04), 309–329.

Al Tobi, M. A. S., Bevan, G., Ramachandran, K. P., Wallace, P., & Harrison, D. (2017). Experimental set-up for investigation of fault diagnosis of a centrifugal pump. World Academy of Science, Engineering and Technology, International Journal of Mechanical, Aerospace, Industrial, Mechatronic and Manufacturing Engineering, 11(3), 481–485.

Al-Deen, K. N., Hummes, D., Fruth, B., Caironi, C., Ghaffar, A. A. and Karas, M. (2018). Signature analysis as a medium for faults detection in induction motors. In 2018 International Conference on Computing Sciences and Engineering (ICCSE) (pp. 1-6). IEEE.

Ali, Y. H. (2018). Artificial intelligence application in machine condition monitoring and fault diagnosis. Artificial Intelligence: Emerging Trends and Applications, 275

Arabacı, H., & Bi̇lgi̇n, O. (2005). The detection of broken rotor bars in squirrel cage induction motors based on neural network approach. MS, Selçuk University graduate school of natural and applied sciences, Konya.

Arabacı, H., & Bilgin, O. (2010). Automatic detection and classification of rotor cage faults in squirrel cage induction motor. Neural Computing and Applications, 19(5), 713–723.

Azadeh, A., Saberi, M., Kazem, A., Ebrahimipour, V., Nourmohammadzadeh, A., & Saberi, Z. (2013). A flexible algorithm for fault diagnosis in a centrifugal pump with corrupted data and noise based on ANN and support vector machine with hyper-parameters optimization. Applied Soft Computing, 13(3), 1478–1485.

Azizi, R., Attaran, B., Hajnayeb, A., Ghanbarzadeh, A., & Changizian, M. (2017). Improving accuracy of cavitation severity detection in centrifugal pumps using a hybrid feature selection technique. Measurement, 108, 9–17.

Bansal, S., Sahoo, S., Tiwari, R., & Bordoloi, D. J. (2013). Multiclass fault diagnosis in gears using support vector machine algorithms based on frequency domain data. Measurement, 46(9), 3469–3481.

Bessam, B., Menacer, A., Boumehraz, M., & Cherif, H. (2015). A novel method for induction motors stator inter-turn short circuit fault diagnosis based on wavelet energy and neural network. In 2015 IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED) (pp. 143-149). IEEE.

Bhavsar, R. C., Patel, R. A., & Bhalja, B. R. (2014). Condition monitoring of induction motor using artificial neural network. In 2014 Annual International Conference on Emerging Research Areas: Magnetics, Machines and Drives (AICERA/iCMMD) (pp. 1-6). IEEE.

Bordoloi, D. J., & Tiwari, R. (2013). Optimization of support vector machine based multi-fault classification with evolutionary algorithms from time domain vibration data of gears. Proceedings of the Institution of Mechanical Engineers, Part c: Journal of Mechanical Engineering Science, 227(11), 2428–2439.

Bordoloi, D. J., & Tiwari, R. (2014a). Optimum multi-fault classification of gears with integration of evolutionary and SVM algorithms. Mechanism and Machine Theory, 73, 49–60.

Bordoloi, D. J., & Tiwari, R. (2014b). Support vector machine based optimization of multi-fault classification of gears with evolutionary algorithms from time–frequency vibration data. Measurement, 55, 1–14.

Bouzid, M., Champenois, G., Bellaaj, N., & Jelassi, K. (2010). Automatic and robust diagnosis of broken rotor bars fault in induction motor. In The XIX International Conference on Electrical Machines-ICEM 2010 (pp. 1-7). IEEE.

Caldera, S., Nuccio, S., Poma, G. and Galluzzo, G. R., (1998). An adaptive network based fuzzy diagnostic system for linear induction motor drives. In IMTC/98 Conference Proceedings. IEEE Instrumentation and Measurement Technology Conference. Where Instrumentation is Going (Cat. No. 98CH36222) (Vol. 1, pp. 320–324). IEEE.