Abstract

Due to clay having little or no impressive engineering properties causes a need to develop its properties prior to construction taking place as foundation play a very essential and important role hence the need for soil stabilization techniques. This study focuses on the utilization of waste glass in stabilizing and improving the soil shear strength parameters. Waste glass passing 0.075 µm sieve and 0.300 µm sieve was sequentially added in soil with 0, 6, 8, 10 and 12%. According to unified soil classification system the soil is low plasticity clay, CL. Direct shear strength tests were performed on un-stabilized soil and waste glass added sample to see the effect of waste glass addition on cohesion and angle of internal friction. From the results obtained 10% was found to be optimum addition value for waste glass for this since it improves cohesion values from 4 to 12 kPa for 0.300 µm sieve passing added waste glass and 4–17 kPa for 0.075 µm sieve passing added waste glass while angle of internal friction showed a continual decrease for each waste glass added which may be attributed to the characteristics of the waste glass and chemical compositions. Results showed 8% to be the optimum value as internal angle of friction and cohesion values peaked but showed decrease as the percent increased afterwards. Waste glass increases the cohesion amongst the soil particles thereby changing the shear strength parameter for the soil. Waste glass is a suitable stabilizer for clay soil.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Soil since inception of time, has always been a crucial and essential building material. However some soils may have low mechanical properties which needs improvement. Such properties include shear strength, lateral earth pressure, consolidation, bearing capacity, slope stability and permeability & seepage amongst others. In which shear strength relates to the amount of shear a substance or material can endure or abide and not fracture. Shear strength knowledge is crucial as it’s used in the design of foundations, embankments for dams, roads, pavement, excavations, levees etc. the analysis of the stability of slope is evaluated using shear strength and the bearing capacity of the soil. A method to overcome weakness of soil is called stabilization in which materials are injected or mixed with the soil to attain certain results which show a positive result on the properties and also an economical way to do so. Shear strength of soils depend on certain factors such as stress history, water content, soil structure, drainage conditions, rate of load, degree of saturation and soil composition amongst others. Waste is a big issue especially as the rate in which waste is generated, for example agriculture, private or commercial industries or hospitals etc. can’t meet up with its rate of safe disposal without harming the area, environment etc. due to massive amount of waste. Emissions from waste sites or landfills are not of good benefit to the environment, humans or the ozone layer. A way to solve this dilemma is to recycle and reuse such materials by making them useful to certain needs and demands. Due to this dilemma, using waste glass a stabilizer was established. The aim of this study is to check the geotechnical properties of soil mainly shear strength which has been mixed and stabilized with waste glass at 0, 6, 8, 10 and 12% with tests conducted in a laboratory. This percentages were used in this study in relation with percentages used in previous studies, to have comparison values and also to see how it affects the clayey soil properties as well as to determine an optimum value. Ibrahim et al. [1] used waste glass on expansive soil [CH]. Tests such as Atterberg limits, unconfined compressive strength etc. was conducted with waste glass added in 6, 12, 18, 27, and 36% of the dry weight of soil. Results from the tests conducted showed a positive result and showed that the characteristics improved by adding glass. Olufowobi-Ogundoju et al. [2] used waste glass with clay soil. Tests such as moisture content, specific gravity, particle size distribution Atterberg limits, and direct shear tests were conducted. The soil was classified as a group 4–6 which was fair to poor. Waste glass was added in percent such as: 2,5,10 and 15%.Maximum values for cohesion and angle of friction were obtained at 10% waste glass although 15/5 cement was used as based throughout. Maximum cohesion and angle of internal friction values of 17.0 and 15.0 respectively were obtained at 10% glass powder content [3] used a clay soil sub grade with waste glass. They carried out tests such as compaction (optimum moisture content), CBR, and Atterberg limits. The soil was a 7–6 clay soil. Results showed that 10% waste glass was optimum percent to add by the dry unit weight of the soil to improve the subgrade. Sambo [4] used a black cotton soil which was obtained at about a depth of 7 m and mixed it with waste glass. Tests such as liquid limit, plastic limit, optimum moisture content, California bearing ratio and maximum dry density were carried out. Waste glass was added in 0, 2, 4, 6, 8% replacement by weight. 8% showed the best results.

2 Research Significance

In this research waste glass (powdered) will be used in stabilizing soil. Shear strength test was be conducted. Two major engineering properties will be namely cohesion[c] and angle of internal friction [ф] as they determined the shear strength of a soil. Comparison will be made between the cohesion and internal angle of friction values for raw soil sample and soil sample mixed with waste glass. A comparison will be made with previous studies to see if the optimum value obtained for them correspond.

3 Materials

3.1 Soil

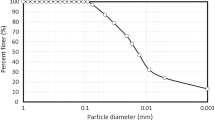

The research was conducted by utilizing different materials such as soil, waste glass, and distilled water. The soil was oven dried and sieved to obtain fine soils [0.075 µm passing]. Only the fine part was used in this study which was 0.075 µm sieve passing. The grain size distribution of the soil was obtained in accordance with ASTM D421. The physical properties of the soil used are shown in Table 1 and sieved soil is shown in Fig. 1.

3.2 Waste Glass

The waste glass was obtained locally, cleaned, crushed using the Los Angeles abrasion machine then sieved to obtain 0.075 and 0.300 µm size passing. Sieved waste glass of 0.075 µm passing and 0.300 µm passing is shown in Figs. 2 and 3, respectively. Figures 4 and 5 show the soil sample before and after mix. Waste glass was added to the soil sample by the dry unit weight of the soil.

4 Results and Discussions

4.1 Direct Shear Test

This test was conducted in drained conditions. As stated in the early part of this article the test was conducted with two different waste glass size sample namely 0.300 µm sieve passing and 0.075 µm sieve passing. Pace rate was kept constant throughout at 0.5 mm/min. Each test completion time until failure ranged from 10 to 13 min’ with 13 min’ been maximum and 10 min’ minimum. For both 0.300 and 0.075 µm, cohesion showed a positive increase up till 10% addition. Figure 6 graph which indicates cohesion values against WG% addition for 0.3 µm and show 10% WG peaking while Fig. 7 graph indicates angle of internal against WG% addition for 0.3 µm and show the gradual decrease as WG increased. Figures 8 and 9 show a combined graph of cohesion and angle of internal friction values for 0.300 µm while Figs. 10 and 11 show a bar graph of cohesion values and angle of internal friction. These figures show even at 6% addition of waste glass for 0.300 and 0.075 µm respectively there is a continuous decrease as the percent goes up. These values corresponds with studies from AbdulZahra (2018), Benny et al. (2020) study which found 8% to be the optimum WG added to clay soil subgrade otherwise there will be a decline in value. Dadkhahs’ et al. [5] pointed out the inverse increase and decrease can be antecedent towards the shape of the shear box and density as well. The variation in the results could also be attributed to soil types for example black cotton soil showed 8% to be optimum, likewise for high plasticity soil and the gradation or granular nature of the waste glass (Sambo 2019, Javed 2020). Jared (2020) shear strength parameter of soil showed the waste glass mixtures changed as there was increase cohesion but decrease in angle of friction among the soil particles mainly after 10%. It can be determined that the angle of internal friction and cohesion values for the soil would increase when Waste glass powder has been added to maximum value of 10% Al-neami et al. [6], Javed and Chakraborty [7]. Jareds’ (2020) study showed 10% to be the optimum percent value to add waste glass (Tables 2 and 3).

4.2 Microstructural Analysis of WG in Fine Soil

Scanning electron microscopy (SEM) was conducted in each percent replaced but only was 0.075 µm at 8% and 0.300 µm at 8% is included in this paper. Circular prints on the images indicate waste glass. X-ray power diffraction (XRD) was conducted in the same fashion and 0.075 at 8% and 0.300 at 8% is included in this paper with 02si (quartz) been the highest mineral content which can be attributed to the waste glass and soil type. Other elements contained include CaCO3, AlO4, S-Ti2, Mg-O etc. Some elements, on the other hand, have to be missing for good bonding with other elements to build a powerful compound that might maintain weak soil (Figs. 12 and 13).

5 Conclusion

For this study, multiple direct shear tests were carried out on low plasticity soil samples with various waste glasses been added at certain percent which have been sieved through 0.300 and 0.075 µm respectively with the intent to check how it impacts the shear strength.

For both 0.300 and 0.075 µm samples, cohesion showed a positive increase up till 10%waste glass addition. Angle of internal friction on the other hand showed a decrease as waste glass percent increased. There is increase in the frictional forces due to the movement of the soils particles which increase the shear strength for the granular materials. The test carried out for this test was bounded to direct shear test with drained conditions. The variation in the results could also be attributed to soil type for example black cotton soil showed 8% to be optimum, likewise for high plasticity soil and the gradation or granular nature of the waste glass according to literature. Shear strength parameter of soil showed the waste glass mixtures changed as there was an increase for cohesion but decrease in angle of friction among the soil particles mainly after 10%. According to the recent finding done, it can be said that the angle of friction and cohesion values for the soil would increase when Waste glass powder has been added to maximum value of 10%. Comprehensively it can be decided that utilization of waste glass for soil stabilization is a suitable, effective, cheap and environment friendly in terms of pollution.

Further studies should be considered with drainage factors for the shear tests and also using various soils types to compare the results. A focus could be in regards to how the chemical composition of waste glass affects soil properties and the values obtained in terms of cohesion and angle of internal friction. Tests can be conducted with various direct shear test box sizes, and the results obtained should be evaluated accordingly.

References

Ibrahim H, Mawlood Y, Alshkane Y (2019) Using waste glass powder for stabilizing high-plasticity clay in Erbil city-Iraq. Int J Geotech Eng 15:1–8. https://doi.org/10.1080/19386362.2019.1647644

Olufowobi J, Ogundoju A, Michael B, Aderinlewo O (2014) Clay Soil Stabilisation Using Powdered GlasS. J Engi Sci Technol 9:541–558

Lingwanda MI (2018) Use of waste glass in improving subgrade soil properties. IJRETijreT. https://ijret.org/volumes/2018v07/i04/IJRET20180704005.pdf

Sambo AHBOA, Sani JE (2019 May 5) Black cotton soil stabilization using glass powder. Int J Innovative Res Sci Eng Technol. https://www.researchgate.net/publication/333547655_Black_Cotton_Soil_Stabilization_using_Glass_Powder

Dadkhah R, Ghafoori M, Ajalloeian R, Lashkaripo G (2010) The effect of scale direct shear test on the strength parameters of clayey sand in Isfahan city, Iran. J Appl Sci 10(18):2027–2033. https://doi.org/10.3923/jas.2010.2027.2033

Al-Neami MA, Al-Soudany K, Dawod A (2015) Remediation Of cohesive soils using waste glass

Javed SA, Chakraborty S (2020) Effects of waste glass powder on subgrade soil improvement. 144, 30–42

Babatunde AO, Sani JE, Sambo H (2019) Black cotton soil stabilization using glass powder. 8, 5208–5214. https://doi.org/10.15680/IJIRSET.2019.0805053

Salamatpoor S, Salamatpoor S (2017) Evaluation of adding crushed glass to different combinations of cement-stabilized sand. Int J Geo-Eng 8(1). https://doi.org/10.1186/s40703-017-0044-0

Siyab Khan M, Tufail M, Mateeullah M (2018) Effects of waste glass powder on the geotechnical properties of loose subsoils. Civil Eng J 4(9):2044. https://doi.org/10.28991/cej-03091137

Lee T (2007) Recycled glass and dredged materials. 13. https://www.researchgate.net/publication/235023644_Recycled_Glass_and_Dredged_Materials

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Ojotisa, V., Balkis, A.P. (2023). Improvement of Shear Strength of Fine-Grained Soils by Waste Glass. In: Atalar, C., Çinicioğlu, F. (eds) 5th International Conference on New Developments in Soil Mechanics and Geotechnical Engineering. ZM 2022. Lecture Notes in Civil Engineering, vol 305. Springer, Cham. https://doi.org/10.1007/978-3-031-20172-1_48

Download citation

DOI: https://doi.org/10.1007/978-3-031-20172-1_48

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-20171-4

Online ISBN: 978-3-031-20172-1

eBook Packages: EngineeringEngineering (R0)