Abstract

Poor clayey soils mainly exhibit the property of swelling/shrinkage when they react to moisture variations. This property causes development of cracks in the structures resting on these soils which poses instability to the structures. Soil stabilization is a technique to enhance the geotechnical characteristics of poor clayey soils by changing their properties. Due to rapid growth in construction industry, a lot of waste material is being generated every day which poses problem of its disposal. If the waste material can be utilized for soil stabilization, it will mitigate the problems of its disposal. This study is an attempt to assess the efficacy of various waste materials such as construction waste and glass waste on numerous properties of soil. The tests results evaluate that the strength of the poor soils increased by use of these two waste materials.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Now a day, the sites with good geotechnical properties hardly exist to fulfill the demand of new infrastructure due to the rise in population. Only option left to overcome this problem is to use sites having poor geotechnical properties like poor drainage characteristics, low bearing capacity etc. Construction on these type of soils leads to cracking and breaking up of pavements, highway embankments, roadway foundations, retaining walls which leads to wastage of huge sum of money in repairing these damaged structures. Structures founded on soils with very high clay content shrink and swell when introduced to water, resulting in settlement of structures and pavements. If the geotechnical properties of concerned soils can be recovered then these losses can be reduced. Various improvement techniques like replacement of poor soil with good one and soil stabilization are used to boost the geotechnical properties of soil. Out of these techniques soil stabilization proves to be the best in terms of cost. Different types of materials are blended with natural soil to enhance physical, mechanical and chemical properties of poor soils. Construction waste if used in soil stabilization, pavement construction then it can become a best remedial measure to management of waste disposal. As proposed by Fatta et al. (2003). Use of recycled concrete aggregate (RCA) in sub base and base course in case of pavement is cost effective (Park 2003). C&D waste which is subjected to crushing decreases the peak friction angle (Sivakumar et al. 2004). The CBR value of RCA was found to be nearly same and thus recycled aggregates can be used for sub-base course construction (Poon and Chan 2005). Ransinchung et al. (2012) conducted UCS, California bearing ratio (CBR), and split tensile strength (STS) tests on various soil mixes by adding fine crushed cubes comprising concrete and cement and noticed a better enhancement in properties of poor soils. The use of RCA waste was found to be beneficial than expending quarry granular sub based constituents (Arulrajah et al. 2012). The use of geogrid along with C&D wastes in roadway applications was found to be significant (Rahman et al. 2014). RCA waste from construction industry may be effectively used as based and sub-base for paving in low traffic flow (Fucale 2014).

2 Experimental Analysis

2.1 Materials

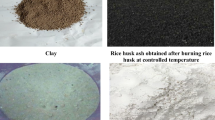

Clayey Soil:

According to Indian Soil Classification system, soil used in the present study is classified as CH. Table 1 shows the properties of the clayey soil. The gradation curve of the clayey soil is presented in Fig. 1. From particle size distribution curve, it is concluded that soil particles finer than 75 microns are in excess and particles finer than clay size is about 33%.

Construction and Demolition Waste:

The construction waste was procured from a demolished building nearby by Anu, Hamirpur. The floor mortar consists of cement and sand mixed in ratio of 1: 2. The material was composed of lumps which were dried, pulverized and were sieved through 4.75 mm sieve. The gradation curve of the construction waste is presented in Fig. 1.

Glass Waste:

Waste glass was procured from a broken window of a demolished building. It was obtained in broken form which was later powdered and passed through 4.75 mm sieve. The gradation curve of glass waste is shown in Fig. 1 which lies in the range of construction waste curve. The chemical composition of glass waste mainly contains SiO2 having 70–75% content, Na2O in the range 12–18% and traces of other chemicals such as K2O, CaO, Al2O3, MgO etc.

3 Results and Discussion

3.1 Compaction Characteristics

Compaction Curve of Clay: C&D Waste

Construction waste in varying proportions from 12 to 24% was added to poor clayey soils. On increasing C&D content up to 24%, both MDD and OMC were found to be decreased from 1.71 g/cc to 1.56 g/cc and from 19% to 16% respectively as presented in Fig. 2. This is mainly attributed to the existence of small grained material of construction waste which yields low specific area and also because of the resistance provided to densification due to flocculation of cementing material which remained unreacted.

Compaction curve of Clay: Glass Waste

Compaction :tests were executed on clayey soil with addition of glass waste in varying proportions of 3, 5, 7, and 9% and compaction curve was drawn in Fig. 3. The accumulation of glass waste: to clayey soil increased its MDD from 1.71 g/cc to 1.76 g/cc and reduced the OMC value from 19% to 16% which is mainly attributed to the occurrence of fine material in glass waste holding low specific area and also can also be contributed to flocculation of unreacted cement providing confrontation to densification.

Compaction Characteristics of Clay: C&D: Glass Waste

Glass waste in percentages of 3%, 5% and 7% was added to clayey soil and percentage of C&D waste was kept constant as 24% as shown in Fig. 4. MDD increased up to 5% after blending both the materials with clayey soil. The MDD increased from 1.71 g/cc to 1.78 g/cc.

Unconfined Compressive Strength Test

The unconfined compressive strength of soil and composite mix were determined as per (IS 2720-10-1991). The addition of C&D waste and glass waste in soil increased the UCS value in comparison of un-stabilized soil with curing period of 1, 7 and 28 days as shown in Figs. 5 and 6. The UCS value increased up to 24% of C&D waste content. The inclusion of glass waste content in soil: C&D waste mix having ratio 76:24 significantly increased the UCS value up to 5% of glass waste content, afterward dropped by adding more content of glass waste. The UCS value for optimum mix of Clay: C&D with varying content of glass waste for 28 days curing period is shown in Fig. 7. The increase in the UCS value occurred as a result of filling of voids present in the poor soil with finer particles of C&D particles and glass waste particles.

4 Conclusions

The waste materials pose a great problem of disposal due to scarcity of land and if same can be used in soil stabilization may prove to be beneficial for environment. Now a day, environmental pollution is of great concern. Based on this, two waste materials were selected for study; construction demolition waste and glass waste. The results showed an overall improvement in different properties of soil which led to its stabilization with the optimum mixes of waste materials. Hence, it can be concluded that CDW and waste glass in optimum content may be used for the betterment of poor soil which will not only solve the problem encountered in construction with poor clayey soils but will also solve the disposal problem of waste materials along with prove to be less costly for stabilization.

References

Fatta D, Papadopoulos A, Avramikos E, Sgourou E, Moustakas K, Kourmoussis F (2003) Generation and management of construction and demolition waste in Greece—an existing challenge. Resour Conserv Recycl 40:81–91

Park T (2003) Application of construction and building debris as base and sub-base materials in rigid pavement. J Transp Eng 129(5):558–563

Sivakumar V, McKinley JD, Ferguson D (2004) Reuse of construction waste: performance under repeated loading. Proc Inst Civil Eng Geotechn Eng 157(2):91–96

Poon CS, Chan D (2005) Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr Build Mater 20(8):578–585

Ransinchung RNGD, Kumar P, Sharma P (2012) Stabilization of clayey soil with fines from waste crushed concrete cubes for construction of pavements. In: Proceedings of International Conference on Engineering and Information Technology (ICEIT), Toronto, Canada, pp 24–28

Arulrajah A, Piratheepan J, Disfani MM, Bo MW (2012) Geotechnical and geo environmental properties of recycled construction and demolition materials in pavement sub base applications. J Mater Civil Eng 25:1077–1088

Rahman MA, Arulrajah A, Piratheepan J, Bo MW, Imteaz MA (2014) Resilient modulus and permanent deformation responses of geo grid-reinforced construction and demolition materials. J Mater Civil Eng 26:512–519

Fucale (2014) Analysis of physical and mechanical properties of recycled aggregates from construction and demolition waste for paving work. EJGE 19:3797–3806

IS-1498 (1970) Indian Standard Methods of test for soils, Edition 2.2, soil classification system

IS-2720 (1973) Indian Standard Methods of test for soils, Part 2, Determination of water content of soil

IS-2720 (1980) Indian Standard Methods of test for soils, Part 3/ Section 1, Determination of specific gravity of fined grained soils

IS-2720 (1985) Indian Standard Methods of test for soils, Part 4, Grain size analysis

IS-2720 (1985) Indian Standard Methods of test for soils, Part 5, Determination of Liquid Limit and Plastic Limit

IS-2720 (1992) Indian Standard Methods of test for soils, Part 7, Determination of water content, dry density relation using light compaction

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Abhishek, Sharma, R.K., Bhardwaj, A. (2019). Effect of Construction Demolition and Glass Waste on Stabilization of Clayey Soil. In: Singh, H., Garg, P., Kaur, I. (eds) Proceedings of the 1st International Conference on Sustainable Waste Management through Design. ICSWMD 2018. Lecture Notes in Civil Engineering , vol 21. Springer, Cham. https://doi.org/10.1007/978-3-030-02707-0_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-02707-0_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-02706-3

Online ISBN: 978-3-030-02707-0

eBook Packages: EngineeringEngineering (R0)