Abstract

The main problem that the world is facing today is the scarcity of natural resources, including freshwater, due to ramping environmental pollution. It is primarily due to rapid industrialization posing a serious threat to the entire ecosystem. Most of the industries discharge effluents to the nearby wetlands and water bodies. As a result, the amount of usable water reduces drastically due to surface and ground waters contamination. The discharged effluents contain various toxic impurities in the form of metals, organic and inorganic particles, suspended solids, etc. If without proper treatment, the water is used, serious health hazards can occur. It is, therefore, necessary to treat the water before it is used for domestic and drinking purposes. There are many stages of treating natural wastewater for removal of organic, inorganic, and suspended loads. The primary process is to remove suspended inorganic solids and for that flocculation is generally used as it is one of the most convenient and cheapest unit operations. At the same time, it has also been found that polymeric flocculants are more effective than conventional inorganic flocculants for settling inorganic suspensions. It works both by charge neutralization and bridging mechanisms to settle the flocs in a reasonably quick time. This chapter vividly described the treatment of wastewater containing suspended inorganic solids with polysaccharide grafted hyperbranched copolymers as flocculants. Hyperbranched polymers have unique properties like higher solubility, higher hydrodynamic volume, more functional ends hence higher zeta potential for charge neutralization and more inner voids for bridging of flocs, which make them a better flocculant than conventional linear polymers. Along with hyperbranched polymer-based natural flocculants, future scope for incorporating various nanoparticles into the polymeric network for further improvement in flocculation efficiency, has also been discussed in this chapter.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

3.1 Introduction

The natural water bodies are getting increasingly polluted daily due to human activity and industrialization, which leads to tremendous pollution to the environment [28]. Not only surface water but also groundwater are getting contaminated with suspended particles, colloidal substances, and dissolved particles. Among the effluents discharged from various industries, toxic metal ions along with numerous organic and inorganic substances share a considerable part [6, 23]. The water discharged from mines contains negatively charged particles, whereas the effluents from ceramic, paints, cosmetics, ink, etc. industries contain kaolin as the main suspended particles [2]. Due to the smaller size, anisotropic shape, and strong repulsive forces among the particles of kaolin, it forms a stable suspension in water and thus present in huge amount in the sludge getting discharges from the industries as mentioned earlier [62]. These particles get settled down due to the gravitational force, but it occurs over a more extended period, and also, the efficiency is too low. The other conventional methods of treating the effluents are sedimentation, filtration, micro-filtration, ultrasonication, coagulation and flocculation [59]. Among these methods of treating coagulation and flocculation are most commonly in use [57]. Coagulation is achieved by adding coagulants to the wastewater, which are mainly inorganic [7]. Flocculation is somewhat similar to coagulants where the particles are agglomerated by the addition of a foreign substance which causes agglomeration, and thus, the law of gravitation is applied. This substance by which it is done is called flocculants [4]. Flocculants can be natural as well as synthetic in nature, and the synthetic variables are made bio-degradable by incorporating a bio-polymer backbone onto them. Moreover, the commercial coagulants, e.g., poly-aluminium chloride (PAC), alum, etc., can cause a lot of sludge formation and hence making its disposal to the environment a difficult task [17].

On the other hand, flocculation leads to the formation of a lesser amount of sludge, thus making the process eco-friendlier. The inorganic metal ions (mostly the charged ones) can cause various diseases in the body. Al present in PAC causes Alzheimer’s disease [41].

The flocculation is achieved by the employment of flocculants which are synthetic as well as natural. The synthetic flocculants are mainly polyacrylamide (PAM), poly (diallyl dimethyl ammonium chloride) (PDADMAC)etc., which are found to be effective in flocculating suspension having a negative surface charge on it. The flocculation occurs following a mechanism called charge neutralization [54]. But acrylamide monomer, when it remains unreacted, leads to carcinogenic diseases, and on the other hand, PAM is found to have good flocculation efficiency [34, 39]. The bio-degradable property can be introduced by introducing a natural polysaccharide backbone into it [5]. This can be done by graft copolymerization, where a free radical initiator is used either thermally or by using a source of radiation. It is due to the grafting of the properties of both natural polysaccharide and its synthetic counterpart hybridized, leading to a mixed property of both the moieties. The graft copolymers can further be modified by nanoparticles to increase their efficiency in flocculation [52]. This chapter elaborates the three types of flocculants, i.e., synthetic, natural, and graft copolymers, which have been used for treating wastewater. Chemical coagulants/flocculants, which are derived from chemical/petroleum-based compounds, are often used in wastewater treatment. Natural bio-flocculants have been thoroughly researched and sourced from natural resources in recent years.

Meanwhile, grafted flocculants have recently been studied and synthesized by mixing chemical and natural flocculants properties [33, 49]. Its flocculating performance, as well as the related flocculating mechanisms for wastewater treatment, are also addressed and discussed. The difference between coagulation and flocculation has been depicted in Fig. 3.1 [55]. Apart from the natural resources nowadays, various synthesized materials are also used for wastewater treatment like graphene oxide, graphene/polymer composite [46], different types of conductive polymers [45], and organic–inorganic hybrid [44].

3.2 Coagulation Versus Flocculation

We have compared the basic difference of coagulation and flocculation in a tabular (Depicted in Table 3.1) form on the basis of the process of work, materials, and application. Inorganic mineral additives/metal salts, which are used as coagulants, and organic polymeric compounds, which are used as flocculants, are the two main classes of synthetic chemicals used in commercial wastewater treatment [19].

3.2.1 Inorganic Coagulants

Alum, poly (aluminum) chloride, ferric chloride, ferrous sulfate, calcium chloride, and magnesium chloride are inorganic salts of multivalent metals that have been commonly used as coagulants for decades. It is primarily due to its low-cost benefit, as their selling price is far lower than chemical flocculants [20].

However, owing to a number of drawbacks, inorganic coagulants are still used in a small number of wastewater applications. According to several reports, its application would have two major environmental consequences: the development of vast concentrations of metal hydroxide (toxic) sludge, which would be difficult to dispose of, and a rise of metal (e.g., aluminum) content in the treated water, which may have human health effects. Other disadvantages include the need for a significant volume of material for effective flocculation, sensitivity to pH, inefficiency against microscopic particles, inefficiency in cold water (e.g., polyaluminum chloride), and application of just a few dispersed structures [22]. Many considerations have been considered in order to identify an alternative to lower the dosage of toxic inorganic flocculants in order to reduce the risks of inorganic flocculants [11] (Fig. 3.2)

.

3.2.2 Synthetic Organic Flocculants

Many synthetic polymers have been used as key flocculants (coagulant aids) in recent years to improve coagulation and flocculation performance, with positive results published. The majority of commercial organic flocculants are linear water-soluble polymers made up of repeated units of different monomers, including acrylamide and acrylic acid. They are derived from oil-based and non-renewable raw materials in the majority of cases. Polyacrylamide, polyacrylic acid (PAAc), poly(diallyl dimethyl ammonium chloride) (DADMAC), polyamine, and other polymeric flocculants are often used [51].

The molecular weight, structure (linear versus branched), amount of charge, charge content, and composition of synthetic polymers vary, but they are usually divided into four types: cationic (positively charged), anionic (negatively charged), amphoteric (contains both cationic and anionic groups), and non-ionic (close to neutral).

Water soluble polymers are widely used as flocculants because of their distinct characteristics. The polymers are simple to useand have little effect on the medium’s pH [40].

They work well for small amounts (a few mg per liter), and the flocs that develop during flocculation are larger and heavier. In certain cases, a suitable polyelectrolyte can increase floc size, resulting in a solid, compact, regular-shaped floc with good settling characteristics [16].

They work well for small amounts (a few mg per liter), and the flocs that develop during flocculation are larger and heavier. In some instances, a suitable polyelectrolyte can increase floc size, resulting in a solid, compact, regular-shaped floc with good settling characteristics [63].

3.2.3 Steps Involving Flocculation

The process of coagulation-flocculation involves several steps, which are depicted in Fig. 3.3.

-

To the wastewater,a coagulant is added in the first step.

-

Formation of hydrolyzedspecies occurs.

-

The hydrolyzedspecies gets dispersed into the fluid.

-

Vigorous agitation should be done to allow proper mixing of the hydrolyzed species and promote contact between the particles presentwithin the fluid.

-

After that, flocculantsare to be added and then filtration and disinfection [25].

3.2.4 Mechanism of Flocculation

The mechanism of flocculation is very important because from the mechanism how the flocculants work to remove the hazardous materials from waste water. Figure 3.4 shows the entire mechanism of the flocculation process.

Floc formation occurs through the following steps taken sequentially:

-

The flocculants get dispersed in the solution

-

Flocculants diffusion towards the solid–liquid interface

-

Adsorption of the flocculants onto the particulate surface

-

Collision with other particles by particles bearing adsorbed flocculants

-

In order to form micro-flocs, adsorption of the flocculants to other particles

-

Development by successive collision and adsorption of the microflocs to larger and stronger flocs.

Several flocculation processes have been suggested to understand the destabilization of colloids and suspensions by polymers, including polymer bridging, polymer adsorption, and charge neutralization (including electrostatic patch effects), depletion flocculation, displacement flocculation, and so on. Charge neutralization, bridge forming, and electrostatic patch are the three primary processes of coagulation/flocculation involved in the removal of dissolved and particulate pollutants that are often mentioned. The adsorption of flocculants on particle surfaces is important for these processes. The whole flocculation process is depicted in Fig. 3.5.

3.3 Charge Neutralization

Charge neutralization is commonly proposed as the primary process where the flocculants and the adsorption site have opposing charges. Since hydrophobic colloidal particles in wastewater are often negatively charged, inorganic flocculants (metal salts) and cationic polyelectrolytes are preferred in many situations. The development of van der Waals force of attraction to encourage initial aggregation of colloidal and fine suspended materials to form micro-flocculation could occur simply as a result of the particles’ reduced surface charge (reduction of zeta potential) and hence a decreased electrical repulsion force between colloidal particles, which causes the formation of van der Waals force of attraction to encourage initial aggregation of colloidal and fine suspended materials to form micro-flocculation. Many experiments have discovered that optimum flocculation occurs at polyelectrolytes dosages around those needed to neutralise particle charge or achieve a zeta potential near zero (isoelectric point). Under the impact of Vander Waals influences, the particles appear to agglomerate at this stage, destabilizing the colloidal suspension. However, if too much polymer is used, a charge reversal will occur, causing the particles to become scattered again, but this time with a positive charge rather than a negative charge. Charge neutralization flocs are often poorly packaged and brittle, and they settle slowly. To cement the micro-flocs together for quick sedimentation and high-water recovery, another high molecular weight polymer with a bridging effect is needed.

3.4 Polymer Bridging

Polymer bridging happens when long-chain polymers with a high molecular weight (up to several million) and low charge density are adsorbed on particles in such a manner that long loops and tails expand or spread well past the electrical double layer into solution. This allows these ‘dangling’ polymer segments to bind and interact with other particles, resulting in ‘bridging’ between particles.

The length of the polymer chains must be adequate to stretch from one particle surface to another for successful bridging to occur. As a result, a polymer with longer chains (high molecular weight) should outperform one with shorter chains (low molecular weight). Furthermore, there must be enough unoccupied surface on a particle to attach polymer chain segments adsorbed on other particles. As a result, the amount of polymer used should not be unnecessary (the amount of polymer absorbed should not be excessive). Otherwise, the particle surfaces will be overly saturated with polymer, leaving no sites for other particles to ‘bridge’ with. Here, the re-establishment of particles occurs.

As a result, only a small amount of adsorbed polymer is required, and excess amounts will cause re-stabilization. Naturally, the adsorbed sum should not be too low; otherwise, insufficient bridging contacts can be created.

As a result of these factors, an optimal dose for bridging flocculation has been proposed. Polymer bridging has long been known to produce much larger and thicker aggregates (flocs) than other methods. Furthermore, at high shear speeds, bridging contacts are more resistant to breakage. This has been depicted in Fig. 3.6 [26].

3.5 Electrostatic Patch

The bridging potential is limited as high charge density polyelectrolytes with low molecular weight adsorb on negative surfaces with a relatively low density of charged areas. Another process known as the “electrostatic patch” mechanism emerges.

The basic concept is that when a strongly charged cationic polymer adsorbs on a weakly charged negative surface to provide total neutrality, each surface charged site cannot be physically neutralized by a cationic polymer segment. Between regions of uncoated negatively charged surfaces cationic ‘patches’ or ‘islands’ shape. As particles approach close together, there is an electrostatic attraction between positive patches and negative regions, resulting in particle association and hence flocculation.

These flocs are not as solid as those formed by bridging, but they are stronger than those formed in the presence of metal salts or by basic charge neutralization. For electrostatic patch flocculation to work, polyelectrolytes must have a high charge density. Bridging flocculation becomes more possible as the charge density is reduced [64].

3.6 Mechanism Followed by Natural Bio-Flocculants

Chitosan's properties, such as its cationic activity (reactive amino and hydroxyl groups) and high molecular weight, can be used for charge neutralization and bridging process flocculation. The anionic dye was electrostatically attracted by protonated amine groups from chitosan, leading to neutralization of the anionic charges of dyes. Then the flocculation was further improved by the bridging process, which binds the agglomerates together and settles, in a study that studied coagulation and flocculation of dye-containing solutions using chitosan. Depending on the type of the colloids, chitosan characteristics such as molecular weight and degree of deacetylation, the pH of the suspension, and the experimental conditions, chitosan activity includes two factors: hydrophobic associations and the probability of chain attachment by hydrogen bridges (i.e., concentrations) [5].

Without the aid of a cationic coagulant/flocculants, anionic bio-flocculants (cellulose, tannin, and sodium alginate) are unable to flocculate anionic pollutants from wastewater.As a result, charge neutralization of negatively charged impurities requires the addition of inorganic metal salts (e.g., aluminum and ferric salts) or a cationic polymer (e.g., chitosan) before the addition of bio-flocculants. Anionic cellulose or tannin with negatively charged atoms after charge neutralization the polymer molecules’ charged backbone allowed them to be extended into solution and create loops and tails to aid in floc bridging [42, 52].

3.7 Mechanism Followed by Grafted Polymeric Flocculants

Charge neutralization and polymer bridging combine to form the flocculation process for grafted flocculants used in wastewater treatment. At the start of the flocculation phase, charge neutralization predominates, resulting in a large number of insoluble complexes generated quickly. The insoluble complexes then aggregate and form larger net-like flocs due to the bridging effect of the flexible polymeric graft chains. Finally, compacted flocs are formed and quickly settled down [47]. Bridging is the most common flocculation pathway, according to other studies. Figure 3.7 demonstrates the flocculation mechanism through bio-polymer.

The polymer bridging process is primarily responsible for graft copolymers’ superior flocculation characteristics over linear polymers. Polymer chain segments adsorbed onto the surfaces of various particles, forming bridges between neighboring particles and eventually linking all of the particles together. The polymer bridging process is primarily responsible for graft copolymers’ superior flocculation characteristics over linear polymers. Polymer chain segments adsorbed onto the surfaces of various particles, forming bridges between neighboring particles and eventually linking all of the particles together. Since the polymer chains of grafted flocculants are longer, and the gyration radius is greater, the adsorbed polymer molecules appear to follow a more expanded structure when dealing with several particles [3, 37].

3.8 Factors Affecting Flocculation

3.8.1 Molecular Weight of Polymers and Charge Density

As a result of the sequence of incorporating these polymers, each polymer molecule has a propensity to adsorb on a single particle with its low molecular weight, reducing the degree of flocculation. Higher molecular weight polymeric materials can have a greater amount of adsorption to form flocs. For high molecular weight polymers, both the settling rate and the optimal dosage improved. For handling coal washery effluents, extremely high molecular weight anionic flocculants are increasingly crucial for achieving faster sedimentation speeds. Polymers with a lower molecular weight, on the other hand, are sufficient for filtration [31].

3.8.2 Flocculants Dosage and Condition of Mixing

The level of flocculation is influenced by the dosing and mixing sequences. There are no further changes in flocculation of any device above a certain maximal dose of polymers, and adding flocculants reduces competence. At low stirring speeds, the size and settling rate of flocs can be easily controlled after polymer inclusion, at higher speeds, with no subsequent decline at high concentrations, the level of flocculation is reduced, and particles are fully encased by absorbed polymer layers. Hydrodynamic conditions induced by mechanical agitation play a critical role in the flocculation phenomenon [58].

3.8.3 Shear Effect on Flocs

The flocs, which are either produced by bridging flocculation or natural coagulation, are concentrated for breaking with intense shaking. Excess polymer agitation causes formulated flocs to degrade faster than flocs formed with the optimal ratio of polymers. The effective formation of flocs is impossible due to the repulsion of excess adsorbed polymer, so the optimum polymeric dose only grips for a precise agitation degree.

3.8.4 Ionic Strength of the Solution

The configuration of polyelectrolyte is greatly influenced by the ionic strength of every solution, which has an effect on the flocculation phenomenon. The ionic concentration of a solution containing polyelectrolyte reduces as the viscosity of the solution increases due to reciprocal charge repulsion.Increased ionic strength shields the charged areas, allowing polymers to fold and implying a smaller hydrodynamic length, as shown by a decrease in solution viscosity. Ionic strength in solution reduces in a device with high solids for flocculation with a polymer with a higher molecular weight, and bridging is increased by increasing the effective particle radius [38].

3.8.5 Effect of pH

Solvated metal ions can influence the flocculation of inorganic flocculants via Schulze-Hardy effects and double-layer compression in the effective class. These organisms become charged as the pH value rises and their mode of action differs. The presence of an ionizable basic or acidic group influences protonation by pH modifications, which in turn affects colloidal particle surface charge [9].

3.8.6 Effect of Particle Size

On the one hand, a brawny relationship occurs between polymer molecular weight and particle size aggregation through the bridging mechanism to form flocs; on the other hand, forces occur to split the flocs, i.e., instability. The charge neutralization potential of a particle's surface is improved by increasing its surface area with polymeric flocculants [60].

3.8.7 Effect of Temperature

Temperature fluctuations help with flocculation, but this isn’t always the case. With increasing temperature, the rate of particle collision and diffusion increased. On the other hand, adsorption is an exothermic process that has an adverse effect at higher temperatures. The temperature of polymeric chains varies as they extend linearly. Predicting the temperature effect of any device is therefore incredibly difficult [10].

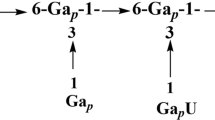

3.9 Flocculation Modeling

The mathematical description of flocculation, or the method of aggregating destabilized suspended objects, has traditionally been focused on thinking of the process as two distinct steps: transport and connection. Local fluctuations in fluid/particle velocities resulting from (a) spontaneous thermal Brownian motion of the particles (perikinetic flocculation), (b) forced velocity gradients from mixing (orthokinetic flocculation), and (c) discrepancies in the settling velocities of individual particles contribute to the collision of two particles. The two precepts can be mathematically interpreted as a probability of effective collision between particles of sizes i and j: The rate of flocculation is simplified in (3.1).

α is the collision efficiency, β (i, j) is the collision frequency between the two particles of size i and j. ni, nj are the concentration of the particles for particles of size i and j, respectively.

The number of collisions is determined by the mode of flocculation, such as perikinetic, orthokinetic, or differential sedimentation. The collision efficiency α (with values ranging from 0 to 1) is a feature of particle destabilization: the higher the degree of destabilization, the higher the value of α.Thus, in effect, β is a measure of the transportefficiency leading to collisions, represents the percentage of those collisions leading to attachment [53].

3.10 Kinetics of Aggregation of Particles

The flocculation, deflocculation, and re-flocculation processes follow the kinetics of Smoluchowski’s classical model which is based on the existence of two processes that are simultaneously working: the aggregation of particles which follows second order kinetics and the breakage of the aggregate that follows first-order kinetics. Equation 3.2 demonstrated the flocculation kinetics.

where N0 is the number concentration of the particles present in the effluent at time t0, Nt is the number concentration at time t, k1 and k2 are kinetic constants for aggregation of particles and kineticconstants for the aggregate breakage, respectively. The kinetics of aggregation of particlesand aggregate breakage at different initial concentrations can be studied effectively using the above equation. The equilibrium situation can be explained using the relationship of both types of kinetics [57, 24].

3.11 Collision Frequency of Particles

It was well established that the process of flocculation follows bimolecular kinetics. The flocculation kinetics model gives the equation (3.3):

where N0 is the initial number of particles present in the effluent, Nt is the number concentration of theseparticles at time t, and k is the rate constant for collisions betweenthe singlets. Aplot of (N0/Nt)1/2 versus t provides a straight line withan intercept 1 for a bimolecular process, and the rate constant (k)can be obtained from the slope of the curve [8, 12].

3.12 Literature Survey

Till now, several works have been done on flocculation by graft copolymers or other modified versions of the natural polysaccharides. Here a list of such works has been provided to give a better insight into the matter.

Afolabi et al. [1] studied the functional properties and flocculation efficiency of Albizia Saman (AS) and Albizia glaberrima (AG) gum which was modified through graft copolymerization with acrylamide. The grafting efficiency of AS and AG was 54 and 58%, respectively. The cold-water solubility of AS and AG were increased from 38.23 and 35.55% to 39.75 and 40.55%, respectively. The oil binding and emulsion capacity of AS and AG were decreased from 4.89 and 3.44% to 3.69 and 2.40%, respectively. The flocculation efficiency gets increases from 74% to above 98% for both these polymers after graft copolymerization.

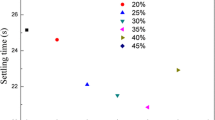

Klein et al. [21] synthesised copolymer of cashew gum with poly(acrylamide) (PAM) using radiation mediated graft copolymerization using potassium persulfate as initiator in aqueous medium. Fourier-transform infrared spectroscopy, nuclear magnetic resonance spectroscopy, and thermogravimetric analysis were used to classify the graft copolymers. The graft copolymers (CG-g-PAM) were tested for their efficacy in flocculating a kaolin suspension.. According to the results, the graft copolymers synthesized with ultrasound energy had greater flocculation properties than those synthesized with microwave energy. Inoculation with the basidiomycete Trametesvillosa in liquid medium was used to assess the biodegradability of the graft copolymers.

Mate et al. [29] synthesized Jhingan-gum grafted acrylamide copolymer by microwave-assisted graft copolymerization technique using potassium persulphate as initiator. Analytical methods were used to validate the synthesized substance, and intrinsic viscosity and grafting percentage were used to determine the best-grafted grade (Jh-g-PAM 3). The efficiency of flocculation under various pH (2–10) and temperature (10–55 °C) conditions revealed that neutral pH and room temperature (25 °C) were optimal for flocculation. Furthermore, as pH was improved, the magnitude of the zeta potential increased from 2.65 to 17.17 mV. However, the particle size declined from 2041 to 1092 dnm, indicating that the kaolin suspension was stable under acidic conditions. The grafted material was found to be capable of removing Cr, Fe, and Pb from 0.004 mg/L to below detection limit (0.003 mg/L), 0.65 mg/L to 0.011 mg/L, and 0.015 mg/L to below detection limit (0.011 mg/L), respectively, in a river sample. With a half-life of 28 days, the grafted material was observed to degrade entirely in 180 days.

Mittal et al. [30] synthesized an environmentally friendly gum ghatti-crosslinked-polyacrylamide (Gg-cl-PAM) from gum ghatti (Gg) and acrylamide (AM) using a microwave-assisted grafting technique and tested it for use in water purification applications as an adsorbent and flocculent. SEM, FTIR, and TGA were used to classify the Gg-cl-PAM, which showed pH-sensitive swelling activity, with the highest swelling observed in neutral pH solution. The flocculation properties of Gg-cl-PAAM in clay solutions were investigated as a function of pH, temperature, and polymer mass filling, with the best results obtained at neutral pH and 40 °C. The adsorption capacities of Gg-cl-PAAM for the removal of various dyes such as brilliant green (BG), rhodamine B (RhB), congo red (CR), and methyl orange (MO) were investigated, and it was discovered that all dyes adopted the Langmuir isotherm model, with qm values of 523.62 mg g–1 for BG, 421.60 mg g–1 for RhB, 179.09 mg.

Sharma et al. [50] done free radical polymerization in an inert environment using ammonium persulfate (APS) as an initiator and Tetra (ethylene glycol) diacrylate (TEGDA) as a crosslinking agent. Polyitaconic acid (PIA) was grafted onto natural polysaccharides xanthan gum. Structure was characterized using scanning electron microscopy and Fourier transform infrared spectroscopy (FTIR). The effects of APS, TEGDA, neutralizing degree, kaolinite content, and xanthan gum were studied. The findings show that PIA successfully grafted onto xanthan gum and developed a 3D structure. The weight ratio of Xanthan gum to kaolin, swelling ability, and gel content all increased as the study progressed.

Sand et al. [43] synthesized graft copolymer of sodium alginate and polyacrylamide using a free radical polymerization technique using a potassium bromate/thiourea redox system in an inert atmosphere. Variation of reaction variables such as acrylamide concentration (3.0102–9.3102 mol dm−3), potassium bromates (8 × 10–3–16 × 10–3 mol dm−3), thiourea (1.6 × 10–3–4.8 × 10–3 mol dm−3), sulphuric acid (3.0 × 10–3–7 × 10–3 mol dm−3), alginate (0.6–1.6 g dm−3), period length (60–180 min), and (30–500 C). In comparison to the parent polymer, water swelling potential, metal ion sorption, flocculation, and resistance to biodegradability studies of synthesized graft copolymer were conducted. FTIR spectroscopy and thermogravimetric processing were used to classify the grafted polymers. The flocculation efficacy of the grafted copolymer was found to be much higher compared to its un-grafted analog.

Nandi et al. [32] synthesized polyacrylamide-grafted-tamarind seed gum (PAM-g-TSG) using free radical method assisted with microwave where cerric (IV) ammonium nitrate (CAN) was used as free radical initiator. On grafting, the effects of monomer, CAN, and microwave irradiation time (MIT) were investigated. Several grafting metrics were measured, including percent grafting (percent G), percent grafting quality (percent GE), and percent conversion (percent Cn). MIT may significant contributions to the synthesis. The batch with 10 g acrylamide, 400 mg CAN, and 1 min MIT had the highest percent grafting (890.3%). Elemental research, FTIR, solid-state 13C NMR, DSC, TGA, XRD, viscosity, SEM, acute oral toxicity, and biodegradability studies were used to classify the grafted TSG. The study showed that PAAm-g-TSG is nontoxic and biodegradable. Finally, the grafted gum's flocculating capacity was tested in a paracetamol suspension. The flocculation analysis shows that all batches of graft copolymer have the strong flocculating ability in paracetamol suspension, with capability increasing as concentration and grafting increase. Among others, the batch (highest percent G = 890.3) has the highest degree of flocculation (=5.14 ± 0.26).

Giri et al. [13] synthesized grafted copolymer using kappa-carregeenan and polyacrylamide by microwave-assisted free radical polymerization using ammonium persulfate (APS) as initiator. The effect of reaction variables such as APS, AAm, and KC concentrations, time length, and microwave power was investigated. To classify the graft copolymer, researchers used FT-IR, X-ray diffraction (XRD), differential scanning calorimetry (DSC), and scanning electron microscopy (SEM). The graft copolymer's actions are mildly vulnerable to external pH, and the swelling has adjustable on/off flipping characteristics. The graft copolymer's flocculation efficacy in coal suspension was investigated in order to see whether it could be used as a flocculent. The graft copolymer's acute oral toxicity report was analyzed according to OECD guidance. During the 14-day trial, mice given the graft copolymer showed no abnormal activity. During the 14 days following therapy with the graft copolymer, no deaths were observed.

Wu et al. [56] and group employed microwave aided initiation to copolymerize AM, DAC, and chitosan (CS) into a novel form of graft modified flocculant (CS-g-PAD), which was employed for sludge conditioning and dewatering. The influence of reaction conditions on microwave-aided copolymerization was examined, and orthogonal experiments were used to determine their ideal values. Microwave aided polymerization can induce the produced side polymer chain of PAD to react with the –NH2 active group in CS, according to the structure and chemical characteristics of CS-g-PAD. As a result, graft copolymerization took place at the amino group linked to the C2 site. In a wide pH range (pH = 3.5–9.5), the synthesized CS-g-PAD outperforms CCPAM, PAD, and CS in sludge dewatering (FCMC: 72.1 percent, SRF: 4.5 1012 m/kg, d50: 679.556 m, Df: 1.72, floc sedimentation rate: 5.72 cm/min).Furthermore, the PAD grafted on CS has a good extension in solution, which increases its adsorption bridging action. The novel grafted CS-g-PAD shows promise and has a wide range of applications in sludge dewatering and conditioning.

Jain et al. [18] discussed the possibility of a polyacrylamide-grafted-polyethylene glycol/SiO2 nanocomposite as a viable addition for drilling difficult shale deposits that might cause significant wellbore instability in this study. FTIR, Field emission scanning electron microscopy (FESEM), Energy dispersive spectroscopy (EDX), Atomic force microscopy (AFM), and thermogravimetric analyses were used to describe the nanocomposite, which was made using the free radical polymerization process (TGA).It was then used in the development of a water-based drilling mud system. Its impact on the designed mud system's rheological properties and filtration control features was carefully investigated. In addition, hot rolling shale dispersion tests and immersion experiments were used to study its shale inhibition properties. Core flooding experiments were also performed to investigate the formation damage produced by the newly created drilling fluid system. The results of the experiments demonstrated that the synthesized nanocomposite had a better shale inhibition property. The nanocomposite worked in tandem with the other additives in the created system to provide good rheological and filtration capabilities. It also outperformed the partly hydrolyzed polyacrylamide (PHPA) polymer in the designed drilling mud system in terms of formation damage, shale recovery, and thermal stability. As a result, this nanocomposite might be employed as a drilling fluid addition in a water-based shale drilling fluid system.

He et al. [15] was devised and manufactured a novel type of flocculant, a ternary copolymer comprising lignosulfonate, acrylamide, and chitosan. FTIR and XRD elemental analysis and structural characterization revealed that acrylamide effectively grafted onto the two natural polymers, resulting in amorphous macromolecules. The natural polymer-based flocculant was pH-independent and water-soluble. The amphoteric flocculant demonstrated strong color removal efficacy to anionic (Acid blue 113, > 95 percent), neutral (Reactive black 5, > 95 percent), and cationic dyes (Methyl orange, > 50 percent) across a wide range of flocculant dose and pH windows because it possessed several functional groups from the raw materials. From the cost, source, and performance standpoint, the ternary flocculant based on lignosulfonate, chitosan, and acrylamide might be a promising material in practical applications.

3.13 Selection of Flocculants

The challenge of achieving the optimal clarity or purification will be much simpler if you understand the treatment procedures, such as coagulation-flocculation and direct flocculation, as well as the various forms of flocculants. The flocculants that have been used for the treatment of various forms of wastewaters, based on literature research. The first step in every wastewater treatment is to analyze the properties of the wastewater, which will decide the treatment procedure to be used. Coagulation-flocculation is often used to treat all wastewater with suspended and dissolved constituents, while direct flocculation is only used to treat organic-based effluents of suspended solids. The next step is to decide which flocculants will be used. Cationic coagulants or flocculants are always chosen since the surface charge in colloidal suspensions is almost always negative. Cationic coagulants are often combined with non ionic or anionic flocculants in the coagulation-flocculation process. There are several different flocculants on the market, each with a different molecular weight and charge density. High molecular weight flocculants are typically preferred because they are associated with a better bridging mechanism than other flocculation mechanisms [14].

3.14 Role of Architectural Polymers in Flocculation

The polymeric flocculants were found to have greater flocculating efficiency than that of the coagulants or the commercial flocculants available. Synthetic polymers, on the other hand, have adverse effect on health and the environment. They are non-biodegradable and cause serious health issues for which ETP has not been given the standard for oral toxicity. The natural polysaccharides are biodegradable, but they are much less efficient. The scientists came up with the solution by combining the properties of the natural polysaccharides and the synthetic polymers by graft copolymerization. The graft copolymers contain both properties.

Moreover, due to the increase in porosity, radius of gyration, hydrophilicity, solubility of the graft copolymers increases. As a result, more and more amount of particles get trapped into the cavity and undergo agglomeration and hence flocculation. With increasing factories and health issues, the amount of sludge needed to be deceased to nullify pollution. Architectural polymers, in this regard, play a crucial role. Hyperbranched polymers are architectural polymers that possess high chain-end functionality. They also have high solubility and low viscosity, for which they possess larger hydrodynamic volume. More number of particles get entrapped into the polymer causing greater flocculation due to greater chain-end functionality [27].

3.15 Graft Copolymer Nanocomposite as Flocculants

Graft copolymer nanocomposites are generally used as flocculants. Natural polymers like potato starchwere mostly used to synthesize the nanocomposite on the basis of the application in the flocculation system. Copolymerization enables materials to be created that combine the desired properties of several compounds in a single polymer chain. Copolymerization is a very effective method for the flocculation system. In 2020, Schmidt et al. [48] described the synthesis of graft copolymer between starch and carbon nanotubes for the potential application in flocculation efficiency. They synthesize the material via radical polymerization in an aqueous environment. In the standard jar test, the products were evaluated for their flocculation efficiency in a model aqueous kaolin suspension. For the removal of suspended solids from mine water and pH regulation, a variety of techniques involving inorganic coagulants are frequently used. However, issues such as the large amount of coagulants required, excessive sludge accumulation, aggregate instability and breakage, and the need for water conditioning have prompted research into alternative flocculants or coagulants. Gum karaya (GK) is an anionic polysaccharide derived from trees such as Sterculia urens, Sterculia villosa, and Sterculia setigera, which grow in India and North Africa, respectively. D-galacturonic acid, D-galactose, L-rhamnose, and Dglucuronic acid make up this strongly branched complex with polysaccharides. Considering the structural richness of gum polysaccharides uses in potential in water treatment applications. Hybrid inorganic–organic nanocomposites, which are made up of inorganic nanoparticles and functional polymers, are a new and unusual material type. Water is the most basic need for the survival of our society. One of the most significant conditions for a healthy public health environment is the availability of pure water. For the treatment of textile industry wastewater, various strategies such as reverse osmosis, activated carbon adsorption, and photocatalytic dye degradation have been suggested. The separation of dyes from wastewater can also be accomplished by efficient adsorption of dye molecules into adsorbents. Bio sorbents for dye removal have received a lot of coverage in recent years. Modified polysaccharides, especially polyacrylamide grafted polysaccharides and poly (acrylic acid) grafted polysaccharides, are widely used as flocculants and drag-reducing agents in wastewater treatment [35]. They are effective flocculants at low doses, managed biodegradable, shear resistant, low-cost, and environmentally safe. Graft copolymers made from polysaccharides are also used as adsorbents. In comparison to the individual components, the strong synergistic effect between inorganic nanofiller and modified polysaccharide matrix produces hybrid composite materials with impressive improvements in mechanical, thermal, and surface properties. Hybrid nanocomposite materials have been widely used for the treatment and remediation of toxic wastewater in recent years due to their intriguing properties. However, they have certain drawbacks, such as a limited surface region, a small hydrodynamic radius, and complex diffusion processes. These disadvantages limit their use as effective adsorbents. The direct discharge of industrial wastewater into bodies of water without proper treatment contaminates them with radioactive elements that are highly detrimental to marine life and human health. Flocculation, precipitation, evaporation, and adsorption are some of the wastewater disposal processes. Flocculation is a cost-effective and reliable method for purifying and recycling manufacturing effluents. The addition of nanoscale filler to a graft copolymer-based matrix will increase surface area and hydrodynamic radius, making it ideal for use as a good adsorbent [36]. Microwave irradiation-based grafting has reformed the area of sustainable green chemistry by reducing the use of non-renewable materials and organic solvents while also reducing the formation of radioactive by-products. As a result, this method is both cost-effective and energy-efficient. Electromagnetic irradiation selectively excites the polar bonds of polysaccharides rather than the non-polar bonds, resulting in polar bond cleavage/breakage. In contrast to traditional chemical grafting techniques, this will produce free radical sites for grafting on the polysaccharide backbone without rupturing the polysaccharide C–C backbone, increasing product selectivity. On the other way cationic polyacrylamide (CPAAm) derivatives have been extensively used in papermaking as preservation and drainage aids, likewastewater and suspension flocculants, water clarification flotation aids, and soil improvers [61]. Biopolymers are distinguished from synthetic polymers by the inclusion of higher-order structures and, in certain cases (as in the case of lignin), the absence of an identifiable repeating unit, as well as a lower polydispersity or even mono-dispersity. Graft copolymers as flocculants have a number of drawbacks, including a low hydrodynamic length, a small radius of gyration, poor thermal stability, and a small surface area. However, there are ways to get around these drawbacks, such as adding nanoscale inorganic fillers on the surface of the polymer matrix, which improves its gyration radius, thermal stability, and surface. In the presence of certain inorganic fillers, such as silica, bentonite, and calcium carbonate, they have been used for papermaking due to their outstanding flocculating properties and special rheological features in aqueous media. CPAAms are primarily responsible for large-scale flocculation in these processes, with charged fillers serving as junctions. Monodisperse silica nanoparticles have been widely used as possible surface modifiers because of their uniform scale, shape, structure, and high specific surface region. Furthermore, polysaccharide hydrogen bonding units can serve as nucleating centers for silica generation and thus as an effective template for the growth of nanoscale silica particles. Biopolymers, especially polysaccharides, have piqued the scientific community's interest because of their supply, biodegradability, and high capacity to absorb contaminants from water. Yoon et al. [61] focused on the effects of the acryl-grafted silica nanoparticles (ASNP) concentration on the flocculation and retention characteristics in papermaking applications. Flocculants are widely used in water and wastewater purification processes to speed up the agglomeration of colloidal particles and the dropping of floc sediments in the water supply, as well as to improve contamination removal quality. Since inorganic flocculants are vulnerable to pH changes, they produce a lot of sludge in the atmosphere. Metal ions from such sludge are a major concern in groundwater [27]. Humans, poultry, and marine species are also highly poisonous to most synthetic flocculants. One example is the carcinogenic effect of acrylamide monomer, which can contaminate the polymer in trace quantities. Limited quantities of polymers can end up in the atmosphere after water treatment in finely divided form or as a diluted solution, posing an additional challenge. Natural polymer-based flocculants are usually efficient in large concentrations and shear stable. They can also be easily adjusted to improve flocculation performance. According to studies in the literature, the combination of natural and water-soluble synthetic polymer properties allows for the creation of new highly successful flocculants.

3.16 Conclusion

The scope for traditional flocculants, bio flocculants, and grafted flocculants to be used in wastewater treatment has been thoroughly investigated. They also showed remarkable results in reducing or eliminating environmental parameters such as TSS, turbidity, COD, and color, with some studies achieving more than 90% removal. While flocculants have been developed and successfully used in the laboratory to remove contaminants from wastewater, there is still a need to enhance their efficiency in the removal of suspended and dissolved impurities, heavy metals, and color or dye molecules, inorganic or organic pollutants to comply with environmental regulations before the wastewater is discharged into the atmosphere. Given the industrial reliance on cost-effective flocculation technology for wastewater treatment, further potential research into the best flocculants capable of producing very promising results in pollutants removal even at broader pH and other contaminants in wastewater is needed.

Because of the extremely complicated nature of the flocculation process and the wide range of polyelectrolytes required, there are still few flocculation optimization practices in the industry for chemical flocculants. Selecting or regulating the molecular weight and charge density ranges of the polymer is one way to improve the flocculation process. Flocculation pathways vary depending on molecular weight and charge density (neutralization or bridging). In order to produce a better choice of flocculants for particular industrial applications, future research should look at how molecular weight and charge density distribution influence flocculation efficiency. Increasing the effectiveness and lowering the cost of chemicals may be achieved by optimizing these variables.

Furthermore, only a small amount of work has been done on a large scale, with most research focused on laboratory studies. Because of the sophistication of coagulation and flocculation processes, a polymer cannot be chosen for a specific application without extensive research. This testing is divided into two stages: (i) laboratory experiments to determine the form of flocculants and, more specifically, the optimal ionicity, and (ii) industrial trials or practices to validate the flocculants selection as well as the volume and molecular weight. As a result, the applicability and efficacy of most bio-flocculants for wastewater treatment have yet to be determined. More research into the efficacy of natural flocculants is also expected. Last but not least, an effective flocculation procedure requires the use of high-efficiency flocculants that can nearly eliminate or reduce all pollutants in wastewater.Environmentally friendly flocculants that can be manufactured using an easy and cost-effective process and show high removal efficiencies and significantly denser flocs are seen as a promising commodity in real-world applications from a performance and cost standpoint.

References

T.A. Afolabi, D.G. Adekanmi, Characterization of native and graft copolymerized albizia gums and their application as a flocculant. J. Polym. 2017, 1–8 (2017). https://doi.org/10.1155/2017/3125385

M.A. Barakat, New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 4, 361–377 (2011). https://doi.org/10.1016/j.arabjc.2010.07.019

D.R. Biswal, R.P. Singh, Characterisation of carboxymethyl cellulose and polyacrylamide graft copolymer. Carbohydr. Polym. 57, 379–387 (2004). https://doi.org/10.1016/j.carbpol.2004.04.020

J. Bratby, Coagulation and flocculation: with an emphasis on water and wastewater treatment (1980). https://doi.org/10.1016/0300-9467(81)80062-7

W. Brostow, H.E. Hagg Lobland, S. Pal, R.P. Singh, polymeric flocculants for wastewater and industrial effluent treatment. J. Mater. Educ. Pal Singh J. Mater. Educ. 31, 3–4 (2009)

A. Carocci, A. Catalano, G. Lauria, M.S. Sinicropi, G. Genchi, Brief history of the development of the transfusion service. How Recruit Volunt Donors Third World? 238, 22–28 (2015). https://doi.org/10.1007/398

H.W. Ching, T.S. Tanaka, M. Elimelech, Dynamics of coagulation of kaolin particles with ferric chloride. Water Res. 28, 559–569 (1994). https://doi.org/10.1016/0043-1354(94)90007-8

K.K. Das, P. Somasundaran, A kinetic investigation of the flocculation of alumina with polyacrylic acid. J. Colloid Interface Sci. 271, 102–109 (2004). https://doi.org/10.1016/j.jcis.2003.11.010

X. Feng, J. Wan, J. Deng, W. Qin, N. Zhao, X. Luo, M. He, X. Chen, Preparation of acrylamide and carboxymethyl cellulose graft copolymers and the effect of molecular weight on the flocculation properties in simulated dyeing wastewater under different pH conditions. Int. J. Biol. Macromol. (2020). https://doi.org/10.1016/j.ijbiomac.2019.11.081

C.S.B. Fitzpatrick, E. Fradin, J. Gregory, Temperature effects on flocculation, using different coagulants. Water Sci. Technol. 50, 171–175 (2004). https://doi.org/10.2166/wst.2004.0710

K. Ghebremichael, J. Abaliwano, G. Amy, Combined natural organic and synthetic inorganic coagulants for surface water treatment. J. Water Supply Res. Technol. - AQUA 58, 267–276 (2009). https://doi.org/10.2166/aqua.2009.060

S. Ghorai, A. Sarkar, A.B. Panda, S. Pal, Evaluation of the flocculation characteristics of polyacrylamide grafted xanthan gum/silica hybrid nanocomposite. Ind. Eng. Chem. Res. 52, 9731–9740 (2013). https://doi.org/10.1021/ie400550m

T.K. Giri, M. Pradhan, D.K. Tripathi, Synthesis of graft copolymer of kappa-carrageenan using microwave energy and studies of swelling capacity, flocculation properties, and preliminary acute toxicity. Turkish J. Chem. 40, 283–295 (2016). https://doi.org/10.3906/kim-1503-16

A.S. Greville, How to select a chemical coagulant and flocculant. Albert Water Wastewater Oper Assoc 24 (1997)

K. He, T. Lou, X. Wang, W. Zhao, Preparation of lignosulfonate-acrylamide-chitosan ternary graft copolymer and its flocculation performance. Int. J. Biol. Macromol. 81, 1053–1058 (2015). https://doi.org/10.1016/j.ijbiomac.2015.09.054

Y.C. Ho, I. Norli, A.F.M. Alkarkhi, N. Morad, Characterization of biopolymeric flocculant (pectin) and organic synthetic flocculant (PAM): A comparative study on treatment and optimization in kaolin suspension. Bioresour. Technol. 101, 1166–1174 (2010). https://doi.org/10.1016/j.biortech.2009.09.064

K.O. Iwuozor, Prospects and challenges of using coagulation-flocculation method in the treatment of effluents. Adv. J. Chem. A 2, 105–127 (2019). https://doi.org/10.29088/sami/ajca.2019.2.105127

R. Jain, V. Mahto, V.P. Sharma, Evaluation of polyacrylamide-grafted-polyethylene glycol/silica nanocomposite as potential additive in water based drilling mud for reactive shale formation. J. Nat. Gas Sci. Eng. 26, 526–537 (2015). https://doi.org/10.1016/j.jngse.2015.06.051

J.Q. Jiang, N.J.D. Graham, Pre-polymerised inorganic coagulants and phosphorus removal by coagulation - a review. Water SA 24, 237–244 (1998)

D.J. Joo, W.S. Shin, J.H. Choi, S.J. Choi, M.C. Kim, M.H. Han, T.W. Ha, Y.H. Kim, Decolorization of reactive dyes using inorganic coagulants and synthetic polymer. Dye Pigment. 73, 59–64 (2007). https://doi.org/10.1016/j.dyepig.2005.10.011

J.M. Klein, V.S. de Lima, J.M. da Feira, M. Camassola, R.N. Brandalise, M.M. de Camargo Forte, Preparation of cashew gum-based flocculants by microwave- and ultrasound-assisted methods. Int. J. Biol. Macromol. 107, 1550–1558 (2018). https://doi.org/10.1016/j.ijbiomac.2017.09.118

J.P. Kushwaha, V. Chandra Srivastava, I.D. Mall, Treatment of dairy wastewater by inorganic coagulants: parametric and disposal studies. Water Res. 44, 5867–5874 (2010). https://doi.org/10.1016/j.watres.2010.07.001

D.G.J. Larsson, Pollution from drug manufacturing: Review and perspectives. Philos. Trans. R. Soc. B Biol. Sci. 369 (2014). https://doi.org/10.1098/rstb.2013.0571

C.S. Lee, M.F. Chong, J. Robinson, E. Binner, A review on development and application of plant-based bioflocculants and grafted bioflocculants. Ind. Eng. Chem. Res. 53, 18357–18369 (2014). https://doi.org/10.1021/ie5034045

C.S. Lee, J. Robinson, M.F. Chong, A review on application of flocculants in wastewater treatment. Process Saf. Environ. Prot. 92, 489–508 (2014). https://doi.org/10.1016/j.psep.2014.04.010

J. Ma, R. Wang, X. Wang, H. Zhang, B. Zhu, L. Lian, D. Lou, Drinking water treatment by stepwise flocculation using polysilicate aluminum magnesium and cationic polyacrylamide. J. Environ. Chem. Eng. 7, 103049 (2019). https://doi.org/10.1016/j.jece.2019.103049

P. Maćczak, H. Kaczmarek, M. Ziegler-Borowska, Recent achievements in polymer bio-based flocculants for water treatment. Materials (Basel) 13 (2020). https://doi.org/10.3390/ma13183951

A. Maria, R. Version, W. Technologies, The costs of water pollution in India (2003)

C.J. Mate, S. Mishra, P.K. Srivastava, Design of low-cost Jhingan gum-based flocculant for remediation of wastewater: flocculation and biodegradation studies. Int. J. Environ. Sci. Technol. 17, 2545–2562 (2020). https://doi.org/10.1007/s13762-019-02587-x

H. Mittal, V. Kumar, S.M. Alhassan, S.S. Ray, Modification of gum ghatti via grafting with acrylamide and analysis of its flocculation, adsorption, and biodegradation properties. Int. J. Biol. Macromol. 114, 283–294 (2018). https://doi.org/10.1016/j.ijbiomac.2018.03.131

K.M. Mostafa, A.A. El-Sanabary, Synthesis and characterization of novel smart flocculant based on poly(MAam)-pregelled starch graft copolymers and their degraded products. Adv. Polym. Technol. 32, 1–10 (2013). https://doi.org/10.1002/adv.21339

G. Nandi, A. Changder, L.K. Ghosh, Graft-copolymer of polyacrylamide-tamarind seed gum: synthesis, characterization and evaluation of flocculating potential in peroral paracetamol suspension. Carbohydr. Polym. 215, 213–225 (2019). https://doi.org/10.1016/j.carbpol.2019.03.088

F.E. Okieimen, Preparation, characterization, and properties of cellulose-polyacrylamide graft copolymers. J. Appl. Polym. Sci. 89, 913–923 (2003). https://doi.org/10.1002/app.12014

A.T. Owen, P.D. Fawell, J.D. Swift, J.B. Farrow, The impact of polyacrylamide flocculant solution age on flocculation performance. Int. J. Miner Process 67, 123–144 (2002). https://doi.org/10.1016/S0301-7516(02)00035-2

S. Pal, S. Ghorai, C. Das, S. Samrat, A. Ghosh, A.B. Panda, Carboxymethyl tamarind-g-poly(acrylamide)/silica: A high performance hybrid nanocomposite for adsorption of methylene blue dye. Ind. Eng. Chem. Res. 51, 15546–15556 (2012). https://doi.org/10.1021/ie301134a

S. Pal, A.S. Patra, S. Ghorai, A.K. Sarkar, R. Das, S. Sarkar, Modified guar gum/SiO2: development and application of a novel hybrid nanocomposite as a flocculant for the treatment of wastewater. Environ. Sci. Water Res. Technol. 1, 84–95 (2015). https://doi.org/10.1039/c4ew00023d

S. Pal, G. Sen, S. Ghosh, R.P. Singh, High performance polymeric flocculants based on modified polysaccharides - microwave assisted synthesis. Carbohydr. Polym. 87, 336–342 (2012). https://doi.org/10.1016/j.carbpol.2011.07.052

S.K. Rath, R.P. Singh, Crafted amylopectin: applications in flocculation. Colloids Surf. Phys. Chem. Eng. Asp. 139, 129–135 (1998). https://doi.org/10.1016/S0927-7757(98)00250-7

R.F. Ben, W. Mnif, S.M. Siddeeg, Microbial flocculants as an alternative to synthetic polymers for wastewater treatment: a review. Symmetry (Basel) 10, 1–19 (2018). https://doi.org/10.3390/sym10110556

F. Roselet, D. Vandamme, M. Roselet, K. Muylaert, P.C. Abreu, Effects of pH, salinity, biomass concentration, and algal organic matter on flocculant efficiency of synthetic versus natural polymers for harvesting microalgae biomass. Bioenergy Res. 10, 427–437 (2017). https://doi.org/10.1007/s12155-016-9806-3

M. Rossini, J.G. Garrido, M. Galluzzo, Optimization of the coagulation-flocculation treatment: influence of rapid mix parameters. Water Res. 33, 1817–1826 (1999). https://doi.org/10.1016/S0043-1354(98)00367-4

H. Salehizadeh, N. Yan, R. Farnood, Recent advances in polysaccharide bio-based flocculants. Biotechnol. Adv. 36, 92–119 (2018). https://doi.org/10.1016/j.biotechadv.2017.10.002

A. Sand, A. Vyas, A.K. Gupta, Graft copolymer based on (sodium alginate-g-acrylamide): characterization and study of water swelling capacity, metal ion sorption, flocculation and resistance to biodegradability. Int. J. Biol. Macromol. 90, 37–43 (2016). https://doi.org/10.1016/j.ijbiomac.2015.11.085

S. Sardar, A. Jana, A. Mukherjee, A. Dhara, A. Bandyopadhyay, Bottom-up synthesis of bright fluorescent, moisture-resistant methylammonium lead bromide@poly(3-bromothiophene). New J. Chem. 44, 2053–2058 (2020). https://doi.org/10.1039/c9nj04734d

S. Sardar, R. Koley, U.K. Ghorai, A. Pal, S. Sengupta, I. Roy, A. Bandyopadhyay, Photophysical and electrochemical properties of oligothiophene in non-polymeric and polymeric solvents. J. Mol. Struct. 1168, 187–194 (2018). https://doi.org/10.1016/j.molstruc.2018.05.037

S. Sardar, I. Roy, S. Chakraborty, A.B. Ghosh, A. Bandyopadhyay, A selective approach towards synthesis of poly (3‑bromo thiophene)/graphene quantum dot composites via in-situ and ex-situ routes: application in light emission and photocurrent generation. Electrochim. Acta 365 (2021). https://doi.org/10.1016/j.electacta.2020.137369

A.K. Sarkar, N.R. Mandre, A.B. Panda, S. Pal, Amylopectin grafted with poly (acrylic acid): development and application of a high performance flocculant. Carbohydr. Polym. 95, 753–759 (2013). https://doi.org/10.1016/j.carbpol.2013.03.025

B. Schmidt, Nanocomposite starch graft copolymers with carbon nanotubes – synthesis and flocculation efficiency. Polimery/Polymers 65, 226–231 (2020). https://doi.org/10.14314/polimery.2020.3.7

G. Sen, R. Kumar, S. Ghosh, S. Pal, A novel polymeric flocculant based on polyacrylamide grafted carboxymethylstarch. Carbohydr. Polym. 77, 822–831 (2009). https://doi.org/10.1016/j.carbpol.2009.03.007

P. Sharma, A. Dagar, V.A. Sapna, A. Sand, Superabsorbent composites (SACs) based on xanthan gum-g-poly (itaconic acid)/kaolinite. Polym. Bull. (2020). https://doi.org/10.1007/s00289-020-03436-5

J.J. Shen, L.L. Ren, Y.Y. Zhuang, Interaction between anionic dyes and cationic flocculant P(AM-DMC) in synthetic solutions. J. Hazard. Mater. 136, 809–815 (2006). https://doi.org/10.1016/j.jhazmat.2006.01.013

R.P. Singh, S. Pal, S.A. Ali, Novel biodegradable polymeric flocculants based on cationic polysaccharides. Adv. Mater. Lett. 5, 24–30 (2014). https://doi.org/10.5185/amlett.2013.6498

D.N. Thomas, S.J. Judd, N. Fawcett, Flocculation modelling: a review. Water Res. 33, 1579–1592 (1999). https://doi.org/10.1016/S0043-1354(98)00392-3

R.C. Tilton, J. Murphy, J.K. Dixon, The flocculation of algae with synthetic polymeric flocculants. Water Res. 6, 155–164 (1972). https://doi.org/10.1016/0043-1354(72)90090-5

H.F. Wang, H. Hu, H.J. Wang, R.J. Zeng, Impact of dosing order of the coagulant and flocculant on sludge dewatering performance during the conditioning process. Sci. Total Environ. 643, 1065–1073 (2018). https://doi.org/10.1016/j.scitotenv.2018.06.161

P. Wu, J. Yi, L. Feng, X. Li, Y. Chen, Z. Liu, S. Tian, S. Li, S. Khan, Y. Sun, Microwave assisted preparation and characterization of a chitosan based flocculant for the application and evaluation of sludge flocculation and dewatering. Int. J. Biol. Macromol. 155, 708–720 (2020). https://doi.org/10.1016/j.ijbiomac.2020.04.011

Z. Yang, H. Peng, W. Wang, T. Liu, Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 116, 2658–2667 (2010). https://doi.org/10.1002/app

Z. Yang, H. Yang, Z. Jiang, T. Cai, H. Li, H. Li, A. Li, R. Cheng, Flocculation of both anionic and cationic dyes in aqueous solutions by the amphoteric grafting flocculant carboxymethyl chitosan-graft-polyacrylamide. J. Hazard. Mater. 254–255, 36–45 (2013). https://doi.org/10.1016/j.jhazmat.2013.03.053

K.-J. Yao, Y.-B. Tang, Synthesis of starch-g-poly(acrylamide-co-sodium allylsulfonate) and its application of flocculation to Kaolin suspension. J. Appl. Polym. Sci. 45, 349–353 (1992). https://doi.org/10.1002/app.1992.070450217

M. Yao, J. Nan, T. Chen, Effect of particle size distribution on turbidity under various water quality levels during flocculation processes. Desalination 354, 116–124 (2014). https://doi.org/10.1016/j.desal.2014.09.029

D.H. Yoon, J.W. Jang, I.W. Cheong, Synthesis of cationic polyacrylamide/silica nanocomposites from inverse emulsion polymerization and their flocculation property for papermaking. Colloids Surf. A Physicochem. Eng. Asp. 411, 18–23 (2012). https://doi.org/10.1016/j.colsurfa.2012.06.036

J. Yu, D. Wang, X. Ge, M. Yan, M. Yang, Flocculation of kaolin particles by two typical polyelectrolytes: A comparative study on the kinetics and floc structures. Colloids Surf. A Physicochem. Eng. Asp. 290, 288–294 (2006). https://doi.org/10.1016/j.colsurfa.2006.05.040

A.Y. Zahrim, C. Tizaoui, N. Hilal, Evaluation of several commercial synthetic polymers as flocculant aids for removal of highly concentrated C.I. Acid Black 210 dye. J. Hazard. Mater. 182, 624–630 (2010). https://doi.org/10.1016/j.jhazmat.2010.06.077

Y. Zhou, G.V. Franks, Flocculation mechanism induced by cationic polymers investigated by light scattering. Langmuir 22, 6775–6786 (2006). https://doi.org/10.1021/la060281+

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Chakraborty, S., Sardar, S., Bandyopadhyay, A. (2022). Flocculation of Waste Water Using Architectural Copolymers: Recent Advancement and Future Perspective. In: Hato, M.J., Sinha Ray, S. (eds) Functional Polymer Nanocomposites for Wastewater Treatment. Springer Series in Materials Science, vol 323. Springer, Cham. https://doi.org/10.1007/978-3-030-94995-2_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-94995-2_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-94994-5

Online ISBN: 978-3-030-94995-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)