Abstract

Preliminary mechanochemical activation of the K2PdCl4 salt forms a heterogeneous catalyst for the reaction of acetylene with methanol to form 1,1-dimethoxyethane and vinyl chloride. An increase in the duration of the palladium salt pre-treatment is accompanied by: (i) an increase in the surface concentration of active sites of the prepared catalyst, which leads to a rise in its catalytic activity; (ii) a monotonic increase in vinyl chloride selectivity. An increase in the reaction temperature has a beneficial effect on the selectivity of the reaction with respect to both observed products.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The new materials formation is one of the central problems of modern engineering and technology development. Engineering, materials science, medicine and other industries require the production of materials with special electrical, magnetic, temperature-dependent, chemical and other properties. One of the methods for obtaining of such materials is mechanochemical activation, which is a combination of uniaxial loading and shear deformation of a substance in various dispersion media [1]. Methods of mechanochemical activation make it possible to obtain nano- and submicrocrystalline materials with special physicochemical characteristics, which differ significantly from the properties of the initial polycrystalline sample. Specific properties are often determined by the nanocrystalline structure, a high degree of defectiveness, and the presence of amorphous, quasicrystalline, and metastable phases. The creating localized on the surface defects of a crystal structure (active sites of heterogeneous catalysts) by mechanochemical grinding opens up wide possibilities for using this method in heterogeneous catalysis [2].

Previously we have found [3, 4], that mechanical treatment in an atmosphere of unsaturated hydrocarbons of a palladium salt K2PdCl4 leads to the formation on the surface of coordinatively unsaturated complexes [PdCl3*]−. Such states are active sites of a heterogeneous catalyst for the hydrochlorination of acetylene with gaseous HCl [5, 6]. If the halogen in the hydrochloride molecule is replaced by the methoxy group OMe, then it can be assumed that the addition of methanol to acetylene will proceed in a similar way. Indeed [7], in the absence of continuous mechanical treatment, the pre-activated in acetylene K2PdCl4 salt catalyzes the reaction of methanol with acetylene to form 1,1-dimethoxyethane. Vinyl chloride is released in parallel.

1.1 Research Purpose

The aim of this work is to determine the effect of the reaction conditions in the system of mechanically pre-activated salt K2PdCl4–C2H2–CH3OH on the regularities of its course.

1.2 Research Scope

In this study, we consider the following frameworks of the problem:

-

(i)

The impact of the mechanical energy absorbed by the palladium salt during its MA on the rate and selectivity of the reaction over the formed catalyst.

-

(ii)

The effect of temperature on the rate and selectivity of the reaction.

2 Research Method

2.1 Preparation of Heterogeneous Catalysts

The salt K2PtCl4 was synthesized via a standard procedure [8] and was dried at 120–140 °C for 3 days. Increasing the drying time did not significantly affect the reaction kinetics. The reactions were carried out in a closed reactor. The reactor was sealed with a replaceable rubber gasket.

To prepare the active catalysts, dry palladium salt (0.25 g) was mechanochemically activated for a certain time in an acetylene atmosphere in a ~ 14 ml glass reactor using a MMVE-0.005 vibratory mill (Hephaestus, Russia) at a specific power input of ~ 15W/kg. Acetylene was obtained from calcium carbide using a standard procedure [9]. The resulting gases were dried over calcined CaCl2. The specific dose of mechanical energy absorbed by the K2PdCl4 powder was determined according to the relation [10]:

where t is the time of the MA of the salt. The specific surface area of the resultant catalysts was determined by the BET method from argon desorption.

2.2 Chromatographic Studies

Gas mixture analyzed by GLC using an LKhM-8-MD chromatograph with a flame-ionization detector and equipped with data acquisition system MultiChrom Ampersand. The components of the mixture were separated on a 2 m column filled with an adsorbent Silochrome S-120. Reagents and reaction products were identified by retention time. The relative content of acetylene and vinyl chloride in the gas phase of the reactor was determined as the ratio of the areas of the corresponding chromatographic peaks to the peak area of ethane used as an internal standard. The amount of compound was calculated using calibration curves for acetylene or vinyl chloride. The amount of vinyl chloride liberated was determined taking account of the difference in sensitivity of the flame ionization detector relative to C2H2 and C2H3Cl by a factor of 1.26.

2.3 Kinetics Studies

The mechanochemically pre-activated catalyst was purged with a flow of dry argon for 15 min to remove foreign gases. Then the reactor was sealed and the required amount of methanol, acetylene and ethane (methane) as an internal standard were introduced through a rubber gasket using a microsyringe. The reactor containing the catalyst and the gas mixture was placed in a thermostat. Probes of the gas phase from the closed reactor were taken without breaking the tightness at regular intervals using a syringe with a fixed volume of 0.121 ml.

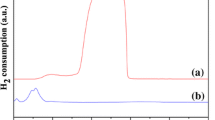

The kinetics of acetylene consumption and vinyl chloride accumulation was studied in the temperature range of 30–100 °C. Selectivity to vinyl chloride was determined chromatographically as the ratio of the amount of the released product to the amount of consumed acetylene.

The yield of the reaction products was determined independently by NMR spectrometry. After the reaction, 1 ml of deuterated chloroform was introduced into the reactor, and 1 μl of HMDS was added to the resulting suspension as an internal standard. The contents of the reactor were transferred to a centrifuge tube, the precipitate was separated by centrifugation, and the solution was transferred to an NMR ampoule. NMR spectra of the reaction products H3C–CH(OCH3)2 and H2C = CHCl were recorded on a Bruker AVANCE-II-400 instrument (Bruker BioSpin GmbH) with an operating frequency of 400 MHz, the software for which allowed integrating the signals.

3 Results and Discussion

3.1 Catalytic Reaction of Acetylene with Methanol

For the formation of the active form of the catalyst, MA of the salt is required, since the reaction does not proceed on the catalyst surface without preliminary treatment. The kinetics of acetylene consumption under conditions of excess methanol corresponds to a first-order equation.

The amount of palladium salt loaded with a mass of m = 0.25 g corresponds to 767 μmol. Taking into account the lattice parameters of the crystal structure of K2PdCl4 (a = b = 7.05 Å and c = 4.1 Å [11]) and the specific surface area of the salt (Ssp ≈ 6.7 m2/g [4]), we can evaluate the upper limit of the amount of palladium complex anions located on the surface:

which is ~ 6 × 1018 anions and corresponds to ~ 10 μmol of Pd on the surface. In our experiments, the maximum amount of acetylene consumed over one catalyst load was at least 1.7 mmol, and catalytic activity did not significantly decrease. Thus, the minimum number of catalytic cycles for palladium complexes located on the surface of the salt is ~ 170, which corresponds to ~ 2.2 cycles based on bulk palladium.

With an excess of methyl alcohol, the acetylene consumption from the gas phase of a closed reactor corresponds to the first-order kinetic law, as in the case of acetylene hydrochlorination [6]. The first order in acetylene can be explained by the fact that Pd(II) does not give stable π-complexes [4, 12]. Their amount on the surface is determined by the partial pressure of acetylene in the gas phase, and the change in the amount of methanol adsorbed on the surface under the above conditions can be neglected.

3.2 Dependence of Catalyst Activity on the Time of Its MA

On the surface of a nonactivated salt, acetylene is not consumed at a noticeable rate. An increase in the pre-activation time of the K2PdCl4 powder leads to a monotonic increase in the catalyst activity (Table 1).

The specific surface area of the catalyst also growths monotonically with an increase in the salt pre-activation time (Table 2) [4].

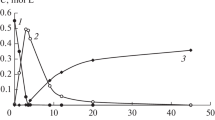

The dependence of the specific surface area Ssp of the catalyst on the dose of mechanical energy Dsp absorbed by the powder has the form of a curve with saturation (Fig. 1) and corresponds to the equation:

where S0 is the specific surface area of the initial K2PdCl4 powder, (S0 + S*sp) is the limiting value of the increase in the specific surface area due to MA, and ηs is the constant characterizing the efficiency of new surface formation (quantity inverse to the specific work of surface formation).

The increase in catalytic activity with an increase in the MA time can be due to two factors, namely, an increase in the specific surface area of the salt and an increase in the surface concentration of active sites. We exclude the impact of the first factor on the observed rate constant of acetylene consumption by considering the rate constant k* per unit catalyst surface area:

The dependence of parameter k* on the specific dose Dsp of mechanical energy absorbed by the powder also has the form of a curve with saturation (Fig. 2) and obeys the equation:

Dependence of the apparent rate constant k* of acetylene consumption per unit area of the catalyst surface on the specific dose Dsp of mechanical energy absorbed by the K2PdCl4 powder. The points are experimental k* values, and the curve represents the data calculated using (5) for k*max = (1.04 ± 0.17) × 10‒5 s‒1 m‒2 and η = (0.7 ± 0.2) × 10‒2 g/J

where k*max is the limiting value of k*,

and η is the constant characterizing the efficiency of the formation of active sites in the catalyst under MA (quantity inverse to the specific work of formation of active sites in the catalyst).

The selectivity of the reaction for vinyl chloride \(Y = \frac{{\nu (C_{2} H_{3} Cl)}}{{\nu (C_{2} H_{2} )}}\) increases with an increase in the duration of the pretreatment of the palladium salt (Table 3).

The dependence of selectivity of the reaction to vinyl chloride YVCM on the specific dose Dsp of mechanical energy absorbed by the powder also appears as a curve with saturation (Fig. 3) and obeys the equation:

Dependence of the selectivity Y of the reaction to vinyl chloride on the specific dose Dsp of mechanical energy absorbed by the K2PdCl4 powder during MA. The points are experimental Y values, and the curve represents the data, calculated using (6) for Y∞ = (16.4 ± 2.2) % and ηY = (1.7 ± 0.6) × 10‒2 g/J

where Y∞ is the limiting value of selectivity of the reaction to vinyl chloride, ηY is constant, characterizing the efficiency of formation of active sites of the catalyst for vinyl chloride production.

The significant difference of the parameter ηs from η and ηY (Table 4) obviously means that the surface growth and the formation of active sites of the catalyst are not related. The close values of η and ηY suggest that 1,1-dimethoxyethane and vinyl chloride are formed at the same active sites. The surface concentration of the active sites of the catalyst increases with a rise of the pre-activation time of the salt, as evidenced by the monotonic increase in the observed rate constant of acetylene consumption reduced to a unit surface area of the catalyst.

3.3 Temperature Dependence of Catalyst Activity and Selectivity

The values of the observed rate constants of acetylene consumption and product yields at different temperatures given in Table 5. As can be seen, an increase in temperature has a beneficial effect on the selectivity of the reaction with respect to both observed products, especially for the vinyl chloride monomer.

4 Conclusion

For K2PdCl4 salt, we have showed:

-

(i)

salt without preliminary MA is inactive for the reaction of methyl alcohol with acetylene;

-

(ii)

the active sites of the catalyst are formed upon mechanically activation of the salt in an acetylene atmosphere;

-

(iii)

an increase in duration of MA of the salt results in a growth of its catalytic activity due to an increase in the surface concentration of active sites and is accompanied by a rise of the yield of vinyl chloride by-product;

-

(iv)

the selectivity for both products increases with raising temperature.

References

G. Heinicke, Tribochemistry (Akademie-Verlag, Berlin, 1984)

S.A. Mitchenko, Theoret. Exp. Chem. 43(4), 199 (2007)

S.A. Mitchenko, T.V. Krasnyakova, I.V. Zhikharev, Theoret. Exp. Chem. 46(1), 32 (2010)

T.V. Krasnyakova, I.V. Zhikharev, R.S. Mitchenko, V.I. Burkhovetski, A.M. Korduban, T.V. Kryshchuk, S.A. Mitchenko, J. Catal. 288, 33 (2012)

S.A. Mitchenko, T.V. Krasnyakova, I.V. Zhikharev, Theoret. Exp. Chem. 44(5), 306 (2008)

S.A. Mitchenko, T.V. Krasnyakova, I.V. Zhikharev, Kinet. Catal. 50(5), 764 (2009)

T.V. Krasnyakova, D.V. Nikitenko, O.V. Khazipov, S.A. Mitchenko, Kinet. Catal. 61(6), 940 (2020)

Synthesis of Platinum Metal Complex Compounds, ed. by I.N. Chernyaev. Handbook, (Nauka, Moscow, 1964). (In Russian)

F.M. Rapoport, A.A. Il’inskaya, Laboratory Methods for Pure Gases Receiving (Goskhimizdat, Moscow, 1963). ((In Russian))

PYu. Butyagin, A.R. Kuznetsov, I.K. Pavlychev, Instruments and Technique of Experiment 6, 201 (1986). ((In Russian))

JCPDS: International Centre for Diffraction Data, No. 12–412

M. Herberhold. Metal π-Complexes. V. II. Complexes with mono-olefinic ligands. (Elsevier, Amsterdam, London, N.-Y., 1972)

Acknowledgements

Research was financially supported by the Ministry of Science and Higher Education of the Russian Federation (State assignment in the field of scientific activity, Southern Federal University, 2020).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Krasnyakova, T.V., Nikitenko, D.V., Verbenko, I.A., Mitchenko, S.A. (2021). The Effect of the Preparation Conditions on the Catalytic Activity of Palladium in the System of Mechanically Pre-activated Salt K2PdCl4–C2H2–CH3OH. In: Parinov, I.A., Chang, SH., Kim, YH., Noda, NA. (eds) Physics and Mechanics of New Materials and Their Applications. PHENMA 2021. Springer Proceedings in Materials, vol 10. Springer, Cham. https://doi.org/10.1007/978-3-030-76481-4_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-76481-4_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-76480-7

Online ISBN: 978-3-030-76481-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)