Abstract

Mining activities are responsible for the increase of pollutants (i.e., metallic elements) in the environment. Mining wastes are highly contaminated by metallic elements which can induce environmental and sanitary risks. For better waste management, valorization appears to be significant especially when it comes to geopolymers since construction sites heavily use these materials at the large scale. In this context, the aim of this study is (i) to synthesize geopolymers from mining waste using silicate solution and (ii) to evaluate speciation and leaching behavior of metallic elements in raw material and new material after geopolymerization. Results demonstrate that metals bearing phases are dissolved during alkaline treatment and redistributed in the geopolymer matrix. Leaching tests evidenced the possibility to stabilize metals into geopolymer matrix. According to this, a new valorization way of mining wastes (alkaline activation) is proposed based on creating new geomaterials which can be used without risks and with low cost.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The northern part of Tunisia, especially the watershed of Medjerda, is the country's most important mining region marked by massive exploitation of metallic reservoirs, such as lead (Pb), zinc (Zn), iron (Fe), and cadmium (Cd).

This study focuses on an old mining site called Fej Lahdoum (FL) in northwestern Tunisia which has been abandoned since 2004. Mining activity there generates large quantities of waste (an area of 10 ha with a volume of 0.39 Mt) which are stored in the forms of dumps without real management. This waste is localized near the mining site, which is an exclusively agricultural zone. Under the climatic conditions of the area (water or/and wind erosions), the mining waste could be a potential source of release of metals that could be moved in the different compartments of the environment.

Mining activities are the primary anthropogenic source of metal (loids) in the environment. These industrial wastes contain inorganic pollutants that represent the secondary sources of pollution for water, soil, and the atmosphere (Belabed et al. 2017). According to this, these wastes can induce health-related consequences through direct particle ingestion or inhalation or food chain impacts (Uzu et al. 2011, 2012; Pascaud et al. 2015).

This study aims to find an efficient way to valorize the waste by creating new geomaterials from the activation of an aluminosilicate source using an alkaline solution at room temperature (Davidovits 2008). This new material may offer a particular advantage in such a harsh environment since it is marked by excellent mechanical properties, good chemical resistance, low shrinkage, and has an environmentally friendly nature with limiting metals mobility and long-term durability. Whatever the waste treatment, the aim is to minimize the leaching of contaminants and their toxicity.

2 Materials and Methods

Various representative samples of tailings (T) were sampled at different levels, going from the top (H1) to the bottom (H5) (H1, H2, H3, H4, H5) in order to evaluate the potential environmental risks of these tailings (Fig. 1).

Speciation has been determined by BCR (the Community Bureau of Reference) sequential extraction and mineralogical characterization using XRD and FTIR analyses. Leaching experiments have been conducted according to the EN12457-2.

The waste-based material was then synthesized with various mixtures using sodium silicate solution mixed with NaOH pellets in substitution of metakaolin supplied by Imerys and waste. XRD and FTIR then characterized synthesized materials. The environmental risk was evaluated based on the high decrease of metallic element speciation and leaching behavior after geopolymerization.

3 Results

-

Mine tailings had high heavy metals concentrations of 20,300, 2650, and 50 mg/kg for Zn, Pb, and Cd, respectively. From XRD, the waste of Fej Lahdoum was composed by calcite, dolomite, quartz, gypsum, galena, sphalerite, kaolinite, and cerussite following the chemical properties.

-

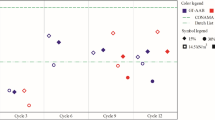

Assessment of the degree of contamination (Igeo) of the waste showed severe pollution with Zn and Cd(Igeo>5) and severe to extremely severe pollution for Pb(3<Igeo<5) (Fig. 2) (Müller et al. 1979; Sougo et al. 2014).

Speciation with BCR experiments was conducted in the way to determine the partitioning of these three elements. The distribution of Pb, Zn, and Cd into the various fractions is F exchangeable>>>F oxidable>F residual>F reductible, so a large part of metals can be mobilized, because the equivalent fraction corresponds to the easily soluble metal fraction (Pascaud et al. 2014). According to the European standard for landfilling, ultimate waste classifies mining waste in different categories according to concentrations of leached contaminants. Leaching tests have shown that mining waste of Fej Lahdoum is considered as non-hazardous waste for Cd and Zn and as inert waste for Pb. Finally, these results clearly show that potential environmental risk is quite a threat (Fig. 6).

In an attempt to inert and to reuse this waste, we used the alkaline activation of waste deposits as the reactive compound with different substitutions. Results pointed out that the alkaline-based geomaterials can highly incorporate the waste. In accordance with the literature, synthesized samples (with 10%, 25%, and 50% of waste) are quite consolidated. The increase of the metakaolin substitution by mining waste decreases the mechanical properties up to 50%. After 50%, the mechanical properties are not realized since the materials are not consolidated due to the limitation of Al and Si (reactive elements) used in the geopolymer network (Pascaud 2015) (Fig. 3).

Moreover, DRX and FTIR investigations evidenced the redistribution of metals into the matrix (Fig. 4).

This experiment is under the BCR experiments showing that the primary pollutants are in the residual fraction (most stable fraction) after alkaline activation (up to 95%) (Fig. 5). This result corroborates the DRX observations which show the presence of quartz particles playing the role of a binder.

The leaching behavior from the EN12457-2 confirms the fact that the environmental risks are quite reduced (Fig. 6).

4 Conclusion

Mineralogical and geochemical approaches coupled with leaching and BCR experiments were applied on Fej Lahdoum, an old mining waste in northwestern Tunisia. Results show that wastes in this area present an environmental risk due to the presence of contaminants such as Pb, Zn, and Cd. Valorization was used based on different mixtures by substituting metakaolin, silicate source, and waste before testing. Results evidence that the geopolymeric matrix can provide an ideal binder for the immobilization of toxic contaminants because of its low permeability, resistance to acid attack, and durability in certain situations where traditional Portland cements experience problems (Zhang et al. 2008; Rao and Liu 2015, Pascaud 2015). More investigations into this valorization method should be conducted to increase its potential.

References

Belabed, B.E., Meddour, A., Samraoui, B., Chenchouni, H.: Modeling seasonal and spatial contamination of surface waters and upper sediments with trace metal elements across industrialized urban areas of the Seybouse watershed in North Africa. Environ. Monit. Assess. 189(6), 265 (2017). https://doi.org/10.1007/s10661-017-5968-5

Sougo, C.A., Mireille, A.E., Colette, A.A., Sylvain, M., Kouamé, A., Blanc, G.: Caractérisation des Indices de Pollution (Igeo, Pli, Tec et Pec) d'un environnement Estuarien à Forte Pression Anthropique: la Baie de Bietry (Cote d'Ivoire, Golf de Guinée). Int. J. Adv. Inf. Sci. Technol. 3(12), 135–139 (2014). https://doi.org/10.15693/ijaist/2014.v3i12.135-139

Davidovits, J.: Geopolymer Chemistry and Applications Institut Géopolymère, 2nd edn. Geopolymer Institute, Saint-Quentin, France (2008)

Muller, G.: Heavy metals in the sediment of the rhine—changes seity. Umschau in Wissenschaft Und Technik 79, 778–783 (1979)

Pascaud, G.: Étude des processus pédogénétique de technosols miniers: de l’analogue naturel a la stratégie de remédiation. PhD thesis, Univ. Limoges, France (2015)

Pascaud, P., Leveque, T., Soubrand, M., Boussen, S., Joussein, E., Dumat, C.: Environmental and health risk assessment of Pb, Zn, As and Sb in soccer field soils and sediments from mine tailings: solid speciation and bioaccessibility. Environ. Sci. Pollut Res. 21, 4254–4264 (2014). https://doi.org/10.1007/s11356-013-2297-2

Rao, F., Liu, Q.: Geopolymerization and its potential application in mine tailings consolidation: a review. Miner Process Extr. Metall Rev. 36, 399–409 (2015). https://doi.org/10.1080/08827508.2015.1055625

Uzu, G., Sauvain, J.-J., Baeza-Squiban, A., et al.: In vitro assessment of the pulmonary toxicity and gastric availability of lead-rich particles from a lead recycling plant. Environ. Sci. Technol. 45, 7888–7895 (2011). https://doi.org/10.1021/es200374c

Uzu, G., Sobanska, S., Sarret, G., et al.: Characterization of lead-recycling facility emissions at various workplaces: Major insights for sanitary risks assessment. J. Hazard Mater. 186, 1018–1027 (2012). https://doi.org/10.1016/j.jhazmat.2010.11.086

Zhang, J., Provis, J.L., Feng, D., Van Deventer, J.S.J.: Geopolymers for immobilization of Cr6+, Cd2+, and Pb2+. J. Hazard. Mater. 157, 587–598 (2008). https://doi.org/10.1016/j.jhazmat.2008.01.053

Acknowledgements

The authors thank the PHC Utique programs Geasmines in Tunisia for the financial support

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Hbaieb, R., Soubrand, M., Joussein, E., Lazaar, S., Medhioub, M. (2022). Durability and Leaching Behavior of Mine Tailings After Inerting Geomaterials in Tunisia. In: Chenchouni, H., et al. New Prospects in Environmental Geosciences and Hydrogeosciences. CAJG 2019. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-030-72543-3_81

Download citation

DOI: https://doi.org/10.1007/978-3-030-72543-3_81

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-72542-6

Online ISBN: 978-3-030-72543-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)