Abstract

Alternative binders produced from waste for the stabilization of mining tailings (especially those considered hazardous) are important for waste management and sustainable engineering. Thus, this manuscript evaluated the leaching behavior of gold mining tailings stabilized/solidified by an alkali-activated binder (AAB) over wetting–drying cycles of durability test. The alternative binder is composed of sugarcane bagasse ash, carbide lime and sodium hydroxide. As a control group, the mining tailings were stabilized/solidified using Portland cement. In general, AAB showed favorable results in encapsulating Al, As, Ba, and Fe, while Portland cement exhibited effectiveness in the immobilization of Al, Ba, Fe, and Hg. For both AAB and Portland cement, higher dry unit weights and binder contents led to the encapsulation of metals in cemented mining tailings matrices. Samples with 30% AAB and 16.5 kN m−3 dry unit weight presented concentrations of Al, As, Ba, Cu, Fe, Hg, Se and Zn below the limits of all water standards. Alkali-activated binder from industrial waste was shown to be a new option to encapsulate contaminants from gold mining tailings.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The management of mining tailings is a serious concern, as these structures may lead to groundwater and soil contamination, posing risks to ecosystems and human health [1,2,3,4]. For instance, the failure of the Fundão tailing dam in Brazil resulted in the deposition of Fe, As, Hg, and Mn at concentrations exceeding sediment quality guidelines. This led to the contamination of the Doce River with a high transport of dissolved Fe, Ba, and Al [5]. Groundwater contamination by Pb and Fe originating from gold mining tailings was also observed in the Virginia areas, posing a threat to the health of the local population [6]. The discharge of tailings from a gold mine tailings dam failure in Karamken, Russia, resulted in damage to local river ecosystems and fisheries, as well as human casualties [7]

In this context, the valorization of mining tailings can be achieved through stabilization and solidification processes using cementing agents, such as Portland cement [8,9,10]. However, the production chain of traditional cement demands intense consumption of electricity and extraction of non-renewable resources (e.g., limestone), releasing around 8% greenhouse gases. This, in turn, has sparked a growing interest in alternative binders, such as alkali-activated ones [11,12,13,14]. These alkaline cements are produced through the alkaline activation technique, in which reactions between amorphous aluminosilicates (precursor) in the presence of an alkaline activator (alkali metal source) form calcium aluminosilicate hydrate (C-A-S-H) and/or sodium aluminosilicate hydrate (N-A-S-H) gels [15].

Mining tailings have been stabilized/solidified with alkali-activated binders originating from metakaolin and industrial waste. In general, these studies have primarily investigated the mechanical behavior and microstructure [2, 3, 16,17,18]. The leaching of metals has become a fundamental assessment to overcome the primary barrier for reusing or recycling waste and to determine the technical feasibility of the alkali-activated materials [19]. Leaching is the process of releasing substances from a solid material into a contacting liquid phase (e.g., water or acid solution), and its assessment is important for determining environmental risks [19, 20]. Through leaching tests, Kiventerã et al. [16] verified that Cr, Cu, Ni, Zn, and Mn from gold mine tailings were immobilized by an alkali-activated binder based on metakaolin and blast furnace slag. Cristelo et al. [17] observed that copper tailings with alkali-activated fly ash presented soluble metals at concentrations below the limit for non-hazardous waste, according to the leaching tests. Bruschi et al. [21] studied the leaching behavior of bauxite tailings with an alkali-activated binder from sugarcane bagasse ash and carbide lime, concluding that Al, Cr, Se, Ba, Fe, Mn, and Zn were efficiently encapsulated in the cemented matrix. Pan et al. [7] reported the immobilization of all harmful elements (including arsenic) from mixtures of gold mine tailings with a waste-based composite geopolymer.

The importance of studying the encapsulation of metals from stabilized/solidified mining tailings is justified by the fact that such waste may contain several contaminants (e.g. heavy metals), which are transported in the environment by natural means (wind, rainwater runoff and surface water flow), as in the case of gold mining tailings [6]. Also, cemented mining tailings not only contribute to the reduction of environmental risks, but also add value to the waste. Stabilized/solidified mining tailings can be used as a material for pavement base and subbase layers, pipe bedding, slope protection, and facing for earth-fill dams [2, 18, 22, 23].

Indeed, there are studies on the mechanical and leaching behavior of gold mining tailings with alkali-activated binders. However, the encapsulation of mining tailings metals using alkali-activated binder from sugarcane bagasse ash and carbide lime is yet to be studied. Furthermore, past studies on leaching from the same mining tailings did not investigate this behavior in heat and water weathering samples. Thus, this paper evaluates the leaching behavior of gold mining tailings stabilized/solidified with alkali-activated binder over wetting–drying cycles of a durability test. The alternative binder is composed of sugarcane bagasse ash, carbide lime, and sodium hydroxide solution. As a control group, the mining tailings were stabilized/solidified using high-early-strength Portland cement.

Materials and Methods

Materials

The materials utilized in this research were gold mining tailings – GT (stabilized/solidified material), sugarcane bagasse ash – SCBA (precursor), carbide lime – CL (calcium source), sodium hydroxide – NaOH (alkaline activator), and high-early-strength Portland cement (type III) – PC. The alkali-activated cement, previously developed by Bruschi et al. [2, 3], was composed of 70% sugarcane bagasse ash (SCBA) and 30% CL, and NaOH solution with an alkalis (Na2O) concentration of 3.86%.

Characterization

The physical, chemical, mineralogical, and environmental characterizations of GT, SCBA, CL, and PC (Tables 1and 2) were performed by previous studies [2, 18, 19, 21]. In this study, the environmental classification of GT was carried out according to ABNT NBR 10004 [24], ABNT NBR 10005 [25], and ABNT NBR 10006 [26]. For both leached extract and solubilized extract tests, a dry GT sample passing through a 9.5 mm sieve was used. For the leached extract test [25], the GT sample (100 g) was exposed to glacial acetic acid-sodium hydroxide solution (pH ~ 4.93) with a solid/liquid ratio of 1:20. The GT-acid solution were agitated in a rotary shaker at 30 rpm for 18 ± 2 h at 23 ± 2 °C. For the solubilized extract test [26], the GT sample (250 g) was submerged in distilled water with a solid/liquid ratio of 1:4 for 7 days at 23 ± 2 °C. The leached and solubilized extracts were filtered through a 0.45-μm membrane filter to remove suspended solids. The determination of metals present in the liquid extracts was performed by inductively coupled plasma optical emission spectrometry (ICP-OES) technique, in a Shimadzu ICP emission spectrometer (model ICPE-9800).

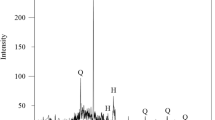

GT is classified as sandy silt, while SCBA and CL as silty clay (Table 1) [2, 18]. GT was constituted by quartz and silica oxide (93.89%) [18]. SCBA was composed by quartz and hematite minerals; and silica (60.65%), iron (13.87%) and aluminum (5.76%) oxides. CL was composed by portlandite and calcite; and mainly constituted by calcium oxide (72.0%) [2]. PC is composed by gypsum, alite, belite, and calcite minerals; and calcium (57%), silica (17.80%), magnesium (5.35%), aluminum (5.28%), and iron (3.97%) oxides [19]. The leached extracts of GT, SCBA, and CL (Table 2) showed metals in concentrations above the limits established by annex F of NBR 10004 [24]. Thus, these wastes are classified as hazardous (class I), i.e., they present characteristics of metal toxicity.

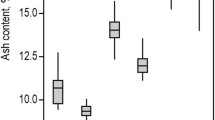

Molding and Curing of the Specimens

Cylindrical specimens with 100 mm in diameter and 127.3 mm in height (in accordance with ASTM D559 [27]) were utilized for the leaching assessment. The molding procedures started by mixing the dry materials (GT, SCBA and CL or PC) with the liquid alkaline activator (NaOH solution) and water until homogenization was achieved. GT-AAB and GT-PC specimens were molded at the factors levels presented in Table 3. These factors were chosen in accordance with the data presented on Pereira dos Santos et al. [18]. Table 4 shows the materials quantities for GT-AAB and GT-PC mixtures.

The molding followed the undercompaction method proposed by Ladd [27], to obtain more consistent and repeatable test results. In the undercompaction method, when preparing the sample, density of each compacted layer is reduced. In this way, it becomes possible to simulate a relatively homogeneous soil condition. The procedure incorporates a tamping method of compacting moist soils in a three-layered sample. Each successive layer is compacted until the specimen reaches the specified unit weight (see Tables 3 and 4). Further details can be found in Ladd [27] and Pereira dos Santos et al. [18].

After specimens were molded and had their dimensions measured, they were sealed in hermetic bags before being stored in a humid room with controlled moisture (95 ± 2%) and temperature (23 ± 2 °C) for 7 days. Specimens considered suitable for testing met the following criteria: degree of compaction within 1% of the target value; water content within 0.5% of the target value; diameter within 0.5 mm of the target value; and height within 1 mm of the target value.

Leaching Assessment Through Wetting and Drying Cycles of the Durability Test

Durability tests (wetting–drying cycles) of the stabilized/solidified GT were executed in accordance with standard ASTM D559 [28] and are presented on Pereira dos Santos et al. [18]. After 7 days of curing at 23 °C, the first cycle initiated with the submersion of the cylindrical specimens in distilled water (pH ~ 7) for 5 h at 23 °C and then oven-drying at 71 °C for 42 h. Subsequently, the specimens were brushed 18–20 times vertically and 4 times on the bottom and top at a required force of approximately 13 N. These procedures were repeated for 12 cycles [28].

The lixiviation of the specimens was measured through an adaptation based on ASTM D559 [28] and NEN 7375 – monolithic tank test [29] proposed by Bruschi et al. [21]. As the durability test was executed, the specimens were placed in separated tanks. Leaching performance was assessed by retrieving eluate samples from these tanks every three durability cycles (3, 6, 9, and 12). The metal concentrations of the eluate samples were determined through the ICP-OES technique, analyzing aluminum (Al), arsenic (As), barium (Ba), cadmium (Cd), chromium (Cr), copper (Cu), iron (Fe), mercury (Hg), lead (Pb), selenium (Se), and zinc (Zn). A mono element solution was utilized on the ICP-OES, with elements in dilute nitric acid-HNO3. The concentrations were compared with three water quality standards: Dutch List [30], CONAMA 460 [31], and EPA [32].

Results and Discussion

Figures 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 and 11 present the leaching performance of the eluate samples of the stabilized/solidified GT. For the Portland cement mixtures (GT-PC), Al concentration reduced with the increase of cement content and dry unit weight, especially in the last cycles. This behavior can be directly associated with the release of calcium hydroxide [Ca(OH)2] from cement hydration, which increases pH values [33]. In pH > 12, a reduction in the leached concentration of Al can occur due to the precipitation of ettringite [34]. Cementitious gels from the Portland cement hydration can immobilize Al and significantly reduce the leaching of this metal [34]. Even though Portland cement is majorly composed of aluminates, Al concentration of the blends was below the limits of CONAMA 460 [31] for all studied cycles. As for the alkali-activated cement (GT-AAB), Al concentration also reduced with the increase of cement content and dry unit weight, presenting a decreasing behavior over the cycles; ash-based alkaline structures present a high solubility of Al on high pH ranges, as the case of alkali-activated mixtures [35]. Furthermore, for all studied cycles, these mixtures met the limit established by CONAMA 460 [31].

As concentration was below the limits of Dutch List [30], CONAMA 460 [31], and EPA [32] for GT-PC mixtures in all cycles, with exception of cycle 12. This behavior can be associated with the durability response of the mixtures; Pereira dos Santos et al. [18] indicated that on the twelfth cycle are samples are more sensible to volume changes and mass loss; other mechanical parameters such as strength and stiffness are also more susceptible to degradation on the last durability cycle, as indicated by Bruschi et al. [3]. Regarding GT-AAB mixtures, As concentration was below the limits of all analyzed standards in all cycles, indicating the viability of the cement in encapsulating this metal. Calcium ions (Ca2+) present a high capability of reducing As mobilization under alkaline conditions, such as the case of alkali-activated mixtures [36]. This behavior can be explained in two distinctive mechanisms: (i) Reduction of the negative electrical potential on the surface of hydroxide minerals by the calcium ions; and (ii) Calcium carbonate precipitation, adsorbing/co-precipitating As [37].

Ba concentration was below the limits of Dutch List [30], CONAMA 460 [31], and EPA [32] with concentration values with little variation, for both conventional and alternative cement in all mixture/cycle combinations (GT-AAB and GT-PC). Leaching of Ba is largely dependent on the solution pH, with the leaching behavior of Ba being amphoteric [38]; an increase in cement content increased the solution pH, which subsequently decreased the leached Ba concentration. The increase in dry unit weight, for both types of cement, also reduced the leaching of Ba, suggesting that the leaching behavior is directly linked to the mechanical one [3, 21].

For GT-PC mixtures, Cd concentration presented an increasing behavior through durability cycles. In cycle 3, Cd concentration was not detected; in cycle 6, Cd was detected, however, all concentrations were below the limits of the three standards (Dutch List [30], CONAMA 460 [31], and EPA [32]); in cycle 9, all mixtures exceeded the limits of Dutch List [30], and the lower dry unit weight and lower cement content combination (14.5kN m−3 and 15% cement content) exceeded the limits of all three standards; finally, in cycle 12 only one combination of lower cement content (15%) exceeded the limits of Dutch List [30], CONAMA 460 [31], and EPA [32]. In all cases, higher the density and cement content, lower the metal concentration. This behavior is associated with the durability characteristics of the materials, in which higher the cycle, lower the strength and encapsulation capacity of the mixtures [21]. In addition, Cd have presents low solubility in highly alkaline environments [39, 40]. The same behavior was evidenced for GT-AAB mixtures, in which in the initial cycle Cd was not identified while the concentration increased over the cycles, exceeding the limits of Dutch List [30], CONAMA 460 [31], and EPA [32]. It is important to highlight that the alkali-activated cement precursors (carbide lime and sugarcane bagasse ash) present Cd in their composition, contributing to Cd leaching capacity and concentration [18, 21].

For the Cr leaching test, the sum of trivalent and hexavalent chromium (total chromium) content was considered; with hexavalent chromium compounds being soluble in water. In general, Cr concentration, for both GT-AAB and GT-PC mixtures, decreased over the durability cycles (on cycles 9–12 when compared to cycles 3–6), indicating that Cr is mainly leached on the first wetting–drying cycles. Similar results have been found by Eckbo et al. [41], in which Cr concentration in high at first due to a first flush effect, but levels out with time. The limits of the three standards (Dutch List [30], CONAMA 460 [31], and EPA [32]) were exceed in all mixtures and all cycles, implying that none of the treatments were able to encapsulate Cr in the proposed conditions (water quality limits). Dermatas and Moon [42] assert that Cr immobilization is mainly controlled by precipitate solubility and not by surface adsorption or cation exchange; Cr precipitates such as hydroxide are highly insoluble at the alkaline pH conditions caused by cement addition [43].

Regarding GT-PC mixtures, Cu concentration was not detected in all combinations in cycles 3, 6, and 9. In cycle 12, the limits of Dutch List [30] were exceed for the lower cement content (15%) lower dry unit weight (14.5 kN m−3) specimen. This behavior indicates that for lower porosities, lower quantities of Portland cement are already sufficient to encapsulate Cu. For GT-AAB mixtures, an increase in cement content led to a decrease in Cu concentration. This once again can be alluded to the mechanical behavior of the mixtures, where more compact and cement samples may lead to a better encapsulation of metals [21]. Nevertheless, Dutch List [30] limits were exceeded for lower cement content mixtures on cycle 6, while for the rest of cycles/mixtures combinations the limits of all three standards were satisfied. The increase in Cu concentration over the cycles on an alkaline media may indicate an amphoteric leaching behavior; amphoteric species are molecules or ions that can react as an acid as well as a base The leaching of Cu is solubility controlled and directly associated with the dissolution/precipitation of CuO and Cu(OH)2 [34, 44].

For Fe concentration, the limits of CONAMA 460 [31] were not surpassed for all cycle/mixture’s combinations for both types of cement (GT-AAB and GT-PC). The increase in cement content resulted in the increase of Fe solubilization for most cases, when comparing same porosity specimens. Mahedi et al. [34] have shown that Fe solubilization decreases in highly alkaline media, such as the case of soil–cement mixtures.

Hg concentration for GT-PC mixtures, was below the limits of Dutch List [30], CONAMA 460 [31], and EPA [32] for all blend/cycle combinations, with non-detected concentrations. As for GT-AAB mixtures, a similar trend was evidenced; however, on cycle 6 all specimens, with the exception of higher density (15 kN m−3) and higher cement content one (30% AAB), surpassed the limits of all standards. Thus, for Hg encapsulation, only conventional cement blends were effective, considering that on cycle 6 Hg concentration exceeded the limits of all standards. Bruschi et al. [21] presented similar results, in which Portland cement was able to encapsulate Hg, while the alkali-activated cement presented lower encapsulation capacity.

Pb concentration exceeded the limits of Dutch List [30], CONAMA 460 [31], and EPA [32] for all specimens/cycles for both cementing agents (GT-AAB and GT-PC), indicating that none of the binders were able to encapsulate this metal. Pb concentration for the conventional cement was lower when compared to the alkali-activated one. In addition, for both cement types, Pb concentration reduced over the cycles. No clear pattern was evidenced regarding Pb concentration over the influence of binder content and dry unit weight of the mixtures. Contessi et al. [45] asserts that Pb behavior is pH-dependent, considering its amphoteric nature. Pb exhibits lower mobilization at neutral pH, while highest releases are evidenced in alkaline media [46].

For GT-PC mixtures, Se concentration was not detected over cycles 3 and 6. On cycle 9, Se was detected only for lower cement content mixtures, with the 15% cement content and 14.5 kN m−3 dry unit weight specimens exceeding the limits of CONAMA 460 [31] and EPA [32]. As for the last cycle, Se was once again only detected for lower cement content mixtures; however, both specimens exceeded the limits of CONAMA 460 [31] and EPA [32]. For GT-AAB mixtures, Se concentration was not detected on cycle 3. On cycle 6, 9, and 12 lower cement content specimens exceeded the limits of CONAMA 460 [31] and some specimens of EPA [32], while higher cement content specimens were able to encapsulate Se. Se leaching is strongly pH dependent, highly alkaline media reduces Se mobilization [47, 48]. Thus, higher the cement content, higher the alkalinity of the mixtures, corroborating the presented results.

For cycles 3 and 6, Zn concentration was below the limits of Dutch List [30] and CONAMA 460 [31] for all GT-PC mixtures. Over cycles 9 and 12, Zn was detected for lower cement content (15%) mixtures, all exceeding the limits of Dutch List [30] and CONAMA 460 [31]; higher cement content (30%) specimens were all below the limits of the standards. For GT-AAB mixtures, all specimens on cycle 3 were below the limits of the standards. As for cycles 6, 9, and 12 a similar behavior to Portland cement was evidenced; in which lower cement content specimens exceeded the limits while higher cement content specimens satisfied the limits. This indicates that Zn follows an amphoteric leaching behavior [44]; Cetin et al. [49] asserts that the dissolution of zincite (ZnO) and Zn(OH)2 control the aqueous concentrations of Zn. In addition, Bestgen et al. [50] state that the lowest concentrations of Zn occur at highly alkaline media due to lower elemental concentration.

For specimens stabilized/solidified with conventional cement, limits of three standards (Dutch List [30], CONAMA 460 [31], and EPA [32]) were not exceeded for Al, Ba, Fe, and Hg in all cycles and molding conditions (Tables 5, 6, 7 and 8). On the other hand, the limits of As, Cd, Cr, Cu, Na, Pb, Se, and Zn were surpassed for at least one standard for one or more cycles/molding conditions. As for the alkali-activated specimens, Al, As, Ba, and Fe concentrations were under the limits of the standards for all combinations, while Cd, Cr, Cu, Hg, Na, Pb, Se, and Zn concentrations exceeded these limits in one or more cycles/molding conditions.

When considering the leaching behavior of samples containing higher binder content (30%) and dry unit weight (16.5 kN m−3), it is noted that Al, As and Ba, metals soluble in the residues (Table 2), were encapsulated in the gold mining tailings stabilized/solidified by alkali-activated binder (Tables 5, 6, 7 and 8). The concentrations of Al, As, Ba, Cu, Fe, Hg, Se and Zn in the 30% alkali-activated binder and 16.5 kN m−3 γd sample satisfied the limits of all water standards, while the Cd concentration was lower than CONAMA 460 and EPA limits. Cr is present at a concentration below the CONAMA 460. However, the encapsulation of Pb in cemented mining tailings requires further investigation.

Finally, the amorphous silica and alumina present in GT may have reacted with the calcium oxide of Portland cement to form calcium silicate and calcium aluminate hydrates (C-S-H and C-A-H). Furthermore, the silica and alumina may also have reacted with calcium hydroxide produced during the hydration of the traditional cement, resulting of additional cementitious compounds. In the system with alkali-activated binder, the amorphous silica and alumina of GT can participate in reactions along with the amorphous aluminosilicates of SBCA, calcium oxide from CL, and alkalis from alkaline activator, forming C-A-S-H and N-A-S-H gels. The cementitious gels formed in GT-AAB and GT-Portland cement systems contribute to chemical stability of mining tailings and the encapsulation of metals.

Conclusions

The aim of this study was to evaluate the encapsulation capacity of metals from gold mine tailings by an alkali-activated binder composed by two waste (sugarcane bagasse ash and carbide lime) and Portland cement (control group), using different binder contents and dry unit weights. The leaching behavior of mining tailings stabilized/solidified over wetting–drying cycles was investigated. Based on results, the following conclusions were drawn:

-

In general, alkali-activated binder showed favorable results in the encapsulation of Al, As, Ba and Fe, while Al, Ba, Fe and Hg were immobilized by Portland cement;

-

For both alkali-activated binder and Portland cement, higher dry unit weights and binder contents lead to the encapsulation of metals in cemented gold mining tailings matrices;

-

The concentrations of Al, As, Ba, Cu, Fe, Hg, Se and Zn in the 30% alkali-activated binder and 16.5 kN m−3 γd sample satisfied the limits of all water standards;

-

Alkali-activated binder based on sugarcane bagasse ash and carbide lime is a new option to encapsulate contaminants from gold mining tailings;

-

This study has endeavored to contribute to the existing knowledge on immobilization matrices by systematically investigating the leaching characteristics and the impact of drying-wetting cycles on stabilized gold tailings with Portland cement and alkali-activated binder. The findings, while revealing variations in leaching outcomes, align with the intricacies associated with environmental conditions and material interactions, as evidenced in the current literature.

The study was not explicitly designed for proposing a new optimized matrix but aimed to enhance our understanding of matrix performance under diverse conditions. The observed complexities underscore the challenges in achieving universal optimization, a topic extensively discussed in the context of existing research. Thus, studies focusing explicitly on optimization of metal immobilization in gold mining tailings are suggested for future research, including a wide range of alkali-activated binder contents (e.g., 5, 10, 15, 20, 25, 30, 35, and 40%).

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Karaca O, Camaselle C, Reddy KR (2018) Mine tailing disposal sites: contamination problems, remedial options and phytocaps for sustainable remediation. Rev Environ Sci Biotechnol 17:205–228. https://doi.org/10.1007/s11157-017-9453-y

Bruschi GJ, dos Santos CP, de Araújo MT, Ferrazzo ST, Marques S, Consoli NC (2021) Green stabilization of bauxite tailings: a mechanical study on alkali-activated materials. J Mater Civ Eng 33(11):06021007. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003949

Bruschi GJ, dos Santos CP, Ferrazzo ST, de Araújo MT, Consoli NC (2021) Parameters controlling loss of mass and stiffness degradation of green stabilized bauxite tailings. Proc Inst Civ Eng Geotech 19:1–21. https://doi.org/10.1680/jgeen.21.00119

Bruschi GJ, Fante F, de Tonini Araújo M, Dias Macedo G, Ruver CA (2021) Analysis of different failure criteria to evaluate bauxite tailings mechanical behavior through numerical modelling. Soils and Rocks 44:1–10. https://doi.org/10.28927/SR.2021.053720

Hatje V, Pedreira RMA, De Rezende CE, Schettini CAF, De Souza GC, Marin DC, Hackspacher PC (2017) The environmental impacts of one of the largest tailing dam failures worldwide. Sci Rep 7:10706. https://doi.org/10.1038/s41598-017-11143-x

Belle G, Fossey A, Esterhuizen L, Moodley R (2021) Contamination of groundwater by potential harmful elements from gold mine tailings and the implications to human health: a case study in Welkom and Virginia, Free State Province, South Africa. Groundw Sustain Dev 12:100507. https://doi.org/10.1016/j.gsd.2020.100507

Pan Z, Zhang C, Li Y, Yang C (2022) Solidification/stabilization of gold ore tailings powder using sustainable waste-based composite geopolymer. Eng Geol 309:106793. https://doi.org/10.1016/j.enggeo.2022.106793

Desogus P, Manca PP, Orrù G, Zucca A (2013) Stabilization/solidification treatment of mining tailings using Portland cement, potassium dihydrogen phosphate and ferric chloride hexahydrate. Miner Eng 45:47–54. https://doi.org/10.1016/j.mineng.2013.01.003

Rachman RM, Bahri AS, Trihadiningrum Y (2018) Stabilization and solidification of tailings from a traditional gold mine using Portland cement. Environ Eng Res 23(2):189–194. https://doi.org/10.4491/eer.2017.104

Consoli NC, Vogt JC, Silva JPS, Chaves HM, Scheuermann Filho HC, Moreira HB, Lotero A (2022) Behaviour of compacted filtered iron ore tailings–portland cement blends: new brazilian trend for tailings disposal by stacking. Appl Sci 12:836. https://doi.org/10.3390/app12020836

Garcia-Lodeiro I, Palomo A, Fernández-Jiménez A (2015) An overview of the chemistry of alkali-activated cement-based binders. In: Pacheco-Torgal F, Labrincha JA, Leonelli C, Palomo A, Chindaprasirt P (eds) Handbook of alkali-activated cements, mortars and concretes. Woodhead Publishing, Sawston, pp 19–47

Miller SA, Myers RJ (2020) Environmental impacts of alternative cement binders. Environ Sci Technol 54:677–686. https://doi.org/10.1021/acs.est.9b05550

Queiróz LC, Dias Miguel G, Bruschi GJ, Deluan MSL (2022) Macro–micro characterization of green stabilized alkali-activated sand. Geotech Geol Eng 40:3763–3778. https://doi.org/10.1007/s10706-022-02130-9

Queiróz LC, Batista LLS, Souza LMP, Lima MD, Danieli S, Bruschi GJ, Bergmann CP (2022) Alkali-activated system of carbide lime and rice husk for granular soil stabilization. Proc Inst Civ Eng Gr Improv 21:1–37. https://doi.org/10.1680/jgrim.21.00048

Provis JL (2018) Alkali-activated materials. Cem Concr Res 114:40–48. https://doi.org/10.1016/j.cemconres.2017.02.009

Kiventerã J, Lancellotti I, Catauro M, Dal Poggetto F, Leonelli C, Illikainen M (2018) Alkali activation as new option for gold mine tailings inertization. J Clean Prod 187:76–84. https://doi.org/10.1016/j.jclepro.2018.03.182

Cristelo N, Coelho J, Oliveira M, Consoli NC, Palomo A, Fernández-Jiménez A (2020) Recycling and application of mine tailings in alkali-activated cements and mortars—Strength development and environmental assessment. Appl Sci 10:2084. https://doi.org/10.3390/app10062084

Pereira dos Santos C, Bruschi GJ, Mattos JRG, Consoli NC (2022) Stabilization of gold mining tailings with alkali-activated carbide lime and sugarcane bagasse ash. Transp Geotech 32:100704. https://doi.org/10.1016/j.trgeo.2021.100704

Ferrazzo ST, Tonini de Araújo M, Bruschi GJ, Korf EP, Levandoski WMK, dos Santos CP, Consoli NC (2023) Metal encapsulation of waste foundry sand stabilized with alkali-activated binder: batch and column leaching tests. J Environ Manage 348:119287. https://doi.org/10.1016/j.jenvman.2023.119287

Spreadbury CJ, Clavier KA, Lin AM, Townsend TG (2021) A critical analysis of leaching and environmental risk assessment for reclaimed asphalt pavement management. Sci Total Environ 775:145741. https://doi.org/10.1016/j.scitotenv.2021.145741

Bruschi GJ, dos Santos CP, Levandoski WMK, Ferrazzo ST, Korf EP, Saldanha RB, Consoli NC (2022) Leaching assessment of cemented bauxite tailings through wetting and drying cycles of durability test. Environ Sci Pollut Res 29:59247–59262. https://doi.org/10.1007/s11356-022-20031-5

Levandoski WMK, Ferrazzo ST, Bruschi GJ, Consoli NC, Korf EP (2023) Mechanical and microstructural properties of iron mining tailings stabilized with alkali-activated binder produced from agro-industrial wastes. Sci Rep 13:15754. https://doi.org/10.1038/s41598-023-42999-x

Sá TSW, Oda S, Balthar VKCBLM, Toledo Filho RD (2022) Use of iron ore tailings and sediments on pavement structure. Constr Build Mater 342:128072. https://doi.org/10.1016/j.conbuildmat.2022.128072

ABNT (2004a) Resíduos sólidos—Classificação. ABNT NBR 10004. Rio de Janeiro, BR

ABNT (2004b) Lixiviação de Resíduos—Procedimento. ABNT NBR 10005. Rio de Janeiro, BR

ABNT (2004c) Solubilização de Resíduos—Procedimento. ABNT NBR 10006. Rio de Janeiro, BR

Ladd RS (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16–23

ASTM (2015) Standard test methods for wetting and drying compacted soil-cement mixtures. ASTM D559/D559M. West Conshohocken, PA

EA (2004) Leaching characteristics—Determination of the leaching of inorganic components from moulded or monolitic materials with a diffusion test—Solid earthy and stony materials. NEN 7375

VROM (2000) Dutch target and intervention values. Ministerie van Volksuisveting Ruimtelijke Ordening en Milieubeheer. See https://www.esdat.net/environmental%20sta ndards/dutch/annexs_i2000dutch%20environmental%20standards.pdf (accessed 11/01/2021)

CONAMA (2013) Altera a Resolução no 420, de 28 de dezembro de 2009, do Conselho Nacional do Meio Ambiente-CONAMA, que dispõe sobre critérios e valores orientadores de qualidade do solo quanto à presença de substâncias químicas e dá outras providências. CONAMA Resolução 460. Official Diary of the Union

USEPA (2020) Ground water and drinking water: national primary drinking water regulations. See https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-water-regulations#Inorg anic (accessed 11/01/2021)

Bye GC (1999) Portland cement composition: production and properties, 2nd edn. Thomas Telford Publishing, London

Mahedi M, Cetin B, Dayioglu AY (2019) Leaching behavior of aluminum, copper, iron and zinc from cement activated fly ash and slag stabilized soils. Waste Manag 95:334–355. https://doi.org/10.1016/j.wasman.2019.06.018

Mitchell JK, Soga K (2005) Fundamentals of soil behavior. John Wiley and Sons, New York

Tangviroon P, Endo Y, Fujinaka R, Kobayashi M, Igarashi T, Yamamoto T (2020) Change in arsenic leaching from silty soil by adding slag cement. Water Air Soil Pollut 231(6):259. https://doi.org/10.1007/s11270-020-04630-x

Ho GD, Tabelin CB, Tangviroon P, Tamamura S, Igarashi T (2021) Effects of cement addition on arsenic leaching from soils excavated from projects employing shield-tunneling method. Geoderma 385:114896. https://doi.org/10.1016/j.geoderma.2020.114896

Mahedi M, Cetin B, Dayioglu AY (2020) Effect of cement incorporation on the leaching characteristics of elements from fly ash and slag treated soils. J Environ Manage 253:109720. https://doi.org/10.1016/j.jenvman.2019.109720

Deja J (2002) Immobilization of Cr6+, Cd2+, Zn2+ and Pb2+ in alkaliactivated slag binders. Cem Concr Res 32:1971–1979. https://doi.org/10.1016/S0008-8846(02)00904-3

Lancellotti I, Barbieri L, Leonelli C (2015) Use of alkali-activated concrete binders for toxic waste immobilization. In: Pacheco-Torgal F, Labrincha JA, Leonelli C, Palomo A, Chindaprasirt P (eds) Handbook of alkali-activated cements, mortars and concretes. Woodhead Publishing, Sawston, pp 539–554

Eckbo C, Okkenhaug G, Hale SE (2022) The effects of soil organic matter on leaching of hexavalent chromium from concrete waste: batch and column experiments. J Environ Manage 309:114708. https://doi.org/10.1016/j.jenvman.2022.114708

Dermatas D, Moon DH (2006) Chromium leaching and immobilization in treated soils. Environ Eng Sci 23(1):77–87. https://doi.org/10.1089/ees.2006.23.77

Zhang WJ, Lin MF (2020) Influence of redox potential on leaching behavior of a solidified chromium contaminated soil. Sci Total Environ 733:139410. https://doi.org/10.1016/j.scitotenv.2020.139410

Özkök E, Davis AP, Aydilek AH (2013) Leaching of As, Cr, and Cu from high-carbon fly ash–soil mixtures. J Environ Eng 139(11):1397–1408. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000751

Contessi S, Calgaro L, Dalconi MC, Bonetto A, Bellotto MP, Ferrari G, Marcomini A, Artioli G (2020) Stabilization of lead contaminated soil with traditional and alternative binders. J Hazard Mater 382:120990. https://doi.org/10.1016/j.jhazmat.2019.120990

Li YY, Zhang TT, Jia SB, Liu J, Quan XH, Zheng W (2019) Mechanical properties and leaching characteristics of geopolymer-solidified/stabilized lead-contaminated soil. Adv Civ Eng 2019:1–8. https://doi.org/10.1155/2019/6015769

Moon DH, Grubb DG, Reilly TL (2009) Stabilization/solidification of selenium-impacted soils using Portland cement and cement kiln dust. J Hazard Mater 168(2–3):944–951. https://doi.org/10.1016/j.jhazmat.2009.02.125

Brandely M, Coussy S, Blanc-Biscarat D, Gourdon R, Blanck G (2022) Chemical stabilization used to reduce geogenic selenium, molybdenum, sulfates and fluorides mobility in rocks and soils from the Parisian Basin. Environments 9(7):78. https://doi.org/10.3390/environments9070078

Cetin B, Aydilek AH, Guney Y (2012) Leaching of trace metals from high carbon fly ash stabilized highway base layers. Resour Conserv Recycl 58:8–17. https://doi.org/10.1016/j.resconrec.2011.10.004

Bestgen JO, Cetin B, Tanyu BF (2016) Effects of extraction methods and factors on leaching of metals from recycled concrete aggregates. Environ Sci Pollut Res 23(13):12983–13002. https://doi.org/10.1007/s11356-016-6456-0

Funding

The present work was supported by CNPq - Conselho Nacional de Desenvolvimento Científico e Tecnológico – Brazil. The authors also wish to express their gratitude to MEC-CAPES, FAPERGS/CNPq December 2014 – PRONEX (Project # 16/2551-0000469-2), and MCT-CNPq (Editais INCT-REAGEO, Universal & Produtividade em Pesquisa) for supporting the research group.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by CPdS, GJB, STF, and WMKL. The first draft of the manuscript was written by Carolina Pereira dos Santos and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript. In addition, EPK, and NCC were also responsible for the supervision.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pereira dos Santos, C., Bruschi, G.J., Tonatto Ferrazzo, S. et al. Leaching Behavior of Alkali-Activated Gold Tailings Over Wetting–Drying Cycles. Indian Geotech J (2024). https://doi.org/10.1007/s40098-024-00886-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40098-024-00886-w