Abstract

Catalytic hydrogenation of 1,3-butadiene to produce selectively 1-butene has considerable importance in the hydrocarbon industry and presents a significant challenge in tuning the catalyst selectivity towards 1-butene, understanding the reaction and kinetic mechanism. Selective hydrogenation over metal oxide-supported palladium catalysts is considered as a standard process; however, selectivity towards 1-butene is achieved by alloying palladium with other metals that facilitate the desorption of adsorbed alkene intermediate and limit further hydrogenation to form butane. In this book chapter, we summarize the current state of the art and perception of various factors that control the catalyst activity, adsorption of intermediates on the active sites and eventually the selectivity. In particular, we present a concise description of active metal dispersion, structure sensitivity, influence of support, promoter and their role in governing the selectivity of 1-butene from 1,3-butadiene hydrogenation. Then, this chapter highlights the detailed analysis of reaction kinetics and reaction mechanisms that are proposed clearly. Finally, a brief overview of the theoretical investigations for 1,3-butadiene hydrogenation using density functional theory (DFT) calculations has also been discussed for a variety of catalysts and followed discussion about summary and future outlook.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Hydrogenation processes of poly-unsaturated hydrocarbons to selectively produce alkenes have attracted significant interest since 1990s, due to the high demand of alkenes from the petrochemical and polymer industries. Initial work on the catalytic hydrogenation was developed considerably during early 1960s, particularly with the boom of olefin production by steam cracking. Majority of the catalytic hydrogenation processes are used in refining and petrochemical sector, specifically the downstream units of the mother plant, the cracker, e.g. selective hydrogenations of acetylenes, methyl acetylenes, propadienes, 1,3-butadienes, selective hydrogenations of C5 unsaturates, etc. All of these molecules are produced in large scale due to their use as fuels, fuel precursors, polymerization precursors, etc. In particular, C4-rich streams consisting of 1-butene are currently used as precursors for the production of polybutene and co-monomer of low-density polyethylene. However, the presence of 1,3-butadiene in the C4 stream blocks the active sites of the polymerization catalyst, which inhibit the polymerization kinetics. Thus, there is a wide scope for understanding and developing newer and improved active, selective and stable catalysts of industrial importance, which can convert 1,3-butadiene into 1-butene selectively. In addition, this specific hydrogenation reaction is considered as a model reaction to investigate the catalytic, structural and electronic properties of the catalyst. Due to these advantages, a continued research activity on hydrogenation of 1,3-butadiene is significant from both fundamental and applied aspects, to achieve a better insight in the catalyst, process, and mechanism—key factors which control the catalyst performance as well as selectivity. Owing to the practical and theoretical importance, it is very important to collate the different aspects of this process from the existing literature to understand the reaction mechanism of hydrogenation reaction. Thus, this book chapter provides a detailed information of the selective catalytic hydrogenation of 1,3-butadiene, and summarizes the knowledge, significance and future scope of this heterogeneous catalytic process. Specifically, product selectivity and kinetics of this reaction, which were correlated to factors such as the effect of the support, the structure sensitivity, size of the active sites, metal dispersion, promoters and additives, are discussed in detail.

1.1 Significance and Background

To realize the potential of a model reaction to probe the catalyst structure, it is important to understand the hydrogenation reaction of 1,3-butadiene, physical properties of both 1,3-butadiene as well as the expected hydrogenated products from 1,3-butadiene (Table 1). Their chemical structures including the reactants and the products in this reaction sequence are also presented in Fig. 1, which clearly shows how the reaction kinetics on different catalyst can affect the product selectivity. From the data listed, the density of butane (2.480 g/cm3) is higher than that of other products and 1,3-butadiene. No other significant differences in physical properties can be observed between the 1,3-butadiene and its products after hydrogenation.

As mentioned in the introduction, the 1-butene-rich cut, also known as C4 alkenes cut, was available after butadiene and isobutene extraction at the downstream operation of cracker unit in any petrochemical industries and refineries [1, 2]. Further, the process of the selective hydrogenation of 1,3-butadiene in C4 alkenes cut could produce a linear low-density polyethylene (LLDPE) polymer [3]. 1-Butene was mainly used as a co-monomer and a trace quantity of 1,3-butadiene present in the feed, can adversely affect the polymerization (olefin) as well as durability of catalysts and this process can reduce the rate of total polymer production. In addition, 1-butene with 99 wt% purity and 1,3-butadiene residue (<10 ppm) are required for an LLDPE co-monomer [4].

Therefore, selective conversion of 1,3-butadiene into 1-butene is a key issue during this hydrogenation process and this high selectivity is prominent for polymer quality [5]. The high selectivity can be achieved if the process overcomes the reaction steps of 1-butene isomerization (to form 2-butenes) and/or its subsequent hydrogenation (to form n-butane). Moreover, selective butadiene hydrogenation is an attractive model reaction, which permits investigation on both activity and selectivity aspects on various catalysts, because there are four probable reaction products (1-butene, butane, cis- and trans-butene) [6].

In the case of 1,3-butadiene hydrogenation, selectivity can take mainly in the forms of regio-selectivity, where the reduction of one C=C bond is favoured over that of another in different surroundings (terminal C=C undergo faster reduction compared to the internal one). Regio-selective hydrogenation of a 1,3-butadiene is basically controlled by the same factors, which control the reactivity of alkenes, when a competitive hydrogenation occurs in binary mixtures. Compared to other substituted double bonds, a terminal C=C bond is preferentially hydrogenated on the active site of the catalyst. However, another kind of selectivity can be observed due to the competition between unreacted diene and intermediately formed monoene for the same active site. Moreover, the other intermediate (trans-2-butene) can be formed due to the isomerization of 1-butene (Scheme 1).

2 Selective Hydrogenation of 1,3-Butadiene: Key Factors in Catalysts Design

To gain a deeper insight into the design of catalysts for selective hydrogenation of 1,3-butadiene, a detailed survey of the literature was carried out and the following key factors were identified. Supported metal catalysts are the main family of catalysts that were tested for their reaction; therefore, their, size, morphology, dispersion, interaction with the support were studied and correlated with the activity of the catalyst and product selectivity. Kinetic study and reaction pathway, order of the reaction, adsorption on metallic surfaces, effect of support, structure sensitive and the effect of metal dispersion and the use of additives, ad-species, and promoters were the key parameters, which were identified as important parameters in controlling the catalyst activity and product selectivity. In the following sections, each of these parameters is discussed in detail; however, it should be noted that all these factors affect the reaction synergistically to control the activity and selectivity. Detailed analysis from the reported literature presented in this chapter is organized as follows.

2.1 Kinetic Study and Reaction Pathway

The selectivity of this hydrogenation reaction is an important parameter, therefore studying the reaction kinetics of this reaction on various catalysts and establishes a probable mechanism that can provide the bridge between the experimental results and theoretical prediction. In this specific heterogeneous catalytic hydrogenation process, reactants and protects are geometrical isomers, therefore the reaction kinetics also provide an insight into stereo/regio-selectivity. The adsorption kinetics of these isomers on the active sites of the catalysts was found to vary with isomer to isomer, therefore studying the kinetics can provide the information about stereo/regio-selectivity on each catalyst. Over many years, the stereochemistry of different heterogeneous catalysts in selective hydrogenation reactions has been a substantially interesting subject [1, 7,8,9,10,11,12,13,14,15,16,17]. The kinetic investigations reported in the open literature are usually carried out in the gas phase or liquid phase (usually under industrial processing conditions: atmospheric pressures and low temperatures). The alkenes hydrogenation over the heterogeneous catalysts has been investigated for almost 80 years. In 1934, Horiuti and Polanyi [16] explained the hydrogenation of 1,3-butadiene reaction mechanism, in which 1,2 and 1,4-addition of two conjugated C=C double bonds produced 1-butene and 2-butene, respectively. In addition, due to the existence of cis or trans isomers of 1,3-butadiene, the hydrogenation reaction can produce either cis- or trans-2-butene. Further hydrogenation of the cis or trans isomer products obviously produces butane [18, 19]. Well et al. investigated initially the 1,3-butadiene hydrogenation reaction over different metals (Ru, Ir, Fe, Pt, Co, Rh, Pd, Cu, Os, and Ni) supported by alumina (Al2O3) [18, 20,21,22]. It was proposed that the reaction mechanism exhibit two types of selective behaviours namely 1,2 and 1,4 addition over alumina-supported metal catalysts (Scheme 1).

As shown, the formation of 1-butene was mainly responsible for 1,2 hydrogenation pathway. Interestingly, 2-butene formation occurred on Pd through a 1,4-addition pathway. Moreover, the relative yields of cis- and trans-2-butene were dependent on the conformational characteristics of adsorbed precursors. On the other hand, Boitiaux et al. reported that 1-butene was formed through syn or anti-adsorbed 1,3-butadiene on Pd, Pt and Rh metals, in which trans-butene and cis-butene were formed through anti- and cis-configurations [8,9,10]. Among active metals, the behaviour of Pt and Rh for the purpose of 1,3-budadiene hydrogenation was found to be quite similar, and each of them nearly resembles to that of Pd, the only difference being in the initial butane formation. 1-Butene can undergo several other consecutive or parallel transformations to generate cis-2-butene, trans-2-butene and butane. Butane formation occurs through a semi-hydrogenated species, generated from a syn-adsorbed 1,3-butadiene, from which cis-2-butenes are formed. Addition of hydrogen occurs mostly/largely in the 1,2 positions, and to some extent at the 1,4 position. Further hydrogenation of 1-butene starts only after a high conversion of butadiene. Pradier et al. [23] reported the hydrogenation of 1,3-butadiene over Pt(110) and Pt(100) and it was found that the process to re-adsorb 1-butene at >50% conversion level, when desorption of a fraction of butadiene occurs, is likely to occur than the process of second hydrogenation of 1-butene in the adsorbate state before it leaves the surface. The proposed pathway was found to be similar to the earlier observation that 1-butene is more strongly bonded to transition metals as compared to that for 2-butenes. Butane formation by the readsorption of 2-butene on the metal site was not considered significant enough to be considered in the kinetics. Further, Boitiaux et al. [24, 25] proposed a mechanism of carbene formation (Scheme 2) on different metal sites, which can explain the selective formation of butane when the ratio of trans/cis-2-butene ratio was found to be low. Pt and Rh show entirely different results to that are obtained over the Pd due to the negligible selectivity towards butane and high ratio of trans/cis butenes over the Pd; the first two yield butane and a small trans/cis ratio. From these studies, it was concluded that the metal site, which would not facilitate carbene formation would not produce butane selectively. To find out the specificity of the hydrogenation process in detail, isotopic labelling studies were conducted, wherein deuterated 1,3-butadiene was used as a reaction. This reaction was investigated over the Al2O3-supported Ni, Cu, Pt, Pd, Rh and Co catalysts [18, 22, 26, 27]. The detailed compositional analysis of the products was studied as a function of different conversion [21] while keeping pressure and temperature constant. Earlier studies have demonstrated that these two variables including pressure and temperature have shown similar results for all the metal catalysts. These studies have shown that the deuterium distributions in the butenes were approximately the same. This could happen only when each of the butenes was an initial product, and not the result of the isomerization of any other as well as the absence of both the 1,2- and 1,4-addition processes. Another major conclusion drawn from this study was that there was limited but adjustable exchange of the hydrogen atoms of the reactant. Appearance of small amounts of hydrogen in the deuterated reactants and products shows that the concentration of atoms on the surface was small under prevailing experimental conditions [18, 21].

2.2 Reaction Order of Reactants: 1.3-Butadiene, Hydrogen, 1-Butene

As the reactants and few products of this reaction have the tendency to competitively adsorb on the catalytic sites, the reaction order was found to be different on different catalysts, therefore understanding the reaction order with respect to the reactants and products can provide valuable information about the product selectivity. The main parameters which characterize the hydrogenation process are (a) the sum of all three butenes (i.e. total butenes) selectivity and (b) individual butene isomer selectivity, i.e. the fraction of butenes that each isomer constitutes (trans, cis-2-butene and 1-butene). Over many of the metal catalysts from Groups 8 to 10, the selectivity to the sum of all three butenes was close to unity and the composition was unaffected until the complete consumption of reactant 1,3-butadiene; therefore, it was more strongly adsorbed than the products. Kinetics studies on hydrogenation of 1,3-butadiene in gas phase or liquid phase have shown that the intrinsic reaction rate was zero order with respect to the butadiene and approximately first order with respect to hydrogen [7,8,9,10,11,12,13,14,15, 17, 28,29,30,31]. Strong and preferential adsorption of 1,3-butadiene over 1-butene were indicated from the measurements of reaction orders and activation energies. Moreover, each unsaturated compound has different adsorption strength and always selectivity for the hydrogenation reaction depends on these adsorption energies. Compared to n-butenes, 1,3-butadiene has high propensity to be hydrogenated. Only, when the concentration of 1,3-butadiene was lower in the mixture, n-butene was found to be hydrogenated preferentially to n-butane. Oudar et al. [32, 33] observed two kinetic regimes for the 1,3-butadiene hydrogenation and H2-D2 exchange over the Pt(110) surface and pressure conditions used for this reaction are 200–400 Torr. Reaction orders with respect to the hydrogen and butadiene were found to be 1 and 0, respectively at >130 Torr of hydrogen pressures. It was also observed that the selectivity was independent of the hydrogen pressure applied, and every two Pt atoms of the catalyst surface was covered by one butadiene molecule. Below critical hydrogen pressure (~125 Torr); the reaction order was 2 and 0 with respect to hydrogen and 1,3-butadiene, respectively. Another important observation was the butane selectivity decreases with the hydrogen pressure. Yoon et al. [31] studied the isomerization and hydrogenation reactions of cis-2-butene and 1-butene on Pt foil and Pt(111), Pt(100), Pt(755) single-crystal surfaces and reported that the reaction selectivity was independent of reactant mixture but changes slightly with reaction temperature.

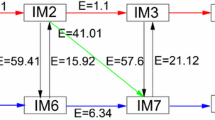

2.3 DFT Studies on Catalytic Hydrogenation of Butadiene

Catalytic hydrogenation of 1,3-butadiene is considered as a model catalytic process for olefin/diene hydrogenation in refining/petrochemical industry and adsorption studies of these unsaturated hydrocarbons on metallic surfaces are of basic and practical interest. Therefore, the majority of studies [19, 29, 34,35,36,37,38,39,40,41] have focused on the use of DFT calculations in comparison with experimental data to investigate the interaction of 1,3-butadiene, 2-cis/trans-butenes and 1-butene on various metal surfaces. Valcárcel et al. first studied the interaction of different hydrocarbons (1,3-butadiene, 1-butene and 2-cis/trans-butenes) over various Pd(111) and Pt (111) surfaces using DFT calculations [41, 42].

Two different modes of 1,3-butadiene adsorption on these surfaces were suggested [36, 37]. They are 1,2,3,4-tetra-σ adsorption and 1,4-metallacycle-type adsorption during the process as shown in Fig. 2, in which the first type adsorption was stable. This structure was consistent with the qualitative molecular orbital calculations[43] as well as the results from the electron energy loss spectroscopy (EELS) and thermal desorption spectroscopy (TDS) [44]. Among different pathways as discussed in Fig. 2, the di-σ-mode was the most stable adsorption structure for the formation of butene isomers [40], as suggested by NEXAFS, UPS, TDS and EELS results [44,45,46]. The experimental observations clearly evidenced the formation of butene over Pd surface with high selectivity. On the other hand, in case of Pt surfaces, the dehydrogenation radical species formation was competitive with the butene, which obviously prefers low selectivity towards butene formation; thereby the butanes will be the primary products. Among the reaction pathways, di-σ mode of the interaction was further strongly supported by additional experimental [47] and theoretical [48] works (Fig. 2). Experimental results from other studies have also reported that 100% formation of 1-butene alone was occurred on Pd(111) surface, whereas 60% of formation was only observed on Pt(111) surface [23, 47, 49, 50]. This variation between the reaction on the Pd and Pt surfaces was mainly attributed to the differences in 1,3-butadiene and butenes adsorption strengths towards these two metal surfaces (Fig. 3). It was considered that the strong adsorption nature of 1,3-butadiene can easily replace the weakly adsorbed butene on Pd(111) surface, thereby higher selectivity obtained. However, in case of Pt(111) surface, equivalent strength of both 1,3-butadiene and butene, a lower selectivity was observed. This hypothesis was supported by extended Huckel theory calculations [48] and experimental studies [51].

Adsorption structures proposed for 1,3-butadiene. (Adapted with permission from [48]. Copyright 1989 American Chemical Society)

However, Mittendorfer et al. [40] found that almost there were no significant differences between Pt and Pd with respect to the relative adsorption energies of butadiene versus butene. These authors suggested that the higher activity over Pd most likely due to the ease of butene desorption from Pd(111) surface as compared with Pt(111) surface. Belelli [34] studied the adsorption of three butene isomers (cis/trans-2-butene and 1-butene) on a stepped Pd(422) surface using a DFT and compared with those found for a free defect surface as Pd(111). The 1-butene was predicted to be more stable on free defect surface when compared with the Pd(422) surface in contrast to the preference of cis/trans-2-butene to be adsorbed on the stepped surface. Yang et al. [19] performed both theoretical calculations and catalytic experiments for the selectivity towards 1,3-butadiene hydrogenation in presence of Au nanoparticles.

Nano Au surfaces preferably produced the cis-form of 2-butene instead of trans-form. It was found that the Au nanoparticle size strongly influenced the cis-/trans ratio. Sheng Chen et al. [52] proposed adsorption configurations of different form of reactants and products over Au(211) surface. As shown in Fig. 4, the adsorption energies of cis/trans-2-butene, and 1-butene were similar, however weaker than those of cis/trans 1,3-butadiene. Due to these differences, the H atom and butadiene adsorbs at the bridge site along the step edges of Au(211) surface, and all the butenes produced adsorb at the step edges with a π-bonded configuration. Similar trend was also observed for Cu and Ag model nanoclusters, when they use theoretical calculations. Another interesting point observed for the case of Pt surfaces, butane formation was predominant from the beginning of the reaction [8,9,10]. Butane was formed in much higher proportion as compared to butenes and becomes the primary product. This different behaviour was not ascribed to a very low desorption rate of the intermediate olefin but to the nature of the partially hydrogenated species. Additionally, the reactivity of metallacyclic intermediates that could play a vital role in hydrogenation-dehydrogenation reactions has been reported in several reports [53,54,55]. Very recently, DFT calculations carried out by Hou et al. [38] and Gomez et al. [36, 37] found that the Pd-terminated bimetallic surface is more reactive and selective to form 1-butene, which was also further supported by TPD experiments. On the Pd1Ni3(111) and PdNiPd(111) surface, a very low binding energy (BE) was seen for 1-butene, which was confirmed that it can readily desorb from the surface to form 1-butene rather than butane. This clearly showed that 1,3-butadiene can be converted to 1-butene avoiding further hydrogenation to form butane. In summary, the structure and adsorption state of unsaturated hydrocarbons on metal surfaces strongly influenced the hydrogenation reactions. It was proved that the reaction of 1,3-butadiene on Pd surfaces selective towards butenes whereas on Pt surfaces it can be hydrogenated to butane along with butenes. The differences between Pd and Pt surfaces were assigned to the difference in adsorption state via the C=C double bonds present in butadiene. Furthermore, it was believed that the catalytic reaction was also influenced by the adsorption structure of the reactant [39]. It can be concluded that the key to the butene selectivity depended on the relative stability of radical intermediates over metal surfaces. This could explain why Pt surfaces always show poor selectivity for the formation of butene rather than it always exhibited high selectivity towards butanes.

Adsorption configurations of trans-/cis-1,3-butadiene, trans-/cis-2-butene, 1-butene and H atoms on Au(211). The yellow, grey and white balls denote the gold, carbon and hydrogen atoms, respectively [52]. (Reprinted from [52], Catalysis Today Sheng Chen et al.Copyright (2018) with permission from Elsevier)

2.4 Influence of the Support on Hydrogenation of 1,3-Butadiene

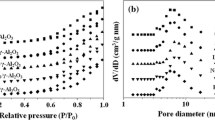

The different metal surfaces clearly showed various mechanisms and selectivities; further, the presence of support can influence the reaction pathway and selectivity towards butenes. There have been a number of studies carried out at investigating the support effects [56,57,58,59,60,61]. Primet et al. [60] investigated various supported platinum catalysts with low metal loading (<1 wt%) for the hydrogenation of 1,3-butadiene. It was found that the acidic sites presented on the support can cause an electron shift through the interface between meta-support interfaces. Consequently, the bond strength between unsaturated hydrocarbons and the metal active sites can be altered, thus changing the selectivity and reaction rate. In addition, the catalyst deactivation can also be affected by the other properties such as acidity of the support and the pore diffusion. Recent work by Pattamakomsan et al. [62] also revealed that the Pd/Al2O3 catalytic performance was improved when the mixed Al2O3 structure support consists of 80% θ- and 20% α-Al2O3 rather than pure Al2O3. The relatively high acidity and BET surface area of Al2O3 yielded higher dispersion of Pd and significantly enhanced rate of hydrogenation. Moreover, the bimodal pore distribution of the mixed-phase θ/α Al2O3 promoted butene desorption products to obtain a much lower formation of butane when compared to the pure θ-Al2O3 that had only small pores. It can be concluded that Al2O3 support with different phase compositions effected the selectivity towards 2-butene. Moreover, Hou et al. [63] investigated the influence of various supports such as Al2O3, SiO2, CeO2, ZrO2, and TiO2 on Pd-Ni surfaces for the selectivity butadiene hydrogenation towards different products. As discussed in Fig. 5, each support favoured different selectivity for the butenes. Among the expected products (1-butene, cis-2-butene, and trans-2-butene), alumina support showed highest selectivity towards 1-butene. The following is the order of selectivity towards 1-butene: Al2O3 > SiO2 > CeO2 ∼ ZrO2 > TiO2. It can be concluded that the strong metal-support interaction between Pd-Ni and alumina played a key role on 1-butene selectivity over other supports. Furthermore, Cukic et al. [56] used high-throughput experimentation for Pd/Al2O3 catalyst with different variables such as stirring rate, calcination temperature, the solution pH, and the time taken for impregnation, and heating rate. It was found that these parameters influenced the conversion of 1,3-butadiene significantly. For example, during the impregnation process, the use of excess solution caused a decrease in activity when compared to the incipient wetness impregnation. On the other hand, the ramping rate for drying, and the holding time for (both drying and calcination) did not show any significant changes in the activity. Several studies also claim that using porous active site can influence the 1,3-butadiene hydrogenation process. It was explained that the hydrogen porous membrane catalyst can provide an independent control of the surface concentrations of hydrogen and other substances which can be readily hydrogenated. That means the membrane can be Pd itself or it may act as support material for the active species. Liu et al. [4] reported the use of mono- and bimetallic hollow-fibre catalytic reactor for the purification of 1-butene. Interestingly, the isomerization of 1-butene was significantly controlled due to the synergistic interaction between bimetals. Moreover, Ciebien et al. [64] reported that Pd nanoclusters membrane catalyst synthesized within microphase-separated di-block copolymer films are active and selective catalysts for the selective hydrogenation of 1,3-butadiene, although the clusters were completely surrounded by a bulk polymer matrix. It was observed that the selectivity was enhanced in case of Pd membranes while compared to non-membranes. The increase in selectivity can be due to the lower hydrogen pressure, which allowed steady-state concentration reactants away from equilibrium and consequently suppressed the side-reactions over the working catalyst. In summary, the above survey appraisal of variables makes evident that there were many important variables involved in the preparation of catalysts for the 1,3-butadiene hydrogenation reaction. Particularly, acidic properties of the support, heating rate of calcination, stirring speed, impregnation time, pH of the solution, drying and calcination temperature were shown to play vital role in promoting the selective hydrogenation of butadiene into butene.

It was worthwhile to emphasize that the selective 1,3-butadiene hydrogenation can be significantly improved with palladium membrane.

2.5 Structure Sensitive and the Effect of Metal Dispersion

As discussed above, the 1,3-butadiene hydrogenation usually leads to the formation of many different products and the desired product selectivity relied on these molecules adsorption preferences towards metal sites. This structure sensitive reaction was first confirmed by Silvestre-Albero et al. [65,66,67]. They found through the kinetic measurements on Pd(110) and Pd(111) for their conversion and selectivity that the selective 1,3-butadiene hydrogenation on Pd catalysts was a structure-sensitive reaction (Fig. 6). The strong structure sensitivity was understood by evoking the unusual electronic structural properties of Pd nanoparticles. Due to the presence of unique electron-deficient Pd clusters, the electron-rich diene molecules can be chemisorbed, which lead to self-poisoning as compared to larger size nanoparticles [32, 33, 68, 69]. The catalytic properties of supported metal catalysts can also be influenced by the particle size, therefore the influence of particle size was studied systematically to understand their role on the activity and the product selectivity. Both activity (turnover frequency; TOF) and selectivity can be affected by the change in dispersion/particle size of the metal which are mostly due to geometric and electronic effects [70, 71]. When metal atoms replaced by other metal atoms through doping approach, the chemisorption nature of catalyst can be altered. This effect can also be called electronic or “ligand effect”.

The activity correlation with the Pd catalysts and its dispersion in the hydrogenation of dienes was more straightforward, in which a strong conflicting behaviour is usually found [12, 13, 15, 72,73,74,75]. In many cases, the specific reactivity of Pd is unchanged until the dispersion amount is 20–35%; however, this might be different, when different supports used [72, 76]. However, the catalytic activity was decreased as the amount of Pd dispersion increased. Furthermore, as the number of active metal particles decreases, the electronic properties of metal particles were influenced. Perfect explanation can be provided through the chemisorption of highly electron–rich diene molecules. If less number of active metal particles available, the selectivity towards 1,3-butadiene hydrogenation for the butene will be decreased. It was also observed that the metal atoms with high coordination number were characteristic of larger particles and whilst small particles possess crystals with atoms of low co-ordination number. Furthermore, the active nanoparticle size can also play a significant role in heterogeneous catalysis due to the unique properties at nanoscale. The utilization of transition metals with a 1–20 nm nanoparticles size in catalysis is vital as they mimic the activation of metal surface which lead to high selectivity and efficacy to the desired reaction. These small-sized nanoparticles can also be called as the clusters derived from metal atoms, and are usually stabilized by ligands, surfactants, and polymers/dendrimers protecting their surfaces with varying sizes (ranging from 10 to 100 nm). However, the most active nanoclusters are only few hundreds of atoms with one or a few nanometres in diameter. It is reported that the sizes of the noble-metal structures and specific crystal facets, such as Pd, Pt, Au and Ni [19, 62, 66,67,68, 73,74,75, 77,78,79,80,81,82,83,84,85] significantly influence on their chemisorption properties and hence, catalytic performance. Hence, special nanostructures with well-defined shapes and uniform sizes are highly needed to control their performance for the hydrogenation reaction. According to Piccolo et al. [86], the conversion rates of butadiene-to-butenes on the fresh model catalysts can be related as follows: Au(111) < Pd-Au(111) < Pd-Au(110) < Pd(111). Unlike on Pd(111), the butane production rate was very low and the butenes selectivity reached ~100% on Pd-Au(111). It should also be noted that the diffusion of hydrogen toward bulk of the Pd-based single-crystals seems to play a key role and the surface hybrid formation accounts for the Pd-Au surface activation. Michalak et al. [39] reported that the catalysts having ensembles of 1.8 and 0.9 nm in size of Pt enhanced 20 and 30% of total hydrogenation of 1,3-butadiene to n-butane when compared to 6.7 and 4.6 nm size of Pt. It can be concluded that the small-sized nanoparticles effected conversion rate. As shown in Fig. 7, the larger size (4.6 and 6.7 nm) Pt nanoparticles favour insertion of H-atom at the terminal site of carbon atom, which is similar to those observed for bulk Pt materials. In case of smaller sized (0.9 and 1.8 nm) Pt nanoparticles, the insertion H-atom occurred at two places, which includes at low coordination sites as well as at terminal carbon site. Moreover, Lucci et al. reported that isolated Pt atoms were responsible for the deactivation of catalyst, thereby less selectivity towards butene formation. This was due to the preferential hydrogen activation and unable to break the C-C bond [87]. In contrast, other researchers reported that the 1,3-butadiene hydrogenation reaction is in fact independent of the metal particle size [66, 67]. In particular, a study was focused on demonstrating the hydrogenation of 1,3-butadiene was independent on particle size (in spite of being structure sensitive) for the case of Pd/Al2O3 catalyst. The catalytic activity of different-sized Pd nanoparticles was correlated with the Pd(110) and Pd(111) surfaces under similar reaction conditions. It was found that the 4 nm-sized Pd nanoparticles showed similar activity while compared to the larger size of Pd nanoparticles.

Proposed reaction pathways for Pt nanoparticles with different sizes. (Reprinted with permission from [39]. Copyright 2013 American Chemical Society)

It was suggested that the author bridges the “materials gap” between the surface science studies on single crystals and heterogeneous catalysis on metal NPs. Besides using Pt and Pd as active sites, 1,3-butadiene hydrogenation reaction catalysed by gold has also received a significant attention due to its potential to catalyse the preferential oxidation and selectivity [88]. Bulk Au is chemically inert (as Au is one of the noble metals), and has seldom rarely been considered to be an effective catalyst. However, small-size gold nanoparticles have been reported to be remarkably selective towards partially hydrogenated product during hydrogenation of alkadienes [58, 75, 86, 88,89,90]. In contrast, the Au catalysts display low activity than that of the group VIII metals and is attributed to its limited capability to dissociate H2 [91]. The dissociation capacity of Au depends strongly on the amount of available low coordination sites on the Au nanoparticles and is thus facilitated with decrease in particle size. In summary, the smaller size metal nanoparticle and metal clusters that are having dynamic surface reorganization played a key role in adsorption and catalytic properties. In fact, Pd nanoparticles showed lateral flexibility, which was benefited for the breaking of olefinic bond in 1,3-butadiene and facilitated hydrogenation reaction for the formation of butene. This was proved from the preferential reaction to the unsaturated coordinated sites (corners and edges) of butadiene, which results in a local Pd lattice expansion and channels formation for barriers less hydrogen diffusion into the pore volume of Pd nanoparticles. Due to lower reaction barrier for H diffusion on Pd surface, the hydrogenation of C=C bond is easily shattered, which facilitated the hydrogenation reaction.

2.6 The Use of Additives, Adspecies and Promoters

Several authors have suggested adding alkali additives on catalyst surface could play a significant role in selective hydrogenation [28, 92]. Massardier [49] investigated the effect of K and Na on Pt single crystals to modify the metal electronic properties. It was found that the improved properties increased the selectivity towards 1,3-butadiene hydrogenation (Table 2). Alkali additives, up to an alkali coverage of 0.4, improved the activity and selectivity towards the 1,3-butadiene hydrogenation. Till this value (0.4), it acted as an electron donor and altered the relative energies of metal orbitals and adsorbate. The enhancement in catalytic activity noticed both on the more open structures and on K-promoted Pt, possibly be related to a weakening of bond strength of the hydrocarbon adsorption and (or) an increase in the H-metal bond strength. It was further proved by Song (2001) [93] that the K addition influenced the electron density around Ni, which increased the 1-butene selectivity.

Fewer studies also have investigated the additive’s influence on competitive hydrogenation of alkenes and dienes and the factors influencing intrinsic selectivity. Pd is the major active metal which features in most of the industrial applications and many promoters have been tested with few being successful. Nitrogen or sulphur-containing organic molecules act as selective poisons, being more strongly held than alkenes but less strongly adsorbed than dienes. Boitiaux et al. investigated the effect of additives in the selective hydrogenation of dienes and alkynes [24, 25]. These work reported that the addition of a donor ligand (e.g., piperidine) and electron-attracting additives (e.g., phosphorus, oxygen, sulphur and chlorine) over Pt and Rh catalysts influenced the activity and selectivity. Piperidine modified metal site showed a decrease in the rate of hydrogenation of 1-butene and 1,3-butadiene over the pure Pt/Rh catalysts. Selectivity for olefin formation from 1,3-butadiene was increased on Pt surface, whereas selectivity change was negligible in case of Rh surface. In case of electron attracting additives , for example, nitrogen compounds increase the hydrogenation rate of 1,3-butadiene on an Rh catalyst. In case of Pt, an increase in the selectivity for l-butene was observed and the direct formation of butane is drastically reduced due to specific preference of 1,2-addition. In contrast with pure geometric effects, no correlation was obtained with the electronic properties of the additive. Sárkány (1995–1997) [69, 94, 95], in a series of 4 papers, investigated the hydrogenation of 1,3-butadiene on catalysts prepared from the different methods in the effects of various poisonings or adspecies. The presence and formation of polyenes in the vicinity of metallic sites was due to the unusual hydrogenation character of the Pd2Ni50Nb48 ribbon. It was further confirmed by Alves [28] that in the case of liquid-phase hydrogenation of 1,3-butadiene, 1-butene in the presence of isoprene on a commercial Pd/Al2O3 catalyst, concentration of 1-butene practically remains unchanged even when the liquid was almost depleted from 1,3-butadiene. It was proven that the isoprene adsorption strength was higher than that of 1-butene and lower than that of 1,3-butadiene. Hence, it was clear that isoprene was a good option to use as an additive to improve the 1-butene selectivity in 1-butene purification processes. Adspecies formed from n-butylamine on Cu/SiO2 seem to influence the competition between diene and n-butenes. The electronic effect of the adspecies can be emphasized by the variation in the intrinsic hydrogenation selectivity towards diene in presence of methanol. Preadsorption of methanol on Cu/SiO2 caused electronic modification of Cu sites (through decomposition of methoxy species), and this increased the cis 2-butene. Formation of 1-butene prevails on the sample reduced at 753 K, and this points to the facile 1,2-addition of hydrogen atoms to adsorbed diene. Improved 2-butene formation rate over the Cu sites perturbed by alcohol appears to show that 1,4 addition mechanism is preferred. These finding points to the formation of π-allyl or π, σ bonded C4H7 species rather than 1-butene isomerization in the gas phase or adsorbed phase. Firmly held adspecies generated from butylamine or diene favour the formation of alkene by the adsorption of n-butene. The presence of carbonaceous or hydrocarbonaceous deposited on Pd/Ag catalyst increases the formation of butane. Several authors [68, 69, 96] have proposed that carbonaceous overlayers present on the catalyst surface play a key role in hydrogenation. Hydrocarbonaceous deposits affect the competition between diene and n-butenes and therefore increases the 1-butene selectivity in the hydrogenation of 1,3-butadiene. Wu et al. [96] studied the selectivity in the hydrogenation of 1,3-butadiene on using molybdenum nitride catalyst and the observed high selectivity towards 1-butene is most likely due to the weak interaction between 1,3-butadiene and nitrogen atoms present in the molybdenum nitride catalyst surface. Silvestre-Albero and co-workers [65] reported that small quantities of CO addition dramatically altered the selectivity over the Pd(110) surface, i.e. the hydrogenation to n-butane was totally suppressed; however, the butenes hydrogenation and isomerization (to cis- and trans-2-butene) were hardly affected. In addition, the presence of CO reduces the surface concentration of hydrogen which is also still adequate for hydrogenation (of 1,3-butadiene) and isomerization (of 1-butene) and is insufficient for butene hydrogenation. Further, Yardimci et al. [97] reported that the selectivity of n-butene goes up when the Rh is selectively poisoned with CO ligands (Scheme 3). The poisoning effect is more evident if the support act as the electron-donor (e.g. MgO) and the Rh is in the form of approximated dimer clusters. The selective Rh/MgO carbonyl dimers limits the activity for dissociation of H2 and thus avoid the formation of butane for controls the butane forming catalytic routes the catalytic routes that yield butane, limiting the activity for dissociation of hydrogen to avoid the formation of butane via primary reactions. This also favours the bonding of 1,3-butadiene over butenes to control secondary reactions giving butane. The selectivity to n-butene of >99% was obtained with 97% of 1,3-butadiene conversion over this catalyst. The catalytic performance of supported metal was influenced by the particle size as well as their interactions with the support material and any other active components (second metal and/or promoter). The promoter and/or the second metal can (a) influence the first metal through electronic interactions and (b) get involved in the reaction by directly bonding to reactants or intermediates. Sometimes, the interactions present between the metals are complex and mostly unidentified/mysterious. Consequently, there are many options to prepare bimetallic catalysts with different properties. One of the major themes of basic and fundamental research having a practical application has been the use of selective bimetallic catalysts for better selectivity as well as minimizing the undesirable side-reactions, i.e. isomerization and hydrogenation of the alkene. Many reported observations discussed the bimetallic catalysts, in which addition of other metal to Pd could selectively hydrogenate butadiene, and explained the high selectivity [6, 38, 58, 68, 79, 80, 82, 90, 98, 99]. Several reports were published, in which for Pd-Ag/Al2O3, Pd-Ag/SiO2, Pd-Au/SiO2 and Pd-Cu/Al2O3, it was found that 99% selectivity was observed without any isomerization of butene [58,100,101,102]. It can be concluded that the bimetallic catalysts showed highest selectivity when compared to monometallic catalyst; however, Pd-Au and Pd-Ag supported on SiO2 showed less selectivity when compared to Al2O3 support.

Reaction pathways for 1,3-butadiene hydrogenation proposed by Yardimci, et al. (Reprinted with permission from [97]. Copyright 2012 American Chemical Society)

To summarize, for the selective hydrogenation reaction on metal surfaces, the selectivity towards 1-butene is tremendously dependent on the electronegativity-supported metal catalyst system, and hence, can be regulated either by modulating the properties of supported metal (by another metal/or promoter species?). Moreover, carbonaceous deposits formed on the surface of a catalyst during the reaction/process under prevailing reaction/operation conditions (ratio of reactants, temperature, etc.) alter the catalyst surface characteristics, e.g. dispersion of metal(s), Promoters further modify the surface and disturb the electronic properties of Pd or metals. Additives affect the adsorption of reactants and formation of surface residues, as well. This knowledge facilitates one to have a better expertise of the overall process to improve the selectivity, by appropriately selected combination of catalysts, additives/promoters and fine tuning the reaction conditions.

3 Summary and Future Outlook

The major findings from the detailed literature review on 1,3-butadiene selective hydrogenation with heterogeneous catalysts are: (a) selectivity in this reaction relies upon the different adsorption strengths of the unsaturated reactants and products. Butadiene tends to be preferentially adsorbed on all active sites blocking the access of n-butenes, when it was present in excess. 1-Butene hydrogenation to butane and its isomerization to cis-butene was found to occur only, when butadiene concentration becomes low during the course of the reaction; (b) the acidity of the support plays a critical role in mediating electron transfer through the metal-support interface, that ultimately changes the bond strength between unsaturated hydrocarbons and the metal active sites which results in changing the selectivity and reaction rate; (c) changing the dispersion and the metal particle size may affect both activity and selectivity. Their role in tuning the activity and selectivity are attributed to their geometric and electronic effects; (d) hydrogenation of butadiene over metal catalysts, the selectivity for 1-butene formation is governed by the electronegativity of the catalyst. Hence, selectivity may be affected either by changing the supported metal and/or by the additive species; (e) the use of bimetallic catalysts has been proved that it is right approach for improved selectivity as well as minimizing the undesirable side-reactions of full isomerization and hydrogenation of the desired alkene. These observations foster the interest to develop bimetallic nanoparticles with well-defined geometric shapes and dimensions and are still continuing with the desire to regulate their performance for selective hydrogenation of 1,3-butadiene. The role of second metal in bimetallic catalysts, various additives and acidity of the supports in controlling the selectivity needs to be studied to gain further insight into the underlying mechanism.

References

Alves JA et al (2012) Kinetic study of the selective catalytic hydrogenation of 1,3-butadiene in a mixture of n-butenes. J Ind Eng Chem 18(4):1353–1365

Pérez D et al (2015) Study of the selective hydrogenation of 1,3-butadiene in three types of industrial reactors. Fuel 149:34–45

Méndez FJ et al (2017) Selective hydrogenation of 1,3-butadiene in the presence of 1-butene under liquid phase conditions using structured catalysts. Catal Today 289:151–161

Liu D et al (2018) Theoretical investigation of selective hydrogenation of 1,3-butadiene on Pt doping Cu nanoparticles. Appl Surf Sci 456:59–68

Aguilar-Tapia A et al (2016) Selective hydrogenation of 1,3-butadiene over bimetallic Au-Ni/TiO2 catalysts prepared by deposition-precipitation with urea. J Catal 344:515–523

Lozano L et al (2013) Influence of toluene on the catalytic activity of NiPdCe catalyst for selective hydrogenation of 1,3-butadiene. Fuel 110:76–82

Ardiaca NO et al (2001) Experimental procedure for kinetic studies on egg-shell catalysts. The case of liquid-phase hydrogenation of 1,3-butadiene and n-butenes on commercial Pd catalysts. Catal Today 64(3–4):205–215

Boitiaux JP et al (1987) Hydrogenation of unsaturated hydrocarbons in liquid phase on palladium, platinum and rhodium catalysts. III. Quantitative selectivity ranking of platinum, palladium and rhodium in the hydrogenation of 1-butene, 1,3-butadiene and 1-butyne using a single reaction scheme. Appl Catal 35(2):193–209

Boitiaux JP et al (1987) Liquid phase hydrogenation of unsaturated hydrocarbons on palladium, platinum and rhodium catalysts. Part I: kinetic study of 1-butene, 1,3-butadiene and 1-butyne hydrogenation on platinum. Appl Catal 32:145–168

Boitiaux JP et al (1987) Liquid phase hydrogenation of unsaturated hydrocarbons on palladium, platinum and rhodium catalysts. Part II: kinetic study of 1-butene, 1,3-butadiene and 1-butyne hydrogenation on rhodium; comparison with platinum and palladium. Appl Catal 32:169–183

Gaube J, Klein HF (2014) Kinetics and mechanism of butene isomerization/hydrogenation and of 1,3-butadiene hydrogenation on palladium. Appl Catal A Gen 470:361–368

Goetz J et al (1996) Kinetic aspects of selectivity and stereoselectivity for the hydrogenation of buta-1,3-diene over a palladium catalyst. Ind Eng Chem Res 35(3):703–711

Goetz J et al (1996) Kinetics of buta-1,3-diene hydrogenation over palladium catalysts. Chem Eng Sci 51(11):2879–2884

Goetz J et al (1997) Kinetics of buta-1,3-diene hydrogenation over 0.5% Pd/γ-Al2O3 catalyst. Chem Eng Technol 20(2):138–143

Goetz J et al (1996) Low-loaded Pd/α-Al2O3 catalysts: influence of metal particle morphology on hydrogenation of buta-1,3-diene and hydrogenation and isomerization of but-1-ene. J Catal 164(2):369–377

Horiuti I, Polanyi M (1934) Exchange reactions of hydrogen on metallic catalysts. Trans Faraday Soc 30:1164–1172

Santiso EE et al (2008) Isomerization kinetics of small hydrocarbons in confinement. Adsorption 14(2–3):181–188

Bates AJ et al (1970) The hydrogenation of akladienes. Part IV. The reaction of buta-1,3-diene with deuterium catalysed by rhodium, palladium, and platinum. J Chem Soc AInorgan Phys Theor:2435–2441

Yang XF et al (2010) Unusual selectivity of gold catalysts for hydrogenation of 1, 3-butadiene toward cis-2-butene: a joint experimental and theoretical investigation. J Phys Chem C 114(7):3131–3139

Bond GC et al (1965) 587. The hydrogenation of alkadienes. Part I. the hydrogenation of buta-1,3-diene catalysed by the noble group VIII metals. J Chem Soc:3218–3227

Phillipson JJ et al (1969) The hydrogenation of alkadienes. Part III. The hydrogenation of buta-1,3-diene catalysed by iron, cobalt, nickel, and copper. J Chem Soc A Inorg Phys Theor:1351–1363

Wells PB, Bates AJ (1968) The hydrogenation of alkadienes, part II. The hydrogenation of buta-1,3-diene catalysed by rhodium, palladium, iridium, and platinum wires. J Chem Soc A Inorg Phys Theor:3064–3069

Pradier CM et al (1988) Hydrogenation of 1,3-butadiene on Pt(111). Comparison with results on Pt(110) and Pt(100). Appl Catal 43(1):177–192

Boitiaux JP et al (1989) Additive effects in the selective hydrogenation of unsaturated hydrocarbons on platinum and rhodium catalysts. II. Influence of various compounds containing phosphorus, oxygen, sulphur and chlorine on the catalytic performance of platinum catalyst. Appl Catal 49(2):235–246

Boitiaux JP et al (1989) Additive effects in the selective hydrogenation of unsaturated hydrocarbons on platinum and rhodium catalysts: I: influence of nitrogen-containing compounds. Appl Catal 49(2):219–234

Meyer EF, Burwell RL (1963) The reaction between deuterium and 1-butyne, 1,2-butadiene, and 1,3-butadiene on palladium-on-alumina catalyst. J Am Chem Soc 85(19):2881–2887

Nudel JN et al (1984) Selective hydrogenation of 1,3-butadiene over LaCoO3 perovskite. J Catal 89(2):362–370

Alves JA et al (2004) Selective hydrogenation of 1,3-butadiene: improvement of selectivity by using additives. Chem Eng J 99(1):45–51

Chizallet C et al (2011) Thermodynamic stability of buta-1,3-diene and but-1-ene on Pd(111) and (100) surfaces under H 2 pressure: a DFT study. J Phys Chem C 115(24):12135–12149

Wuchter N et al (2006) Comparison of selective gas phase- and liquid phase hydrogenation of (cyclo-)alkadienes towards cycloalkenes on Pd/alumina egg-shell catalysts. Chem Eng Technol 29(12):1487–1495

Yoon C et al (1997) Hydrogenation of 1,3-butadiene on platinum surfaces of different structures. Catal Lett 46(1–2):37–41

Oudar J et al (1987) 1,3-Butadiene hydrogenation on single crystals of platinum: I. mechanism and carbon deactivation on Pt(110). J Catal 107(2):434–444

Oudar J et al (1987) 1,3-Butadiene hydrogenation on single crystals of platinum: II. Sulfur poisoning of Pt(110). J Catal 107(2):445–450

Belelli PG et al (2010) Unsaturated hydrocarbons adsorbed on low coordinated Pd surface: a periodic DFT study. Surf Sci 604(3–4):386–395

Feixas F et al (2011) Understanding conjugation and hyperconjugation from electronic delocalization measures. J Phys Chem A 115(45):13104–13113

Gómez G et al (2010) The adsorption of 1,3-butadiene on Pd/Ni multilayers: the interplay between spin polarization and chemisorption strength. J Solid State Chem 183(12):3086–3092

Gómez G et al (2014) Evaluating Pd–Ni layered catalysts for selective hydrogenation of 1,3-butadiene: a theoretical perspective. J Mol Catal A Chem 394:151–161

Hou R et al (2014) Selective hydrogenation of 1,3-butadiene on PdNi bimetallic catalyst: from model surfaces to supported catalysts. J Catal 316:1–10

Michalak WD et al (2013) Structure sensitivity in Pt nanoparticle catalysts for hydrogenation of 1,3-butadiene: in situ study of reaction intermediates using SFG vibrational spectroscopy. J Phys Chem C 117(4):1809–1817

Mittendorfer F et al (2003) Adsorption of unsaturated hydrocarbons on Pd(111) and Pt(111): a DFT study. J Phys Chem B 107(44):12287–12295

Valcárcel A et al (2004) Comparative DFT study of the adsorption of 1,3-butadiene, 1-butene and 2-cis/trans-butenes on the Pt(1 1 1) and Pd(1 1 1) surfaces. Surf Sci 549(2):121–133

Valcárcel A et al (2005) Selectivity control for the catalytic 1,3-butadiene hydrogenation on Pt(111) and Pd(111) surfaces: radical versus closed-shell intermediates. J Phys Chem B 109(29):14175–14182

Baetzold RC (1987) Properties of chemisorbed ethylene and butadiene. Langmuir 3(2):189–197

Avery NR, Sheppard N (1986) The use of thermal desorption and electron energy loss spectroscopy for the determination of the structures of unsaturated hydrocarbons chemisorbed on metal single-crystal surfaces. II. Cis- and trans-but-2-ene, but-2-yne and buta-1,3-diene on Pt(111). Proc R Soc Lond A Math Phys Sci 405(1828):27–39

Cassuto A, Tourillon G (1994) The adsorption of butene-1, isobutene, cis-2-butene and trans-2-butene on Pt(111) at 95 K: NEXAFS and UPS results. Surf Sci 307–309(Part A):65–69

Tsai Y-L, Koel BE (1997) Temperature-programmed desorption investigation of the adsorption and reaction of butene isomers on Pt(111) and ordered Pt−Sn surface alloys. J Phys Chem B 101(15):2895–2906

Tourillon G et al (1996) Buta-1,3-diene and but-1-ene chemisorption on Pt(111), Pd(111), Pd(110) and Pd50Cu50(111) as studied by UPS, NEXAFS and HREELS in relation to catalysis. J Chem Soc Faraday Trans 92(23):4835–4841

Maurice V, Minot C (1989) A theoretical investigation of the adsorption modes of ethene, 1,3-butadiene, 1-butene, and cis- and trans-2-butenes on the unreconstructed (110) surface of platinum. Langmuir 5(3):734–741

Massardier J et al (1988) Platinum single crystals: the effect of surface structure and the influence of K and Na on the activity and the selectivity for 1,3-butadiene hydrogenation. J Catal 112(1):21–33

Ouchaib T et al (1989) Competitive hydrogenation of butadiene and butene on palladium and platinum catalysts. J Catal 119(2):517–520

Bertolini JC et al (1996) A comparative study of 1,3-butadiene and 1-butene chemisorbed on Pt(111), and Pd(111). Surf Sci 349(1):88–96

Chen S, Yang B (2020) Theoretical understandings on the unusual selectivity of 1,3-butadiene hydrogenation to butenes over gold catalysts. Catal Today 347:134–141

Bent BE et al (1991) Thermal decomposition of alkyl halides on aluminum. 2. The formation and thermal decomposition of surface metallacycles derived from the dissociative chemisorption of dihaloalkanes. J Am Chem Soc 113(4):1143–1148

Chrysostomou D et al (2001) Thermal chemistry of C3 metallacycles on Pt(111) surfaces. J Phys Chem B 105(25):5968–5978

Scoggins TB, White JM (1997) Thermal chemistry of allyl bromide adsorbed on Pt(111). J Phys Chem B 101(40):7958–7967

Cukic T et al (2007) The influence of preparation variables on the performance of Pd/Al2O3 catalyst in the hydrogenation of 1,3-butadiene: building a basis for reproducible catalyst synthesis. Appl Catal A Gen 323:25–37

Hugon A et al (2009) Influence of the reactant concentration in selective hydrogenation of 1,3-butadiene over supported gold catalysts under alkene rich conditions: a consideration of reaction mechanism. Gold Bull 42(4):310–320

Kolli NE et al (2013) Bimetallic Au-Pd catalysts for selective hydrogenation of butadiene: influence of the preparation method on catalytic properties. J Catal 297:79–92

Liu C et al (2015) Hydrogenation of 1,3-butadiene over Au and Pt/SiO2-N catalysts at low temperature. Catal Commun 67:72–77

Primet M et al (1990) Influence of the support towards platinum catalysed 1,3-butadiene hydrogenation. Appl Catal 58(1):241–253

Sarkany A et al (1995) Participation of support sites in hydrogenation of 1,3-butadiene over Pt/Al2O3 catalysts. Appl Catal A Gen 127(1–2):77–92

Pattamakomsan K et al (2010) Effect of mixed Al2O3 structure between θ- and α-Al2O3 on the properties of Pd/Al2O3 in the selective hydrogenation of 1,3-butadiene. Catal Commun 11(5):311–316

Hou R et al (2015) Effect of oxide supports on Pd–Ni bimetallic catalysts for 1,3-butadiene hydrogenation. Appl Catal A Gen 490:17–23

Ciebien JF et al (1999) Membrane catalysts for partial hydrogenation of 1,3-butadiene: catalytic properties of palladium nanoclusters synthesized within diblock copolymer films. Mater Sci Eng C 7(1):45–50

Silvestre-Albero J et al (2005) Atmospheric pressure studies of selective 1,3-butadiene hydrogenation on Pd single crystals: effect of CO addition. J Catal 235(1):52–59

Silvestre-Albero J et al (2006) From Pd nanoparticles to single crystals: 1,3-butadiene hydrogenation on well-defined model catalysts. Chem Commun (1):80–82

Silvestre-Albero J et al (2006) Atmospheric pressure studies of selective 1,3-butadiene hydrogenation on well-defined Pd/Al2O3/NiAl(110) model catalysts: effect of Pd particle size. J Catal 240(1):58–65

Cooper A et al (2014) Design of surface sites for the selective hydrogenation of 1,3-butadiene on Pd nanoparticles: Cu bimetallic formation and sulfur poisoning. Catal Sci Technol 4(5):1446–1455

Sárkány A et al (1995) Hydrogenation of 1,3-butadiene over catalysts prepared from amorphous Pd2Ni50Nb48 ribbon: effect of self-poisoning on competitive adsorption. Appl Catal A Gen 124(2):L181–L187

Ponec V (1983) Catalysis by alloys in hydrocarbon reactions. In: Eley HPDD, Paul BW (eds) Advances in catalysis, vol 32. Academic, New York, pp 149–214

van Santen RA (1982) Chemical-bonding aspects of heterogeneous catalysis. I. Chemisorption by metals and alloys. Recueil des Travaux Chimiques des Pays-Bas 101(4):121–136

Boitiaux JP et al (1983) Preparation and characterisation of highly dispersed palladium catalysts on low surface alumina, their notable effects in hydrogenation. In: Poncelet PGG, Jacobs PA (eds) Studies in surface science and catalysis, vol 16. Elsevier, Amsterdam, pp 123–134

Schimpf S et al (2002) Supported gold nanoparticles: in-depth catalyst characterization and application in hydrogenation and oxidation reactions. Catal Today 72(1–2):63–78

Umpierre AP et al (2005) Selective hydrogenation of 1,3-butadiene to 1-butene by Pd(0) nanoparticles embedded in imidazolium ionic liquids. Adv Synth Catal 347(10):1404–1412

Zhang X, Xu BQ (2005) Size effect of zirconia nanoparticles in Au/ZrO2 catalysts for 1,3-butadiene hydrogenation. Chem J Chin Univ 26(1):106–110

Tardy B et al (1991) Catalytic hydrogenation of 1,3-butadiene on Pd particles evaporated on carbonaceous supports: particle size effect. J Catal 129(1):1–11

Berhault G et al (2007) Preparation of nanostructured Pd particles using a seeding synthesis approach-application to the selective hydrogenation of buta-1,3-diene. Appl Catal A Gen 327(1):32–43

Dal Santo V et al (2012) Selective butadiene hydrogenation by Pd nanoparticles deposed onto nano-sized oxide supports by CVD of Pd-hexafluoroacetylacetonate. Inorg Chim Acta 380(1):216–222

Delannoy L et al (2014) Selective hydrogenation of butadiene over TiO2 supported copper, gold and gold-copper catalysts prepared by deposition-precipitation. Phys Chem Chem Phys 16(48):26514–26527

Lu F et al (2014) Plant-mediated synthesis of Ag-Pd alloy nanoparticles and their application as catalyst toward selective hydrogenation. ACS Sustain Chem Eng 2(5):1212–1218

Luza L et al (2014) The partial hydrogenation of 1,3-dienes catalysed by soluble transition-metal nanoparticles. ChemCatChem 6(3):702–710

Massard R et al (2007) Strained Pd overlayers on Ni nanoparticles supported on alumina and catalytic activity for buta-1,3-diene selective hydrogenation. J Catal 245(1):133–143

Piccolo L et al (2008) Tuning the shape of nanoparticles to control their catalytic properties: selective hydrogenation of 1,3-butadiene on Pd/Al2O3. Phys Chem Chem Phys 10(36):5504–5506

Zhang W, Wang D, Yan R (2011) Supported Nanoparticles and Selective Catalysis: A Surface Science Approach. In Selective Nanocatalysts and Nanoscience (eds A. Zecchina, S. Bordiga and E. Groppo).

Zhang ZC et al (2012) Pd cluster nanowires as highly efficient catalysts for selective hydrogenation reactions. Chem Eur J 18(9):2639–2645

Piccolo L et al (2005) Pd-Au single-crystal surfaces: segregation properties and catalytic activity in the selective hydrogenation of 1,3-butadiene. Surf Sci 592(1–3):169–181

Lucci FR et al (2015) Selective hydrogenation of 1,3-butadiene on platinum–copper alloys at the single-atom limit. Nat Commun 6:8550

Zhang X et al (2007) Comparative study of Au/ZrO2 catalysts in CO oxidation and 1,3-butadiene hydrogenation. Catal Today 122(3–4):330–337

Okumura M et al (2002) Hydrogenation of 1,3-butadiene and of crotonaldehyde over highly dispersed Au catalysts. Catal Today 74(3–4):265–269

Redjala T et al (2006) Bimetallic Au-Pd and Ag-Pd clusters synthesised by γ or electron beam radiolysis and study of the reactivity/structure relationships in the selective hydrogenation of buta-1,3-diene. Oil Gas Sci Technol 61(6):789–797

Stobiński L et al (1999) Molecular hydrogen interactions with discontinuous and continuous thin gold films. Appl Surf Sci 141(3–4):319–325

Yi H et al (2017) Coating Pd/Al2O3 catalysts with FeOx enhances both activity and selectivity in 1,3-butadiene hydrogenation. Chin J Catal 38(9):1581–1587

Song MW et al (2001) The enhancement of 1-butene selectivity in the hydrogenation of 1,3-butadiene over K-Ni catalysts. J Chem Eng Japan 34(11):1407–1414

Sarkany A (1997) Semi-hydrogenation of 1,3-butadiene on adspecies modified Pd-Ni, Co and Cu catalysts. Appl Catal A Gen 149(1):207–223

Sarkany A (1997) Semi-hydrogenation of 1,3-butadiene over Pd-Ag/α-Al2O3 poisoned by hydrocarbonaceous deposits. Appl Catal A Gen 165(1–2):87–101

Wu Z et al (2000) IR study on selective hydrogenation of 1,3-butadiene on transition metal nitrides: 1,3-butadiene and 1-butene adsorption on Mo2N/γ-Al2O3 catalyst. J Phys Chem B 104(51):12275–12281

Yardimci D et al (2012) Tuning catalytic selectivity: zeolite- and magnesium oxide-supported molecular rhodium catalysts for hydrogenation of 1,3-butadiene. ACS Catal 2(10):2100–2113

Pattamakomsan K et al (2011) Selective hydrogenation of 1,3-butadiene over Pd and Pd-Sn catalysts supported on different phases of alumina. Catal Today 164(1):28–33

Wang T et al (2013) Selection of oxide supports to anchor desirable bimetallic structures for ethanol reforming and 1,3-butadiene hydrogenation. Chin J Catal 34(11):2009–2017

Furlong BK et al (1994) 1,3-butadiene selective hydrogenation over Pd/alumina and CuPd/alumina catalysts. Appl Catal A Gen 117(1):41–51

Miura H et al (1993) Preparation of egg-shell type Pd-Ag and Pd-Au catalysts by selective deposition and hydrogenation of 1,3-butadiene. Stud Surf Sci Catal 75:2379–2382

Liu C et al (1998) Mono- and bimetallic catalytic hollow-fiber reactors for the selective hydrogenation of butadiene in 1-butene. Appl Catal A Gen 172(1):23–29

Acknowledgements

The authors acknowledge the RMIT-CSIRO collaborative research on hydrogenation of olefins. They also acknowledge Dr. Manh Hoang (CSIRO) and Dr. Sarvesh Kumar Soni (RMIT) for their suggestions and technical discussion.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Selvakannan, P.R. et al. (2021). Selective Hydrogenation of 1,3-Butadiene to 1-Butene: Review on Catalysts, Selectivity, Kinetics and Reaction Mechanism. In: Pant, K.K., Gupta, S.K., Ahmad, E. (eds) Catalysis for Clean Energy and Environmental Sustainability. Springer, Cham. https://doi.org/10.1007/978-3-030-65021-6_6

Download citation

DOI: https://doi.org/10.1007/978-3-030-65021-6_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65020-9

Online ISBN: 978-3-030-65021-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)