Abstract

Worldwide dietary guidelines recommended that not more than 30% of the total daily energy intake should be derived from the dietary fat. Obesity, along with heart diseases such as hypertension and high blood pressure, are often attributed to the consumption of fat rich foods. Cheese prepared from whole milk is high in fat content and a rich source of dietary fat (Drake et al, 1999). Hence, demand for low fat cheese (LFC) has increased globally due to generalized conciousness about consumer health issues. Manufacturing low fat cheese with characteristics similar to that of full fat cheese (i.e. flavour and texture) has been a topic of interest in the cheese industries for many years. Role of fat in cheese is vital as it acts as a filler in the protein network of the cheese besides imparting creaminess, mouth fell and lubricity to the product. Hence, hard, rubbery, off flavoured and poor coloured cheese is produced due to removal of the fat. Several technologies have been proposed to manufacture LFC that has characteristics comparable to those of the full fat cheese. This book chapter reviews several different technological approaches and fat replacers used in producing LFC.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

Cheese is a fermented dairy product which features a variety of flavours and is produced all over the world. It is prepared by coagulation of milk proteins with the help of coagulant enzyme, acid or both. Lactic acid bacteria are commonly used to produce acid in situ during cheesemaking (McElhatton & El Idrissi, 2016). The earliest cheese was made in Central Asia by Nomadic tribes (Dalby, 2009; Scott, Robinson, & Wilbey, 1998). The cheese was believed to have evolved from Tigris and Euphrates rivers (current Iraq) 8000 years ago when people started to domesticate plants and animals as a source of food (Fox, 2011). More than 1400 kinds of cheeses are listed in a record of the University of Wisconsin Centre for Dairy Research (CDR, 2014). Nevertheless, there are 18 common types of cheese: Brick, Trappist, Camembert, Neufchatel, Roquefort, Edam, Gouda, Sapsago, Hand, Cheddar, Limburger, Provolone, Cottage, Cream, Parmesan, Romano, Swiss and Whey cheese (McSweeney, Ottogalli, & Fox, 2017). There are different classes of cheese. The majority of cheeses are classified according to their texture and moisture content, namely very hard, hard, semi-hard, semisoft and soft. Cheese can be prepared from whole milk, partially skimmed milk or skimmed milk, all of which can be obtained from cow, buffalo, camel, goat, yak, sheep, reindeer, horse, and donkey milk, in addition to milk powder (Fox & McSweeney, 2017).

Milk and dairy products including cheese provide vital nutrients for our body such as proteins, fat and other minerals like calcium and phosphorous (Johnson, 2016). Cheese contains 3–40% protein and 4–48% fat depending upon the type of cheese and method of manufacturing. Furthermore, cheese is a good source of vitamin A, B12, riboflavin and folates. All the essential amino acids excluding cysteine and methionine are present in cheese in an abundant amount (McCarthy, O’Connor, & O’Brien, 2014). Besides other nutrients present in cheese, fat plays a crucial role in sensory perception of cheese. Fat acts as filler particles in three dimensional protein network of cheese (Khanal, Bhandari, Prakash, & Bansal, 2017) and provide lubricity, creaminess and mouthfeel in cheese along with other sensory and functional properties. Besides, it also helps to develop the flavor and affects the storage stability of food products (Lashkari, Khosrowshahi Asl, Madadlou, & Alizadeh, 2014). Removal of fat from cheese leads to a hard and rubbery texture, off-flavours, poor colour and poor meltability as compared to their full-fat counterparts (Ibáñez, Waldron, & McSweeney, 2016; Zahra, Mohammad, Sahel, & Mohammad Ali, 2013). Hence, production of low-fat cheese that has comparable characteristics and consumer acceptance as its full-fat counterpart with more than 50% fat reduction has always being a challenging task for the researchers and manufacturers (Johnson, 2016; Jooyandeh, Goudarzi, Rostamabadi, & Hojjati, 2017).

Of late, preference for consumption of low-fat cheese (LFC) over the regular full-fat cheese has been increasing due to low risk of obesity and cardiovascular diseases. Owing to health benefits of LFC, its sale in the market has increased due to high consumer demand (Di Cagno et al., 2014; Ibáñez et al., 2016). Due to increase in obesity percentage (BMI > 30) in men and women from 1979 to 2012 along with increase in percentage of extremely obese (BMI > 40) population, the United States has recommended to limit calories from added sugars and saturated fats and consume less than 10 percent calories per day from saturated fats (Reedy, 2016). The US Department of Health and Human Services has given greater attention to consumption of fat-free or low-fat dairy products including milk, yoghurt, cheese and/or fortified soy beverages as a key recommendation in its five overarching guidelines (USDA, 2016). WHO has also given advice on maintaining a healthy diet by limiting the consumption of foods containing high amounts of saturated fats, such as cheese, ice-cream and fatty meat (WHO, 2015). One study conducted in the Netherlands found that cheese was the major contributor (17.4%) to the dietary saturated fat among other dairy products. Hence, dairy products like cheese, due to high levels of saturated fat and cholesterol need to be cut down from the diets of dyslipidaemia patents (Reedy, 2016).

1.1 Definition of LFC

According to Food and Drug Administration (FDA, 2017), cheese is described by the level of fat to other solid matters in/or permissible amount of moisture and fat in dry matter. CODEX has not given any legitimacy for the zero-fat Cheddar cheese for the international trade. Nevertheless, each country can fix their standards for internal trade from their corresponding referenced variety of cheese (CODEX, 2013). In the United States of America, the cheese with 6% fat is considered as a LFC while the cheese in which fat level is reduced to at least 25% from the original one is termed as reduced fat cheese (Johnson, 2011). Composition of cheese with different fat levels is shown in Table 23.1.

1.2 Issues with LFC

Although industrial-scale production of LFC has been started more than two decades ago, the massive growth in market for LFC has slowed down due to reduced consumer acceptance of the first generation LFC owing to their inadequate flavor and texture as compared to full fat cheese (Banks, 2004; Di Cagno et al., 2014). LFC exhibits hard or firm and grainy texture, dry, off- flavor, bitterness and dull colour as well as possess inferior mechanical and melting properties as compared to full-fat cheese (Costa et al., 2010; Drake, Miracle, & McMahon, 2010; Zahra et al., 2013; Zisu, 2005). The hardness and springiness of LFC is more than full-fat cheese, while adhesiveness and cohesiveness are less than that of full-fat cheese (Bryant, Ustunol, & Steffe, 1995; Rodriguez, 1998; Zahra et al., 2013). This is due to the larger structural protein matrix per unit cross-sectional area in low and reduced fat cheese (Katsiari & Voutsinas, 1994; Rodriguez, 1998). In LFC, there is a high amount of protein/casein with respect to the fat and as a result, high amount of calcium is retained in cheese as colloidal calcium. This higher amount of calcium is also responsible for the poor melt and stretch properties of some cheeses (Koca & Metin, 2004; Nauth & Hayashi, 1995).

Lactose crystallization is another factor responsible for the rubbery and firm body of LFC (Emmons, Emmons, Kalab, Larmond, & Lowrie, 1980). LFC cheese milk has less fat, which consequently leads to higher protein concentration. Colloidal calcium (bound form) is increased by a higher amount of protein. Hence, the concentration of soluble calcium will be increased by the increase in colloidal calcium if cheese has low pH. The soluble calcium can combine with lactose and form calcium lactate. Several factors such as milk composition and quality, cheese making techniques, starter culture used and cheese ripening conditions affect the formation of calcium lactate crystals, which thus leads to difference in textural and visual attributes (Agarwal, Powers, Swanson, Chen, & Clark, 2008). The degree of proteolysis is also a major factor in determining texture, i.e. the cheese firmness. During proteolysis, peptides and amino acids are produced by hydrolyzing casein network by the action of the protease enzymes. Amino acids and peptides produced by proteolysis are responsible for the development of improved characteristics, desirable and undesirable flavor in cheese (Johnson, 2016; Khosrowshahi, Madadlou, Ebrahim zadeh Mousavi, & Emam-Djomeh, 2006). Fat reduction in cheese leads to off flavours and bitterness, and is also due to high moisture content and low amount of available aromatic compounds formed by degradation of fat (Di Cagno et al., 2014; Rogers et al., 2009). Rheology and microstructure of cheese are also affected by the reduction of fat level. Open-intricate microstructure of cheese vanishes by reducing the fat content. Removal of fat in cheese decreases the yield of cheese as well (Farkye & Guinee, 2017; Katsiari & Voutsinas, 1994; Rodriguez, 1998).

2 LFC Technology: Processing Modifications During Cheese Making

Modern technical approaches have been established currently to overcome flavor and texture defects in the LFC through the application of sound knowledge to physicochemical and biochemical properties of LFC. Considering the important function of fat in relation to textural characteristics and acceptability of LFC, several modification approaches and different types of fat replacers or hydrocolloids have been recommended (Johnson, 2016; Jooyandeh et al., 2017). Fat replacers are used either to partially or fully replace milk fat. The common LFC prepared by different modification techniques are both soft and hard ripened varieties such as Cottage, Minash fresh, Gouda, Kasar, Cream, Cheddar, Keshire, Mozzarella and Feta cheese (Banks, Brechany, & Christie, 1989; Chatli, Gandhi, & Singh, 2017; Diamantino, Beraldo, Sunakozawa, & Penna, 2014; Felfoul, Bornaz, Baccouche, Sahli, & Attia, 2015; Sanli, Gursel, Sanli, Acar, & Benli, 2013).

Improvement in LFC can be made by increasing the moisture content of the cheese and by modifying cheese manufacturing procedure (Johnson, 2016). Some of the processing interventions are discussed below.

2.1 Starter Microorganisms, Adjunct Cultures, Coagulants and Enzymes

Starter bacteria used in cheese making play a crucial role during proteolysis and hence the development of texture and flavor in cheese during ripening. There is a high possibility of change in growth and microbial metabolism due to different nutritional environment in LFC (Farkye & Guinee, 2017). High moisture in LFC develops off flavor and bitterness due to the activity of bacteria and formation of bitter peptides. Use of heat treated lactobacilli enhances flavor production and decreases bitterness in 10% fat semi-hard, round-eye cheese (Ardö, Mansson, Hedenberg, & Larsson, 1989). It is recommended to use the starter with low proteolytic and high peptidolytic activity (Mistry, 2001). Reduction of fat in Cheddar cheese is associated with the changes in the number of bacterial population, whereas it does not change the predominant bacteria in cheese. Hence, this indicates the difference in ripening biochemistry in LFC and FFC, thus adjunct culture is needed to enhance the flavour in LFC (Broadbent et al., 2013). Studies carried out using Lactobacillus casei TINE36 and L. plantaram TINE18 (Skeie et al., 2013) in LFC resulted in improved firmness; and L. plantarum LP and L. rhamnosus LRA in low-fat Caciotta-type cheese (Di Cagno et al., 2014) showed higher levels of acetic acid, diacetyl and other volatile compounds, thus increasing overall acceptability of cheese.

Protease enzymes from the plant origin, such as Cynara cardunculus, are used instead of rennet to produce some cheese varieties such as Quwso Serra Cheese of Portugal and this enzyme improves the flavor of low fat (13%) Cheddar cheese. Nonetheless, it develops bitterness during ripening period (Banks, Roa, & Muir, 1998).

Proteolysis in cheese is triggered by increasing the amount of coagulant enzyme used, using coagulant with higher rate of proteolytic to milk clotting activity than calf rennet, and such proteases are extracted from Rhizomucor miehei and R. pusillus (McCarthy, Wilkinson, & Guinee, 2017b). Similarly, proteolysis in LFC can be altered by replacing the bovine rennet with camel rennet that has a higher ratio between clotting and general proteolytic (C/P) activity and has C/P ratio seven times higher than bovine rennet. Furthermore, camel rennet hydrolyses κ-CN Phe105-Met106 bond faster than bovine rennet in milk, and is less sensitive to calcium content, pH and heat (from 40 to 55 °C) (Børsting et al., 2012; Soodam, Ong, Powell, Kentish, & Gras, 2015a). However, other studies reported that due to slower rate of proteolysis, low-fat Cheddar cheese and ultra-filtered Iranian white cheese prepared by recombinant camel rennet as a coagulant had a thicker protein network as compared to the one made from microbial rennet. In addition, these cheeses had less protein breakdown (possessed a lower ratio of pH 4.6 soluble nitrogen/total nitrogen) than the cheese made from microbial rennet (Soltani, Boran, & Hayaloglu, 2016; Soodam, Ong, Powell, Kentish, & Gras, 2015b). Moreover, study conducted by Akkerman et al. (2017) in NaCl reduced semi-hard Danish cheese and (McCarthy et al., 2017b) in half-fat, half-salt Cheddar cheese, use of camel rennet resulted in a higher firmness than using bovine chymosin.

2.2 Cooking Temperature, Calcium Reduction, Cutting pH, Pre-acidification and Ripening Temperature

Calcium in cheese is reduced by lowering pH at coagulation and during whey drainage. Calcium-induced crosslinking would help to alleviate adverse effect by dense casein network in a cheese texture (McCarthy, Wilkinson, & Guinee, 2017c). Calcium reduction in half-fat, half-salt Cheddar style cheese is characterized by higher primary proteolysis and lower secondary proteolysis and higher water holding capacity. In addition, it counterbalances the detrimental effect of fat reduction in textural and cooking properties, provides more extensive flow on heating, lowers fracture stress and strain (Farkye & Guinee, 2017; McCarthy et al., 2017c). Both pH and temperature play an important role for dissolution of calcium and dissociation of casein from the casein micelles. Pre-acidification of milk to pH 5.4 at 4 °C solubilizes more calcium, which thus results in a maximum dissociation of casein (30%) (Farkye & Guinee, 2017). Pre-acidification of milk or lowering pH of milk is achieved by different approaches such as using food grade acids (e.g. lactic), using higher level of starter culture, CO2 injection and prolonging the curd holding time in a cheese vat. Moisture content of cheese is increased by the use of pre-acidified milk, which is accomplished by extending holding time prior to whey drainage (McCarthy et al., 2017c). Furthermore, to alter textural properties of cheese, pH during manufacturing can also be controlled by adding salt, altering the buffering capacity of cheese and decreasing the level of residual lactose (Chevanan, Muthukumarappan, Upreti, & Metzger, 2006).

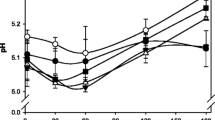

In LFC manufacturing, low cooking temperature and high pH at draining have been practised to overcome possible defects. To manufacture 25 and 50% reduced fat Cheddar cheese, 37 °C and 35 °C cooking temperature have been recommended, respectively (Farkye & Guinee, 2017). Holding time during cooking, pH at milling and rate of salting are also considered to manipulate manufacturing steps to produce LFC (Mistry, 2001). Rise in pH (from 5.35 to 5.75) also results in increased moisture in reduced fat Cheddar cheese (Guinee et al., 1998). Furthermore, different ripening temperature has been used to manufacture reduced fat Cheddar cheese prepared from condensed milk. The cheese ripened at 12 °C was significantly softer than cheese ripened at 7 °C (Fenelon et al., 1999). However, elevated ripening temperature (11 °C) increases rate of proteolysis and off-flavor develops after 12 weeks of storage (Brandsma, Mistry, Anderson, & Baldwin, 1994). Another study by Nauth and Hayashi (1995) used cultured skim milk to lower the pH of cheese milk very slowly. They believed that ionic calcium would increase at the expense of colloidal calcium, but most of the ionic calcium was lost in the whey. Hence, there was a decrease in total calcium retained in the cheese. As a result, the cheese showed improved melt and stretch characteristics (Nauth & Hayashi, 1995).

2.3 Moisture Control by Different Approaches

Low-fat Cheddar cheese manufactured from the low-fat milk has a very firm and rubbery texture. The physical properties of cheese are determined by the casein gel network structure formed by renneting and moisture removal during syneresis. Firm structure of LFC is governed by the formation of compact para-casein network (Amelia, Drake, Nelson, & Barbano, 2013; Anderson, Mistry, Brandsma, & Baldwin, 1993; Drake, Herfett, Boylston, & Swanson, 1995). Hence, curd moisture needs to be increased to overcome textural defects and is achieved by manipulating stirring time and scalding temperature. Furthermore, the moisture content of LFC can be improved by increasing milk pasteurization temperature, short pressing time, decreasing the whey draining temperature (Johnson, 2011; Rodriguez, 1998).

To manufacture reduced fat Cheddar cheese, increase in pasteurization temperature interferes with rennet curd formation, increases setting time of the curd and thus increases the moisture in a curd (Guinee et al., 1998). Apart from pasteurization, high heat-treatment (HHT) of milk is also used to improve texture and rheology of unheated reduced fat cheese. Whey proteins are denatured in situ by HHT in milk resulting in the formation of filamentous appendages, which protrude from the micelle surface, thus preventing comprehensive fusion of casein micelles during gelation (Farkye & Guinee, 2017).

Curd washing is also another approach used to increase the moisture content in cheese. Many manufacturers in the USA use cold water (22 °C) to rinse or soak the cheese curd after whey draining to increase moisture and to decrease the rate of syneresis. The low rate of syneresis helps to allow absorption of more water by the curd (Drake et al., 1995; Johnson, 2016; Johnson & Chen, 1995). However, curd washing causes lack of flavor development and poor keeping quality leading to decrease in shelf life in a reduced fat cheese (Johnson, 2016; Rodriguez, 1998). Though young Cheddar cheese possess softer and smoother body with no flavor defects, it deteriorates into a weak pasty cheese (Johnson & Chen, 1995), and possess objectionable flavors such as meaty and brothy after a week if manufactured by curd washing process (Farkye & Guinee, 2017). So, researchers have recommended curd washing to limited kinds of starter cultures used in cheese making. There is also a possibility of acquiring high pH in a washed curd cheese due to less buffering capacity than the cheese made without curd washing (Johnson & Chen, 1995). In addition, there is an inverse relationship between decrease in yield of Gouda cheese (measured after 12 days of manufacture) and the amount of added water in a curd (El-Gawad & Ahmed, 2011).

Johnson and Chen (1995) used high pH (5.8–5.9) during cutting and milling with the curd washing at 22 and 35 °C. Their results showed that the cheese washed at 22 °C showed highest moisture content and lower pH than the curd washed at 35 °C. Nevertheless, curd washing prevents the formation of calcium lactate crystals by removing soluble calcium and lactic acid from the curd. Additionally, it restricts undesirable fermentation in cheese by removing the residual lactose from the curd (Farkye & Guinee, 2017). Hou, Hannon, McSweeney, Beresford, and Guinee (2014) used curd washing to achieve different target levels of lactose plus lactic acid (5.3, 4.5, 4.3 and 3.9%) in cheese and found curd washing had less effect on composition and proteolysis (measured as pH 4.6 soluble nitrogen) and resulted in less flavour development, firmer and less brittle cheese. Comparison of the composition of reduced fat Cheddar cheese with wash and non-wash curd procedures are given in Table 23.2. Other methods to increase moisture content in LFC are: increasing size of the curd, delaying the cutting time, matting the curd after whey separation, using less pressure during pressing, reducing the stir-out time before and after whey drainage, using low concentration brine or brining for the short time etc. (Johnson, 2016).

2.4 Casein/Fat Ratio

Since, fat content in cheese is associated with texture, lubricity and flavor development (Farkye & Guinee, 2017; Ohren & Tuckey, 1969), casein to fat ratio is also a very important parameter for LFC manufacturing. Kosikowski and Mistry (1990) suggested 1.58 casein to fat ratio to manufacture 33% reduced fat Cheddar cheese, whereas Merrill, Oberg and McMahon (1994) suggested 2.4 ratio to manufacture 50% reduced fat Mozzarella cheese. Ohren and Tuckey (1969) found typical flavor in Cheddar cheese when the fat in dry matter was 50% or above and flavour was not developed in 16% fat cheese.

2.5 Homogenization and Micro-Fluidization of Cheese Milk

Emulsification or homogenization can reduce the size of milk fat globules (2 μm or less) and can modify the milk fat globule membrane. During homogenization, caseins, the primary proteins of the milk, are adsorbed on the surface of newly formed fat globule (Kelly, Huppertz, & Sheehan, 2008; Vélez, Hynes, Meinardi, Wolf, & Perotti, 2017). This has the following effects on the characteristics of milk:

-

Reduction in the amount of micellar casein but casein surface area in the milk is increased.

-

Formation of two types of casein micelle surface layer, native casein micelles and casein cover for the fat globules.

-

Increase in effective surface area and a decrease in surface density of κ-casein due to spreading of casein micelles over the surface of fat globules (Kelly et al., 2008).

Emulsification or homogenization reduces fat loss in whey, increases yield of cheese and higher moisture retention in cheese due to slower whey expulsion (Madadlou, Mousavi, Khosrowshahiasl, Emam-Djome, & Zargaran, 2007; Rudan, Barbano, Guo, & Kindstedt, 1998). A higher degree of fat emulsification reduces leakage of fat during melting, decreases the level of free oil in cheese and decreases the rate of hydrolysis during lipid oxidation. Homogenization decreases curd firmness and syneresis (Lemay, Paquin, & Lacroix, 1994). Homogenization of milk can not only increase the yield of cheese but also reduce the amount of fat loss into whey (Kelly et al., 2008; Zamora, Ferragut, Jaramillo, Guamis, & Trujillo, 2007). Homogenization has also been shown to increase the moisture content in cheese (Karaman & Akalın, 2013; Madadlou et al., 2007), reduce coagulation time and improve acid production rate, curd tension, curd fusion and elasticity of curd (Jana & Upadhyay, 1992; O’Mahony, Auty, & McSweeney, 2005).

Homogenization is carried out either for the whole milk or only for the cream part and/or addition of the homogenized cream to skim milk (Karaman & Akalın, 2013). Usually, homogenization of whole cheese milk is not suggested because of its deleterious effects on flavour and texture of cheese (Deegan, Holopainen, McSweeney, Alatossava, & Tuorila, 2014). Selective homogenization of cheese milk, such as homogenization of cream and its incorporation into the skim milk (Deegan et al., 2013; Karaman & Akalın, 2013), is utilized to preserve optimal flavour and texture. Selective or complete homogenization of cheese milk has been reported to impart high moisture content, improved flavour, texture, body, microstructure, sensory qualities and functional properties in baby Gouda, Cheddar, Roquefort, Blue, Edam, Nyamunas, Kariesh, low fat Iranian white and pickled cheeses (Emmons et al., 1980; Jana & Upadhyay, 1992; Madadlou et al., 2007). Selective homogenization has also been reported to reduce free oil in reduced-fat Cheddar and Mozzarella cheese (Metzger & Mistry, 1995).

Though, homogenization is considered as a good processing tool in manufacturing LFC, Mozzarella cheese (26% fat) prepared from homogenized milk reportedly showed less meltability than the cheese prepared by un-homogenized milk in one study (Rudan, Barbano, Guo, & Kindstedt, 1998) while textural properties of cheese in unmelted condition (at 10 °C) were not influenced by the homogenization of cream part only. Hence, homogenization of cream only is recommended by some authors (El-Gawad, Ahmed, El-Abd, & El-Rafee, 2012; Rudan, Barbano, Guo, & Kindstedt, 1998).

One study compared the rheological and proteolytic proprieties of full and low-fat Mozzarella cheese prepared from un-homogenized milk and milk homogenized at different pressures (10.3 and 17.2 Mpa) (Tunick et al., 1993). Cooking temperature of samples were also varied in this study. The cheese prepared at a lower temperature (cooked at 32.4 °C) produced high moisture in a non-fat product as compared to the cheese prepared at a higher temperature (cooked at 45.9 °C). The casein (αs1) partly degraded to (αs1-1) casein in the cheese cooked at a lower temperature during 6 weeks storage. It was concluded that the LFC with equivalent textural and melting characteristics to full-fat cheese could be prepared using homogenized milk, lower cooking temperature and storage at refrigeration temperature (Tunick et al., 1993).

Although several studies describe the effect of milk homogenisation on cheese quality, much fewer studies have reported the effect of fat globule size. MFGs help to disrupt the dense protein network in cheese and act as inert fillers (Michalski, Cariou, Michel, & Garnier, 2002). During renneting, MFGs affect the rate of gelation, curd firmness and the elasticity of the curd, which in turn affect the texture and flavour characteristics of cheese (Logan et al., 2017; Lucey, Johnson, & Horne, 2003; Michalski et al., 2007). MFGs’ size and the interactions of MFGs and/or free fat within the casein matrix may have a leading role in cheese meltability (Rowney, Hickey, Roupas, & Everett, 2003).

Most studies so far (Deegan et al., 2013; Karaman & Akalın, 2013; Logan et al., 2015; O’Mahony et al., 2005) have reported on the effect of size of MFGs on full and reduced fat cheeses only. Small MFGs (D[4,3] ~ 3 μm) have been reported to improve the textural, flavour and sensory properties of full-fat Cheddar cheese (Logan et al., 2017) and Emmental and Camembert cheese (Michalski et al., 2003, 2004, 2007). Additionally, Logan et al. (2014) reported firmer texture of the cheese curd prepared from large MFGs (D[4,3] = 3.88–5.78 μm) in combination of small casein micelles (D[4,3] = 153–159 nm) because the large MFGs acted as local filler particles and did not break the protein network. However, O’Mahony et al. (2005) reported lowest firmness (storage modulus) in rennet gel containing large size MFGs (D[4,3] = 4.68 μm) compared to smaller MFGs (D[4,3] = 3.45 μm) during miniature Cheddar-type cheese manufacture. Similarly, bigger MFGs (D[3,2] = 4.6 μm decreased G′ compared to the smaller (D [3,2] = 1.89 μm) and medium sized (1.46 μm) MFGs in rennet gels (Michalski et al., 2002). The porous area within a protein gel network is too large to fit the small and medium sized MFGs as filler particles to reinforce the overall gel firmness; while, MFGs larger than the size casein micelles are deleterious to the gel strength (Michalski et al., 2002). Hence, some conflicting results have been reported in literature on the effect of MFG size on textural properties of cheese. In our latest study, we analysed the physico-chemical and biochemical properties of low fat Cheddar cheese made from micron to nano sized milk fat emulsions (Khanal et al., 2019). We found that the emulsion size affected the textural, microstructure, compositional, proteolysis and color properties of LFCs, but the textural properties were not significantly improved and were not found to be comparable to control full fat cheese and textural properties did not change significantly during cheese ripening. At size smaller than 1 μm, emulsions might not have been effective in disrupting the protein network. Sub-micron emulsions probably acted as inert particles and did not improve moisture retention in LFCs. This might be the reason for differences in results compared to studies showing textural improvement using homogenised milk. Homogenisation of milk not only reduces the fat particle size but also leads to high moisture retention leading to significant improvement in texture of LFC.

Microfluidization, due to its high emulsification and energy input, gives more stable emulsion and smaller droplet size than the conventional high-pressure homogenization (Dissanayake, Kelly, & Vasiljevic, 2010; Iordache & Jelen, 2003). One study has reported the effect of microfluidization of cheese milk on microstructure of full-fat and low-fat Mozzarella cheese. The micro-fluidization caused poor meltability and did not improve rheological properties of LFC (Tunick, Van Hekken, Cooke, Smith, & Malin, 2000). Later, Van Hekken, Tunick, Malin, and Holsinger (2007) demonstrated changes in melting and rheological properties of full- fat and low-fat Mozzarella cheese by micro-fluidization of cheese milk at different pressure and temperature. The LFC made from milk micro-fluidized at 10 °C (103 or 172 Mpa) and the full-fat control cheese could be stretched during hot water stretching. However, other cheese did not fuse together due to short curds (Van Hekken et al., 2007) leading to poor stretchability.

2.6 Membrane Filtration

Membrane filtration is commonly used in the dairy industry to remove bacteria from the milk without application of heat (using microfiltration, MF) (Amornkul & Henning, 2007) and to standarise the protein content in milk (using ultrafiltration, UF) (Salvatore, Pirisi, & Corredig, 2011). It has also been used to modify αs-/βcasein ratio or enrichment of caseins (Huppertz, Düsterhöft, & Engels, 2017; Mistry, Mistry, & Maubois, 1993). The existing cheese manufacturing technologies can be strengthened by membrane filtration of the cheese milk (Thomann, Schenkel, & Hinrichs, 2008). Membrane filtration can be used in cheese making to manipulate the texture of cheese by fractionating globular milk fat and to manufacture high-solids dairy products such as hard cheese, soft cheese and cheese base for further food processing (Henning, Baer, Hassan, & Dave, 2006).

The separation processes, such as MF and UF, may impart several advantages during cheese making such as increased cheese yield, enhanced coagulation properties and improved quality and safety of cheese (Heino, Uusi-Rauva, & Outinen, 2010; Kosikowski & Mistry, 1990). Researchers have claimed that cheese prepared from MF milk are hygienically safer compared to cheese made from pasteurized milk due to removal of a large amount of spore-forming bacteria, Clostridium tyrobutyricum (Saboya & Maubois, 2000).

MF of cheese milk (skim milk) through a 0.1 μm ceramic membrane can selectively concentrate micellar casein and calcium phosphate in the MF concentrate while removing water, α-lactalbumin, non-protein nitrogen, β-lactoglobulin, lactose and soluble minerals in the permeate (Neocleous, Barbano, & Rudan, 2002a). Hence, MF concentrate was successfully used to prepare ripened Cheddar cheese without any negative impact on cheese yield, texture, proteolysis and flavor.

While the retained, undenatured serum proteins (Lawrence, Creamer, & Gilles, 1987) and other minor milk serum proteins (Lelievre et al., 1990) during UF may have a negative impact on the normal proteolytic process during the aging, resulting in cheese texture and flavor development defects in some hard and semi-hard ripened cheeses, UF technique has been widely used for preparation of several varieties of fresh cheeses, namely Camembert, Feta, Cream, Quarg and Cottage cheese (Heino et al., 2010; Salvatore et al., 2011; Waungana, Singh, & Bennett, 1998). Cheese made from UF milk is firmer than those made from un-concentrated milk as minerals associated with caseins are concentrated in the retentate during UF (Caron, St-Gelais, & Pouliot, 1997).

Currently, UF has gained popularity in research because of the possibility of enriching cheese milk and to increase yield of a final product (Boivin-Piché, Vuillemard, & St-Gelais, 2016). Better rennet coagulation properties can be achieved by increasing the concentration of the protein with UF and or MF process (Heino et al., 2010). There is also a higher moisture retention and recovery of whey proteins in UF cheese depending on the heat treatment of milk (Lo & Bastian, 1998). Due to different coagulation properties of UF milk and un-concentrated milk, clotting time is less in UF milk and gel is firmer (Caron et al., 1997; Kelly et al., 2008).

In one study, low-fat Cheddar cheese was prepared from low mineral MF retentate (LMR) and high mineral retentate (HMR) powders with different sized milk fat globules. In this study, the cheese prepared from the large fat globule (LFG) milk (surface weighted diameter ~2.4 μm) resulted in higher scores in terms of flavor, texture and color than the cheese prepared from small milk fat globules (surface weighted diameter ~1.6 μm). The overall quality (texture, flavor and color) of low-fat Cheddar cheese was best for the LFG fraction combined with LMR (St-gelais, Piette, & Belanger, 1995; St-Gelais, Roy, & Audet, 1998). Flavor and aroma of LFC prepared from UF milk are acceptable though the texture is regarded as too soft due to retention of whey proteins (Rodriguez, Requena, Fontecha, Goudedranche, & Juarez, 1999). However, some authors reported flavor defects such as bitterness are common for the long-ripened cheese prepared from UF milk. Flavor intensity also decreases and the hardness of the Cheddar cheese also increases using MF cheese milk (Thomann et al., 2008). While another study reported acceptable texture and sensory score for the cheese made from UF milk (Miočinović et al., 2011).

In another study, low-moisture part-skim Mozzarella cheese was prepared from highly concentrated skim milk MF retentate and reducing the rennet by 93%. MF cheese in this study achieved 66–71% depletion of whey proteins(Ardisson-Korat & Rizvi, 2004). The composition of cheese prepared from MF retentate was similar to the commercial samples. However, proteolysis (measured as pH 4.6 and 12% TCA soluble nitrogen) was significantly slower than the commercial samples (Ardisson-Korat & Rizvi, 2004). This was due to low moisture in cheese prepared from MF milk, low residual chymosin and inhibition of chymosin activity by high molecular weight whey protein retentates (Neocleous et al., 2002a; Neocleous, Barbano, & Rudan, 2002b). Mistry, Metzger, and Maubois (1996) used UF sweet buttermilk to produce reduced fat Cheddar cheese and after 4 weeks of storage, the cheese made with the buttermilk concentrate was softer than the cheese prepared from the control milk. Furthermore, body of the cheese was also improved as compared to the control cheese. This was due to the presence of large amounts of milk fat globule membrane material in the buttermilk which acts as a surface-active agent and improves texture and flavour of the cheese (Mistry et al., 1996).

3 Use of Fat Replacers

Fat replacer is a substance responsible for delivering full or partial functions of the fat so as to provide lower calories than the regular fat, or the substance which provides one or more sensory and physical functions of the fat in food (Awad, Hassan, & Halaweish, 2005; Chavan, Khedkar, & Bhatt, 2016; Jooyandeh et al., 2017; Koca & Metin, 2004). Fat replacers can be divided into two categories: fat mimetic and fat substitute. Fat substitute comprises similar functional and physical characteristics of conventional fat molecules, such as triglycerides. Fat mimetics can mimic some of the organoleptic and physical characteristics of conventional fat molecules, but they cannot replace fat molecules in foods on a weight-for-weight basis, for example, protein or carbohydrate-based molecules used to replace fat (Chavan et al., 2016; Jooyandeh et al., 2017; Koca & Metin, 2004; O’Connor & O’Brien, 2011). Fat replacers used in LFC production can also be categorized into three groups based on their source: materials based on protein, carbohydrate and lipids source. Microparticulated whey protein is an example of protein-based fat replacers. Similarly, carbohydrate-based fat replacers include starch, fiber, modified starch, pectin, dextrins, maltodextrins, polydextrose, cellulose and bacterial gums such as guar gums and xanthan gums (Khanal et al., 2017). FDA has categorized the fat replacers into two types: one is as GRAS (generally recognized as a safe), and other is as food additive. Most of the fat replacers used in food at present fall under GRAS category (Artz, Lai, & Hansen, 2007).

Fat replacers have now been effectively used for the production of different food items including bakery items, salad dressings, processed cheese and confectionary products. Their use has been restricted for frying but can be used for baking or other purposes (McMahon, Alleyne, Fife, & Oberg, 1996; Position of the American Dietetic Association: fat replacers, 2005). Fat replacers have been used to increase moisture content in cheese by holding water but type and characteristics of fat replacers determine the level of increased functionality in cheese (McMahon et al., 1996; Plug & Haring, 1993; Setser & Racette, 1992; Shamil, Wyeth, & Kilcast, 1991; Zisu, 2005). The cheese prepared with fat content less than 10% and without adding fat replacers is tough in texture, dull in colour and poor in flavor, hence, these properties can be improved by using whey proteins or other fat replacers that have high water retention capacity and resemble fat. Fat replacers can modify functional, structural and sensory characteristics of LFC with improved sensory and mechanical properties besides increasing the yield (Drake, Boylston, & Swanson, 1996; Lobato-Calleros, Lobato-Calleros, Robles-Martinez, Caballero-Perez, & Vernon-Carter, 2000). On the other hand, they may produce undesirable flavor, reduce shredability and escalate stickiness in cheese, if used in enormous level (Johnson, 2016).

3.1 Carbohydrate-Based Fat Replacers

Some examples of carbohydrate-based fat replacers are pectin, alginate, potato starch, lecithin, starch guar gum, gum arabic, gum tragacanth, κ- and λ-carrageenans, β-glucan, maize starch and pre-gelatinize starch (Drake, Drake, Truong, & Daubert, 1999; Khanal et al., 2017: Khanal et al., 2018; Kavas, Oysun, Kinik, & Uysal, 2004; Konuklar, Inglett, Carriere, & Felker, 2004; Lashkari et al., 2014; Lobato-Calleros et al., 2000; Mounsey & O’Riordan, 2007; Oliveira et al., 2010; Rahimi, Khosrowshahi, Madadlou, & Aziznia, 2007; Sipahioglu, Alvarez, & Solano-Lopez, 1999; Totosaus & Guemes-Vera, 2008; Volikakis, Biliaderis, Vamvakas, & Zerfiridis, 2004). Use of all these aforementioned fat replacers provide softer texture in LFC. Other commonly used synthetic carbohydrate fat replacers are inulin, oatrim, Z-trim, polydextrose, maltodextrin, NovagelTM NC-200, Avicel® RCN 30, Raftuline® and Slendid™ (Akoh, 1994; Drake et al., 1996; Lashkari et al., 2014; McMahon et al., 1996; Plug & Haring, 1993; Position of the American Dietetic Association: fat replacers, 2005; Romeih, Michaelidou, Biliaderis, & Zerfiridis, 2002; Zisu, 2005). Good textural properties, bulkiness, thickness and creaminess can be achieved if two or more fat replacers’ mixtures combined with other modification of procedure are used to prepare LFC (Position of the American Dietetic Association: fat replacers, 2005). Commercially available novel fat replacers are also a mixture of two or more types, and they balance functions of each other. For example, Rice Trin 3 (Zumbro Inc., Hayfield, MN) is a mixture of rice protein and maltodextrin. The combined effect of these two substances provides Rice Trin 3 good gelling properties similar to microparticulated proteins (Lucca & Tepper, 1994; Plug & Haring, 1993; Position of the American Dietetic Association: Fat Replacers, 2005; Zisu, 2005).

Several studies have been conducted using different types of carbohydrate-based fat replacers. McMahon et al. (1996) used water soluble microparticulated carbohydrate (Stellar™ and Novagel™) and microparticulated protein (Simplesse® and Dairy-Lo®) as fat replacers to manufacture low-fat (4–5% fat) Mozzarella cheese and determined its composition and functionality. They did not find any difference in the functionality of experimental Mozzarella cheese stored until 28 days at 4 °C. However, they found a significant effect (p < 0.05) on meltability. The heating behaviour of carbohydrate and protein based materials are different to that of fat. This is a major problem in Mozzarella cheese as it is consumed in a melted form in pizza. Additionally, moisture content of LFC containing fat replacers was increased significantly as compared to the control cheese without fat replacers (McMahon et al., 1996). Use of tragacanth gum as a fat replacer improved the texture of low-fat Iranian white brined cheese. On the other hand, the cheese containing a greater level of tragacanth gum exhibited objectionable characteristics after 6 weeks of ageing (Rahimi et al., 2007). Another study has found greater moisture retention and softer texture in reduced fat Cheddar cheese prepared from pectin (amidated pectin) and overall increase in functionality (Ibáñez et al., 2016).

In a recent study, we (Khanal et al., 2018) prepared LFC with up to 91% fat reduction using sodium alginate as a fat replacer. Cheese yield was directly proportional to the fat and alginate levels in milk, whereas the moisture and total protein in cheese were inversely proportional to the fat in milk. Texture profile analysis illustrated a significant improvement in the texture of alginate added LFC as compared to control low fat cheese (CLFC). The textural attributes of alginate added LFC ripened for 30 days were comparable to control full fat cheese (CFFC) ripened for 60 days and beyond. A close resemblance in textural attributes between alginate added LFC and CFFC, not previously reported when using other fat replacers, was observed. Scanning electron micrograph (SEM) images revealed that alginate added LFCs had smoother surfaces as compared to CFFC and CLFC, and the dense and compact protein matrix characteristic of CLFC was not observed. Confocal laser scanning microscopy (CLSM) suggested that the fat particle size, area and volume were affected in all LFCs due to their lower fat level and these parameters increased during ripening in CFFC. Nuclear magnetic resonance (NMR) results revealed an increase in higher mobility water fraction in alginate added cheese compared to CFFC and CLFC. Magnetic Resonance Imaging (MRI) results verified the presence of more water in alginate added cheese, and signal intensity and moisture were directly proportional with each other. Hunter L, a and b values for alginate added LFCs indicated that they were whiter than CLFC and less yellowish than CFFC at the beginning of ripening; the color of some of the alginate added LFCs was comparable to CFFC after 120 days of ripening. Overall, the addition of alginate significantly improved the textural, microstructural properties and color of LFCs, affirming its potential as a promising texture modifier.

Furthermore, coefficient of friction (CoFmin) of CFFC and LFCA were not different from each other and were lower than CLFC. Rate of protein release and cheese matrix disintegration were directly influenced by cheese composition (moisture and fat content and presence of alginate) and textural properties of cheese. Presence of fat and sodium alginate in cheese exhibited more lubrication and enhanced digestion compared to CLFC, whereas sensory properties of all cheeses were similar to each other (Khanal et al., 2020).

3.2 Protein-Based Fat Replacers

Protein-based fat replacers are usually prepared from whey, milk, vegetables or eggs. They provide 1–4 kcal/g. They are small globular particles and provide a creamy mouthfeel comparable to fat particles. One gram of protein-based fat mimetics can be used instead of 3 g of fat in the cream (Hahn, 1997; Position of the American Dietetic Association: Fat Replacers, 2005). Some protein-based fat replacers and their functions in food have been compiled in Table 23.3.

Microparticulated whey protein (MWP) is a commonly used protein based fat replacer in cheese (Stankey et al., 2017). MWP provides only 1–2 kcal/g and is approved as GRAS (Hahn, 1997). Microparticulation is a process of exposing the whey proteins to high-pressure shearing with or without heating to form uniform, microscopic spheres which are analogous to fat particles (Dissanayake et al., 2010; Hahn, 1997). MWP gives several textural benefits in various food preparations (Dissanayake et al., 2010). Microparticulated protein or carbohydrate materials provide lubricity and creaminess by entrapping the water mechanically. However, they cannot substitute non-polar and flavor carrying properties of the fat (Amelia et al., 2013; Romeih et al., 2002). Commercial MWP used in cheese and other foods are Simplesse®100 and DairyLo®, they contain whey particles/aggregates of different size (0.5–5 μm) (Farkye & Guinee, 2017). Texture of low-fat Kashar cheese, White brined cheese and Cheddar cheese is improved by adding Simplesse®100, but less effect on flavor is observed. Improvement in texture is due to increase in moisture content in cheese as a result of combined effect of water binding and occlusion of the para-casein by whey protein particles (Fenelon & Guinee, 1997; Koca & Metin, 2004; Romeih et al., 2002; Sahan, Yasar, Hayaloglu, Karaca, & Kaya, 2008; Schenkel, Samudrala, & Hinrichs, 2013). MWP used up to 0.5% in low fat Cheddar cheese resulted in higher moisture, yield and lower G′ (Stankey et al., 2017). Other types of synthetic protein based replacers used in dairy foods and cheese are ALACO PALS™ and Lita® (Plug & Haring, 1993; Position of the American Dietetic Association: Fat Replacers, 2005; Setser & Racette, 1992; Zisu, 2005).

A study on the effect of incorporation of a mixture of low methyl pectin (LMP) and whey protein concentrate (WPC) on microstructure of LFC proved that LMP and WPC help to form looser and open protein network. The textural characteristics of LFC (prepared from LMP and WPC) such as hardness, springiness, cohesiveness and chewiness were not significantly different from FFC through their structural characteristics were different from FFC. Similarly, sensory characteristics of LFC containing WPC were also similar to the full-fat Manchego cheese (Lobato-Calleros, Lobato Calleros, Vernon Carter, Sanchez Garcia, & Garcia Galindo, 1999). Texture and rheological properties of cheese are inter-related and rely on the network composition, structure and molecular interactions (Lucey et al., 2003). Similar to microparticulated protein, soy-protein isolate has been used as a fat replacer in paneer and 0.2% soy-protein isolate containing paneer was found to have superior quality (Kumar et al., 2011).

3.3 Fat-Based Fat Replacers

Fat-based substitutes are derived from either chemical modifications of fatty acids or from synthetic fats. In modified fats, their configuration is changed by altering the fatty-acids on glycerol molecules (O’Connor & O’Brien, 2011). Caprenin and Salatrim (short- and long-chain acyl triglyceride molecule) are common examples of fat-based substitutes. Salatrim is produced by interesterification of tripropionin, triacetin, tributyrin and hydrogenated vegetable oils. Caprenin contains caprylic (8:0), capric (10:0) and behinic (22:0) fatty acids esterified to glycerol and is formed after esterification of glycerol with these fatty acids (Artz et al., 2007; O’Connor & O’Brien, 2011).

Olestra (sucrose fatty acid polyester) is the only synthetic fat-based substitute recommended for food use (Hahn, 1997; Position of the American Dietetic association: fat replacers, 2005). Olestra contains mixture of hexa, hepta and octa fatty acid esters of saturated and unsaturated fatty acids having a chain length of ≥12 carbons with sucrose (Artz et al., 2007). Olestra has similar mouthfeel, appearance, flash point, heat and oxidative stability as conventional fats. It is applicable to deep frying or baking. Though Olestra provides no calories to the diet, a few side effects like abdominal cramping, reduced absorption of fat soluble vitamins and loose stools have been reported (O’Connor & O’Brien, 2011). Other fat-based fat replacers used in food are colestra, trialkoxy citrate (TAC) esterified propoxylated glycerol (EPG), raffinose and sorbestin (fatreplacers from net.pdf; Position of the American Dietetic Association: fat replacers, 2005; Setser & Racette, 1992; Zisu, 2005). Table 23.4 shows examples of fat-based fat replacers.

Salatrim (short and long acyl triglyceride molecule) belongs to the group of structured triglycerides and has at least one short chain fatty acid (2:0, 3:0, 4:0) and at least one long chain fatty acid (generally 18:0) haphazardly esterified to glycerol. Hardness of salatrim is governed by the types and levels of short and long chain fatty acids present on it (O’Connor & O’Brien, 2011). Researchers used Salatrim to manufacture reduced fat Mozzarella cheese. They found a considerably lower degree of hardness, higher moisture content and more proteolysis than the control low-fat cheese. However, there was less effect of salatrim on meltability of Mozzarella cheese (Rudan, Barbano, & Kindstedt, 1998). The degree of lipolysis and proteolysis were increased significantly in low-fat-white-brined cheese prepared with fat replacers than in FFC. The maximum stress (σ max) (at 80% deformation on uniaxial compression) and the mean value of texture profile parameters of the LFC containing fat replacers were considerably less than full-fat cheese. Hence, they suggested a significant improvement in a cheese texture made with fat replacers (Romeih et al., 2002).

3.4 Use of Exopolysaccharide (EPS)-Producing Bacteria

Some strains of lactic acid bacteria (LAB) used in dairy products processing can produce EPS. EPS can protect the microbial cell from harsh conditions such as drying of the cells, osmotic stress, toxic compounds and phagocytosis (De Vuyst & Degeest, 1999; Zisu, 2005). EPS generally denotes both types of extracellular polysaccharides; cell bound EPS (it conglutinate to the surface of bacterial cell) and EPS that is released into the surrounding environment (Tang et al., 2017). This polysaccharide can sometimes be secreted in the cell wall of the capsule or in the growth medium as a slime. Hence, capsular EPS is extracellular material of bacterial metabolites covering the cell surface and remains attached to the cell surface, while ropy EPS is a slime produced by the bacteria and these polysaccharides are released from the microbial cells (Duguid & Duguid, 1951; Lynch, Coffey, & Arendt, 2017).

EPS produced by different microorganisms vary in their size, types of linkage, structure and composition (Zafar, Siddiqui, Shahid, Qader, & Aman, 2017). Composition of EPS produced by EPS-producing microorganism depends on the environmental conditions such as pH, temperature and available carbon sources (De Vuyst et al., 2003). A high carbon to nitrogen ratio at neutral pH is the best condition for EPS production (Gancel & Novel, 1994). Though the chemical composition of EPS produced by different microorganisms differs from one another, the basic composition is the same i.e. D-galactose and D-glucose are predominant in different proportions (De Vuyst & Degeest, 1999).

Table 23.5 shows some EPS-producing LAB. Some strains of EPS-producing LAB have already been used to increase the moisture retention, yield and functional properties of Mozzarella cheese. Use of EPS in LFC helps to increase moisture (up to 5%) retention, and affects gel strength, rheology and curd syneresis during coagulation of milk during cheesemaking, which then helps to improve texture and organoleptic properties of cheese (Di Cagno et al., 2014; Lynch et al., 2017). Use of EPS producing microorganisms (Weissella cibaria MG1 and Lactobacillus reuteri cc2) in low fat Cheddar cheese resulted in a higher moisture content and its microstructure was comparable to control full fat cheese (Lynch et al., 2014). Manufacture of half-fat Cheddar cheese by EPS producing Lactococcus lactis starter and it’s isogenic Non-EPS producing varient resulted in a significant increase in moisture in cheese produced by EPS prodcing L. lactis. Increase in moisture was attributed due to retention of water by the EPS through hydrogen bonding (Costa et al., 2010).

Incorporation of EPS-producing capsular type microorganisms in low-fat Mozzarella cheese enhances the textural and functional properties and cheese yield. EPS-producing S. thermophilus strains 285 and 1275 in low-fat Mozzarella cheese decrease processing time (Zisu, 2005). The moisture retention, hardness, springiness, chewiness, stretch and melt characteristics are significantly improved by the use of capsular EPS-producing S. thermophilus 285 and ropy EPS- producing S. thermophile (Zisu, 2005). Use of EPS-producing starter and the adjunct cultures in low-fat Mozzarella cheese help to increase moisture content by 4% compared to the control cheese sample (Perry, McMahon, & Oberg, 1997). Yield (0.29–1.19%) and moisture retention (3.6–4.8%) in Cheddar cheese were also increased using capsular and ropy EPS-producing Lactobacillus lactis subsp. lactis (RBL259) and Lactobacillus lactis subsp. cremoris (RBL132) (Dabour, Kheadr, Fliss, & LaPointe, 2005). Higher rate of moisture retention and primary proteolysis were also observed by Awad et al. (2005) using ropy strain Lactobacillus lactis subsp. cremoris (JFR1) and capsule forming nonropy (and moderately ropy) strains of Streptococcus thermophilus in reduced-fat Cheddar cheese.

Furthermore, Hassan, Awad, and Mistry (2007) manufactured reduced fat Cheddar cheese from young reduced fat Cheddar cheese base containing EPS. They reported softer texture, less chewiness and gumminess and better flow in cheese containing EPS bacteria. On the other hand, they did not find any correlation between the physical and melting properties of cheese with EPS base and control cheese samples. Other previous studies indicated improvements in texture and quality of LFC by incorporating EPS-producing strains in various kinds of cheese varieties (Ayyash, Abu-Jdayil, Hamed, & Shaker, 2018; Jimenez-Guzman, Flores-Najera, Cruz-Guerrero, & Garcia-Garibay, 2009; Lynch et al., 2014; Nepomuceno, Costa Junior, & Costa, 2016; Oluk, Guven, & Hayaloglu, 2014; Sanli et al., 2013). It is recommended to use EPS-producing organism along with cheese starter in Mozzarella cheese to increase moisture retention and yield. However, its use sometimes is limited as the EPS cultures increases viscosity of whey by accumulating EPS and is not desirable during whey concentration process because it decreases the efficiency of membrane used for concentration (Cerning, 1995; Petersen, Dave, McMahon, Oberg, & Broadbent, 2000).

Previously used different approaches for the manufacture of low fat Cheddar cheese are compiled in Table 23.6 and approaches used for production of other types of LFC are given in Table 23.7.

4 Conclusion

With the increasing demand of LFC, several factors need to be considered during its production to make it comparable to the full-fat counterpart. Properties of LFC are entirely different to the FFC in terms of texture, body, appearance and flavor. Improvement in only one parameter may not be sufficient to meet consumer’s expectations of the quality of LFC. Hence, sound knowledge of technology, chemistry, structure, functionality and microbiology is necessary to prepare an ideal LFC. In future, genomics and proteomics will be helpful in understanding the key role of microbiology and biochemical reactions in cheese. Texture and functionality of the cheese will be understood by molecular interactions. Use of some of the fat replacers has provided satisfactory results for the texture in up to 30% reduced-fat cheese. Further research is required to produce the LFC with more than 90% fat reduction. Choice of appropriate starter adjunct could improve and optimize the aroma and flavor of LFC. In addition, most of the studies have been conducted on the hard and semi-hard varieties of commercial cheese. Hence, work is necessary on other traditional varieties too.

References

Agarwal, S., Powers, J., Swanson, B., Chen, S., & Clark, S. (2008). Influence of salt-to-moisture ratio on starter culture and calcium lactate crystal formation. Journal of Dairy Science, 91(8), 2967–2980.

Akkerman, M., Kristensen, L. S., Jespersen, L., Ryssel, M. B., Mackie, A., Larsen, N. N., et al. (2017). Interaction between sodium chloride and texture in semi-hard Danish cheese as affected by brining time, dl-starter culture, chymosin type and cheese ripening. International Dairy Journal, 70(Suppl C), 34–45.

Akoh, C. C. (1994). Carbohydrate polyesters as fat substitutes (Vol. 62). Boca Raton, FL: CRC Press.

Amelia, I., Drake, M., Nelson, B., & Barbano, D. M. (2013). A new method for the production of low-fat Cheddar cheese. Journal of Dairy Science, 96(8), 4870–4884.

Amornkul, Y., & Henning, D. R. (2007). Utilization of microfiltration or lactoperoxidase system or both for manufacture of cheddar cheese from raw milk. Journal of Dairy Science, 90(11), 4988–5000.

Anderson, D. L., Mistry, V. V., Brandsma, R. L., & Baldwin, K. A. (1993). Reduced fat cheddar cheese from condensed milk. 1. Manufacture, composition, and ripening. Journal of Dairy Science, 76(10), 2832–2844.

Ardisson-Korat, A. V., & Rizvi, S. S. H. (2004). Vatless manufacturing of low-moisture part-skim mozzarella cheese from highly concentrated skim milk microfiltration retentates. Journal of Dairy Science, 87(11), 3601–3613.

Ardö, Y., Mansson, H. L., Hedenberg, A., & Larsson, P. O. (1989). Studies of peptidolysis during early maturation and its influence on low-fat cheese quality. Milchwissenschaft-Milk Science International, 44(8), 485–495.

Artz, W. E., Lai, L. L., & Hansen, S. L. (2007). Chapter 11 - The chemistry and nutrition of nonnutritive fats A2. In M. D. Erickson (Ed.), Deep frying (2nd ed., pp. 229–249). Urbana, IL: AOCS Press.

Awad, S., Hassan, A. N., & Halaweish, F. (2005). Application of exopolysaccharide-producing cultures in reduced-fat cheddar cheese: Composition and proteolysis. Journal of Dairy Science, 88(12), 4195–4203.

Ayyash, M., Abu-Jdayil, B., Hamed, F., & Shaker, R. (2018). Rheological, textural, microstructural and sensory impact of exopolysaccharide-producing Lactobacillus plantarum isolated from camel milk on low-fat akawi cheese. LWT - Food Science and Technology, 87(Suppl C), 423–431.

Banks, J. M. (2004). The technology of low-fat cheese manufacture. International Journal of Dairy Technology, 57(4), 199–207.

Banks, J. M., Brechany, E. Y., & Christie, W. W. (1989). The production of low fat cheddar type cheese. International Journal of Dairy Technology, 42(1), 6–9.

Banks, J. M., Roa, I., & Muir, D. D. (1998). Manipulation of the texture of low-fat chedder using a plant protease extracted from cynara cardunculus. Australian Journal of Dairy Technology, 53(2), 105.

Benech, R. O., Kheadr, E. E., Lacroix, C., & Fliss, I. (2003). Impact of Nisin producing culture and liposome-encapsulated Nisin on ripening of Lactobacillus added-Cheddar cheese. Journal of Dairy Science, 86(6), 1895–1909.

Boivin-Piché, J., Vuillemard, J.-C., & St-Gelais, D. (2016). Technical note: Vitamin D-fortified cheddar type cheese produced from concentrated milk. Journal of Dairy Science, 99(6), 4140–4145.

Børsting, M. W., Qvist, K. B., Rasmussen, M., Vindeløv, J., Vogensen, F. K., & Ardö, Y. (2012). Impact of selected coagulants and starters on primary proteolysis and amino acid release related to bitterness and structure of reduced-fat cheddar cheese. Dairy Science & Technology, 92(5), 593–612.

Brandsma, R. L., Mistry, V. V., Anderson, D. L., & Baldwin, K. A. (1994). Reduced fat cheddar cheese from condensed milk. 3. Accelerated ripening. Journal of Dairy Science, 77(4), 897–906.

Broadbent, J. R., Brighton, C., McMahon, D. J., Farkye, N. Y., Johnson, M. E., & Steele, J. L. (2013). Microbiology of cheddar cheese made with different fat contents using a Lactococcus lactis single-strain starter. Journal of Dairy Science, 96(7), 4212–4222.

Bryant, A., Ustunol, Z., & Steffe, J. (1995). Texture of cheddar cheese as influenced by fat reduction. Journal of Food Science, 60(6), 1216–1219.

Caron, A., St-Gelais, D., & Pouliot, Y. (1997). Coagulation of milk enriched with ultrafiltered or diafiltered microfiltered milk retentate powders. International Dairy Journal, 7(6-7), 445–451.

CDR. (2014). College of agriculture and life sciences, University of Wisconsin-Madison.

Cerning, J. (1995). Production of exopolysaccharides by lactic acid bacteria and dairy propionibacteria. Le Lait, 75(4-5), 463–472.

Chatli, M. K., Gandhi, N., & Singh, P. (2017). Efficacy of sodium alginate as fat replacer on the processing and storage quality of buffalo mozzarella cheese. Nutrition & Food Science, 47, 3.

Chavan, R. S., Khedkar, C. D., & Bhatt, S. (2016). Fat replacer. In B. Caballero, P. M. Finglas, & F. Toldrá (Eds.), Encyclopedia of food and health (pp. 589–595). Oxford: Academic Press.

Chevanan, N., Muthukumarappan, K., Upreti, P., & Metzger, L. (2006). Effect of calcium and phosphorus, residual lactose and salt to moisture ratio on textural properties of cheddar cheese during ripening. Journal of Texture Studies, 37(6), 711–730.

CODEX. (2013). General standard for cheese. Retrieved from http://www.google.com.au/url?sa=t&rct=j&q=&esrc=s&source=web&cd=2&ved=0CCUQFjAB&url=http%3A%2F%2Fwww.codexalimentarius.org%2Finput%2Fdownload%2Fstandards%2F186%2FCXS_263e.pdf&ei=YYKLVIXzPIqk8QXP7oLYCQ&usg=AFQjCNH3B5pBiab-pEBV1UdI9c9fnllYJw&bvm=bv.81828268

Costa, N. E., Hannon, J. A., Guinee, T. P., Auty, M. A., McSweeney, P. L., & Beresford, T. P. (2010). Effect of exopolysaccharide produced by isogenic strains of Lactococcus lactis on half-fat cheddar cheese. Journal of Dairy Science, 93(8), 3469–3486.

Dabour, N., Kheadr, E. E., Fliss, I., & LaPointe, G. (2005). Impact of ropy and capsular exopolysaccharide-producing strains of Lactococcus lactis subsp. cremoris on reduced-fat cheddar cheese production and whey composition. International Dairy Journal, 15(5), 459–471.

Dalby, A. (2009). Cheese a global history. London, UK: Reaktion Books.

De Vuyst, L., & Degeest, B. (1999). Heteropolysaccharides from lactic acid bacteria. FEMS Microbiology Reviews, 23(2), 153–177.

De Vuyst, L., Zamfir, M., Mozzi, F., Adriany, T., Marshall, V., Degeest, B., et al. (2003). Exopolysaccharide-producing Streptococcus thermophilus strains as functional starter cultures in the production of fermented milks. International Dairy Journal, 13(8), 707–717.

Deegan, K. C., Heikintalo, N., Ritvanen, T., Putkonen, T., Rekonen, J., McSweeney, P. L. H., et al. (2013). Effects of low-pressure homogenisation on the sensory and chemical properties of Emmental cheese. Innovative Food Science & Emerging Technologies, 19, 104–114.

Deegan, K. C., Holopainen, U., McSweeney, P. L. H., Alatossava, T., & Tuorila, H. (2014). Characterisation of the sensory properties and market positioning of novel reduced-fat cheese. Innovative Food Science & Emerging Technologies, 21, 169–178.

Di Cagno, R., De Pasquale, I., De Angelis, M., Buchin, S., Rizzello, C. G., & Gobbetti, M. (2014). Use of microparticulated whey protein concentrate, exopolysaccharide-producing Streptococcus thermophilus, and adjunct cultures for making low-fat Italian Caciotta-type cheese. Journal of Dairy Science, 97(1), 72–84.

Diamantino, V. R., Beraldo, F. A., Sunakozawa, T. N., & Penna, A. L. B. (2014). Effect of octenyl succinylated waxy starch as a fat mimetic on texture, microstructure and physicochemical properties of Minas fresh cheese. LWT - Food Science and Technology, 56(2), 356–362.

Dissanayake, M., Kelly, A. L., & Vasiljevic, T. (2010). Gelling properties of microparticulated whey proteins. Journal of Agricultural and Food Chemistry, 58(11), 6825–6832.

Drake, M. A., Boylston, T. D., & Swanson, B. G. (1996). Fat mimetics in low-fat cheddar cheese. Journal of Food Science, 61(6), 1267–1270.

Drake, M. A., Drake, M. A., Truong, V. D., & Daubert, C. R. (1999). Rheological and sensory properties of reduced-fat processed cheeses containing lecithin. Journal of Food Science, 64(4), 744–747.

Drake, M. A., Herfett, W., Boylston, T. D., & Swanson, B. G. (1995). Sensory evaluation of reduced fat cheeses. Journal of Food Science, 60(5), 898–901.

Drake, M. A., Miracle, R. E., & McMahon, D. J. (2010). Impact of fat reduction on flavor and flavor chemistry of Cheddar cheeses. Journal of Dairy Science, 93(11), 5069–5081.

Duguid, J. P., & Duguid, J. P. (1951). The demonstration of bacterial capsules and slime. Journal of Pathology and Bacteriology, 63(4), 673–685.

El-Gawad, A., Ahmed, N. S., El-Abd, M., & El-Rafee, S. A. (2012). Effect of homogenization on the properties and microstructure of Mozzarella cheese from buffalo milk. Acta scientiarum polonorum. Technologia Alimentaria, 11(2), 121–135.

El-Gawad, M. A. A., & Ahmed, N. S. (2011). Cheese yield as affected by some parameters review. Acta Scientiarum Polonorum. Technologia Alimentaria, 10(2), 131–153.

Emmons, D. B., Emmons, D. B., Kalab, M., Larmond, E., & Lowrie, R. J. (1980). Milk gel structure. X. Texture and Microstructure in Cheddar cheese made from whole milk and from homogenized low-fat milk. Journal of Texture Studies, 11(1), 15–34.

Farkye, N. Y., & Guinee, T. P. (2017). Chapter 28 - Low-fat and low-sodium cheeses cheese (4th ed.pp. 699–714). San Diego, CA: Academic Press.

FDA. (2017). Code of federal regulations, chapter 21.

Felfoul, I., Bornaz, S., Baccouche, A., Sahli, A., & Attia, H. (2015). Low-fat Gouda cheese made from bovine milk-olive oil emulsion: Physicochemical and sensory attributes. Journal of Food Science and Technology, 52(10), 6749–6755. https://doi.org/10.1007/s13197-015-1736-0

Fenelon, M., & Guinee, T. (1997). The compositional, textural and maturation characteristics of reduced-fat cheddar made from milk containing added dairy-Lo. Milchwissenschaft, 52(7), 385–389.

Fenelon, M. A., Ryan, M. P., Rea, M. C., Guinee, T. P., Ross, R. P., Hill, C., et al. (1999). Elevated temperature ripening of reduced fat cheddar made with or without lacticin 3147-producing starter culture. Journal of Dairy Science, 82(1), 10–22.

Fox, P. F. (2011). Cheese: overview. In J. W. Fuquay (Ed.), Encyclopedia of dairy sciences (2nd ed., pp. 533–543). San Diego, CA: Academic Press.

Fox, P. F., & McSweeney, P. L. H. (2017). Chapter 1 - Cheese: An overview. In P. L. H. McSweeney, P. F. Fox, P. D. Cotter, & D. W. Everett (Eds.), Cheese (4th ed., pp. 5–21). San Diego, CA: Academic Press.

Gancel, F., & Novel, G. (1994). Exopolysaccharide production by Streptococcus salivarius ssp. thermophilu cultures. 1. Conditions of production. Journal of Dairy Science, 77(3), 685–688.

Guinee, T. P., Fenelon, M. A., Mulholland, E. O., O’Kennedy, B. T., O’Brien, N., & Reville, W. J. (1998). The influence of milk pasteurization temperature and pH at curd milling on the composition, texture and maturation of reduced fat cheddar cheese. International Journal of Dairy Technology, 51(1), 1–10.

Hahn, N. I. (1997). Replacing fat with food technology. Journal of the American Dietetic Association, 97(1), 15–16.

Hassan, A. N., Awad, S., & Mistry, V. V. (2007). Reduced fat process cheese made from young reduced fat cheddar cheese manufactured with exopolysaccharide-producing cultures. Journal of Dairy Science, 90(8), 3604–3612.

Heino, A., Uusi-Rauva, J., & Outinen, M. (2010). Pre-treatment methods of Edam cheese milk. Effect on cheese yield and quality. LWT - Food Science and Technology, 43(4), 640–646.

Henning, D. R., Baer, R. J., Hassan, A. N., & Dave, R. (2006). Major advances in concentrated and dry milk products, cheese, and milk fat-based spreads. Journal of Dairy Science, 89(4), 1179–1188.

Hou, J., Hannon, J. A., McSweeney, P. L., Beresford, T. P., & Guinee, T. P. (2014). Effect of curd washing on cheese proteolysis, texture, volatile compounds, and sensory grading in full fat cheddar cheese. International Dairy Journal, 34(2), 190–198.

Huppertz, T., Düsterhöft, E.-M., & Engels, W. (2017). Pre-treatment of cheese-milk reference module in food science. London, UK: Elsevier.

Ibáñez, R. A., Waldron, D. S., & McSweeney, P. L. (2016). Effect of pectin on the composition, microbiology, texture, and functionality of reduced-fat cheddar cheese. Dairy Science & Technology, 96(3), 297–316.

Iordache, M., & Jelen, P. (2003). High pressure microfluidization treatment of heat denatured whey proteins for improved functionality. Innovative Food Science & Emerging Technologies, 4(4), 367–376.

Ismail, M., Ammar, E.-T., & El-Metwally, R. (2011). Improvement of low fat mozzarella cheese properties using denatured whey protein. International Journal of Dairy Technology, 64(2), 207–217.

Jana, A. H., & Upadhyay, K. G. (1992). Homogenization of milk for cheese making – A review. Australian Journal of Dairy Technology, 47(1), 72–79.

Jimenez-Guzman, J., Flores-Najera, A., Cruz-Guerrero, A. E., & Garcia-Garibay, M. (2009). Use of an exopolysaccharide-producing strain of Streptococcus thermophilus in the manufacture of Mexican Panela cheese. LWT- Food Science and Technology, 42(9), 1508–1512.

Johnson, M. E. (2011). Cheese: Low-fat and reduced-fat cheese. In J. W. Fuquay (Ed.), Encyclopedia of dairy sciences (2nd ed., pp. 833–842). San Diego, CA: Academic Press.

Johnson, M. E. (2016). Cheese: Low-fat and reduced-fat cheese reference module in food science. London, UK: Elsevier.

Johnson, M. E., & Chen, C. M. (1995). Technology of manufacturing reduced-fat cheddar cheese. Advances in Experimental Medicine and Biology, 367, 331–337.

Jooyandeh, H., Goudarzi, M., Rostamabadi, H., & Hojjati, M. (2017). Effect of Persian and almond gums as fat replacers on the physicochemical, rheological, and microstructural attributes of low-fat Iranian White cheese. Food Science & Nutrition, 5(3), 669–677.

Karaman, A. D., & Akalın, A. S. (2013). Improving quality characteristics of reduced and low fat Turkish white cheeses using homogenized cream. LWT - Food Science and Technology, 50(2), 503–510.

Karaman, A. D., Benli, M., & Akalin, A. S. (2012). Microstructure of industrially produced reduced and low fat Turkish white cheese as influenced by the homogenization of cream. Grasas y Aceites, 63(3), 267–273.

Katsiari, M. C., & Voutsinas, L. P. (1994). Manufacture of low-fat feta cheese. Food Chemistry, 49(1), 53–60.

Kavas, G., Oysun, G., Kinik, O., & Uysal, H. (2004). Effect of some fat replacers on chemical, physical and sensory attributes of low-fat white pickled cheese. Food Chemistry, 88(3), 381–388.

Kelly, A. L., Huppertz, T., & Sheehan, J. J. (2008). Pre-treatment of cheese milk: Principles and developments. Dairy Science and Technology, 88(4-5), 549–572.

Khanal, B. K. S., Bhandari, B., Prakash, S., & Bansal, N. (2017). Effect of sodium alginate addition on physical properties of rennet milk gels. Food Biophysics, 12(2), 141–150.

Khanal, B. K. S., Bhandari, B., Prakash, S., Liu, D., Zhou, P., & Bansal, N. (2018). Modifying textural and microstructural properties of low fat Cheddar cheese using sodium alginate. Food Hydrocolloids, 83, 97–108.

Khanal, B. K. S., Budiman, C., Hodson, M. P., Plan, M. R. R., Prakash, S., Bhandari, B., et al. (2019). Physico-chemical and biochemical properties of low fat cheddar cheese made from micron to nano sized milk fat emulsions. Journal of Food Engineering, 242, 94–105.

Khanal, B. K. S., Bhandari, B., Prakash, S., & Bansal, N. (2020). Simulated oral processing, in vitro digestibility and sensory perception of low fat Cheddar cheese containing sodium alginate. Journal of Food Engineering, 270, 109749.

Kheadr, E. E., Vachon, J. F., Paquin, P., & Fliss, I. (2002). Effect of dynamic high pressure on microbiological, rheological and microstructural quality of Cheddar cheese. International Dairy Journal, 12(5), 435–446.

Khosrowshahi, A., Madadlou, A., Ebrahim zadeh Mousavi, M., & Emam-Djomeh, Z. (2006). Monitoring the Chemical and textural changes during ripening of Iranian white cheese made with different concentrations of starter. Journal of Dairy Science, 89(9), 3318–3325.

Koca, N., & Metin, M. (2004). Textural, melting and sensory properties of low-fat fresh kashar cheeses produced by using fat replacers. International Dairy Journal, 14(4), 365–373.

Konuklar, G., Inglett, G. E., Carriere, C. J., & Felker, F. C. (2004). Use of a beta-glucan hydrocolloidal suspension in the manufacture of low-fat cheddar cheese: manufacture, composition, yield and microstructure. International Journal of Food Science and Technology, 39(1), 109–119.

Kosikowski, F. V., & Mistry, V. V. (1990). Microfiltration, ultrafiltration, and centrifugation separation and sterilization processes for improving milk and cheese quality. Journal of Dairy Science, 73(6), 1411–1419.

Kumar, R. (2012). An investigation into improvement of low fat cheddar cheese by the addition of hydrocolloids. (Masters Thesis), University of Minnesota, USA.

Kumar, S. S., Balasubramanian, S., Biswas, A. K., Chatli, M. K., Devatkal, S. K., & Sahoo, J. (2011). Efficacy of soy protein isolate as a fat replacer on physico-chemical and sensory characteristics of low-fat paneer. Journal of Food Science and Technology, 48(4), 498–501.

Lashkari, H., Khosrowshahi Asl, A., Madadlou, A., & Alizadeh, M. (2014). Chemical composition and rheology of low-fat Iranian white cheese incorporated with guar gum and gum arabic as fat replacers. Journal of Food Science and Technology, 51(10), 2584–2591.

Lawrence, R. C., Creamer, L. K., & Gilles, J. (1987). Texture development during cheese ripening. Journal of Dairy Science, 70(8), 1748–1760.

Lelievre, J., Creamer, L. K., & Tate, K. L. (1990). Inhibition of calf vell and microbial rennet action by whey-protein concentrate. Milchwissenschaft-Milk Science International, 45(2), 71–75.

Lemay, A., Paquin, P., & Lacroix, C. (1994). Influence of microfluidization of milk on Cheddar cheese composition, color, texture, and yield. Journal of Dairy Science, 77(10), 2870–2879.

Lo, C. G., & Bastian, E. D. (1998). Incorporation of native and denatured whey proteins into cheese curd for manufacture of reduced fat, havarti-type cheese. Journal of Dairy Science, 81(1), 16–24.

Lobato-Calleros, C., Lobato Calleros, C., Vernon Carter, E. J., Sanchez Garcia, J., & Garcia Galindo, H. S. (1999). Textural characteristics of cheese analogs incorporating fat replacers. Journal of Texture Studies, 30(5), 533–548.

Lobato-Calleros, C., Lobato-Calleros, C., Robles-Martinez, J. C., Caballero-Perez, J. F., & Vernon-Carter, E. J. (2000). Fat replacers in low-fat Mexican manchego cheese. Journal of Texture Studies, 32(1), 1–14.

Logan, A., Day, L., Pin, A., Auldist, M., Leis, A., Puvanenthiran, A., et al. (2014). Interactive effects of milk fat globule and casein micelle size on the renneting properties of milk. Food and Bioprocess Technology, 7(11), 3175–3185.

Logan, A., Leis, A., Day, L., Øiseth, S. K., Puvanenthiran, A., & Augustin, M. A. (2015). Rennet gelation properties of milk: Influence of natural variation in milk fat globule size and casein micelle size. International Dairy Journal, 46, 71–77.

Logan, A., Xu, M., Day, L., Singh, T., Moore, S. C., Mazzonetto, M., et al. (2017). Milk fat globule size affects cheddar cheese properties. International Dairy Journal, 70(Suppl C), 46–54.

Lucca, P. A., & Tepper, B. J. (1994). Fat replacers and the functionality of fat in foods. Trends in Food Science & Technology, 5(1), 12–19.

Lucey, J., Johnson, M., & Horne, D. (2003). Invited review: Perspectives on the basis of the rheology and texture properties of cheese. Journal of Dairy Science, 86(9), 2725–2743.

Lynch, K. M., Coffey, A., & Arendt, E. K. (2017). Exopolysaccharide producing lactic acid bacteria: Their techno-functional role and potential application in gluten-free bread products. Food Research International, 110, 52–61.

Lynch, K. M., McSweeney, P. L. H., Arendt, E. K., Uniacke-Lowe, T., Galle, S., & Coffey, A. (2014). Isolation and characterisation of exopolysaccharide-producing Weissella and Lactobacillus and their application as adjunct cultures in Cheddar cheese. International Dairy Journal, 34(1), 125–134.

Madadlou, A., Mousavi, M. E., Khosrowshahiasl, A., Emam-Djome, Z., & Zargaran, M. (2007). Effect of cream homogenization on textural characteristics of low-fat Iranian white cheese. International Dairy Journal, 17(5), 547–554.

Marshall, V. M., & Tamime, A. Y. (1997). Starter cultures employed in the manufacture of biofermented milks. International Journal of Dairy Technology, 50(1), 35–41.

McCarthy, A. L., O’Connor, T. P., & O’Brien, N. M. (2014). Cheese in the context of diet and nutrition. In V. R. Preddy, R. R. Watson, & V. B. Patel (Eds.), Handbook of cheese in health: Production, nutrition and medical sciences (Vol. 1, pp. 15–26). Wageningen, Netherlands: Wageningen Academic Publishers.

McCarthy, C. M., Wilkinson, M. G., & Guinee, T. P. (2017b). Effect of coagulant type and level on the properties of half-salt, half-fat Cheddar cheese made with or without adjunct starter: Improving texture and functionality. International Dairy Journal, 75(Suppl C), 30–40.

McCarthy, C. M., Wilkinson, M. G., & Guinee, T. P. (2017c). Effect of calcium reduction on the properties of half-fat Cheddar-style cheeses with full-salt or half-salt. International Dairy Journal, 73(Suppl C), 38–49.

McElhatton, A., & El Idrissi, M. M. (2016). Traditional polish curd cheeses. In Modernization of traditional food processes and products (pp. 4–12). Boston, MA: Springer.