Abstract

Despite substantial research, it is still difficult to produce high quality reduced-fat Cheddar cheese. The objective of this study was to investigate how two coagulants, bovine chymosin (BC) and camel chymosin (CC) having different proteolytic activities and two starter cultures, an O-culture (O) and a thermophilic strain of Lactobacillus plus O-culture (OLb) having different abilities to release amino acids, contribute to the structure and flavour development in reduced-fat Cheddar cheese. Cheeses manufactured using the four combinations of coagulants and cultures were analysed during a 28-week ripening period for the composition of casein, peptides, free amino acids, rheological properties and for sensory properties at end of ripening. Cheeses with CC, showed less extensive primary proteolysis, lower levels of bitterness and higher stress at fracture, which correlates to a harder structure. Whereas cheeses with BC had a higher amount of peptides released by chymosin, e.g. the bitter peptide β-casein (f193–209) or by starter proteases from the chymosin-produced peptide αs1-CN (f1–23). BC cheeses were also judged to be softer by the sensory panel. Cheeses containing the OLb-culture had a higher amount of free amino acids and lower strain at fracture, which correlates to a shorter structure, and the peptide profiles of cheeses produced with BC and CC were rather similar after 28 weeks in contradiction to cheeses with O-culture. Replacing the traditional coagulant BC with CC reduced bitterness but increased hardness of the reduced-fat Cheddar cheese. Replacing O- with OLb-culture also reduced bitterness but resulted in a shorter structure. The results highlight tools which could be employed to alter primary proteolysis and amino acid release, respectively, for the optimisation of flavour and structure of reduced-fat cheese.

摘要

虽然对低脂切达干酪进行了大量的研究,但是要生产高质量的低脂切达干酪任然面临着较大的困难。本文研究了具有不同蛋白水解活性的两种凝固剂牛凝乳酶(BC)和骆驼凝乳酶(CC),以及具有不同氨基酸释放能力的两种发酵剂O-发酵剂(O)和混合发酵剂嗜热乳杆菌+O-发酵剂(OLb)对低脂切达干酪结构和风味形成的作用。采用四种组合的凝固剂和发酵剂生产不同的低脂切达干酪,在28周的成熟期间,分析了干酪的酪蛋白、肽、游离氨基酸的组成及流变学特性,同时对成熟末期的干酪进行了感官评价。骆驼凝乳酶加工的低脂切达干酪,干酪蛋白酶解的程度较低,苦味物质含量也较低,但断裂应力较高,体现在较硬的干酪质构。然而用牛凝乳酶加工的低脂切达干酪,由凝乳酶释放的苦味肽β-酪蛋白(f193-209),或者由发酵剂蛋白酶产生的αS1-CN (f1-23) 肽含量都较高,干酪的质构较软。用OLb-发酵剂加工的低脂切达干酪中游离氨基酸含量较高,干酪的断裂应力也较高,这与干酪的脆性结构相一致;并且在28周成熟后期,牛凝乳酶和骆驼凝乳酶加工的低脂切达干酪的肽组成相似,但与O-发酵剂加工的干酪相反。采用骆驼凝乳酶替代传统的牛凝乳酶可以降低低脂切达干酪的苦味,但是增强了其硬度。用OLb-发酵剂替代O-发酵剂也能够降低干酪的苦味,但却导致了干酪质地变脆。因此,有望通过改变蛋白酶解和氨基酸的释放特性,从而改善低脂切达干酪的风味和结构。

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For several decades there has been an interest in producing reduced-fat Cheddar cheese with high gastronomic quality (Johnson and Law 2010). In spite of the considerable efforts and progress in research leading to the development of several varieties of reduced-fat cheese on the market, high-quality reduced-fat Cheddar cheese is still difficult to produce. The main objectives are to achieve a lower firmness and a less rubbery structure, proper binding of an increased amount of water and a balanced and more intense flavour without the development of bitter off-flavour. The problems are to a high degree related to cheese proteolysis, which contributes to structure as well as flavour and off-flavour (bitterness) formation during ripening (Sousa et al. 2001). Fenelon and Guinee (2000) investigated the primary proteolysis and structural changes during the ripening of Cheddar cheese containing different fat contents. These authors reported that reducing the fat content led to a slower hydrolysis of intact αs1-CN, higher firmness as well as higher stress and strain at fracture.

Proteolysis in Cheddar is initiated by the coagulant and continues by enzymatic activities of lactic acid bacteria (LAB). The principal role of chymosin is to initiate the milk clotting during cheese manufacture by cleaving the κ-casein (κ-CN) Phe105-Met106 bond. During cheese ripening, chymosin first hydrolyses the αs1-CN bond at Phe23-Phe24, which has been shown to contribute to the softening of the cheese structure (Creamer and Olson 1982). The primary chymosin activity on β-casein (β-CN) in cheese has been shown to involve the bond Leu192-Tyr193, which produces the bitter tasting peptide β-CN (f193–209) (Kelly et al. 1996). The use of bovine chymosin (BC) has been preferred in several cheese varieties for a long time as it possesses the highest ratio between clotting and general proteolytic activities (C/P) among known coagulants. Recently, camel chymosin (CC) has been launched with a C/P ratio seven times higher in comparison to BC (Kappeler et al. 2006). Kappeler et al. (2006) also showed that CC hydrolysed the κ-CN Phe105-Met106 bond in bovine milk faster than BC, and that it was less sensitive to changes in pH and calcium content as well as to heat in the interval 40–55 °C.

Bansal et al. (2009) investigated the differences between BC and CC in full-fat Cheddar. Hydrolysis of αs1-CN to αs1-CN (f1–23) and (f24–199) was largely decreased in cheese made with CC and needed 180 days to achieve the same amount of pH 4.6 soluble N in comparison to levels detected in cheeses made with BC after 60 days. They found large quantitative differences in the peptide profiles of the cheeses until 4 months of ripening but less pronounced differences after 180 days. The total amount of free amino acids was similar after 180 days. Sensory evaluation characterised the cheese with CC to have lower intensities of sulphur and brothy flavours as well as lower bitterness. The cheese produced with BC had a greater breakdown of structure, higher smoothness and mouth coating and were more cohesive and adhesive. The overall conclusion was that CC was suitable for making full-fat Cheddar. Production of low-fat Cheddar (6% fat in cheese) with CC was investigated by Govindasamy-Lucey et al. (2010). The cheeses with CC were harder and less bitter than those with BC, which was explained mainly by a lower degree of ripening.

The peptides released by chymosin action on casein are further hydrolysed by cell envelope proteases (CEP), and amino acids are released by intracellular aminopeptidases of starter and non-starter LAB (Sousa et al. 2001). Bacterial CEP may contribute to the release of bitter peptides, which are further broken down by the aminopeptidases to amino acids, resulting in a reduction in the bitterness in the cheeses (Ardö and Pettersson 1988). Pronounced acceleration of amino acid release (two to five times faster) by use of thermophilic lactobacilli in semi-hard cheese also increases water binding and thereby improves the structure of low-fat cheeses in making it less cohesive and more firm (Skeie et al. 1995).

The aim of this study was to investigate how changes in the primary proteolysis and in the amino acid release can be used to improve the structure and remove bitterness in reduced-fat Cheddar cheese. Levels of primary proteolysis was varied by using BC and CC. Amino acid release was accelerated using Lactobacillus delbrueckii subsp. lactis (Lb. delbrueckii). Cheeses were analysed during ripening for cheese composition, pH, casein components, peptides composition and amino acids, rheological properties and finally for sensory properties after 28 weeks of ripening.

2 Material and method

2.1 Experimental design

The cheese making was made using a Latin square design with three experimental factors: cheese-making day (4 days), chymosin (BC vs. CC) and cultures (O-culture vs. OLb-culture), with all combinations of the two latter factors made at each cheese-making day (BC-O, CC-O, BC-OLb and CC-OLb).

2.2 Starter cultures

Two combinations of starter cultures were used in this experiment: (a) frozen-direct-vat-set (F-DVS) multiple culture containing Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris (R604, Chr. Hansen, Denmark) referred to as O-culture (O), inoculation rate of 0.0125%; (b) F-DVS single strain culture, Lb. delbrueckii (CHCC 5718, Chr. Hansen, Denmark) at an inoculation rate of 0.075% plus O-culture at an inoculation rate of 0.0035% to obtain the same acidification rate in all cheeses. This culture is referred to as OLb-culture.

2.3 Coagulants

The two coagulants used for the cheese production were the fermentation-produced chymosin: BC (CHY-MAX®, Chr. Hansen, Denmark) and CC (CHY-MAX® M, Chr. Hansen, Denmark). The accurate international milk-clotting units (IMCU) of the coagulants were measured 1 day before the first cheese trial according to IDF (2007). The IMCU of the BC was 194 IMCU·mL−1 and CC was 1,025 IMCU·mL−1. The required amount of each coagulant to obtain the same coagulation time (45 min) was determined upon recommendation from Chr. Hansen and subsequently adjusted after a cheese production which was not included in the data. The amounts of coagulants used for BC were 3,650 IMCU per 100 L of milk and for CC, 2,880 IMCU per 100 L of milk.

2.4 Cheese production

The cheeses were produced in the Application and Technology Centre of Chr. Hansen A/S (Hørsholm, Denmark). The composition of the pasteurised cheese milk was measured by Fourier transform infrared spectrometry using a Milkoscan (FOSS, Hillerød, Denmark), and the fat level was adjusted with pasteurised cream (38% fat) to obtain a fat/protein ratio of 0.45–0.46. Each cheese vat contained 165 L of milk, which was heated to 32 °C and ripened for 45 min with O- or OLb-culture before the coagulant was added. After 45 min of coagulation, the gel was ready to be cut in 10 × 10-mm cubes. The cheese curd was stirred for 15 min before heating to 38 °C within 40 min, and the final stirring period was 15 min before whey drainage when the pH had reached 6.4–6.5. After 20 min, the cheese curd was cut into 12 pieces and rearranged in blocks five times during the next 80 min. Then, milling, salting (3.5% of the cheese weight) and pressing (two bars for 15 min + five bars for 15 h and 45 min) followed. The pH was measured after 24 h, and the cheeses were vacuum-packed and stored at 9 °C until sampling after 1, 2, 4, 8, 16 and 28 weeks of ripening.

2.5 Gross composition

The pH was measured after 24 h, 2, 8 and 28 weeks by mixing 10 g of cheese with 10 g of demineralised water. Other components of the gross composition were measured after 8 weeks of ripening. Fat content was measured by the Gerber-van Gulik method (Ardö and Polychroniadou 1999). Total solid/moisture was analysed according to IDF (1982). The total calcium (Ca) content was measured by Pearce complexometric titration method (Pearce 1977) and carried out by the laboratory Actilait, Mamirolle, France. Salt content was measured by potentiometric titration (IDF 1988; Ardö and Polychroniadou 1999). All analyses were carried out in duplicate, except for Ca which was only a single measurement.

2.6 Casein degradation by capillary electrophoresis

The cheeses were dispersed in citrate buffer according to (Ardö and Polychroniadou 1999) centrifuged (10,000 × g, 5 min), and the supernatant was frozen at −20 °C until analysis. Before analysis, the supernatant was mixed 1:1 with sample buffer and analysed by using capillary electrophoresis (CE) as described by Jensen et al. (2009). Capillary electropherograms were evaluated visually, and normalised areas of selected peaks were calculated by dividing the integrated peak area with the migration time for the given peak.

2.7 Peptide analysis by liquid chromatography–mass spectrometry

Samples for analysis of peptide composition by liquid chromatography–mass spectrometry (LCMS/MS) were prepared by adjusting the pH of the citrate dispersion of the cheese (also used for CE analysis) to 4.6 with HCl, centrifuging (10,000 × g, 5 min) and filtering (0.2 μm), and the supernatant was frozen at −20 °C until analysis. The LCMS analyses of the samples were performed using an Agilent 1290 infinity coupled to a 6540 Q-TOF (Agilent Technologies A/S, Hørsholm, Denmark). Column, eluents and gradients were as described by Jensen et al. (2009). Fifteen microlitres was injected into the column, and mass spectra were collected by running MS scans from 100 to 3,000 m/z followed by MS/MS analysis of the two most intense ions.

The UV chromatograms were evaluated visually, and peptides behind the peaks, which differed clearly between the experimental groups, were identified by manual investigation of the MS/MS spectra and using the free analytical software MassAI V0.105 (www.massai.dk) on a standard PC (core, RAM, Windows version). Prior to searching with MassAI, the MS/MS datasets were converted from raw format into mgf files in the software R. The resulting mgf files were noise-reduced using the free software MGF-filter V0.104 (www.massai.dk) to remove low-intensity and low-charge “scans” and to reduce background noise peaks from the individual scans. The noise-reduced mgf files were used for searching peptides in the MassAI search space comprising αs1-, α s2-, β- and κ-CN sequences, using the search settings as follows: parent-mass tolerance 0.03 Da and MS/MS tolerance 0.05 m/z.

MassAI is a general-purpose search program for peptide/protein/post-translational modifications identification from MS/MS datasets. In this study, several of the hydrolysis sites are not known in contrast to proteomic studies where proteases with known digestion patterns are used. The identification of peptides in MassAI is performed in two steps: first, MassAI initiates the search for possible peptide matches from MS/MS data by matching the mass of each precursor to that of the theoretical peptides. Subsequently, the peptide candidates are validated by matching the observed fragmentation pattern to the theoretical pattern(s). Each identified peptide can be visualised in a scan with annotated b- and y-ions, isotopes, losses and unmatched peaks. A result list reports the identified peptides, the number of recognised fragment ions, parent intensity and reliability score for each peptide based on a combined algorithm (see www.massai.dk).

2.8 Amino acids by HPLC

The analysis of free amino acids was performed by reversed phase high performance liquid chromatography according to Bütikofer and Ardö (1999). The analyses were carried out using an Alliance, Waters 2695 Separation Module with a Waters 996 Photodiode Array Detector and an X-Terra RP18 column, 3.5 μm (Waters Corporation, Hedehusene, Denmark), with associated Millennium 32 software version 3.20. The concentration of each individual amino acid was calculated as millimoles per kilogram of cheese based on standard curves. The 18 amino acids present in casein were analysed as well as the breakdown products citrulline and ornithine from arginine and γ-amino butyric acid (GABA) from glutamic acid. Cysteine, tryptophan and α-aminobutyric acid were also analysed, however, their concentrations were below detections limit.

2.9 Rheology by uniaxial compression

Cheese slices (2.5-cm thick) were temperature-equilibrated at 20 °C. The rind was removed; and seven to nine cylinders (diameter of 15 mm and height of 20 mm) were cut out using a borer lubricated with paraffin oil. The cylinders were placed in a closed Petri dish sealed with Parafilm®M at 20 °C until analysis. Uniaxial compression was performed at a constant deformation rate of 50 mm·min−1 to 80% deformation using an Instron 5564 Universal Testing Machine equipped with a 500 N loadcell (Instron Ltd, High Wycombe, UK). Raw data for force (in Newtons) and deformation (in millimetres) were recalculated into stress and strain, and three parameters were derived from the stress vs. strain curves: stress as fracture, strain at fracture and modulus of deformability (elastic modulus) as described by Wium and Qvist (1997). If a sample was an outlier in one of the three parameters, it was excluded in all parameters.

2.10 Sensory evaluation

Sensory evaluation was performed after 28 weeks of ripening. The cheeses were cut into sticks and tempered to 13 °C before evaluation on a scale from 0 to 12, where 12 had the highest intensity. Six trained assessors participated in a training session where they agreed on the structure attributes: hard, dry, sticky and solubility; and the flavour attributes: buttery, fruity, acidic, salty and bitter. Four evaluation sessions took place on different days and each time with cheeses from the same production day.

2.11 Statistics and multivariate data analysis

The software R version 2.12.1 was used for linear mixed-effects model (LME) analysis of variance (ANOVA) to test for significant differences in cheese composition, level of free amino acids and rheological parameters. Experimental groups were used as fixed factor and production day, as random effect. Four models were created, with the four different experimental cheese groups as reference, respectively. The sensory evaluation was analysed using the free software PanelCheck V1.4.0 (http://www.panelcheck.com) with two-way ANOVA with experimental groups and assessor as factors. Principal component analysis (PCA) loading plot of data from 28 weeks of ripening was performed using SIMCA-P + 12.0.1. Average data of each variable have been used in each experimental cheese groups. The variables were autoscaled to unit variance.

3 Results

3.1 Cheese production

A day-to-day variation was seen in the milk composition (P < 0.001) (data not shown) which contributed to a 1.2% higher fat content in the cheeses made on the second day, which resulted in lower protein and corresponding lower Ca content. The only significant (P < 0.05) difference in gross composition between experimental groups was found for a lower Ca content in the BC-OLb cheeses (Table 1). The pH was mainly similar in the experimental groups during manufacture and ripening (Table 2); however, after milling, a significantly (P < 0.05) lower pH was found in cheeses with OLb-culture of 0.02–0.03 pH units, which was no longer detected after 24 h, 8 and 28 weeks of ripening.

3.2 Primary casein breakdown by CE

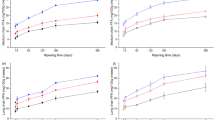

The primary breakdown of casein was not influenced by choice of starter in these experiments. Data for BC-O and CC-O are shown in Fig. 1. Cheeses made with the two coagulants, BC and CC, showed a similar limited breakdown pattern in the CE analysis for β-casein, from which only γ-caseins (γ-CN) were formed (Fig. 1) (γ-CN: γ1-CN refers to β-CN (f29-109) peak 5 (A1)/peak 7 (A2), γ2-CN refers to β-CN (f106-209) peak 3, γ3-CN refers to β-CN (f107-209) peak 9). The effects of the two coagulants, however, were clearly different in the breakdown of αs1-CN. A slower hydrolysis of αs1-CN (8 phosphate groups (P) and 9P) (Fig. 1, peaks 6 and 8) was demonstrated in the cheeses with CC compared to BC. Of the αs1-CN present in cheese after 24 h, 87 and 60% was hydrolysed during 28 weeks of ripening in cheeses made with BC and CC, respectively (Fig. 2c). The primary breakdown product produced from αs1-CN in cheeses made by both coagulants was found to be αs1-CN (f24–199) (8P and 9P) (Fig. 1, peak 13 and peak 14), the levels of which were present in lower amounts in cheeses made with CC in comparison to BC. A maximum amount of αs1-CN (f24–199) was detected after 8 weeks in cheeses made with BC, whereas it increased during the whole ripening period in cheeses made with CC (Fig. 2b). A new breakdown product (peptide identified as peak 4 in Fig. 1) was observed for the first time after 4 weeks of ripening in cheeses made with BC and after 8 weeks in cheeses with CC.

Capillary electrophoresis chromatograms. BC bovine chymosin, CC camel chymosin and O O-culture after 1, 4, 8 and 28 weeks of ripening. The peaks identification is according to that of Otte et al. (1999). 1 κ (f1–105). 2 Unknown. 3 β-CN (f106–209). 4 αs1-casein (f102–199). 5 β-CN (f29–109) A1. 6 αs1-CN 8P. 7 β-CN (f29–109) A2. 8 αs1-CN 9P. 9 β-CN (f107–209). 10 β-CN B. 11 β-CN A1. 12 β-CN A2. 13 αs1-CN (f24–199) 8P. 14 αs1-CN (f24–199) 9P

3.3 Peptide formation and breakdown

The same peptide peaks were detected in the UV chromatograms for the cheeses made with BC or CC; however, the use of BC accelerated their formation during ripening (Fig. 3). Peptides contained in the differing predominant peak of each of the experimental cheeses in Fig. 3 were selected for identification using MS/MS analysis by MassAI (Table 3). The parent intensity is shown in the table and can only be used as an indication of the peptide level within the same peptide in the cheeses. Peptides detected in higher amounts in cheeses made with BC originated directly or indirectly from chymosin activity in the cheeses. Direct chymosin activity was seen by the identification of β-CN (f193–209) (peak M). Indirectly, chymosin activity was seen by the identification of peptides that were derived from αs1-CN (f1–23), which is the primary chymosin product formed in cheese: αs1-CN (f1–9) (peak B), αs1-CN (f1–13) (peak D), αs1-CN (f1–14) (peak E), αs1-CN (f1–17) (peak G), αs1-CN (f10–16) (peak H), and αs1-CN (f17–23)/αs1-CN (f18–23) (peak K). The peak for αs1-CN (f1–13) was higher than the peak for αs1-CN (f1–14) when an O-culture was used, while these peptides rapidly disappeared in cheeses made with the OLb-culture and the proportion between them was reversed. Formation of another peptide from the amino end of αs1-CN was an effect of the OLb-culture; the peptide αs1-CN (f4–9) (peak A) was detected in cheeses containing the OLb-culture from 1 week of ripening and first detected in cheeses made with containing the O-culture after 8 weeks in a very low amount. Peptides like β -CN (f22-28) (peak C), (f47-52) (peak F), (f44-52) (peak I) is seen in a higher amount in cheeses made with O-culture compared to OLb-culture.

UV chromatogram of the four experimental cheese groups ripened 1, 8 and 28 weeks. Peak letters refers to peptides identified in Table 3. BC bovine chymosin, CC camel chymosin, O O-culture, Lb Lb. delbrueckii

In cheeses manufactured using the O-culture, the differences detected in the peptide composition were reduced during ripening. However, more peptides were present in cheeses made with BC compared to cheeses made with CC. In cheeses made with the OLb-culture, differences detected in the peptide composition between cheeses made with BC and cheeses made with CC were much less over the whole ripening period than in cheeses made with O culture.

3.4 Amino acids

The amount of free amino acids detected was greater in cheeses made with the OLb-culture throughout ripening; after 28 weeks, it was 3.5 times higher than the levels detected in cheeses made with the O-culture (Fig. 4). Cheeses made with the OLb-culture had a significantly greater amount (P < 0.001) of each individual free amino acid compared to cheeses made with the O-culture except for GABA. The influence of the coagulant was less pronounced, but the use of BC increased the total amount of free amino acids by 10–15% after 28 weeks of ripening. The majority of the free amino acids had a significantly higher concentration in cheeses made with BC compared to CC (Fig. 5), however, with the exception of threonine which was significantly higher (P < 0.01) in cheeses made with CC after 28 weeks. Significantly higher levels of (P < 0.05) isoleucine were also detected in cheeses in the experimental group CC-OLb compared to BC-OLb.

Amount of free amino acids (in millimoles per kilogram of cheese) after 28 weeks of ripening incl. standard deviation. Black BC-O, black pattern CC-O, grey BC-OLb, grey pattern CC-OLb. BC bovine chymosin, CC camel chymosin, O O-culture, Lb Lb. delbrueckii. Significant differences are seen between O- and OLb-cultures in all amino acids (not marked). S in the figure shows significant differences between O-culture and OLb-culture in cheese within each type of coagulant (P < 0.05)

3.5 Rheology

The cheese curds were not completely fused after 2 weeks, which caused a slightly higher variation in the results at this time point. Stress at fracture (Fig. 6a) decreased for all four experimental groups from 8 to 28 weeks. A lower stress at fracture was obtained in cheeses made with BC compared to CC, and the use of the O-culture gave a lower stress compared to the OLb-culture. After 28 weeks of ripening, all four experimental groups were significantly (P < 0.001) different from each other in the following order: BC-O < BC-OLb < CC-O < CC-OLb.

Illustration of a stress at fracture (in kilopascals), b strain at fracture (-) and c modulus of deformability (in kilopascals), respectively. BC-O (black square), CC-O (black triangle), BC-OLb (white square), CC-OLb (white triangle). BC bovine chymosin, CC camel chymosin, O O-culture, Lb Lb. delbrueckii

Strain at fracture decreased during ripening from 8 to 28 weeks for all four experimental groups (Fig. 6b). Strain at fracture was influenced by the culture and not by the coagulant. The use of the O-culture resulted in a significantly (P < 0.001) higher strain at fracture compared to the OLb-culture.

Modulus of deformability (elastic modulus) (Fig. 6c) decreased during ripening from 8 to 28 weeks when using the O-culture, whereas the modulus increased when using the OLb-culture. After 28 weeks of ripening, the modulus of deformability of all four experimental groups was significantly (P < 0.001) different from each other: BC-O < CC-O < BC-OLb < CC-OLb.

3.6 Sensory evaluation

The sensory panel scored the cheeses made with BC-O to be significantly less hard (P < 0.01), less dry (P < 0.001) and stickier (P < 0.001) compared to the cheeses of the other three experimental groups (Table 4). Furthermore, cheeses made with BC-O were found to be significantly more bitter (P < 0.05) than cheeses made with CC-O, CC-OLb or BC-OLb. Cheeses made with CC-OLb were found to be significantly drier (P < 0.001) compared to the other experimental groups. The sensory panel did not find any significant differences in the attributes buttery, fruity, astringent and acidic (data not shown).

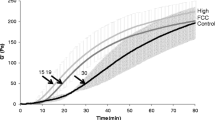

3.7 PCA plot

A PCA loading plot of coagulants, cultures and data from CE, total amino acids, rheological and sensory data of structure parameters and bitterness after 28 weeks of ripening was performed. Principal component (PC) 1 explained 48% and PC2, 25% of the variation in the data (Fig. 7). The PCA plot indicated that cheeses made with the CC were positively correlated with high amounts of intact αs1-CN, while the opposite was true for cheeses made with BC. Cheeses made with the OLb-culture correlated positively with high levels of free amino acids and low levels of strain at fracture, while the opposite was true for cheeses made with the O-culture. Cheeses containing CC and/or OLb had a high modulus of deformability and high stress at fracture which was positively correlated with the sensory attributes hard and dry and negatively correlated with solubility, stickiness and bitterness. The opposite was valid for cheeses containing BC and/or O.

4 Discussion

Four cheese replicates of each experimental group (BC-O (typical Cheddar procedure), BC-OLb, CC-O and CC-OLb) were successfully produced with only minor differences in acidification and gross composition. Electropherograms showed no other breakdown products from β-CN than the γ-CNs, which indicates that mainly plasmin activity had occurred on β-CN. Considerable amount of intact β-CN was still present after 28 weeks of ripening in the cheeses of all four experimental groups. The breakdown of αs1-CN was much more pronounced, and it divided the experimental cheeses into two groups according to coagulants. Slower initial breakdown of αs1-CN was observed in cheeses produced with CC in comparison to BC. The primary chymosin breakdown product of αs1-CN, αs1-CN (f24–199) (McSweeney et al. 1993), reached a maximum level after 8 weeks and subsequently decreased between 8 and 28 weeks of ripening in cheeses made with BC. It is assumed that the decrease of αs1-CN (f24–199) after 8 weeks was due to more rapid further hydrolysis of αs1-CN (f24–199) than formation from intact αs1-CN. Cheeses made with CC had a lower level of αs1-CN (f24–199), which increased during the whole ripening period. The second most preferred chymosin hydrolysis site of αs1-CN in Cheddar has been shown to be Leu101-Lys102 (Sousa et al. 2001); Fig. 1, peak 4 is likely to be αs1-CN (f102–199) because it appears and increases on the electropherograms while αs1-CN (f24–199) decreases. This suggested identification is supported by the fact that the peptide αs1-CN (f102–199) should migrate faster than αs1-CN as it has lost a highly negatively charged peptide part containing seven to eight phosphate groups. The peak containing αs1-CN (f102–199) was observed on the electropherograms after 4 weeks of ripening in cheeses made with BC and after 8 weeks in cheeses made with CC (Fig. 2a), confirming that chymosin is involved in its formation.

Accordingly, the dynamics in peptide composition over time was more pronounced in cheeses made with BC in comparison to cheeses made with CC, as analysed by LC/MS/MS. After 28 weeks of ripening, fewer differences in the peptide profiles were detected between cheeses made with BC and, especially in cheeses made with the OLb-culture, due to higher aminopeptidase activities. Bansal et al. (2009) produced a full-fat Cheddar cheese with the same O-culture as used in this study and found a similar peptide profile after 26 weeks in the cheeses made with BC and CC. The peptides that varied in this study were primarily those released by the CEP from the chymosin-produced peptide αs1-CN (f1–23) (Exterkate et al. 1993; McSweeney et al. 1993), and also the chymosin-produced peptide β-CN (f 193–209), which has been documented to be bitter (Kelly et al. 1996). Lee et al. (1996) and Broadbent et al. (1998) also claimed αs1-CN (f1–7), αs1-CN (f1–9) and αs1-CN (f1–13) to be bitter, of which the latter two were found in this study. After 28 weeks of ripening, the sensory panel found cheeses made with BC-O to be more bitter than the other experimental cheeses, which agreed with a higher amount of these peptides. Bansal et al. (2009) also reported that full-fat Cheddar cheese made with BC to be more bitter than cheeses made with CC, and Govindasamy-Lucey et al. (2010) reported a similar finding in low-fat Cheddar cheese. By using the OLb-culture, the level of bitterness was reduced in cheeses made with BC compared to cheese made using the O-culture, which indicated that the bitter peptides were further hydrolysed. The peptide αs1-CN (f4–9) was detected at high levels in cheeses made with the OLb-culture. This could be explained by other enzymatic activities due to the presence of the thermophilic strain of lactobacillus used in addition to the O-culture. Peptides similar to αs1-CN (f4–9) have been shown to be produced by Lactobacillus helveticus (Ardö et al. 2004). Furthermore, the peak for αs1-CN (f1–14) was higher than the peak for αs1-CN (f1–13) when the OLb-culture was used. This agreed with Hebert et al. (2008) who claimed that one of the specific cleavage sites for L. delbrueckii subsp. lactis CRL 581 was αs1-CN Glu14-Val15.

Cheeses made with the OLb-culture generally had 3.5 times higher levels of free amino acids after 28 weeks compared to cheeses made with the O-culture. The levels of the majority of individual free amino acids were significantly greater in cheeses made with BC. An exception to this was threonine which was significantly greater in cheese made with CC compared to BC. A similar observation was reported by O'Mahony et al. (2005), who inhibited chymosin activity in cheese by the use of pepstatin and found a higher level of threonine in cheese made with the most inhibited chymosin activity. An explanation could be a higher CEP activity on β-CN from the starter culture when the proteolytic activity from chymosin was reduced; β-CN contains twice as much threonine as αs1-CN.

Stress at fracture is correlated to hardness/firmness of the cheese (O'Challaghan and Guinee 2004; van Vliet 1991). A high stress at fracture correlated positively with a high level of intact αs1-CN as seen in cheeses made with CC. The sensory panel confirmed that cheeses made with BC-O were softer, stickier and less dry than the cheeses of the other experimental groups. The use of the OLb-culture in cheeses resulted in a higher stress at fracture compared to the use of the O-culture, which could be explained by the accelerated release of free amino acids and increased water binding. This study showed a clear correlation between the hydrolysis of αs1-CN at the Phe23-Phe24 site and the softening of Cheddar cheese in agreement to Creamer and Olson (1982) and Brickley et al. (2007). The softening of Cheddar during the first couple of weeks has been proposed to principally be due to the partial solubilisation of colloidal calcium phosphate associated with the para-CN matrix of the curd (O'Mahony et al. 2005); however, in this study, Ca content and pH development were the same, and only the αs1-CN hydrolysis differed. Bansal et al. (2009) found a similar pattern in full-fat Cheddar cheese with a slower hydrolysis of αs1-CN, leading to a slower formation of αs1-CN (f24–199) and a harder structure when using CC instead of BC. Govindasamy-Lucey et al. (2010) reported that low-fat Cheddar cheese produced with CC to be harder than cheeses produced with BC.

Strain at fracture correlates with brittleness/shortness/longness (O'Challaghan and Guinee 2004; van Vliet 1991). A high release of amino acids in cheeses made with the OLb-cultures correlated positively with a low strain at fracture (see Figs. 4 and 6). During proteolysis, each peptide bond cleavage will covalently bind one molecule of water and form one new carboxylic acid and one new amino group which interact with the water molecules in the cheese matrix. This will decrease the water activity and affect the cheese structure (McSweeney 2004). In this study, a high level of amino acids resulted in higher stress at fracture and lower strain at fracture, which can be correlated with a harder and shorter cheese structure. After 28 weeks, the strain at fracture was only influenced by the culture and not the coagulant. The sensory panel confirmed that cheeses containing the OLb-cultures were significantly harder, stickier and drier in structure than cheeses made with BC-O, but not those made with CC-O.

5 Conclusion

It could be concluded from the results that it is possible to change the structure and bitterness of reduced-fat Cheddar cheese by using other combinations of coagulants and starter cultures other than those used in traditional Cheddar cheese manufacture (BC-O). The cheeses made with BC-O had the lowest stress at fracture which is correlated to low hardness, and they were also evaluated by the sensory panel to be significantly softer. Furthermore, the cheeses were more soluble, stickier and less dry in structure but also more bitter than the other experimental cheese. Replacing BC in cheese with a lower proteolytic coagulant (CC) resulted in a marked lower activity of the chymosin cleavage of the peptide bond αs1-CN Phe23-Phe24, a lower level of peptides derived from αs1-CN (f1–23) and a lower level of the bitter peptide β-CN (f193–209). It was clear that the chymosin cleavage of αs1-CN Phe23-Phe24 influenced the softening process of Cheddar cheese. Cheeses made with CC-O had a higher stress at fracture, harder structure and lower bitterness compared to cheeses made with BC-O. The starter culture OLb rapidly hydrolysed the peptides of the cheeses and accelerated the release of amino acids, which resulted in a lower strain at fracture which is correlated with shortness. Cheeses made with BC-OLb were harder, drier, less sticky, and soluble and bitter compared to BC-O. Cheeses made with CC-OLb had higher stress at fracture, higher modulus of deformability and lower bitterness.

The results of this study have highlighted tools which can change primary proteolysis and amino acid release, respectively, for the optimisation of flavour and structure of reduced-fat cheese.

References

Ardö Y, Pettersson HE (1988) Accelerated cheese ripening with heat-treated cells of Lactobacillus helveticus and a commercial proteolytic-enzyme. J Dairy Res 55:239–245

Ardö Y, Polychroniadou A (1999) Laboratory manual for chemical analysis of cheese. European Communities, Office for Official Publications of the European Communities, Luxemburg

Ardö Y, Tähtinen HM, Madsen A, Guldager HS, Larsen AB, Otte J, Zakore M, Sørensen NK (2004) Lactobacillus helveticus as adjunct culture in low-fat semi-hard cheese. IDF symposium on cheese ripening, characterisation and technology. The Czech Republic, poster 109

Bansal N, Drake MA, Piraino P, Broe ML, Harboe M, Fox PF, McSweeney PLH (2009) Suitability of recombinant camel (Camelus dromedarius) chymosin as a coagulant for cheddar cheese. Int Dairy J 19:510–517

Brickley CA, Auty MAE, Piraino P, McSweeney PLH (2007) The effect of natural cheddar cheese ripening on the functional and textural properties of the processed cheese manufactured therefrom. J Food Sci 72:C483–C490

Broadbent J, Strickland M, Weimer B, Johnson M, Steele J (1998) Peptide accumulation and bitterness in cheddar cheese made using single-strain Lactococcus lactis starters with distinct proteinase specificities RID A-9626-2010. J Dairy Sci 81:327–337

Bütikofer U, Ardö Y (1999) Quantitative determination of free amino acids in cheese. Bull Int Dairy Fed 337:24–32

Creamer LK, Olson NF (1982) Rheological evaluation of maturing cheddar cheese. J. Food Sci. 47:631-&

Exterkate F, Alting A, Bruinenberg P (1993) Diversity of cell-envelope proteinase specificity among strains of Lactococcus lactis and its relationship to charge characteristics of the substrate-binding region. Appl Environ Microbiol 59:3640–3647

Fenelon M, Guinee T (2000) Primary proteolysis and textural changes during ripening in cheddar cheeses manufactured to different fat contents. Int Dairy J 10:151–158

Govindasamy-Lucey S, Lu Y, Jaeggi JJ, Johnson ME, Lucey JA (2010) Impact of camel chymosin on the texture and sensory properties of low-fat cheddar cheese. Aust J Dairy Technol 65:139–142

Hebert EM, Mamone G, Picariello G, Raya RR, Savoy G, Ferranti P, Addeo F (2008) Characterization of the pattern of αs1- and β- casein breakdown and release of a bioactive peptide by a cell envelope proteinase from Lactobacillus delbrueckii subsp. lactis CRL 581. Appl Environ Microbiol 74:3682–3689

IDF (1982) IDF Standard 4A. Cheese and processed cheese, determination of the total solids content (reference method). Int. Dairy Fed., Brussels, Belgium

IDF (1988) IDF Standard 88A. Cheese and processed cheese products determination of chloride content potentiometric titration method. Int. Dairy Fed., Brussels, Belgium

IDF (2007) Standard 157. Determination of total milk-clotting activity of bovine rennets. Int. Dairy Fed., Brussels, Belgium

Jensen MP, Vogensen FK, Ardo Y (2009) Variation in caseinolytic properties of six cheese related Lactobacillus helveticus strains. Int Dairy J 19:661–668

Johnson M, Law BA (2010) The origins, development and basic operations of cheesemaking technology. In: Law BA, Tamime AY (eds) Technology of Cheesemaking, 2nd edn. Wiley, Singapore

Kappeler S, van den Brink H, Rahbek-Nielsen H, Farah Z, Puhan Z, Hansen E, Johansen E (2006) Characterization of recombinant camel chymosin reveals superior properties for the coagulation of bovine and camel milk. Biochem Biophys Res Commun 342:647–654

Kelly M, Fox PF, McSweeney PLH (1996) Effect of salt-in-moisture on proteolysis in cheddar-type cheese. Milchwiss Sci Int 51:498–501

Lee K, Lo C, Warthesen J (1996) Removal of bitterness from the bitter peptides extracted from cheddar cheese with peptidases from Lactococcus lactis ssp cremoris SK11. J Dairy Sci 79:1521–1528

McSweeney PLH (2004) Biochemistry of cheese ripening. Int J Dairy Technol 57:127–144

McSweeney PLH, Olson NF, Fox PF, Healy A, Højrup P (1993) Proteolytic specificity of chymosin on bovine alpha-S1-casein. J Dairy Res 60:401–412

O'Challaghan DJ, Guinee TP (2004) Rheology and texture of cheese. In: Fox PF, McSweeney PLH, Cogan TM, Guinee TP (eds) Cheese chemistry, physics and microbiology—general aspects, 3rd edn. Elsevier, Amsterdam

O'Mahony J, Lucey J, McSweeney PLH (2005) Chymosin-mediated proteolysis, calcium solubilization, and texture development during the ripening of cheddar cheese. J Dairy Sci 88:3101–3114

Otte J, Ardö Y, Weimer B, Sørensen J (1999) Capillary electrophoresis used to measure proteolysis in cheese. Bull Int Dairy Fed 337:10–16

Pearce KN (1977) The complexometric determination of calcium in dairy products. N Z J Dairy Sci Technol 12:113–115

Skeie S, Narvhus J, Ardö Y, Abrahamsen R (1995) Influence of liposome-encapsulated neutrase and heat-treated lactobacilli on the quality of low-fat gouda-type cheese. J Dairy Res 62:131–139

Sousa M, Ardo Y, McSweeney PLH (2001) Advances in the study of proteolysis during cheese ripening. Int Dairy J 11:327–345

van Vliet T (1991) Terminology to be used in cheese rheology. Bull Int Dairy Fed 268:5–15

Wium H, Qvist K (1997) Rheological properties of UF-feta cheese determined by uniaxial compression and dynamic testing. J Texture Stud 28:435–454

Acknowledgments

The authors would like to thank Anders Neimann-Sørensen and Brian Kløvgaard Rasmussen (Chr. Hansen A/S, Hørsholm, Denmark) for helping with the cheese production; Marianne Richelieu and Asger Geppel (Chr. Hansen A/S, Hørsholm, Denmark) for helping with LCMS equipment; Anni Nielsen Bager (University of Copenhagen, Denmark) for running the amino acid analysis; Jes Kundsen (University of Copenhagen, Denmark) for providing support with the rheological equipment; and Ditte Marie Brandt and Birgit Hansen (Chr. Hansen A/S, Hørsholm, Denmark) for running the sensory evaluation.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Børsting, M.W., Qvist, K.B., Rasmussen, M. et al. Impact of selected coagulants and starters on primary proteolysis and amino acid release related to bitterness and structure of reduced-fat Cheddar cheese. Dairy Sci. & Technol. 92, 593–612 (2012). https://doi.org/10.1007/s13594-012-0080-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13594-012-0080-7