Abstract

The reduction of CO2 emissions requires the combination of measures that prevent the emission of this compound in the electrical and industrial sector. Each region will have different characteristics that should be accentuated to apply the most viable technologies. In this case, a study is carried out in the North of Spain, where a potential CO2 store is located and, in this work, the development of a cluster CCS is studied, which is defined as the region with minimum CO2 emissions. In this case, the connection of different industrial nodes with the storage is studied, and a cluster CCS definition methodology is proposed. Those nodes that are economically and/or environmentally unviable in connection with the geological storage may apply other technologies for direct or indirect use of CO2.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

Global warming is one of the biggest challenges that humanity must solve: the use of fossil fuels since the industrial era has led to a greater presence of greenhouse gases in the composition of the Earth’s atmosphere. The greatest evidence, recorded in the observatory of Mauna Loa (USA), where the milestone of exceeding 410 ppm of CO2 in the atmosphere was reached, was exceeded last February 2019. And what is worse, the rate of growth is between 2 and 3 ppm CO2 per year.

In this way, and if no measures are taken to stop this increase, the 450 ppm CO2 equivalent limit established after the Paris Protocol (COPS21, 2015) for the entire twenty-first century to keep the temperature rise to less than 2 °C will be clearly exceeded. The energy transition is emerging as the main vector to reduce CO2 emissions—considering not only the electricity sector, but also transport. The promotion of renewable sources will be the main development in the OECD countries. However, the forecasts of the International Energy Agency predict a continuous use of fossil fuels as the main primary energy in the coming decades.

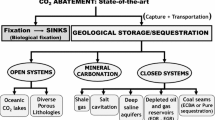

According to Fig. 1, the different strategies for the mitigation of CO2 emissions in large stationary sources are described. Carbon dioxide capture and storage (CCS) or carbon capture and use (CCU) is recognized as one of the most promising options to mitigate the increase of atmospheric carbon dioxide concentration [1].

The study of a particular region and CO2 sources should include the consideration of a wide range of technologies. In this case, the study and development of a cluster in the North of Spain, where there are different emission sources distributed by the region—with different characteristics and emission volumes—and a potential CO2 storage has been defined (structure defined by the Geological and Mining Institute of Spain, and named Villameriel).

2 Carbon Capture and Storage, CCS

The CCS technology is considered for the significant reduction of CO2 emissions in large emission sources [2]. The European Union regulated the emissions of six industrial sectors [3] in order to promote the decarbonization of these sectors.

The CCS technology is composed of three clearly differentiated phases: (i) capture, (ii) transport and (iii) storage of CO2. Among the three phases, the last one requires a local solution to the emitting focus—considering that the competitive CO2 capture technology can be developed anywhere in the world—which requires a country or region strategy.

2.1 CO2 Capture

Current CO2 capture technology (first generation) is adapted from gas separation processes already in industrial use [4, 5]. Technologies may be classified according to: pre-combustion, oxy-fuel and post-combustion. Various processes can be envisaged for separation of the CO2 contained in a gas mixture. They are based on chemical, physical or hybrid absorption, adsorption, membranes separation or cryogenic separation [6].

2.1.1 Pre-combustion

The pre-combustion capture systems are characterized by eliminating CO2 before the synthesis gas enters the turbine. The capture process is initiated by processing the fuel in the gasifier with water vapour and air or oxygen to produce the synthesis gas, which is composed mostly of carbon monoxide and hydrogen. This is then further converted to more hydrogen through the water-gas shift (WGS) reaction, resulting in high pressure CO2 and H2. Separation of these two components allows for the storage of CO2, while H2 can be used for a number of processes, such as power generation [7]. Finally, CO2 is captured by a physical sorbent-based system.

The processes for CO2 capture prior to combustion have a greater complexity than those after combustion. However, the products generated in pre-combustion have more favourable conditions for separation, high pressure and CO2 concentration, as well as a higher efficiency.

2.1.2 Oxy-combustion

This capture process consists of carrying out the combustion in the presence of an oxidizer, pure oxygen or CO2–O2 mixture, instead of air to carry out the reaction.

The flue gas obtained from this system consists mainly of CO2 and H2O and is accompanied by minor quantities of N2, SOX, NOX, Ar and Hg. The CO2 content varies from 70 to 95%v/v in the oxy-fuel combustion, which is beneficial for the CO2 capture and reduction of flue gas emission. Besides enriching the flue gas with CO2, oxy-fuel combustion also has some other inherent advantages, like high combustion efficiency, low volume of flue gas, low fuel consumption and less NOx formation [8]. This is being dependent on the process configuration, air in-leakages, fuel characteristics and the purity of O2.

2.1.3 Post-combustion

Post-combustion capture systems separate CO2 from combustion gases (mainly nitrogen), after the reaction of the primary fuel with air. Therefore, flue gas condition is defined by a low concentration in CO2 and a large flow:

-

Thermal power station (MW), coal: 12–14% CO2 and volumes above 5 Mt CO2/year.

-

Combined cycle power plant (MW), natural gas: 5–7% and volumes above 3 Mt CO2/year.

This technology can be used for existing installations based mainly on chemical absorption processes and based on amines that have an affinity for acidic compounds [9].

2.2 CO2 Transport

To a greater or lesser extent, CO2 must be transported from the emitting source to the geological CO2 store, thus being necessary to deploy a CO2 transport network [10]. For the correct sizing of the CO2 pipeline, it will be necessary to consider:

-

CO2 should be transported in supercritical conditions (31.1 °C and 7.38 MPa) since in these conditions, the CO2 shows optimal characteristics for transport: viscosity of a gas and a density of a liquid. In the operation of CO2 ducts, the most common is a lower temperature and a higher pressure than stipulated in the supercritical behaviour parameters of CO2, obtaining a very similar behaviour [11].

-

Acidic character of CO2, which can degrade some components of the transport system: elastomers, valves and others could be affected. The presence of other compounds such as water will aggravate the acid character of the fluid transported [12].

2.3 CO2 Storage (CCS)

The geological storage of carbon dioxide is a technology directly applicable through experience in exploration and production of oil, gas, coal, waste injection and protection of groundwater. The retention time of CO2 is hundreds to millions of years in stable structures, although the biggest drawback is the lack of knowledge of the potential and geographical location of these structures [2].

The objective is the permanent confinement of CO2 in geological formations in safe, health and environmental conditions, in order to reduce anthropogenic CO2 emissions into the atmosphere.

There are two fundamental requirements:

-

The existence of pairs of geological storage/seals formations, with sufficient thickness and extension, and under structural conditions, guarantees the confinement of the storage.

-

Injection of CO2 must be carried out at more than 800 m depth to ensure that CO2 is in supercritical state due to hydrostatic pressure. In addition, this fact optimizes the storage capacity of CO2 since in supercritical conditions it behaves like a gas but much denser and occupies much less volume. The most common types of geological storage are usually: depleted oil and gas reservoirs, deep saline aquifers and non-exploitable coal reservoirs.

The way in which CO2 moves is very conditioned by the characteristics and the heterogeneity of the storage. There is migration due to mobility difference, because supercritical CO2 is less viscous than water, which generates greater mobility and displacement of water. A vertical flow is also generated by the density difference between saline water and CO2 in the supercritical state which is quite significant, since the density of CO2 at 35 °C and 100 bar is 0.71281 g/ml.

Depending on the geological and migratory characteristics of the store, the following trapping mechanisms can be classified [13, 14]:

-

Structural and stratigraphic trapping. Physical confinement of CO2, considering different layout of the storage and seal formations.

-

Hydrodynamic trapping which is produced by CO2 and water displacement throughout the storage formation.

-

Residual trapping which occurs in the intergranular space due to capillarity forces.

-

Dissolution trapping which is produced by dissolving the CO2 in the water of the formation.

-

Mineral trapping which is produced by the chemical fixation by reactions of the CO2 with the storage rock and the water formation.

2.4 CO2 Utilization (CCU)

Nowadays, many industrial applications demand CO2 as a fluid for different uses. It demonstrates that CO2 is a useful, versatile and safe product.

Life cycle assessment is the only normalized methodology to quantify the environmental impact of a product or a process. Although the CO2 utilization technologies have the potential to reduce CO2 emissions by at least 3.7 gigatonnes per year (Gt/y) [15], which are the environmental impacts of the different uses of CO2? Life cycle assessment is the methodology proposed to evaluate those impacts.

The Carbon Sequestration Leadership Forum [16] classified the technologies into three main categories: resource recovery (e.g. enhanced gas and oil recovery), non-consumptive (reuse) applications and consumptive applications. In the following, reuse and consumptive applications are going to be taken into account.

2.4.1 Reuse (Non-consumptive) Applications

Technologies may be classified according to the CO2-use:

-

Use of CO2 for desalination (5 kg of supercritical CO2 would produce 50 kg of potable water),

-

Use of CO2 as a working fluid (i.e. coal cleaning; heat transfer fluid in power systems; transport media in freight pipelines; recovery or rare earth elements, treating hazardous waste via solvent extraction and others),

-

Production of fuels and chemicals (i.e. gasoline, distillate fuel (diesel), methanol, acrylic acid, polyethylene carbonate (plastics), urea production, formic acid, algal fuels).

Non-consumptive CO2-use applications have an indirect CO2 reduction benefit in the form of production of freshwater or valuable minerals, higher efficiency or the displacement of fossil fuels.

2.4.2 Consumptive Applications

These applications involve the formation of minerals, or long-lived compounds from CO2 leading to net-carbon sequestration by “locking-up” carbon. The primary benefits from the consumptive uses are comprised of avoided CO2 emissions (use of mineral carbonates, and various by-products such as hydrogen, chlorine and aggregate) and the sale of the mineral carbonates and by-products.

Cuéllar-Franca and Azapagic [17] reviewed the life cycle environmental impacts of different carbon capture, storage and utilization technologies. Their conclusion is that the option that has lower Global Warming Potential (GWP) is CCS, estimated in 276 kg CO2-eq/t CO2-removed.

The worst CCU option was the production of dimethyl carbonate, DMC (GWP is 216 times higher than CCS), followed by biodiesel production (with a GWP four times higher). Carbon mineralization has a GWP 2.9 times higher, and enhanced oil recovery has a GWP 1.8 times higher than CCS. Although the CCS studies suggest that the GWP from power plants can be reduced by 63–82%, other environmental impacts as acidification and human toxicity are higher with than without CCS.

They conclude that the GWP of CCS is significantly lower than of the CCU options, but its other environmental impacts are higher compared to CCU except from DMC production. However, they propose to develop guidelines for the application of the LCA methodology to CCS and CCU technologies due to the inconsistencies in the system boundaries and functional units.

3 Case of Study: North of Spain

3.1 Cluster Description

According to Directive 2009/31/CE [18], a geological storage of CO2 must guarantee access to third parties. In this way, the operation model should be based on the search for a suitable geological structure [19]. For this reason, the strategy to define a cluster must consider all the industries in a determined region. Economic and environmental conditions will limit the capacity to store totally the CO2 emissions, but the aim of the cluster is to minimize these emissions; for this reason, not only CCS technology will be considered: some other technologies would be considered such as direct or indirect utilization of CO2.

3.2 Villameriel Area

The structure object of the modelling is located in the Duero basin, being described in the ALGECO2 project of the Geological and Mining Institute of Spain [20]. The available preliminary information is based on: analysis of surface geology, seismic sections and stratigraphic column of the well Villameriel-1 (Fig. 2).

After the study of the geological formations, the storage formation in the Utrillas formation can be described [21]: alternation of sands and clays with conglomerates in the base with an average porosity of 14% with a thickness of 150 m and with a salinity of 60,000 ppm of NaCleq. The seal of the formation described above is formed by a formation consists of clays and marls of texture and varied constitution and an average thickness of 100 m (Fig. 3).

The structure is defined as a sequence of sub-horizontal layers, with an extension of 105 km2 and whose theoretical storage volume is set at 118.5 million tons of CO2 (Eq. 1).

Theoretical capacity of CO2 geological storage formations (IEA GHG)

Since RV is the total volume of rock (in this case: 7074 × 106 m3), considering also a net storage (Storagenet) of 60% and porosity of 14%. The CO2 density (\(\rho_{{{\text{CO}}_{2} }}\)) value is set at 650 kg/m3 and, the storage efficiency coefficient (Seff) of 0.3 (dimensionless).

With the density considered and knowing the geothermal gradient of the basin (25.5 °C/km), the proposed training can be considered as feasible storage.

3.3 CO2 Transport: Storage Connection with Emission Sources. Cluster Definition

To carry out this study, the CO2 sources regulated by Directive 2003/87/EC [22] and Directive 2009/29/EC have been taken into account. The region under study has several CO2 emission sources, which could be representative for the case of Spain and Europe (Table 1).

According to the transport criteria [10], aspects such as environmentally protected spaces, populations and infrastructures that could be affected by the development of CO2 transport should be considered.

3.3.1 Cluster CCS: Zero Emissions in the Industry

The potential storage of CO2 is considered in the present study where according to the data (storage capacity and emitters), it can be established that the Villameriel warehouse would allow establishing a region with zero industrial CO2 emissions during the next 15 years.

The transport of CO2 and its viability are the stages that will allow to reach this zero-emission objective. To this end, the formulas indicated by the International Energy Agency will be established where it is possible to determine the cost of this stage and, in this way, determine the optimal CCS cluster.

The calculated cost includes those related to the existence of possible pumping stations, whose costs are added to the costs per km of pipeline. The installation of these pumping stations is justified by comparing the costs of their installation against the existence of longer pipes and consequently larger in diameter and greater thickness.

CO2-pipeline investment

Diameter of the CO2-pipeline

The investment costs related to pumping stations, to recompress CO2 during long-distance transport, is independent of its flow. The costs of these pumping stations are, therefore, considered constant and estimated at 7 M€/200 km for onshore compress station.

Compression Station Investment

The energy consumption for the intermediate compression station is calculated considering an average pressure difference for each station of ΔP = 4 MPa, a density of carbon dioxide of 800 kg/m3 and a pump efficiency of 75%. The energy consumed by the station is 6.7 kJ/kg (1.9 kWh/t CO2) for every 200 km of pipeline.

Energy Consumption

The annual costs will be the sum of the annualized investment costs and the operating expenses, and others can be determined by the Eq. 6.

Annual Cost, CO2-pipeline

In this last step, transport costs (expressed in €/t CO2) are calculated by dividing the annual costs by the total volume of carbon dioxide transported, according to the following equation:

Cost of CO2 transport

3.4 EU Emissions Market

The European Union Emissions Trading Scheme creates an incentive or economic disincentive that pursues an environmental benefit that several industrial sectors, defined by Directive 2003/87/EC [22] collectively, reduce CO2 emissions. The price of emission rights is closely linked to the environmental and economic policies that produce changes in energy consumption. At present, the quotation of the emission right is in clear growth (Fig. 4) after 5 years of stability (2012–2017). It seems clear that the reform agreed by the European Union in the framework of reducing emissions, which seeks to reduce the emission rights existing in this market as of 2019, has caused the cost of the tonne of CO2 to have increased [22].

The forecasts made here indicate that during the year 2019, the reference price of €30/t CO2 will be reached. However, in the present study, and in order to develop the cluster zero emissions, quote scenarios of 30, 50 and 100 €/t CO2 will be considered.

4 Results: Cluster Definition

4.1 Economic Analysis

For this study, two variables are considered: volume of emissions and distance source emitter-warehouse. In this case, the differentiation between sectors—all those considered by Directive 2003/87/EC [22]—is not considered, since according to the European Directive 2009/31/EC [18] access to third parties must be guaranteed. Together with the first study in Llamas et al. [4, 10], it is considered the most favourable centralized transport compared to point-to-point transportation.

In this case, four scenarios are considered:

-

1.

Transportation and conduction of CO2 produced by all the industries considered in the project.

-

2.

Transportation and conduction of CO2 produced by the industries belonging to the centralized networks that carry the greatest volume.

-

3.

Transportation of the CO2 generated by the most relevant facilities in the region (more than 400,000 t CO2/year).

-

4.

Transport of the CO2 produced by the power generation plants and the cement plants of the same centralized network.

A geographical information system (GIS) has been built that allows analysing and defining up to five different nodes within the cluster under study, defined by the compression points, which are defined by Table 2.

The cost associated to CO2 transport phase is shown in Table 3. It is possible to differentiate each emitter in a specific node.

4.2 Environmental Analysis

CCS activities have the potential to affect the environment. Although each project must be analysed in detail to identify the potential environmental impacts, a brief description of this potential impacts associated with transport will be done. Transport of CO2 through pipelines would probably be the main way of transport [23].

Leakages could occur through pipeline corrosion, physical external impacts (i.e. through agricultural practices) or through inadequate sealant materials. Small leakages could be unnoticed and could pose environmental problems to soil, water and flora through acidification.

Surficial water quality could be affected in the preoperational phase due to discharges during the pipelines testing, causing the surficial water acidification. The groundwater hydrogeology could be affected through the construction of the pipelines if groundwater is shallow. Moreover, the groundwater could get acidified due to an uncontrolled emission of CO2 during transport, which could let to the lixiviation of metals of the surroundings. The abnormal liberation could also reduce the pH of soils, resulting in oxygen-depleted soils and in the mobilization of heavy metals. This would reduce the soil quality and could result in toxic conditions for flora.

CO2 emissions during the operation of the pipeline could let to the deposition of impurities of the CO2 stream in the surrounding environment and could cause a reduction in the quality of the air, being worse in calm weather conditions. Local air quality changes may have implications for human beings, flora and fauna. Any significant release of CO2 has the potential of accumulate in the surface, posing a risk for humans in the affected area.

Due to these potential impacts, a careful selection of the place, design and route of CO2 transport must be done. The construction phase is important to detect the possible ways of leakage. The pipeline route selection has to avoid high population densities and sensible places.

To reduce the risks associated with CO2 pipelines leakages, a management/security plan must be implemented to set out the operational requirements, and the inspection, supervision, and emergency protocols. Pipelines should be monitored by internal inspection, external corrosion checks and leak detection (where possible) and regular foot and air patrols. The early detection of a leakage should initiate a planned reparation to stop the leakage and repair the damage.

5 Conclusions

According to the work presented here, progress is being made in defining a local development model to address the reduction of CO2 emissions in the industrial sector.

In this case, the existence of a potential geological storage of CO2 offers the possibility of studying the possible development of the cluster, understood as a region with low industrial CO2 emissions. The different nodes that make up the cluster are defined as that group of industries located in a local area.

In this case, the viability of addressing the development of nodes with large emissions in the region is studied, discarding those nodes that have little representation in the volume of CO2 emissions (below 10% of the total emissions of the emission sources). Considering those emissions and industries, it might be possible to apply other technologies for CO2 use, thus avoiding the transport of CO2 to the emitting source.

The feasibility of studying each cluster in a particular way has been demonstrated, proposing solutions based on its characteristics. Again, CO2 transport and storage technology are considered as the most attractive solution in the reduction of CO2 emissions in large stationary sources.

According to the present work, the geological structure (with a theoretical capacity of 100 Mt CO2) which could be considered in the north of Spain, might generated a business case of up to 3000 × 106 € (considering 30 €/t CO2 of the cost of the CO2 European Emission Allowance). This economic model should attract new industries and emitters, considering a free CO2 emissions area, thanks to the CO2 geological storage considered in the present work.

References

Koytsoumpa EI, Bergins C, Kakaras E (2018) The CO2 economy: review of CO2 capture and reuse technologies. J Supercrit Fluids 132:3–16

IPCC (2005) In: Metz B, Davidson O, de Coninck H, Loos M, Meyer L (eds) Carbon dioxide capture and storage. Cambridge University Press, United Kingdom, pp 431

European Parliament: Directive 2003/87/CE establishing a scheme for greenhouse gas emission allowance trading within the Community and amending Council Directive 96/61/EC. Brussels, 2003

Llamas B, Hernández A, Mazadiego LF (2016a) Economic modeling of the CO2 transportation phase and its application to the Duero Basin, Spain. Greenhouse Gas Sci Technol 00:1–14. https://doi.org/10.1002/ghg

Rubin ES, Davison JE, Herzog HJ (2015) The cost of CO2 capture and storage. Int J Greenhouse Control 40:378–400

Kanniche M, Gros-Bonnivard R, Jaud P et al (2010) Pre-combustion, post-combustion and oxy-combustion in thermal power plant for CO2 capture. Appl Therm Eng 30:53–62. https://doi.org/10.1016/J.APPLTHERMALENG.2009.05.005

Scholes CA, Smith KH, Kentish SE, Stevens GW (2010) CO2 capture from pre-combustion processes—strategies for membrane gas separation. Int J Greenhouse Gas Control 4:739–755. https://doi.org/10.1016/J.IJGGC.2010.04.001

Hu Y, Yan J (2012) Characterization of flue gas in oxy-coal combustion processes for CO2 capture. Appl Energy 90:113–121. https://doi.org/10.1016/j.apenergy.2011.03.005

Kohl AL, Nielsen R (1997) Alkanolamines for hydrogen sulfide and carbon dioxide removal in gas purification, 5th edn. Gulf Publishing Company, Houston, pp 40–186

Llamas B, Navarrete B, Vega F, Rodríguez E, Mazadiego LF, Cámara Á, Otero P (2016b) Greenhouse gas emissions – carbon capture, storage and utilisation. Intechopen, Croatia, pp 81–114

Onyebuchi VE, Kolios A, Hanak DP, Biliyok C, Manovic V (2018) A systematic review of key challenges of CO2 transport via pipelines. Renew Sustain Energy Rev 81:2563–2583

Jensen MD, Schlasner SM, Sorensen JA, Hamling JA (2014) Operational flexibility of CO2 transport and storage. Energy Procedia 63:2715–2722

Johnson JW, Nitao JJ, Knauss KG (2004) Reactive transport modelling of CO2 storage in saline aquifers to elucidate fundamental processes, trapping mechanisms and sequestration partitioning. Geol Soc Lond Spec Publ 233(1):107–128

Benson SM (2005) In: Thomas DC, Benson SM (eds) Overview of geologic storage of CO2 in carbon dioxide capture for storage in deep geologic formations, vol 2. Elsevier

Bocin-Dumitriu A, Perez M, Sveen T, Bocin-Dumitriu A (2013) Carbon capture and utilisation workshop: background and proceedings

Carbon Sequestration Leadership Forum: TECHNICAL GROUP Phase I Final Report by the CSLF Task Force on CO2 Utilization Options Background, 2012

Cuéllar-Franca RM, Azapagic A (2015) Carbon capture, storage and utilisation technologies: a critical analysis and comparison of their life cycle environmental impacts. J CO2 Util 9:82–102. https://doi.org/10.1016/j.jcou.2014.12.001

European Parliament: Directive 2009/31/EC on the geological storage of carbon dioxide and amending Council Directive 85/337/EEC, European Parliament and Council Directives 2000/60/EC, 2001/80/EC, 2004/35/EC, 2006/12/EC, 2008/1/EC and Regulation (EC) No 1013/2006. Brussels, 2009

Llamas B, Cienfuegos P (2012) Multicriteria decision methodology to select suitable areas for storing CO2. Energy Environ 23:2–3

Instituto Geológico y Minero de España. http://info.igme.es/geologiasubsuelo/AlmacenamientoCO2/Algeco2.aspx. Access on 20th Apr 2019

Llamas B, Camara A (2014) Application of multicriteria algorithm to select suitable areas for storing CO2: CO2SiteAssess software. Energy Procedia 63:4977–4986

European Parliament: Directive 2018/410 amending Directive 2003/87/EC to enhance cost-effective emission reductions and low-carbon investments, and Decision (EU) 2015/1814. Brussels, 2018

Environment Agency Scoping guidelines on the Environmental Impact Assessment (EIA) of projects: scoping the environmental impacts of windfarms (on-shore and off-shore)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Llamas, B., Ortega, M.F., García, M.J., Mora, P. (2020). Carbon Storage and Utilization as a Local Response to Use Fossil Fuels in a Sustainable Manner. In: Stagner, J., Ting, DK. (eds) Sustaining Resources for Tomorrow. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-030-27676-8_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-27676-8_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-27675-1

Online ISBN: 978-3-030-27676-8

eBook Packages: EnergyEnergy (R0)