Abstract

Fossil-based energy conversion and energy-intensive industries are sources of a large part of global CO2 emissions. Carbon capture and storage (CCS) technologies are regarded as important technical options to reduce worldwide CO2 emissions. However, the discussion on the potential of CCS is highly controversial concerning four perspectives: technology development, economic competitiveness, environmental and safety impacts, and social acceptance. The following chapters focus on these aspects and analyze the potential and the possible role of CCS technologies. The study is based on methods of Integrated Technology Assessment. When regional considerations are important for evaluation, e.g. in case of social acceptance, the focus is on the German perspective.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1.1 CCS as an Option for Climate Change Mitigation and CO2 for Industrial Application

In order to limit the anthropogenic increase in the average global temperature by 2100 to 2 °C, the concentration of CO2 in the atmosphere must be restricted to 450 ppmv according to the Intergovernmental Panel on Climate Change (IPCC). To achieve this target, global CO2 emissions must be cut by 50 % by 2050 compared to levels in 1990. However, global energy consumption is growing year by year and the use of fossil energy carriers is not only continuing, but coal in particular is becoming even more important as an energy carrier globally.

In their analyses on stabilizing global CO2 emissions, Pacala and Socolow identified strategies (‘wedges’) to help reduce future CO2 emissions (Pacala and Socolow 2004). A ‘wedge’ is a strategy or measure to reduce CO2 emissions, which are forecast to increase in 50 years to 3.67 billion tonnes of CO2 (GtCO2) per year (= 1 GtC/a). Over 50 years, this represents a cumulative total of approx. 92 GtCO2 (25 GtC). These wedges include energy efficiency, a fuel shift, nuclear energy, wind energy, solar energy, bioenergy, and natural CO2 sinks, as well as carbon capture and storage (CCS) (Fig. 1.1).

Numerous analyses of and projections for the global energy system also emphasize the importance of CCS in strategies for reducing greenhouse gases, e.g. the Stern Report and the World Energy Outlook (IEA 2009b, 2010, 2011; Stern 2006). The IEA projects an increase in CO2 emissions in a business-as-usual scenario from 29 GtCO2 per year today to some 62 GtCO2 per year by 2050 (IEA 2008). This would be accompanied by an increase in the concentration of CO2 in the atmosphere to approx. 550 ppmv, and by a mean temperature rise of 3–4 °C. The IEA proposes two scenarios for reducing these emissions, both of which cover the period up to 2050. In the ACT Map scenario, a clear reduction in CO2 is achieved, saving some 35 GtCO2 per year by 2050 compared to the business-as-usual scenario. This would mean maintaining today’s levels of CO2 emissions in 2050, which would be equivalent to a CO2 concentration of around 485 ppmv. The BLUE Map scenario goes even further, cutting CO2 emissions in 2050 by 48 GtCO2 per year, representing a reduction of 77 % compared to the business-as-usual scenario. This would be equivalent to a CO2 concentration of around 445 ppmv in 2050.

In both cases, power generation would make the highest contribution of any sector and CCS would lead to the biggest reductions of any individual measure. CCS would reduce CO2 emissions in the power sector by approx. 21 % in the ACT Map scenario and by approx. 26 % in the BLUE Map scenario. The results highlight the importance of CCS technology in the global context and show how attractive CCS is if stringent greenhouse gas reduction targets are to be achieved.

Worldwide, industrial processes are responsible for almost 30 % of CO2 emissions (IEA 2009a), whereby some of these emissions are process-induced. CCS can therefore also help to reduce CO2 emissions in industrial sectors (Gale 2012). The most pertinent sectors are the cement industry, the iron and steel industry, and the production of other metals, as well as industries that process crude oil.

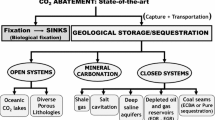

In contrast, the current usage of CO2 as an industrial gas amounts to approx. 20 Mt/a and as a chemical raw material around 110 Mt/a (Peters et al. 2011). The options for utilizing CO2 in the future would mean that these two areas could contribute to a welcome, albeit limited, direct reduction in carbon dioxide emissions. The interest in utilizing carbon dioxide (CCU) stems primarily from the fact that CO2 is a potentially recyclable material with an interesting application profile and great potential for the chemical industry. Carbon utilization would also positively affect the evaluation of strategies aiming to reduce CO2 emissions if product-related CO2 balances show a reduction in the emission of CO2. In this way, the greenhouse gas carbon dioxide can be transformed on a limited scale into a raw material for the material value chain (Ausfelder and Bazzanella 2008) (see schematic in Fig. 1.2).

Schematic of carbon capture and storage as well as the utilization of CO2 as a raw material for manufacturing (Source: Kuckshinrichs et al. 2010)

1.2 Methodological Approach of an Integrated Technology Assessment for CCS and Structure of the Study

The objective of a technology evaluation is to determine the importance of a technology in relation to a set of criteria. The set of criteria selected here is rooted in the regulatory framework governing the concept of sustainable development, which has led to the need for the transformation of the energy sector in favour of sustainable technologies and systems. The principle involves investigating the development of energy technologies (and energy systems) in terms of their technical, economic, ecological, and social impacts, and thus evaluating what contribution technologies can make to the transformation of energy systems.

The range of methods for technology evaluations is very broad. They include technologically oriented methods (e.g. risk assessments), economically oriented methods (e.g. cost analyses), politically oriented methods (e.g. voting procedures), systematic considerations (e.g. cost-benefit analyses), and methods based on systems theory (e.g. scenario techniques) (Renn 2010). IEK-STE pursues a systems analysis approach here, which focuses on the interdependencies between technologies and their associated fields in the economy and in society, and is mainly based on quantitative modelling (Fig. 1.3).

This volume is a compilation of separate chapters written by a range of experts on the technological, economic, ecological and social aspects of CCS technologies. This structure allows specific aspects to be reviewed more closely on the basis of differentiated methodological approaches used to analyse possible technical applications and prerequisites for application, as well as development potential, economic and social perspectives on applications in the energy sector and in industry, and also energy- and climate-policy aspects from a German and a European point of view.

1.2.1 Technical Potential, R&D Work, and Degree of Technical Maturity

Some of the technologies are characterized by a very different degree of maturity and only a few are already in commercial use. Notably, carbon capture in power plants has not yet been implemented on a commercial scale, and strategies for a broader utilization of CO2 are still in their infancy. While some technologies are already in commercial use (e.g. enhanced oil recovery (EOR), production of urea and methanol), others are only being prepared for demonstration or are at the pilot stage (e.g. oxyfuel, production of aliphatic polycarbonates). Others again are at a very early stage of technical development (laboratory scale) or are only at the initial design phase (e.g. CO2 membranes, artificial photosynthesis) (Fig. 1.4) (Markewitz et al. 2012).

Schematic of innovation stages for technologies for the capture, transportation, storage and utilization of CO2 (Source: Adapted from McKinsey 2008)

The chapters in Part I of the study are dedicated to the technological state of the art and conceivable R&D approaches along the CCS and CCU process chain. Markewitz and Bongartz (Chap. 2) analyse the major development lines of first-generation carbon capture in power plants (post-combustion, pre-combustion, oxyfuel) as well as energy-intensive and carbon-intensive industries. They also take a look at second-generation technologies such as membranes. For carbon capture systems, the most important considerations include possible improvements in efficiency, the influence of the purity of CO2, the flexibility of system operation, and the retrofitting of coal-fired power plants. Bongartz et al. (Chap. 3) focus on the transportation of CO2 and address safety issues as well as the purity of the CO2 stream. Müller et al. (Chap. 4) take a look at the options and concepts for utilizing CO2. In addition to organic-chemical usage as well as inorganic and material use, priority is given to product-related evaluation criteria such as CO2 fixation (amount and duration), technical implementation, and total CO2 balance. Schreiber et al. (Chap. 5) analyse the environmental impacts of the use of CCS technologies. Using a life cycle assessment, they create CCS process chains including upstream and downstream processes, and analyse them in their environmental impact categories. To conclude, Kühn et al. (Chap. 6) discuss safety issues and risks associated with the geological storage of CO2. Here, the focus is on the underground retention of the compressed CO2 stream and possible negative impacts on groundwater resources using the example of the Ketzin test site for carbon dioxide storage.

1.2.2 Application in Science and Industry

The use of CCS on a large scale in the energy sector and in industry can only be described within the framework of climate protection strategies. The additional costs for the implementation of CCS compared to the conventional conversion of fossil fuels into electricity are reflected in the internalization of CO2 costs. CCS systems are characterized by high capital expenditure and long-term capital tie-up, which means that each investment decision must account for the long-term profit potential. The implications of climate, energy and technology policy decisions must be taken into consideration here, together with the development prospects of competing technologies, and the way in which society views energy and climate-friendly technologies in general and CCS in particular (ETP ZEP 2011; Global CCS Institute 2011; IEA 2007, 2010; IPCC 2005; McKinsey 2008). Social acceptance is considered an important prerequisite for testing and implementing CCS.

The chapters in Part II concentrate on the economic and social perspectives of the use of CCS in the energy sector, and in energy-intensive and CO2-intensive industries. Kuckshinrichs and Vögele (Chap. 7) discuss the use of CCS in the energy sector and analyse the costs associated with electricity generation and CO2 mitigation on the basis of technology-specific cost and process parameters. In addition, a merit-order approach is used to illustrate possible implications of CCS facilities for electricity prices and quantities of electricity, as well as the ensuing options for refinancing CCS investments. Fleer and Kuckshinrichs (Chap. 8) outline the costs of CCS application in energy- and CO2-intensive industries using reference plants. Geske (Chap. 9) analyses the system characteristics of CCS infrastructures, and shows that the infrastructure cost function depends on the ratio of fixed to variable costs, as well as on the spatial distribution of CO2 sources and storage facilities. With an energy system model, Martinsen et al. (Chap. 10) analyse cross-sector carbon mitigation strategies and their impacts on the energy and CO2 balance. In this context, they estimate the system value should other technology lines be implemented instead of CCS. Using an acceptance analysis, Schumann (Chap. 11) discusses the awareness and knowledge of CCS, as well as spontaneous attitudes towards it, and how the risks and benefits of CCS are perceived in Germany. In addition, she looks at the factors that influence spontaneous attitudes towards CCS among the German population.

1.2.3 Framework for Energy and Climate Policy

Energy and industrial strategies for the development and utilization of CCS are embedded in the energy, climate and technology policy guidelines of the European Union and Germany. This is where the EU framework for the implementation of CCS (European Parliament and the Council 2009) and instruments for funding investments in demonstration projects (Europäisches Parlament und Rat 2009) come into play. The basis for German energy and climate policy is the German federal government’s energy concept, which is rooted in the resolutions of 2010 and 2011 (Bundesregierung 2010, 2011), and rests upon the elements of CO2 reduction, renewable energies, energy efficiency, and the move away from nuclear energy. To implement the European CCS Directive in national legislation, Germany has introduced a CCS law.

The chapters in Part III concentrate on aspects of energy and climate policy from a European and German perspective. Fischer (Chap. 12) analyses the legislative process for CCS in Germany with reference to the federal system, the parties, and social organizations in Germany. This is characterized by contradictory policies and conflicts. Schenk and Hake (Chap. 13) examine CCS policy in the European Union, and review political measures and challenges promoting the demonstration and commercial use of CCS. This part of the study concludes with Hake and Schenk (Chap. 14) analysing important international cooperation in the area of CCS and the significance of international cooperation for the implementation of CCS in Germany.

1.3 Energy and Industrial Policy Implications from a German Perspective

In the preceding chapters, the focus was on individual technical, economic, ecological, and social aspects which are important for a technology evaluation of CCS. The final chapter by Kuckshinrichs and Markewitz (Chap. 15) summarizes the central arguments, and draws a conclusion regarding the potential role that could be played by carbon capture and utilization within the framework of a German transformation strategy. In addition, the findings regarding prospects in Germany are presented in the European and international context.

References

Ausfelder F, Bazzanella A (2008) Verwertung und Speicherung von CO2. Diskussionspapier der DECHEMA. DECHEMA, Frankfurt

Bundesregierung (2010) Energiekonzept für eine umweltschonende, zuverlässige und bezahlbare Energieversorgung, Berlin. http://www.bundesregierung.de/ContentArchiv/DE/Archiv17/_Anlagen/2012/02/energiekonzept-final.pdf?_blob=publicationFile&v=5

Bundesregierung (2011) Eckpunkte “Der Weg in die Energie der Zukunft”, Berlin, http://www.bundesregierung.de/Content/DE/Artikel/2011/06/2011-06-06-energiewende-kabinettsbeschluss-doorpage-energiekonzept.html

Carbon Mitigation Initiative (CMI) (2013) Stabilization wedges [Online]. Princeton University, http://cmi.princeton.edu/wedges. (2012)

CS Institute Global (2011) Economic assessment of carbon capture and storage technologies. 2011 update. Global CCS Institute, Canberra

ETP ZEP (2011) The costs of CO2 capture. http://www.zeroemissionsplatform.eu/library/publication/165-zep-cost-report-summary.html, 15 Aug 2012: European Technology Platform for Zero Emission Fossil Fuel Power Plants (ZEP)

Europäisches Parlament und Rat (2009) Verordnung über ein Programm zu Konjunkturbelebung durch eine finanzielle Unterstützung der Gemeinschaft zugunsten von Vorhaben im Energiebereich. Verordnung Nr. 663/2009, Brussels

European Parliament and the Council (2009) Directive on the geological storage of carbon dioxide. DIRECTIVE 2009/31/EC, Brussels

Gale J (2012) In: GHG I (ed) Challenges and opportunities of CO2 capture and storage for the iron and steel industry. IEA GHG, London

IEA (2007) Climate policy uncertainty and investment risk. International Energy Agency IEA/OECD, Paris

IEA (2008) Energy technology perspectives – scenarios & strategies to 2050. International Energy Agency IEA/OECD, Paris

IEA (2009a) Energy technology transitions for industry. International Energy Agency IEA/OECD, Paris

IEA (2009b) World energy outlook 2009. International Energy Agency OECD/IEA, Paris

IEA (2010) Energy technology perspectives – scenarios & strategies to 2050. OECD/IEA, Paris

IEA (2011) World energy outlook 2011. International Energy Agency OECD/IEA, Paris

IPCC (2005) Carbon dioxide capture and storage – special report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge

Kuckshinrichs W, Markewitz P, Linssen J, Zapp P, Peters M, Köhler B, Müller T, Leitner W (2010) Weltweite Innovationen bei der Entwicklung von CCS-Technologien und Möglichkeiten der Nutzung und des Recyclings von CO2. Schriften des Forschungszentrums Jülich, Reihe Energie & Umwelt/Energy & Environment 60. Forschungszentrum Jülich, Jülich

Markewitz P, Kuckshinrichs W, Leitner W, Linssen J, Zapp P, Bongartz R, Schreiber A, Müller T (2012) Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy Environ Sci 5:7281–7305

Mckinsey (2008) Carbon capture and storage: assessing the economics. www.mckinsey.com

Pacala S, Socolow R (2004) Stabilization wedges: solving the climate problem for the next 50 years with current technologies. Science 305:968–972

Peters M, Köhler B, Kuckshinrichs W, Leitner W, Markewitz P, Müller TE (2011) Chemical technologies for exploiting and recycling carbon dioxide into the value chain. ChemSusChem Special Issue Carbon Dioxide Recycling 4:1216–1240

Renn O (2010) Methoden und Verfahren der Technikfolgenabschätzung und der Technologiebewertung. Available: www.elib.uni-stuttgart.de/opus/volltexte/2010/5286/pdf/ren2.pdf

Stern N (2006) Stern review: the economics of climate change, London, http://webarchive.nationalarchives.gov.uk/+/http://www.hm-treasury.gov.uk/stern_review_report.htm. 21 June 2012

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Kuckshinrichs, W. (2015). Carbon Capture and Utilization as an Option for Climate Change Mitigation: Integrated Technology Assessment. In: Kuckshinrichs, W., Hake, JF. (eds) Carbon Capture, Storage and Use. Springer, Cham. https://doi.org/10.1007/978-3-319-11943-4_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-11943-4_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-11942-7

Online ISBN: 978-3-319-11943-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)