Abstract

Pollutants are released into the atmosphere due to production and consumption energy especially from fossil. However, not only the environmental concerns but also the increase in energy demand promotes the researchers to develop new and current energy alternatives that cause zero- or low-negative environmental impact. Anaerobic fermentation can be used for the treatment of organic wastes (OW) such as kitchen waste, municipal solid waste, industrial organic waste, animal manure, and agricultural residues. The fuel produced from anaerobic digestion is environmental friendly. Kitchen wastes (KWs) are easily biodegradable organic material with high moisture, carbohydrate, lipid, and protein. The use of KW only in anaerobic digestion reduces the activity of methanogenic bacteria as a result of rapid accumulation of volatile fatty acids followed by a pH drop in the reactor, thus, adjusting C/N by some additives to accelerate the growth of methanogens and methane formation is necessary. The favorable pH for methanogens’ growth range of 6.5 to 7.2. Furthermore, the key factors controlling the production of volatile fatty acids during fermentation for methanogenesis represented in pH, temperature, C/N ratio, and hydraulic retention time.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

The common use of fossil fuels in the present energy infrastructure is the main source of anthropogenic emissions of carbon dioxide (CO2), which is considered the largest reason for global warming and climate changing. Realizing solutions to the environmental problems that we meet today needs possible long-term solutions for sustainable development [10]. Increasing world energy demand and the incoming depletion of fossil fuels has increased concern in the development of renewable energy resources [17]. Renewable energy resources, such as solar, wind, geothermal, hydropower, and biofuels such as biogas, biodiesel, and bioethanol seem to be one of the most effective and effectual solutions. [10].

The amount of global waste production has increased in the past decade from 0.68 billion tons to 1.3 billion tons, and it is expected to be 2.2 billion tons by 2025. In addition to the increase in population, changes in lifestyle, industrialization, rapid economic growth, and grown rate of urbanization in lots of developing countries are some other reasons for the increased production of waste [11].

The treatment of organic wastes (OW) which includes industrial organic wastes, municipal solid wastes, animal manure, in addition to agricultural wastes by anaerobic digestion (AD) can be utilized as vehicle fuel or as co-generator of electricity and heat, and accordingly, can reduce greenhouse gas emissions (GHGs) [30].

Kitchen waste (KW), as organic waste, is an easily biodegradable organic matter with high-moisture, protein, carbohydrate, lipid contents. However, the major restraint of AD of KW alone is the rapid collection of volatile fatty acids then the pH drop in the reactor, which hinders methanogenic bacteria [7, 28]. To avoid such inhibition, using waste activated sludge to adjust C/N [5], and employing two-stage or three-stage systems [26] is very helpful.

7.2 Biogas Definition

Biogas, a mixture consisted mainly of methane (CH4) and CO2, is a renewable and cleaner type of energy that could partially offset the conventional petroleum-based energy sources. (i.e., oil, natural gas, and coal). Furthermore, it is not only alternative source energy but also an appropriate solution to environmental issues as well it is depleting faster [10, 32, 42]. Biogas production by the AD is gaining significant attention as an advanced sustainable energy technology [2]. Attention in biogas production has changed during the time from a source of energy production to a mean of waste management, nutrients delivery, and GHGs reduction and currently back to energy production through new perspective toward centralized plants [39]. Globally, much knowledge is currently available for the large-scale management of biogas production in controlled reactors. However, under conditions in developing countries, our knowledge is relatively low because of few studies of biogas production [33].

7.3 Advantages of Biogas Production

Globally, the consumption of renewable energy is growing. Concerns of energy security, efforts of mitigating the environmental impacts of conventional fuels, and improvements of the standards in living and renewable technologies are the components of sustainable energy usage. Therefore, bioenergy is known as a potential source, which can lead to a key role in indorsing renewable alternatives [44]. In the prospect of sustainable development, the role of biogas is becoming crucial. Indeed, recently, the worldwide bioenergy demand is greatly rising, and the anticipating indicates an additional rise to 2035, due to increasing the support strategies, by several governments over the world for reducing air pollution [29].

The usage of modern bioenergy has many benefits such as enhanced health and sanitation, creating job opportunities, replacing chemical fertilizers with organic fertilizer and reducing GHGs. Biogas production is a sustainable source of both energy and organic fertilizer (the bio-slurry) enriches the soil. As well, it provides a good opportunity to treat and re-utilize OW and reduces land-use problems related to the disposal of OW [38]. Furthermore, biogas production reduces GHGs emissions by substituting fossil fuels and diesel. It is usually produced from AD of several digestible organic substrates like domestic wastes and resources, or from landfills to produce renewable energy accompanied by reducing environmental risks from waste products in households, agriculture, and industry [9, 12, 16, 39, 46].

As well, the collection of biogas can be utilized for generating on-site thermal energy and electricity [9]. Chen et al. [8] reported that biogas is one of the most highly greatly opportunities to utilize particular types of biomass to satisfy some of the world’s energy demands. Biogas refers to a mixture of gases generated by the biological degradation of OM in the absence of oxygen, where CH4, H2, and CO can be combusted or oxidized with oxygen. The energy output/input can record about 28.8 MJ/MJ under ideal conditions, providing very proficient usage of the valuable biomass. This resulting energy allows biogas using as a biofuel for replacing conventional fossil energy sources, such as coal, oil, natural gas, in power and heat production, as well as a versatile renewable energy source, especially to low-price fuel vehicles compared to diesel and petrol. As well, Matheri et al. [27] illustrated that in combustion, CH4 is transferred into bioenergy not released to the surrounding environments.

Nevertheless, a small amount of CO2 is released, but not affects the atmosphere compared to released CH4 and nitrous oxide N2O to the atmosphere. The presence of CH4 and N2O in the atmosphere has a great impact because of their greater ability to trap energy comparing to CO2. Biogas also can contribute to a transition for a more circular and bio-based economy by supplying biomaterials and bioenergy [12]. Generally, widespread installation and appropriate functioning of biogas production systems can offer several advantages to users and the larger community. Of these advantages, energy sustainability, resource conservation, and environmental protection can be considered [8, 27].

Furthermore, the long-term utilization of reducing fossil fuels has reflected the unsustainability owing to their limited reservoirs and non-renewable nature. Subsequently, biogas derived from different biological sources can decline the heavy dependency on such depleting natural resources and give the attention to the energy insecurity concerns because of its renewable, broadly applicable, and plentiful characteristics. On the other hand, the valorization of the produced biogas is the energy efficiency (a typical electrical efficiency value is 33% while thermal efficiency value is 45%) and environmentally friendship due to the low emissions of hazardous pollutants, such as volatile organic compounds [8].

In brief, biogas is a gas produced through the AD and is primarily a mixture of CH4 and CO2 and smaller amounts of different substances. These substrates and types of production result in several compositions of the biogas. Finally, the raw biogas can be utilized as it is for generating electricity and heat, or purified into 97% methane and be used in the transporting sector [12]. However, recently, bioenergy and biogas production have faced increasing criticism, such as the effects on food prices and hence food security [13].

7.4 Appropriate Wastes for Biogas Production

Various low-cost materials such as sewage sludge, municipal wastes, food wastes, animal manure, and waste animal cadavers can be reacted for biogas production [16]. Ideally, biogas can be generated from the organic fraction of some material, such as crop residue, fruit waste, wood, industrial food waste, chicken feathers, textile wool, and lignocellulosic waste. Though, today, biogas is usually produced only from the easily utilizable feedstock by the microbial community responsible for converting this feedstock into biogas. Nevertheless, if this easily digestible feedstock (i.e., crop and livestock residues, wastewater with high-organic content, food waste, source sorted municipal waste, etc.) is not as plentiful or readily available for biogas production, the amount of produced biogas will be limited [31].

As mentioned before, biogas can be produced from KW, which is a simply biodegradable organic matter (OM) with high-moisture, protein, carbohydrate, lipid contents. The major limitation of AD of KW alone is the inhabitation of methanogenic bacteria due to rapid collection of volatile fatty acids after a pH drop in the reactor [7, 28]. Therefore, some material can be added to avoid this accumulation of volatile acid such as rice straw or animal manure [41]. Thus, the development of novel technologies that aim to utilize the readily available but not easily degradable feedstocks would develop the biogas production [31].

The major reasons for not perfecting some feedstocks for biogas production are representing in: (1) the inability or difficulty of digestion by microorganisms, (2) slow digestion, and (3) inhibitors present in the feedstock or producing inhibitory compounds through microbial degradation. For these reasons, the goal of the pretreatment (physical, chemical, physicochemical, and biological) is facilitating the digestion by eliminating these obstacles and making the organic content of the reacted material easily available and utilizable by the microbial communities [31].

7.5 Mechanism of Biogas Production

Biogas can be produced widely from solid or liquid wastes through the AD process. During the AD, several organic materials are degraded by microbial communities in anaerobic conditions, causing the production of energy-rich biogas used for many purposes such as vehicle fuel, electric power, or heat [10]. When the process is operated under the optimum conditions, the CH4:CO2 is around 60:40 [27]. Also, the plant nutrients in the digested organic material are reserved in a digestate, which can be applied as a plant fertilizer. In the AD, the rate-limiting time is hydrolysis. To improve hydrolysis and AD performance, pretreatment technique can be used as one possibility for that. Many pretreatment techniques can be applied (such as chemical, mechanical, thermal, or biological treatments). Many pretreatment techniques can be applied (such as chemical, mechanical, thermal, or biological treatments) to solubilize organic compounds and especially refractory compounds, and to make them more biodegradable. Furthermore, pretreatment can improve the OM reduction [10].

Biogas can be produced by AD using the locally presented residual biomass from different sources such as agricultural wastes, animal wastes, industrial wastewater, and domestic sewage). The AD of complex OM to biogas involves four main stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. A balanced process of CH4 fermentation needs individual degradation phases to be achieved by distinct consortia of bacteria, namely fermentative bacteria, syntrophic acetogens, homoacetogens, hydrogenetrophic methanogens, and aceticlastic methanogens. The symbiotic relation among those microorganisms leads to efficient AD and biogas production. The final stage, conducted by CH4 forming bacteria, is the most critical stage in biogas production because the methanogens transfer their primary substrates consisting of acetate, H2, and CO2 into CH4. There are two ways for CH4 production, in which about 75% of CH4 production arises from decarboxylation of acetate, and the other 25% come from CO2 and H2. As well, the CH4 production stage is the most sensitive and rate-limiting stage in the whole process since CH4-producing bacteria have a much slower growing speed compared to acid-producing bacteria and is sensitive to inhibitors like pH, temperature, ammonia, and other operative conditions. It is, therefore, necessary to maintain sufficient slow-growing methanogenic bacteria and protect active biomass from washing out from the fermenter and to decline inhibitory levels [8].

7.6 Biogas Digesters

Biogas is generated in an anaerobic digester operating in two way; mono-digestion or co-digestion. The last one favors high production of CH4 due to the availability of several vital trace elements provided by different substrates, while in mono-digestion, these essential trace elements are lacking [27]. Biogas digesters realized as a green technology for utilizing animal manure into bioenergy and reducing environmental pollution. Therefore, millions of simple biogas unheated digesters are established underground in many developing countries [33].

The digesters design is varied based on geographic locations, substrate availability, and climatic conditions. For example, a digester used in mountains is designed to contain less gas volume to avoid gas loss. Whereas in the tropicals, it is preferred to contain digesters underground because of the geothermal energy. Out of all the various developed digesters, the fixed dome model in China and the floating drum model in India have continued to operate till today. Recently, the attention is increased toward plug flow digesters due to its portability and easy performance [34].

7.7 Kitchen Wastes (KWs) in Biogas Production

Due to the rapid growth of urban people and variations in consumption patterns, a large amount of KW is yearly generated. Thus, KW has globally become a major issue, if no reasonable treatment is adopted. The amount of these waste generates many challenges (in terms of protecting the environment and public health) and represents a huge amount of utilizable biomass [14, 23, 24]; Zhang et al. [48, 49]. Approximately, 1.3 billion tons of KW is generated yearly over the world. This amount of KW is growing continuously [36, 37]. Li and Jin [22] also affirmed that a great environmental challenge resulted from producing great amount of KW, and several harmful environmental effects may result due to ineffective treatment and disposal; such as odor pollution, water pollution, and garbage accumulation.

Disposal or ineffective of KW management such as disposing of open dumps causes several adverse consequences such as the public health hazards in addition to diseases (such as malaria, cholera, and typhoid). Thus, it not only causes polluting surface and groundwater because of leaching and further promoting the breeding of mosquitoes, flies, rats, and further disease-bearing vectors. It also emits an undesired odor and methane (which is the main greenhouse gas causing global warming). Also, the techniques such as incineration and pyrolysis have many disadvantages such as it is expensive and less effective for generating energy from KW because it contains high-moisture content [4]. Therefore, there is an urgent need for selecting eco-friendly options for saving the environment and natural resources. Reddy et al. [35]. Due to the environmental impacts of improper treatment of these wastes, its management has become an environmental and social concern [36, 37]. Moreover, with the upcoming global warming, ever-increasing energy costs, as well increasing cost in crop straw disposing of, more attention should be paid to the effective biomass disposal, such as bioconversion into methane-rich biogas [25]. Consequently, converting biodegradable KW into biogas has many benefits:

-

Producing a renewable bioenergy from KW,

-

Reducing air pollution,

-

Finding eco-friendly methods for waste disposal,

-

Generating revenue and wealth from the waste, and

-

Reducing global warming [35].

For this purpose, the AD will be an economic and viable option [4]. The AD is a very promising technology for the effective management of OW such as KW [36, 37]. The high biodegradability of KW, in addition to its water content, makes it suitable for the AD with the associated advantage of biogas production. This is an appropriate solution for waste management because of its low cost, its low residual waste, and its usage as a renewable energy source. Furthermore, the resulting digestate can also be applied as a fertilizer or conditioner to the soil because it is nutrient-rich [23, 24]. Zhang et al. [48, 49] mentioned that AD, compared with any traditional landfill and burning, is a more attractive method for treating KW because it can produce biogas. In addition, the AD has a major advantage in reducing greenhouse gases emission since both methane and carbon dioxide produced in a closed reactor, which avoids its uncontrolled production and releases into the atmosphere.

7.8 Composition of Kitchen Wastes

The KW is comprised from organic rapidly biodegradable substances such as protein, carbohydrate, cellulose and lipids, and high-moisture content, which make it an attractive feedstock for operating an anaerobic digester [45]; Sahu et al. [18, 36, 37]. Wang et al. [43] confirmed that the high-organic compounds and moisture content of KW result in numerous harmful impacts such as water pollution, garbage accumulation, and odor pollution. Furthermore, high compositional variation in KW recorded in different parts of the world is a challenge to develop a robust technology for biogas production for the proper treatment and management of KW [36, 37]. Li et al. [23] added that KW has a high lipid content ranges from 2 to 3% (wet basis). This indicates that KW distinguished by a higher biochemical methane potential than other types of OW. Nevertheless, high lipid content has negative effects because of its low degradation rate, resulting in the increasing of intermediate products and weakens the stability and continuousness methane production. Li et al. [24] also reported that KW contents high amount of macromolecular organic matters in the KW (such as fat, oil, grease, and crude proteins) that estimated by 30–70% of the total content of dryly basis organic matter. This could easily result in rather longer started-up time when applying AD, as well, causing higher acidification and inhibition of nutrients transport, thus the undesired condition for sustaining and stabling degradation during the digestion process. Wang et al. [43] also added at present, intensively research on the AD of KW has been performed since the OM in KW is suitable for anaerobic microbial growth. Thus, AD of KW could be not only highly effective for degradation of OM but also be able to supply renewable biomass energy and organic fertilizer. Although, the high-volatile solids of KW cause the fast hydrolysis during the digestion bringing about a severe acidification due to a drastic drop in pH followed by serious inhibiting to the methanogenesis. Li et al. [24] characterized KW as in Table 7.1.

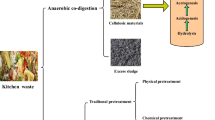

Sahu et al. [36] explained (in Fig. 7.1) that complex carbohydrates (i.e., starch and cellulose) are degraded. During hydrolysis and acidogenesis into sugars that are consequently converted to fatty acids. On the other hand, fats are converted to glycerol and fatty acids, while proteins are converted to amino acids that are converted by deamination process into fatty acids and ammonia/amines. Fatty acids are exhausted by acetogens to generate acetic acid, which is used by methanogens for methane production. The rapid breakdown of KW results in high-volatile fatty acids and ammonia production. The accumulation of both compounds affects adversely the process of the biomethanation process. Thus, as mention by [1], AD is a highly sophisticated process that includes four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. However, they mentioned that many reports revealed the advantages of separating the breaking down the process into two stages optimized each either for acidification or methane production. In the first one, biopolymers are broken down into monomers such as various volatile short-chain fatty acids, while in the second stage, generated acids are converted into CH4 and CO2.

Overview of biogas production from kitchen wastes [36]

7.9 Anaerobic Digestion for Biogas Production

The AD is the process of breaking down OM of wastes for producing biogas and biofertilizer, resulting in efficient resource recovery along with conserving non-renewable energy resources [36, 37]. Ye et al. [45] also reported that AD has become a recognized and established technology for the treating the organic wastes such as agricultural residues, animal manure, municipal solid waste, and industrial organic waste. Producing a vehicle fuel or co-generating of electricity and heat is the main benefit of this process, and thus reducing the greenhouse gas emissions.

Therefore, the AD, as one of the most credible commercial solutions for biogas production [47] and one of the biological treatments for organic wastes (OW), is getting growing attention because of its high valorization value for waste. AD of OW provides good opportunities for energy regeneration and nutrient reclamation which needless requirement of space and input energy for operating than composting, landfilling, and incineration [6]. However, the AD is a complex process for bioenergy production since the included biochemical and physical mechanisms are not yet obviously understood, which make bioreactor design, set-up and control not yet fully optimized [21]. Sahu et al. [36, 37] stated that KW is contained of organic substances such as protein, carbohydrate, cellulose, and fats (which are rapidly biodegraded and making it an attractive feedstock for running the AD). However, the AD plants meet difficulties in getting clean feedstock which leads to technical problems. Furthermore, there were found significant compositional variations in KW worldwide, posing a challenge to the developing production technology.

Furthermore, the AD is a very sensitive process including diverse microorganisms with ultimate functioning environmental conditions. As well, the type and structure of substrates influence the efficacy of biogas production. However, the AD is a suitable and effective technology for managing organic materials, as well it is expected to play a vital role in the forthcoming renewable energy production [15]. As well, Patinvoh et al. [31] emphasized also on that biogas production through AD technology has advanced greatly over time. Currently, due to high energy demand and environmental concerns because of increasing the world’s population, the drive for AD anaerobic digestion technology is receiving momentum within research and the industry for generating sustainable energy resources. They also added, although the previous advantages of the AD, many challenges such as high retention time, the existence of some toxic compounds (that can inhibit the process), low biogas product, and high investment cost obstruct the highest performance of biogas production in AD systems. These bottlenecks are highly reliant on the availability, composition, and degradability of the digested material for biogas production. However, the abundance of such low-cost materials (i.e., organic wastes) confirm that there is an urgent need for finding new approaches for better utilization of these wastes [31].

The organic reacted materials are mainly consisting of proteins, carbohydrates, and lipids which can be broken down into simple composites by microorganisms in an oxygen-free (anaerobic) environment with the subsequent process stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis [15]. As AD is a multistage microbial process, production rate and proficiency largely depend on some factors such as substrate temperature, pH level, hydraulic retention time (HRT), and substrate solid content. Temperature, as one of the most effective factors, controls the microbial growth rate and its activities inside the digester. Recently, mesophilic temperature regime (25–40 °C) is operated in most digesters for many reasons such as lower energy requirements and higher stability than thermophilic treatment (>45 °C) [47].

The microbial communities in an AD reactor contain three typical populations (i.e., fermentative bacteria, acetogenic bacteria, and methanogenic bacteria). Methanogenic bacteria is the most sensitive to environmental changes due to their slower growth than fermentative and acetogenic bacteria [25].

Energy conversion efficacy is the most critical issue for energy production. Both the AD biogas production and biogas upgrading depend on chemical scrubbing needs additional thermal energy in their stages. In an ideal AD biogas plant, about 10–15% of the generated energy is internally utilized for heating substrates. While, in other chemical scrubbing processes such as the amine-based process, the thermal production of CO2 rich solvent, for releasing captured CO2, uses a large amount of heat and concurrently with producing a large amount of waste heat that is generally not allowed in the cooling system [46].

7.10 Affecting Factors on Biogas Production

Biogas production is affected by the added amount of organic materials, the digester pH, toxic substances, and anaerobic condition C:N ratio. Additionally, biogas production is influenced by the characteristics and chemical composition of the primary organic materials which lead to significant effects on the efficiency of decomposition of the anaerobic organic materials and methane production. The ratio in the components of organic wastes varies based on seasons and regions, and the performance of the AD differs accordingly [19]. Stefaniuk et al. [40] reported that in the fermentation process, the use materials are in various proportions as well at various temperatures (i.e., mesophilic, thermophilic). Abendroth et al. [1] stated that high temperature from 200 to 300 is required for increasing the accessibility of lignocellulose. However, they also reported recent studies to suggest that low temperatures (such as 120 °C) or even 70 °C can already considerably increase degradability. Stable reactor functioning has been stated even for hyperthermophilic digestion circumstances up to at least 65 °C, however, at such temperatures, microorganisms require very long adaptation periods.

In addition, Wang et al. [43] reported that during the AD, volatile fatty acid determines pH which considers one of the most important factors affecting AD. The serious, volatile fatty acid inhibition on the methanogens activity results from a pH drop in reactors, which may cause the activity loss of acid-sensitive glycolytic enzymes. As well, high levels of undissociated acids will damage macromolecules. The fermentative bacteria pH ranges from 4.0 to 8.5 (they are not sensitive to changes in pH values), while a limiting range of 6.5–7.2 is desired for methanogens’ growth. Improving volatile fatty acid content and its suitable component are required for methanogenesis. Therefore, pH, temperature, C:N ratio and hydraulic retention period had been stated to be the essential factors controlling volatile fatty acid production during fermentation. Stable pH conditions around neutral were required for protecting the methanogens and its growth.

7.11 Pretreatment for Enhancing Anaerobic Digestion for Kitchen Wastes

Pretreatment is a key step to improve the substrate characteristics to increase the AD. For this target, several pretreatment options, such as microwave, ultrasonic, chemical thermal, electrical, and freeze/thaw techniques, can be performed. The effects of such pretreatments are highly different based on the characterization of the substrate and the pretreatment type [23]. Li et al. [24] added that previous researches have largely focused on optimizing the AD conditions of KW, (either single, double or three stages, continuous/sequencing-batch digestion, retention time and temperature and of digestion, mono- or co-digestion, etc.). As well they focused on the factors affecting inhibiting of the digestion process feedstock (i.e., C/N ratio, ammonia nitrogen, organic compositions, salt content, volatile fatty acid, long-chain fatty acid, organic loads, etc.). In addition, they paid attention to the pretreatment methods (e.g., biological, thermal, chemical and thermochemical, ultrasonic and microwave pretreatment) for enhancing organic reduction and methane production. Furthermore, the long retention period of the AD of KW is a major issue and several methods have been developed for pretreating KW before the AD process for accelerating the digestion process and enhancing the biomethane production [24]. Of the pretreatments, a thermal method is one of the most studied pretreatments and has been successfully used at the industrial scale. This pretreatment leads to the solubilization of organic compounds, reducing the exogenous pollution, and disinfection by sterilization, this favors the hydrolysis step, increases the production biogas, and reduces the retention period. Furthermore, it also enhances phase separation, which enhances the recovery rate of floating oil, which can be applied as the raw oil for producing biodiesel. In addition, its removal effectively alleviates the induced biological inhibitory reactions [23]. Abendroth et al. [1] mentioned that thermal pretreatment, that need high energy (temperatures as high as 200–300 °C), can successfully elevate the accessibility of lignocellulose.

As well, Zhao and Ruan [50] stated that KW is not very effective and stable because of accumulating the volatile fatty acids. Thus, co-digestion of KW with organic wastes, such as agricultural straw, municipal sludge, and animal manure become more popular. Zhao and Ruan [50] also mentioned that co-digestion of Taihu algae and KW could balance the nutrients fermentation during the digestion process. Ye et al. [45] also states that great efforts have been spent to avoid volatile compounds accumulation to ensure the efficiency of AD of KW; such as co-digestion with dairy manure, applying waste activated sludge for adjusting C/N, using trace metals to accelerate the methanogens growth and methane formation and utilizing two- or three-stage systems. Zhang et al. [48] stated that recently, KW had become a critical problem because of its environmental pollution. Afterward, the AD process, the resultant digested effluent from KW can still severely pollute the environment due to its high pollutants’ concentration, mainly ammonium and phosphate. However, this effluent can be utilized in something such as applying to microalgae cultivation, which can not only reduce the pollutants’ concentration but also can effectively utilize the nutrients for biodiesel production. Additionally, cultivating microalgae in this effluent would also reduce the cultivation cost.

The KW contains easily convertible carbohydrates, (such as starchy compounds), and highly recalcitrant components (such as lignocelluloses. Lignocellulosic materials which mainly consist of carbohydrates (including cellulose and hemicellulose), lignin, and extraneous materials. Therefore, pretreatment process is very necessary for efficient bioconversion of these components. In this context, using diluted sulfuric acid is one of the most efficient pretreatments (Fig. 7.2) which widely applied in this purpose [18].

Biogas and ethanol production from kitchen wastes after pretreatment by diluted acid [18]

Recently, few studies have examined the co-digestion of black water (i.e., urine and faecal matter) and KW in the anaerobic system. As well, to avoid the issues raised over accumulation of ammonia, the addition of brown water (i.e., faecal matter without urine) to KW before the AD was also studied. Brown water can improve the stability of the AD process by maintaining the buffer capacity and providing additional nutrients. The advantages of co-digesting brown water and KW were elevating biogas production in addition to the remarkable biodegradation efficiencies after adding brown water as a co-substrate to the anaerobic breakdown of KW. This is likely because of the adequate buffering capacity provided by brown water to KW digestion. Subsequently, methane production by anaerobic co-digestion of KW and brown water not only provides a greener and cheaper alternative to disposal, but may also help to reduce the using of fossil-fuel-derived energy and, thus, the negative impacts on global warming [20].

7.12 Digestate and Plant Nutrition

Digestate is the residual product of the AD process and contains a lot of essential nutrients for plant growth. Thus, it can be applied as biofertilizer [12]. Such fertilizer is rich in nutrients and organic matter. It also integrates the characteristics of slow and quick acting fertilizers. These fertilizers are distinguished by consuming low net energy compared to chemical fertilizers, and consequently, this biofertilizer produces more CO2 to the atmosphere [38]. Stefaniuk et al. [40] also state that there is another product of anaerobic fermentation apart from biogas, this product fermentation is the post-fermentation digestate (RBP), this digestate is often separated into two phases (i.e., liquid and solid). RBP can be composted, or landfilled, but it is mostly used as an agricultural fertilizer. Nevertheless, the studies show some disadvantages of the direct application of RBP to soils which makes it limited to soil application. These disadvantages are represented in the probability to contain some harmful things such as heavy metals, seeds of weeds or infrequent parasites and polycyclic aromatic hydrocarbons in addition to the high mobility of its nutrients which causes leaching of the nutrients from the soils to groundwater and increases the eutrophication of water.

7.13 Proposed Roadmap for Egypt

In Egypt either in rural or urban areas, tons of KW are produced yearly. According to the ministry of environment in Egypt, there are thousands of tons from collected yearly from garbage (Table 7.2). These wastes present a challenge in terms of eliminating and disposing of them. However, as mentioned above, these wastes are a potential source of wealth. Thus, each household (or group of households) can benefit from this potential source in generating biogas, especially with raising the energy costs. Installing biogas units will be more effective and mostly more beneficial in case of utilizing the kitchen wastes from group of households as well animal manure for more AD efficiency. According to Amigun and von Blottnitz [3], there are several small/medium biogas digesters (>100 m3) in Egypt and few large ones (≤100m3) with a high technology level.

In a primary experiment for unpublished work for the authors of this chapter, kitchen wastes 6 kg of kitchen wastes +1.5 kg cow manure +30 L water was mixed in a large plastic tank connected by tire frame (as a storage for produced biogas) such as presented in Fig. 7.3. This means that the percentage of KW to animal manure was 4:1. After 20 days, remarkable amount of gas was noticed (the tire frame became swollen). This is affirmed the above-mentioned statement that animal manure is working as an activator for the anaerobic digestion of KW to improve biogas production in addition to utilizing digestate as a fertilizer. Therefore, it is very important to enhance the methods of biogas production from KW, especially these wastes equal to approximately 30% of all household wastes yearly.

Biogas digester diagram (WWW.PAKSC.ORG)

7.14 Conclusions

Kitchen wastes are increased day by day because of increasing world population. This will pose many impacts on the environment in case of an appropriate disposing burning, or wasting potential resources. Biogas production from kitchen wastes will solve many of such environmental problems, especially with elevating the energy price in all over the world. Anaerobic digestion after some pretreatments will be very effective method in utilizing these easy digestible wastes and generation biogas. It is supposed that this method will help many households either rural or urban ones not only to benefit from KW as a potential source of wealth and saving many in purchasing energy, but also to contribute in solving environmental problems from accumulating wastes. Thus, this method is promising in biogas production.

7.15 Recommendations

The authors highlight the following recommendations:

-

1.

Investigating new methods and pretreatments to minimize the problems of utilize kitchen wastes in biogas production for households and improve the biogas generation from such valuable wastes, and

-

2.

Supporting the decision makers and governments to the households for installing biogas units with low cost.

References

Abendroth C, Hahnke S, Simeonov C, Klocke M, Casani-Miravalls S, Ramm P, Bürger C, Luschnig O, Porcar M (2017) Microbial communities involved in biogas production exhibit high resilience to heat shocks. Bioresource Technology. https://doi.org/10.1016/j.biortech.2017.10.093

Afridi ZUR, Wu J, Cao ZP, Zhang ZL, Li ZH, Poncin S, Li HZ (2017) Insight into mass transfer by convective diffusion in anaerobic granules to enhance biogas production. Biochem Eng J 127:154–160. https://doi.org/10.1016/j.bej.2017.07.012

Amigun B, von Blottnitz H (2010) Capacity-cost and location-cost analyses for biogas plants in Africa. Resour Conserv Recycl 55:63–73. https://doi.org/10.1016/j.resconrec.2010.07.004

Apte A, Cheernam V, Kamat M, Kamat S, Kashikar P, Jeswani H (2013) Potential of using kitchen waste in a biogas plant. Int J Environ Sci Dev 4(4)

Astals S, Ariso M, Gal A, Mata-Alvarez J (2011) Co-digestion of pig manure and glycerine: experimental and modelling study. J Environ Manage 92(4):1091–1096

Bong CPC, Lim LY, Lee CT, Klemeš JJ, Ho CS, Ho WS (2018) The characterisation and treatment of food waste for improvement of biogas production during anaerobic digestion—a review. J Cleaner Prod 172:1545–1558. https://doi.org/10.1016/j.jclepro.2017.10.199

Bouallagui H, Touhami Y, Ben Cheikh R, Hamdi M (2005) Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem 40(3–4):989–995

Chen C, Guo W, Ngo HH, Lee D, Tung K, Jin P, Wang J, Wu Y (2016) Challenges in biogas production from anaerobic membrane bioreactors. Renew Energy 98:120–134. https://doi.org/10.1016/j.renene.2016.03.095

Choong YY, Chou KW, Norli I (2017) Strategies for improving biogas production of palm oil mill effluent (POME) anaerobic digestion: a critical review. Renew Sustain Energy Rev 82(3):2993–3006. http://dx.doi.org/10.1016/j.rser.2017.10.036

Deepanraj B, Sivasubramanian V, Jayara S (2017) Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int J Hydrogen Energy 42:26522–26528. http://dx.doi.org/10.1016/j.ijhydene.2017.06.178

Ebrahimi A, Hashemi H, Eslami H, Fallahzadeh RA, Khosravi R, Askari R, Ghahramani E (2018) Kinetics of biogas production and chemical oxygen demand removal from compost leachate in an anaerobic migrating blanket reactor. J Environ Manage 206:707–714. https://doi.org/10.1016/j.jenvman.2017.10.038

Feiz R, Ammenberg J (2017) Assessment of feedstocks for biogas production, part I—a multi-criteria approach. Resour Conserv Recycl 122:373–387. https://doi.org/10.1016/j.resconrec.2017.01.019

Guenther-Lübbers W, Bergmann H, Theuvsen l (2016) Potential analysis of the biogas production e as measured by effects of added value and employment. J Clean Prod 129:556–564. https://doi.org/10.1016/j.jclepro.2016.03.157

Hafida HS, Abdul Rahmana NA, Shaha UK, Baharuddinb AS, Ariffc AB (2017) Feasibility of using kitchen waste as future substrate for bioethanol production: a review. Renew Sustain Energy Rev 74:671–686. https://doi.org/10.1016/j.rser.2017.02.071

Hagos K, Zong J, Li D, Liu C, Lu X (2017) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sustain Energy Rev 76:1485–1496. https://doi.org/10.1016/j.rser.2016.11.184

Huang C, Guo H, Wang C, Xiong L, Luo M, Chen X, Zhang H, Li H, Chen X (2017) Efficient continuous biogas production using lignocellulosic hydrolysates as substrate: a semi-pilot scale long-term study. Energy Convers Manag 151:53–62

Jabłoński SJ, Kułażyński M, Sikora I, Łukaszewicz M (2017) The influence of different pretreatment methods on biogas production from Jatropha curcas oil cake. J Environ Manage 203:714–719. https://doi.org/10.1016/j.jenvman.2016.06.001

Karimi S, Karimi K (2018) Efficient ethanol production from kitchen and garden wastes and biogas from the residues. J Clean Prod 187(2018):37–45. https://doi.org/10.1016/j.jclepro.2018.03.172

Kim MJ, Kim SH (2017). Minimization of diauxic growth lag-phase for high-efficiency biogas production. J Environ Manage 187:456e463. http://dx.doi.org/10.1016/j.jenvman.2016.11.002

Lavagnolo MC, Girotto F, Hirata O, Cossu R (2017) Lab-scale co-digestion of kitchen waste and brown water for a preliminary performance evaluation of a decentralized waste and wastewater management. Waste Manag 66:155–160. https://doi.org/10.1016/j.wasman.2017.05.005

Lebranchu A, Delaunay S, Marchal P, Blanchard F, Pacaud S, Fick M, Olmos E (2017) Impact of shear stress and impeller design on the production of biogas in anaerobic digesters. Biores Technol 245:1139–1147. https://doi.org/10.1016/j.biortech.2017.07.113

Li YY, Jin YY (2015) Effects of thermal pretreatment on acidification phase during two-phase batch anaerobic digestion of kitchen waste. Renew Energy 77:550–557

Li Y, Jin Y, Li J, Li H, Yu Z (2016) Effects of thermal pretreatment on the biomethane yield and hydrolysis rate of kitchen waste. Appl Energy 172:47–58. https://doi.org/10.1016/j.apenergy.2016.03.080

Li Y, Jin Y, Li J, Li H, Yu Z, Nie Y (2017) Effects of thermal pretreatment on degradation kinetics of organics during kitchen waste anaerobic digestion. Energy 118:377–386. https://doi.org/10.1016/j.energy.2016.12.041

Liu Y, Zhu Y, Jia H, Yong X, Zhang L, Zhou J, Cao Z, Kruse A, Wei P (2017) Effects of different biofilm carriers on biogas production during anaerobic digestion of corn straw. Biores Technol 244:445–451. https://doi.org/10.1016/j.biortech.2017.07.171

Lokshina L, Vavilin V, Salminen E, Rintala J (2003) Modeling of anaerobic degradation of solid slaughterhouse waste. Appl Biochem Biotechnol 109(1):15–32

Matheri AN, Ndiweni SN, Belaid M, Muzenda E, Hubert R (2017) Optimising biogas production from anaerobic co-digestion of chicken manure and organic fraction of municipal solid waste. Renew Sustain Energy Rev 80(2017):756–764. https://doi.org/10.1016/j.rser.2017.05.068

Misi SN, Forster CF (2001) Batch co-digestion of multi-component agro-wastes. Biores Technol 80(1):19–28

Moreno VC, Papasidero S, Scarponi GE, Guglielmi D, Cozzani V (2016) Analysis of accidents in biogas production and upgrading. Renew Energy 96(2016):1127–1134. https://doi.org/10.1016/j.renene.2015.10.017

Paritosh K, Kushwaha SK, Yadav M, Pareek N, Chawade A, Vivekanand V (2017) Food waste to energy: an overview of sustainable approaches for food waste management and nutrient recycling. Biomed Res Int 2017(2017):2370927. https://doi.org/10.1155/2017/2370927

Patinvoh RJ, Osadolor OA, Chandolias K, Horváth IS, Taherzadeh MJ (2017) Innovative pretreatment strategies for biogas production. Biores Technol 224(2017):13–24. https://doi.org/10.1016/j.biortech.2016.11.083

Pérez-Rodríguez N, García-Bernet D, Domínguez JM (2017) Extrusion and enzymatic hydrolysis as pretreatments on corn cob for biogas production. Renew Energy 107:597–603

Pham CH, Saggar S, Vu CC, Tate KR, Tran TTT, Luu TT, Ha HT, Nguyen HLT, Sommer SG (2017) Biogas production from steer manures in Vietnam: effects of feed supplements and tannin contents. Waste Manag 69:492–497. https://doi.org/10.1016/j.wasman.2017.08.002

Rajendran K, Aslanzadeh S, Taherzadeh MJ (2012) Household biogas digesters—a review. Energies 5:2911–2942. https://doi.org/10.3390/en5082911

Reddy SN, Satyanarayana SV, Sudha G (2017) Bio gas generation from biodegradable kitchen waste. Int J Environ Agric Biotech (IJEAB) 2(2). http://dx.doi.org/10.22161/ijeab/2.2.15. ISSN: 2456-1878

Sahu N, Sharma A, Mishra P, Chandrashekhar B, Sharma G, Kapley A, Pandey RA (2017a) Evaluation of biogas production potential of kitchen waste in the presence of spices. Waste Manag 70:236–246. https://doi.org/10.1016/j.wasman.2017.08.045

Sahu N, Deshmukh S, Chandrashekhar B, Sharma G, Kapley A, Pandey RA (2017b) Optimization of hydrolysis conditions for minimizing ammonia accumulation in two-stage biogas production process using kitchen waste for sustainable process development. J Environ Chem Eng 5:2378–2387. https://doi.org/10.1016/j.jece.2017.04.045

Shane A, Gheewala SH (2017) Missed environmental benefits of biogas production in Zambia. J Clean Prod 142(2017):1200–1209. https://doi.org/10.1016/j.jclepro.2016.07.060

Skovsgaard L, Jacobsen HK (2017) Economies of scale in biogas production and the significance of flexible regulation. Energy Policy 101:77–89

Stefaniuk M, Oleszczuk P, Bartmi´nski P (2016) Chemical and ecotoxicological evaluation of biochar produced from residues of biogas production. J Hazard Mater 318:417–424. https://doi.org/10.1016/j.jhazmat.2016.06.013

Sun M, Fan X, Zhao X, Fu S, He S, Manasa MRK, Guo R (2017) Effects of organic loading rate on biogas production from macroalgae: performance and microbial community structure. Biores Technol 235(2017):292–300. https://doi.org/10.1016/j.biortech.2017.03.075

Tonrangklang P, Therdyothin A, Preechawuttipong I (2017) Overview of biogas production potential from industry sector to produce compressed bio-methane gas in Thailand. In: 2017 International conference on alternative energy in developing countries and emerging economies 2017 AEDCEE, 25–26 May 2017, Bangkok, Thailand. Energy Procedia 138:919–924. https://doi.org/10.1016/j.egypro.2017.10.140

Wang Y, Zang B, Li L, Liu Y (2016) Evaluation the anaerobic hydrolysis acidification stage of kitchen waste by pH regulation. Waste Manag 53:62–67. https://doi.org/10.1016/j.wasman.2016.04.018

Yadav D, Barbora L, Bora D, Mitra S, Rangan L, Mahanta P (2017) An assessment of duckweed as a potential lignocellulosic feedstock for biogas production. Int Biodeterior Biodegradation 119(2017):253–259. https://doi.org/10.1016/j.ibiod.2016.09.007

Ye J, Li D, Sun Y, Wang G, Yuana Z, Zhena F, Wang Y (2013) Improved biogas production from rice straw by co-digestion with kitchen waste and pig manure. Waste Manag 33:2653–2658. https://doi.org/10.1016/j.wasman.2013.05.014

Zhang X, Yan J, Li H, Chekani S, Liu L (2015) Investigation of thermal integration between biogas production and upgrading q. Energy Convers Manag 102:131–139. https://doi.org/10.1016/j.enconman.2015.03.023

Zhang G, Li Y, Dai YJ, Wang RZ (2016) Design and analysis of a biogas production system utilizing residual energy for a hybrid CSP and biogas power plant. Appl Therm Eng 109:423–431. https://doi.org/10.1016/j.applthermaleng.2016.08.092

Zhang D, Duan N, Tiana H, Lina C, Zhang Y, Liu Z (2018a) Comparing two enhancing methods for improving kitchen waste anaerobic digestion: Bentonite addition and autoclaved de-oiling pretreatment. In: Process safety and environmental protection, vol 1188,p 9. http://dx.doi.org/10.1016/j.psep.2017.09.011

Zhang L, Cheng J, Pei H, Pan J, Jiang L, Hou Q, Han F (2018b) Cultivation of microalgae using anaerobically digested effluent from kitchen waste as a nutrient source for biodiesel production. Renew Energy 115:276–287. https://doi.org/10.1016/j.renene.2017.08.034

Zhao M, Ruan W (2013) Biogas performance from co-digestion of Taihu algae and kitchen wastes. Energy Convers Manag 75:21–24. https://doi.org/10.1016/j.enconm

How to make biogas plant, anaerobic digester experiment. https://paksc.org/pk/diy-projects/764-biogas-plant-experiment/. Accessed 15 Nov 2018

http://www.sis.gov.eg. Accessed 15 Nov 2018

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Mostafa, A.A., Elbanna, B.A., Elbehiry, F., Elbasiouny, H. (2020). Biogas Production from Kitchen Wastes: Special Focus on Kitchen and Household Wastes in Egypt. In: Negm, A., Shareef, N. (eds) Waste Management in MENA Regions. Springer Water. Springer, Cham. https://doi.org/10.1007/978-3-030-18350-9_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-18350-9_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-18349-3

Online ISBN: 978-3-030-18350-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)