Abstract

Mangrove ecosystems are one of the most versatile habitats for microorganisms with a high potential for producing a variety of extracellular hydrolytic enzymes. In this study, bacteria with urease activity, enzymes that catalyze the hydrolysis of urea into carbon dioxide and ammonia, were isolated from mangrove sediments of Poovar (Trivandrum, India). Bacillus halodurans, strain PO15, isolated in this study with high urease (UA) activity (28 U/ml) was subjected to optimization using a Box-Behnken experimental design. Incubation variables included incubation period, pH, inoculation percentage and temperature. Significant factors identified based on the model were incubation period, pH, incubation temperature, and inoculum percentage; variations in these produced a tenfold increase in UA activity (295.80 U/ml). The specific activity of the purified UA enzyme was 62.34 U/mg and was found to be thermostable (active up to 60 °C). UA of B. halodurans PO15 has potential for microbial-induced biomineralization with a reduction of free Ca2+ to about 82.8% ± 0.17%. The microbial-induced calcium precipitation (MICP) using the UA enzyme will potentially be beneficial in the process of biomineralization as well as for a variety of industrial applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microorganisms play a major role in ecosystem engineering through several biogeochemical process (Graham et al. 2016). These processes are mostly driven by microbial enzymes. Microbial enzymes have been well studied for their industrial applications, and environment management. Urease, secreted by bacteria, is one such enzyme that has numerous applications. Urease is extensively used as a diagnostic tool in the detection of urea in blood (Smith et al. 1993), in alcoholic beverages to remove urea, biosensors for detection of heavy metal ions, and biocalcification (Sarda et al. 2009). Microbial ureases can induce calcite precipitation through reaction of urea and free calcium ions, a function that has applications in civil and geotechnical engineering for enhancing the strength and stiffness properties of soil through the process of biomineralization (Anitha et al. 2018; Bibi et al. 2018; Cheng and Cord-Ruwisch 2013; Ivanov and Chu 2008).

Urease (EC 3.5.1.15) is a nickel-containing enzyme which catalyzes the formation of carbon dioxide and ammonia from urea (Cheng and Cord-Ruwisch 2013) resulting in an increase in pH in the surrounding media (Mora and Arioli 2014). Urease-producing microorganisms are relevant to human microbiota, which hydrolyses urea (Chen and Burne 2003; Morou-Bermudez and Burne 2000; Wegmann et al. 2013; Yatsunenko et al. 2012). The production of urease enzyme by ureolytic bacteria in soil may be influenced by a variety of factors. It is induced in the presence of urea and inhibited in the presence of ammonia and nitrogen compounds (Mobley et al. 1995). Several studies have reported the isolation of indigenous ureolytic bacteria, using enrichment cultures from soil, ground water and cement samples (Achal and Pan 2011; Burbank et al. 2012; Elmanama et al. 2013; Hammes et al. 2003; Rivadeneyra et al. 1993). Urease has been identified as a virulence factor for several microbial pathogens (Mora and Arioli 2014). Its role in microbial infections was well established through studies on Helicobacter pylori (Mora and Arioli 2014). The urease activity of microorganisms, such as Proteus mirabilis and Staphylococcus saprophyticus, plays a vital role in urinary tract infections through struvite–carbonate–apatite urinary stone formation. Based on the urease properties on formation of carbonate apatite stones, this enzyme has an application in environmental engineering. In addition to the above, urease enzyme also has many medical applications, including use as new drug targets.

Despite their application in the fields of biomedical and environmental engineering, the production conditions of the urease enzyme remain poorly understood. Previous studies have been limited to one-factor optimization (Bakhtiari et al. 2006; El-Bessoumy et al. 2009) and have not concluded suitable production parameters for enhancing urease activity. For industrial applications, it is important to determine the optimal conditions for enzyme production. Traditionally, factorial methods were used in kinetic studies on microbially induced carbon precipitation (MICP) but this method is costly and time-consuming. Methods such as response surface methodology (RSM) in the form of the Box-Behnken experimental design were used to determine the optimum levels of key conditions as determined by Plackett–Burman design (PBD) (Box and Behnken 1960; Plackett and Burnam 1946). This method could overcome the challenges of the conventional optimization techniques, which are laborious and result in unreliable and inaccurate results. These statistical techniques could help in designing experiments, building models, evaluating the interactive effects of variables, and determining optimum conditions (Shivam et al. 2009). RSM is widely used in bioprocessing technology for optimization of fermentation media (Desai 2008; Rishad et al. 2016; Sunitha et al. 1999). In a study by Khodadadi and Bilsel (2015), a central composite face-centered (CCF) design was used to fit a second-order model to evaluate microbial urease efficacy in the biocementation process. Optimum conditions of enzyme-specific rate and urea hydrolysis were found to be significant. RSM or statistical modelling has been employed in the optimization of several enzymes, due to their reliability (Ameri et al. 2019; Nathan et al. 2018; Raza et al. 2019; Vijayaraghavan and Vincent 2014). This approach resulted in greater enzyme production of the microbial strains and are essential for any industrial applications. In this paper, we focus on a urease-producing bacterium, Bacillus halodurans PO15, isolated from mangrove sediment. We used statistical models for optimizing urease production at different incubation periods, pH, inoculation percentage and incubation temperatures, to achieve maximum enzyme activity. The biomineralization ability of the urease was also evaluated. This is the first report of urease optimization through statistical models.

Results and discussion

Screening of urease-producing bacteria

Fifty-two bacterial cultures were isolated from Poovar mangrove ecosystem sediment samples. Of these, 21 isolates gave urease positive results on urease agar. These bacterial strains were inoculated into urease broth and urease production was quantified, based on a spectrophotometric assay. The urease activity of these isolates ranged from 1.8 to 28 U/ml. The bacterial isolate with the highest activity was selected for the further experiments. The strains with high urease activity were identified as B. halodurans through 16S rRNA ribotyping. The urease-producing bacteria is ubiquitous in natural environments. However, other common urease-producing strains reported here, Helicobacter pylori, Proteus vulgaris, Staphylococcus aureus, and Pseudomonas aeruginosa, etc., are pathogenic or opportunistic pathogens to humans (Stabnikov et al. 2013). Additionally, many other bacterial strains that are used in microbial-induced calcium precipitation (MICP) with urease production Bacillus sp. VS1 and Bacillus sp. were reported (El-Bessoumy et al. 2009; Stabnikov et al. 2013). VUK5 has been extensively used in MICP studies (Stabnikov et al. 2013). In biocementation studies, spore-forming strains of urease-producing bacteria, were found to be more compatible to environments with high salt concentrations (Bachmeier et al. 2002; Stabnikov et al. 2013). For this reason, the optimization experiment in the present study was conducted for the B. halodurans, isolate PO15 alone. The major concern for environmental applications is the selection of an avirulent bacterial that has no adverse effect on humans or animals. Though many high urease-producing bacteria have been reported, they are mostly associated with human pathogenesis and cannot be used for any in situ environmental applications. In the present study, the mangrove bacterium, B. halodurans strain PO15, has no reported virulence and so could be employed in the optimization analysis.

Statistical optimization for urease production

In the present study, the most promising urease-producing isolate (B. halodurans, isolate PO15) was selected, based on urease activity. Figure 1 presents a schematic representation of urease production in the B. halodurans isolate P015, based on Box-Behnken experimental design. Initial urease activity of B. halodurans isolate PO15 was about 28 U/ml. This value was quite higher than the activity reported for Bacillus thuringiensis N2, a marine bacterium (3.53 U/ml) (El-Bessoumy et al. 2009). To determine the effect of different factors on urease production, culture conditions were optimized using a Box-Behnken experimental design. A maximum urease activity of 295.80 U/ml, a tenfold increase from initial activity, was achieved using the design (Table 1). Significant factors identified, based on the model, were the incubation period, pH, incubation temperature, and inoculum percentage. Though aeration was reported as a major factor in enzyme production, for urease production, oxygen concentration has no role except in MICP (Bakhtiari et al. 2006). The design predicted from the experiment was found to be significant (R2 value of 0.9961). Equation 1 represents the quadratic model regression equation describing the predicted model. Khodadadi and Bilsel (2015) reported that the conditions favouring the urease production of S. pasteurii, the amount of urea hydrolyzed, and the rate of hydrolysis all inhibited bacterial cell growth and the specific hydrolysis rate of urea and vice versa. However, in this study, a better urease production using B. halodurans PO15 was achieved. However, it is difficult to draw a comparison with other studies as most of them reported on the urea hydrolysis rate rather than urease production.

The fitted model is represented as Eq. 1

The interaction between the various medium components and factors for achieving maximum urease production are shown in contour plots (Fig. 2). From the interaction between the variables, it was found that the pH of the production medium is a critical factor for urease production. When the medium pH vs. incubation period was tested, maximum urease activity of ~ 140 U/ml was achieved on the 6th day of incubation. For temperature vs. incubation period, urease activity reached a maximum after the 5th day only. Inoculum percentage vs incubation period achieved a maximum activity of 167 U/ml after 5 days. This suggests that a minimum of 5 days of incubation with a pH 5–7 is ideal for urease production, irrespective of all tested inoculum percentages and incubation temperatures. In another study on urease optimization of A. niger PTCC 5011, using conventional one-factor method, a maximum activity of 2.44 U/ml was obtained (Bakhtiari et al. 2006). Significant factors identified, based on the model, were incubation period, pH, incubation temperature, and inoculum percentage. The production of the enzyme depended on process variables such as nutrients, pH, temperature, incubation period, inoculum level and inducer concentration (Sharma et al. 2009). Optimization of medium by the classical methods involved changing one independent variable (i.e., nutrient, pH, temperature) while keeping all other variables constant. However, one-factor optimization is extremely time-consuming, expensive for a large number of variables (Okyay and Rodrigues 2014) and often results in wrong conclusions. Use of statistical-based approaches, such as response surface methodology (RSM), could overcome the limitations of the single-factor optimization process. Also, the RSM-based approach requires fewer trials to calculate the different variables and their interactions, compared to other optimization methods (Managamuri et al. 2017; Peng et al. 2018).

Contour plot showing response of variable influencing urease production using Bacillus halodurans isolate PO15 based on Box-Behnken experimental design. The interaction between variables are shown: a incubation period vs. pH; b incubation period vs. temperature; c incubation period vs. inoculum (%); d pH vs. temperature; e pH vs. inoculum (%); f temperature vs. inoculum (%)

Except for the orthogonal array design-based approach for urease production using A. niger (Bakhtiari et al. 2006) and response surface methodology (RSM) (Khan et al. 2019), there are no statistical optimization-based reports available for other bacteria. This is the first report on the statistical optimization of urease production of B. halodurans. From the ANOVA results, the model F value of 6.65 and the P values < 0.005 indicate that the model was significant (Supplementary Table S1). The statistical model was validated through detection of 295 U/ml urease activity with optimized factors. Recently, El-Bessoumy et al. (2009) reported extracellular urease production from B. thuringiensis N2, however, the enzyme activity was very low.

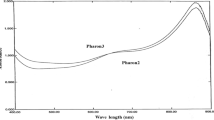

Purification and characterization of UA

A specific activity of 62.34 U/mg was observed for purified urease with 5.6-purification fold and a yield of 87%. The specific activity of the isolate PO15 was higher than those derived from Aspergillus creatinolyticus (32.74 U/mg), Lactobacillus reuteri (13.0 U/mg) (Kakimoto et al. 1989), A. niger (0.325 U/mg) (Smith et al. 1993), and R. oryzae (0.18 U/mg) (Geweely 2006). Based on the LB plot, a Vmax of 333.33 mmol L−1 mg−1 min−1 with Km values of 1.7 mmol/L was observed for UA. The LB plot showing the enzyme kinetics is shown in Fig. 3a. The UA enzyme was tested for its thermostability and was found to be stable up to 60 °C (Fig. 3b). In another study, the fungal urease of Aspergillus exhibited maximum production and urease activity at 35 °C and the least activity was at 50 °C (Khan et al. 2019). Others reported 35 °C and 40 °C as the optimum temperature for urease activity (Danial et al. 2015; Fathima and Jayalakshmi 2012). In this study, however, a maximum urease activity at 35 °C was observed, the enzyme had no significant decrease in urease activity even at 60 °C. This clearly validates the thermostable property of the urease enzyme.

Characterization of UA enzyme from B. halodurans isolate PO15 and evaluation of its biomineralization ability. (a) LB plot showing enzyme kinetics; (b) enzyme activity at different temperature; (c) enzyme activity at different pH; (d) Relative reduction of free Ca2+ in the media using urease enzyme produced by the Bacillus halodurans isolate PO15 [values expressed as mean ± S.D of triplicate experiment]

Similarly, the optimal pH for maximum urease activity was found to be pH 7 (Fig. 3c). There was an increase in urease activity with an increase of pH from 3.0–9.0 (Khan et al. 2019). Some bacterial ureases exhibited high activity in alkaline conditions (pH of 9.0) (Phang et al. 2018), while some had maximum urease activity at pH 8 (Danial et al. 2015; Mirbod et al. 2002). Two fungal isolates of the genus Aspergillus had an optimum pH of 8.0 and 8.5 (Kappaun et al. 2018). In general, the fungal urease had their maximum activity in the basic medium, while bacterial urease tended to be more variable (Khan et al. 2019). The higher thermostability favours the application of UA in a variety of industrial and environmental engineering applications.

Urease-mediated calcium precipitation

To understand the rate at which CO2 is trapped as carbonates, a calcium carbonate precipitation study was carried out. The relative reduction of free calcium in the media is shown in Fig. 3d. B. halodurans PO15 was able to achieve a reduction of (82.8 ± 0.17)% free Ca2+. Maximum reduction was observed after 48 h incubation. For the bioremediation of CO2, the microbial biomineralization ability is of great importance (Silva-Castro et al. 2015). Application of urease derived from Sporosarcina pasteurii for processes of biomineralization and co-precipitation of CaCO3 was reported by Whiffin et al. (2007) and Al-Thawadi (2011). This process of urease-aided CaCO3 mineralization has a great potential in environmental engineering applications as well as for remediation and cementation in in situ conditions (Krajewska 2018). Bibi et al. (2018) reported indigenous Bacillus bacteria with biomineralization capability that could enhance soil stabilization isolated from Qatari soil. A similar report observed that B. licheniformis was able to precipitate calcium carbonate by ureolysis (Helmi et al. 2016). This precipitation process uses carbonate ions released during urea hydrolysis and a pH shift to highly alkaline condition. It was found that the ureolytic property of Bacillus sp. is high with respect to any other genus and that this might be due to their physiological ability to adapt to stressed conditions (Helmi et al. 2016). Moreover, this also facilitates bioremediation of toxic metals and radionuclides through solid-phase capture (Fujita et al. 2000).

Conclusion

This is the first report on the statistical optimization of extracellular urease production using a mangrove bacterium. A maximum urease activity of 295 U/ml was achieved by B. halodurans PO15 strain during statistical optimization. There was a tenfold increase in enzyme activity and the purified enzyme exhibited a high specific activity of 62.34 U/mg. The thermostable urease was active up to 60 °C and exhibited maximum activity at pH 7. UA of B. halodurans PO15 has potential for microbial-induced biomineralization with a reduction of free Ca2+ to about (82.8 ± 0.17)%. The microbial-induced calcium precipitation (MICP) using the UA enzyme could be useful in many environmental engineering applications and this opens up new avenues for simultaneous carbon mitigation and biomineralization.

Materials and methods

Isolation and screening of urease-producing bacteria

Five sediment samples were collected from different locations of the Poovar mangrove system (N. Lat. 8°18′32′′ to 8°18′6′′ and E. Long. 77°4′32′′ to 77°5′14′′), located in southern Kerala, India. The samples were collected using sterile cylindrical PVC cores with a diameter of 10 cm. The samples were stored in iceboxes and transported to the laboratory. Upon reaching the laboratory, the samples were serially diluted up to 10–6 in physiological saline (0.85% NaCl) and plated onto nutrient agar (NA) (Hi Media, Mumbai, India) supplemented with 5% NaCl (Sigma Aldrich, USA) for the isolation of distinct bacterial colonies. Isolated bacterial colonies were subjected to urease enzyme screening on Urea agar base agar plates. The colour change of media from orange–yellow to deep pink indicated urease production.

Bacterial culture

A positive bacterial strain with high urease enzyme activity was isolated. The strain was identified as B. halodurans, strain PO15, based on the 16S rRNA ribotyping (Refer Nathan et al. 2018 for details of isolation and characterization). In this study, B. halodurans, strain PO15 was used for statistical optimization. The bacterium was grown in nutrient broth with 5% NaCl and incubated at 37 °C for 24 h. The culture was centrifuged at 10,000 r/min at 4 °C for 10 min to obtain crude urease enzyme.

Urease activity

The urease activity was determined by spectrophotometric assay based on the Nesslerization reaction. Briefly, 1.7 ml 10 mmol/L urea was mixed with 0.2 ml of 0.05 mol/L Tris—HCl (pH 7.0) and 20 µl of the urease. The mixture was incubated at 37 ˚C for 10 min and the reaction was stopped by adding 1.5 mol/L Trichloro acetic acid (TCA) (Sigma, USA). The reaction mixture was again incubated after adding 0.5 ml of Nessler's reagent at 37˚C for 10 min and absorbance was read at 405 nm on double beam UV–Vis spectrophotometer (SYSTRONIC MAKE, MODEL 101). One unit of urease was defined as the amount of enzyme required to release one micromole of ammonia as determined from an ammonium chloride standard curve (Kayastha et al. 1995).

Statistical optimization and model validation

For enhancing the urease activity, the optimization of culture conditions was carried out based on the Box-Behnken design, using the Design Expert 9.0 software. The response surface methodology (RSM) helped develop the mathematical models for understanding the enzyme activity on independent variables (Cui and Zhao 2012). The factors that varied during optimization were incubation period, pH, inoculation percentage and incubation temperature. Each factor was studied at two different levels (− 1 low and + 1 high) (Box and Behnken 1960). Forty-three experiments were carried out in triplicate in 250 ml Erlenmeyer flasks. Bacterial inocula were prepared with 0.5 OD McFarland Standards and added according to the inoculum percentage (3–10%). The response experimental values were derived from the mean ± S.D of three independent experiments. The Box-Behnken design (BBD) is based on a second-order polynomial equation (Eq. 2). The statistical model obtained from the experiments was validated using the optimized fermentation conditions. The enzyme assay was performed and urease activity was calculated.

where Y represents the response urease activity in U/ml; A, B, and C-coded independent variables; β1, β2, and β3 -linear coefficients; β0—intercept term; β1β1, β2β2, and β3β3–quadratic coefficients; β1β2, β1β3, and β2β3–interactive coefficients.

Purification and characterization of urease

For the purification process, crude enzyme was obtained after centrifugation of the bacterial culture at 10,000 r/min at 4 °C. 80% ammonium sulphate was added to the enzyme and the pellet was dialyzed against 250 mmol/L Tris HCl buffer, pH 8.3 at 4 °C for 48 h. The lysate was purified using affinity column chromatography (Sepharose®4B-L-tyrosine-p-aminobenzene sulfonamide). The purified enzyme fraction was dried in a vacuum desiccator, resuspended in 10 mmol/L phosphate buffer (pH 7.2), which was stored at 4 °C for further experiments. The specific activity and yield (%) of urease were calculated. The enzyme–substrate interaction was further studied using the Line weaver Burk (LB) plot. Km and Vmax values were derived from the LB plot. The optimum pH and temperature for the maximum urease activity was also evaluated.

Calcite precipitation experiment

The ability of the bacterial isolate to sequester atmospheric CO2 was demonstrated using the calcium precipitation assay. For this, nutrient broth was fortified with NaHCO3 (25.2 mmol/L) and CaCl2 (25.2 mmol/L). The relation of UA with free Ca2+ reduction was evaluated over a time period of 48 h. The bacterial isolate was inoculated to the medium and incubated under static conditions at (35 ± 2) °C. The samples were retrieved at 12 h interval, were subjected to free Ca2+ analysis using an atomic absorption spectrophotometer (AAS) (Elico, India) after centrifuging the broth at 10,000 r/min for 5 min to obtain the supernatant. Free calcium reduction (%) was expressed as mean ± S.D from the triplicate experiments performed.

References

Achal V, Pan X (2011) Characterization of urease and carbonic anhydrase producing bacteria and their role in calcite precipitation. Curr Microbiol 62:894–902

Al-Thawadi SM (2011) Ureolytic bacteria and calcium carbonate formation as a mechanism of strength enhancement of sand. J Adv Sci Eng Res 1:98–114

Ameri A, Shakibaie M, Soleimani-Kermani M, Faramarzi MA, Doostmohammadi M, Forootanfar H (2019) Overproduction of thermoalkalophilic lipase secreted by Bacillus atrophaeus FSHM2 using UV-induced mutagenesis and statistical optimization of medium components. Prep Biochem Biotechnol 49:184–191

Anitha V, Abinaya K, Prakash S, Seshagiri Rao A, Vanavil B (2018) Bacillus cereus KLUVAA mediated biocement production using hard water and urea. Chem Biochem Eng Q 32:257–266

Bachmeier KL, Williams AE, Warmington JR, Bang SS (2002) Urease activity in microbiologically-induced calcite precipitation. J Biotechnol 93:171–181

Bakhtiari MR, Faezi MG, Fallahpour M, Noohi A, Moazami N, Amidi Z (2006) Medium optimization by orthogonal array designs for urease production by Aspergillus niger PTCC5011. Process Biochem 41:547–551

Bibi S, Oualha M, Ashfaq MY, Suleiman MT, Zouari N (2018) Isolation, differentiation and biodiversity of ureolytic bacteria of Qatari soil and their potential in microbially induced calcite precipitation (MICP) for soil stabilization. RSC Adv 8:5854–5863

Box GE, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

Burbank MB, Weaver TJ, Williams BC, Crawford RL (2012) Urease activity of ureolytic bacteria isolated from six soils in which calcite was precipitated by indigenous bacteria. Geomicrobiol J 29:389–395

Chen YM, Burne RA (2003) Identification and characterization of the nickel transport system for urease biogenesis in Streptococcus salivaius 57.I. J Bacteriol 185:6773–6779

Cheng L, Cord-Ruwisch R (2013) Selective enrichment and production of highly urease active bacteria by non-sterile (open) chemostat culture. J Ind Microbiol Biotechnol 40:1095–1104

Cui F, Zhao L (2012) Optimization of xylanase production from Penicillium sp.WX-Z1 by a two-step statistical strategy: Plackett-Burman and Box-Behnken experimental design. Int J Mol Sci 13:10630–10646

Danial EN, Hamza AH, Mahmoud RH (2015) Characteristics of immobilized urease on grafted alginate bead systems. Braz Arch Biol Technol 58:147–153

Desai KM (2008) Comparison of artificial neural network (ANN) and response surface methodology (RSM) in fermentation media optimization: case study of fermentative production of scleroglucan. Biochem Eng J 41:266–273

El-Bessoumy A, El-Sharouny EB, Olam Z, Mothana A (2009) Purification and characterization of marine Bacillus thuringiensis N2 urease. Egyptian J Biochem Mole Biol 27:61–78

Elmanama AA, Alhour MT (2013) Isolation, characterization and application of calcite producing bacteria from urea rich soils. J Adv Sci Eng Res 3:377–399

Fathima F, Jayalakshmi S (2012) Characterization of urease enzyme from marine bacterium Klebsiella species. Afr J Microbiolo Res 6:5914–5923

Fujita Y, Ferris FG, Lawson RD, Colwell FS, Smith RW (2000) Subscribed content calcium carbonate precipitation by ureolytic subsurface bacteria. Geomicrobiol J 17:305–318

Geweely NS (2006) Purification and characterization of intracellular urease enzyme isolated from Rhizopus oryzae. Biotechnol 5:358–364

Graham EB, Knelman JE, Schindlbacher A, Siciliano S, Breulmann M, Yannarell A, Beman JM, Abell G, Philippot L, Prosser J, Foulquier A (2016) Microbes as engines of ecosystem function: when does community structure enhance predictions of ecosystem processes? Front Microbiol 7:214

Hammes F, Boon N, de Villiers J, Verstraete W, Siciliano SD (2003) Strain-specific ureolytic microbial calcium carbonate precipitation. Appl Environ Microbiol 69:4901–4909

Helmi FM, Elmitwalli HR, Elnagdy SM, El-Hagrassy AF (2016) Calcium carbonate precipitation induced by ureolytic bacteria Bacillus licheniformis. Ecol Eng 90:367–371

Ivanov V, Chu J (2008) Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev Environ Sci Biotechnol 7:139–153

Kakimoto S, Sumino Y, Akiyama S, Nakao Y (1989) Purification and characterization of acid urease from Lactobacillus reuteri. Agric Biol Chem 53:1119–2112

Kappaun K, Piovesan AR, Carlini CR, Ligabue-Braun R (2018) Ureases: historical aspects, catalytic, and non-catalytic properties a review. J Adv Res 13:3–17

Kayastha AM, Das N, Malhotra OP (1995) Urease from the seeds of pigeonpea (Cajanus cajan L.). In: Biopolymers and bioproducts: structure, function and applications. Dokya Pub, Bangkok, pp 382–386

Khan YM, Munir H, Anwar Z (2019) Optimization of process variables for enhanced production of urease by indigenous Aspergillus niger strains through response surface methodology. Biocatal Agric Biotechnol 11:101–202

Khodadadi HT, Bilsel H (2015) Statistical modeling of environmental factors on microbial urea hydrolysis process for biocement production. Adv Mat Sci Eng 2015:340930

Krajewska B (2018) Urease-aided calcium carbonate mineralization for engineering applications: a review. J Adv Res 13:59–67

Managamuri U, Vijayalakshmi M, Ganduri VRK, Rajulapati SB, Bonigala B, Kalyani BS, Poda S (2017) Isolation, identification, optimization, and metabolite profiling of Streptomyces sparsus VSM-30. 3 Biotech 7:217

Mirbod F, Schaller RA, Cole GT (2002) Purification and characterization of urease isolated from the pathogenic fungus Coccidioides immitis. Med Mycol 40:35–44

Mobley HL, Island MD, Hausinger RP (1995) Molecular biology of microbial ureases. Microbiol Mol Biol Rev 59:451–480

Mora D, Arioli S (2014) Microbial urease in health and disease. PLoS Pathog 10:e1004472

Morou-Bermudez E, Burne RA (2000) Genetic and physiologic characterization of urease of Actinomyces naeslundii. Infect Immun 67:504–512

Nathan VK, Kanthimathinathan SR, Rani ME, Rathinasamy G, Kannan ND (2018) Biobleaching of waste paper using lignolytic enzyme from Fusarium equiseti VKF2: a mangrove isolate. Cellulose 25:4179–4192

Okyay TO, Rodrigues DF (2014) Optimized carbonate micro-particle production by Sporosarcina pasteurii using response surface methodology. Ecol Eng 62:168–174

Peng H, Tan J, Bilal M, Wang W, Hu H, Zhang X (2018) Enhanced biosynthesis of phenazine-1-carboxamide by Pseudomonas chlororaphis strains using statistical experimental designs. World J Microbiol Biotechnol 34:129

Phang IRK, San Chan Y, Wong KS, Lau SY (2018) Isolation and characterization of urease-producing bacteria from tropical peat. Biocatal Agric Biotechnol 13:168–175

Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrika 33:305–325

Raza A, Bashir S, Tabassum R (2019) Statistical based experimental optimization for co-production of endo-glucanase and xylanase from Bacillus sonorensis BD92 with their application in biomass saccharification. Folia Microbiol 64:295–305

Rishad KS, Rebello S, Nathan VK, Shabanamol S, Jisha MS (2016) Optimised production of chitinase from a novel mangrove isolate, Bacillus pumilus MCB-7 using response surface methodology. Biocatal Agric Biotechnol 5:143–149

Rivadeneyra MA, Delgado R, Delgado G, Moral AD, Ferrer MR, Ramos-Cormenzana A (1993) Precipitation of carbonates by Bacillus sp. isolated from saline soils. Geomicrobiol J 11:175–184

Sarda D, Choonia HS, Sarode DD, Lele SS (2009) Biocalcification by Bacillus pasteurii urease: a novel application. J Indust Microbiol Biotechnol 36:1111–1115

Sharma A, Bardhan D, Patel R (2009) Optimization of physical parameters for lipase production from Arthrobacter sp. BGCC# 490. Indian J Biochem Biophys 46:178–183

Shivam K, Chandra P, Tripathi M, Mishra SK (2009) Culture conditions for the production of α-galactosidase by Aspergillus parasiticus MTCC-2796: a novel source. Electron J Biotechnol 12:1–9

Silva-Castro GA, Uad I, Gonzalez-Martinez A, Rivadeneyra A, Gonzalez-Lopez J, Rivadeneyra MA (2015) Bioprecipitation of calcium carbonate crystals by bacteria isolated from saline environments grown in culture media amended with seawater and real brine. BioMed Res Int 2015:816102

Smith PT, King AD Jr, Goodman N (1993) Isolation and characterization of urease from Aspergillus niger. Microbiol 139:957–962

Stabnikov V, Jian C, Ivanov V, Li Y (2013) Halotolerant, alkaliphilic urease-producing bacteria from different climate zones and their application for biocementation of sand. World J Microbiol Biotechnol 29:1453–1460

Sunitha K, Lee JK, Oh TK (1999) Optimization of medium components for phytase production by E. coli using response surface methodology. Bioprocess Eng 21:477–481

Vijayaraghavan P, Vincent SGP (2014) Statistical optimization of fibrinolytic enzyme production by Pseudoalteromonas sp. IND11 using cow dung substrate by response surface methodology. Springerplus 3:60

Wegmann U, Louis P, Goesmann A, Henrissat B, Duncan SH, Flint HJ (2013) Complete genome of a new Firmicutes species belonging to the dominant human colonic microbiota (‘Ruminococcus bicirculans’) reveals two chromosomes and a selective capacity to utilize plant glucans. Environ Microbiol 16:2879–2890

Whiffin VS, van Paassen LA, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423

Yatsunenko T, Rey FE, Manary M, Trehan I, Dominguez-Bello MG, Contreras M, Magris M, Hidalgo G, Baldassano RN, Anokhin AP, Heath AC, Warner B, Reeder J, Kuczynski J, Caporaso JG, Lozupone CA, Lauber C, Clemente JC, Knights D, Knight R et al (2012) Human gut microbiome viewed across age and geography. Nature 486:222–227

Acknowledgements

The authors are grateful to the Director, NIO, Goa and Scientist-in-charge, CSIR-NIO (RC), Kochi for their support and advice. This research was funded by Science and Engineering Research Board (SERB), Government of India [PDF/2016/000438].

Author information

Authors and Affiliations

Contributions

VKN is involved in work design, execution and manuscript preparation. JV and PA involved in manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Animal and human rights statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Edited by Chengchao Chen.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nathan, V.K., Vijayan, J. & Parvathi, A. Optimization of urease production by Bacillus halodurans PO15: a mangrove bacterium from Poovar mangroves, India. Mar Life Sci Technol 2, 194–202 (2020). https://doi.org/10.1007/s42995-020-00031-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42995-020-00031-5