Abstract

Many growing cities of Sub-Saharan Africa (SSA) are marred by the inefficient collection, management, disposal and reuse of organic waste. The purpose of this study was to review and compare the energy recovery potential as well as bio-fertilizer perspective, from the organic waste volumes generated in SSA countries. Based on computations made with a literature review, we find that the amount of organic wastes varies across countries translating to differences in the energy and bio-fertilizer production potentials across countries. Organic wastes generated in SSA can potentially generate about 133 million GWh of energy per year. The organic waste to bio-fertilizer production potentials range from 11.08 million tons to 306.26 million tons annually. Ghana has the highest energy and bio-fertilizer potential among the SSA countries with a total per capita of 630 MWh/year and 306.26 million tons, respectively. The challenges and technical considerations for energy and bio-fertilizer approaches in the management of organic waste in SSA have also been discussed. This study is of help to the readers and strategic decision makers in understanding the contribution of bioenergy and bio-fertilizer to achieving sustainable development goals, namely, 7 (Affordable and Clean Energy) and 13 (Climate Action) in SSA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

On average, about 48.7% of waste generated in countries of Sub-Saharan Africa (SSA) is organic [1]. Organic waste is defined as waste (material) that comes from living organisms, either a plant or an animal, and can be decomposed by microorganisms [2, 3]. Organic wastes include the organic fraction of municipal solid waste (OFMSW), livestock and human manure, agricultural or crop primary equivalent waste, and wastewater [4]. In major towns and cities of SSA, decomposing heaps of organic wastes can be seen in open places around buildings, drainage system, institutions, playing grounds, roads side, and uncompleted buildings [5]. Thus, major cities and towns of SSA are marred by the inefficient collection, management, and disposal [5,6,7], which is of concern to society.

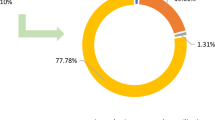

Waste conversion technologies to energy and bio-fertilizer have been presented as sustainable ways to manage organic waste [8,9,10,11]. Figure 1 shows the processes of organic waste conversion, in which there are three widely used technologies [12]. These are thermal conversion, biological conversion, and landfilling with gas recovery. In SSA, organic waste thermal conversion technologies account for 1%, biological conversion also stands at 1%, and landfilling accounts for 38%, while the remaining 60% of waste is reported to be indiscriminately dumped [13]. A review of the literature, such as the work of [10] and [14], suggests that the energy contained in the organic portion can be extracted in two ways to produce heat or electricity. The first is a biological method of converting organic waste components with and without oxygen to produce compost and energy using anaerobic digestion (AD) and composting processes (Fig. 1). The other is thermo-chemical conversion that generates heat energy and syngas. Literature on waste transformation processes shows that because of the high moisture content and biodegradable organic matter in municipal solid waste (MSW), AD is the most preferred technology [12, 14, 15].

Waste to energy technologies for recycling organic waste. Reprinted from [12] with permission

A schematic of an organic waste-fed AD plant as designed and studied by [15] is shown in Fig. 2. In the context, separated organic wastes are fed into the pre-digestion units (A) to enhance their biodegradability. Then, the pretreated organic waste feedstock is transferred into the digester (B). Various sensors measuring pH, pressure, and temperature can be installed on different points of the digesters for monitoring and controlling the process. In the digestion unit, the organic waste is continuously digested to produce bioenergy (biogas) and bio-fertilizer (liquid and solid digestate). The majority of the digestate leaving the digester is fed back into the pre-digesters for feed preparation (process 5). The other fraction of the digestate was dewatered in the centrifuge separator (C) and sundried for use as bio-fertilizer.

A schematic view of a typical waste to energy and bio-fertilizer plant. A pre-digestion unit, B digester, C separation unit, D wet chemical scrubber, E vapor-compression refrigerator, F chilling unit, G blower, H pressure regulator, I genset, J freshwater cooler, K heat exchanger, L pump and pipeline, M pump and pipeline. Reprinted from [15] with permission

In that same study of Aghbashlo, the evolved biogas (through pipeline 3) in Fig. 2, constituted methane, carbon dioxide, oxygen and other trace elements such as hydrogen sulfide. Aghbashlo et al. [15] noted that traces of hydrogen sulfide and the evolved carbon dioxide were removed in a wet chemical scrubber (D) using sodium hydroxide solution. The vapor-compression refrigerator (E) provided the cooling water required for the dehumidification of the moist biogas. Thereafter, the moisture content of the sulfur-free biogas was decreased using a chiller (F) in order to meet the fuel purity requirement of the engine. Since the lower heating value of the evolved biogas was lower than that of its petroleum-derived counterpart, it was compressed using the blower (G). The regulator (H) was used to lower the pressure of the biogas. The desulfurized and dehumidified biogas was then charged into turbocharged gensets (with a maximum power of 1042 kW). The freshwater cooling system (J) was used to cool down the turbocharged intake air in order to make the combustion process more efficient. In addition, the raw water was heated up through the heat exchanger (K) to sustain the metabolic functions of the mesophilic bacteria and archaea in the digesters. Reference [15] states that for each 30 tons of fresh organic waste fed in the digester, up to 1042 kW can be generated. The advantages of the AD plant on the environmental categories of which human health (reducing pathogens), ecosystem quality (recycling nutrients), climate change (reducing greenhouse gas emissions), and resources (businesses in nutrients, manure solids and energy markets) were reported to be economically viable and environmentally sustainable. It can thus be pointed out that this approach is one of the technologies that can be considered in SSA so that cities can benefit from the generated electricity and bio-fertilizer contained in organic waste.

Various studies in SSA cities have focused on the issues and challenges of managing solid waste [14, 16,17,18,19,20], ascertaining that few studies have been conducted to assess organic waste to energy and bio-fertilizer recovery potential, especially in low income countries of SSA in contrast to high-income countries. This article addresses this gap by conducting a comprehensive review of different countries’ total organic waste, biogas production potential, converted net energy potential, and bio-fertilizer production potential in the context of SSA. The introduction presents scenarios in waste conversion technologies. “Overview of Sub-Saharan Africa, its present energy needs, fertilizer demand and future requirement” provides a brief overview of Sub-Saharan Africa, current energy needs and bio-fertilizer demand as well as its future requirement. “The potential of organic waste to energy and bio-fertilizer in sub-Saharan Africa” discusses in detail the biomass waste potential for energy, and the research and development undertaken in selected SSA countries. Finally, barriers and some technical considerations are presented in “Challenges and technical considerations for energy and bio-fertilizer approaches in the management of organic waste in SSA”.

Overview of Sub-Saharan Africa, its present energy needs, fertilizer demand and future requirements

Sub-Saharan Africa comprises all of Africa except the five Arab-dominated states of North Africa (Algeria, Morocco, Egypt, Tunisia and Libya) and Sudan, which is considered a north-central state [21]. As of 2020, the population of sub-Saharan Africa was close to 1.14 billion people, making it the highest growth rate worldwide [22]. Most of the SSA countries have average access rates of about 20%, and two out of three persons have no access to modern energy [18]. Aryampa et al. [19] points out that only 280 million of the population had access in 2015. Dlamini et al. [18] also noted that close to 500 million people have no access to electricity, and rely heavily on firewood, and agricultural residues to meet their energy needs.

In addition, the International Energy Agency [23] estimates that electricity demand in sub-Saharan Africa has grown by about 35% since 2000 and predicts that the total demand for electricity in Africa will increase by an average of 4% per year through 2040. To meet this growing demand, African Development Bank Group [24] argues that the region needs to significantly increase its installed capacity since about half a billion people are expected to remain without access to electricity by 2040, and full availability of electricity in the region is not anticipated to be achieved by 2080 [23].

Moreover, the energy crisis impacts food security since agriculture and food industries use energy for various purposes [25]. Energy use includes electricity for automated water irrigation, fuel consumption for farm machinery, and energy required at various stages of food processing, packaging, transportation and distribution. Higher energy and fertilizer prices inevitably translate into higher production costs, and ultimately into higher food prices [25]. The World Food programme reports that dependency on fossil fuels coupled with failure to promote diversified energy systems has forced millions around the world, especially in SSA, to become food insecure [25]. African Development Bank Group [24] also notes that higher-yielding agriculture in SSA is currently in a disadvantaged state because of a daunting set of barriers, including the high cost of fertilizer use to achieve agricultural crop potential. With the planet having only a finite amount of resources, SSA countries need to increase access to energy and fertilizer production using indigenous renewable energy resources, following a growing global trend. To mention just one example, a review of literature by Chimuka et al. reveals that AD technology has the potential to reduce energy problems in the towns and cities of Sub-Saharan Africa as well as high costs of fertilizer use and environmental burden. Also, Medoc et al. [26] argued that replacing mineral fertilizer, especially in low income countries of SSA, with local fertilizer (AD bio-fertilizer) as a soil conditioner, can help farmers enjoy financial benefits.

The potential of organic waste to energy and bio-fertilizer in sub-Saharan Africa

The conversion of organic wastes to energy and bio-fertilizer is centered on generated and collected bio-waste volumes [26]. This section presents studies on the conversion of organic waste in nature to energy and bio-fertilizer in Sub-Saharan Africa. Table 1 presents different countries' total organic waste, biogas production potential, converted net energy potential, and bio-fertilizer production potential based on other papers [27, 28], as well as computations made with a literature review by the author. Organic wastes generated in SSA can potentially generate about 12.8 billion m3 of biogas, equivalent to 133 million GWh of energy annually [29]. Detailed comparisons and discussions of energy production and bio-fertilizer production potentials from organic wastes are presented next.

From Table 1, it can be seen that Nigeria generates about 542.5 million tons of organic waste [33]. This waste has a per capita energy production potential of 181.29 MWh/per capita/year or 169541.66 MWh [29]. The equivalence of this energy potential to common fuel sources in Nigeria, including firewood, kerosene and liquefied petroleum gas can be estimated to 41.52 million tons, 14.17 million tons, and 13.15 million tons, respectively [27]. In context, a population of about 114,317,707 consumes on average 877 kWh in a developing country [34], and a family of five consumes about 0.08 kW per capita for cooking [35]. Using studies of [34] and [36], the 169,541.66 MWh potentially produced from organic waste is adequate to support the cooking needs for a family of five, support about six fluorescent light bulbs, a television and a refrigerator (freezer) for the population of 114,317,707 in Nigeria. The bio-fertilizer (dry by-product of AD) of the organic wastes as researched by [27] in Nigeria, can yield about 88.19 million tons of dry bio-fertilizer. This is approximately 13 times the quantity of synthetic fertilizer bought in Nigeria between 2001 and 2012, during which the Federal Government of Nigeria spent USD 410,828,025.48 on fertilizer subsidies [37]. IPE [38] also demonstrated how such a well-planned system is a need of time in countries like Nigeria and analyses the contribution of biogas and bio-fertilizer to achieving sustainable development goals, namely, 2 (Zero Hunger), 7 (Affordable and Clean Energy) and 13 (Climate Action).

Longfor (2020) analyzed organic waste based on energy potential in Cameroon [30]. The results showed that all 10 regions of Cameroon have electricity generating potential through the recycling of organic wastes dumped in various cities of up to 297.45 MWh/per capita/year (560 TWh/a), a result lower than 181.29 MWh/per capita/year in Nigeria [29]. Uganda, with a total energy demand of 173,287 GWh [39], is presented with a rare opportunity of 119.51 MWh/per capita/year (Table 1), and dry bio-fertilizer of about 58.14 million tons annually, which could lift millions out of energy poverty as well as an opportunity for an integrated waste management system for bio-fertilizer [40]. The situation in South Africa, one of the largest and most urbanized SSA countries [17], is not different from that of Nigeria, Cameroon and Uganda since organic waste is often landfilled, dumped and burned in open places [41]. Whereas a country such as Uganda has more than double the estimated 300 AD plants operating in South Africa [42], it has a per capita energy potential of 183.67 MWh/a higher than that of Uganda (Table 1). The first large-scale waste to energy and bio-fertilizer plant in Africa was opened in Athlone in Cape Town in South Africa, transforming 50 tons of organic waste per day [43]. Nyika et al. [44] pointed out that such development has not only unlocked the value of organic waste through electricity generation and natural fertilizers, but has also caused 93% diversion of waste at the Cape Town landfill, and other SSA countries can benchmark for technology transfer.

Ghana has the highest energy production and bio-fertilizer potential from organic waste of all the SSA countries with a total per capita of 630 MWh annually and 306.26 million tons, respectively (Table 1). This is probably due to the higher OFMSW and residues of primary crops generated in Ghana and other West African countries [29]. This statement is in agreement with the findings of [29], where the net energy production potential for OFMSW in West Africa was about 26 million GWh/a higher than the 18 million GWh/a of East African countries, 9 million GWh/a of Central Africa, and 3 million GWh/a of South Africa. In that same study, primary crop residues showed a net energy potential of about 42 million GWh/a in West Africa, which was higher than the 18.5 million GWh/a of East African countries, the 7 million Gwh/a of Central Africa, and the 8.5 million GWh/a of South Africa.

Challenges and technical considerations for energy and bio-fertilizer approaches in the management of organic waste in SSA

Environmental barriers and health risks

Despite the important environmental benefits of converting waste to energy and bio-fertilizers, this review recognizes a few potential negative environmental aspects. These include odor problems that occur primarily at the stages of organic waste storage, fermentation preparation, and digestate dewatering [45]. According to Tsai et al. [46], terpenes and sulfur-containing compounds are the leading causes of odors. A review by [45] notes that long-term exposure to these compounds can cause asthma or asthmatic symptoms such as dyspnea, coughing, wheezing, chest tightness, and difficulty breathing, as well as affect the central nervous system, causing symptoms such as headache and dizziness, nausea, fatigue, agitation, and disorientation. The other barrier is the need of many water resources for the technology/ anaerobic digesters [52,53,49]. AD requires abundant water resources, with a ratio of 1:1 of the water and substrate to be loaded into the digester [49]. For that reason, biogas production might not be a problem during the rainy season, but it may be a problem in the dry seasons, especially where the distance to water supply is large and in SSA regions with limited water availability.

Studies of [50, 51] reveal that in many parts of SSA, the use of products recovered from organic waste streams is perceived by the public and farmers as associated with potential risks to health. [52], also notes that digestate to be used as a bio-fertilizer may contain high concentrations of pathogens, and its land application may play a role in pathogen transmission to humans through the food chain, with ready-to-eat crops being potential critical vectors as they may be eaten without further treatment or processing. Implementation of organic waste to energy and bio-fertilizer approaches in SSA could be determined by whether the perceptions of risks among local stakeholders outweigh the perception of benefits. The digestate may also contain metals, particularly heavy metals, in varying concentrations [53]. When applied to farmland, high levels of these metals in soil can lead to phytotoxicity, which ultimately ends up in the human diet through crop uptake [54]. The ingestion of heavy metals is associated with health risks, and reports show that countries like Bangladesh have high levels of lead and Arsenic in their cereals and pulses [54]. To overcome this, international threshold standards for heavy metal concentrations in digestate have been set, and for operators who cannot meet this standard, digestate resources cannot be spread on farmland.

Unstable production of biogas due to influent substrate complexity and inhibition

According to [55], feeding of complex organic matrices such as agricultural wastes in conventional anaerobic digesters leads to low conversion performances. OFMSW is very heterogeneous and is often mixed with agricultural wastes, which contain lignocellulosic structures and are recalcitrant to anaerobic microbial degradation. [60,61,62,58] point out that some feedstock also has inhibitory effects on AD microbes and thus reduces the biogas yield. An example of an inhibitor is limonene from citrus peel. Limonene occurs naturally in citrus peel, and a study by [59] showed that the compound can inhibit the AD process at concentrations of 65 g/L to 88 g/L. In this regard, [56] reports the main approaches being considered for the enhancement of AD processes of these wastes include: feedstock pre-treatment, co-digestion, optimization of the process parameters as well as bioreactor configurations, and application of genetic technologies.

Collection, storage and logistic issues during waste transportation

According to [60], there is a high degree of correlation (about 90%) between the performance of waste management logistics and variables such as commitment, intensity of traffic, tonnage of loading, pick-uptime, and volume of waste that are a characteristic of most SSA countries. Difficulties including the costs of fuel, vehicle maintenance, and wages also technically hinder the collection of organic wastes [30]. According to [60], the volume of waste and commitment of staff are crucial to waste management logistics, and one factor that strongly affects waste logistics is traffic. Thus, traffic that is usually experienced daily in the cities and towns of SSA countries needs to be mitigated to have effective waste management logistics. The commitment of waste management logistics staff is important, so skilled personnel with a passion for the job can be used. Governments can introduce a Public–Private Partnership (PPP) programme that can facilitate repairs and proper maintenance if the cost is too high to bear [60].

Implementation of the energy policy

Although many countries have recognized the significance of converting organic waste to energy as a way out to their current energy crisis, there is a slow implementation of supportive policies [59, 60]. There is also a dearth of political willingness for governments to pursue the implementation of energy policies on conversion of organic wastes [61, 62]. Besides, there is a lack of budget or funding allocated to promote organic waste to energy initiatives as well as an absence of enforcement mechanisms in those countries [63]. For these policies to be fully implemented, there must be less reliance on state controlled monopoly and privately owned initiatives need to be well-thought-out. There should be a conducive environment to promote local entrepreneurs in the sector. To accelerate the waste to energy development policies, a feed-in tariff system can be implemented in sub-Saharan African countries. Countries in Europe (UK, Spain, Germany) [64] and Asian countries (Malaysia, Thailand, and Indonesia) [65] already have a functional feed-in tariff system on which the countries in SSA can benchmark to implement a subsidized policy to promote waste to energy.

Investment and financing

Many SSA countries face daunting challenges in investing and financing renewable energy technologies [66]. For example, Longfor [30] demonstrates that organic waste conversion would require an investment worth USD 110.84 million, equivalent to 0.32% of gross domestic product (GDP) of Cameroon in 2017. Regulatory policies, including the net metering system and feed in tariff, can be adopted to develop and scale AD based plants as proposed by [30]. Economic policies such as tax incentives, declining sales and value added tax may also apply in Cameroon. In USA, the federal government has reinstated a tax credit incentive that allows house owners to obtain 30% credit for installing wind turbines at their homes [67]. Such fiscal incentives can be adopted where households benefit from some credits for installing small scale biogas plants that convert both wastewater and other biomass wastes into electricity.

Inadequate technical capability and information

A number of SSA countries have no accurate data on organic waste resources [63, 68]. The available ones are not related to art technology such as satellites [69]. The absence of local technical skills in the national institution for technical labor in partnership with the private sector. Governments need to put in place effective monitoring and evaluation strategies to promote energy and bio-fertilizer technology.

Mismatch between theory and practice among stakeholders encouraging the development of organic waste conversion

Ddiba et al. [20] demonstrates some degree of differences between theory and practice in the conversion of organic waste to energy and bio-fertilizer approaches. In the context of theory, resource recovery from organic wastes, for instance, enables local authorities to recycle organic waste to produce electricity that can be used for public lighting or to heat the water in a community, city hall or school. It therefore enables the operating costs of public administration to be reduced [70]. The same is true for industries where AD helps firms lower their energy bill and the cost of waste treatment [70]. From this perspective, AD enables the local production and consumption of energy using the region’s organic waste resources. While these examples for recovering resources from organic waste streams exist, some stakeholders do not acknowledge the benefits of local AD installation as a viable approach, which is problematic [71]. Garcia et al. [72] reveals the importance of raising awareness, fostering collaboration, as well as mechanisms for public participation to enable current practices and information about energy and bio-fertilizer concepts from organic wastes. This therefore emphasizes the significance of incorporating information gathered from communities of practice into the theoretical concepts of resource recovery when implementing these technologies in SSA.

Conclusions

In this review, the findings demonstrate the great energy recovery and bio-fertilizer production potential of recycling organic waste streams generated and disposed of in different SSA cities and towns. The energy and nutrients that can be generated from these wastes can lead to significant economic and a few environmental benefits in the SSA. Policy makers need to implement policies that aim to accelerate the diffusion of organic waste recycling technologies in SSA. This is because government policies and laws, financial support, and improved technologies can strengthen the development of waste to energy (AD) technology in these developing countries. This paper will benefit readers and strategic decision makers in identifying and understanding potential resources embedded in organic waste streams. Further research is needed to review the integration of wastes such as agricultural residues from farmlands, solid wastes from commercial sites, and industrial wastewater for optimized resource recovery in SSA.

Data availability

The authors declare that the data supporting the findings of this study are available within the article (however, datasets generated during computations and approximations are available from the corresponding author).

References

Khan, I., Chowdhury, S., and Techato, K. 2022. Waste to energy in developing countries-a rapid review: Opportunities, challenges, and policies in selected countries of Sub-Saharan Africa and South Asia. Sustainability 14(7):27. https://doi.org/10.3390/su14073740.

Patel, P., Modi, A., Minipara, D., et al. 2021. Microbial biosurfactants in management of organic waste. In Sustainable Environmental Clean-up. Amsterdam: Elsevier. https://doi.org/10.1016/B978-0-12-823828-8.00010-4.

Contreras, M., Gázquez. M.J., Romero, M., et al. 2020. Recycling of industrial wastes for value-added applications in clay-based ceramic products: A global review. In: New materials in Civil Engineering. Oxford: Butterworth-Heinemann.https://doi.org/10.1016/B978-0-12-818961-0.00005-3.

Chernysh, Y., Shtepa, V., Roy, I., et al. 2021. The potential of organic waste as a substrate for anaerobic digestion in Ukraine: Trend definitions and environmental safety of the practices. Environmental Problems 6(3):135–144.

Orhorhoro, E.K., Oghoghorie, O. 2019. Review on solid waste generation and management in Sub-Saharan Africa : A case study of Nigeria. Journal of Applied Sciences and Environmental Management 23(9):1729–1737. https://doi.org/10.4314/jasem.v23i9.19.

Bobeck, M. 2010. Organic household waste in developing countries: An overview of environmental and health consequences, and appropriate decentralised technologies and strategies for sustainable management. Saarbrucken: VDM Verlag Dr. Müller.

World Bank. 2018. Global waste to grow by 70 percent by 2050 unless urgent action is taken: World Bank report. Available at: https://www.worldbank.org/en/news/press-release/2018/09/20/global-waste-to-grow-by-70-percent-by-2050-unless-urgent-action-is-taken-world-bank-report. Accessed 4 Jan 2022.

Psomopoulos, C.S., Bourka, A., and Themelis, N.J. 2009. Waste-to-energy: A review of the status and benefits in USA. Waste Management 29(5):1718–1724. https://doi.org/10.1016/j.wasman.2008.11.020.

Hoornweg, D., Bhada-Tata, P. 2012. What a Waste : A global review of solid waste management. Washington, DC: World Bank Group. https://openknowledge.worldbank.org/handle/10986/17388.

Moya, D., Aldás, C., and López, G. 2017. Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using waste-to-energy technologies. Energy Procedia 134(1):286–295. https://doi.org/10.1016/j.egypro.2017.09.618.

Farooq, A., Haputta, P., Silalertruksa, T., et al. 2021. A framework for the selection of suitable waste to energy technologies for a sustainable municipal solid waste management system. Frontier Sustainability 2(1):1–17. https://doi.org/10.3389/frsus.2021.681690.

Kalyani, K.A., and Pandey, K.K. 2014. Waste to energy status in India: A short review. Renewable and Sustainable Energy Reviews 31:113–120. https://doi.org/10.1016/j.rser.2013.11.020.

Idowu, I. A., Atherton, W., Hashim, K., et al. 2019. An analyses of the status of landfill classification systems in developing countries: Sub Saharan Africa landfill experiences. Waste Management 87:761–771. https://doi.org/10.1016/j.wasman.2019.03.011.

Ogunjuyigbe, A.S.O., Ayodele, T.R., and Alao, M.A. 2017. Electricity generation from municipal solid waste in some selected cities of Nigeria: An assessment of feasibility, potential and technologies. Renewable and Sustainable Energy Reviews 80:149–162. https://doi.org/10.1016/j.rser.2017.05.177.

Aghbashlo, M., Tabatabaei, M., Soltanian, S., et al. 2019. Biopower and biofertilizer production from organic municipal solid waste: An exergoenvironmental analysis. Renewable Energy 143: 64–76. https://doi.org/10.1016/j.renene.2019.04.109.

Mohee, T., and Simelane, R. 2015. Future Directions of Municipal Solid Waste Management in Africa. Pretoria: Africa Institute of South Africa.

Simatele, D.M., Dlamini, S., and Kubanza, N.S. 2017. From informality to formality: Perspectives on the challenges of integrating solid waste management into the urban development and planning policy in Johannesburg, South Africa. Habitat International 63:122–130. https://doi.org/10.1016/j.habitatint.2017.03.018.

Dlamini, S., Simatele, M. D., and Serge Kubanza, N. 2018. Municipal solid waste management in South Africa: from waste to energy recovery through waste-to-energy technologies in Johannesburg. Local Environment 24(3):249–257. https://doi.org/10.1080/13549839.2018.1561656.

Aryampa, S., Maheshwari, B., Sabiiti, E., et al. 2019. Status of waste management in the East African cities: Understanding the drivers of Waste Generation, collection and disposal and their impacts on Kampala City’s sustainability. Sustainability 11(19):5523. https://doi.org/10.3390/su11195523.

Ddiba, D., Andersson, K., Rosemarin, A., et al. 2022. The circular economy potential of urban organic waste streams in low- and middle-income countries. Environment, Development Sustainability 24(1):1116–1144. https://doi.org/10.1007/s10668-021-01487-w.

Ekwe-Ekwe, H. 2010. What-is-Sub-Sahara-Africa. In: West Africa Review, Adeeko, A., Nzegwu, N., and Taiwo O, eds. Cape Town: Africa Resource Center.

UN. 2020. United Nations, department of economic and social affairs, population division. World Population Prospects 2019. Volume II: Demographic Profiles. Available at: https://population.un.org/wpp/publications. Accessed 25 Jan 2022.

IEA. 2019. Africa Energy Outlook 2019. In: World energy outlook special Report 2019. Paris: International Energy Agency. Available at: https://www.iea.org/reports/africa-energy-outlook-2019. Accessed 25 Jan 2022.

African Development Bank Group. 2021. African Economic Outlook 2021- From Debt Resolution to Growth: The Road Ahead for Africa. Available at: https://www.afdb.org/en/documents/african-economic-outlook-2021. Accessed 25 Jan 2022.

World Food Programme (WFP). 2022. Understanding the energy crisis and its impact on food security. Available at: https://www.wfp.org/publications/understanding-energy-crisis-and-its-impact-food-security. Accessed 23 Sept 2022.

Médoc, J.-M., and van Veenhuizen, R. 2017. WABEF: Western Africa bio-wastes for energy and fertilisers. Urban Agriculture 32:11–17.

Ngumah, C.C., Ogbulie, J.N., Orji, J.C., et al. 2021. Biogas potential of organic waste in Nigeria. Environmental Engineering 7(1):110–116. https://doi.org/10.5755/j01.erem.63.1.2912.

Raimi, A., Roopnarain, A., and Adeleke, R. 2021. Biofertilizer production in Africa: Current status, factors impeding adoption and strategies for success. Scientific African 11:e00694. https://doi.org/10.1016/j.sciaf.2021.e00694.

Rupf, G., and De Boer, K. 2015. The energy production potential from organic solid waste in Sub-Saharan Africa. Available at: http://researchrepository.murdoch.edu.au/id/eprint/28351. Accessed 25 Jan 2022.

Longfor, N.R. 2020. Biomass waste to energy in Cameroon: Analysis of its potential. Presented at 18th Asia Pacific Conference.

Nhubu, T., and Muzenda, E. 2019. Determination of the least impactful municipal solid waste management option in Harare, Zimbabwe. Processes 7 (11): 785. https://doi.org/10.3390/pr7110785.

Nelson, N., Darkwa, J., Calautit, J., et al. 2021. Potential of bioenergy in rural Ghana. Sustainability 13:381. https://doi.org/10.3390/su13010381.

Olujobi, O.J., Ufua, D.E., Olokundun, M., et al. 2022. Conversion of organic wastes to electricity in Nigeria: Legal perspective on the challenges and prospects. International Journal Environronmental Science Technology 19(2):939–950. https://doi.org/10.1007/s13762-020-03059-3.

Goldemberg, J., Reddy, A.K.N., Smith, K.R., et al. 2020. Rural energy in developing countries: A challenge for economic development. Annual Review of Energy and the Environment 10(1):367–384. https://doi.org/10.1146/annurev.energy.21.1.497.

IRENA. 2016. Measuring small-scale biogas capacity and production. International Renewable Energy Agency (IRENA). Abu Dhabi 31.

Renewables Info Grid. 2014. About Medication Errors: What is a Megawatt? Available at: http://www.utilipoint.com/2003/06/what-is-a-megawatt. Accessed 10 Feb 2022.

Alabi, R.-A., Adams, O. O. 2015. The Pro-Poorness of Fertilizer Subsidy and Its Implications on Food Security in Nigeria. Work in Progress (WIP) report submitted to African Economic research Consortium, Nairobi, Kenya.

IPE. 2021. Demonstrating the potential of biogas to contribute to the SDGs. IPE Triple Line. Available at: https://shellfoundation.org/Demonstrating_Biogas_Contribution_SDGs_Final.pdf. Accessed 25 Jan 2022.

Waves. 2019. Uganda Woodfuels Overview. Technical report. https://www.docplayer.net/187887689/wavespartnership.org/UgandaNCA/Woodfuels/Overview

McCord, A.I., Stefanos, S.A., Tumwesige, V., et al. 2020. Anaerobic digestion in Uganda: Risks and opportunities for integration of waste management and agricultural systems. Renewable Agriculture and Food Systems 35(6):678–687. https://doi.org/10.1017/S1742170519000346.

Dada, O.R., Mbohwa, C. 2016. Municipal solid waste from landfills a solution to energy crisis in South Africa. Conference paper. https://hdl.handle.net/10210/215015

EPCM. 2022. Anaerobic digester design in South Africa. EPCM Consultants. Available at: https://epcmholdings.com/anaerobic-digester-design-in-south-africa. Accessed 11 Nov 2022.

Cloete, K. 2018. Ground-breaking waste-to-energy plant opens in Cape Town. Environmental Home. https://www.engineering.co.za/article/ground-breaking-waste-to-energy-plant-opens-in-cape-town.

Nyika, J. M., Onyari, E. K., and Dinka, M.O. 2020. Waste Management in South Africa. In Sustainable Waste Management Challenges in Developing Countries. Hershey: IGI Global. https://doi.org/10.4018/978-1-7998-0198-6.ch014

Wiśniewska, M., Kulig, A., and Lelicińska-Serafin, K. 2021. Odour nuisance at municipal waste biogas plants and the effect of feedstock modification on the circular economy—A review. Energies 14(20):6470. https://doi.org/10.3390/en14206470.

Tsai, C.J., Chen, M.L., Ye, A., et al. 2008. The relationship of odor concentration and the critical components emitted from food waste composting plants. Atmospheric Environment 42(35):8246–8251. https://doi.org/10.1016/j.atmosenv.2008.07.055.

Shane, A., Gheewala, S.H., and Kasali, G. 2015. Potential, barriers and prospects of biogas production in Zambia. Sustainable Energy & Environment 6:21–27.

Kamp, L.M., and Bermúdez Forn, E. 2016. Ethiopia’s emerging domestic biogas sector: Current status, bottlenecks and drivers. Renewable and Sustainable Energy Reviews 60:475–488. https://doi.org/10.1016/j.rser.2016.01.068.

Kelebe, H.E. 2018. Returns, setbacks, and future prospects of bio-energy promotion in northern Ethiopia: The case of family-sized biogas energy. Energy, Sustainability and Society 8(1):1–14.

Ekane, N., Mertz, C.K., Slovic, P., et al. 2016. Risk and benefit judgment of excreta as fertilizer in agriculture: An exploratory investigation in Rwanda and Uganda. Human Ecological Risk Assessment 22:639–666. https://doi.org/10.1080/10807039.2015.1100515.

Danso, G.K., Otoo, M., Ekere, M., et al. 2017. Feasibility of Faecal sludge and municipal solid waste-based compost as measured by farmers’ willingness-to-pay for product attributes: Evidence from Kampala, Uganda. Resources 6(3):31. https://doi.org/10.3390/resources6030031.

Nag, R., Auer, A., Nolan, S., et al. 2021. Evaluation of pathogen concentration in anaerobic digestate using a predictive modelling approach (ADRISK ). Science of Total Environment 800:149574. https://doi.org/10.1016/j.scitotenv.2021.149574.

Demirel, B., Gol, N. P., and Onay, T. T. 2013. Evaluation of heavy metal content in digestate from batch anaerobic co-digestion of sunflower hulls and poultry manure. Journal of Material Cycles and Waste Management 15(2):242–246.

Islam, M. S., Ahmed, M. K., and Habibullah-Al-Mamun, M. 2014. Heavy metals in cereals and pulses: Health implications in Bangladesh. Agricultural and food chemistry 62(44):28–35. https://doi.org/10.1021/jf502486q.

Siciliano, A., Limonti, C., and Curcio, G.M. 2021. Improvement of Biomethane production from organic fraction of municipal solid waste ( OFMSW ) through alkaline hydrogen peroxide ( AHP ) Pretreatment. Fermentation 7 (197): 16. https://doi.org/10.3390/fermentation7030197.

Siciliano, V., Limonti, A., Curcio, C., et al. 2019. Biogas generation through anaerobic digestion of stirred tank reactors. Processes 7(9),635. https://doi.org/10.3390/pr7090635.

Holden, N. M., and Wolfe, M. L. 2021. Biogas energy from organic wastes. In Introduction to Biosystems Engineering. St. Joseph: American Society of Agricultural and Biological Engineers.

Akinbomi, J. G., Patinvoh, R. J., and Taherzadeh, M. J. 2022. Current challenges of high solid anaerobic digestion and possible measures for its effective applications: A review. Biotechnology for Biofuels and Bioproduction 15:52. https://doi.org/10.1186/s13068-022-02151-9.

Fagbohungbe, M. O., Herbert, B. M. J., Hurst, L., et al. 2021. The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Management 61:236–249. https://doi.org/10.1016/j.wasman.2016.11.028.

Ayantoyinbo, B.B., and Adepoju, O. O. 2018. Analysis of solid waste management logistics and its attendant challenges in Lagos metropolis. Logistics 2(2):11. https://doi.org/10.3390/logistics2020011.

Mathias, J. F. C. M. 2014. Manure as a resource: Livestock waste management from anaerobic digestion opportunities and challenges for Brazil. International Food and Agribusiness Management Review 17(4):87–110. https://doi.org/10.22004/ag.econ.188711.

Msibi, S. S., Kornelius, G. 2017. Potential for domestic biogas as household energy supply in South Africa. Journal of Energy in Southern Africa 28(2):1–13. https://doi.org/10.17159/2413-3051/2017/v28i2a1754.

Nevzorova, T., and Kutcherov, V. 2019. Barriers to the wider implementation of biogas as a source of energy: A state-of-the-art review. Energy Strategy Reviews 26:100414. https://doi.org/10.1016/j.esr.2019.100414.

Scarlat, N., Dallemand, J.F., and Fahl, F. 2018. Biogas: Developments and perspectives in Europe. Renewable Energy 129:457–472. https://doi.org/10.1016/j.renene.2018.03.006.

Van Nes, W. J. 2016. Asia hits the gas: Biogas from anaerobic digestion rolls out across Asia. Renewable Energy World 1:102–111.

Frix, P. 2017. The main Challenges for Financing Sustainable Energy in Africa: Lessons from the past and new Opportunities for PPP. viewed from an European Point of view. http://www.kaowarsom.be/documents/Energy4Africa/SustainableEnergy4Africa_Frix.pdf

REN21. 2019. Renewable energy policy network for the 21st century renewables 2019: Global Status Report. https://doi.org/10.3390/resources8030139

Stan, F., Gheorghe, A., and Ghenea, A. 2017. State of the art of waste prevention and ‘Urban Wins’ Countries and Municipalities.

Purkus, A., Gawel, E., Szarka, N. et al. 2018. Contributions of flexible power generation from biomass to a secure and cost-effective electricity supply—A review of potentials, incentives and obstacles in Germany. Energy, Sustainability and Society 8:18.

Sebastien, B., and Fabien, N. 2020. The role of a local authority as a stakeholder encouraging the development of biogas: a study on territorial intermediation. Environmental Management 258:110009. https://doi.org/10.1016/j.jenvman.2019.110009.

Koop, S. H. A., Koetsier, L., Doornhof, A., et al. 2017. Assessing the governance capacity of cities to address challenges of water, waste, and climate change. Water Resources Management 31:3427–3443. https://doi.org/10.1007/s11269-017-1677-7.

Aguilarab, M. G., Jaramillo, J. F., Ddiba, D., et al. 2021. Governance challenges and opportunities for implementing resource recovery from organic waste streams in urban areas of Latin America: Insights from Chía, Colombia. Sustainable Production and Consumption 30:53–63. https://doi.org/10.1016/j.spc.2021.11.025.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rubagumya, I., Komakech, A.J., Kabenge, I. et al. Potential of organic waste to energy and bio-fertilizer production in Sub-Saharan Africa: a review. Waste Dispos. Sustain. Energy 5, 259–267 (2023). https://doi.org/10.1007/s42768-022-00131-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-022-00131-1