Abstract

Purpose

The purpose of this paper is to study detection, microstretch function, temperature distribution function and thermoelastic damping analysis due to thermal variations and stretch forces in homogeneous, isotropic microstretch, generalized thermoelastic thin circular plate.

Method

This theory is based on the Kirchho-Love plate theory assumptions. The governing equations for the transverse vibrations of microstretch thermoelastic thin circular plate have been derived. The analytical expressions for detection, microstretch function, temperature distribution function and thermoelastic damping have been numerically analyzed for clamped and simply supported boundary conditions in case of both non-Fourier and Fourier microstretch thermoelastic circular plate with the help of MATLAB programming software.

Results

Finally the analytical development for thermoelastic damping have been illustrated numerically for Silicon-like material. The computer simulated results have been presented graphically under different boundary conditions.

Conclusion

It leads to the conclusion that thermal relaxation time and microstretch parameters contribute to an increase in the magnitude of the critical value of damping.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The theory of micropolar elasticity for solids perhaps established by Eringen [5], which provides a model that can support body and surface couples by including the intrinsic rotation of microstructures. Eringen [6] extended his work to include the effect of axial stretch during rotation of molecules and developed theory of microstretch by considering microstructure expansions and contractions. Eringen [7] also extended the theory of microstretch elastic solids to include the effect of heat conduction. Eringen [8] gave an exposition of the development in the microcontinuum field theories for solids (micromorphic, microstretch, and micropolar) including electro magnetic and thermal effects.

Micro-electro-mechanical resonators have high sensitivity along with rapid-response and are frequently used such as sensors, communicators and modulators. Many researchers have stated various dissipation mechanism in MEMS, such as support-related losses, thermoelastic damping, as well as the radiation of energy away from the resonators into its surroundings. Thermoelastic damping (TED) arises from thermal currents generated by contraction/extension in elastic media. Zener [31] first identified the existence of thermoelastic damping as a significant dissipation mechanism in flexural resonators. This work was experimentally described by Berry [1] for \(\alpha\)-brass, in which the damping factor was measured as a function of frequency at room temperature. Lifshitz and Roukes [15] studied TED and derived quality factor for a beam with rectangular cross section. Nayfeh and Younis [17] developed analytical expressions for the quality factor of micro-plates of general shapes due to thermoelastic damping. Wong et al. [30] considered thermoelastic damping of the in-plane vibration of thin silicon rings. Sun and Tohmyoh [26] discussed thermoelastic damping analysis of the axisymmetric vibration of circular plate. Sun and Saka [27] studied the damping analysis of the vibrations in arbitrary direction in a coupled thermoelastic circular plate. Kumar and Ray [13] investigated the active constrained layer damping of smart laminated composite sandwich plates using the vertically reinforced 1–3 piezoelectric composite materials. Biswas and Ray [2] investigated the active constrained layer damping of geometrically nonlinear vibrations of rotating laminated composite beams using the vertically reinforced 1–3 piezoelectric composite materials. Sharma and Grover [25] discussed thermoelastic vibrations in micro- and nano-plate resonators with voids. Grover [9, 10] studied transverse vibrations in viscothermoelastic beam and in thin circular viscothermoelastic plate, respectively. Grover and Seth [11, 12] discussed analytical expressions for thermoelastic damping and frequency shift of dual-phase-lagging generalized viscothermoelastic thin beam and circular plates, respectively. Alghamdi [18] discussed analysis and numerical results for the thermoelastic of an isotropic homogeneous, thermally conducting, Kelvin–Voigt-type circular micro-plate in the context of Kirchhoff’s Love plate theory.

The present paper is devoted to study deflection, microstretch function, temperature distribution function and thermoelastic damping due to thermal variations and stretch forces in homogeneous, isotropic thin circular plate. The obtained expressions for clamped and simply supported circular plate have also been computed numerically by using MATLAB programming software. The numerically illustrated results have been presented graphically for comparison and for explanation of analytical expressions of TED.

Model Description and Problem Formulation

In this section, the governing equations for microstretch thermoelastic coupling problem of thin circular plate are derived. To analysis the derivation for thin circular plate, the following basic hypotheses, involving the Kirchhoff–Love plate theory, are employed in this analysis:

-

(i)

Normal stress \(\sigma _{zz}\) can be neglected relative to the principal stresses, i.e. \(\sigma _{zz}=0\).

-

(ii)

The rectilinear element normal to the middle surface before deformation remains perpendicular to the strained surface after deformation and their elongation can be neglected, i.e. \(e_{rz}=e_{\theta z}=0\).

-

(iii)

For small deformation vibration, the deformation along the middle surface can be neglected, i.e. \(e_{zz}=0\).

Equations of Transverse Motion for Thin Circular Plate

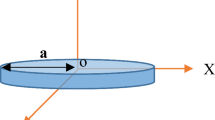

Now here, we consider a thin circular plate with uniform thickness h and radius a. A cylindrical coordinate system \((r,\theta ,z)\) is employed with its origin at the center of the plate. The \((r,\theta )\) plane is kept on the neutral surface of the plate and the z axis is perpendicular to the neutral surface. In equilibrium, the plate is unstrained, unstressed and kept at the uniform temperature \(T_0\) everywhere.

We define \(u_{r}(r,\theta ,z,t), u_{\theta }(r,\theta ,z,t)\) and \(u_{z}(r,\theta ,z,t)\) to be displacement components along with the radial, circumferential and axial directions, respectively, \(\phi ^*(r,\theta ,z,t)\) and \(T(r,\theta ,z,t)\) are microstretch and temperature distribution functions of the field. By above hypothesis, the strain-displacement relations can be written as follows by [3, 14, 24, 28]

where \(\gamma _{ij}=\gamma _{ji},(i,j=1,2,3)\) represent the mechanical strain components.

By integration of \(\frac{\partial u_z}{\partial z}=0\) provides us

Also, the integration for \(\gamma _{rz}, \gamma _{\theta z}\) as mentioned in equation(1), give us

Therefore, strain components written in equation(1) are given by

Now, stress components for microstretch thermoelastic media are given by

where \(\lambda , \mu , K\) are material constants and \(\mu ^*=2 \mu +K\).

Thus, the expressions for radial moment \(M_{rr}\), tangential moment \(M_{\theta \theta }\) and twisting moment \(M_{r \theta }\) of thin circular plates are evaluated as follows [14, 22]

where \(M_{\phi ^*}= \int _\frac{-h}{2}^\frac{h}{2} \phi ^* z dz\) and \(M_T= \int _\frac{-h}{2}^\frac{h}{2} T z dz\) , are denoted as the moments of thin circular plate due to the presence of microstretch and thermal effects, respectively.

The equation of transverse motion of thin circular plate can be derived in polar coordinates by considering the dynamic equilibrium of the element. Moment equilibrium about the tangential \(\theta\) direction is given by

Moment equilibrium about the radial r direction

Force equilibrium in the z direction

By solving system of Eqs. (7)–(9), the transverse motion equation for a thin circular plate can be obtained as

Now, by substituting Eq. (6) into Eq. (10), the equation of motion for circular plate in the absence of body force \((f=0)\) is given by

where \(\nabla _1^2=\frac{\partial ^2}{\partial r^2}+\frac{1}{r} \frac{\partial }{\partial r}+\frac{1}{r^2}\frac{\partial ^2}{\partial \theta ^2}\).

Equations of Microstretch Thermoelastic Media

Consider a homogeneous, isotropic, microstretch, thermally conductive media in the context of generalized thermoelasticity (LS model). The microstretch and heat conduction equations in the absence of stretch forces and heat sources are given by [19,20,21]:

Here, \(K^*\) is the thermal conductivity, \(C_e\) is the specific heat at constant strain, \(\rho\) is the density of medium, T is the temperature change and \(T_0\) is initial uniform temperature, \(t_0\) is thermal relaxation time, \(\beta _1=(3 \lambda +2 \mu +K)\alpha _{t_1}\) and \(\beta _2=(3 \lambda +2 \mu +K)\alpha _{t_2}\), \(\alpha _{t_1}\), \(\alpha _{t_2}\) are coefficients of linear thermal expansion, \(\alpha _0, \lambda _0, \lambda _1\) are microstretch constants, \(j_0\) is the microinertia of microelement, t is time and \(\nabla ^2=\frac{\partial ^2}{\partial r^2}+\frac{1}{r} \frac{\partial }{\partial r}+\frac{1}{r^2}\frac{\partial ^2}{\partial \theta ^2}+\frac{\partial ^2}{\partial z^2}\) is Laplacian operator.

Using Eq. (4) in Eqs. (12)–(13), we get

In summary, Eqs. (11) and (14)–(15) makes the governing equation of this problem.

Introducing non-dimensional quantities by [19, 20] as follows:

Upon utilizing these non-dimensional expressions in Eq. (11) and Eqs. (14)–(15), the following system of equations are given by

(After dropping the superscript for conveniences)

where

and

Boundary Conditions

The following two types of boundary conditions are considered by [22] as below:

Case I: The Plate is Clamped at the edge, i.e.

Case II: The Plate is Simply Supported at the edge, i.e.

Analytical Solution

To analyze microstretch thermoelastic coupling effect on vibrations of thin circular plate, we solve the system of Eqs. (17)–(19). For this, consider harmonic vibration solution of the circular plate as follows

where \(\omega _{nm}\) is the frequency, \(n=0,1,2,3,....\) represents the number of nodal diameters and \(m=1,2,3,....\) represents the number of nodal circles.

Substituting Eq. (23) in system of Eqs. (17)–(19), we obtained

where \(\nabla _1^{*^2}=\frac{\partial ^2 }{\partial r^2}+\frac{1}{r} \frac{\partial }{\partial r}-\frac{n^2}{r^2}\) and

To evaluate approximate solution under some assumptions and uncoupled system(\({\bar{v}}=0\)) of above Eqs. (24)–(25) and also there is no flow of heat and microstretch parameters on the upper and lower surfaces of the circular plate (i.e.\(\frac{\partial \Phi _{nm}^*}{\partial z}=\frac{\partial \Theta _{nm}}{\partial z}=0\) at \(z=\pm \frac{1}{2}\)). Thus, the trial solution of resulting system of equations are given as follows:

where the values of p and q are still subjected to modifications.

Now by substituting expression (28) in Eqs. (24)–(25), we obtained

where

Now from Eq. (27),

with the help of Eq. (29), we get that

where

Eliminating \(M_{\Phi _{nm}^*}\) and \(M_{\Theta _{nm}}\) from Eq. (26) by using Eq. (30), we get

where the value of coefficients \(F(\omega _{nm})\) and \(G(\omega _{nm})\) are defined by

On the other hand, by substituting Eq. (28) in Eq. (27), we obtained the following equation

Now, on comparing both equations of (30) to both equations of (33), we obtained

Therefore, by substituting Eq. (34) in Eq. (31), we obtained

where

Here \(\varepsilon _{\phi }\) and \(\varepsilon _T\) describe the elasto-stretch and thermo-mechanical coupling constants of the circular plate respectively. As the gradient of microstretch element and thermal gradient along the axial length of the circular plate quite small as compared to that along its thickness direction. Therefore, under these assumptions, we have

Therefore the result mentioned in Eq. (28) represent the result of coupled Eqs. (24)–(25) with modified values of p and q given by Eq. (37).

Now Eq. (35) can be written as follows

Equation(39) can be rewritten as

The solution of Eq. (40) can be obtained from [29] as

where \(J_{n} \text { and } Y_{n}\) are bessel functions of first and second kind, \(I_{n} \text { and } K_{n}\) are modified Bessel functions of first and second kind of order n respectively and \(c_{i}^s\) are arbitrary constants.

Now, because solution \(W_{nm}\) must be finite at all points within the plate. This makes constants \(c_2\) and \(c_4\) vanish since the Bessel functions of second kind \(Y_{n}\) and \(K_{n}\) become infinite at \(r=0\) ([23, 27]). Therefore,

Upon using Eq. (42) in Eq. (28), we obtained Microstretch function and Temperature distribution function of thin circular plate as follows:

Now by substituting expression (42) into boundary conditions (21) and (22), we obtained the following characteristics equations

The solution of characteristics Eq. (44) as \(\eta =\sqrt{q_{nm}}\) where the value of \(q_{nm}(n=0,1,2;m=1,2,3)\) are listed in Table 1 for clamped and simply supported plates which coincides with the available results [14] and [10].

Thermoelastic Damping

Now, the vibration frequency of the circular plate considering microstretch, thermoelastic coupling effect can be obtained as

where

and the values of \(\eta _{nm}^2\) are mentioned in Table 1 for \(n=0,1,2\) and \(m=1,2,3\).

Noting that \(\varepsilon _{\phi }\ll 1, \varepsilon _T\ll 1\) for silicon material, therefore we can replace \(f(\omega _{nm})\) with \(f(\omega _0)\) and \(g(\omega _{nm})\) with \(g(\omega _0)\) and expand Eq. (45) into a series up to first order. Then Eq. (45) becomes

Here, the values of parameters p and q given by Eq. (37) are complex, therefore, using Euler’s theorem and transforming \(\omega _{nm}\) with \(\omega _0\), we obtain

where

On using Eqs. (47)–(48) in Eq. (46) and simplifying Eq. (46), we obtain

where

and

The thermoelastic damping arises from thermal currents generated due to contraction and expansion of elastic structures. Thus, for thin choice of the value of characteristic time, we take relaxation times (due to stretch and thermal effects) as \(t_R=t_0=\omega ^{-1}\). Therefore Eqs. (47)–(48) becomes

where

Therefore we get the expression for thermoelastic damping in circular plate as given by

where

In the absence of thermal relaxation time, i.e when\((t_0\rightarrow 0)\) for coupled thermoelasticity, we have

where

Therefore, thermoelastic damping for coupled thermoelasticity plate is given by

where

Validation of the Analytical Results

In this section, we will discuss one special case to investigate our results.

For Thermoelastic Plate

In absence of microstretch effects, elasto-stretch coupling constants are zero i.e.\((\varepsilon _{\phi }=0)\) then

which completely agrees for dimensional case of generalized thermoelastic (\(t_{0}\ne 0\)) circular plate as well as for coupled thermoelastic (\(t_{0}=0\)) circular plate [10]. Thus Thermoelastic damping for both generalized and coupled thermoelasticity is reduced to analytic expressions discussed below

Numerical Simulations and Graphical Illustrations

With the aim to analyze the theoretical results obtained in the previous sections, we present some numerical simulations under this section. The material of the plate structure for this purpose has been taken as Silicon. Here, the physical parameters for Silicon material are as follows [4, 27](under the temperature \(T_{0}=293^{\circ }\) K)

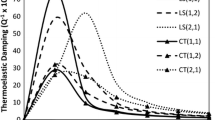

As thermoelastic damping is an important design variable in plate resonators development. The dependency of thermoelastic damping factor on the plate dimensions, boundary conditions, microstretch effect, thermal relaxation time and vibration modes for silicon MEMS devices are discussed. The computer simulated results have been presented graphically in Figs. 1, 2, 3 and 4.

First, we consider the case of a circular plate with fixed radius \(a=500\,\, \mu m\) and varying thickness h for vibration modes(1, 1), (1, 2), (2, 1). Figure 1 depicts the behavior of TED in case of clamped plate although Fig. 2 depicts the behavior of TED in case of simply supported plate. According to these figures, the thermoelastic damping on vibration modes (1, 1), (1, 2), (2, 1) increases first and then decreases with increasing value of thickness. Thus, there exists a critical thickness for which the maximum value of the damping factor occurs. The value of damping factor of vibration modes is observed to have greater value in case of the Fourier (coupled) microstretch thermoelastic plate in comparison to non-Fourier (generalized) microstretch thermoelastic circular plate in both clamped and simply supported cases. It is also mentioned that for \((1,1) \text { and } (2,1)\) modes, the value of thermoelastic damping is greater in case of clamped circular plate in comparison to simply supported circular plate where as for (1, 2) mode the value of thermoelastic damping is greater in case of simply supported circular plate in comparison to clamped circular plate.

In Figs. 3 and 4, the variation of thermoelastic damping in clamped and simply supported axisymmetric circular microstretch thermoelastic plates are described. Here, it is also observed that the damping factor firstly increases and then decreases in the considered range of thickness. The value of damping factor of vibration modes is observed to have greater magnitude in case of the Fourier (coupled) microstretch thermoelastic plate in comparison to non-Fourier (generalized) microstretch thermoelastic plate in both clamped and simply supported cases. It is also noticed that for \((0,1) \text { and }(0,2)\) modes, the value of thermoelastic damping is higher in case of clamped circular plates in comparison to simply supported circular plate although for (0, 3) mode the value of thermoelastic damping is greater in case of simply supported circular plate in comparison to clamped circular plate.

Conclusion

It leads to the conclusion that thermal relaxation time and microstretch parameters contribute to increase in the magnitude of critical value of damping. For fixed radius and varying thickness, thermoelastic damping is higher in case of Fourier (coupled) microstretch thermoelastic in comparison to non-Fourier (generalized) microstretch thermoelastic case for both clamped and simply supported circular plate. It is also observed that the thermoelastic damping on vibration modes (1, 1), (1, 2), (2, 1) and for axisymmetric modes (0, 1), (0, 2), (0, 3) have symmetric behavior with different value of critical thickness.

References

Berry BS (1955) Precise investigation of the theory of damping by transverse thermal currents. J Appl Phys 26:1221–1224

Biswas D, Ray MC (2013) Active constrained layer damping of geometrically nonlinear vibration of rotating composite beams using 1–3 piezoelectric composite. Int J Mech Mater Des 9:83–104

Chandrashekhara K (2001) Theory Pates. Universities Press, India, Orient Blackswan

Dhaliwal RS, Singh A (1980) Dynamic coupled thermoelasticity. Hindustan Publication Corporation, New Delhi, India

Eringen AC (1966) Linear theory of micropolar elasticity. J Math Mech 909–923

Eringen AC (1971) Micropolar elastic solids with stretch. Ari Kitabevi Matbassi 24:1–18

Eringen AC (1990) Theory of thermo- microstretch elastic solids. Int J Eng Sci 28:1291–1301

Eringen AC (1999) Microcontinuum field theories I: Foundation and Solids. Springer, New York

Grover D (2013) Transverse vibrations in micro-scale viscothermoelastic beam resonators. Arch Appl Mech 83(2):303–314

Grover D (2015) Damping in thin circular viscothermoelastic plate resonators. Can J Phys 93(12):1597–1605

Grover D, Seth RK (2017) Viscothermoelastic micro-scale beam resonators based on dual-phase lagging model. Microsyst Technol. https://doi.org/10.1007/s00542-017-3515-5

Grover D, Seth RK (2018) Generalized viscothermoelasticity theory of dual-phase-lagging model for damping analysis in circular micro-plate resonators. Mech Time Depend Mater 23(1).https://doi.org/10.1007/s11043-018-9388-x

Kumar RS, Ray MC (2012) Active constrained layer damping of smart laminated composite sandwich plates using 1–3 piezoelectric composites. Int J Mech Mater Des 8:197–218

Leissa AW (1969) Vibration of Plates. Scientific and Technical Information Division (National Aeronautics and Space Administration), Washington

Lifshitz R, Roukes ML (2000) Thermoelastic damping in micro and nanomechanical systems. Phys. Rev. B 61:5600–5609

Lord HW, Shulman Y (1967) The generalized dynamical theory of thermoelasticity. J Mech Phys Solids 15:299–309

Nayfeh AH, Younis MI (2004) Modeling and simulations of thermoelastic damping in microplates. J Micromech Microeng 14:1711–1717

Alghamdi NA (2019) Vibration of circular micro-ceramic (Si 3 N4) plate resonators in the context of the generalized viscothermoelastic dual-phase-lagging theory. Adv Mech Eng 11(11):1. https://doi.org/10.1177/1687814019889480

Partap G, Chugh N (2017a) Deflection analysis of micro-scale microstretch thermoelastic beam resonators under harmonic loading. Appl Math Model 46:16–27

Partap G, Chugh N (2017b) Thermoelastic damping in microstretch thermoelastic rectangular plate. Microsyst Technol 23:5875–5886

Partap G, Chugh N (2017c) Study of deflection and damping in micro-beam resonator based on micro-stretch thermoelastic theory. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2017.1365988

Rao SS (2007) Vibration of continuous systems. Wiley, New Jersey, USA

Rashidifar MA, Rashidifar AA (2015) Vibrations Analysis of circulare plate with piezoelectric actuator using thin plate theory and bessel function. Am J Eng Technol Soc 2(6):140–156

Reddy JN (1999) Theory and analysis of elastic plates. Taylor and Francis, Philadelphia, PA

Sharma JN, Grover D (2012) Thermoelastic vibration analysis of Mems/ Nems plate resonators with void. Acta Mech 223:167–187

Sun YX, Tohmyoh H (2009) Thermoelastic damping of the axisymmetric vibration of circular plate resonators. J Sound Vib 319:392–405

Sun Y, Saka M (2010) Thermoelastic damping in micro-scale circular plate resonators. J Sound Vib 329:328–337

Ventsel E, Krauthammer T (2001) Thin plates and shells: theory, analysis, and applications. Marcel Dekker Inc., New York

Watson GN (1922) A Treatise on the theory of Bessel functions. Cambridge University Press, UK

Wong SJ, Fox CHJ, McWilliam S (2006) Thermoelastic damping of the in-plane vibration of thin silicon rings. J Sound Vib 293:266–285

Zener C (1937) Internal friction in solids I, Theory of internal friction in reeds. Phys Rev 52:230–235

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chugh, N., Partap, G. Study of Thermoelastic Damping in Microstretch Thermoelastic Thin Circular Plate. J. Vib. Eng. Technol. 9, 105–114 (2021). https://doi.org/10.1007/s42417-020-00213-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-020-00213-6