Abstract

Edible films and coatings have received incredible consideration over years in view of their preference over synthetic films in diminishing environmental pollution. Edible films and coatings can also incorporate live microorganisms. One of the recent advancements in this field is development of probiotic edible films and coatings that serve as a potential carrier for these microorganisms by enhancing their survival. The potential utilization of edible films and coatings as stabilizing matrices for holding probiotic microorganism is to counteract the disadvantage of their direct application and to enhance the functional properties of edible coatings through the incorporation of probiotics. Probiotics incorporation into edible films and coatings allows them to reach the consumers gut in sufficient amount, so as to exert any health advantages to the host, and thus adds value to the food product. Microorganisms such as bacteria or yeast can be used as a biocontrol agent for extending the shelf life of food products; one such way is their incorporation into edible films and coatings. The scope of this review is to provide comprehensive information about the incorporation of probiotic microorganisms into edible films and coatings along with discussing various future prospects, applications and associated concerns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Edible films and coatings have received great attention over years because of their various advantages over synthetic films mainly concerning environmental pollution. The major advantage associated with the use of these films over traditional synthetic polymer is that they are biodegradable and can be consumed along with the product. Edible films and coatings developed using biodegradable edible ingredients can be easily degraded as compared to synthetic polymeric materials [1]. Various components are used for the development of edible films and coatings; these components are mainly categorized into three broad categories, i.e., hydrocolloids (such as proteins, polysaccharides, and alginate), lipids (such as fatty acids, acylglycerol, waxes) and composites [2]. Apart from being an alternative to non-biodegradable films, these films can also contribute to enhancing the organoleptic properties of packaged foods as they can incorporate components such as flavorings, colorings, sweeteners, etc. But the one limiting factor associated with the use of edible films is their poorer permeability and mechanical properties over synthetic films [3]. Ample work or research needs to be done for the development of new materials, films formation procedures that enhance film properties and their potential applications to various food products. One of the major advantages associated with the use of these films is that they serve as a potential carrier for various substances such as flavors, antimicrobials, antioxidants, nutraceuticals, etc. One of the most recent advances in this direction is the incorporation of probiotic strains in edible films and coatings that provide an efficient delivery alternative for increased survival of these microorganisms.

Probiotics are live microorganisms which when administered in adequate amount confers health benefit to the host [4]. The most widely used probiotic strains belong to the genera Bifidobacterium and Lactobacillus. Furthermore, yeast such as Saccharomyces boulardii is generally accepted for use as probiotics. These probiotic microorganisms possess many health benefits such as production of vitamins [5, 6], cholesterol lowering [7,8,9], alleviation of lactose intolerance [10], cancer prevention [11, 12], stimulation of the immune system [13, 14], enhancement of bowel movement [15, 16], relief from constipation [17, 18], prevention from rotavirus and reduction in antibiotic-associated diarrhea [19]. Probiotics can be incorporated within edible polymer matrices which serve as a potential carrier and can be used by the food packaging industry for various applications as an active/bioactive food packaging system for controlling the growth of pathogenic microorganism [20]. This improves food stability and safety and most importantly promotes consumers’ health. Recently, probiotic incorporation in edible films or coatings had gained a lot of attention from the researchers and needs to be explored more. The present review gives a comprehensive overview on this subject highlighting the nature of probiotics, summarizes scientific studies dealing with their incorporation in edible films and coatings, and discusses their applications as well as associated concerns, future prospects and legislation aspects with their use.

Probiotics in Active Edible Films and Coatings

Food packaging provides convenience to the consumer during handling of food products. The traditional packaging fulfills the basic requirements such as containment, barrier properties, enhancing shelf life, etc. Presently, with the changing lifestyles, the consumer’s demands are also changing. This had encouraged the development of innovative packaging that is more advanced and more profound than the ones that are currently offered. Development of an active packaging system is the result of innovating thinking in packaging. Active packaging is a type of packaging in which all the components of the packaging systems, the packaging material, the food product, and the environment interact. The main aim of this type of packaging system is to enhance the performance of the packaging system. Bioactive food packaging systems may provide health benefits to consumers [21]. It is a recent approach based on the concept of functional foods, which suggests that any food that provides an additional health benefit besides the basic nutrition is considered as functional. For the development of improved functional products, the vehicles for efficient delivery of probiotics play a major role in promoting human health [22]. Issues that relates to the viability and survival of probiotics in the finished product have been raised. Various intrinsic and extrinsic factors can affect the behavior of a microorganism within a food environment such as the type of culture used, the physical state of the cells, the food matrix, the pH, the temperature, the manufacturing processes and the storage conditions [23]. Apart from these parameters, the another most important parameter is the viability of probiotics during their passage through gastrointestinal tract, where they come across with hurdles like low pH and bile. To overcome these limitations and to enhance the viability of the microorganism, an important strategy had been suggested that involves the inclusion of probiotics into edible films and coatings or their microencapsulation into polymeric matrices [22]. The bioactive packaging materials may contain (bioactive) agents that are eventually released into the food product [21]. In the particular case of edible coatings containing probiotics, the release is not even required, since the coating itself is supposed to be eaten with the food [22]. A few studies had been conducted that involve incorporation of probiotic strain into edible films and coatings; one study was conducted to show that application of probiotic edible films to different food matrices acts as an effective method for efficient delivery of probiotics to the consumers as well as enhances the food stability and food safety by controlling the growth of spoilage-causing microbes by competing with them or through antimicrobial substances produced by probiotics.

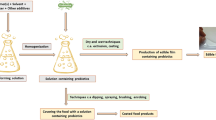

Incorporation Techniques

Use of probiotic bacteria for the development of functional foods exerting beneficial health effects is gaining an interest in the food industry. However, the stability of probiotics is not always optimal. Microencapsulation is one such efficient technique that perpetuates the survival of probiotic bacteria during processing and storage of food products. A few studies have been conducted that deal with incorporation of probiotics in edible films and coatings. Use of edible matrix as a probiotic carrier had shown better survival rates during storage and consumption. Use of edible films or coatings for entrapping cells makes incorporation of probiotics in foods easier and less expensive. Microencapsulation uses different ingredients (solid, liquid or gaseous) for entrapping substances providing a protective covering for control release [24]. In case of probiotics, the main goal of encapsulation is to protect these bacteria from the adverse effects of the low pH and bile with which these bacteria came across during their passage through the gastrointestinal tract [24, 25].

Additionally, microencapsulation techniques tend to enhance the viability of the encapsulated probiotics during food processing and storage conditions of the food products until their consumption. Low water activity or oxygen exposures are some factors that can affect the efficacy of this technique. Biodegradable polymers are mainly used as the materials for microencapsulation [24, 26]. A few microencapsulation techniques that are widely used includes prilling, spraying, emulsification, etc. [27]. Microencapsulation is a fast and cost-effective technique, but use of high temperatures may impair the viability of the microorganism [26]. To negotiate this effect of high temperature on the survival of microorganisms, an effective solution could be the use of thermoprotectors or growth promoting factors that can be added to the media before the spray drying or use of less-destructive methods such as spray freeze-drying or electrospray [28, 29].

Materials for Probiotic Edible Films and Coatings

Edible films and coatings can be produced from a variety of materials exhibiting film-forming ability. These components are generally characterized into three categories such as [1, 30]:

Hydrocolloids (i.e., proteins, polysaccharides)

Lipids

Composites

Other important components of the film-forming solution are plasticizers and emulsifiers that are added to enchance their mechanical properties or to enhance stability when lipids and hydrocolloids are combined [31]. Plasticizers are low-molecular-weight agents that are usually incorporated into film-forming materials to lower the glass transition temperature. Some of the common examples are glycerol, sorbitol, sucrose and polyethylene glycol [32]. Addition of plasticizers to the film-forming solution enhances flexibility, toughness and the tear resistance of the film. The hydrocolloids group used as a base for film development mainly comprises of polysaccharides and proteins. Polysaccharides used as edible films or coatings components include cellulose and its derivatives, dextrans, alginate, carrageenan, starch, pectin, chitosan, galactomannans, etc., [1, 31, 33, 34]. Edible films and coatings based on polysaccharides as a base material possess good barrier properties against oxygen and odor along with good mechanical properties but has a major drawback of high moisture permeability due to their hydrophilic nature [32]. Materials that serve as a base for various protein-based edible films and coatings include gelatin, corn zein, wheat gluten, soy protein, collagen, and casein. Protein films are mainly developed by evaporating solvent from the solutions or dispersions of the protein. The solvent that is most commonly used is water, ethanol or their mixture. Proteins should be denatured by heat, acid, base or solvent so as to give a more extended structure to the film [1]. Another important class of materials used for development of these films is lipids (natural waxes, vegetable oils, fatty acids, and resins) but these lipid compounds exhibit certain limitations such as mechanical and chemical instabilities as well as diminished organoleptic properties [32]. Lipids are generally used in combination with other film-forming materials such as polysaccharides or proteins to increase their resistance to water penetration [33]. Since each of these individual materials possesses some unique, but limited functions, different materials are used in combinations to give more effective properties to the films and coatings [30].

Probiotic Strains for Edible Films and Coatings

The efficacy of microorganism as a nutraceutical component or antimicrobial agent can be affected by several factors that had encouraged the development of newer and more effective strategies to enhance their functionality. One possible solution to overcome these limitations is the use of edible coatings or films as a possible carrier of these microorganisms for maintaining a suitable concentration on the surface of the food product and guaranteeing higher stability of the microorganisms when entrapped in the film matrix. Possible use of edible matrix as a carrier for viable probiotic strains can enhance the survival rates during storage and consumption and could also enhance sensorial characteristics, control of probiotic dosage and their novel applications in food products. The use of edible films or coatings to entrap cells can make application of probiotics in foods easier and less expensive. In fact, the use of edible films and coatings appears as an alternative to encapsulation techniques. Lactic acid bacteria (LAB) form a major group of probiotic bacteria used in the food industry. LAB are indeed good candidates to be used as probiotics, since several LAB strains are native to the human oral cavity and intestinal tract and have a positive influence, preventing the growth of harmful microbiota, and modulating mucosal immunity in these environments [35,36,37]. Some yeast had also shown to be associated with probiotic properties for human consumption such as Saccharomyces cerevisiae var. boulardii [38]. Some other yeast species includes Debaryomyces hansenii, Torulaspora delbrueckii, Kluyveromyces lactis, Yarrowia lipolytica, S. cerevisiae, Kluyveromyces marxianus, and Kluyveromyces lodderae that had shown to possess potential probiotic ability [39,40,41,42], but amongst, these only S. boulardii is considered to be most effective in terms of probiotic ability [43]. Yeasts possess certain advantages as compared to bacteria as a probiotic as they are insensitive to antibiotics and hence, serve as an effective treatment for diarrhea and intestinal infections caused by the administration of antibiotics and can also produce vitamins [38, 44, 45]. Effects of probiotics are strain specific; so genus, species, and strain of probiotic need to be specified when proclaiming health benefits [46].

Effects of Edible Films on Probiotic Viability

One of the most important parameters of consideration for development of probiotics-incorporated edible films and coatings is the viability of the incorporated probiotic strains till it reaches the gastrointestinal tract. The chemistry of the film and the film-forming process are the two important parameters affecting the survival and viability of the microorganism [47]. The most important effective factors on the viability of probiotics are the temperature of distribution and storage conditions [48]. Various studies had been conducted to study the viability of probiotic strain post incorporation into edible films and coatings.

A study was conducted to study the stability of films incorporated with probiotic Lactobacillus rhamnosus GG of different biopolymers with the addition of whey protein concentrate [47]. The results indicated that the population of the strain after 1 h of inoculation was high indicating no acute toxic effects of the biopolymer type or of the whey protein concentrate on its cell viability; whereas, the composition of the film-forming solution was found to be influential. The films developed from pectin, low- and high-viscosity sodium alginate, locust bean gum, and carrageenan had shown high cell lethality as compared to the one that contains whey protein concentrate. The possible cause for this could be the low pH film solution without addition of whey protein concentrate (pH 3.9–4.2) in case of pectin. Other intrinsic parameters may have affected the viability of the cells such as low redox potential and the substrate surface tension [47]. Also, it was concluded that the physical entrapment of probiotic cells in hydrogel interspaces may enhance the viability of L. rhamnosus GG cells by maintaining their physical cell structure for better performance.

Another study was conducted to investigate the survival of four probiotic strains such as Lactobacillus acidophilus, L. casei, L. rhamnosus, and Bifidobacterium bifidum) incorporated in carboxymethyl cellulose (CMC)-based edible films [49]. Various physicochemical properties of films were investigated during 42 days of storage at 4° and 25 °C and showed a significant decrease in the viability of bacterial cells. However, the viability of L. acidophilus and L. rhamnosus was in the range of recommended levels during the storage at 4 °C (107 CFU/g). Probiotic films caused more water vapor permeability (WVP) and opacity, and less tensile strength (TS) and elongation at break (EB) compared to the control film. However, no prominent changes in the physicochemical properties were observed in the probiotic films containing different strains. Hence, it could be concluded that refrigeration temperatures are favorable for the survival of probiotic strains. Another similar study was conducted to examine the survival rates of different probiotic strains of Lactobacillus plantarum and Lactobacillus pentosus incorporated in sodium alginate-based edible films in contact with ham slices throughout the storage period (66 days at 4 °C, 47 days at 8 °C and 40 days at 12 °C) [50]. The storage temperature was found to have no effect on the population of inoculated strains but was strain dependent. Generally, the reduction in the probiotics population was detected in the films at sampling point after their application on ham for all temperatures, probably due to the drying process and the subsequent stress. However, this had a limited effect on the probiotic survival at adequate levels (> 106 CFU/g).

Incorporation of prebiotic components is a promising technology for increasing the efficiency of probiotic strains. Only a few studies had been conducted that deals with the incorporation of prebiotics in probiotic edible films as an additional component to supplement and enhance the stability and functionality of the entrapped probiotic bacteria [51]. A study was conducted to investigate the viability of the probiotic Lactobacillus rhamnosus GG in gelatin films with the addition of certain prebiotic components such as inulin, polydextrose, wheat dextrin, and glucose-oligosaccharides [23]. It was found that the presence of glucose-oligosaccharides and polydextrose in the films had favored the survival of the probiotic strain, whereas inulin and wheat dextrin had shown to exert an adverse effect on cell viability. The inactivation rates of L. rhamnosus GG were found to be higher in the films stored at room temperature (25 °C) as compared to the films stored under refrigerated conditions except for the polydextrose edible films stored at 25 °C. The pure pullulan-based film had retained 80% more cell viability even after storage of 30 days under refrigerated conditions, the reason for this could be the decreased bacterial metabolism.

Applications

Fruits and Vegetables

Consumer preferences for minimally processed foods have encouraged researchers to focus on the development of an innovative and alternative approach for enhancing the quality of products without compromising food safety [52]. Active packaging is one such method in which the packaging material, the product, and the environment interact during storage to enhance the shelf-life and quality of the products. Advancement of bioactive food packaging systems containing bioactive agents that are released gradually (controlled release) in the product is required to provide health benefits to the consumers. In case of bioactive edible films and coatings, this release of bioactive agent is not required as the film or coating itself is supposed to be eaten along with the food [21]. Due to the sensitivity of probiotics to common processing conditions such as heat treatment, acidic environment, high osmotic pressure, and high redox potential, it is important to provide an efficient physicochemical barrier to provide stability to the organisms [47]. A possible solution to this problem was the incorporation of probiotic cultures into an edible coating matrix. Use of probiotic edible films was first proposed in 2007 for application on fresh fruits [53]. Important barrier properties required in the case of fruits and vegetables are the prevention of weight loss (retain moisture), inhibition of microorganisms, slowing down aerobic respiration and improving appearance by providing gloss. Edible coatings for fresh fruits are useful for controlling ripeness by reducing oxygen penetration into the fruit, thus reducing metabolic activity and softening changes [54].

Meat and Meat Products

Natural collagen casings from animal intestine represent one of the earliest uses of edible protein packaging materials [55]. Studies of collagen edible films have shown their potential to reduce moisture loss, minimize lipid oxidation, prevent discoloration, and reduce dripping of muscle foods [56]. Different methods of application can be adopted for application of edible films and coatings to meat and fish products such as dipping, spraying, casting, rolling, brushing, and foaming. Application of probiotic edible film in meat and meat products needs to be explored. A study was conducted to evaluate the efficiency of Na-alginate edible films as vehicles for delivering probiotic bacteria applied to sliced ham with or without pretreatment using high-pressure processing (HPP) incorporated with three different strains of probiotic bacteria in film-forming solution. Ham slices pretreated with or without HPP at 500 MPa for 2 min were packed with the films under vacuum and stored at 4°, 8°and 12 °C for 66, 47 and 40 days, respectively. Microbiological analysis, pH and color analysis were also performed. Sensory characteristics were also assessed for the relative abundance of each probiotic strain during storage using pulsed field gel electrophoresis. In case of ham slices without treatment, probiotic bacteria were enumerated above 106 CFU/g at all temperatures during storage. Similar results were observed in cases of HPP-treated samples, but showed difference in pH in case of latter ones which exhibit higher values. Sensory evaluation revealed that probiotic samples without HPP treatment possess a more acidic taste and odor than the control ones; whereas, these characteristics were markedly compromised in samples treated with HPP. Overall, the results of the study were promising since probiotic bacteria were successfully delivered in the products by edible films regardless of the HPP treatment [50].

Bakery Products

Edible films and coatings had appeared as an alternative solution to plastic packaging for various food product applications such as fruits and vegetables, dairy products, nutritional products, meat and meat products, etc. Another possible application of edible films and coatings could be in bakery and confectionary products. The appearance of baked products is an important quality attribute that greatly affects the visual perceptions of the buyers and the potential purchase of the product. One of the major contributors to the appearance and appeal of the product is the packaging of the product. The important characteristic of the package which is intended to contain bakery products must be considered for the following parameters:

Water vapor permeability of packages

Exchange of oxygen from within and outside a package

Aroma impermeability of packaging materials

Resistance to seepage of fats and oils

Protection from light

Provide physical, mechanical protection

Maintain adequate shelf-life

Run on automatic machinery

Strong and inexpensive

Edible films and coatings possessing properties comparable to these parameters can be applied to various bakery products. Nowadays, probiotic incorporation in edible films or coatings had gained a tremendous popularity amongst researchers as a potential area to be explored. Several studies had been conducted to study the effect of the application of probiotic edible films and coatings on the shelf-life and quality attributes of bakery products. The present review summarizes some of those studies.

Composition of film-forming solution was a critical factor affecting the viability of L. rhamnosus GG during preparation of air dried probiotic edible film as presence of whey proteins in the film-forming solution reduced L. rhamnosus GG viability during drying and storage whereas film based specifically on sodium alginate showed good performance under in vitro digestion, which could be due to an ionic setting mechanism. Further, no significant difference was found in organoleptic and thermo-physical properties of bread crust samples in both conventional and probiotic breads [47].

Another study was undertaken to indicate the use of triticale-based edible film coating on muffins to retard the staling process. Various parameters such as measuring weight, height, volume, density, color, texture and image analysis of control and coated muffins were evaluated during storage and showed reduction in hardness values in triticale-coated muffins during storage and faster staling in control muffins than coated ones. Descriptive parameters such as shape and size of crumb’s structure had shown that amount of small pores and decreased solidity value of pores of control muffins increased significantly in case of control during storage, while no significant difference was found in coated muffins [57].

This idea might be expandable additionally to other surface-contaminated foods as well. Since there are limited studies in this area, the advancement of films and coatings supplemented with probiotics still needs a considerable research.

Related Concerns

Apart from the various advantages of these developed films and coatings, there are certain concerns associated with these films and coatings that need to be put across. One of the most important criteria that are considered by a manufacturing company prior to commercial production of any food product should be the regulatory status and the current legislation [58]. It is important to note that, all the materials used should be edible, all film-forming components, as well as any additives should be food-grade, safe materials and all processing facilities should meet high hygienic levels [30]. The edible film or coating must meet these requirements to serve as food contact materials ensuring food safety and must be labeled as an active packaging material [59, 60]. Another important issue is associated with the ingredients that are used for the production of these films such as milk proteins (whey/casein), wheat protein, soy protein that may serve as possible allergens in the films or coatings and hence, their presence must be clearly labeled. Successful market applications in the future will be a result of the combined academic and industrial focus, to confront the numerous regulatory, scientific and economic issues [22, 61]. Incorporation of probiotic bacteria in free form in food products can strongly affect their sensory characteristics as extreme acidification or excessive proteolysis can occur that may decrease the product acceptability by consumers. Incorporation of probiotics in edible films or coatings may contribute in eliminating or controlling undesirable alterations that may result due to their addition in the free form [62]. As edibility of these films and coatings is an important parameter, they must have neutral organoleptic properties [63]. In a recent study, the impact of probiotic-supplemented sodium alginate films on the sensory properties of ham slices was studied. Application of film had found to significantly affect the sensory parameters such as aroma and taste of the ham slices as well as the total organoleptic scores independent of the storage temperature tested (4°, 8° and 12 °C) [50]. Samples with probiotic film were found to have more acidic taste than the control ones. Another important issue of concern needed to be put forward includes study of the effect of probiotic incorporation on various mechanical and barrier properties of these edible films and coatings.

Future Prospects

Edible films and coatings incorporated with probiotics have attained immense popularity as an emerging technology. The future applications of these films and coatings to food product mainly rely upon few parameters. The first most important parameter relates to the legislation frame that should allow the makers to invest in developing new technologies for compelling more effective probiotic production. Many other aspects of edible film technology needs to be explored; these may include evaluating current or other media that have not yet been mechanically used, choosing appropriate probiotic bacteria to be incorporated in each sort of edible film, also evaluating the impact of distinct edible films and coatings on different food products. It is also of great concern to evaluate the various properties of the current materials used for development of these edible films, so as to determine whether they provide the suitable environment for the incorporated probiotic microorganism to survive or may hinder their growth and viability. In addition to this, the other important aspect that needs to be explored in this direction is the use of a combination of probiotic and prebiotic for development of these active edible films and coatings. Also, in vivo studies need to be carried out to assess the viability of the incorporated probiotics under gastrointestinal conditions as well as to determine the level of probiotics that is to be delivered all through these systems, keeping in mind the ultimate goal to provide health benefits.

Conclusion

Edible films and coatings appeared to be an efficient carrier of live microorganisms leading to the improved viability of probiotics during processing and storage of the food products. Various factors such as the presence of a microorganism, type of plasticizer used as well as the base material used may affect the mechanical and physicochemical properties of these films and coatings. Different methods can be used to incorporate microorganism into these edible films and coatings. The method employed directly affect the viability and effective delivery of the microorganism within the polymer matrix. Moreover, various studies have revealed that incorporation of microorganism with antimicrobial properties limits the growth of pathogen when used for food packaging. However, further studies need to be conducted to explicate the influence of various process variables involved in the development of these films and coatings. A few new techniques have been developed that can potentiate the utilization of microorganisms in edible films and coatings. One such example is the combination of bio-control microorganisms with particular compounds that can stimulate the secretion of antimicrobial metabolites or combinations of microorganisms that can maintain probiotic populations in sufficient numbers that can benefit the host. Also, new formulations are being developed that combine films and coatings with emulsions, micro- or nano-encapsulations or liposomes that give a homogenous distribution and enhance the stability of microorganisms. Nevertheless, extensive research is needed on the newer methods of films and coatings formation and microorganism incorporation.

References

Bourtoom T (2008) Edible films and coatings: characteristics and properties. Int Food Res J 15(3):237–248

Donhowe IG, Fennema OR (1993) The effects of plasticizers on crystallinity, permeability, and mechanical properties of methylcellulose films. J Food Process Preserv 17:247–257

Kester JJ, Fennema OR (1986) Edible films and coatings: a review. Food Technol 40(12):47–59

Araya M, Morelli L, Reid G, Sanders ME, Stanton C, Pineiro M (2002) Joint FAO/WHO working group report on drafting guidelines for the evaluation of probiotics in food. World Health Organization, London

Capozzi V, Russo P, Dueñas MT, Lopez P, Spano G (2012) Lactic acid bacteria producing B-group vitamins: a great potential for functional cereals products. Appl Microbiol Biotechnol 96:1383–1394

LeBlanc JG, Lain JE, del Valle MJ, Vannini V, van Sinderen D, Taranto MP, de Valdez GF, de Giori GS, Sesma F (2011) B-Group vitamin production by lactic acid bacteria—current knowledge and potential applications. J Appl Microbiol 111:1297–1309

Shimizu M, Hashiguchi M, Shiga T, Tamura H, Mochizuki M (2015) Meta-analysis: effects of probiotic supplementation on lipid profiles in normal to mildly hypercholesterolemic individuals. PLoS One 10:e0139795

Choi EA, Chang HC (2015) Cholesterol-lowering effects of a putative probiotic strain Lactobacillus plantarum EM isolated from kimchi. LWT Food Sci Technol 62:210–217

Huang Y, Wu F, Wang X, Sui Y, Yang L, Wang J (2013) Characterization of Lactobacillus plantarum Lp27 isolatedfrom Tibetan kefir grains: a potential probiotic bacterium with cholesterol-lowering effects. J Dairy Sci 96:2816–2825

He T, Priebe MG, Zhong Y, Huang C, Harmsen HJM (2007) Effects of yogurt and Bifidobacteria supplementation on the colonic microbiota in lactose-intolerant subjects. J Appl Microbiol 104:595–604

Le Leu RK, Hu Y, Brown IL, Woodman RJ, Young GP (2010) Synbiotic intervention of Bifidobacterium lactis and resistant starch protects against colorectal cancer development in rats. Carcinogenesis 31:246–251

Rafter J, Bennett M, Caderni G, Clune Y, Hughes R (2007) Dietary synbiotics reduce cancer risk factors in polypectomized and colon cancer patients. Am J Clin Nutr 85:488–496

Molina MA, Díaz AM, Hesse C, GinterW Gentilini MV, Nuñez GG, Canellada AM, Sparwasser T, Berod L, Castro MS (2015) Immunostimulatory effects triggered by Enterococcus faecalis CECT7121 probiotic strain involve activation of dendritic cells and interferon- production. PLoS One 10:e0127262

Ashraf R, Shah NP (2014) Immune system stimulation by probiotic microorganisms. Crit Rev Food Sci Nutr 54:938–956

Reddy VS, Patole SK, Rao S (2013) Role of probiotics in short bowel syndrome in infants and children—a systematic review. Nutrients 5:679–699

Whelan K, Quigley EMM (2013) Probiotics in the management of irritable bowel syndrome and inflammatory bowel disease. Curr Opin Gastroenterol 29:184–189

Kim SE, Choi SC, Park KS, Park MI, Shin JE (2015) Change of fecal flora and effectiveness of the short-term VSL#3 probiotic treatment in patients with functional constipation. J Neurogastroenterol Motil 21:111–120

Riezzo G, Orlando A, Attoma BD, Guerra V, Valerio F et al (2012) Randomised clinical trial: efficacy of Lactobacillus paracasei enriched artichokes in the treatment of patients with functional constipation–a double-blind, controlled, crossover study. Aliment Pharmacol Ther 35:441–450

McFarland LV (2007) Meta-analysis of probiotics for the prevention of traveler’s diarrhea. Travel Med Infect Dis 5:97–105

Coma V (2008) Bioactive packaging technologies for extended shelf life of meat-based products. Meat Sci 78:90–103

Lopez-Rubio A, Gavara R, Lagaron JM (2006) Bioactive packaging: turning foods into healthier foods through biomaterials. Trends Food Sci Technol 17:567–575

Espitia PJP, Batista RA, Azeredo HMC, Otoni CG (2016) Probiotics and their potential application in active edible films and coatings. Food Res Int 90:42–52

Soukoulis C, Behboudi-Jobbehdar S, Yonekura L, Parmenter C, Fisk ID (2014) Stability of Lactobacillus rhamnosus GG in prebiotic edible films. Food Chem 159:302–308

De Prisco A, Mauriello G (2016) Probiotication of foods: a focus on microencapsulation tool. Trends Food Sci Technol 48:27–39

Pinto SS, Verruck S, Vieira CRW, Prudêncio ES, Amante ER, Amboni RDMC (2015) Influence of microencapsulation with sweet whey and prebiotics on the survival of Bifidobacterium-BB-12 under simulated gastrointestinal conditions and heat treatments. LWT Food Sci Technol 64:1004–1009

Anal AK, Singh H (2007) Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery. Trends Food Sci Technol 18:240–251

Poncelet D (2006) Microencapsulation: fundamentals, methods and applications. In: Blitz JP, Gunk’ko VM (eds) Surface chemistry in biomedical and environmental science. Springer, Dordrecht, pp 23–34

Conrad PB, Miller DP, Cielenski PR, de Pablo JJ (2000) Stabilization and preservation of Lactobacillus acidophilus in saccharide matrices. Cryobiology 41:17–24

Desmond C, Ross RP, O’Callaghan E, Fitzgerald G, Stanton C (2002) Improved survival of Lactobacillus paracasei NFBC 338 in spray-dried powders containing gum acacia. J Appl Microbiol 93:1003–1011

Rojas-Grau MA, Soliva-Fortuny R, Martin-Belloso O (2009) Edible coatings to incorporate active ingredients to fresh-cut fruits: a review. Trends Food Sci Technol 20:438–447

Valencia-Chamorro SA, Palou L, del Río MA, Pérez-Gago MB (2011) Antimicrobial edible films and coatings for fresh and minimally processed fruits and vegetables: a review. Crit Rev Food Sci Nutr 51:872–900

Ramos OL, Fernandes JC, Silva SI, Pintado ME, Xavier Malcata F (2012) Edible films and coatings from whey proteins: a review on formulation, and on mechanical and bioactive properties. Crit Rev Food Sci Nutr 52:533–552

Suput DZ, Lazic VL, Popovic SZ, Hromis NM (2015) Edible films and coatings-sources, properties and application. Food Feed Res 42:11–22

Cerqueira MA, Bourbon AI, Pinheiro AC, Martins JT, Souza BWS, Teixeira JA, Vicente AA (2011) Galactomannans use in the development of edible films/coatings for food applications. Trends Food Sci Technol 22:662–671

Bosch M, Nart J, Audivert S, Bonachera MA, Alemany AS, Fuentes MC, Cun´e J (2012) Isolation and characterization of probiotic strains for improving oral health. Arch Oral Biol 57:539–549

Holzapfel WH, Schillinger U (2002) Introduction to pre- and probiotics. Food Res Int 35:109–116

Ohland CL, MacNaughton WK (2010) Probiotic bacteria and intestinal epithelial barrier function. Am J Physiol Gastrointest Liver Physiol 298:G807–G819

Surawicz CM, Elmer GW, Speelman P, McFarland LV, Chinn J, Van Belle G (1989) Prevention of antibiotic-associated diarrhea by Saccharomyces boulardii: a prospective study. Gastroenterology 96:981–988

Ceugniez A, Coucheney F, Jacques P, Daube G, Delcenserie V, Drider D (2017) Anti-Salmonella activity and probiotic trends of Kluyveromyces marxianus S-2-05 and Kluyveromyces lactis S-3-05 isolated from a French cheese, Tomme d’Orchies. Res Microbiol 168:575–582

Kumura H, Tanoue Y, Tsukahara M, Tanaka T, Shimazaki K (2004) Screening of dairy yeast strains for probiotic applications. J Dairy Sci 87:4050–4056

Psani M, Kotzekidou P (2006) Technological characteristics of yeast strains and their potential as starter adjuncts in Greek-style black olive fermentation. World J Microbiol Biotechnol 22:1329–1336

Aa Vander, K¨uhle A, Skovgaard K, Jespersen L (2005) In vitro screening of probiotic properties of Saccharomyces cerevisiae var. boulardii and food-borne Saccharomyces cerevisiae strains. Int J Food Microbiol 101:29–39

Sazawal S, Hiremath G, Dhingra U, Malik P, Deb S, Black RE (2006) Efficacy of probiotics in prevention of acute diarrhoea: a meta-analysis of masked, randomised, placebo-controlled trials. Lancet Infect Dis 6:374–382

Czerucka D, Piche T, Rampal P (2007) Review article: yeast as probiotics—Saccharomyces boulardii. Aliment Pharmacol Ther 26:767–778

Silva T, Reto M, Sol M, Peito A, Peres CM, Peres C, Malcata FX (2011) Characterization of yeasts from Portuguese brined olives, with afocus on their potentially probiotic behavior. LWT J Food Sci Technol 44:1349–1354

Burgain J, Gaiani C, Linder M, Scher J (2011) Encapsulation of probiotic living cells: from laboratory scale to industrial applications. J Food Eng 104:467–483

Soukoulis C, Behboudi-Jobbehdar S, Macnaughtan W, Parmenter C, Fisk ID (2017) Stability of Lactobacillus rhamnosus GG incorporated in edible films: impact of anionic biopolymers and whey protein concentrate. Food Hydrocoll 70:345–355

Ferdousi R, Rouhi M, Mohammadi R, Mortazavian AM, Khosravi-Darani K, Rad AH (2013) Evaluation of probiotic survivability in yogurt exposed to cold chain interruption. Iran J Pharm Res 12:139

Ebrahimi B, Mohammadi R, Rouhi M, Mohammad Mortazavian A, Shojaee-Aliabadi S, Reza Koushki M (2018) Survival of probiotic bacteria in carboxymethyl cellulose-based edible film and assessment of quality parameters. LWT Food Sci Technol 87:54–60

Pavli F, Kovaiou I, Apostolakopoulou G, Kapetanakou A, Skandamis P, Nychas GE, Tassou C, Chorianopoulos N (2017) Alginate-based edible films delivering probiotic bacteria to sliced ham pretreated with high pressure processing. Int J Mol Sci 18:1867

Romano N, José Tavera-Quiroz M, Bertola N, Mobili P, Pinotti A, Gómez-Zavaglia A (2014) Edible methylcellulose-based films containing fructo-oligosaccharides as vehicles for lactic acid bacteria. Food Res Int 64:560–566

Kapetanakou A, Karyotis D, Skandamis PN (2016) Control of Listeria monocytogenes by applying ethanol-based antimicrobial edible films on ham slices and microwave-reheated frankfurters. Food Microbiol 54:80–90

Tapia MS, Rojas-Graü MA, Rodríguez FJ, Ramírez J, Carmona A, Martin-Belloso O (2007) Alginate- and gellan-based edible films for probiotic coatings on fresh-cut fruits. J Food Sci 72:E190–E196

Conforti FD, Zinck JB (2002) Hydrocolloid-lipid coating affect on weight loss, pectin content, and textural quality of green bell peppers. J Food Sci 67(4):1360–1363

McHug TH, Avena-Bustillos RJ (2012) Applications of edible films and coatings to processed foods. In: Baldwin EA, Hagenmaier R, Bai J (eds) Edible coatings and films to improve food quality. CRC Press, Boca Raton, pp 291–318

Gennadios A, Hanna MA, Kurth LB (1997) Application of edible coatings on meats, poultry, and seafoods: a review. LWT Food Sci Technol 30(4):337–350

Bartolozzo J, Borneo R, Aguirre A (2016) Effect of triticale-based edible coating on muffin quality maintenance during storage. Food Meas 10:88–95

Kapetanakou AE, Skandamis PN (2016) Applications of active packaging for increasing microbial stability in foods: natural volatile antimicrobial compounds. Curr Opin Food Sci 12:1–12

European Commission (2011) Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food. Off J Eur Union 12:1–89

Commission Regulation (EC) 450/(2009) Active and intelligent materials and articles intended to come into contact with food; Official Journal of the European Union: Brussels, Belgium

Miquel S, Beaumont M, Martín R, Langella P, Braesco V, Thomas M (2015) A proposed framework for an appropriate evaluation scheme for microorganisms as novel foods with a health claim in Europe. Microb Cell Fact 14:48

Corona-Hernandez RI, Alvarez-Parilla E, Lizardi-Mendoza J, Islas-Rubio AR, de la Rosa LA, Wall-Medrano A (2013) Structural stability and viability of microencapsulated probiotic bacteria: a review. Compr Rev Food Sci Food Saf 12:614–628

Guilbert S, Gontard N, Cuq B (1995) Technology and applications of edible protective films. Package Technol Sci 8:339–346

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandhi, S., Kumar, A. & Alam, T. Probiotic Edible Films and Coatings: Concerns, Applications and Future Prospects. J Package Technol Res 3, 261–268 (2019). https://doi.org/10.1007/s41783-019-00069-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-019-00069-6