Abstract

The open literature evidently indicates that the shear capacity of reinforced concrete beams is adversely affected by the replacement of natural concrete aggregate by recycled concrete aggregate (RCA), and several equations for estimating the shear capacity were proposed. This paper provides a critical assessment of the existing prediction equations for estimating the shear capacity of RAC beams. The assessment is conducted utilizing Bayesian parameter estimation for comparison between the seventeen existing prediction models of the shear capacity of RAC beams. This robust assessment technique against false conclusions yields more informative and richer inferences than a mere comparison with the experimental shear capacities by providing a complete distribution of the mean and standard deviation of the quality of the prediction (i.e., test-to-predict shear values). A clear ranking of the existing prediction equations is performed based on the degree of conservatism and uniformity of the design provided by each of the shear strength prediction equations. This paper also directly addresses the significant parameters that influence the shear strength of RAC beams based on the grey correlation analysis (GCA) and check whether the existing prediction equations include these important parameters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The insufficiency in available spaces for concrete demolition wastes disposal and the exhaustion of natural resources of aggregate is a common concern, specifically in urban areas [1]. One of the promising solutions concerning this problem is processing these wastes through a process that involves removing impurities, crushing, and sieving the demolition waste to generate a new aggregate so-called recycled concrete aggregate. When recycled concrete aggregate is utilized in concrete production, with partial or complete replacement of natural aggregate, this concrete is denoted as recycled aggregate concrete. Recycling concrete waste is considered an effective method for waste processing that has many economic and environmental advantages [2]. Such technology is considered a major deal, especially in countries that suffer from a shortage in natural aggregate and landfill capacity (e.g., Japan and the Netherlands) [3,4,5].

Despite the large quantities of recycled aggregate in some countries, the majority of recycled aggregate is used predominantly as a filling for retaining walls, a pavement base, and non-structural concrete sections (fences, curbs, trails), and only small quantities are used for structural concrete [6]. The major reasons for this are related to the quality of recycled aggregate such as lower density, higher water absorption, and the high content of impurities (e.g., glass, soil, plaster) compared to natural aggregate. Large variations in these aforementioned properties are common, which significantly affects the performance of recycled aggregate concrete. To expand the usage of recycled aggregate for structural concrete, much research focused on classifying recycled aggregate by using a performance-based approach rather than composition only [7], which has been found to be a more general approach to estimate the performance of recycled aggregate [7, 8]; thus, produce a structural concrete with predictable performance.

Although a lot of research was devoted to investigating the properties of recycled aggregate, its rheology, and durability characteristics, limited research was conducted on the behavior of recycled aggregate concrete structural members [9,10,11,12,13,14,15,16]. These studies are very significant because it is difficult to predict the behavior of reinforced recycled aggregate concrete members based only on the test results obtained from the material characteristics of recycled aggregate [17].

In the open literature, the shear behavior of recycled aggregate concrete (RAC) beams was investigated at various levels of replacement of natural concrete aggregate. Knaack and Kurama [16, 18], in their experimental investigation, observed that the shear capacity of RAC beams was reduced by the inclusion of recycled aggregate; however, they concluded that the existing design standards were adequate for the design of RAC beams regardless of the aggregate replacement ratio due to their inherently conservative nature. Moreover, Arezoumandi et al. [16, 18] conducted an experimental study to investigate the shear behavior of RAC beams with 100% and 50% replacement ratio of natural aggregate at longitudinal reinforcement ratios of 2.73%, 2.03%, and 1.27%. The load–deflection relationship and the crack pattern were very similar to the natural aggregate concrete (NAC) beams. The results also indicated that even though the shear capacity of the tested RAC beams was reduced compared to the corresponding NAC beams, the shear capacity of RAC beams was located within the 95% confidence level of the shear capacity of the conventional NAC beams in the existing literature. Further, Choi et al. [19] performed an experimental investigation to study the shear performance of RAC beams at different replacement ratios of natural aggregate (30%, 50%, and 100%), different longitudinal reinforcement ratios (0.53%, 0.81%, and 1.61%), and at different shear span ratio (1.5, 2.5, and 3.25). All the tested beams demonstrated a shear tension failure mode; however, the shear capacity of the RAC beams was observed to be lower than the corresponding NAC beams. Moreover, the results indicated that as the shear span increases the reduction in shear capacity in RAC beams is greater than the corresponding NAC beams. Once more, Choi et al. [19] established that existing design standards are suitable for the design of RAC beams due to their inherently conservative nature. Ignijatovic et al. [20] also investigated the shear behavior of RAC beams with and without shear reinforcement at different replacement ratios of natural aggregate (50% and 100), it was concluded that the existing design standards need no further modifications for RAC beams design. Conversely, Rahal and Alrefaei [21] showed by comparison with experimental results of forty-nine RAC beams that the simplified ACI 318 [22] equation are generally unconservative in predicting the shear capacity of RAC beams and suggested a 20% reduction to the shear strength estimated using the ACI equation when designing RAC beams. In addition, Etxeberria et al. [23, 24], based on their experimental program, suggested that codes design equations should be only used for the design of RAC beams with a 25% replacement ratio of natural aggregate or less and recommended further research to investigate the shear behavior of RAC beams at a higher recycled aggregate replacement ratio. Tošić et al. [25] also established that the [26] shear prediction equations are inaccurate and imprecise in predicting the shear performance of RAC beams with stirrups. In addition, Pradhan et al. [27] claimed, based on their experimental program and statistical analysis results, that the existing shear prediction equations are inadequate for predicting the shear capacity of RAC beams and proposed other equations to predict the shear strength of RAC beams.

From these observations on the shear behavior of RAC beams, it may be seen that confirming the existing design codes are capable to predict the shear capacity of RAC beams still need further evaluation and more critical assessment. Moreover, despite the possibility that code equations may offer a conservative prediction of the shear capacity of RAC beams, due to their inherently conservative nature, this degree of conservatism should be accurately quantified for further safety assessment and reliability of the shear design of RAC beams.

The assessment of existing design equations using mere comparison with experimental data may be susceptible to false conclusions due to the possibility that the collected data may contain accidental coincidences of erroneous data [28]. In this study, a Bayesian framework for assessing different shear prediction models of RAC beams is proposed. The Bayesian parameter estimation allows overcoming the sensitivity of any drawn conclusion from the properties of the collected database. Bayesian parameter estimation addresses the possibility of false conclusions issue by providing a complete distribution of credible values of the mean \(\mu\), standard deviation \(\sigma\), and effect size of experimental-to- estimated capacity values.

Any design equation is required to provide a uniform strength prediction across the different design parameters (i.e., variability of the strength predictions from the experimental values is as low as possible). To assess if existing prediction equations of shear capacity of RAC beams can offer a uniform design across different design parameters, the distribution of the plausible values of the standard deviation of test-to-predict shear strength and its associated highest density interval (HDI) are estimated using the Bayesian approach. The HDI is defined as the interval of most credible values that covers 95% of the distribution. To perform this Bayesian assessment a comprehensive and up-to-date dataset of RAC beams that failed in shear was collected and analyzed using Bayesian statistics.

Finally, based on the collected experimental database, a grey correlation analysis is performed to estimate the parametric sensitivity of the shear strength of RAC beams. The existing shear prediction equations, to describe the real shear behavior, should offer similar sensitivity to the different parameters. As a part of the assessment, it will be checked that the important parameters in the shear prediction are not ignored in the different prediction models.

Surveyed experimental database

A comprehensive literature review was performed to collect data from tests conducted on RAC beams [11, 12, 15, 16, 18, 19, 25, 27]. The beams have different features concerning recycled aggregate replacement ratio \(\left( r \right)\), maximum aggregate size \(\left( {d_{\max } } \right)\), cross section size, shear span-to-depth ratio \((a/d)\), longitudinal reinforcement ratio \(\left( \rho \right)\), shear reinforcement ratio \((\rho_{w} )\), concrete compressive strength \((f_{{\text{c}}}^{^{\prime}} )\), and longitudinal yield strength \((f_{{\text{y}}} )\). The distribution of these variables as well as the experimental shear capacity values are shown in Fig. 1, where count indicates the number a certain range of a specific variable appeared in the dataset. The dataset consists of 276 beams that failed in shear, only 38 beams out of the 276 beams are with stirrups (i.e., shear reinforcement).

The shear span-to-depth ratio \(a/d\) in the dataset has a wide range extending between a minimum of 1 and a maximum of 5.1, mainly within the range (\(2 < a/d < 4)\). Most of the collected specimens have used reinforcing steel with a yield strength \(f_{{\text{y}}}\) of less than 600 MPa. The compressive strength of concrete \(f_{{\text{c}}}^{^{\prime}}\) has a range between 20 and 50 MPa. The dominant maximum aggregate sizes \(d_{\max }\) in the dataset are 19 mm and 25 mm.

Existing shear strength prediction equations

The related literature indicated that the shear capacity of reinforced concrete (RC) beams is adversely affected by the replacement of natural aggregate by recycled aggregate [9, 16, 18]. However, whether existing code prediction equations are suitable for estimating the shear capacity of RAC beams still needs further evaluation as explained earlier. In this regard, the existing shear prediction equations, summarized in Table 1, are compared to experimental results to validate their suitability for use in the design of RAC beams.

The prediction models available in the ACI 318-19 [22], Eurocode 2 [26], IS:456 (2000) [29], BS 8110 [30], and the proposed equation by Bazant and Yu [31, 32] only consider the longitudinal reinforcement ratio, shear reinforcement ratio, compressive strength of concrete, and the beam effective depth to predict the shear capacity of reinforced concrete (RC) beam. In addition to this, CEB-FIP [33], the proposed equations by Zsutty [34, 35], Niwa et al. [36], Gastebled and May [37], Kim and Park [38], and Rebeiz [39] also account for the shear span-to-depth ratio. However, the New Zealand code [40] only considers the effect of compressive strength of concrete along with longitudinal reinforcement ratio. The equation proposed by Arslan [41] only accounts for the compressive strength of concrete, the shear reinforcement ratio, and the shear span-to-depth ratio to predict the shear capacity. The shear equations proposed by Bazant and Sun [42] and Bazant and Kim [43], which were derived based on the fracture mechanics approach, account for compressive strength of concrete along with longitudinal reinforcement ratio, the effective depth of the beam, shear reinforcement ratio, and shear span-to-depth ratio. The shear equation was proposed by Russo et al. [44] also considers the same parameters as Bazant and Sun [42] and Bazant and Kim [43] while the equation prosed by Pradhan et al. [27] considers the effect of aggregate replacement ratio, concrete compressive strength, depth of the beam, shear span-to-depth ratio, and maximum aggregate size.

Proposed Bayesian framework for assessment

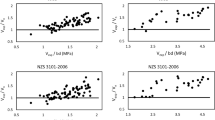

Collected data are not enough for making inferences as they only provide sample statistics (e.g., point estimates of the mean \(\mu\) and standard deviation \(\sigma\) of test-to-predict shear values) that are dependent on the set of the collected data that may contain accidental coincidences of erroneous values, rather than a possible set of statistics with their degree of credibilities (i.e., possible hypotheses) given that there is a certain set of observed data. For example, a simple comparison between the experimental values of shear capacity of RAC beams \((v_{{{\text{test}}}} )\) and the values provided by different code prediction equations, as shown in Fig. 2. Result in one set of sample statistics (e.g., \(\mu\) and \(\sigma\)) for each comparison that is sensitive to the collected dataset; thus, the risk of change of these values are high when using different datasets (in sample size or values). This risk of change may cause some uncertainty about the correct conclusions. As an alternative, Bayesian parameter estimation can provide complete distributions of parameters (i.e., distributions of sample statistics) that indicate the relative credibility of each possible value; thus, it is more general and robust to false alarm situations (i.e., arriving at false conclusions). The robustness comes from the adaptive nature of the credibility values as new data are observed; however, the set of the possible parameters is less likely to change to alter the conclusions. In other words, Bayesian parameter estimation provides us with possible parameters in which their credibilities are the only thing at risk to change with new observations.

In this study, a set of values of tested-to-predicted shear strength of RAC beams have been observed. For assessment, it is essential to quantify the difference between the typical shear capacities (i.e., measured in the test) and the predicted values. To reach a more robust assessment, Bayesian parameter estimation is performed. Bayesian parameter estimation is a superlative technique to estimate the data parameters (e.g., \(\mu\) and \(\sigma\)) and assess the uncertainty of the estimates.

The test-to-predict shear strengths of RAC beams (i.e., \(V_{{{\text{test}}}} /V_{{{\text{pred}}}} )\) are modeled as log-normal random variables. Thus, the natural logarithms of these values \(x_{i}\) are normally distributed, and the Bayesian method developed for normally distributed random variables can then be used. In Bayesian statistics, the parameters are considered as random variables in which their probability distributions can be updated as new data is observed. The method for updating the joint probability distribution of the parameters \(\mu\) and \(\sigma^{2}\) based on the observed data is

where \(f^{\prime\prime}\left( {\mu ,\sigma^{2} |{\mathbf{x}}} \right)\) and \(f^{\prime}\left( {\mu ,\sigma^{2} } \right)\) are the posterior and prior density function of the parameters, respectively. The symbol \(\propto\) stands for that the terms are proportional (i.e., equal up to a product with a constant). \(L\left( {\mu ,\sigma^{2} {|}{\mathbf{x}}} \right)\) are the likelihood of parameters according to the observed data represented by a vector \({\mathbf{x}}.\) The likelihood term can be written as the product of the probability densities of each of the \(n\) observed data points \(x_{i}\) and it depends on the value of the parameters \(\mu\) and \(\sigma^{2}\):

The prior probability distribution can either be modeled to consist of prior knowledge regarding the distribution of the parameters, or it could be noninformative, this means that the posterior distribution only is a function of the data. In this study, the approach is to choose a prior distribution that is noninformative for the mean and variance values. This approach is selected because a very wide range of the mean and standard deviation of test-to-predict shear strength of RAC beams is assumed. A similar approach was used by Caspeele and Taerwe [45] for concrete structures and Müller and Graubner [46] for masonry structures. Here, it is sought to assign broad priors to the parameters relative to the observed data, so that priors have a small influence on the posteriors. On lie of this, a normal distribution is assigned to the parameter \(\mu\) with a mean \(M\) that is equal to the average of the data \(m\), and a standard deviation \(S\) that is equal to a large multiple (e.g., 1000) of the standard deviation of the observed data \(s\),

\({\mathcal{N}}\left( {M, S^{2} } \right)\) refer to a normal distribution with a mean \(M\) and variance \(S^{2} .\) This way, the prior of the mean is assured of being vague. Similarly, a uniform prior on \(\sigma\) is assigned with an upper bound \(H\) that is a large multiple of the standard deviation of the data and a lower bound \(L\) that is a small fraction of the standard deviation of the data.

\(U\left( {L,H} \right)\) represent a uniform distribution with a lower bound \(L\) and an upper bound \(H\). Again, this means that the prior on \(\sigma\) is vague relative to the data. Figure 3 illustrates the model structure of the Bayesian estimation adopted here. At the top of the diagram, the priors for the parameters (\(\mu\) and \(\sigma )\) are shown. The sampling distribution of the data was described by a log-normal distribution as recommended in related literature as a viable description of the model error (i.e., the distribution of \(V_{{{\text{test}}}} /V_{{{\text{pred}}}}\)) [47], this description will be validated at the end of the assessment. The joint density function of the prior (i.e., \(f^{\prime}\left( {\mu ,\sigma^{2} } \right)\)) is assumed to be the product of \(f^{\prime}\left( \mu \right)\) and \(f^{\prime}\left( \sigma \right)\) (i.e., independent parameters assumption),

Although the analytical solution of Eq. (1) may be reached, the exact analytical solutions will be abandoned, and instead, the Markov chain Monte Carlo (MCMC) method to estimate the posteriors will be used. MCMC algorithms create samples from probability distributions (i.e., priors and likelihood), and these samples are used to compute the posteriors by Eq. (1). The innovation of MCMC algorithms, along with fast computers, and software for automatically generating samples for complex models, allowed Bayesian statistics to gain practical use [25]. Assessment is performed by interpreting the generated posterior distributions. The final step of the assessment requires validating that the sampling distribution (likelihood) specified in the previous step is a good representation of the data. Figure 4 summarizes the steps of the Bayesian assessment framework.

Posterior distributions

Performing the MCMC algorithm [48] to approximate the posteriors using the Bayes’ rule, priors, and likelihood described earlier results in the posterior distribution of \(\mu\) and \(\sigma\) for each code comparison as shown in Fig. 5. The posteriors related to the comparison of the other existing prediction models proposed by different authors to the experimental results are shown in Fig. 1A. From Fig. 5, it can be observed that each code has a varying degree of conservatism in estimating the shear capacity of RAC beams. This degree of conservatism can be seen in the mean and the effect size distribution of \(V_{{{\text{test}}}} /V_{{{\text{pred}}}}\). When the HDI of the mean distribution falls within the region that is greater than one, as in the case of all the codes except the New Zealand code (see Fig. 5), this means that the prediction equation offers some conservatism in the prediction on average. The effect size distribution represents the standardized difference measured in a unit of standard deviation. The effect size can offer another metric to indicate the degree of conservatism in the mean prediction. However, for safety or reliability analysis, both the mean and standard deviation of the model error (i.e., \(V_{{{\text{test}}}} /V_{{{\text{pred}}}} )\) controls the final conservatism score of the prediction equation. The most plausible values of \(\mu\) and \(\sigma\) that can be used in reliability analysis are illustrated by the HDI interval of each distribution.

Besides providing parameters for the model error required by reliability and safety analysis of different prediction equations, Bayesian estimation can be used to indicate the degree of uniformity in the design across different design parameters offered by prediction equations. The degree of uniformity can be estimated by two values: the range of the plausible mean values (i.e., the range of the HDI of the mean distribution), and the values of the plausible \(\sigma\) values. The large range of plausible mean values indicates that the observed data cannot give strong evidence that the bias (i.e., \(\mu\)) in the estimation is toward a single value. Thus, the mean estimate has high estimation uncertainty which may indicate a possible nonuniform design offered by the prediction equation. High values of plausible \(\sigma\) values suggest that the quality of prediction varies with different designs; thus, the prediction equation doesn't satisfy the uniform design requirement.

Moreover, the posteriors can be used for comparing different prediction equations. For example, comparing the posteriors of the New Zealand code and the CEP-FIP code, one will observe that the CEP-FIP offers a more uniform and conservative design in contrast with the New Zealand code.

Posteriors predictive check

The last step of the assessment requires checking if the posterior predictions can imitate the data with reasonable accuracy. If not, another model structure of the data should be described. This process is called “posterior predictive check”. There is no unique way for verifying that the model predictions systematically or meaningfully mimic the data because there are many ways to measure the systematic variation of the actual data from its predictions. One approach is to plot the histogram of the actual data (i.e., collected \({\mathrm{V}}_{test}/{\mathrm{V}}_{pred}\) data) against distributions of the predicted data from the model structure (see Fig. 3). First, random samples of the parameters \(\mu\) and \(\sigma\) are generated from their posterior distributions and plugged into the data model (here it is the log-normal distribution) to generate different log-normal distributions. This is done a large number of times to create representative distributions of the data model. The results of this simulation are illustrated in Fig. 6 for three code predictions, and the rest of the results were not shown in this study for brevity. By visual inspection of the results illustrated in Fig. 6, the actual data appears to be well-described by the log-normal distribution; thus, no need to change the model of the data. The inspection of other prediction equations yielded the same conclusion.

Grey correlation analysis

To estimate the parametric sensitivity of the shear capacity of RAC beams, the grey correlation analysis (GCA) was performed in this study. The goal here is to determine the significant parameters that influence the shear strength of RAC beams (i.e., highly correlated with shear strength); thus, should be considered in modeling the shear behavior of RAC beams. As a part of the assessment, the existing prediction equations will be checked whether it includes these important parameters.

GCA is a method to decide whether parameters are correlated and to determine their degree of correlation [49]. The GCA is conducted here between the shear capacity (called main factor or main array) and the design parameters of the RAC beams (called sub-factors or sub-arrays) to determine the important parameters in the model development of the shear capacity of RAC beams. The detailed calculation requires assigning the shear strength values to a sequence denoted as the reference sequence \(({\varvec{X}}_{0} = \{ X_{0} \left( 1 \right),X_{0} \left( 2 \right), \ldots ,X_{0} \left( n \right)\} )\) while the critical RAC beam parameters including concrete strength, recycled aggregate content, yield strength of longitudinal reinforcement, beam effective depth, shear span-to-depth ratio, and maximum aggregate size are considered as the comparative sequences, \(({\varvec{X}}_{i} = \{ X_{i} \left( 1 \right),X_{i} \left( 2 \right), \ldots ,X_{i} \left( n \right)\} , i = 1,2, \ldots ,m)\). Then, the reference sequence and the comparative sequences are normalized to the same scale to reduce the influence of the numerical variations and parametric dimensions of the original sequences. The normalization of each value in the sequence is conducted as follows:

The grey relational coefficient \(\gamma_{i}\) between the reference sequence and the comparative sequence \(i\) can be calculated as follows:

where \(\xi\) is a coefficient, a value of 0.5 is often used [49], and:

To estimate the degree of correlation, the grey relational grade \(\lambda_{i}\) is used:

The higher the relational grade, the greater the correlation between the comparative sequence and the reference sequence. Figure 7 shows the grey relational grade between the shear strength of RAC beams and the varying design parameters.

From Fig. 7, it can be observed that the correlation grade varies with the design parameters. In case the full dataset of RAC beams is used in the GCA, the ranking of influential parameters based on the correlation grade is as follows: \(d_{\max } > d > \rho > f_{{\text{c}}}^{^{\prime}} > r, a/d\). Thus, for the prediction equations that specify one shear equation for beams without regard to the value of \(a/d\) or \(A_{v}\) (e.g., CEB-FIP prediction equation), these influential parameters should be included in the model development of shear capacity. In the case of RAC beams without shear reinforcement or with \(A_{v} < A_{v\min }\), the ranking of the parameters is as follows: \(d > d_{\max } > \rho > f_{{\text{y}}} > f_{{\text{c}}}^{^{\prime}} > r\). This ranking is surprising as \(f_{{\text{y}}}\) correlation grade exceeded the one for \(f_{{\text{c}}}^{^{\prime}}\). This could be explained by the properties of the collected dataset as most beams have a low concrete strength and limited \(f_{{\text{y}}}\) values. Extending the dataset to cover a wide range of concrete strength and steel yield strength may increase the correlation grade of \(f_{{\text{c}}}^{^{\prime}}\). Therefore, here \(f_{{\text{c}}}^{^{\prime}}\) will be considered an influential parameter despite the correlation grade. Another surprising observation from the GCA results is the correlation grade of \(d\) in the case of RAC beams with or without shear reinforcement as the GCA results indicate that the influence of \(d\) on the shear capacity is the same regardless of shear reinforcement. This opposed what the ACI 318-19 prediction equation suggests as it only includes the parameter \(d\) for the case of \(A_{v} < A_{v\min } .\) For the case \(a/d < 2.5\), it can be seen that more correlation grade is given to \(f_{{\text{c}}}^{^{\prime}}\) than \(\rho\), conversely when \(a/d \ge 2.5\) a more correlation grade is given to \(\rho\) compared to \(f_{{\text{c}}}^{^{\prime}} .\) This phenomenon has been observed in previous research [50] that indicated that steel shear contribution was more effective for beams with high \(a/d\) ratios than for deeper beams with \(a/d < 2.5\). This could be explained by the fact that slender beams with high \(a/d\) ratios mostly exhibit an S-shaped critical diagonal crack prior to shear failure, resulting from the more apparent effect of normal stress resulting by flexural moment [51,52,53,54,55,56] from which it is well understood in the literature [57] that steel reinforcement ratio \(\rho\) has the highest influence on the flexural resistance. From Fig. 7a–e, it can be seen that aggregate replacement ratio \(r\%\), as observed in previous literature [15, 19, 20], does not significantly contribute to shear strength prediction. However, this conclusion is based on the GCA of the dataset with a wide range of replacement ratios \(r\% .\) Performing GCA to the subset of the data with \(r\%\) greater than 25% results in the correlation grades as shown in Fig. 7f. From Fig. 7f, it is indicated that \(r\%\) has a significant contribution to the shear prediction at high values of the replacement ratios. This could justify the recommendation of Etxeberria et al.[23, 24] to limit the use of codes design equations for the design of RAC beams with a 25% replacement ratio of natural aggregate or less.

Results and discussion

Based on the Bayesian estimation results a ranking score is given to each of the seventeen prediction equations. These scores are based on the degree of conservatism, and uniformity of the design offered by the different prediction equations. To account for the effect of both the mean bias and standard deviation of the model error on the safety of the prediction equation, the conservatism score was computed as the value of the mean of the bias (i.e., mean of \(\mu )\) subtracted from the median of \(\sigma\) (i.e., the median of \(\mu - \sigma\)). The uniformity in the design score is measured as the 95th percentile of \(\sigma\) as the value of \(\sigma\) expresses the variability of the prediction equation from the experimental results. For example, the comparison between the ACI 318-19 and the New Zealand code (see Fig. 8) show that the value of the median of \(\mu - \sigma\) for the ACI 318-19 code is higher than that for the New Zealand code which implies that the ACI 318-19 shear prediction equation provides more conservative predictions. Another observation, the value of the 95th percentile of \(\sigma\) for the ACI 318-19 is lower than that for the New Zealand code which indicates that the ACI 318-19 provides more uniform predictions of shear capacity (i.e., less variability from the experimental values).

Comparing the mean bias (i.e., \(\mu\) of \(V_{{{\text{test}}}} /V_{{{\text{pred}}}} )\) and \(\sigma\) of RAC beams with NAC beams (the bias and variability of shear capacity of NAC beams were evaluated using the data from [47]), one could observe whether safety factors of RAC beams are adequate. Safety factors refer to resistance factors or partial safety factors included in the design equations to provide a safe prediction (i.e., that ensure that the prediction can attain the required reliability level) for design purposes. For example, the ACI 318-19 uses a resistance factor of 0.75 for the shear design equation. A lower mean bias and higher \(\sigma\) of RAC beams than NAC beams could suggest that the required target reliability level cannot be met. In Table 2, the results of this comparison are summarized by affirming if safety factors for shear should be revised or not. Lastly, Table 2 summarizes the GCA results by verifying if all important parameters are included in the model development.

In Table 2, the higher the rank the greater the conservatism and uniformity in design degree. Picking the prediction equation with the best uniformity in design score and including all important parameters will be the best choice. The conservatism degree can be calibrated using safety factors for design; thus, does not represent as significant as the uniformity and correlation score. An unexpected observation from Table 2 is the ranks of the prediction equation by Russo et al. [44] which includes all important parameters; however, it has the worst performance compared to the other models concerning uniformity score. This could be explained by the equation format where it seems that it does not correlate well with the data. All codes except the New Zealand code and Eurocode code can safely be used for estimating the shear capacity of RAC beams using the same safety factors as NAC beams. This could be a result of the inherently conservative nature of most codes.

Advantages and disadvantages of each prediction model

In terms of uniformity of the design, Kim and Park [38] and Rebeiz [39] shear prediction models provide the most uniform design of RAC beams in comparison to the other investigated models. However, Rebeiz's [39] shear prediction model may require new safety factors than the one used for NAC beams this is due to the low possible biases (i.e., \(\mu\) of of \(V_{{{\text{test}}}} /V_{{{\text{pred}}}} )\) provided by this model (see Fig. 1A). Moreover, based on the analysis results, Bazant and Yu [31, 32] shear prediction model showed the most conservative prediction of the shear capacity of RAC beams and a low uniformity score compared to the other models. Therefore, Bazant and Yu's [31, 32] shear prediction model may not be the best model to be used for shear capacity prediction of RAC beams. The other prediction models provide conservativism and uniformity levels that fall between the aforementioned models.

Concerning codes’ shear prediction equations, Eurocode 2 and CEB-FIP provide the most uniform design of the RAC beams compared to the other codes, and the least uniform design is provided by the IS:456 (2000) and BS 8110 codes. Moreover, the New Zealand code showed the least conservative predictions of the shear capacity of RAC beams compared to the other codes which explain the need to revise the safety factors for this code when used for the design of RAC beams. Further, none of the codes’ equations seem to include all the influential parameters for the prediction of the shear capacity of RAC beams.

Conclusions

This paper presents a comprehensive advanced assessment of different shear prediction models for RAC beams. The assessment study was conducted using Bayesian parameter estimation and GCA analysis. The following remarks can be pointed out:

-

Different prediction models have varying performances in estimating the shear strength of RAC beams. This performance was computed by the posterior distribution of the mean, standard deviation, and effect size of test-to-predict values. The performance metrics were based on a proposed conservatism and uniformity in the design score. These scores were used for ranking the existing prediction equations in terms of conservatism and uniformity in the design. This ranking could serve as a tool to express a preference for some of the equations.

-

The comparison between the bias and variability of the RAC beams and NAC beams revealed that some of the safety factors (i.e., resistance factor or partial safety factors used for the design of NAC beams) for some existing shear models (e.g., The New Zealand code shear design equation) need to be revised to ensure that the required target reliability can be met for the shear design of RAC beams.

-

The GCA analysis showed that the correlation grade varies with design parameters. The most influential parameters that are required to be considered in the model development fluctuate depending on the conditions the prediction equations cover. For example, at \(a/d < 2.5\) the correlation grade of \(f_{{\text{c}}}^{^{\prime}}\) is larger than \(\rho\), conversely when \(a/d \ge 2.5\) a more correlation grade is given to \(\rho\) compared to \(f_{{\text{c}}}^{^{\prime}} .\) For RAC beams with a high aggregate replacement ratio \(r\) the correlation grade for \(r\) increases significantly which implies that \(r\) is an influential parameter for the shear prediction of RAC beams with a high replacement ratio. Relying on the GCA analysis results, it was able to verify whether the influential parameters are included in the model development for each of the considered existing prediction equations.

Code and data availability

The code and data that support the findings in this study are available from the corresponding author upon reasonable request.

References

Meyer C (2002) Concrete and sustainable development. ACI Spec Publ 206:501–512

Marinković S, Radonjanin V, Malešev M, Ignjatović I (2010) Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag 30(11):2255–2264

Meyer C (2009) The greening of the concrete industry. Cem Concr Compos 31(8):601–605

Sakai K (2005) Environmental design for concrete structures. J Adv Concr Technol 3(1):17–28

Symonds A, Cowi PRC (2012) Bouwcentrum (1999) Construction and demolition waste management practices and their economic impact. Report of the Project Group to the European Commission

Oikonomou ND (2005) Recycled concrete aggregates. Cem Concr Compos 27(2):315–318

Ignjatović IS, Marinković SB, Mišković ZM, Savić AR (2013) Flexural behavior of reinforced recycled aggregate concrete beams under short-term loading. Mater Struct 46(6):1045–1059

Poon CS, Kou SC, Lam L (2007) Influence of recycled aggregate on slump and bleeding of fresh concrete. Mater Struct 40(9):981–988

Sato R, Maruyama I, Sogabe T, Sogo M (2007) Flexural behavior of reinforced recycled concrete beams. J Adv Concr Technol 5(1):43–61

Fathifazl G, Razaqpur AG, Isgor OB, Abbas A, Fournier B, Foo S (2009) Flexural performance of steel-reinforced recycled concrete beams. ACI Struct J. https://doi.org/10.1435/51663187

Fathifazl G, Razaqpur AG, Isgor OB, Abbas A, Fournier B, Foo S (2011) Shear capacity evaluation of steel reinforced recycled concrete (RRC) beams. Eng Struct 33(3):1025–1033

Gonzalez-Fonteboa B, Martinez-Abella F (2007) Shear strength of recycled concrete beams. Constr Build Mater 21(4):887–893

Xiao J, Sun Y, Falkner H (2006) Seismic performance of frame structures with recycled aggregate concrete. Eng Struct 28(1):1–8

Ajdukiewicz AB, Kliszczewicz AT (2007) Comparative tests of beams and columns made of recycled aggregate concrete and natural aggregate concrete. J Adv Concr Technol 5(2):259–273

Knaack AM, Kurama YC (2015) Behavior of reinforced concrete beams with recycled concrete coarse aggregates. J Struct Eng 141(3):B4014009

Arezoumandi M, Smith A, Volz JS, Khayat KH (2014) An experimental study on shear strength of reinforced concrete beams with 100% recycled concrete aggregate. Constr Build Mater 53:612–620

B. S. EN (2009) 12390-6. Testing hardened concrete. In: Tensile splitting strength of test specimens. BSI (2009)

Arezoumandi M, Drury J, Volz JS, Khayat KH (2015) Effect of recycled concrete aggregate replacement level on shear strength of reinforced concrete beams. ACI Mater J 112(4):559

Choi HB, Yi C, Cho HH, Kang KI (2010) Experimental study on the shear strength of recycled aggregate concrete beams. Mag Concr Res 62(2):103–114

Ignjatović IS, Marinković SB, Tošić N (2017) Shear behaviour of recycled aggregate concrete beams with and without shear reinforcement. Eng Struct 141:386–401

Rahal KN, Alrefaei YT (2017) Shear strength of longitudinally reinforced recycled aggregate concrete beams. Eng Struct 145:273–282

A. C. I. Committee (2019) Building code requirements for structural concrete (ACI 318-19) and commentary

EtxeberriaLarrañaga M (2004) Experimental study on microstructure and structural behaviour of recycled aggregate concrete. Universitat Politècnica de Catalunya

Etxeberria M, Marí AR, Vázquez E (2007) Recycled aggregate concrete as structural material. Mater Struct 40(5):529–541

Tošić N, Marinković S, Ignjatović I (2016) A database on flexural and shear strength of reinforced recycled aggregate concrete beams and comparison to Eurocode 2 predictions. Constr Build Mater 127:932–944

B. Standard (2004) Eurocode 2: design of concrete structures—part 1, vol 1, p 230

Pradhan S, Kumar S, Barai SV (2018) Shear performance of recycled aggregate concrete beams: An insight for design aspects. Constr Build Mater 178:593–611

Kruschke J (2014) Doing Bayesian data analysis: a tutorial with R, JAGS, and Stan

I. S. Indian Standard (2000) 456 (2000) Indian standard for plain and reinforced concrete code of practice. Bureau of Indian Standards, New Delhi

B. Standard (1997) Structural use of concrete. Part 1: code of practice for design and construction. BS8110-1

Bažant ZP, Yu Q (2005) Designing against size effect on shear strength of reinforced concrete beams without stirrups: I. Formulation. J Struct Eng 131(12):1877–1885

Bažant ZP, Yu Q (2005) Designing against size effect on shear strength of reinforced concrete beams without stirrups: II. Verification and calibration. J Struct Eng 131(12):1886–1897

Ceb-Fip M (1993) 90, Design of concrete structures. CEB-FIP Model Code 1990. British Standard Institution, London

Zsutty T (1971) Shear strength prediction for separate catagories of simple beam tests. J Proc 68(2):138–143

Zsutty TC (1968) Beam shear strength prediction by analysis of existing data. J Proc 65(11):943–951

Niwa J, Yamada K, Yokozawa K, Okamura H (1986) Revaluation of the equation for shear strength of reinforced concrete beams without web reinforcement. Doboku Gakkai Ronbunshu 1986(372):167–176

Gastebled OJ, May IM (2001) Fracture mechanics model applied to shear failure of reinforced concrete beams without stirrups. Struct J 98(2):184–190

Kim J-K, Park Y-D (1996) Prediction of shear strength of reinforced concrete beams without web reinforcement

Rebeiz KS (1999) Shear strength prediction for concrete members. J Struct Eng 125(3):301–308

S. A. of N. Zealand (1984) Code of practice for general structural design and design loadings for buildings. Standards Association of New Zealand

Arslan G (2008) Shear strength of reinforced concrete beams with stirrups. Mater Struct 41(1):113–122

Bazant ZP, Sun H-H (1987) Size effect in diagonal shear failure: influence of aggregate size and stirrups. ACI Mater J 84(4):259–272

Bazant ZP, Kim J-K (1984) Size effect in shear failure of longitudinally reinforced beams

Russo G, Somma G, Mitri D (2005) Shear strength analysis and prediction for reinforced concrete beams without stirrups. J Struct Eng 131(1):66–74

Caspeele R, Taerwe L (2012) Bayesian assessment of the characteristic concrete compressive strength using combined vague–informative priors. Constr Build Mater 28(1):342–350

Müller D, Graubner C-A (2021) Assessment of masonry compressive strength in existing structures using a Bayesian method. ASCE-ASME J Risk Uncertain Eng Syst Part A Civ Eng 7(1):04020057

Olalusi OB, Viljoen C (2020) Model uncertainties and bias in SHEAR strength predictions of slender stirrup reinforced concrete beams. Struct Concr 21(1):316–332

Papaioannou I, Betz W, Zwirglmaier K, Straub D (2015) MCMC algorithms for subset simulation. Probab Eng Mech 41:89–103

Wang Z, Wang Q, Ai T (2014) Comparative study on effects of binders and curing ages on properties of cement emulsified asphalt mixture using gray correlation entropy analysis. Constr Build Mater 54:615–622

Hu B, Wu Y-F (2018) Effect of shear span-to-depth ratio on shear strength components of RC beams. Eng Struct 168:770–783

Wu YF, Griffith MC, Oehlers DJ (2003) Improving the strength and ductility of rectangular reinforced concrete columns through composite partial interaction: tests. J Struct Eng 129(9):1183–1190

Wu Y-F, Liu T, Wang L (2008) Experimental investigation on seismic retrofitting of square RC columns by carbon FRP sheet confinement combined with transverse short glass FRP bars in bored holes. J Compos Constr 12(1):53–60

Hong-Gun P, Choi K-K, Wight JK (2006) Strain-based shear strength model for slender beams without web reinforcement. ACI Struct J 103(6):783

Li W, Leung CKY (2016) Shear span–depth ratio effect on behavior of RC beam shear strengthened with full-wrapping FRP strip. J Compos Constr 20(3):04015067

Tompos EJ, Frosch RJ (2002) Influence of beam size, longitudinal reinforcement, and stirrup effectiveness on concrete shear strength. Struct J 99(5):559–567

Lee J-Y, Lee DH, Lee J-E, Choi S-H (2015) Shear behavior and diagonal crack width for reinforced concrete beams with high-strength shear reinforcement. ACI Struct J. https://doi.org/10.14359/51687422

Birrcher DB, Tuchscherer RG, Huizinga M, Bayrak O (2013) Minimum web reinforcement in deep beams. ACI Struct J 110(2):297–306

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author states that there is no conflict of interest.

Appendix

Rights and permissions

About this article

Cite this article

Saleh, E., Tarawneh, A. & Alghossoon, A. A critical assessment of existing prediction models on the shear capacity of recycled aggregate concrete beams. Innov. Infrastruct. Solut. 7, 239 (2022). https://doi.org/10.1007/s41062-022-00839-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00839-3