Abstract

This paper presents the results of 135 laboratory model tests performed on square footings resting on the nonwoven geotextile–reinforced sand. Unlike in most previous investigations, in this study, the vertical spacing between the geotextile layers was not constant. On the other words, 12 different arrangements with three relative densities and with two plates were examined. At the first step, the effect of the first layer thickness of geotextile, the width of geotextile, as well as vertical spacing and number of geotextile layers on the bearing capacity of footings were investigated. As a result, the experimental results comprehensively exhibited that nonwoven geotextiles increase the bearing capacity of footings in all cases. It was found that the optimum values of vertical spaces between geotextile layers with different distances from the upper layer are ranging from 0.3 to 0.4B. Additionally, the results suggested that the bearing capacity ratio increases gradually with the increase in the relative density.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As defined by ASTM D-4439, a geosynthetic is a planar product manufactured from a polymeric material used with soil, rock and other geotechnical engineering-related materials as an integral part of a human-made project, structure or system [1]. The primary advantages of geosynthetics are low cost, lightweight, ease of transportation and easy installation [2]. As a commonly used geosynthetic material, geotextiles are prepared in various sizes. They can be used in many applications including reinforcement, separation, drainage and filtration. Specifically, nonwoven geotextiles can increase soil strength in lower strain and reduce soil brittleness [3,4,5,6,7]. Geotextile must deform before its reinforcing benefit is realized [8].

Woven and nonwoven geosynthetics are pragmatic and economic materials that can increase the bearing capacity of shallow foundations, which has been proven in numerous studies [9,10,11,12,13,14,15]. For example, Fragaszy and Lawton [12] evaluated the bearing capacity of footings on reinforced sandy soil using laboratory model tests. They concluded that the load-bearing capacity of footings increased as the width of reinforcements was enhanced from 3 to 7B, in which B is the plate width. Yetimoglu et al. [13] studied the bearing capacity of footings on sandy soil reinforced with one layer of geogrid, and they found that the optimum reinforcement depth is 0.3B. In another research study, Akinmusuru and Akinbolade [14] employed woven strips for reinforcement and investigated the impact of the first layer depth of geotextile and the number of geotextile layers upon the load-bearing capacity of square footings on reinforced sand. They observed that using more than three layers of geotextiles did not significantly increase the bearing capacity of footings; therefore, they concluded that the optimum value of geotextile layers was three. They also observed the optimum depth of the first layer of geotextile was less than 0.5B within the sand reinforced by three-layer geotextile. Ferrotti et al. [16] studied the interface bond strength of a reinforcement. They found that the tensile bonding of reinforcements at the interface was strongly influenced by the type of geosynthetics. Guido et al. [15] compared the reinforcement mechanisms of geotextiles and geogrids on sandy soil. They observed that the reinforcing mechanisms of geotextiles and geogrids were different. On the other hand, the reinforcing mechanism of geotextiles which created tensile bonding was based on the sand–geotextile friction, while the reinforcement mechanism of geogrids was dependant upon the sand and geogrid interlock.

Mosallanezhad et al. [17] used an anchor as a reinforcing element, by connecting it to a geogrid to improve the pullout resistance and the load-bearing capacity of square footings placed on sand. The results suggest that a grid anchor is able to increase the ultimate bearing capacity of the footing 3 and 1.8 times in comparison with unreinforced and geogrid-reinforced soils, respectively. Hataf et al. [18] examined the influences of applying geogrids and grid anchors for cyclic loading conditions. For entire cases, the foundation was tested initially under the effect of constant static loading. Afterward, the cyclic load was applied as various amounts of ultimate load. The results demonstrated that for a certain initial constant load, the number of loading cycles had to reach a specific dimensionless settlement (ratio of settlement to the width of plate) decreases with an increment in the number of reinforcement layers. Lutenegger and Cerato [19] studied five different sand samples within three square shear boxes, each having different relative densities. The findings showed that the friction angle increased by increasing the relative density. They mentioned that the friction angle for different densities at the interface of soil and reinforcement plays an important role in improving the soil load-bearing capacity.

According to the previous studies which dealt with different types of geotextiles [20,21,22], this study focused on the effects of different vertical spacing between the nonwoven geotextile layers on bearing capacity. The plate load test was employed to measure the bearing capacity of the reinforced and unreinforced soils.

Laboratory model test

Test configuration

For the laboratory model test, a system was designed consisting of a concrete foundation for the box of the test, a box (135 × 135 × 100 cm3) and the main beam with the features IPB 24 attached to two steel columns with diameters of 45 mm to provide the predicted reaction load of 300 kN tons (Fig. 1). The end of the columns was threaded to roughly 350 mm to adjust the distance between the main beam and the plate for loading. The box sidewalls were made by plexiglass to monitor the mechanism of failure during the test. In this research, square plates 25 cm × 25 cm and 35 cm × 35 cm and 2.5-cm thick were utilized for modeling foundation. The selected dimensions were in the specified range which suggested by ASTM D-1194. It is worth noting that a 50-ton hydraulic jack was employed to apply the load to the specimens. Three dial gauges were mounted on reference beams to measure the displacement of footings during the tests.

Test materials

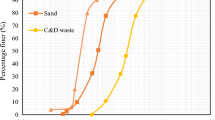

Sand

The sand used in this study was classified as poorly graded sand (SP) based on the Unified Soil Classification System (USCS). The particle size distribution of the sand is shown in Fig. 2. The values of the coefficient of uniformity (Cu) and coefficient of curvature (Cc) are 1.40 and 1.14, respectively.

Nonwoven geotextile

The nonwoven geotextile used in this study is shown in Fig. 3. The advantage of using nonwoven geotextile compared to other types of geotextiles is its higher flexibility which causes the increasing axial strain at failure and also reduces the brittleness of reinforcement sand [23, 24]. Table 1 presents the physical and mechanical properties of the nonwoven geotextile. The width of the geotextile (W), the depth of the first layer of geotextile (U) and the distance between the geotextile layers (Z) are schematically illustrated in Fig. 4.

Test setup and programs

For each plate load test, the box height was divided into different required parts. Then, sand poured into the box and compacted in several steps. Each of the layers was compressed using by a 10-kg steel plate, falling from a height of 200 mm to have a uniform compacted layer before pouring the subsequent layer [25]. Given the weight of upper layers on lower layers, the under-compaction technique was used to compact all layers. Since the layers located at the bottom of the box frequently compacted when the steel plate compressed the upper layer, the sample had a relatively high density at the bottom of the box [26]. Eventually, for uniform compaction of all samples, the first layers, which are placed at the bottom of the box, should be higher than the upper ones, as argued by Ladd [27]. This compaction method is different from the previous method used by other researchers [28,29,30]. The standard deviation of density for each test was in the range of ± 2%. Maximum and minimum void ratio of free draining soils was obtained with vertically vibrating table according to ASTM D 4253 [1]. In this research, the loading was exerted at a constant rate, i.e., vertical strain of 1.0 mm/min, for whole tests. After applying load at intervals of 0.5, 1, 2, 4 and 8 min, their corresponding settlement was measured.

The average loads were recorded by each of settlement increments until the plate settlement reached to 10% of diameter of the plate. Also the average displacements are recorded using three dial gauges. Finally, the effects of width and number of geotextile layers and vertical spacing between the layers of geotextile with sand of relative densities of 55%, 65% and 75% were determined using plate load tests based on BCR values (Table 2). After obtaining the optimum conditions, the effect of vertical spacing between geotextile layers considering the depth of the geotextile was examined with sand relative densities of 55%, 65% and 75% (Table 3).

Results and discussion

The footings placed on nonwoven geotextile–reinforced sand are tested by a laboratory to determine the ultimate bearing capacity of footings from load to displacement curves. In this study, the 0.1B method was used for determination of ultimate bearing capacity of both reinforced sand and unreinforced sand. In this method, the ultimate bearing capacity at a settlement of 10% of the footing width is taken. Bearing capacity ratio (BCR) was also investigated in the present research [31]. The bearing capacity ratio (BCR) refers to the ratio of the ultimate load-bearing capacity of a square footing relying on reinforced sand to the ultimate load-bearing capacity of the same footing relying upon pure sand [32,33,34].

Optimal amounts of U and W

The BCR with U/B (the ratio of the first layer depth of geotextile to the plate width) for a footing reinforced with one layer of a geotextile is shown in Fig. 5. In order to avoid the influence of the optimum width of the geotextile on the results, 1350 × 1350 mm were chosen as the dimensions of the geotextile. It should be mentioned that the optimum values of U/B were obtained from different sand relative densities (Fig. 5). The results suggested that the BCR was at the maximum value when U/B = 0.20.

For the case with U/B = 0.10, in initial loading steps, the stiffness of sand reinforced using a layer of geotextile was lower than that for unreinforced one. The amount of elastic deformation which is allowed by the geotextile will govern the deformation of the embankment [8]. In the early steps of loading, the effective stress at sand and geotextile interface was low, the tensile bonding between sand and the geotextile was also weak. The amount of tensile bonding, that is related to frictional properties, was at the largest amount when the highest compressive stress of sand was perpendicular to the reinforcement plane [35]. The geotextiles should be placed in main strain direction in order to attain maximum use of reinforcement [8]. Moreover, the amount of the friction angle at the sand and geotextile interface was smaller than the internal friction angle of soil [36,37,38].

For this reason, a footing reinforced using a single-layer geotextile showed lower bearing capacity than an unreinforced one at the initial steps of loading. However, by increasing the load, the stiffness of the reinforced footing increased due to the generation of high effective stress at the sand and geotextile interface, which causes higher bearing capacity. Also, the results suggested that the relative density between 55 and 75% has no significant effect on the optimum value for depths of the first layer of the geotextile.

According to Fig. 6, after W/B = 4, the load-bearing capacity ratios are almost the same for different relative densities, due to the mechanism of pressure distribution along geotextile layers in order to reduce the transferring pressure to the soil [8]. Although the trends of the graphs of different densities are similar, the enhancement of the relative density from 55 to 75% leads to an increased amount of bearing capacity, especially after W = 2B. Nonwoven geosynthetics are considered for improving stability, separation and filtration. In many cases, it considerably improves the service behavior of railways lines on the soft ground (note: the nonwoven geosynthetics with reinforcement would be used as a bridging structures above local weak points) [8]. Based on previous studies, the tensile behavior of geotextiles would remarkably reduce the compressive stress applied on the soil. This function is more evident for geotextile with higher stiffness, on the other hand, the higher the stiffness, the greater is the bearing capacity [39]. Moreover, geotextiles can increase the bearing capacity of footings when located within the internal radial zones beneath them. However, the impact of increased width of geotextiles on the bearing capacity of footings is negligible as they are out of these zones [40].

Optimum value of z

In this section, the effect of the vertical spacing between layers of geotextile (Z) on load-bearing capacity of footings was investigated using the optimum U/B and W/B values as 0.20 and 4, respectively. The variation in BCR, as the Z/B is constant for the second, third and fourth layers, is shown in Fig. 7. It was observed that the bearing capacity of the reinforced footing shows the maximum value at Z = 0.3B for different relative densities and a constant vertical spacing between geotextile layers.

Figure 8 presents the variation in compressive stress with their corresponding displacement at the relative density of 55%. The curves do not exhibit any peak point since geotextiles have not reached their maximum tensile strengths. Thus, the tensile strength of the geotextile had no effect on failure. Namely, deformation at tensile strength of geotextile is much higher than deformation at ultimate load-bearing capacity. Also, the findings indicated that there was no significant difference between the curves at the first steps of the loadings (displacement lower than 5 mm), while at a higher displacement the difference between curves was more obvious. Note that when z = 0.3, the bearing capacity and confining pressure are at their highest and lowest values, respectively. Moreover, it was observed that increasing the vertical depth caused the increase in confining pressure; however, no significant differences was observed for z = 0.35–0.45B.

The deformation of geotextiles was not feasible to observe during the test. Also, no rupture was observed after the test for the nonwoven geotextile due to its high elongation characteristic. Therefore, it was derived that the studied nonwoven geotextile could not reach its highest tensile strength during the test. According to the previous studies, woven geotextiles or geogrids used to reinforce the soil led to a high post-peak strength loss which was more considerable when steel reinforcement is utilized [35, 41].

Therefore, using nonwoven geotextiles under high strain range relating to failure was a suitable technique to solve the problem. However, given the load–elongation impact of geotextiles on the reinforced sand stiffness, it is recommended to use nonwoven geotextiles with a low elongation to obtain higher BCR values. According to the EBGEO, the load-extension behavior of nonwovens geotextiles would be changed by different types of soil. The conducted research has suggested that the load-extension behavior of nonwovens is related to the soil and the surcharge [8].

Figure 9 shows that for constant vertical spaces between the layers of geotextile (z = 0.3B), the impact of using more than four geotextile layers did not have a significant effect on the growth of load-bearing capacity of footings. Therefore, in this research, the optimal number of layers of geotextile was obtained 4. After obtaining optimum values of vertical spacing, eight different cases as shown in Table 3 for relative densities of 55%, 65% and 75% were studied. A well-known study proved that the all types of soil’s resistance increase with the increase in confining pressure. The effect of reinforcement on the BCR value was significant for low confining pressures [5, 42, 43]. The bearing capacity of the reinforced footing increased more considerably when geotextiles were placed near the ground surface (which generates low confining pressure). In this study, the density of sand is between 55 and 75%; however, local shear occurs when a footing rests on sand with moderate density (36% < Dr < 70). A small bulge may occur, but considerable settlement (0.5 the foundation width) is necessary before a clear shear surface forms near the ground [8].

Figures 10 and 11 present the results of the plate load test on different spaces of nonwoven geotextile with two square plates with a side of 250 and 350 mm. The results show that the maximum bearing capacity values of the footings occur at different values of vertical spacing between geotextile layers (Z) (Figs. 10 and 11). Thus, it can be concluded that determining a single value of vertical spaces between layers of geotextile to optimize load-bearing capacity is not a correct procedure as reported by previous studies [37, 38]. In the case that the first and second layers had the lower space between layers, the bearing capacity ratio (BCR) had a higher value. Furthermore, in these tests the vertical space for the last layer was 0.4B. For test numbers 1, 2 and 3, in the same relative density, although vertical space for the first layers was smaller than test numbers 4, 5 and 6, it was observed that bearing capacity ratio (BCR) was reduced versus test numbers 4, 5 and 6, due to reducing the effective stress at the interface of the soil and the geotextile, since vertical space between layers was too low. Meanwhile, Figs. 10 and 11 illustrate that for test numbers 9, 10, 11 and 12, a decrease in bearing capacity versus the other test by increasing vertical space between layers was observed, especially for the first layers. On the other hand, either increasing or decreasing vertical space between layers did not increase the bearing capacity ratio for all cases. The results exhibited that maximum bearing capacity was achieved with a system that included four geotextile layers in which the spaces between layers from top to bottom were 0.3B, 0.35B and 0.4B, respectively. This conclusion was achieved for two plates in three relative densities of 55%, 65% and 75%. Moreover, Figs. 10 and 11 show that for test numbers 4, 5 and 6, in which vertical spaces, especially for the first layers, have a smaller value, improving the relative density led to a tangible difference for bearing capacity ratio (BCR) compared to other cases. According to the EBGEO, the vertical distance between the individual reinforcement layers should be the smaller value of the two equations [8]:

Values of BCR using 25 cm × 25 cm square plate for 12 different cases according to Table 3 (every box which is below the test number shows the vertical spacing between geotextile layers from first layer to forth layer)

Values of BCR using 35 cm × 35 cm square plate for 12 different cases according to Table 3 (every box which is below the test number shows the vertical spaces between layers of geotextile from first layer to forth layer)

The maximum BCR was observed at the relative density of 75%. Figure 10 shows that the ratio of the BCR values is in the very narrow limits for the same density, if the vertical space between layers Z is ranging from 0.3 to 0.4B where placing near the ground surface with lower confining pressure between layers.

Conclusions

High flexibility is one of the most important advantages of nonwoven geotextile, in comparison with different woven geosynthetic materials. No rupture was observed after the test for the nonwoven geotextile due to its high elongation characteristic. Therefore, it was derived that the studied nonwoven geotextile was not reached to its maximum tensile strength during the test. Nonwoven geotextiles improve sand-bearing capacity, and the maximum BCR value obtained with this type of nonwoven geotextile was about 1.6. In order to obtain higher BCR values in this study, nonwoven geotextiles with low elongation (54%) were used. The optimum values of the depth of the first geotextile layer (U) and geotextile width (Z) were found to be 0.2B and 4B (B represents the width of the plate), respectively. The consequence of geotextiles on the sand-bearing capacity was greater when they were placed near the ground surface. Therefore, the BCR value was the highest when geotextiles were close to the ground surface. The maximum bearing capacity ratio was obtained for optimum numbers of the fourth layer. The ratios of the BCR are in the very narrow limits for the same density, if the vertical space between layers Z is ranging from 0.3 to 0.4B. However, it cannot be concluded that the bearing capacity increased with the decrease in the distance between geotextile layers in all cases. Furthermore, the results indicated that BCR values increased with the rise of sand relative density. However, the rate of the increase in BCR became lower when the relative density increased.

Abbreviations

- U :

-

The first layer depth of geotextile

- W :

-

Geotextile width

- Z :

-

Vertical spacing between geotextile layers

- N :

-

Number of geotextile layers

- B :

-

Width of the plate

- BCR:

-

The ratio of the bearing capacity of reinforced sand to that of the unreinforced sand

References

American society for testing and materials (ed) (1977) Standards, vol 04–09

Koerner RM (2012) Designing with geosynthetics, vol 1. Xlibris Corporation, Bloomington

Broms BB (1977) Triaxial tests with fabric-reinforced soil. In: Proceedings of the international conference on the use of fabrics in geotechnics. Ecole Nationale des Ponts et Chaussées, Laboratoire Central des Ponts et Chaussées, Paris

Gray D, Athanasopoulos G, Ohashi H (1982) Internal/external fabric reinforcement of sand. In: Proceedings of the second international conference on geotextiles

Gray DH, Al-Refeai T (1986) Behavior of fabric-versus fiber-reinforced sand. J Geotech Eng 112(8):804–820

Subbarao C, Prasad J (1987) Triaxial tests on sand reinforced with polypropylene fabric. In: Proceeding of the Indian geotechnical conference (IGC87), Bangalore

Chandrasekaran B, Broms BB, Wong KS (1989) Strength of fabric reinforced sand under axisymmetric loading. Geotext Geomembr 8(4):293–310

Johnson A (2011) Recommendations for design and analysis of earth structures using geosynthetic reinforcements—EBGEO. The German Geotechnical Society (Deutsche Gesellschaft für Geotechnik e. V., DGGT), Schneeberg

Golder HQ et al (1941) The ultimate bearing pressure of rectangular footings. J Inst Civ Eng 17(2):161–174

Meyerhof G (1948) An investigation of the bearing capacity of shallow footings on dry sand. In: Proceedings of the 2nd international conference on soil mechanics and foundation engineering, Rotterdam

Guido V (1988) Bearing capacity and settlement characteristics of geoweb-reinforced earth slabs. In: Special topics in foundations, pp 21–36

Fragaszy RJ, Lawton E (1984) Bearing capacity of reinforced sand subgrades. J Geotech Eng 110(10):1500–1507

Yetimoglu T, Wu JT, Saglamer A (1994) Bearing capacity of rectangular footings on geogrid–reinforced sand. J Geotech Eng 120(12):2083–2099

Akinmusuru JO, Akinbolade JA (1981) Stability of loaded footings on reinforced soil. J Geotech Geoenvironmental Eng 107(ASCE 16320 Proceeding)

Guido VA, Chang DK, Sweeney MA (1986) Comparison of geogrid and geotextile reinforced earth slabs. Can Geotech J 23(4):435–440

Ferrotti G, Canestrari F, Pasquini E, Virgili A (2012) Experimental evaluation of the influence of surface coating on fiberglass geogrid performance in asphalt pavements. Geotext Geomembr 34:11–18

Mosallanezhad M, Hataf N, Ghahramani A (2008) Experimental study of bearing capacity of granular soils, reinforced with innovative grid-anchor system. Geotech Geol Eng 26(3):299–312

Hataf N, Boushehrian A, Ghahramani A (2010) Experimental and numerical behavior of shallow foundations on sand reinforced with geogrid and grid anchor under cyclic loading. Sci Iran Trans A Civ Eng 17(1):1

Lutenegger AJ, Cerato AB (2006) Specimen size and scale effects of direct shear box tests of sands. Geotech Test J 29(6):507–516

Holtz RD, Tobin WR, Burke WW (1982) Creep characteristics and stress–strain behavior of a geotextile–reinforced sand. In: Second international conference on geotextiles, Las Vegas

Gray DH, Athanasopoulos G, Ohashi H (1982) Internal/external fabric reinforcement of sand. In: Second international conference on geotextiles, Las Vegas

Rao GV, Gupta KK, Kachhawah R (1987) Triaxial behavior of geotextile reinforced sand. In: Indian geotechnical conference (IGC87), Bangalore

Mc Gown A, Andrawes KZ (1977) The influences of non-woven fabric inclusion on the stress–strain behavior of soil mass. In: International conference on use of fabric in geotechnics, L. Paris

Mc Gown A, Andrawes KZ, Al-Hasani MM (1978) Effect of inclusion properties on the behavior of sand. Geotechnique 8(3):327–346

Tavangar Y, Shooshpasha I (2016) Experimental and numerical study of bearing capacity and effect of specimen size on uniform sand with medium density, reinforced with nonwoven geotextile. Arab J Sci Eng 41(10):4127–4137

Shooshpasha I, Shirvani RA (2015) Effect of cement stabilization on geotechnical properties of sandy soils. Geomech Eng 8(1):17–31

Ladd R (1978) Preparing test specimens using undercompaction. Geotech Test J 1:16–23

Boushehrian JH, Hataf N (2003) Experimental and numerical investigation of the bearing capacity of model circular and ring footings on reinforced sand. Geotext Geomembr 21(4):241–256

DeMerchant M, Valsangkar A, Schriver A (2002) Plate load tests on geogrid-reinforced expanded shale lightweight aggregate. Geotext Geomembr 20(3):173–190

Alamshahi S, Hataf N (2009) Bearing capacity of strip footings on sand slopes reinforced with geogrid and grid-anchor. Geotext Geomembr 27(3):217–226

Briud JL, P Jeanjean (1994) Load settlement curve method for spread footings on sand, vertical and horizontal deformation of foundation and embankments. In: ASCE, vol 2, pp 1774–1804

Cerato AB, Lutenegger AJ (2007) Scale effects of shallow foundation bearing capacity on granular material. J Geotech Geoenvironmental Eng 133(10):1192–1202

Anvari SM, Shooshpasha I (2016) Influence of size of granulated rubber on bearing capacity of fine-grained sand. Arab J Geosci 9(18):707

Vukićević M et al (2015) Stabilization of fine-grained soils with fly ash. Građevinar 67(08):761–770

McGown A, Andrawes K, Al-Hasani M (1978) Effect of inclusion properties on the behaviour of sand. Geotechnique 28(3):327–346

Richards E, Scott J (1985) Soil geotextile frictional properties. In: Proceedings of the second Canadian symposium on geotextiles and geomembranes

Goodhue MJ, Edil TB, Benson CH (2001) Interaction of foundry sands with geosynthetics. J Geotech Geoenvironmental Eng 127(4):353–362

Minažek K, Mulabdić M (2013) A review of soil and reinforcement interaction testing in reinforced soil by pullout test. Građevinar 65(03):235–250

Jewell R (1996) Soil reinforcement with geotextiles. CIRLA Special Publication, Thomas Telford, Westminster

Morel J, Gourc J (1997) Mechanical behavior of sand reinforced with mesh elements. Geosynth Int 4(5):481–508

McGown A, Andrawes K (1977) Influences of non-woven fabric inclusions on the stress strain behavior of a soil mass. In: International conference on the use of fabrics in geotechnical. Paper and discussion, Paris

Maher MH (1988) Static and dynamic force response of sands reinforced with discrete, randomly distributed fibers. Michigan University, Ann Arbor

Yang Z (1972) Strength and deformation characteristics of reinforced sand [Sl: sn]

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tavangar, Y., Shooshpasha, I. Impacts of a nonwoven geotextile arrangement on load-bearing capacity of reinforced sand: a laboratory study. Innov. Infrastruct. Solut. 5, 8 (2020). https://doi.org/10.1007/s41062-019-0253-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-019-0253-9