Abstract

The main purpose of this research is to determine the dry and saturated strength of different sedimentary rocks including travertine, conglomerate, sandstone and limestone by using the Schmidt hammer test. To determine the strength of the studied rocks, comprehensive geotechnical tests including Brazilian tensile strength (BTS), block punch strength (BPS), point load strength (PLS) and uniaxial compressive strength (UCS) were performed in dry and saturated conditions on prepared standard specimens. Results show under BTS, BPS, PLS and UCS tests, the strength of the studied rocks after saturating is averagely reduced by 24.95, 31.80, 34.36 and 18.97%, respectively. Therefore, under saturated conditions, the strength of the studied samples reduced 27.52% averagely. The correlation between Schmidt rebound hardness and geotechnical properties in dry and saturated conditions was performed by simple regression analysis and experimental equations were obtained with a correlation coefficient from 0.65 to 0.93. For evaluating the performance of predictive models, some statistical parameters including RMSE, VAF, MAPE and PI were calculated and the 45° line and 95% confidence limit curves were also extracted for evaluating the validity of the concluded empirical equations. The results of this research demonstrate that the Schmidt hammer test is a reliable method for estimating the strength of rocks in dry and saturated conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Determining the geotechnical properties of rocks is an essential factor in different engineering projects including dams, tunnels and mining (Tuğrul and Zarif 1999; Diamantis et al. 2014; Mishra et al. 2019). The strength of different rocks is a substantial characteristic when investigating the engineering behavior of rocks in geotechnical practices (Diamantis et al. 2021). Many researches indicated that the interaction between water and rocks is a significant challenge in the field of rock mechanics (Vásárhelyi 2005; Erguler and Ulusay 2009; Huang et al. 2010; Li et al. 2012; Karakul and Ulusay 2013; Wong et al. 2016; Wasantha et al. 2018; Tang 2018; Fereidooni and Khajevand 2019; Yu et al. 2019; Luo 2020; Yao et al. 2020; Liu et al. 2020). It is obviously accepted that the existence of water weakens all of the mechanical characteristics of rocks (Török and Vásárhelyi 2010; Yilmaz 2010; Rajabzadeh et al. 2012; Duda and Renner 2013; Zhou et al. 2016; Li and Wang 2019; Ma et al. 2020; Zhao et al. 2021).

For determining the mechanical characteristics of intact rocks, direct tests are performed on cylindrical core specimens. These tests are expensive, destructive and require a considerable amount of time (Asheghi et al. 2019; Khajevand and Fereidooni 2019; Jing et al. 2021). Instead, indirect methods have several advantages, including little or no specimen preparation, easy operation and low cost (Sonmez et al. 2006; Armaghani et al. 2018; Wen et al. 2019). The Schmidt hammer test, as a simple, quick, portable, cheap and non-destructive test, has been used in geotechnical practices including determining uniaxial compressive strength and elasticity modulus of different rocks both on-site and in the laboratory since the early 1960s (Basu and Aydin 2004; Aydin and Basu 2005). The International Society of Rock Mechanics and American Society for Testing and Materials presented standard procedures for this test.

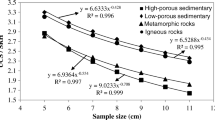

In recent years, many researchers have developed predictive models based on Schmidt rebound hardness (SRH) for estimating some geotechnical properties of rocks such as uniaxial compressive strength, point load strength, Brazilian tensile strength and block punch strength (e.g., Tandon and Gupta 2015; Fereidooni 2016; Fereidooni and Khajevand 2018; Heidari et al. 2018; Diamantis 2019; Aladejare 2020; Bilen 2021; etc.). Several researchers particularly attempted to determine the uniaxial compressive strength of different rocks using N and L-type Schmidt hammer by regression analysis (Aufmuth 1973; Yılmaz and Sendir 2002; Bruno et al. 2013; Karaman and Kesimal 2015; Liang et al. 2016; Hebib et al. 2017; Kong and Shang 2018; Moosavi and Mohammadi 2021; Tang et al. 2021). Moreover, some researchers studied the effect of many parameters including the size of samples (Demirdag et al. 2009, 2018), mineralogy and mineral grain size (Ajalloeian et al. 2020; Rahimi et al. 2022), anisotropy orientation (Kong et al. 2021), Schmidt hammer type (Aydin and Basu 2005; Buyuksagis and Goktan 2007), hammer axis orientation (Basu and Aydin 2004; Karakul 2020), water content and degree of saturation (Sumner and Werner 2002; Karakul 2017) and effect of weathering grade (Kogure 2019) on the value of Schmidt hardness.

In this regard, Sharma et al. (2011) developed empirical equations to predict the P-wave velocity and slake durability index of rocks by Schmidt hammer rebound numbers. Karaman et al. (2015) found strong correlations between Schmidt hardness, UCS and BTS with the coefficient of determination (R2) of 0.84 and 0.85 for sedimentary, metamorphic and igneous rocks. Mishra et al. (2015) used soft computing methods including adaptive neuro-fuzzy inference system (ANFIS), fuzzy inference system (FIS) and artificial neural network (ANN) to estimate the UCS of rocks by laboratory tests such as Schmidt hardness, point load, block punch and wave velocity. Tandon and Gupta (2015) by testing some rock samples including granite, quartzite, gneiss and metabasic suggested a linear equation for determining UCS from SRH with an acceptable coefficient of determination of R2 = 0.75. Karakul (2017) investigated the correlation between SRH and compressive strength in dry and fully saturated conditions by simple and multivariate regression analyses. Fattahi (2017) applied the ANFIS method to predict the UCS of igneous and metamorphic rocks including basalt and metabasalt, using Schmidt rebound hardness. The results of this research indicated that the ANFIS has a high potential for indirect estimating the UCS. Wang and Wan (2019) suggested a new empirical formula for the correlation between UCS and the L-type Schmidt hammer using gene expression programming. Ajalloeian et al. (2020) attempted to estimate the BTS and UCS of granitic rocks from Schmidt hammer hardness by regression analysis and a strong correlation was found. Asteris et al. (2021) by soft computing approaches including genetic programming (GP) and artificial neural networks correlated N and L-type Schmidt rebound hardness.

In this study, some geotechnical properties including Brazilian tensile strength, point load strength, block punch strength and uniaxial compressive strength were determined based on the standard procedures in dry and saturated conditions. Studied rocks including travertine, conglomerate, limestone and sandstone were collected from north and northwest parts of Damghan in the northeast of Iran. These rocks as construction materials and building stones are extracted from regional quarries and mines and have been used in a variety of engineering projects, such as pavement, kerb, foundation, railway ballast, facade stone and the rip-rap of dams. Considering the advantage of the Schmidt hammer test that is mentioned in the literature, the main aim of this research is to determine the strength of sedimentary rocks in both dry and saturated conditions in the simplest and cheapest way possible in the field and laboratory based on Schmidt rebound hardness. The present research is generally significant because strength is one of the most important aspects of geotechnical projects, and determining it, especially in saturated conditions, is of prime importance. Finally, experimental models were developed using simple regression analysis, and some statistical parameters were utilized for comparing the results. The novelty of this research is in the comprehensiveness of geotechnical tests and strength parameters so that all parameters have been reviewed and compared with each other by statistical methods, which is not seen in previous researches.

2 Material and Methods

2.1 Physical Properties

Physical properties including specific gravity (GS), dry unit weight (γdry), saturated unit weight (γsat), water absorption (Wa) and effective porosity (ne) were determined using prepared NX core specimens following the standard procedure recommended in ISRM (2007). By calculating the ratio of sample weight to bulk volume, the dry and saturated unit weight of the studied rocks were obtained. The values of effective porosity for each specimen were obtained from the ratio of pore volume to the sample volume. The dry mass of samples was determined after drying in an oven at a temperature of 110 °C for a period of 24 h. The average values of physical properties are presented in Table 1. According to the results, the minimum and maximum values of dry unit weight are 20.91 kN/m3 (TS6) and 26.05 kN/m3 (LS1), respectively, and the minimum and maximum values of effective porosity are 2.80% (TS1) and 10.32% (SS3), respectively.

2.2 Schmidt Rebound Hardness

The Schmidt hammer is a simple, portable and inexpensive device that gives the rebound hardness value for an intact rock specimen in the laboratory or the rock mass in the field. The test is generally a non-destructive and a popular index test on rocks, and the rebound hardness has been correlated with rock properties such as UCS. In the current research, the Schmidt rebound hardness test was performed on the rock block samples by an L-type Schmidt hammer (impact energy of 0.735 Nm) according to ISRM (2007). For obtaining the final SRH values, 20 impacts were applied vertically downward at different smoothed locations of the samples. Based on the results, Schmidt rebound hardness values were obtained in the range of 15 to 44. Therefore, CS2 and LS3 samples have the lowest and the highest values of SRH, respectively. Minimum, maximum, mean and standard deviation values of Schmidt rebound hardness are presented in Table 2. Also, a comparative diagram of the obtained values of Schmidt rebound hardness, including minimum, maximum, mean and standard deviation is presented in Fig. 1.

2.3 Mechanical Properties

Rock blocks were cored in the laboratory using 54 mm diameter (NX core) diamond coring bits. The cut end faces of cores were smoothed and made perpendicular to the core axes with a polishing and lapping machine. Brazilian tensile strength (BTS), block punch strength (BPS), point load strength (PLS) and uniaxial compressive strength (UCS) were performed as mechanical tests on the prepared cylindrical core specimens. To avoid any influence on mechanical properties, the length to diameter ratio of the test specimens was prepared carefully following the suggested method of ISRM (2007). Firstly, the specimens were inspected macroscopically and only the homogeneous, isotropic, un-weathered and free of visible joints, cracks, fissures, or other discontinuities, rocks were considered. All tests were conducted at room temperature and under the same conditions. For determining geotechnical properties in dry conditions, prepared core specimens were dried in an oven for 24 h at 105 °C and then cooled at room temperature. In saturated conditions, core specimens were immersed in water for 72 h until the saturation process was completed. The obtained values of BTS, BPS, PLS and UCS for the studied samples in dry and saturated conditions are presented in Tables 3, 4, 5 and 6.

The Brazilian tensile strength test was performed on a NX prepared disk shaped core with length-to-diameter ratios from 0.5 to 0.75, according to ISRM (2007). The obtained values of BTS for the studied samples in dry and saturated conditions, sat/dry values and decrease rate are presented in Table 3. BTS values averagely obtained equal to 5.83 and 4.31 MPa in dry and saturated conditions, respectively. Calculating the decrease rate indicated that the strength of the studied samples in saturated conditions under the Brazilian test was reduced in the range of 11.22–39.02% and averagely 24.95%. A comparative diagram of Brazilian tensile strength in dry and saturated conditions is shown in Fig. 2a. Failure mode of the studied rocks under the Brazilian tensile strength test is presented in Fig. 3a. In sandstone and travertine samples, central failure mode was found. While in limestone and conglomerate specimens, central and layer activation failure patterns were observed.

The block punch strength test was carried out on thin disk shape of NX core specimens with thicknesses ranging between 5 and 15 mm based on the ISRM (2007) suggested method. Results of the BPS test, including minimum, maximum, mean and standard deviation in dry and saturated conditions, are presented in Table 4. Based on the results, in dry conditions, BPS values were obtained in the range of 4.25–10.27 MPa and in saturated conditions, BPS values are between 2.30 and 8.35 MPa. Therefore, the strength of the studied samples under the BPS test in saturated conditions on the average reduced 31.80%. A comparative diagram of block punch strength in dry and saturated conditions is shown in Fig. 2b. The failure mode of the studied rocks under the block punch test is presented in Fig. 3b and shows that after failure, the specimens are broken into three parts. Two marginal parts of specimens were fixed in the punch apparatus and the middle part was punched out. As can be seen, regular failure occurred and fractured planes were parallel together. In a few travertine samples, during the block punch test cross joints developed and unexampled fracture planes as irregular failures were observed. For this reason, the test was rejected as invalid results, and the block punch test was repeated.

The point load strength test was carried out based on ISRM (2007) on obtained NX core samples with the length to diameter ratio equal to 1. Obtained values of PLS, including minimum, maximum, mean and standard deviation, are presented in Table 5. Based on the results, PLS values averagely obtained equal to 7.88 and 5.19 MPa in dry and saturated conditions, respectively. Therefore, on the average, the strength of the studied samples under the point load test in saturated conditions was reduced 34.36%. A comparative diagram of point load strength in dry and saturated conditions is shown in Fig. 2c. The failure mode of the studied samples in the point load test is presented in Fig. 3c and shows that tested specimens fail in typical tensile splitting failure modes. As regards axial point load tests performed, in most samples, a unique failure mode was observed and rock specimens were split into two pieces. Also, a few specimens fail to split into three blocks.

For determining the UCS of the studied samples, ten NX cores with a 2:2.5 length-to-diameter ratio were tested for each rock sample based on the ASTM D2938 (1995) and ISRM (1979) suggested methods. Obtained values of UCS in dry and saturated conditions, including minimum, maximum, mean and standard deviation, are presented in Table 6. In dry conditions, the CS2 and LS3 samples had the lowest and the highest values of UCS, equal to 14.97 and 51.51 MPa, respectively. In saturated conditions, the SS3 and LS3 samples had the lowest and the highest values of UCS, equal to 10.82 and 46.82 MPa, respectively. Calculating the sat to dry ratio shows that the decrease of the UCS is in the range of 7.10 to 32.75% under saturated conditions. Therefore, the UCS of the studied samples averagely reduced 18.97% after saturating. For comparative study, the diagram of the UCS values in dry and saturated conditions is presented in Fig. 2d. For the studied rocks, different failure modes were observed under the UCS test (Fig. 3d). Results of the UCS test show that most of the sandstone samples failed in Y-shaped. The failure mode of the limestone samples is axial splitting and most conglomerate specimens have axial splitting.

3 Results

In this research, simple regression analysis was conducted to create relationships between Schmidt rebound hardness and mechanical properties. In this method, values of Schmidt rebound hardness are considered as independent variables and values of mechanical properties, including Brazilian tensile strength, block punch strength, point load strength and uniaxial compressive strength both in dry and saturated conditions, are considered as dependent parameters. The correlation coefficient is the result of this method and a high value indicates high accuracy of experimental equations. The coefficient of determination (R2) and correlation coefficient (r) are calculated as follows:

Diagrams of the relationships between SRH and BTS, BPS, PLS and UCS in dry and saturated conditions are shown in Fig. 4a–d, respectively. The basic descriptive statistics of variables are presented in Table 7. Obtained experimental equations by simple regression analysis and correlation coefficients are presented in this table.

The correlation between Schmidt rebound hardness with dry and saturated values of Brazilian tensile strength is presented in Fig. 4a. These relations are direct linear (y = ax + b) and low correlation coefficients r = 0.76 and 0.65 were found in dry and saturated conditions, respectively. For calculating dry and saturated BTS, Eqs. 1 and 2 are presented in Table 7. The correlation between Schmidt rebound hardness with dry and saturated values of block punch strength is presented in Fig. 4b. These relationships are direct linear with good correlation coefficients of r = 0.87 and 0.83 in dry and saturated conditions, respectively. Values of BPS in dry and saturated conditions can be calculated by Eqs. 3 and 4 that are presented in Table 7. The correlation between Schmidt rebound hardness with dry and saturated values of point load strength is shown in Fig. 4c. These relationships are direct linear with high correlation coefficients of r = 0.93 and 0.80 in dry and saturated conditions, respectively. The PLS values in dry and saturated conditions are determined using the experimental equations numbers 5 and 6 which are presented in Table 7. The correlation between Schmidt rebound hardness with dry and saturated values of uniaxial compressive strength is shown in Fig. 4d. Direct linear relationships with high correlation coefficients equal to r = 0.87 and 0.88 were found for dry and saturated conditions, respectively. Equations 7 and 8 from Table 7 can determine dry and saturated UCS.

4 Discussion

For assessing the performance of the obtained models, statistical parameters including root mean square error (RMSE), variance account for (VAF), mean absolute percentage error (MAPE) and performance index (PI) were calculated by the following equations in Microsoft Office Excel software (Microsoft Corporation 2018):

where y and y′ are the experimental and calculated values, respectively; and N is the total number of data. The model will be excellent if r = 1, RMSE = 0, VAF = 100, MAPE = 0 and the PI has the biggest value. When the RMSE value approaches zero, the predicted values from the regression equations are closer to the experimental values. Values of statistical parameters were calculated and are presented in Table 8. Also, a comparative diagram of obtained statistical coefficients is presented in Fig. 5. Based on the results, RMSE values were obtained in the range of 0.64 to 5.49. Model 5 that predicted PLS has the best VAF value equal to 86.37%.

For comparing the results of experimental equations, calculated values versus experimental data, a 45° line (y = x) and 95% confidence limit curves have been plotted on diagrams. The correlations between experimental and calculated values of Brazilian tensile strength, block punch strength, point load strength and uniaxial compressive strength in dry and saturated conditions are presented in Fig. 6a–h, respectively. It should be noted that the adaption rate of trend lines with the 45° line shows the validity of predictive models. Based on the graphs, the trend lines of BPS and UCS partly fit the 45° line and are between the 95% confidence limit curves, especially in dry conditions (Fig. 6c, g). According to Fig. 6a, b, the trend lines of BTS in dry and saturated conditions partly intercept the y = x line. The trend lines of point load strength in dry and saturated conditions fit the 45° line and are between the 95% confidence limit curves (Fig. 6e, f). Therefore, confirm low values of RMSE equal to 0.64 and 0.81 for dry and saturated conditions, respectively.

5 Conclusions

In this research, some sedimentary rocks with different lithology including travertine, conglomerate, limestone and sandstone were collected from north and northwest parts of Damghan in the northeast of Iran and comprehensive geotechnical tests were performed. Physical properties of the studied rocks, including dry unit weight, saturated unit weight, water absorption and effective porosity, were determined by using standard prepared core specimens. The Schmidt rebound hardness test was performed on the rock block samples by the L-type Schmidt hammer and SRH values were obtained in the range from 15 to 44. Some geotechnical tests including Brazilian tensile strength, block punch strength, point load strength and uniaxial compressive strength were performed based on recommended standard methods by the ISRM and ASTM in both dry and saturated conditions. Based on the results, the strength of the studied samples under the Brazilian test reduced in saturated conditions between 11.22 and 39.02% and in average 24.95%. Correlation between Schmidt rebound hardness with dry and saturated values of BTS showed direct linear relationships with correlation coefficients of r = 0.76 and 0.65, respectively. Based on the results of the Block punch test, the average BPS of the studied samples in saturated conditions was reduced 31.80%. The relationships between Schmidt rebound hardness and dry and saturated values of BPS were direct linear with correlation coefficients of r = 0.87 and 0.83, respectively. Results of the point load test demonstrated that the strength of the studied samples under the PLS test was in average reduced 34.36% at saturated conditions. The relationships between SRH and PLS values in dry and saturated conditions were direct linear with correlation coefficients r = 0.93 and 0.80, respectively. Obtained values of the UCS show the decrease rate of UCS after saturating is in the range of 7.10–32.75%. Therefore, the UCS of the studied samples in saturated conditions was reduced 18.97% in average. The correlations between SRH and dry and saturated values of the UCS were obtained with high correlation coefficients of r = 0.87 and 0.88, respectively. Statistical parameters including regression coefficient, root mean square error, variance account for, mean absolute percentage error and performance index were calculated for assessing the performance of experimental models. Based on the results, R, RMSE, VAF, MAPE and PI values were obtained in the range of 0.65–0.93, 0.64–5.49, 41.82–86.37%, 0.70–22.43% and 41.60–86.22%, respectively. The relationship between Schmidt rebound hardness and dry point load strength has the highest correlation coefficient, VAF and PI, and has the smallest RMSE. The results of the correlation between experimental and calculated values of BTS, BPS, PLS and UCS in dry and saturated conditions show trend lines of BTS partly intercept, BPS and UCS partly fit, and PLS more fit to 45° line (y = x) and are between the 95% confidence limit curves. Therefore, the results of this research indicated that the Schmidt hammer test can be successfully employed for predicting the strength of sedimentary rocks in dry and saturated conditions.

References

Ajalloeian R, Jamshidi A, Khorasani R (2020) Evaluating the effects of mineral grain size and mineralogical composition on the correlated equations between strength and Schmidt hardness of granitic rocks. Geotech Geol Eng. https://doi.org/10.1007/s10706-020-01321-6

Aladejare AE (2020) Evaluation of empirical estimation of uniaxial compressive strength of rock using measurements from index and physical tests. J Rock Mech Geotech Eng 12(2):256–268

Armaghani DJ, Safari V, Fahimifar A, Amin MFM, Monjezi M, Mohammadi MA (2018) Uniaxial compressive strength prediction through a new technique based on gene expression programming. Neural Comput Appl 30:3523–3532

Asheghi R, Shahri AA, Zak MK (2019) Prediction of uniaxial compressive strength of different quarried rocks using metaheuristic algorithm. Arab J Sci Eng 44:8645–8659

Asteris PG, Mamou A, Hajihassani M, Hasanipanah M, Koopialipoor M, Le T, Kardani N, Armaghani DJ (2021) Soft computing based closed form equations correlating L and N-type Schmidt hammer rebound numbers of rocks. Trans Geotech. https://doi.org/10.1016/j.trgeo.2021.100588

ASTM International (1995) Standard test method for unconfined compressive strength of intact rock core specimens. ASTM standards on disc 04.08; Designation: D2938

Aufmuth RE (1973) A systematic determination of engineering criteria for rocks. Bull Assoc Eng Geol 11:235–245

Aydin A, Basu A (2005) The Schmidt hammer in rock material characterization. Eng Geol 81(1):1–14

Basu A, Aydin A (2004) A method for normalization of Schmidt hammer rebound values. Int J Rock Mech Min Sci 41(7):1211–1214

Bilen C (2021) Schmidt hammer rebound (SHR) values as a guide for the initial estimate of limestone uniaxial compressive strength (UCS) and Hardgrove grindability index (HGI). Arab J Geosci 14. https://doi.org/10.1007/s12517-021-08421-4

Bruno G, Vessia G, Bobbo L (2013) Statistical method for assessing the uniaxial compressive strength of carbonate rock by Schmidt hammer tests performed on core samples. Rock Mech Rock Eng 46:199–206

Buyuksagis IS, Goktan RM (2007) The effect of Schmidt hammer type on uniaxial compressive strength prediction of rock. Int J Rock Mech Min Sci 44:299–307

Demirdag S, Sengun N, Ugur I, Altindag R (2018) Estimating the uniaxial compressive strength of rocks with Schmidt rebound hardness by considering the sample size. Arab J Geosci. https://doi.org/10.1007/s12517-018-3847-1

Demirdag S, Yavuz H, Altindag R (2009) The effect of sample size on Schmidt rebound hardness value of rocks. Int J Rock Mech Min Sci 46:725–730

Diamantis K (2019) Estimation of tensile strength of ultramafic rocks using indirect approaches. Geomech Eng 17(3):261–270

Diamantis K, Fereidooni D, Khajevand R, Migiros G (2021) Effect of textural characteristics on engineering properties of some sedimentary rocks. J Cent South Univ 28:926–938

Diamantis K, Gartzos E, Migiros G (2014) Influence of petrographic characteristics on physico-mechanical properties of ultrabasic rocks from central Greece. Bull Eng Geol Environ 73:1273–1292

Duda M, Renner J (2013) The weakening effect of water on the brittle failure strength of sandstone. Geophys J Int 192(3):1091–1108

Erguler ZA, Ulusay R (2009) Water-induced variations in mechanical properties of clay-bearing rocks. Int J Rock Mech Min Sci 46:355–370

Fattahi H (2017) Applying soft computing methods to predict the uniaxial compressive strength of rocks from Schmidt hammer rebound values. Comput Geosci 21:665–681

Fereidooni D (2016) Determination of the geotechnical characteristics of Hornfelsic rocks with a particular emphasis on the correlation between physical and mechanical properties. Rock Mech Rock Eng 49:2595–2608

Fereidooni D, Khajevand R (2018) Determining the geotechnical characteristics of some sedimentary rocks from Iran with an emphasis on the correlations between physical, index, and mechanical properties. Geotech Test J 41(3):555–573

Fereidooni D, Khajevand R (2019) Utilization of the accelerated weathering test method for evaluating the durability of sedimentary rocks. Bull Eng Geol Environ 78:2697–2716

Hebib R, Belhai D, Alloul B (2017) Estimation of uniaxial compressive strength of North Algeria sedimentary rocks using density, porosity, and Schmidt hardness. Arab J Geosci. https://doi.org/10.1007/s12517-017-3144-4

Heidari M, Mohseni H, Jalali SH (2018) Prediction of uniaxial compressive strength of some sedimentary rocks by fuzzy and regression models. Geotech Geol Eng 36:401–412

Huang S, Xia K, Yan F, Feng XT (2010) An experimental study of the rate dependence of tensile strength softening of Longyou sandstone. Rock Mech Rock Eng 43(6):677–683

ISRM (1979) Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci Geomech Abstr 16(2):135–140

ISRM (2007) The Blue Book: the complete ISRM suggested methods for rock characterization, testing and monitoring, 1974–2006, Compilation Arranged by the ISRM Turkish National Group, Ankara, Turkey, R Ulusay and JA Hudson, Eds., Kazan Offset Press, Ankara

Jing H, Nikafshan Rad H, Hasanipanah M, Armaghani DJ, Noman Qasem S (2021) Design and implementation of a new tuned hybrid intelligent model to predict the uniaxial compressive strength of the rock using SFS-ANFIS. Eng Comput 37:2717–2734

Karakul H (2017) Investigation of saturation effect on the relationship between compressive strength and Schmidt hammer rebound. Bull Eng Geol Environ 76:1143–1152

Karakul H (2020) Investigation of the effect of impact direction on Schmidt rebound values by multivariate regression and neuro-fuzzy model. SN Appl Sci. https://doi.org/10.1007/s42452-020-03600-6

Karakul H, Ulusay R (2013) Empirical correlations for predicting strength properties of rocks from P-wave velocity under different degrees of saturation. Rock Mech Rock Eng 46(5):981–999

Karaman K, Kesimal A (2015) Correlation of Schmidt rebound hardness with uniaxial compressive strength and P-wave velocity of rock materials. Arab J Sci Eng 40:1897–1906

Karaman K, Kesimal A, Ersoy H (2015) A comparative assessment of indirect methods for estimating the uniaxial compressive and tensile strength of rocks. Arab J Geosci 8:2393–2403

Khajevand R, Fereidooni D (2019) Utilization of the point load and block punch strengths to predict the mechanical properties of several rock samples using regression analysis methods. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-019-0201-8

Kogure T (2019) Analysis of Schmidt hammer rebound test results with repetitive impacts for determining the mechanical characteristics of weathered pyroclastic rock surfaces: a case study along the Isotake coast, Japan. Bull Eng Geol Environ 78:3425–3432

Kong F, Shang J (2018) A validation study for the estimation of uniaxial compressive strength based on index tests. Rock Mech Rock Eng 51:2289–2297

Kong F, Xue Y, Qiu D, Gong H, Ning Z (2021) Effect of grain size or anisotropy on the correlation between uniaxial compressive strength and Schmidt hammer test for building stones. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2021.123941

Li D, Wang W (2019) Quantitative analysis of the influence of saturation on rock strength reduction considering the distribution of water. Geomech Geophys Geo-Energy Geo-Resour 5:197–207

Li D, Wong LNY, Liu G, Zhang XP (2012) Influence of water content and anisotropy on the strength and deformability of low porosity meta-sedimentary rocks under triaxial compression. Eng Geol 126:46–66

Liang M, Mohamad ET, Faradonbeh RS, Armaghani DJ, Ghoraba S (2016) Rock strength assessment based on regression tree technique. Eng Comput 32:343–354

Liu Y, Cai Y, Huang S, Guo Y, Liu G (2020) Effect of water saturation on uniaxial compressive strength and damage degree of clay-bearing sandstone under freeze-thaw. Bull Eng Geol Environ 79:2021–2036

Luo Y (2020) Influence of water on mechanical behavior of surrounding rock in hard-rock tunnels: an experimental simulation. Eng Geol. https://doi.org/10.1016/j.enggeo.2020.105816

Ma L, Wu J, Wang M, Dong L, Wei H (2020) Dynamic compressive properties of dry and saturated coral rocks at high strain rates. Eng Geol. https://doi.org/10.1016/j.enggeo.2020.105615

Microsoft Corporation (2018) Microsoft Excel. Retrieved from https://office.microsoft.com/excel

Mishra DA, Srigyan M, Basu A, Rokade PJ (2015) Soft computing methods for estimating the uniaxial compressive strength of intact rock from index tests. Int J Rock Mech Min Sci 80:418–424

Mishra S, Khetwal A, Chakraborty T (2019) Physio-mechanical characterization of rocks. J Test Eval 49(3):1976–1998

Moosavi SA, Mohammadi M (2021) Development of a new empirical model and adaptive neuro-fuzzy inference systems in predicting unconfined compressive strength of weathered granite grade III. Bull Eng Geol Environ 80:2399–2413

Rahimi MR, Mohammadi SD, Beydokhti AT (2022) Correlation between Schmidt hammer hardness, strength properties and mineral compositions of sulfate rocks. Geotech Geol Eng 40:545–574

Rajabzadeh MA, Moosavinasab Z, Rakhshandehroo G (2012) Effects of rock classes and porosity on the relation between uniaxial compressive strength and some rock properties for carbonate rocks. Rock Mech Rock Eng 45(1):113–122

Sharma PK, Khandelwal M, Singh TN (2011) A correlation between Schmidt hammer rebound numbers with impact strength index, slake durability index and P-wave velocity. Int J Earth Sci 100:189–195

Sonmez H, Gokceoglu C, Nefeslioglu HA, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43(2):224–235

Sumner P, Werner N (2002) The effect of rock moisture on Schmidt hammer rebound: tests on rock samples from Marion Island and South Africa. Earth Surf Proc Land 27(10):1137–1142

Tandon RS, Gupta V (2015) Estimation of strength characteristics of different Himalayan rocks from Schmidt hammer rebound, point load index, and compressional wave velocity. Bull Eng Geol Environ 74:521–533

Tang S (2018) The effects of water on the strength of black sandstone in a brittle regime. Eng Geol 239:167–178

Tang Z, Li S, Huang S, Huang F, Wan F (2021) Indirect estimation of rock uniaxial compressive strength from simple index tests: review and improved least squares regression tree predictive model. Geotech Geol Eng 39:3843–3862

Török A, Vásárhelyi B (2010) The influence of fabric and water content on selected rock mechanical parameters of travertine, examples from Hungary. Eng Geol 115:237–245

Tuğrul A, Zarif IH (1999) Correlation of mineralogical and textural, characteristics with engineering properties of selected granitic rocks from Turkey. Eng Geol 51(4):303–317

Vásárhelyi B (2005) Statistical analysis of the influence of water content on the strength of the Miocene limestone. Rock Mech Rock Eng 38(1):69–76

Wang M, Wan W (2019) A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2019.104094

Wasantha PLP, Ranjith PG, Permata G, Bing D (2018) Damage evolution and deformation behaviour of dry and saturated sandstones: insights gleaned from optical measurements. Measurement 130:8–17

Wen L, Luo ZQ, Yang SJ, Qin YG, Wang W (2019) Correlation of geo-mechanics parameters with uniaxial compressive strength and P-wave velocity on dolomitic limestone using a statistical method. Geotech Geol Eng 37:1079–1094

Wong LNY, Maruvanchery V, Liu G (2016) Water effects on rock strength and stiffness degradation. Acta Geotech 11(4):713–737

Yao W, Li C, Zhan H, Zhou JQ, Criss RE, Xiong S, Jiang X (2020) Multiscale study of physical and mechanical properties of sandstone in three Gorges reservoir region subjected to cyclic wetting–drying of Yangtze River Water. Rock Mech Rock Eng 53:2215–2231

Yilmaz I (2010) Influence of water content on the strength and deformability of gypsum. Int J Rock Mech Min Sci 47(2):342–347

Yılmaz I, Sendir H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66:211–219

Yu CY, Tang SB, Tang CA, Duan D, Zhang YJ, Liang ZZ, Ma K, Ma TH (2019) The effect of water on the creep behavior of red sandstone. Eng Geol 253:64–74

Zhao K, Yang D, Zeng P, Huang Z, Wu W, Li B, Teng T (2021) Effect of water content on the failure pattern and acoustic emission characteristics of red sandstone. Int J Rock Mech Min Sci 142:104709. https://doi.org/10.1016/j.ijrmms.2021.104709

Zhou Z, Cai X, Cao W, Li X, Xiong C (2016) Influence of water content on mechanical properties of rock in both saturation and drying processes. Rock Mech Rock Eng 49:3009–3025

Acknowledgements

The author like to express his thanks to Mr. P. Khajevand for the English editing.

Funding

No external funding was used.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author does not have any conflict of interest.

Ethical Approval

This article does not contain any studies with human participants.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khajevand, R. Determining Dry and Saturated Strength of Rocks by Using the Schmidt Hammer. Iran J Sci 47, 779–790 (2023). https://doi.org/10.1007/s40995-023-01436-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-023-01436-4