Abstract

The Schmidt hammer is commonly used for the prediction of unconfined compressive strength and other mechanical properties of rocks from surface rebound hardness values since it is quick, easy, inexpensive, and non-destructive testing method. In this study, metamorphic, sedimentary, and igneous rock samples were collected from various locations in Turkey to predict the rock strength from Schmidt rebound hardness. Schmidt rebound tests were performed on cubic samples with an edge length of 11 cm and uniaxial compressive strength tests were carried out on cubic samples with an edge length of 5 cm in accordance with ASTM and EN standards and suggested procedure by ISRM. New relationship coefficients between unconfined compressive strength and Schmidt rebound hardness values were suggested according to rock type. Finally, some diagrams were developed to be practically used for estimating the uniaxial compressive strength from Schmidt rebound hardness values by considering the sample size obtained from the experimental work.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Schmidt rebound hammer, which was originally developed in the late 1940s to test the surface rebound hardness of concrete (Schmidt 1951), has been used in rock mechanics practice since the early 1960s, mainly for estimating the uniaxial compressive strength (UCS) and Young’s modulus of rock materials (Aydin and Basu 2005; Aydin 2015). The estimation of rock and concrete strength by nondestructive test methods is of great interest for both civil and mining engineering applications and equipments such as excavator, roadheader, and tunnel boring machine performance, machine drilling rate, rock rippability, mine-roof control, excavation classification, in situ strength predictions, assessment of rock discontinuities, abrasion resistance of rock aggregates, state of weathering (Kidybinski 1968; Day and Goudie 1977; Young 1978; Kazi and Al-Mansour 1980; Matthews and Shakesby 1984; Goktan and Gunes 2005; Buyuksagis and Goktan 2007; Aydin 2009; Aksoy 2009).

Rock engineers widely use the UCS of rocks in designing surface and underground structures, since UCS is considered as one of the key properties in characterization of rock materials in engineering practices (Basu and Aydin 2006; Palassi and Pirpanahi 2013). Gurocak and Yalcin (2016) used Schmidt hardness as input parameter in the excavatability classifications. Ansari et al. (2015) proposed an empirical equation based on regression analysis and will be applicable to calculate the normal coefficient of restitution (Rn) for different rock types from their Schmidt hardness.

UCS test is time consuming, expensive, and difficult to perform in the field. Therefore, some indirect tests have been developed for indirect estimation of the UCS (Palassi and Pirpanahi 2013). Schmidt rebound hardness (SRH) testing is one of the most commonly used indirect test method to estimate UCS of rocks. Currently, there are two different types of Schmidt rebound hammers available. L-type Schmidt hammer is commonly used for testing rocks while N-type Schmidt hammer is used for testing concrete. The L-type hammer delivers smaller rebound values for the same rock samples than the N-type hammer. Because the ‘L’ type hammer has an impact energy three times lower than the ‘N’ type (0.735 compared to 2.207 Nm). The N-type hammer is less sensitive to surface irregularities and should be preferred in field applications, while the L-type hammer has greater sensitivity in the lower range and gives better results when testing weak, porous, and weathered rocks (Aydin 2009).

There is huge amount of work related to predicting the rock strength parameters from SRH measurements. The researchers obtained very substantial values of R2 and suggested different empirical equations between UCS and SRH from all rock types, which are given in Table 1, as explained by Yasar and Erdogan (2004), Basarir et al. (2004), Goudie (2006), Torabi et al. (2010), and Nazir et al. (2013).

There are some advantages and limitations of estimating the UCS value by using SRH, as explained by Goudie (2006). The advantages of the SRH are portability, cheapness, ability to make many in situ readings in the field, lack of operator variance, simplicity, empirical evidence, and the fact that its calibration can be achieved easily with a test anvil. On the other hand, the limitations of the SRH are: being extremely sensitive to discontinuities in a rock, sensitive to moisture contents, surface texture, and surface polishing. Moreover, the other reason that causes some differences in the equations developed to predict the UCS from SRH values of the rock samples may be explained by these tests being commonly performed on different sample size. Therefore, the sample size should be considered when predicting the UCS from SRH values.

The aim of this work is to predict the rock strength parameters from SRH measurements on 32 sedimentary (20 low-porous limestone and 12 high-porous travertines and lymra), 17 metamorphic, and 10 igneous rocks. The influence of different rock types and sample size on the estimated rock strength was investigated by using measured and calculated SRH values and some new coefficients were suggested for each rock type.

Experimental method

In order to predict the strength properties of rocks from SRH values, a total of 59 various rock types from different origins were tested. The UCS and open porosity tests were carried out in accordance with ASTM (2005, 2009) and TS EN (2007) standards and ISRM (2007, 2015) suggested methods. UCS tests were performed on at least six cubic samples with edge lengths of 5 cm for each rock type as specified in the principles of related standards. A force-controlled hydraulic press ELE ADR 2000 model having 200 tons of loading capacity at a constant loading rate of 0.5–1 kN/s was used. The uniaxial load was applied continuously on the specimen at a constant stress rate until the failure would occur within 5–10 min of loading. Open porosity measurements were also determined using saturation and buoyancy techniques, as recommended by related standards.

The SRH testing procedures suggested by ISRM require recording of at least 20 rebound values from single impacts separated by at least a plunger diameter and averaging the upper 10 values. All the cubic samples have a minimum edge dimension of 11 cm as suggested by Demirdag et al. (2009). Four rock samples were tested for each rock type using L-type Schmidt hammer having an impact energy of 0.74 Nm by holding vertically downwards (± 5o) on smoothened sample surface. Each sample surface was smoothened with abrasive of 220 grit size and flat over area covered by the plunger. Attention was paid to ascertain that all samples were free from cracks and having natural water content. The testing was carried out on a rigid steel base with a minimum weight of 20 kg in order to adequately secure the specimen against vibration and movement during the test in accordance with ISRM.

Results and discussion

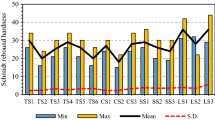

In this research, in order to estimate the true value of UCS from the SRH values, open porosity, UCS, and SRH tests were performed on different rock types. Tables 2, 3, 4 and 5 illustrate the values of average open porosity, UCS, and SRH values of the rock samples and the means of the constant coefficients obtained from the UCS/SRH ratio according to each rock type. UCS and SRH values were obtained from cubic samples having edge lengths of 5 cm and 11 cm, respectively. Then, SRH values for cubic samples with different edge lengths of 5, 6, 7, 8, 9, and 10 cm were calculated by using Eq. 1 as suggested by Demirdag et al. (2009) and given in Tables 2–5.

where SRHc is the estimated consistent SRH value, EDm is the edge length of tested sample, cm, SRHm is the measured SRH value of the sample with EDm edge length.

From these analyses, it can be assumed that the average coefficients to predict the UCS from SRH value vary between 2.36 and 3.30 for low-porous sedimentary rocks, 1.64 and 2.87 for high-porous sedimentary rocks, 1.82 and 2.81 for metamorphic rocks, and 2.28 and 3.21 for igneous rocks depending on the sizes of different samples. The results illustrated in the tables indicate considerable differences in constant coefficients obtained by the analyses depending on the origin of rock and sample size. The UCS/SRH ratio of the low-porous sedimentary rocks is found higher than that of high-porous rock. It was not possible to get reliable measurements using the Schmidt hammer on the porous surface, since the thin walls between the pores were broken when the plunger impacted to the surface. Therefore, the lower surface area contact with the plunger will absorb the energy and lower the hardness of porous structure. Hence, it can be stated that the porosity and matrix structure are of significant parameters on this ratio. Also, a significant increase was noticed in the coefficient values for the samples having porosity values lower than 2%. Thus, low-porous rocks are more sensitive in the prediction of the UCS from SRH values.

Although porosity is a key parameter to determine the coefficients for sedimentary rocks, it does not play an important role on UCS/SRH ratio for metamorphic and igneous rocks. This outcome may be explained by considerable influence of bond structure and crystal size on UCS/SRH ratio for metamorphic rocks. In addition, brittle and hard granular minerals such as quartz and feldspars in igneous rocks have an important role than other minerals, as amphibole and pyroxene.

For each rock type, the relation between UCS/SRH ratio and calculated SRH values for different sample sizes was analyzed and graphically presented in Fig. 1. It can be seen from the Fig. 1 that UCS/SRH ratio was decreased when the sample size was increased in different rock types. Therefore, it may be suggested that the SRH values must be used for the cubic samples with an edge length of at least 11 cm. The equations (Fig. 1) obtained from this study are similar to the generalized expressions suggested by Aydın (2015). In addition, rock type and sample size were taken into account in these equations (Eqs. 2–5) with fairly high correlation coefficients.

For low-porous sedimentary rocks:

For high-porous sedimentary rocks:

For metamorphic rocks:

For igneous rocks:

where y is the UCS/SRH ratio and x is the cubic sample size in cm.

If the use of samples having lower edge length is necessary for the prediction of the UCS from SRH, the coefficient values obtained from the Figs. 2, 3, 4 and 5 should be used depending on the type of rock. Diagrams to be practically used to estimate the true UCS values from the SRH values of different rock types were plotted in Figs. 2–5 based on the data given in the Tables 2–5. In addition, the relationship between the calculated UCS and the measured UCS for different rock types with a 95% confidence level was also plotted in Fig. 6.

In the literature, there is huge amount of work related to predicting the UCS from some index test such as point load strength, P wave velocity, and block punch index. In this research, different conversion ratios and correlation coefficient are suggested. For example, the conversion ratio between compressive strength and point load strength has exhibited a very large range; the ratio for the equations using the zero-intercept varies between 8.6 and 29 (Fener et al. 2005; Singh et al. 2012). Sharma and Singh (2008) stated correlation coefficients between compressive strength and P wave velocity as 0.53 and 0.90. Mishra and Basu (2012) used of the block punch test to predict the UCS of rocks. Based on this study, they mention that correlation coefficient varies between 0.82 and 0.95 with the different equations in the relation between block punch index and UCS. For these index tests, it is necessary to prepare samples with different geometries in the laboratory. For this reason, different predicting models have been developed due to different sample dimensions and testing methods. There is no clear consensus in the literature about which is more accurate. With the SRH test used in this study, experiments can be performed easily in the laboratory or in the field and accurate UCS estimation can be performed with high correlation coefficient (Fig. 6). Also in present study, some coefficients are suggested (Fig. 1) which can be used to eliminate prediction errors caused by sample size difference to the prediction UCS of rocks.

Conclusions

In this research, experimental work was carried out and the findings were analyzed to determine the coefficients to relate SRH to compressive strength for different rock types. A new and true coefficient was suggested to predict the UCS from SRH values based on the sample size. In addition, some diagrams were developed to be practically used for estimating the uniaxial compressive strength from SRH values by considering the sample size for each rock type. It is seen that when the sample size increases, the UCS/SRH ratio decreases.

From the analysis of UCS and SRH values of rocks which have 5 and 11 cm cubic sample, respectively, UCS/SRH ratio was obtained as 2.36 for low-porous sedimentary rocks, 1.64 for high-porous sedimentary rocks, 1.82 for metamorphic rocks, and 2.28 for igneous rocks. It can also be concluded that the porosity has a significant effect on the UCS/SRH ratio for sedimentary rocks in comparison to metamorphic and igneous rocks. Among the different rock types, the UCS/SRH ratio of low-porous sedimentary rocks appeared to have higher values.

References

Aggistalis G, Alivizatos S, Stamoulis D, Stournaras G (1996) Correlating uniaxial compressive strength with Schmidt hardness, point load index, Young's Modulus, and mineralogy of gabbros and basalts (northern Greece). Bull Assoc Eng Geol 54:3–11

Aksoy CO (2009) Performance prediction of impact hammers by block punch index for weak rock masses. Int J Rock Mech Min Sci 46:1383–1388

Ansari MK, Ahmad M, Singh R, Singh TN (2015) Correlation between Schmidt hardness and coefficient of restitution of rocks. J Afr Earth Sci 104:1–5

ASTM (2005) Standard test method for determination of rock hardness by Rebound Hammer Method 2005:D5873–05

ASTM (2009) Standard test method for compressive strength of dimension stone. ASTM C170/C170M – 09

Aufmuth RE (1973) A systematic determination of engineering criteria for rock. Bull Assoc Eng Geol 11:235–245

Aydin A (2009) ISRM suggested method for determination of the Schmidt hammer rebound hardness: revised version. Int J Rock Mech Min Sci 46:627–634

Aydin A (2015) ISRM suggested method for determination of the Schmidt hammer rebound hardness: revised version. ISRM., 2015. The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014, editor: R. Ulusay. Springer Int. Publishing, Switzerland, pp 24–33

Aydin A, Basu A (2005) The Schmidt hammer in rock material characterization. Eng Geol 81:1–14

Basarir H, Kumral M, Ozsan A (2004) Predicting uniaxial compressive strength of rocks from simple test methods. Rockmec′2004-VIIth Regional Rock Mechanics Symposium. Sivas, Turkey

Basu A, Aydin A (2006) Predicting uniaxial compressive strength by point load test: significance of cone penetration. Rock Mech Rock Eng 39:483–490

Beverly BE, Schoenwolf DA, Brierly GS (1979) Correlations of rock index values with engineering properties and the classification of intact rock. FHWA, Washington, DC

Buyuksagis IS, Goktan RM (2007) The effect of Schmidt hammer type on uniaxial compressive strength prediction of rock. Int J Rock Mech Min Sci 44:299–307

Cargill JS, Shakoor A (1990) Evaluation of empirical methods for measuring the uniaxial strength of rock. Int J Rock Mech Min Sci 27:495–503

Day MJ, Goudie AS (1977) Field assessment of rock hardness using the Schmidt test hammer. Br Geomorph Res Group Tech Bull 18:19–29

Deere DU, Miller RP (1966) Engineering classification and index properties of intact rock. Tech rep no. AFWL-TR 65-116. Univ Illinois:300

Demirdag S, Yavuz H, Altindag R (2009) The effect of sample size on Schmidt rebound hardness value of rocks. Int J Rock Mech Min Sci 46:725–730

Dincer I, Acar A, Cobangulu I, Uras Y (2004) Correlation between Schmidt hardness, uniaxial compressive strength and Young's modulus for andesites, basalts and tuffs. Bull Eng Geol Environ 63:141–148

Fener M, Kahraman S, Bilgil A, Gunaydin O (2005) A comparative evaluation of indirect methods to estimate the compressive strength of rocks. Rock Mech Rock Eng 38(4):329–343

Ghose AK, Chakraborti S (1986) Empirical strength indices of Indian coals: an investigation. Proceedings 27th US Symposium on Rock Mechanics, Rotterdam: Balkema, 59–61

Gokceoglu C (1996) Schmidt sertlik çekici kullanılarak tahmin edilen tek eksenli sıkışma dayanımı verilerinin güvenilirliği üzerine bir değerlendirme. Jeoloji Mühendisliği 48:78–81 [in Turkish]

Goktan RM, Gunes N (2005) A comparative study of Schmidt hammer testing procedures with reference to rock cutting machine performance prediction. Int J Rock Mech Min Sci 42:466–472

Goudie AS (2006) The Schmidt hammer in geomorphological research. Prog Phys Geogr 30(6):703–718

Gurocak Z, Yalcin E (2016) Excavatability and the effect of weathering degree on the excavatability of rock masses: an example from eastern Turkey. J Afr Earth Sci 118:1–11

Haramy KY, De Marco MJ (1985) Use of Schmidt hammer for rock and coal testing. In: Proc 26th US Symp rock Mech, 26–28 June, Rapid City, SD. Balkema, Rotterdam, pp 549–555

ISRM (2007) The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, Editors: R. Ulusay & J.A. Hudson. Compilation Arranged by The ISRM Turkish National Group, Ankara, Turkey, 628

ISRM (2015) The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014, editor: R. Ulusay. Springer Int. Publishing, Switzerland, p 293

Kahraman S (1996) Basınc direnci tahmininde Schmidt ve nokta yuk indeksi kullanmanın guvenilirligi. In: Korkmaz, S., ve Akcay, M. (Eds.), K.T.U. Jeoloji Muhendisligi Bolumu, vol. 30. Yıl Semp. Bildiriler Kitabi, Trabzon, pp. 362– 369 [in Turkish]

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Min Sci 38:981–994

Katz O, Reches Z, Roegiers JC (2000) Evaluation of mechanical rock properties using a Schmidt hammer. Int J Rock Mech Min Sci 37:723–728

Kazi A, Al-Mansour ZR (1980) Empirical relationship between Los Angeles abrasion and Schmidt hammer strength tests with application to aggregates around Jeddah. Q J Eng Geol 13:45–52

Kidybinski A (1968) Rebound number and the quality of mine roof strata. Int J Rock Mech Min Sci 5:283–292

Kılıc A, Teymen A (2008) Determination of mechanical properties of rocks using simple methods. Bull Eng Geol Environ 67:237–244

Matthews JA, Shakesby RA (1984) The status of the little ice age in southern Norway: relative-age dating of Neoglacial moraines with Schmidt hammer and lichenometry. Boreas 13:333–346

Mishra DA, Basu A (2012) Use of the block punch test to predict the compressive and tensile strengths of rocks. Int J Rock Mech Min Sci 51:119–127

Nazir R, Momeni E, Armaghani DJ, Mohd Amin MFM (2013) Prediction of unconfined compressive strength of limestone rock samples using L-type Schmidt hammer. EJGE 18(I):1767–1775

O'Rourke JE (1989) Rock index properties for geoengineering, underground development. Min Eng:106–110

Palassi M, Pirpanahi M (2013) Edge load strength test for indirect estimation of unconfined compressive strength. Int J Rock Mech Min Sci 61:111–117

Schmidt E (1951) A non-destructive concrete tester. Concrete 59(8):34–35

Sharma PK, Singh TN (2008) A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial compressive strength. Bull Eng Geol Environ 67:17–22

Sheorey PR, Barat D, Das MN, Mukherjee KP, Singh B (1984) Schmidt hammer rebound data for estimation of large scale in situ coal strength. Int J Rock Mech Min Sci 21:39–42

Singh RN, Hassani FP, Elkington PAS (1983) The application of strength and deformation index testing to the stability assessment of coal measures excavations. In: Proc 24th US Symp rock Mech, Texas, a&M University, AEG. Balkema, Rotterdam, pp 599–609

Singh TN, Kainthola A, Venkatesh A (2012) Correlation between point load index and uniaxial compressive strength for different rock types. Rock Mech Rock Eng 45:259–264

Torabi SR, Ataei M, Javanshir M (2010) Application of Schmidt rebound number for estimating rock strength under specific geological conditions. J Min Environ 1(2):1–8

TS EN 1926 (2007) Natural stone test methods - determination of uniaxial compressive strength. Institute of Turkish Standards 19

Yasar E, Erdogan Y (2004) Estimation of rock physiomechanical properties using hardness methods. Eng Geol 71:281–288

Yilmaz I, Sendir H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66:211–219

Young RP (1978) Assessing rock discontinuities. Tunnels and Tunnelling:45–48

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demirdag, S., Sengun, N., Ugur, I. et al. Estimating the uniaxial compressive strength of rocks with Schmidt rebound hardness by considering the sample size. Arab J Geosci 11, 502 (2018). https://doi.org/10.1007/s12517-018-3847-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3847-1